Page 1

PROGRESSION

602FC602FC

602FC

602FC602FC

STRINGING MASTRINGING MA

STRINGING MA

STRINGING MASTRINGING MA

CHINECHINE

CHINE

CHINECHINE

OO

WNER'S MANUWNER'S MANU

O

WNER'S MANU

OO

WNER'S MANUWNER'S MANU

Issue 1 - April, 2000Issue 1 - April, 2000

Issue 1 - April, 2000

Issue 1 - April, 2000Issue 1 - April, 2000

Copyright 2000 GAMMA Sports - All Rights Reserved

ALAL

AL

ALAL

Page 2

PROGRESSION

602FC602FC

602FC

602FC602FC

STRINGING MACHINE

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PAGE 1 ................................................................................... WARRANTY

PAGE 2 .....................................................................................FEATURES

PAGE 3 ...........................................................ASSEMBLY INSTRUCTIONS

PAGE 5 ................................................................ MOUNTING THE FRAME

PAGE 7 ................................................................ STRINGING THE FRAME

PAGE 11 ....................................................................... PATHFINDER AWL

PAGE 12 ............................................................................MAINTENANCE

PAGE 13 .......................................................... TROUBLESHOOTING TIPS

PAGE 13 ................................................................. CARE AND CLEANING

PAGE 14 ............................................................. EXPLODED PARTS VIEW

PAGE 15 ................................................................................. PARTS LIST

LIMITED WARRANTYLIMITED WARRANTY

LIMITED WARRANTY

LIMITED WARRANTYLIMITED WARRANTY

GAMMA SPORTS ("GAMMA") warrants to the original purchaser that the GAMMA PROGRESSION stringing machine ("EQUIPMENT") purchased is free

from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding electrical parts

and string clamps), and for a period of one (1) year from the date of purchase for all electrical parts and string clamps. Should any defects develop under

normal use within the specified time periods, GAMMA will at its option, repair or replace the defective EQUIPMENT provided it is returned to GAMMA prepaid

at the purchaser's expense. This warranty does not apply to any damage or defect caused by negligence, abuse, misuse, unauthorized alteration, shipping,

handling, or part wear and tear as a result of normal use.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized to promise any other liability.

GAMMA shall in no event be liable for any incidental or consequential damages.

To return defective EQUIPMENT, a return authorization (RA#) must be obtained from a GAMMA customer service representative by calling 1-800-333-0337.

The RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped prepaid by the customer to GAMMA. Please retain

the original shipping carton and packing materials for any future shipments. GAMMA will not be responsible for machines which are not sent in the original

undamaged packaging.

