Page 1

5800 Els

STRINGING MACHINE

6 POINT MOUNTING

OWNER'S MANUAL

Issue 3 - January 2009

Page 2

OWNER'S MANUAL

5800 Els

TABLE OF CONTENTS

PAGE 1................................................................................................ WARRANTY

PAGE 2................................................................................................. FEATURES

PAGE 3....................................................................... UNPACKING & ASSEMBLY

PAGE 8..................................................... POWER CONNECTION & CONTROLS

PAGE 10.................................................. TENSIONER & GRIPPER OPERATION

PAGE 11......................................................................... MOUNTING THE FRAME

PAGE 13.........................................................................STRINGING THE FRAME

PAGE 15................................................. STRING LENGTH METER OPERATION

PAGE 16.........................................................................ADDITIONAL FEATURES

PAGE 17...............................MAINTENANCE, ADJUSTMENTS & CALIBRATION

PAGE 19..................................................................... TROUBLESHOOTING TIPS

PAGE 20...................................................................................PATHFINDER AWL

PAGE 21..............................................................................................PARTS LIST

PAGE 22....................................................................................PARTS DRAWING

LIMITED WARRANTY

GAMMA SPORTS warrants to the original purchaser that the 5800 Els stringing machine ("EQUIPMENT") purchased is free from

defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding

electrical parts and string clamps), and for a period of one (1) year from the date of purchase for all electrical parts and string clamps.

Should any defects develop under normal use within the specified time periods, GAMMA will at its option, repair or replace the defective

EQUIPMENT provided it is returned to GAMMA prepaid at the purchaser's expense. This warranty does not apply to any damage or

defect caused by negligence, abuse, misuse, unauthorized alteration, shipping, handling, or part wear and tear as a result of normal

use.

Routine maintenance, adjustment, and cleaning required to ensure proper operation are the responsibility of the purchaser and are not

covered under the terms of this warranty. These include, but are not limited to: String Clamp adjustment, as described on page 18,

Quick Action Clamp Base adjustment, as described on page 18, and the cleaning procedures listed on page 19.

GAMMA’s obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized to

promise any other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

To return defective EQUIPMENT, a return authorization (RA#) must be obtained from a GAMMA customer service representative. The

RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped prepaid by the customer

to GAMMA. Please retain the original shipping carton and packing materials for any future shipments. GAMMA will not be

responsible for machines which are not sent in the original undamaged packaging.

An Extended Warranty is available through a GAMMA customer service representative, call 800.333.0337 for details.

1

Page 3

FEATURES

MACHINE FEATURES

Electric Constant Pull Tensioner w/ 11 lbs. to 89 lbs. Tension

Range

Digital Tension Setting Display

Professional Six Point “Quick Mount” Racquet Mounting

System- Accomodates All Racquets Without Adapters

Parallel Jaw Linear Gripper w/ Diamond Dust Coated

Gripping Surfaces

Professional Dual Action, Rotating, Diamond Dust Coated,

Fixed String Clamps

High Strength Extruded Aluminum Frame with Durable

Anodized Finish and 2-Convenient Padded Tool Trays

Unique Internal Drawer System for Storing Tools and Adap-

tors.

Convenient Foot Actuated Tensioner Switch

2

Page 4

5800 Els

Unpacking Instructions & Contents

Instructions for Unpacking and Preparing for Assembly

The stringing machine is shipped in three cartons, a large master carton for the stringing

machine base with tensioner module and accessories, a medium carton for the turntable

and mounting system and a smaller carton for the floor stand post and base legs. Please

save the cartons and packing materials for possible shipments in the future.

Gamma Sports cannot be responsible for machines that are not returned, shipped in their

original, undamaged packaging. The tools you will need to assemble the machine are

provided with the machine. Due to the weight of the tensioner unit, you may need the

assistance of someone to help lift the tensioner unit out of the carton.

Once the cartons are opened, remove all inner cartons and check to be sure that all parts

are present and accounted for.

Contents of Base & Leg Carton

(1) Lower Column

(1) Upper Column with Flange Plate

(4) Legs

(1) Locking Knob Screw

(4) M8 x 25 Flat Head Screws

(4) M8 x 30 Cap Screws

(8) M8 Nuts

(6) M6 x 20 Cap Screws

(1) M8 x 25 Cap Screws for Height Adjustment

(1) String Reel Holder (M8 Threaded Pin), (1) Knob, (10) Spacers, & (2) M8 Washers

Contents of Mounting System Carton

(1) Turntable Assembly w/ String Clamp Baes and Mounting Stands w/ Frame Support

Slide, Side Supports, and Adapters

(2) String Clamp

(1) 5mm T-Handle Allen Wrench

(1) Package of Spare plastic adapters for mounting system supports (contains 16 pcs)

Contents of Large Master Carton (including accessory cartons packed inside)

(1) Stringer Assembly Unit w/ Tensioner Module

(1) Power Cord

(1) Foot Pedal Tensioner Switch

(1) Tool Kit (contains side cutter, bent nose pliers, needle nose pliers, starting clamp)

