Page 1

INSTALLATION INSTRUCTIONS

Product Date Form #

ShortStack 2-Unit Mount

SM-212

2/19/2001 INST-98

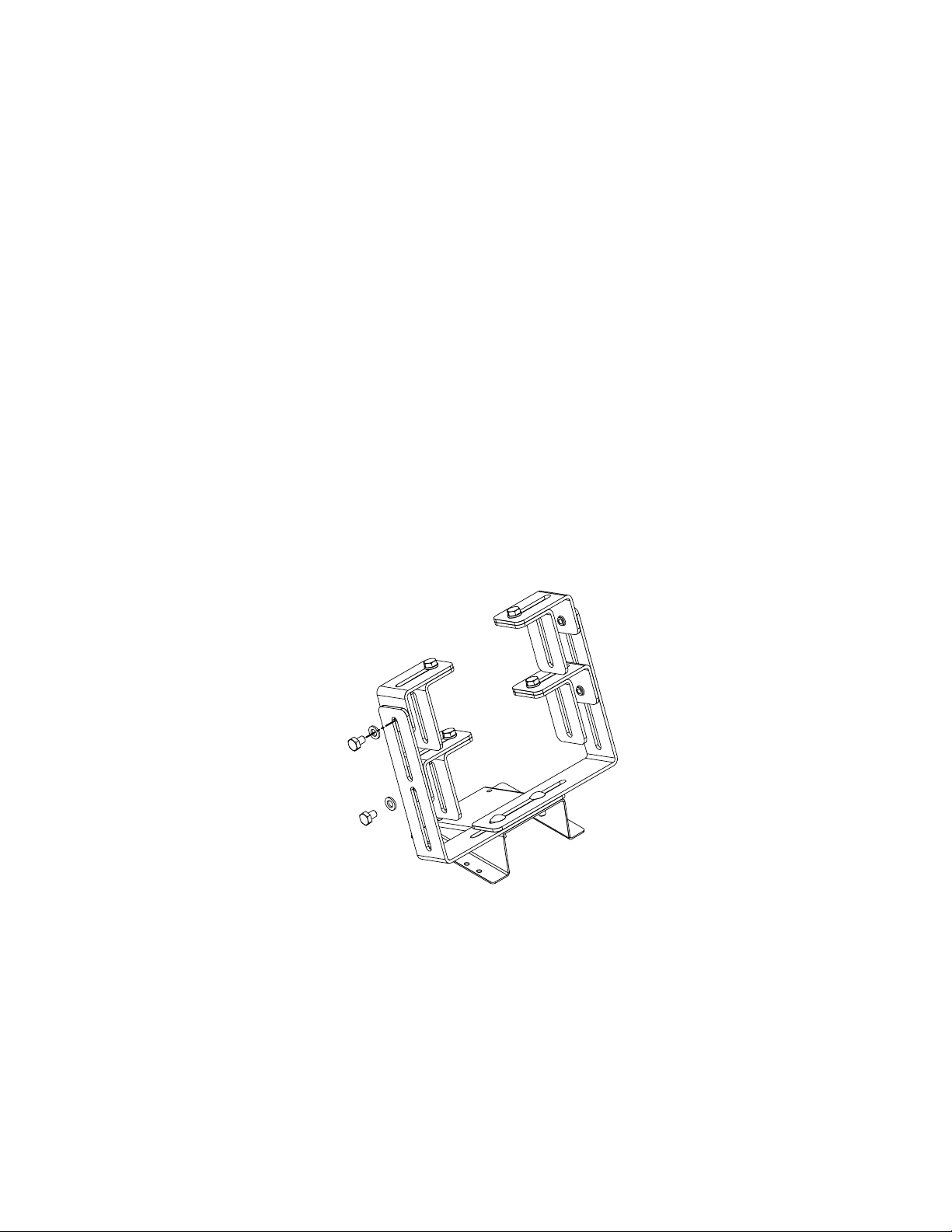

Assembling the Mount Frame

Note: The hardware bag contains more hardware than is required. You will have hardware

left over.

1. Unit is shipped unassembled. Assemble as shown above attaching the two side brackets by

their single slotted legs to the base using (2) .25-20 x .75 carriage bolts and hex nuts. Adjust the

"W" distance (Fig. 1) between the side brackets to 1" more than the widest equipment to be

installed and tighten nuts.

W

W

STEP 3

.12

Fig. 2

Fig. 1

2. Fasten equipment mounting brackets to your equipment by bolting the slotted legs to the

equipment mounting holes on each side (Fig. 2). Use 1/4-20 x 3/8" hex head bolts with washers.

The tapped legs should extend over the top of the equipment, and there should be 1/8" of space

between the tapped legs and the top of the equipment, see Fig. 3.

Note: If there is not a centered 1/4-20 mounting hole on each side of the equipment, install the

mounting bracket or tray that came with the equipment instead of the two brackets.

STEP 2

Fig. 3

If you need assistance or have questions, call Gamber-Johnson at 1-800-456-6868

Page 2

3. See Fig. 2. Fasten another pair of equipment mounting brackets to the tapped hole of each

side bracket, installed in step 2, - or to the equipment tray furnished with your equipment using 1/4-20 x 3/8" hex head bolts and washers. Before tightening, adjust the outside width

across the brackets to equal width "W", so that the assembly will fit the opening in the

mounting frame (shown in Fig.1). If the unit is to narrow to do this, turn one or both of the

brackets installed in step 2 to face outward, instead of over the equipment.

Final Assembly

4. Fasten the mount to the vehicle floor using appropriate screws, (not furnished with the

mount).

IMPORTANT: Before drilling holes or fastening the mount to the vehicle floor, check

underneath the vehicle to be sure you will not damage the transmission housing or other

parts under the floor pan.

5. Mount the equipment in the frame, begining with the bottom unit. Equipment can be

tilted forward or back as desired. Use one 1/4-20 x 3/8 hex head bolt and washer into each

hole in the mounting brackets. See figure 4.

Fig. 4

Loading...

Loading...