1

Page 3

FEATURES

! Drop Weight Tensioner w/ 8lb. to 90lb. range and Permanently Engraved

Weight Scale

! Professional Six Point “Quick Mount” Racquet Mounting System -

Accomodates All Racquets Without Adapters

! Patented Parallel Jaw Rotating Ratchet Gripper w/ Diamond Dust Coated

Gripping Surfaces - U.S. Patent #4,491,322

! Professional Dual Action, Diamond Dust Coated, Fixed String Clamps

! Durable Polystyrene Base Cover w/ Convenient Padded Tool Tray

! Strong, Light Weight, Powder Coated Molded Aluminum Construction

2

Page 4

ASSEMBLY INSTRUCTIONS

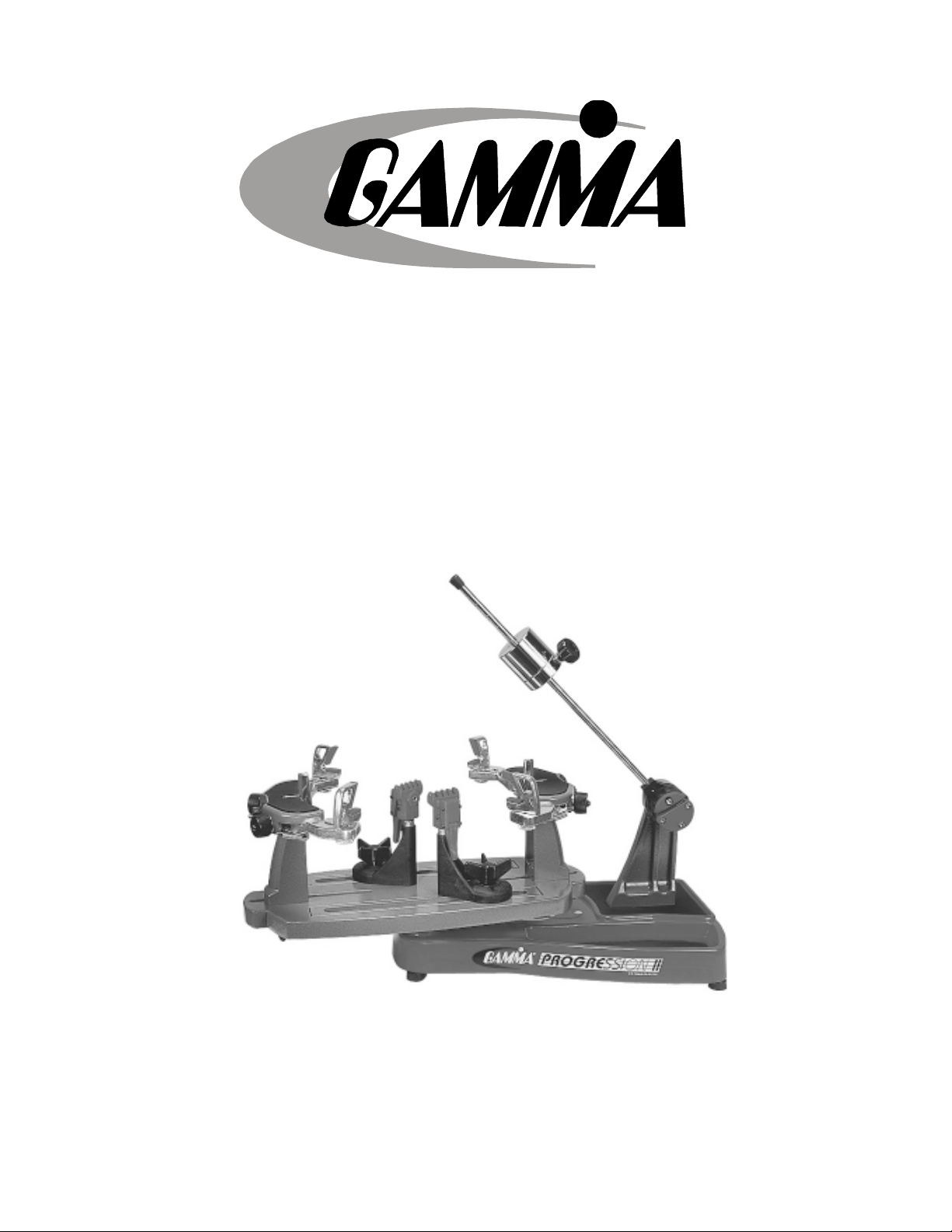

Engaging the Drop Weight Bar Stop

The stringing machine is shipped with the drop weight

bar in the horizontal position. To prevent racquet

damage during stringing, the bar stop must be engaged.

Remove the machine base from the shipping carton

being careful to avoid lifting by the plastic cover.

Hold the drop weight bar in the vertical position as shown

while turning the stop screw clockwise with the supplied

5mm hex wrench.