(1) Straight Stringers Awl & (1) Pathfinder Specialty Awl

(1) Tools for assembly and maintenance

3

Page 5

ASSEMBLY INSTRUCTIONS

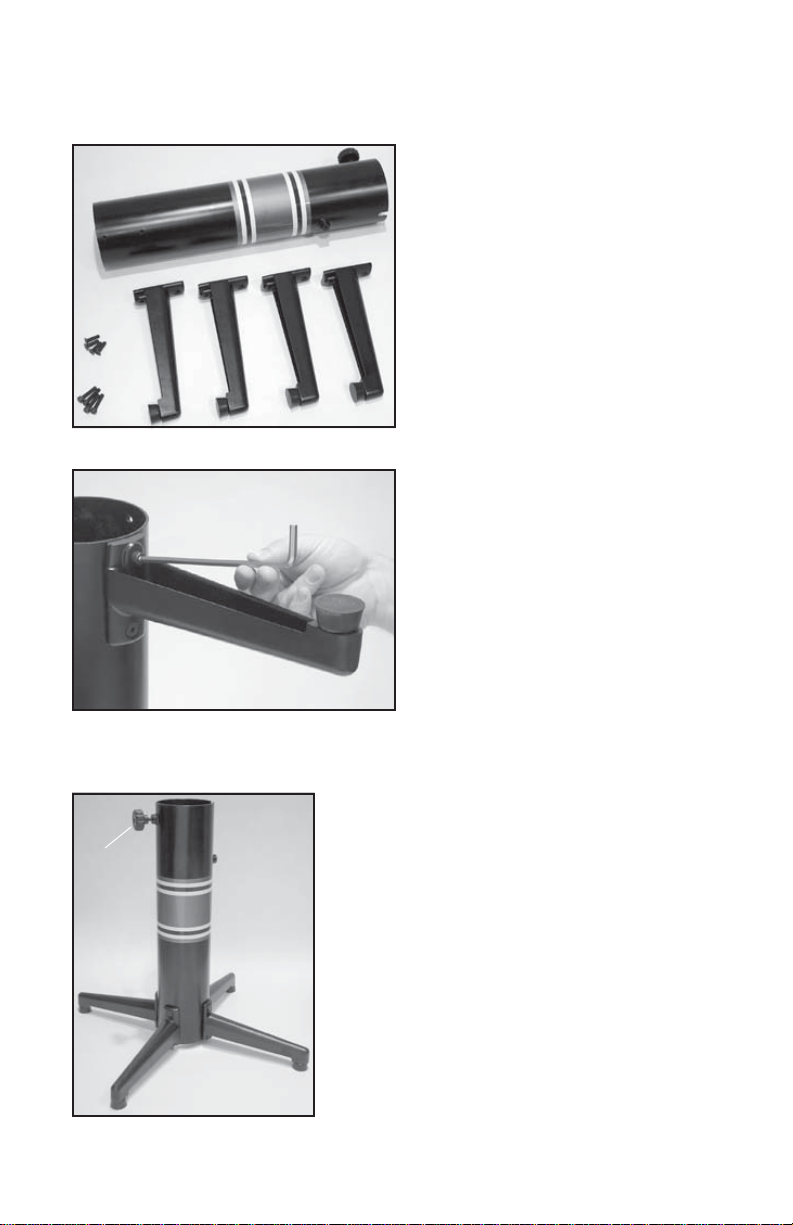

Base Leg Assembly

The stringing machine uses a four leg floor

stand design. The legs must be assembled

to the lower column before use. Remove all

parts from the shipping carton to confirm that

contents match the list of parts on Page 3.

Base Leg Assembly (Cont.)

Align the holes in the leg flange with the

matching holes in the lower column. Secure

the leg with one M8 FLAT HEAD screw

through the upper hole, and one M8 SOCKET

HEAD cap screw through the bottom hole.

Install one 8mm nut on each screw. Repeat

this procedure for the three remaining legs.

“A”

Base Leg Assembly (Cont.)

To complete the floor stand, screw the height adjustment locking knob (“A”) into the side of the lower column.

The locking knob should not protrude beyond the inside

of the lower column at this time.

