Page 1

Service Manual

Spray Unit

Easy Spray-H

Issue 1.9 15/02/19

Ref. NR-00088-ENG

Before preparing the unit and starting it up, please take the

time to read all the technical and safety instructions in this

manual. It is essential that you follow these instructions

carefully so that you can handle and use the unit properly.

These instructions are intended to maximize user safety and

avoid malfunctions deriving from the incorrect use of the unit.

Page 2

Easy Spray-H

Service manual

2/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

HI-TECH SPRAY EQUIPMENT, S. A. (“HI-TECH”) provides this LIMITED WARRANTY (“Warranty”) to the

original purchaser (“Customer”) covering the equipment and the original accessories delivered with the

equipment (“Product”) against defects in the design, materials or manufacture of the Product from the

moment of initial purchase by the user and for a period of two (2) years from this date.

If during the Warranty Period and under conditions of normal use, the Product stops working correctly for

reasons connected with its design, materials or manufacture, the authorized dealer for the country where

the Product was purchased or the HI-TECH technical assistance service shall repair or replace the Product

in accordance with the following

CONDITIONS

a) This Warranty is only valid if accompanied, on presentation of the Product for its repair or

substitution, by the original invoice issued by a HI-TECH dealer authorized to sell the Product,

and which should indicate the date of purchase and serial number. HI-TECH reserves the right to

withhold the provision of Warranty where the aforementioned information does not appear on the

invoice or has been altered after the purchase of the Product.

b) The repaired or replaced Product shall be covered by the original Warranty for the time remaining

until its expiry or for three (3) months subsequent to the repair date, where the remaining

Warranty period is shorter.

c) This Warranty does not apply to Product malfunctions caused by: its defective installation, natural

wear of parts, its use for purposes other than those considered normal for this Product or in a

manner which does not strictly comply with the instructions for use provided by HI-TECH;

accident, recklessness, or adjustments, alterations or modifications to the Product not authorized

by HI-TECH; or the use of accessories, heating devices, pumping apparatus and/or dispensers

not approved or manufactured by HI-TECH.

d) Parts and accessories which are part of the Product and not manufactured by HI-TECH are

covered by the warranties offered by their original manufacturers.

HI-TECH SHALL HONOUR NO VERBAL OR WRITTEN WARRANTY OTHER THAN THE PRESENT LIMITED WARRANTY IN ITS

PRINTED FORM. ALL IMPLIED WARRANTIES, INCLUDING AND WITHOUT LIMIT FITNESS FOR A PARTICULAR PURPOSE,

EXPIRE WHEN THIS WRITTEN GUARANTEE EXPIRES. HI-TECH SHALL NOT BE HELD LIABLE FOR ANY DAMAGE OR LOSSES

CAUSED BY THE DEFECTIVE PERFORMANCE OR OPERATION OF THE PRODUCT, OR BY THE MATERIAL DISPENSED BY

THE PRODUCT, INCLUDING ALL LOSSES DERIVING FROM DAMAGES TO PERSONS OR PROPERTY. HI-TECH SHALL NOT IN

ANY CIRCUMSTANCES BE HELD LIABLE FOR LOSSES IN SPECULATIVE GAINS OR PROFITS. THE REPAIR OR

REPLACEMENT OF THE DEFECTIVE PRODUCT SHALL CONSTITUTE THE FULL DISCHARGE OF HI-TECH’S

RESPONSIBILITIES TOWARDS THE CUSTOMER. HI-TECH CANNOT GUARANTEE THE SUITABILITY OR FITNESS FOR

PURPOSE OF ITS PRODUCT FOR ANY GIVEN USE OR APPLICATION.

All information on parts not manufactured by HI-TECH and based on the statements of the original

manufacturer is given without warranty or liability of any kind, express or implied, even if considered

accurate and reliable.

Under no circumstances shall the transfer, sale or financial leasing of the Product by HI-TECH constitute

express or implied authorization, assent or permission for the use of rights or patents, or provide grounds

for, encourage or endorse their violation.

Warranty restrictions do not limit the legal rights of the consumer as provided in applicable national

legislation or affect the rights deriving from the purchase agreement between consumer and provider.

