Page 1

INSTALLATION INSTRUCTIONS

Product Revision Form #

MCS-ERGOBOX, MCS-ERGOBOX12, & ACCESSORIES

Rev C

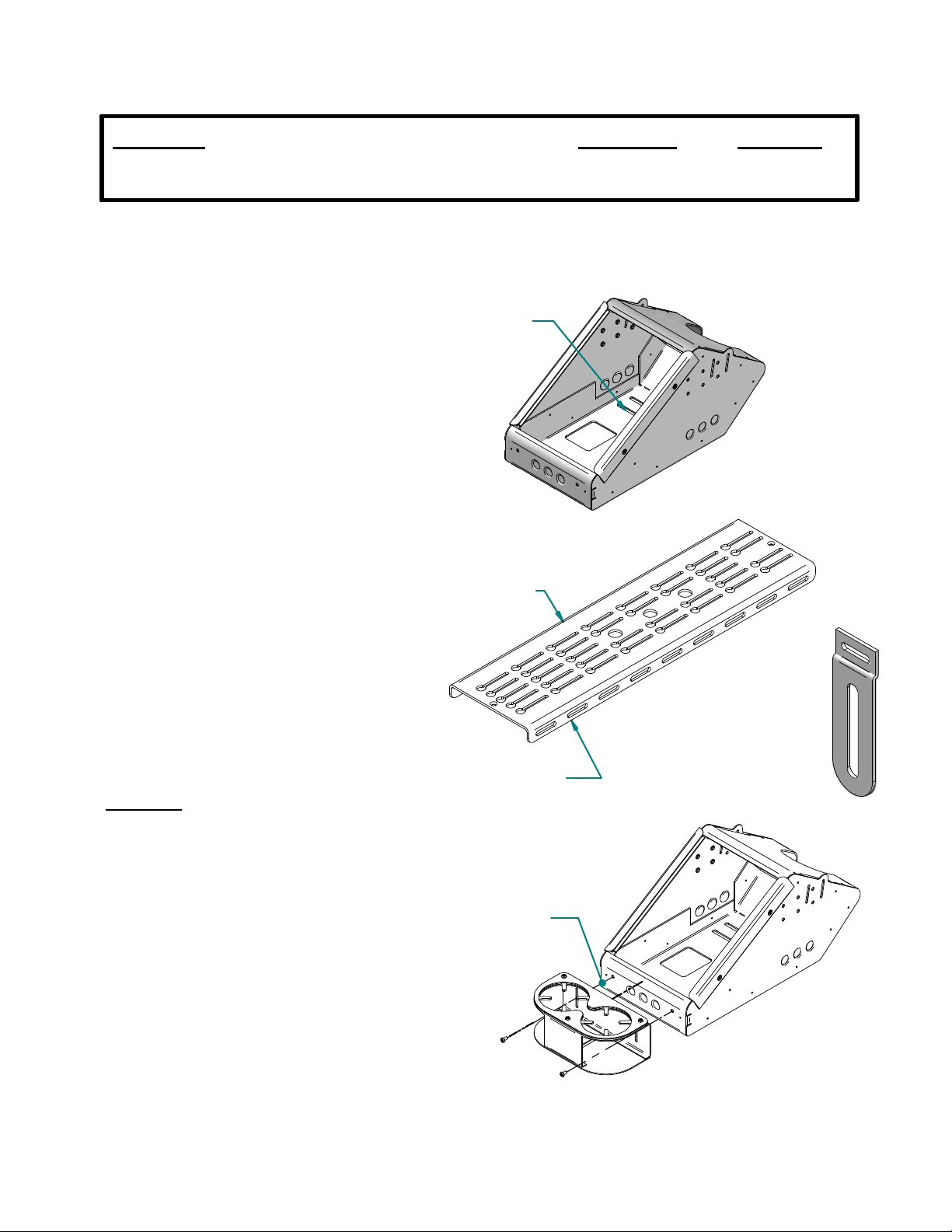

UNIVERSAL VERTICAL CONSOLE BOX

The purpose of this instruction sheet is to illustrate the manufacturer's recomended method for installing the

MCS-ERGOBOX.