4

Page 6

ASSEMBLY INSTRUCTIONS

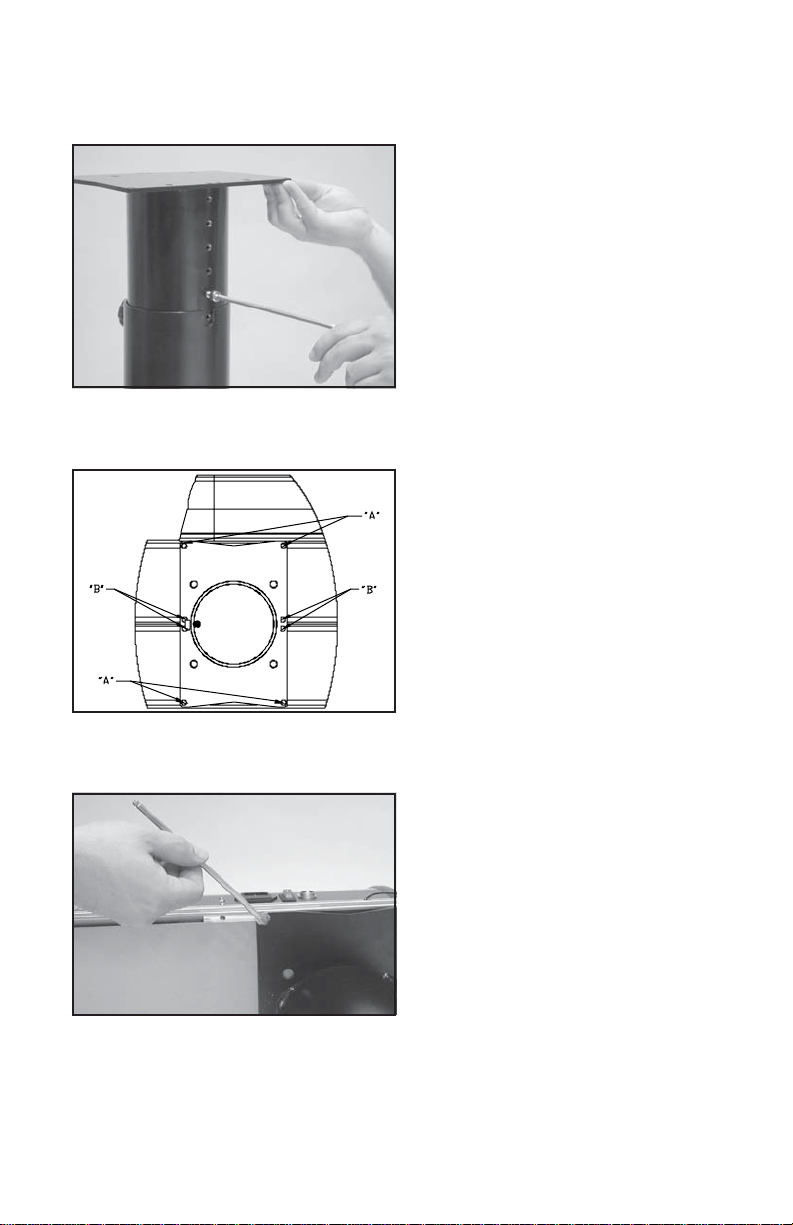

Height Adjustment

The height of the machine is adjustable from

39” to 46” in approximate 1” increments. To

change the height, remove the socket head

cap screw from its current position and

place it in the appropriate hole to set the

desired height of the machine. Be sure to

thread the screw completely into the upper

column so the head of the cap screw rests

in the notch of the lower column.

Stand Upper Post Installation

With the height adjustment cap screw on the

upper column facing the brake lever & string

length meter, align the six holes marked “X”

in the upper column flange with the threaded

holes in the slide brackets of the machine

base.

Floor Stand Upper Column Installation

(cont.)

Secure the flange to the base of the machine

with the six M6 cap screws packed with the

floor stand.

USE CAUTION WHEN SECURING SCREWS

TO SLIDE BRACKETS. CROSS THREADING OR OVER TIGHTENING MAY DAMAGE

THE THREADS IN THE SLIDE BRACKET OR

CAUSE THE THREADS TO STRIP OUT.

5

Page 7

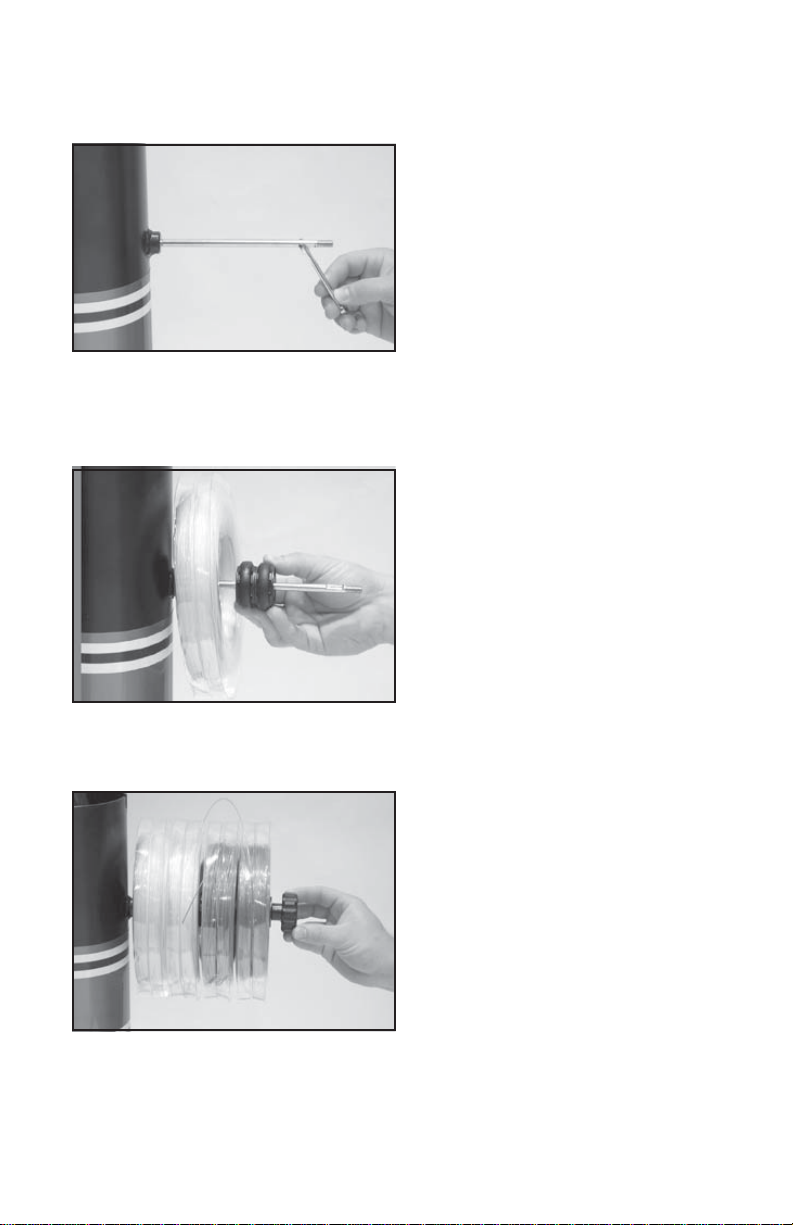

STRING REEL HOLDER INSTALLA TION

The string reel holder pin is an 8 mm rod with

threads on both ends, and flat surfaces

machined on one end. Thread the end of the

pin without the flat surfaces into the threaded

boss on the right side of the lower column.