WARRANTY

Page 3

Easy Spray-H

Service Manual

3/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

All of the information in this Service Manual is given in good faith, but is not subject to any

implied or explicit warranty. HI-TECH reserves the right to make the necessary improvements

and modifications to this Service Manual, at any time and without prior notice, with the intention

of rectifying possible typographical errors, expanding on existing information or incorporating

changes to the characteristics and performance of the unit.

The Easy Spray-H proportioning unit is designed and manufactured in accordance with the

European “Machinery” Directive 89/392/EEC as modified by the legislation which transposed it

to national statutes. It also complies with European directives on electromagnetic compatibility

and electrical safety, as well as applicable Harmonized Standards.

This section contains important information on the safe handling and operation of the Easy

Spray-H proportioning unit.

Before preparing the unit and starting it up, please take the

time to read all the technical and safety instructions in this

manual. It is essential that you follow these instructions

carefully so that you can handle and use the unit properly.

These instructions are intended to maximize user safety and

avoid malfunctions deriving from the incorrect use of the unit.

A DANGER! indication alerts you to situations which may result in serious injury if the

instructions are not followed.

A WARNING! indication gives information on how to avoid damaging the unit and

situations likely to cause minor injury.

A NOTE indication provides useful information on the procedure in question.

Read this manual carefully to familiarize yourself with the unit’s characteristics and operating

procedures. By following the instructions and recommendations contained in this manual you

will reduce the risk of accidents in the preparation, use and maintenance of the unit, ensuring

incident-free operation for a longer time, improved performance and the quick and easy

detection of problems.

Keep this Service Manual handy for reference at all times. If you lose this manual, ask for a new

copy from your local HI-TECH distributor or directly contact HI-TECH SPRAY EQUIPMENT,

S.A.

WARNING! The Easy Spray-H proportioning unit is not designed for use in potentially

explosive environments. Pressure and temperature must not exceed the limits indicated

in the technical specifications of this manual.

SAFETY AND HANDLING

Page 4

Easy Spray-H

Service manual

4/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

When working with the unit, it is essential that you wear suitable clothing and personal

protective equipment including but not limited to gloves, protective goggles, safety footwear and

face masks. Use breathing equipment when working with the unit in enclosed spaces or in

areas with insufficient ventilation. The safety measures given in in this manual are part of a

wider safety procedure. Before powering up the unit, you must perform a comprehensive

analysis of the risks associated with the products it dispenses, the type of application, and the

working environment.

To avoid bodily damage caused by the incorrect handling of

the substances and solvents used with this unit, read

carefully the safety information provided by their suppliers.

Dispose of waste as required by applicable legislation.

Disconnect the unit from the power supply before opening

the electrical console.

Electrical maintenance should only be carried out by a

qualified electrician.

To avoid exposure to pressurized fluids, do not release any

connectors or perform maintenance work on parts subjected

to pressure until the pressure has been completely

eliminated.

Use suitable protection when using or performing

maintenance on the unit, or when in its vicinity. This

protection includes, but is not limited to, the use of masks,

protective goggles, gloves, safety footwear and safety

clothing.

This unit includes parts which reach temperatures likely to

cause burns. Do not touch or handle the hot parts of the unit

until they have cooled down.

To avoid the risk of crushing or amputation, only use this unit

when its moving parts are fitted with correctly installed safety

guards. Make sure all safety guards are correctly mounted

after completing repair or maintenance work.

Page 5

Easy Spray-H

Service Manual

5/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

The Easy Spray-H proportioning unit is designed for the application of polyurea chemical

systems for polyurethane foaming and certain two-component epoxy systems.

Principal heating system

Consists of two independent heaters without gaskets. Each heater has two 900 W heating

elements delivering total power of 1800 W, and the necessary control and safety mechanisms

for the correct operation of the system. Their special configuration permits a temperature

differential (ΔT) of 30º C and application temperatures of 80ºC under normal ambient

temperature conditions.