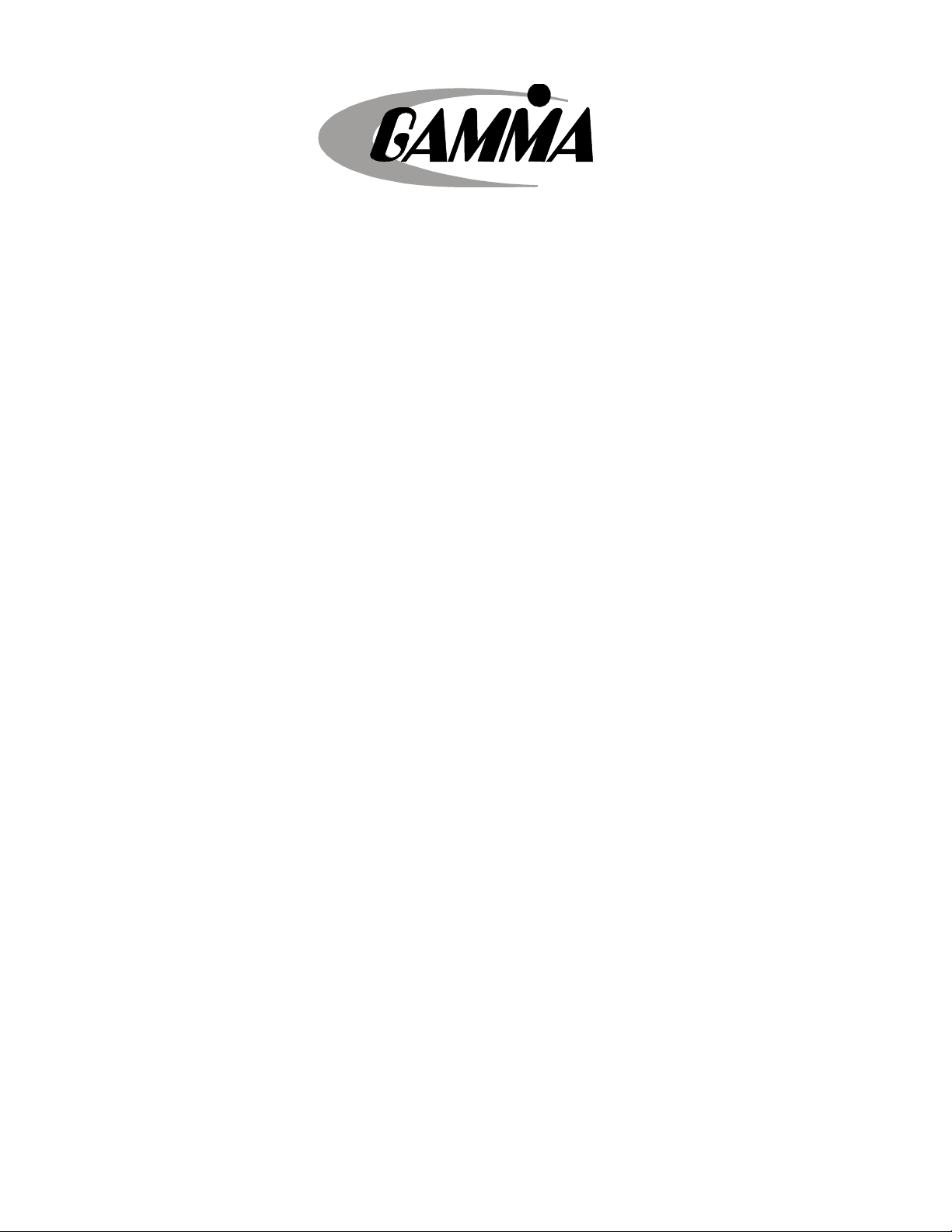

Installing the Turntable

The turntable is located under the foam packing in the

bottom of the shipping carton.

Insert the center post of the turntable into the bushing

of the stringing machine base.