Using the M6 open end wrench positioned on

the flat surfaces, securely tighten the pin to

the lower column.

The string reel holder can hold up to 5 reels

of string (depending on the size of the string

reel). Before placing the first reel on the rod,

slide two M8 washers over the pin and slide

them to the boss on the lower column. After

the first reel is placed onto the rod, place two

spacers between each reel to provide

enough space between reels and allow

them to turn freely without rubbing against

one another. (To provide a smooth feed to

the String Length Meter, place the reels on

the rod so the string spools off the reel from

the underside of the reel.)

After the last reel is installed, place the

remaining spacer(s) on the pin and attach

the threaded knob to the end of the rod.

6

Page 8

ASSEMBLY INSTRUCTIONS

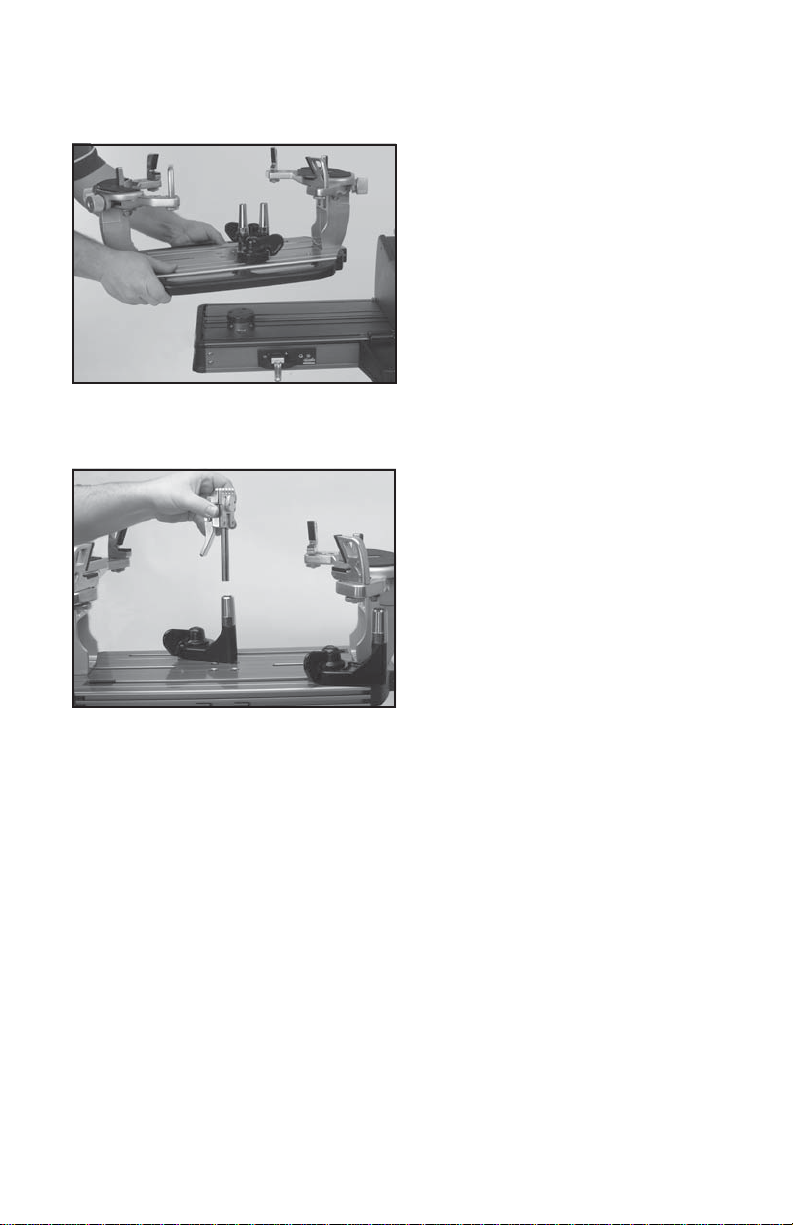

Turntable and Mounting System Installation

To install the turntable remove the four nuts

underneath holding the mounting bolts in

place. Position the turntable over the turntable pin and align the bolts with the holes in

the flange. Secure them with the included

allen wrench.

String Clamp Installation

The post of the string clamp and tube of the

string clamp base are treated with grease to

provide protection against corrosion during

shipping and while in storage. Remove any

excessive grease with a clean cloth prior to

use. The post and tube may also be cleaned

with isopropyl alcohol. After this type of

thorough cleaning, the post and tube should

be treated with a light coating of machine oil

to protect the surfaces against corrosion

and to ensure smooth operation.

7

Page 9

POWER CONNECTION & CONTROLS

Front Panel Features

BCAD

B

DAC

Instructions for Power Connection and Controls

A - String Gripper

B - Tension Button

C - Control Panel

D - L.E.D. Tension Display

Back Panel Features

A - Lighted Power Switch

B - A/C Power Cord Socket

C - Foot Pedal Switch Receptacle

D - String Length Meter Receptacle

CAUTION ! Before connecting to the power supply, check the voltage source

that the machine is being connected to. The acceptable range of input voltages for this machine is between 100 V and 240 V @ 50 to 60 Hz. If you have

any questions regarding the input voltage supply for your area, please ask

your electric utility company.