Includ e d with the

end of the console box, these Faceplate Vertical Offsets must be used in place of the Vertical Offsets that come with

Gamber-Johnson Faceplate Kits (see INST-3).

1. When installing the MCS-ERGOBOX onto a

Gambe r-Johnso n MCS Top Plate, insert and loosely

assembl e f our 1/4-20 ca rri age bolts, fo ur 1/4 " Dia.

washers, four 1/4" lock washers and four 1/4-20 hex

nuts about the desired mounting slots in the bottom of

the box (see FIG. 1). Orient the head of the carriage

bolts below the box.

2. Insert the four heads of the carriage bolts into the

desired corresponding key holes (see FIG. 1) o n the

MCS-Top Plate until the bolt heads drop below the

Top Plate. If the chosen mounting slots d o not line

up with the key holes on the Top Plate it will be

necessary to assemble the hardware about the box

and the Top Plate at the same time. Place box in

desired position and tighten hardware.

3. Due to the shallow depth of the face nearest the

vehicl e occupants (see FIG. 3), as compared to the

MCS-Epic console box series, it is necessary to replace

the standard Vertical Offsets with a set of shorter

Vertical Offsets (1 set is included with the

MCS-ERGOBOX). The radio/radio head in the lowest

position on the box will require the Short Vertical

Offset. Follow instruction sheet INST-3 for assembly

and installation instructions, substituting the short

Faceplate Vertical Offsets (s ee FIG. 2) w ith the

Vertical Offsets that come with Gamber-Johnson

Facplate Kits.

ccessories

A

MCS-ERGOBOX is a descrete solution for mounting various mobile communication control heads.

MCS-ERGOBOX is one set of short Faceplate Vertical Offsets. Due to a shallow depth in the front

MOUNTING

SLOTS

FIG. 1

KEY HOLES

MCS TOP PLATE

INST-284

FIG. 2

The MCS-ERGOBOX has many accessories that are designed to attach to the

exterior of the box. The next few sections of this instruction sheet are dedicated to

illustrating how to attach the various accessories.

Cup Holder (MCS-CUP2)

1. The cup holder is designed to mount to either

the short, front face of the MCS-ERGOBOX or

directly to an MCS Top Plate. There are two

10-32 x .375 Phillips Pan Head screws included

to attach the cup holder to the box (see FIG. 3)

Product Mounting Disclaimer

Gamber-Johnson is not liable under any theory of contract or tort law for any loss, damage, personal injury, special, incidental or consequential damages for personal injury or other damage

of any nature arising directly or indirectly as a result of the improper installation or use of its products in vehicle or any other application. In order to safely install and use Gamber-Johnson

products full consideration of vehicle occupants, vehicle systems (i.e., the location of fuel lines, brakes lines, electrical, drive train or other systems), air-bags and other safety equipment is

required. Gamber-Johnson specifically disclaims any responsibility for the improper use or installation of its products not consistent with the original vehicle manufactures specifications

and recommendations, Gamber-Johnson product instruction sheets, or workmanship standards as endorsed through the Gamber-Johnson Certified Installer Program.

© copyright 2009 Gamber-Johnson, LLC

FRONT FACE

FIG. 3

If y ou need assistance or have questions, call Gambe r-Johnson at 1-800-456-6868