Hose heating system

The unit features two systems for keeping the products hot

while in the hoses:

Recirculation hoses (maximum length 11 metres)

Hose heated by woven elements at 230V fitted with

temperature sensor (maximum length 15 metres)

If longer hoses are required, a standard HI-TECH hose

(maximum length 48 metres) heated by transformer can be

used.

Proportioning pumps

This assembly comprises two positive-displacement piston pumps operated by a dual-piston

hydraulic cylinder.

The parallel piston pump configuration ensures constant volume and guarantees uniformity of

pressure in both directions of pump movement.

CHARACTERISTICS

Page 6

Easy Spray-H

Service manual

6/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Electrical

Voltage: ________________________________________________________________ 230V

Frequency: ____________________________________________________________ 50/60Hz

Connections 1 and 2:________________________ 2 x 220V phases /1 x 400V phase + neutral

Connection 1 power consumption: ______ ____________3.3 kW (1.8 kW motor + 1.5 kW hoses)

Connection 2 power consumption: _____________________________ ______ 3.6 kW (heaters)

Connection 1 consumption:__________________________________________________ 16A

Connection 2 consumption:__________________________________________________ 16A

Mechanical

Maximum working pressure: ____________________________ 175 bar (17.5 MPa) / 2,540 psi

Maximum output at 1:1 ratio: _____________________________________ 4 kg/min / 8,8 lb/min

Minimum output: _______________________________________________ 1 kg/min / 2,2 lb/min

Length of recirculation hose: ____________________________________________ 11 m / 36 ft

Maximum heated hose length (230V): _____________________________________ 15 m / 49 ft

Recommended compressor: ______________________________________ 1 HP single-phase

Approximate weight: ________________________________________________ 172 kg / 380 lb

Dimensions: ___________________________________ H: 1165 mm / W: 605 mm / D: 744 mm

_________________________________________________ H: 45,9 in / W: 23,8 in / D: 29,3 in

TECHNICAL SPECIFICATIONS

Page 7

Easy Spray-H

Service Manual

7/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Figure 1. General view

OVERVIEW

Page 8

Easy Spray-H

Service manual

8/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

1. Isocyanate tank

Contains chemical component “A”. Capacity 30 litres.

2. Polyol tank

Contains chemical component “R”. Capacity 30 litres.

3. Isocyanate recirculation valve (recirculation hoses only)

Enables selection between recirculation and spray for the isocyanate circuit.

4. Polyol recirculation valve (recirculation hoses only)

Enables selection between recirculation and spray for the polyol circuit.

5. Hoses with built-in heating (230V)

Keeps spray products at the right temperature.

6. Hose temperature sensor (heated hoses only)

Monitors the temperature of the spray products.

7. Control panel

Controls the correct operation of the unit.

8. Isocyanate proportioning pump

Delivers metered quantities of isocyanate to the system.

9. Polyol proportioning pump

Delivers metered quantities of polyol to the system.

10. Isocyanate heater

Heats the isocyanate to the pre-set temperature.

11. Polyol heater

Heats the polyol to the pre-set temperature.

12. Isocyanate pressure gauge

Indicates the pressure in the isocyanate circuit.

13. Polyol pressure gauge

Indicates the pressure in the polyol circuit.

14. Isocyanate heater sensor

Provides information on the temperature of the isocyanate heater.

15. Polyol heater sensor

Provides information on the temperature of the polyol heater.

16. Isocyanate intake filters

Prevent solid particles from the entering the unit’s isocyanate pump.

17. Polyol intake filters

Prevent solid particles from the entering the unit’s polyol pump.

18. Hydraulic pressure gauge

Indicates the pressure of the hydraulic circuit.

19. Isocyanate circuit safety pressure switch

Shuts off the solenoid valve in the event of excess pressure in the isocyanate circuit.

20. Polyol circuit safety pressure switch

Shuts off the solenoid valve in the event of excess pressure in the polyol circuit.