To install the power cord, insert the female end of the power cord into the AC Adapter

and then insert the female end of the cord from the AC Adapter into the A/C Power Cord

Socket “C” located on the back panel of the tensioner. Plug the male end of the power

cord into a grounded power outlet. When usi ng extension cords, use grounded heavy

duty extension cords rated for 15 AMP service.

To connect the foot pedal switch, insert the male pin at the end of the foot pedal switch

cord into the Foot Pedal Switch Receptacle “B” located on the back panel of the tensioner.

Switch on the machine by pressing the Lighted On-Off Power Switch on the back panel.

At start-up, the LED will display a countdown from “9.0” to “0.0” while the machine

performs a self diagnostics check at start-up.

W ARNING! FOR INDOOR USE ONLY. TO BE USED BY

ADULTS OR UNDER ADULT SUPERVISION ONLY.

NEVER OPEN UNIT WITH POWER CONNECTED.

8

Page 10

CONTROL P ANEL FUNCTIONS

AND FEATURES

Tension Index Buttons - Changes

tension setting in +/- 1.0 or +/- 0.1 Lb or

Kg increments. Holding the button down

will scroll the tension setting values up

or down. Tension settings entered with

the tension index buttons are placed

into temporary memory setting “0”.

Clear Button - Clears display to enter a

new tension or to reset String Length

Meter measurement

Test Button & Racquet Strung - Press

once for approximate number of racquets

strung. Press again to return. Press and

hold for 5 seconds and the machine does

an internal diagnostic check, such as the

one performed at start-up.

Single Digit (1-9)

Memory LED Display

Memory Button - Indexes from 9 preset

tension settings that can be stored in

memory. Settings are retained even if

machine is turned off. Each press of the

button indexes to the next memory setting.

Memory settings 1-9 must be entered using

the keypad followed by pressing the “ENT”

button.

Enter Button - Saves displayed tension for

Memory setting - when tension is entered

using the keypad display flashes until this

button is pressed to save the setting. Also

Clears display for String Length Meter

measurements

Knot Function - Increases pulling tension by

10% over the setting value (max 90 lbs / 40.8

kgs) for one pull. During the pull the LED stays

lit to indicate the Knot function is enabled.

Three Digit (XX.X)

Tension Setting Display

or String Length LED

Display

Lbs/Kgs Button - Changes tension

display from Lbs to Kgs. Each press of

the button toggles back and forth

between Lbs and Kgs.

Pre-Stretch Function - Pulls string 10%

or 20% over the tension setting (up to 90

lbs / 40.8 kgs), releases the string, and

repulls to the tension setting. Each press of

the button toggles between 10%, 20% or no

pre-stretch.

Speed Button - Changes pulling speed

of winder from Fast (default) to Medium

to Slow. Slow speed is recommended

for low stretch strings, such as Kevlar.

Each press of the button toggles

between Fast, Medium and Slow

speeds.

String Length Meter Button - Enables

string length meter function. Each press

of the button toggles back and forth

between Meters and Feet measurement. To switch back to tensioning

function, press the “Lbs/Kgs” button.

9

Page 11

STRING GRIPPER OPERATION

String Gripper Operation

To insert a string into the linear string gripper,

wrap the string clockwise around the roller

guide and insert the string between the

diamond dust coated string gripper plates.

Excessive slack in the string should be

removed before applying tension. Pull the

string perpendicular to the gripper plates and

begin tensioning. As tension is applied, the

grippers will engage to hold the string. For

adjustment of the parallel plates, see “Setting

the Gripper Plate Spacing” on page 17.

CAUTION ! CHILDREN SHOULD NEVER BE PERMITTED TO OPERATE THIS MACHINE

WITHOUT ADULT SUPERVISION.

TENSIONER OPERATION

Setting the String Tension

String tensions may be entered and stored

into one of nine memory storage settings

(See section on Control panel Functions

and features) by using the tension index

buttons. While tension setting is entered,

the value displayed will be temporary until

the “Enter” button is pressed to store it in

one of the nine permanent memory settings.

Tensioning a String

Tensioning

Button

be ready to clamp off. In the event that one of the keys on the control panel are accidently

pressed while tensioning a string, the tensioner will automatically reverse and release the

string being tensioned.

After wrapping the string around the roller

guide and guiding it between the gripper

jaws, while gently pulling the string perpendicular to the gripper plates, press the

tensioning lever switch at the end of the

gripper or press the foot pedal switch to

activate the tensioner. The tensioner will

start pulling at full speed and then slow

down as the tension in the string approaches

the tension setting. When the tension in the

string reaches the tension setting, the LED

display will begin to flash, and the string will

10

Page 12

STRING CLAMPS

String Clamp Operation

The string c

where the string clamp and clamp base

operate independently of one another.

To clamp a string, lift the clamp head and

place the string between the jaws and

depress the string clamp lever to secure the

string. The clamping pressure applied to the

string should be adjusted as needed (see

Page 18) to provide sufficient pressure to

secure the string when subjected to the

desired pulling tension. The diamond coated

gripper plates provide for increased friction

between the clamps and the string to allow for reduced clamping pressure while securing

and holding the string under tension.

Clamp Base Operation

To lock the string clamp base to the turntable,

rotate the clamp base locking lever clockwise. To release the string clamp base from

the turntable, rotate the clamp base locking

lever counter-clockwise.