SHEET 1 OF 3

Page 2

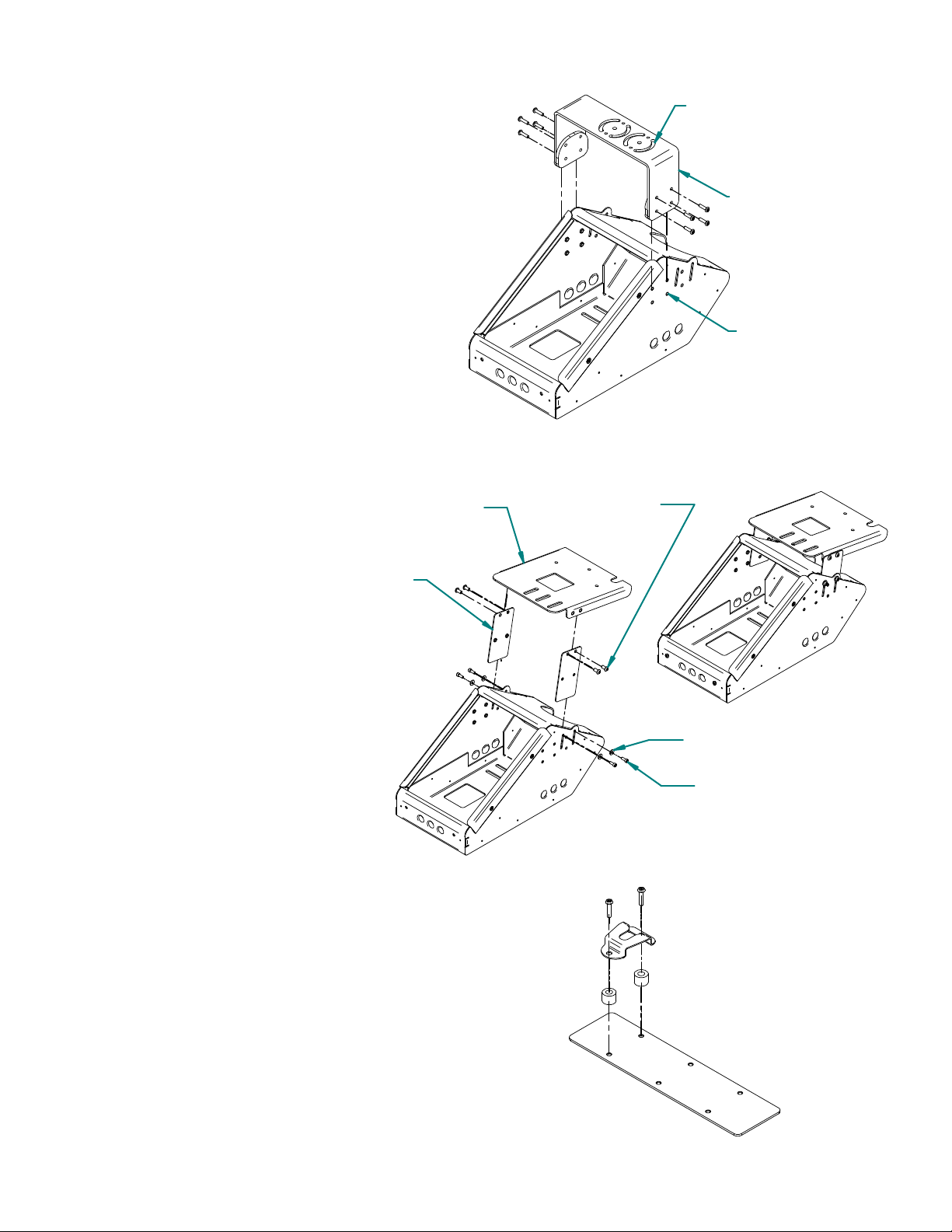

Com munications Bracket (MCS-COMBRKT)

1. The communications bracket is designed to

have any Gamber Johnson Clevis device

mounted to it. In order to mount a

Clevis/Docking Station, or Computer Cradle,

assembly to the MCS-COMBRKT, the

MCS-ERGOBOX must be pulled away from the

dash. Assemble the MCS-COMBRKT, desired

Clevis Device, and MCS-ERGOBOX proir to

attaching the box to the Top Plate (see FIG. 4).

2. Adjust the assembly to the desired position.

Attach to Top Plate by assembling four 1/4-20

carriage bolts, four 1/4" DIA. flat washers, four

1/4" lock washers and four 1/4-20 hex nuts about

the bottom of the box and the Top Plate.

NOTE: The pattern of mounting holes for the

MCS -COM B RKT is k nown as an AMPS pattern.

