Page 1

INSTALLATION INSTRUCTIONS

Product Revision Form

7160-0356 - 0-90 CLEVIS WITH 3" ARM

Rev C

7160-0357 - LOWER CLAM SHELL MOUNT

7160-0363 - EXTENSION TUBE ASSEMBLY

7160-0364 - PILLAR ASSEMBLY, 0-90 CLEVIS

7160-0365 - PILLAR ASSEMBLEY, 0-90 CLEVIS w/ LARGE BACK PLATE

7160-0366 - PILLAR ASSEMBLY, DUAL CLAMSHELL

7160-0367 - PILLAR ASSEMBLY, DUAL CLAMSHELL w/ LARGE BACK PLATE

7160-0368 - ROOF MOUNT WITH CLAM SHELL

7160-0369 - ROOF MOUNT WITH 0-90 CLEVIS

7160-0370 - LOWER CLAM SHELL MOUNT WITH LARGE BACK PLATE

7160-0371 - SECONDARY CLAM SHELL

7160-0420 - DUAL CLAMSHELL w/ 3" ARM & SMALL BACK PLATE

7160-0421 - DUAL CLAMSHELL w/ 3" ARM & LARGE BACK PLATE

Printing Spec: PS-001

The following instruction sheet is for the mounting the part numbers listed

above. These mounts are designed to attach to the pillars and roof racks of

various fork trucks.

INST-541

Mounting the clam shell assembly to the pillar:

7160-0364, 7160-0366, 7160-0420, 7160-0365, 7160-0367 & 7160-0421

The clam shell assemblies attach to the pillar on the fork truck. They can fit a

rectangular pillar from 1 1/2" to 5" wide. The mounts are held in place with

3/8" dia. carriage bolts.

Attach the clam shell assembly to the pillar using the 3/8" carrage bolts and

back plate.

7160-0364, 7160-0366 & 7160-0420 fit tubes 1 1/2" to 2 1/2" wide.

7160-0365, 7160-0367 & 7160-0421 fit tubes 2 1/2" to 5" wide.

The clam shell should be positioned so the top surface of the mount is relatively

level. (See figures 1 & 2.)

Product Mounting Disclaimer

Product Mounting Disclaimer

Gamber-Johnson is not liable under any theory of contract or tort law for any loss, damage, personal injury, special, incidental or consequential damages for personal injury or other damage

Gamber-Johnson is not liable under any theory of contract or tort law for any loss, damage, personal injury, special, incidental or consequential damages for personal injury or other damage

of any nature arising directly or indirectly as a result of the improper installation or use of its products in vehicle or any other application. In order to safely install and use Gamber-Johnson

of any nature arising directly or indirectly as a result of the improper installation or use of its products in vehicle or any other application. In order to safely install and use Gamber-Johnson

products full consideration of vehicle occupants, vehicle systems (i.e., the location of fuel lines, brakes lines, electrical, drive train or other systems), air-bags and other safety equipment is

products full consideration of vehicle occupants, vehicle systems (i.e., the location of fuel lines, brakes lines, electrical, drive train or other systems), air-bags and other safety equipment is

required. Gamber-Johnson specifically disclaims any responsibility for the improper use or installation of its products not consistent with the original vehicle manufactures specifications

required. Gamber-Johnson specifically disclaims any responsibility for the improper use or installation of its products not consistent with the original vehicle manufactures specifications

and recommendations, Gamber-Johnson product instruction sheets, or workmanship standards as endorsed through the Gamber-Johnson Certified Installer Program.

and recommendations, Gamber-Johnson product instruction sheets, or workmanship standards as endorsed through the Gamber-Johnson Certified Installer Program.