The Locking Lever should be tightened

enough to prevent clamp base slippage on

the turntable, when the desired tension is

placed on the string. To go from the loose

position to the clamped position and back,

generally requires the rotation permitted by

the slot in th clamp base.

lamps are a dual action design

MOUNTING THE FRAME

Adjusting the Frame Support Posts

Loosen the lock bolts of the frame support

posts and space them apart with the frame

support slides separated by the approxi-

mate length of the racquet head. Although it

is not required, it is good practice to center

the support posts on the turntable. Lock one

of the posts in position by tightening the lock

bolt and position the other post until the frame

support slide is positioned near the inside

surface of the racquet frame. Securely

tighten the lock bolt of the second support

post.

Caution: To avoid racquet damage, the

center posts should not contact the racquet

prior to locking down the support posts.

11

Page 13

MOUNTING THE FRAME

Tightening the Frame Supports

Tighten the Frame Support Slides by turning

the adjustment knob clockwise until snug

against the racquet frame and slight resis-

tance is felt.

Caution: Overtightening the Center Sup-

ports will stretch the head of the racquet and

could cause racquet damage.

Frame Shoulder Support Adjustment

Being sure the shoulder supports are free to

swivel in their mountings, simultaneously

rotate the shoulder support adjustment knobs

clockwise until both shoulder supports gen-

tly and squarely contact the frame.

Securing the Frame Shoulder Clamps

Lock the shoulder supports in position by

turning the knob at the base clockwise.

Repeat the adjustment procedure for the

remaining support post.

Re-tighten all of the frame supports in the

same order as before.

Do not overtighten any of the supports as

racquet damage may occur.

The supports should be tightened to the

in the mounting system when the handle is grasped and attempts are made to move it. Should

any supports lose contact with the frame while stringing, they should be re-tightened.

point where the racquet frame will not move

12

Page 14

STRINGING THE FRAME

Getting Started

To begin stringing the main strings, thread

the two ends of the string through the two

center holes at the appropriate end of the

frame and continue through the opposite

center holes. Thread one end of the string

through the adjacent grommet hole and pull

excess by hand.

Secure one of the strings using a string

clamp.

Pulling Tension

To apply tension, wrap the string being

tensioned clockwise around the roller guide

and position the string between the gripper

jaws.

The string must pass over the roller guide

before being placed between the gripper

jaws to ensure that the proper tension is

applied to the string.

Pull the string until all slack is removed before

pressing the tension lever switch.

WARNING: KEEP FINGERS AW AY FROM ROLLER

GUIDE WHILE TENSIONING STRING. TO RELEASE

TENSION BEING APPLIED TO THE STRING PRESS THE

PUSH TENSION LEVER SWITCH OR ANY BUTTON ON

THE KEYPAD IN CASE OF EMERGENCY.

Tensioning

Button

If the string gripper does not release the string, push the gripper plates to the right to help

disengage and release the string from the gripper.

To apply tension to a string, press the

tension lever switch or the foot pedal

switch. The string gripper will move to the

right, away from the racquet, and gradually

apply tension to the string. When the set

tension has been attained, the gripper will

stop moving. As the tensioned string relaxes, the gripper will continue to pull intermittently, to maintain the set tension.

To release the string after clamping, press

the tension lever switch or foot pedal switch.

13

Page 15

STRINGING THE FRAME

Clamping the First Main String

Secure the tensioned main string using the

remaining fixed clamp. Repeat the procedure for all of the remaining main strings and

tie off following the racquet manufacturers

recommendations.

Follow the manufacturer's recommended

stringing pattern for one or two piece stringing. This will determine the starting point for

the cross strings. If applicable, tie the first

cross string using an appropriate starting

knot.

Weaving the Cross Strings

Weave the cross strings over and under the

main strings being careful to alternate the

weave direction of each consecutive cross

string so as to be opposite of the previously

installed cross string.

Completing the String Job

Once the final cross string is tensioned and

clamped, tie off at the appropriate hole

specified by the racquet manufacturer.

Remove the frame from the mounting system by loosening the shoulder supports and

frame supports.

14

Page 16

STRING LENGTH METER OPERATION

To enable the String Length Meter (SLM)

function, press the String Length button on

the keypad. When the String Length button

is pressed, one of the LED indicators above

“M” or “FT” will light up to indicate that the

SLM function is enabled. Pressing the String

Length button will toggle between “M” and

“FT” to set the measurement units for either

Meters (“M”) or Feet (“FT”). Measurements

are displayed in 0.1 increments.

SLM button

To measure a length of string from a reel or

set of string, insert the end of the string

through the loop from the backside of the

string guide attached to the front of the SLM.

Lift the clamp pad and insert the string

through the entry hole on the face plate of the

SLM. Continue to feed the string into the entry

hole until it exits the SLM through the hole on

the right side and release the clamp pad. (In

addition to aligning the strings with the entry

to the SLM, the felt clamp pads apply a slight

amount of pressure to the string and wipe

down the surface of the string to prevent

debris from entering the SLM).

When the end of the string exits through the

hole on the right, press the “C” or “Entry/

Clear” button on the keypad to “Zero” the

display, and the length of string will be mea-

sured from the point on the string located at

the edge of the exit hole. Pull the end of the

string at a slow steady rate and the SLM will

begin measuring the length of string as it is

pulled through the SLM and indicate the mea-

surement on the LED display. When the de-

sired length of string is measured, cut the

string at the edge of the exit hole.