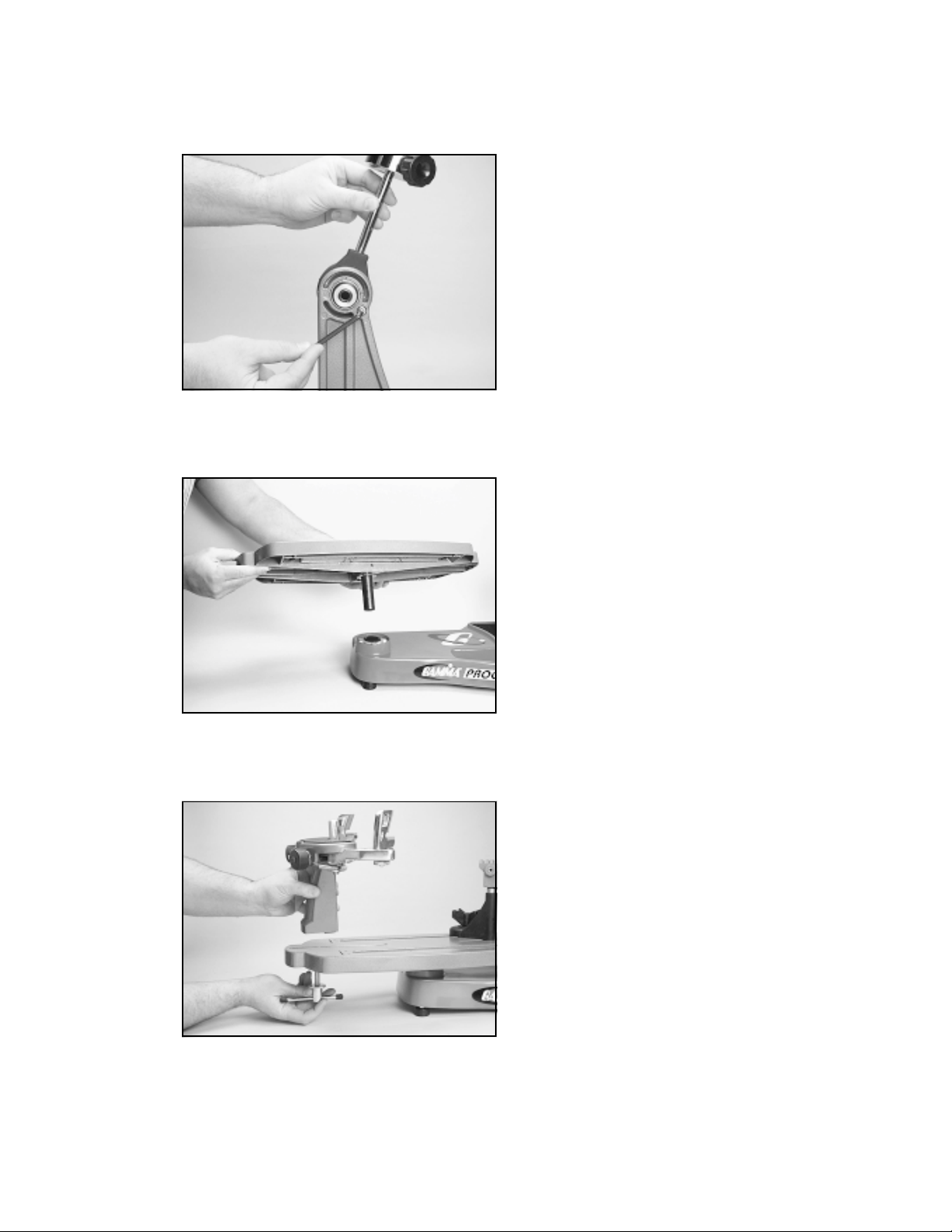

Installing the Frame Support Posts

The GAMMA 600FC support post assemblies are precision aligned at the factory and are marked for proper

installation on the turntable.

Install the support post with the dot on its base to an

identical dot on the turntable. Align the threaded hole in

the bottom of the frame support post with the slot in the

turntable. Screw the lever lock bolt with washer into the

bottom of the support post and tighten gently.Position

the washer the rounded side toward the turntable.