© copyright 2011 Gamber-Johnson, LLC

If you need assistance or have questions, call Gamber-Johnson at 1-800-456-6868

1 of 5

Page 2

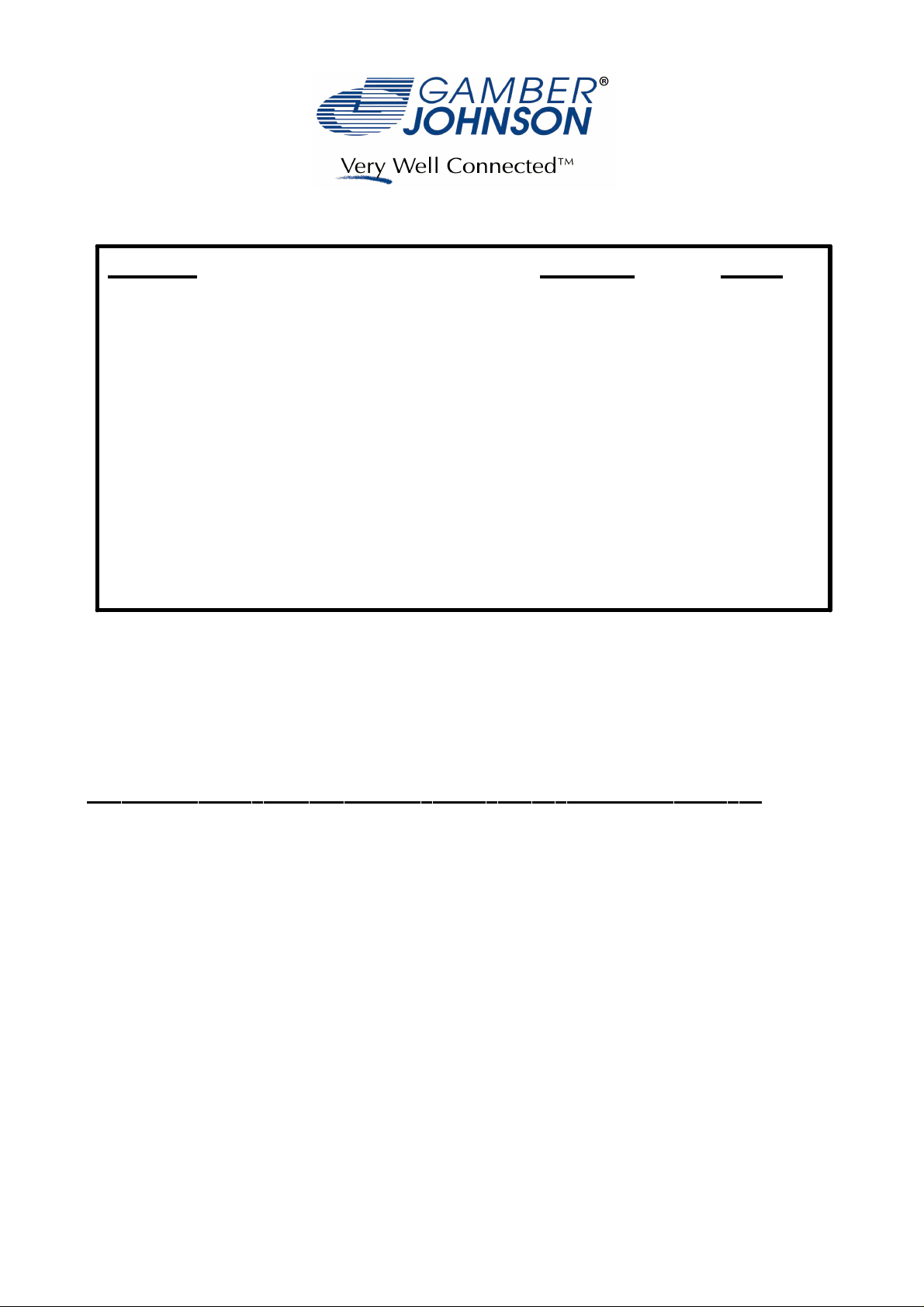

Figure 1. - Example of Dual Clam Shell Assembly

7160-0366 = Full Assembly with Small Back Plate

7160-0367 = Full Assembly with Adapter and

Large Back Plate

Position so this surface

is relatively level

Position the 3/8 bolts as close to

the pillar as possible to prevent

bowing the components

Note orientation of bends

on backer plate

Note: 1/4" bolts and flat washers have been provided

in the hardware bag and can be installed in the open

location opposite the lever handles to lock the clam

shells in place.