NOTE: When reaching the end of a string,

pull the string through the SLM slowly

to avoid inaccurate measurement.

The string length meter was designed to measure strings between 1.10 mm (18 ga) and 1.45

mm (15 ga) at an accuracy of +/- 0.3% of the indicated value and +/- 2 inches (50 mm) absolute.

When measuring strings smaller than 1.10 mm (such as badminton strings) the error will be

-2.5% of the indicated value (up to 6” short in 40 ft) and +/- 2 inches (50 mm) absolute.

15

Page 17

ADDITIONAL FEATURES

Turntable Brake

The turntable may be locked in any position.

Flip the lever to the right to lock the turntable

brake and flip the lever to the left to release

the turntable brake.

Storage Drawers

There are two storage drawers located in

the base of the machine. The drawers open

from the right side of the base and lock into

the end cap with a spring loaded latch.

To open the drawers depress that latch in

the face of the drawer and slide it to the right.

To close the drawer simply slide the drawer

back inside the base and the latch with

automatically lock into place.

Cutting Block

A cutting block is provided to provide a

surface for cutting a point on the strings

using a razor blade cutter.

16

Page 18

P A THFINDER AWL

The machine includes the Pathfinder stringing awl which creates a pathway between

or around strings to make inserting a string

through tight grommets easier and quicker.

Insert the awl through the grommet hole in

the same manner as for traditional awls.

The Pathfinder awl must be in the closed

position before insertion.

Once the awl is inserted, pull the handle of

the awl outward while holding the tip section

in place, leaving the outer sheath in the

grommet hole. Insert the end of the string into

the center of the sheath.

While holding pressure on the string, slowly

pull the sheath out of the grommet hole to

leave the end of the string exposed.

17

Page 19

MAINTENANCE & ADJUSTMENTS

Tension Calibration Procedure

Each stringing machine has been checked

and calibrated at the factory using accurate load sensing devices to ensure that

the machine pulls at the correct tension.

However, if you suspect that your machine

may not be pulling at the correct tension you

can check the pulling tension with a calibrator and make adjustments if needed.

Most tension calibrators (such as a Gamma Tension Calibrator) function by clamping off the

string attached to one the end of the calibrator and applying tension to the string located

on the opposite end of the calibrator. The tension measured by the calibrator will then display

the tension being applied to the calibrator by the machine. If the calibrator and tensioner

do not match then you can adjust the tensioner as follows:

(1) Turn the machine off and restart the machine while holding down the Test buttonuntil

count down is complete. 22 lbs should appear on the display. (2) Apply tension to the

calibrator. (3) If the tension reading on the calibrator does not match the tension displayed

on the machine, use the tension indexing buttons to match the display to the calibrator reading

and press the Enter/Clear button (4) Release the tension applied to the calibrator and 44 lbs

should appear on the display. (5) Repeat steps #2-#4 for 44, 66 & 88lbs. (6) After completing

the adjustment at 88lbs the display will show 00 lbs. (7) Restart the machine without holding

any buttons and the calibration adjustment will be complete.

Switching the Buzzer Off and On

The stringing machine is equipped with a buzzer that sounds when any key or button is

pressed, when the tensioner has pulled a string to the end of its travel and is not yet at tension,

or when there is a problem with the some fucntion of the machine. The buzzer can, however,

be disabled if desired for normal keypad entries.

To disable the buzzer, turn the machine on and while the display is counting down from 9 to

0, press and hold the Enter/Clear button for at least 5 seconds. The buzzer will be disabled

and will remain disabled. It can be enabled again by following the same steps listed above.

NOTE: Even when disabled, the buzzer will sound if the tensioner has pulled a string and

reached the end of the track prior to reaching the desired tension in the string, or if there is

some other problem with the machine that requires attention.This is meant to alert the user

of a problem, and can not be disabled.

Adjusting the Clamp Base

In the event the Locking Lever rotation is

insufficient to ensure smooth operation of

the clamp base, very minor adjustments to

the Clamp Base Locking Nut can be made

with a 17mm socket. Tighten or loosen the

locking nut in very small increments to provide more clamping pressure or running

clearance as needed.

18

Page 20

MAINTENANCE & ADJUSTMENTS

Quick Action Clamp Base Removal

Quick Action clamp bases can be removed

from the turntable for maintenance or cleaning by removing clamp stop located at the end

of the slot in the turntable. To remove the

clamp stop, remove the two screws holding

the clamp stop in place from the underside of

the turntable. Lift the clamp stop out of the

slot, slide the clamp base to the end of the slot

and lift it out. Replace the clamp base and

clamp stop in reverse order.

Gripper Plate Spacing Adjustment

The parallel plates of the string gripper are

adjustable to accomodate varying string

gauges and types of string. If the string slips

through the gripper plates while pulling tension, rotate the gripper adjustment screw

counter-clockwise. If the string is damaged

while pulling tension, rotate the gripper adjustment screw clockwise. The gripper is

properly adjusted when there is enough

Adjustment

Screw

pressure to securely hold the string without

causing damage to the string. If you move

the gripper to the right hand end of the track

it is easier to access the screw.

Adjusting the String Clamp Jaw Spacing

The string clamps will need minor adjustments according

to what string type, construction, and gauge you are

using.