Repeat procedure on the opposite side of the turntable

3

Page 5

ASSEMBLY INSTRUCTIONS

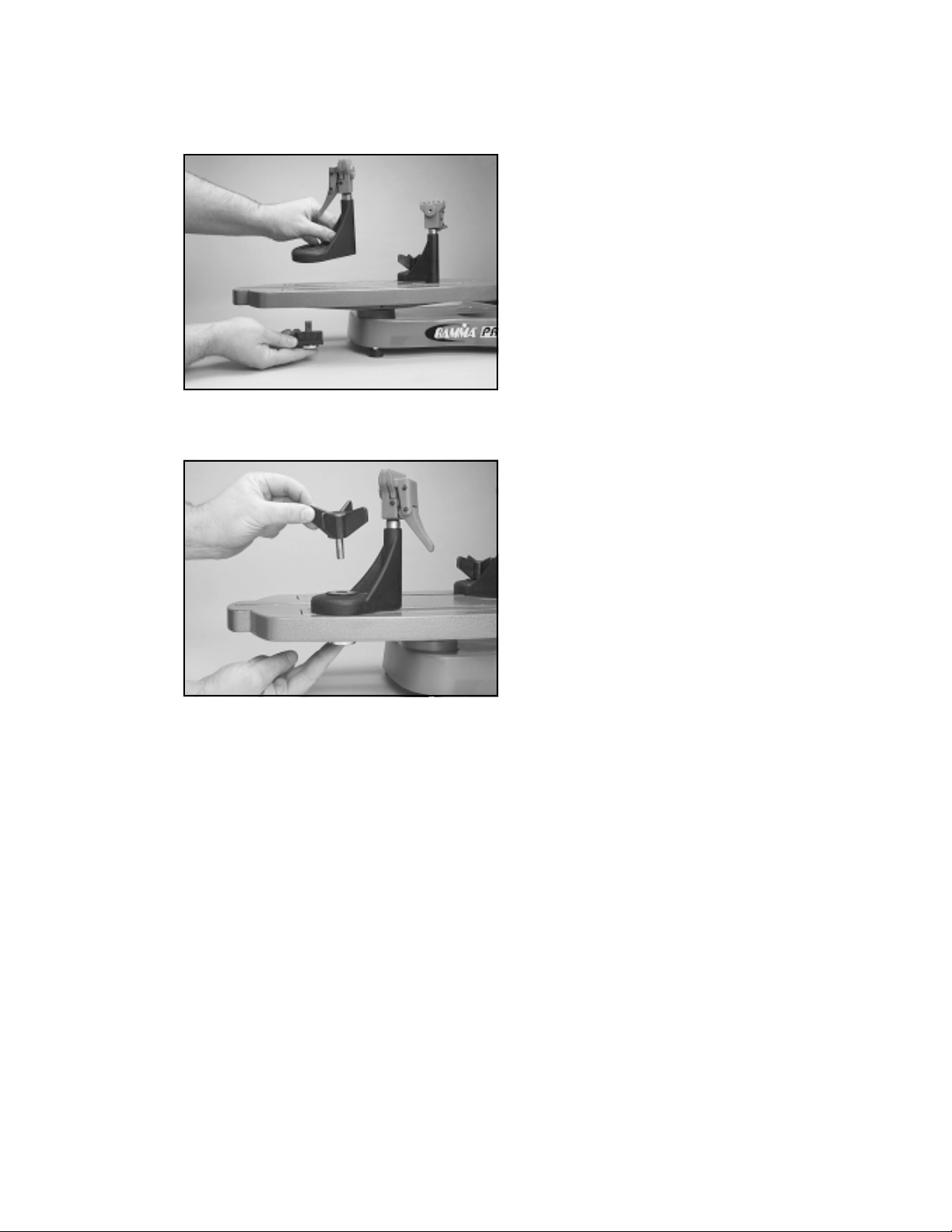

Fixed Clamp Installation

To install the clamps, remove the winged lock knob to

separate the knob from the lower guide bushing. Be

careful not to lose the radial thrust bearing components

located in the center recess of the knob.