Page 9

Easy Spray-H

Service Manual

9/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

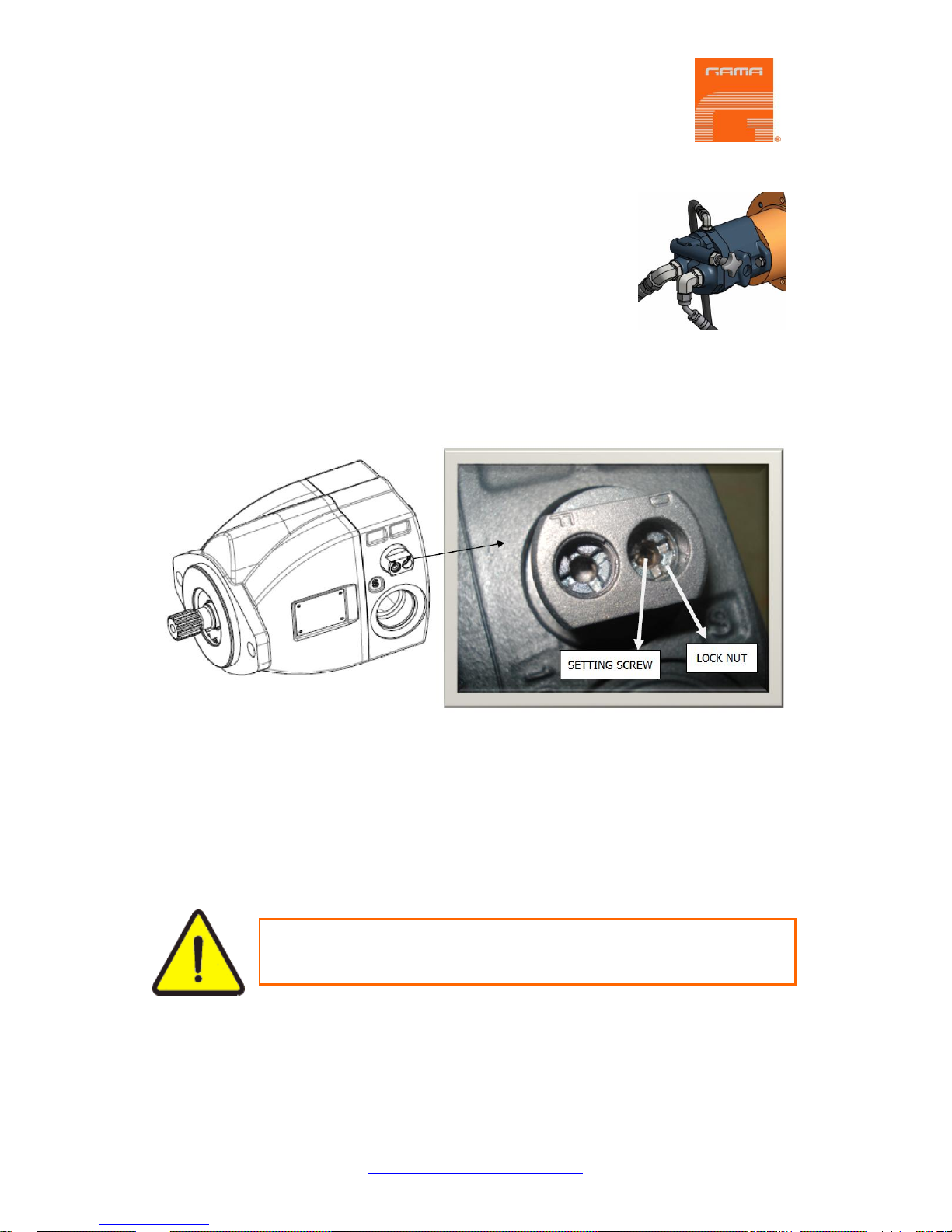

21. Hydraulic pressure regulator

Enables the pressure of the hydraulic circuit to be increased or

reduced.

With VK Pump.- To increase pressure, turn the tap clockwise;

to reduce pressure, turn the tap anti-clockwise.

With BR Pump.- The pressure is set with the pressure setting screw (position D).

Undo the lock nut with a short length screwdriver to set the pressure range by turning the

pressure screw with hexagon socket 4 mm. Turning the setting screw clockwise increases the

flow. Turning the setting screw counter clockwise decreases the flow. One turn of the setting

screw corresponds to 50 bar pressure.