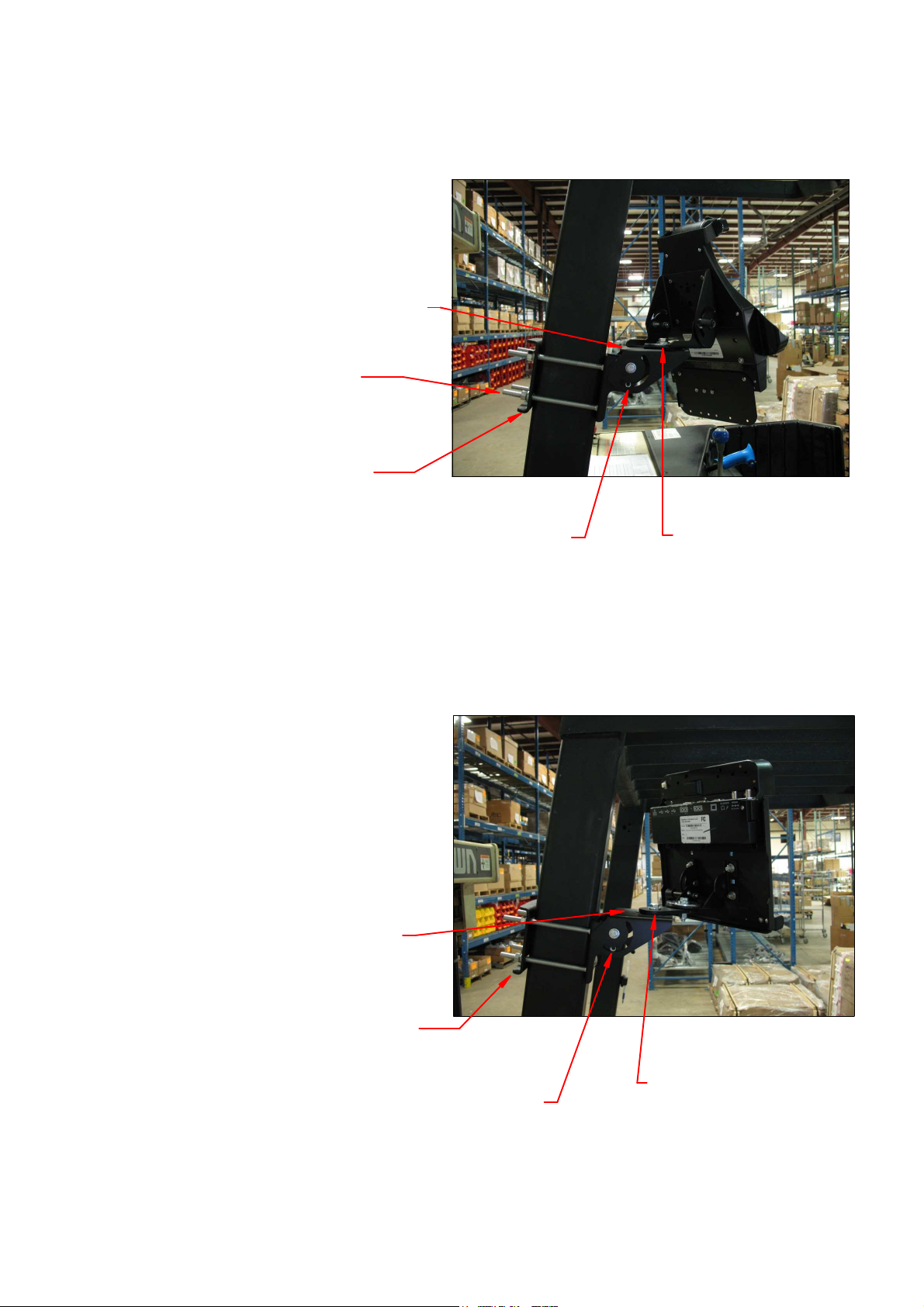

Figure 2. - Example of Clam Shell with

0-90 Clevis and 3" Arm

7160-0364 = Full Assembly with Small Back Plate

7160-0365 = Full Assembly with Adapter and

Large Back Plate

Position so this surface

is relatively level

Note: The 3/8" pivot bolt

can be tightened to lock

the mount in place.

Note orientation of bends

on backer plate

Note: 1/4" bolts and flat washers have been provided

in the hardware bag and can be installed in the open

location opposite the lever handles to lock the clam

shells in place.

Note: The 3/8" pivot bolt

can be tightened to lock

the mount in place.

2 of 5

Page 3

The components to build a pillar mount can also be purchased separetly if required.

The hardware to assemble the Secondary Clam Shell or 0-90 Clevis to the lower

portion are provided with each assembly (7160-0371 or 7160-0356).

3/8" hex bolt

3/8" flat washer

Secondary Clam Shell

7160-0371

nylon bearing

bearing backup plate

3/8" flat washer

bearing backup plate

nylon bearing

nylon bearing

Lower Clam Shell Mount

7160-0357 or

7160-0370

0-90 Clevis

7160-0356

3/8" flat washer

3/8" nulok hex nut

nylon bearing

3" arm

3/8" nylok hex nut

3/8 hex bolt

3/8 flat washer

bearing backup plate

nylon bearing

3/8 hex bolt

3/8 flat washer

nylon bearing

Lower Clam Shell Mount

7160-0357 or

7160-0370

nylon bearing

bearing backup plate

3/8" flat washer

3/8 nylok hex nut

3 of 5

Page 4

An Extention Tube Assembly (7160-0363) can be added to a pillar to move the

loction of the pillar mount assembly to the front or side of the fork truck as

required. This assembly attaches to the pillar with 3/8 hardware that are provided

with the mount.

7160-0363

Views of pillar mount 7160-0364

mounted on an Extension tube to

position the computer equipment

in front of the fork truck

Note orientation of bends

on backer plate

Note orientation of bends

on backer plate

4 of 5

Page 5

The Roof Mounts (7160-0368 & 7160-0369) hang from the upper cage of a fork

truck. The mount compresses the cage between the lower portion of the mount and

the back plate using 3/8" hardware.

Back plate

Lower portion

of mount

7160-0368 7160-0369

View of roof mount 7160-0368 mounted to upper

rack of fork truck

5 of 5

Loading...

Loading...