Align the clamp base with the clamp slot of the turntable

base. Insert the clamp guide bushing into the clamp from

the bottom of the turntable making sure to engage the

guide with the clamp slot.

Place the load bushing into the top of the clamp base

mating it to the lower guide bushing. After checking that

the thrust bearing is positioned correctly in the base of

the winged lock knob, screw the knob into the base

bushing until fully seated.

The post of the string clamp head and tube of the string

clamp base are treated with grease to provide protection

against corrosion during shipping. Remove any excessive grease with a clean cloth prior to use. The post and

tube may also be cleaned with isopropyl alcohol. After

this type of thorough cleaning, the post and tube should

be treated with a light coating of machine oil to protect

the surfaces against corrosion and to ensure smooth

operation.

4

Page 6

MOUNTING THE FRAME

Adjusting the Frame Support Posts

Place the racquet frame over the center posts and onto

the frame support. Loosen the lever lock bolt on one

support post. Slide the post outward until the center

support of the racquet support slide is positioned near

the inside surface of the racquet frame. Securely tighten

the lever lock bolt.

Adjust the opposite post using the same procedure.

Caution: To avoid racquet damage, the center posts

should not contact the racquet prior to fixing the support

posts.

Tightening the Center Supports

Tighten the Center Supports by turning the adjustment

knob clockwise until slight resistance is felt.

Caution: Overtightening the Center Supports may cause

racquet damage.

Frame Shoulder Support Adjustment

Being sure the shoulder supports are free to swivel in

their mountings, simultaneously rotate the shoulder

support adjustment knobs clockwise until both shoulder

supports gently and squarely contact the frame.

5

Page 7

MOUNTING THE FRAME

Securing the Frame

Lock the shoulder supports in position by turning the

knob at the base clockwise.

Repeat the adjustment procedure for the remaining

support post.

Re-tighten all of the frame supports in the same order as

before.

Do not overtighten any of the supports as racquet

damage may occur.

The supports should be tightened to the point where the

racquet frame will not move in the mounting system

when the handle is grasped and attempts are made to

move it. Should any supports lose contact with the frame

while stringing, they should be re-tightened.

6

Page 8

STRINGING THE FRAME

Setting Tension

To set the stringing tension, loosen the locking knob on

the side of the drop weight. Slide the weight in the

appropriate direction until the face closest to the string

gripper is indexed with the desired tension mark on the

tension bar.

The drop weight is of a two piece design. When

assembled, it will accomodate tensions from 20 lbs. to

90 lbs. For tensions from 8 to 20 lbs., remove the 5mm

bolt on the face of the drop weight, and use the smaller

portion of the weight as described above.

Note:Note:

Note: Tensions above 77lbs. require removal of the

Note:Note:

drop weight bar endcap.

7

Page 9

STRINGING THE FRAME

Fixed Clamp Operation

The fixed clamps for the GAMMA 600FC are of a dual

action design. The string clamp and the clamp base

operate independently of one another.

To clamp a string, lift the clamp head and place the string

between the jaws. Depress the clamp head lever to

secure the string. The clamping pressure applied to the

string should be adjusted to provide sufficient pressure

to secure the string when subjected to the desired pulling

tension. The diamond coated gripper plates provide for

increased friction between the clamps and the string to

allow for reduced clamping pressure while securing and

holding the string under tension.

Rotate the winged lock knob clockwise to secure the

clamp base to the turntable.

Reverse the clamping procedure to unlock the string

clamp.

The winged lock knob should be tightened enough to

prevent clamp base slippage on the turntable, when the

desired tension is placed on the string. To go from the

loose position to the clamped position and back, generally requires about 1/2 to 3/4 quarters of a turn. Although

when stringing at extremely high tensions, additional

tightness may be required.

Note: If the string slips in the string clamp while

tensioning, adjust the gap between the clamp jaws

as per the instructions on page 12.