When the setting screw cannot be turned clockwise or counter clockwise easily, is because the

lock nut is jammed up against the setting screw. In this case, turn clockwise the setting screw to

unlock the lock nut.

The flow regulation (standby pressure) setting screw (position F) should not require adjustment

In both cases the NORMAL or RETRACT commands must be active before you can adjust the

pressure of the hydraulic circuit.

The hydraulic circuit should be regulated to ensure that the

unit’s output pressure never exceeds the working pressure of

the product hoses fitted to the unit.

Page 10

Easy Spray-H

Service manual

10/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

22. Hydraulic oil tank

Contains the oil used by the unit’s hydraulic system.

23. Hydraulic cylinder

Drives the pumps.

24. Oil level and thermometer

Displays the fluid level and temperature of the hydraulic oil tank.

25. Electric motor

Drives the hydraulic pump.

26. Hydraulic pump

Axial piston pumps are swash plate design variable displacement pumps.

The flow and pressure compensator control, also known as a load sensing control, matches

pump output flow and pressure to the system demand.

Pumps oil to the hydraulic cylinder.

27. Hydraulic return filter

Filters impurities from the hydraulic oil.

28. Hydraulic oil fill cap

For topping up the oil tank.

29. Heated hose sensor switch

Enables control of the temperature in the hoses.

30. TCS DIP switches

Enables selection of the hose heater control mode depending on

whether hoses incorporate a temperature control sensor (TCS).

See page 11 point 2 of this manual for instructions on selecting the

correct control mode. The unit must be disconnected before

operating the DIP switch.

31. Temperature units DIP switch

Enables selection of temperature units on the control panel

displays. Set this switch to the “EU” position to display the

temperature in degrees Celsius (ºC), or “USA” to display the

temperature in degrees Fahrenheit. The unit must be disconnected before operating the

DIP switch.

32. Motor DIP switch

Activates/deactivates the hydraulic drive. Factory settings depend

on the model. The “Motor DIP” selector function is only active

in units with hydraulic drive. The unit must be disconnected

before operating the DIP switch.