To adjust the gap (clamping pressure) between the clamp

jaws, insert the string through the racquet as if you were

beginning the main strings. Clamp the strings and pull

tension. If the string slips through the jaws of the clamp,

tighten the clamp by compressing the clamp jaws together

Adjustment

Knob

wise to open the gap between the jaws. The clamp jaws should be cleaned periodically to

be free from dirt, oil, and any string coating for them to grip properly. Knife sharpening stones

are excellent for removing build-up on the diamond coated surfaces and are available.

Note: The string clamps supplied with your stringing machine can accomodate tight string

patterns such as badminton. Depending on the string pattern, the clamp may spread the strings

slightly which will not compromise the quality of the string job. String clamps designed

specifically for badminton racquets are available.

by hand while turning the Adjustment Knob, in the clockwise direction. If the clamp leaves impressions or damages the string, it may be excessively tight and should be

adjusted by turning the Adjustment Knob counter clock-

19

Page 21

TROUBLESHOOTING TIPS

PROBLEM SOLUTION

String slips in clamps - Adjust gap between clamp jaws

- Clean clamp jaws

String slips in gripper - Adjust gripper jaws spacing

- Clean gripper jaws

String clamp base slips on turntable - Adjust clamp base

Electrical system does not function - Check power source

- Check power cord connection

String tension too tight or too loose - Check tension using a tension

calibrator, adjust machine

calibration if necessary

CARE & CLEANING

With time and use, the clamping surfaces of your machine may become oily or dirty and result

in string or clamp slippage while stringing. Periodic cleaning of the String Clamps, String

Clamp Base, and String Gripper is recommended using a cleaning solvent such as isoproyl

alcohol and a mild abrasive tool such as a toothbrush.

OPTIONAL TOOLS AND ACCESS

MGEMC

MDCSC

MFSC

MTC

SGSM

MACHINE COVER

FIXED BAD STRING CLAMPS

FLOOR STAND CASTERS

CALIBRATOR

STRINGER’S MAT

20

Page 22

PARTS LIST

PART#

6B

9

14

21A

106

114

115

121

133

140

141

142

143

144

146A

148L

148R

203

210

211

212

265

270

274

276

277

278

282

283

285

286

287

288

289

292

293

295

296

297

298

DESCRIPTION

CAP SCREW- M8

WASHER- M8

WASHER- M10

FRAME SUPP SLIDE

STAND BRAKE KNOB

SHORT LEG

FLAT HEAD SCREW (M8X25)

LEVELING FOOT

FRAME SUPP SLIDE KNOB

MTNG. STAND TOP PLATE

MTNG. STAND PAD

SUPPORT ARM- LEFT

SUPPORT ARM- RIGHT

SUPPORT LOCK KNOB

ARM ADJ. KNOB & SCREW

SHOULDER V-CLAMP

SHOULDER V-CLAMP

TURNTABLE CAP SCREW

STRING REEL HOLDER BOLT

STRING REEL HOLDER SPACER

STRING REEL HOLDER KNOB

LEFT DRAWER END CAP

SUPP POST MOUNTING PL

CHOP BLOCK

RIGHT DRAWER END CAP

BASE CORNER CAP

BASE CORNER CAP

TURNTABLE

END CAP

TT END CAP- RIGHT

TT END CAP- LEFT

BASE END CAP

BASE END CAP

TT HANDLES

BASE

TOOL TRAY

TOOL TRAY PAD

SUPPORT POST

BLACK LOWER COLUMN

BLACK UPPER COLUMN

PART #

MDCSC

MQAC

DESCRIPTION

STRING LENGTH METER

299

RUBBER FOOT

301

BRAKE RING

320

BRAKE BOX (ES)

321

LARGE DRAWER

322

SMALL DRAWER

323

FOOT PEDAL SWITCH

324

DIECAST LINEAR GRIPPER

325

TENSIONER

326

TURNTABLE PIN

327

A/C POWER CORD

E16

A/C ADAPTER

E23

KEYPAD / ELECTRONICS

E77

FIXED TEN STRING CLAMP

TALL QA BASE CLAMP

TOOLS AND ACCESSORIES

6MM T-HANDLE HEX WRENCH

71

10MM WRENCH

98

NEEDLE NOSE PLIERS

109

BENT NOSE PLIERS

110

DIAGONAL CUTTERS

171

17MM SOCKET

196

SLM PADS

221

HEX WRENCH SET

251

STRINGER’S AWL

MA

MBFC

MFSPP

MMSPP

MMSSA

MPG

MPS

MPSA

21

FLOATING BAD CLAMP

FRAME SUPP PADS

SQUASH (SQ)

SHORT BADMINTON (SB)

TENNIS (T)

BADMINTON (B)

TENNIS SHLDER SUPP PAD

SHLDER SUPP PADS (L TO R)

RACQUETBALL

BADMITON

STARTING CLAMP

POLISHING STONE

PATHFINDER AWL

Page 23

PARTS SUMMARY

142

MFSPP

146A

6B

283

285

286

320

288

278

MMSPP

296

9

321

MDCSC

289

143

282

21A

327

140

MQAC

270

292

274

141

144

133

6B

14

148R

325

E77

326

322

323

298

106

265

276

287

MFSPP

SQ BTSB

277

299

293

MMSPP

212

295

MMSSA

22

211

114

210

297

6B

115

121

Page 24

GAMMA SPORTS

200 Waterfront Drive

Pittsburgh, Pennsylvania 15222

Phone: 800.333.0337 Fax: 412.323.0317

Visit our website at www.gammasports.com

Copyright 2009 GAMMA Sports - All Rights Reserved

Loading...

Loading...