Clamping the First Main String

To begin stringing the main strings, thread the two ends

of the string through the two center holes at the appropriate end of the frame and continue through the opposite center holes. Thread one end of the string through

the adjacent grommet hole and pull excess by hand.

Secure one of the strings using a string clamp.

8

Page 10

STRINGING THE FRAME

Gripping the String

While holding the tension bar slightly above horizontal,

wrap the free string clockwise around the gripper drum

once and position between the gripper jaw.

Gently turn the gripper clockwise while squeezing the

jaws together until all slack in the string is removed.

Note: For proper operation, the string gripper jaw must

be in the position shown. The tension in the string

provides the clamping force to the jaws.

Pulling Tension

While securely holding the string gripper drum with your

hand, lift the tension bar above horizontal and gently

lower the bar under its own weight. If the tension bar

drops below horizontal, repeat the above action until the

bar comes to rest parallel to the racquet.

WARNING: TO AVOID INJURY, KEEP FINGERS AWAY FROM GRIP-

PER JAWS WHILE TENSIONING STRING.

When the correct tension is attained, the drop weight bar

will rest horizontally as shown. For accurate tensioning,

it must be lowered and come to rest at horizontal without

assistance. Manually forcing the tension bar to the

horizontal position will greatly increase the string tension and may result in racquet damage.

If the tension bar comes to rest above horizontal, release

the string by lifting the bar and re-pull the string.

9

Page 11

STRINGING THE FRAME

Clamping the First Main String

Secure the tensioned main string using the remaining

fixed clamp. Repeat the procedure for all of the remaining main strings and tie off following the racquet manufacturers recommendations.

Follow the manufacturer's recommended stringing pattern for one or two piece stringing. This will determine

the starting point for the cross strings. If applicable, tie

the first cross string using an appropriate starting knot.

Weaving the Cross Strings

Weave the cross strings over and under the main strings

being careful to alternate the weave direction of each

consecutive cross string so as to be opposite of the

previously installed cross string.

Once the final cross string is tensioned and clamped, tie

off at the appropriate hole specified by the racquet

manufacturer.

10

Page 12

PATHFINDER AWL

The Progression 600FC includes the new Pathfinder

stringing awl which creates a pathway between and

around strings to make inserting a string through tight

grommets easier and quicker.

Insert the awl through the grommet hole in the same

manner as for traditional awls. The Pathfinder awl must

be in the closed position before insertion.

Once the awl is inserted, pull the handle of the awl

outward while holding the tip section in place, leaving the

outer sheath in the grommet hole.

Insert the end of the string into the center of the sheath.

While holding pressure on the string, slowly pull the

sheath out of the grommet hole to leave the end of the

string exposed.

11

Page 13

MAINTENANCE

Your GAMMA 600FC stringing machine is adjusted for optimum performance at the factory and needs no further

adjustments before use. After extensive use however, the machine may need minor adjusments as follows :

Adjusting the Turntable Bushings

There are two adjustment points on the machine base.

One is located beneath the polystyrene base cover while

the other is accessed from below the machine.

Using the supplied 3mm hex wrench, tighten both set

screws slightly until the turntable rotates smoothly without excessive free play.

Repeat procedure until final adjustment is reached.

Adjusting the Clamp Pressure

The clamps provided with your stringing machine will

need minor adjustments according to what string type,

construction, and gauge you are using.

To adjust the gap (clamping pressure) between the

clamp jaws, insert the string through the racquet as if you

were beginning the main strings. Clamp the strings and

pull tension. If the string slips through the jaws of the

clamp, tighten the clamp by compressing the clamp

jaws together by hand while turning the Adjustment

Knob, in the clockwise direction. If the clamp leaves

impressions or damages the string, it may be excessively tight and should be adjusted by turning the hex

screw counter clockwise to open the gap between the

jaws. The clamp jaws should be cleaned periodically to

grip properly.