Page 11

Easy Spray-H

Service Manual

11/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

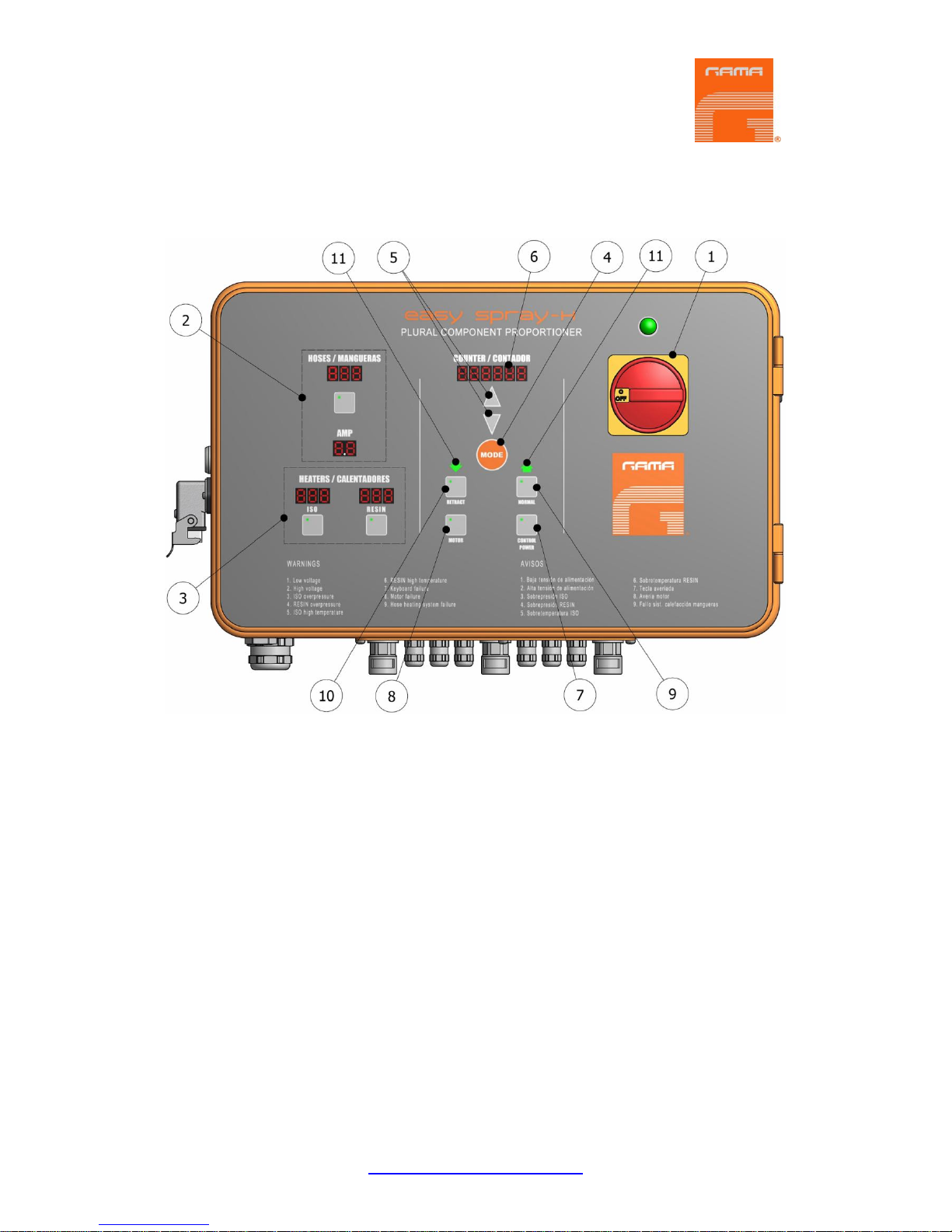

Figure 2. Control panel

The control panel enables you to set the optimum operating conditions for the characteristics

and requirements of the products dispensed. Press the MODE button to enter the desired

settings for temperature, intensity and number of cycles to run. The selected parameter remains

flashing for a few seconds, allowing you to change the values by touching the UP / DOWN

buttons. After changing the value, press the MODE button again to confirm your selection.

The parameter modification function automatically cancels after a few seconds if there is no

further activity on the buttons.

The parameters that can be selected and viewed are:

Hose temperature in automatic control mode (maximum 80ºC)

Hose heating intensity in manual control mode (maximum 5.0 amps)

Isocyanate heater temperature (maximum 90ºC)

Polyol heater temperature (maximum 90ºC)

Number of cycles to run.

Number of cycles completed.

CONTROL PANEL

Page 12

Easy Spray-H

Service manual

12/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

1. Power switch

Connects and disconnects the unit from the electricity supply. This switch must be in the ON

position for the unit to work. When this switch is in the ON position, the green pilot light above

the switch lights up.