SMILEY FACE PATTERN FOR

MOUNTING CLEVIS DEVICE

MCS-COMBRKT

AMPS PATTERN

FIG. 4

Mounting to the In-Dash Bracket

1. If mounting the MCS-VERTBOX12 in

a Ford Crown Victoria, the b ox can also

attach to the In-Dash Bracket for further

stability, using NP-DASH-KT (see FIG.

5).

2. After the In-Dash Bracket is attached

to the vehicle, align the MCS-ERGOBOX

and fasten to the In-Dash Bracket using

two braces, four 1/4-20 x .50" Socket

Button Head screws, four 10-32 x .50"

Socket Head C a p Screws an d four #10

flat washers all found in NP-DASH-KT.

Assemble as illustrated in FIG. 5.

Assembling the MCS-MICPLT

1. The MCS-MICPLT is a kit that allows a

radio microphone to be mounted in the same

fashion as all Gamber Johnson Faceplates.

The mic clip itself is not provided with the

MCS -MICPLT kit as it is standard that a mic

clip is shipped with most communication

devices that use a microphone. Assemble as

illustrated in FIG. 6.

BRACE

IN-DASH

BRACKET

1/4-20 X .50"

#10 WASHER

10-32 X .50"

FIG. 5

2. It is recommended that if using the

MCS-MICPLT kit to place the finished

assembly in the lowest position on the

MCS-ERGOBOX. By assembling the kit in

this fashion you be able to avoid using the

short Faceplate Vertical Offset (see FIG. 2).

FIG. 6

SHEET 2 OF 3

Page 3

Addition al MCS A c c e ss o r ie s

MCS-ARMREST

MCS-CUPHOLD2

MCS-CUP2

7160-0110

(6 Circuit Power Strip)

7160-0063

(Cigarette Lighter Adapter Kit)

3130-0361

(Knockout Filler Panel)

7160-0100

(L ED Light Assembly)

SHEET 3 OF 3

Page 4

INSTALLATION INSTRUCTIONS

Product Date Form #

Faceplates 02/23/01 INST3

ASSEMBLING MCS FACEPLATES: (Refer to figure 1)

1. Check that the following pieces are present:

Dual lock fastener (supplied w/console box)

(1) faceplate vertical offset

(1) faceplate top bracket

(1) flat washer #6

(1) 6-32 nut

2. For each faceplate, slide the faceplate vertical offset

(item 1) on the stud in faceplate top bracket (item 2).

Add flat washer (item 3) and hex nut (item 4). Remove

the extra strips of dual lock fastener pressed onto each

console box under holddown rails, cut to same length as

each faceplate, remove protective film covering the

adhesive strip and apply to top bracket as shown.

3. If the faceplates are being mounted in an older style MCS Console Box (those with threaded inserts on the

top surface of the side panels/holddown screws passing through slots in existing face plates or blank

panels), DO NOT attach the strip of dual lock fastener on each faceplate as described above. When

installing faceplates into these MCS Console Boxes, mark any that cover the threaded inserts and drill a .312

diameter clearance hole as shown in Figure 1.

ASSEMBLING MCS FACEPLATES TO CONTROL HEADS AND INSTALLING IN MCS CONSOLE BOXES (Refer to figures

2 & 3).

1. Install the faceplates on each control head as shown in figure 2. Adjust the faceplates so the mounting

holes in the sides of the control head line up in the slots of the faceplate vertical offsets and so the desired

amount of the control head will extend from the console. Make sure to allow enough room underneath for

any connectors that may be required. Test the fit of each control head, the tallest heads may need to be

installed near the higher end of the console.

2. Arrange the control heads in the console box as desired. Blank panels of various sizes have been provided to

act as spacers between each control head, if needed. Secure in place by attaching a piece of dual lock

fastener to each end of the blank panel and then pressing the strips of dual lock fastener on the faceplates,

blank panels and console box together.

3. Attach the MCS Console Box holddowns to the sides of the console box and over faceplates with (6) 10-32 x

.38 Phillips head machine screws.

Loading...

Loading...