Note: The string clamps supplied with your stringing machine can accomodate tight string patterns such as

badminton. Depending on the string pattern, the clamp may spread the strings slightly which will not compromise the

quality of the string job.

be free from dirt, oil, and any string coating for them to

12

Page 14

TROUBLESHOOTING TIPS

PROBLEM SOLUTION

String slips in clamps. - Adjust gap between jaws.

- Clean clamp jaws.

String slips in gripper. - Clean gripper jaws.

- Make sure string is wrapped over top jaw of

gripper prior to inserting between gripper jaws.

String clamp base slips on turntable. - Clean Clamp Base and Turntable surface.

CARE and CLEANING

With time and use, the clamping surfaces of your machine may become oily or dirty and result in string or clamp

slippage while stringing. Periodic cleaning of the following parts is recommended.

String Clamps

Clean the inside gripping surfaces of the string clamp jaws by inserting a cloth or pipe cleaner soaked with isopropyl

alcohol between the jaws and rub back and forth. If the build-up is excessive, dismantle the string clamp jaws to

expose the gripping surfaces by removing the adjustment screw. Using a small nylon brush, (such as a toothbrush),

scrub the inside surfaces until all debris is removed. Clean the jaws with isopropyl alcohol and re-assemble.

String Clamp Base

Clean the base of the clamps and the top of the turntable with isopropyl alcohol.

String Gripper

Follow the same procedure for cleaning the string clamps.

13

Page 15

EXPLODED P ARTS VIEW

14

Page 16

PARTS LIST

PART #

4

5

6

7

8

9

10A

13

14

15A

21

22

23

24

25

25A

26

27

28

29

30

30A

31

32B

33B

34

35

36

37

40

53

54

55

56

DESCRIPTION

TURNTABLE BUSHING

RUBBER FEET

CAP SCREW

FOOT NUT

BUSHING SET SCREW

WASHER - M8

WINDER STAND - B/S

POST LOCK LEVER

WASHER - M10

2021 SUPPORT POST

FRAME SUPPORT SLIDE

BADMINTON ADAPTER

TENNIS ADAPTER

SUPPORT SLIDE KNOB

TENSION BAR

SET SCREW

TENSION BAR CAP

DROP WEIGHT KNOB

FRONT WT. - BADMINTON

BACK WIEGHT - TENNIS

TENSION BAR DRUM

SET SCREW

STRING GRIPPER DRUM

UPPER JAW w/ INSERT

LOWER JAW w/ INSERT

RATCHET TEETH

RATCHET TEETH SPRING

GRIPPER JAW SPRING

CAP SCREW

CAP SCREW

CLAMP BASE ASSEMBLY

CLAMP BASE

GUIDE BUSHING

GUIDE BUSHING NUT

PART #

57

57A

58

122

140

141

142

143

144

145

146A

147

148

161

162

163

172

179

181

187

188

189

190

DESCRIPTION

LOAD BUSHING

RADIAL BEARING

WINGED KNOB

SHOULDER PADS (RED)

MTNG. STAND TOP PLATE

MTNG. STAND PAD

SUPPORT ARM - LEFT

SUPPORT ARM - RIGHT

SUPPORT LOCK KNOB

ARM RETURN SPRING

ARM ADJUSTMENT KNOB

ARM ADJUSTMENT SCREW

SHOULDER V-CLAMP

WINDER BEARING

GRIPPER PIVOT PIN -B/S

PIVOT PIN RTNG. COLLAR

2020-25 TURNTABLE

GLIDE BAR - ALUM.

COMP. FIXED CLAMP - RED

PII ALUMINUM BASE

PII BASE COVER

PII LOWER TRAY PAD

PII UPPER TRAY PAD

TOOLS AND ACCESSORIES

70

72

73

108

109

167

170

196

HEX WRENCH - 5MM

PATHFINDER AWL

STRINGERS AWL

UTILITY KNIFE

BOX WRENCH - 17MM

M10 SUPP - POST SCREWS

10 PC. HEX WRENCH SET

PLIERS

15

Loading...

Loading...