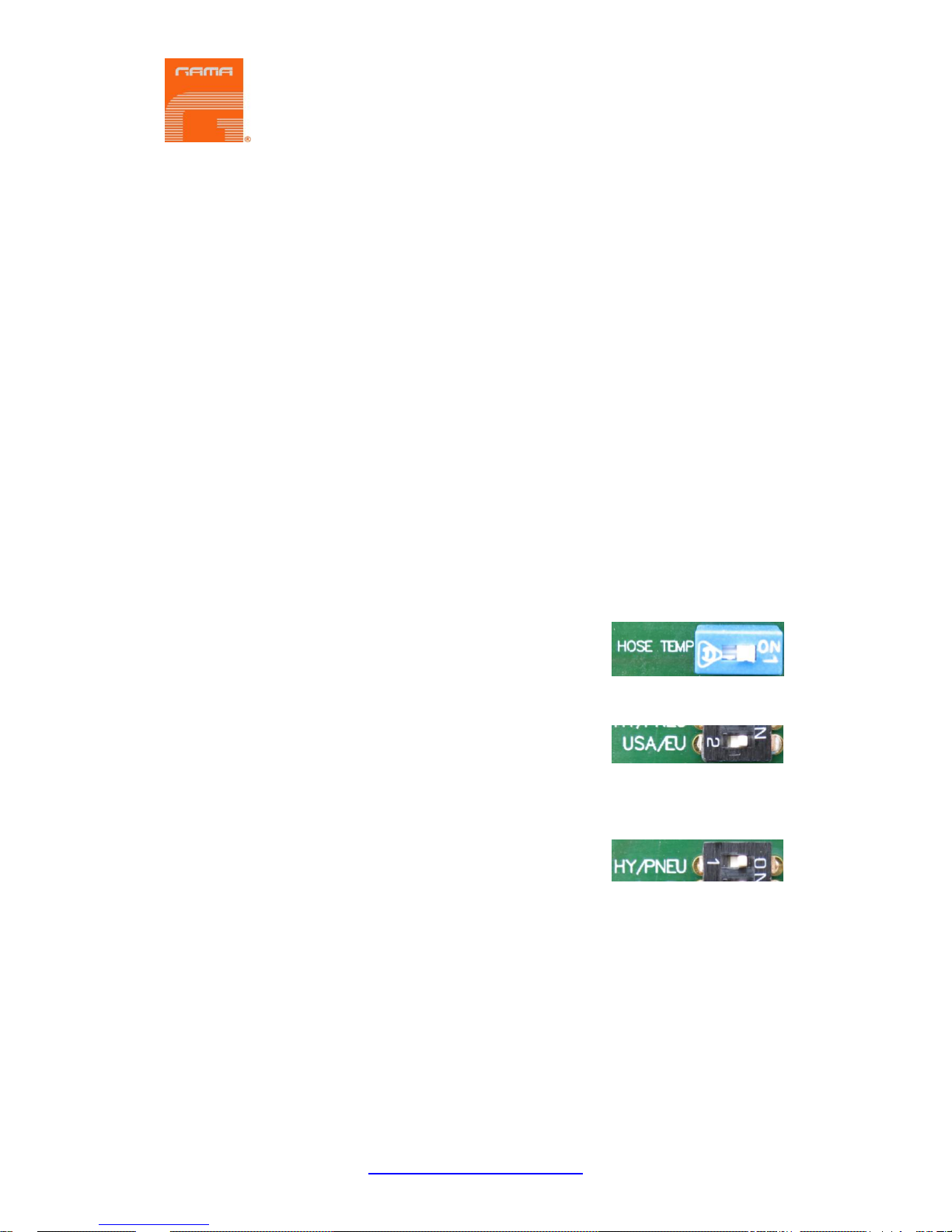

2. Hoses / Mangueras

Hose heating control can be automatic (optional) when a

temperature control sensor is used for direct temperature control,

or manual where no temperature control sensor is used. The

control mode is selected via a DIP switch on the printed circuit

board. Set the “HOSE TEMP” DIP to ON if the isocyanate hose incorporates a temperature

control sensor. If the isocyanate hose does not incorporate a temperature control sensor, or if it

is not working due to malfunction or other reasons, set the DIP to OFF.

In automatic control mode, the temperature in the isocyanate (ISO) hose is shown on the

corresponding display. In manual control mode, only the selected amperage value is shown.

The unit must be disconnected before operating the DIP selector.

HOSE TEMP ON

with temperature control sensor in ISO

hose

HOSE TEMP OFF

manual control

To select the temperature when the unit is working in automatic heating control mode, touch the

MODE button, select the desired temperature using the UP/DOWN buttons and touch the

MODE button again to confirm the setting. Follow the same procedure to select the amperage.

When the unit is operating in automatic control mode, this value should be set to between 4.5

and 5.0 amps.

The temperature setting of the hoses cannot be higher than the temperature setting of the

heaters.

In cases where only one automatic temperature control system is working (ISO or POL), the

limit temperature value is the higher of the two heater settings.

Maximum temperature settings are 80ºC for hoses and 90ºC for heaters.

Page 13

Easy Spray-H

Service Manual

13/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

The sequence for entering commands is as follows:

First we set the temperature of the ISO and POL heaters.

Next, we set the temperature of the ISO hoses.

Then we set the hose current consumption in amps.

Finally, we enter the cycle preselector setting.

If the temperature control sensor is not active, the symbol (---) appears on the display and the

heating switches off.

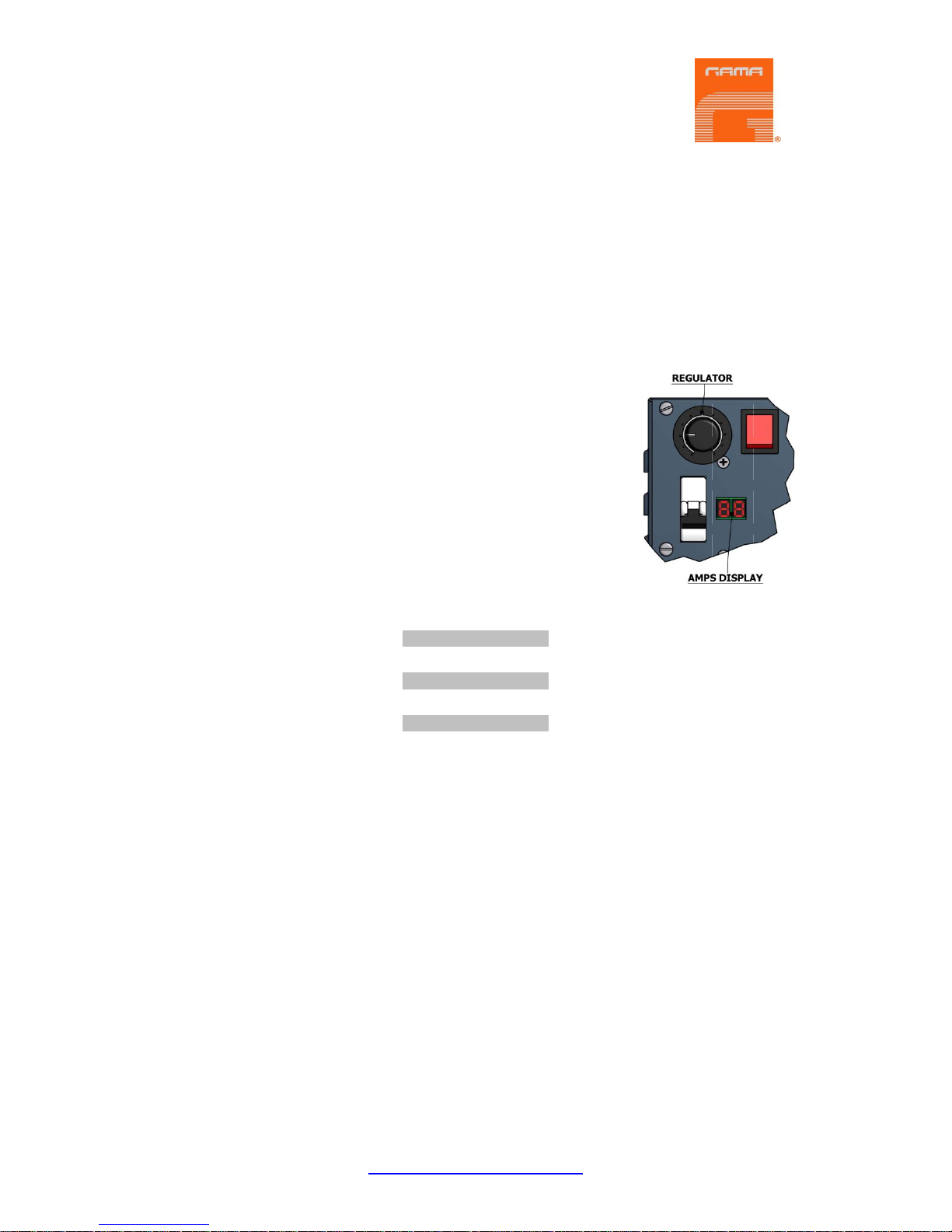

In versions with a transformer, the lower pushbutton on the

transformer switches the hose heating on and off. This

pushbutton incorporates an LED which lights up when the

heating is operating; a flashing LED indicates that the heater

is on but is not heating up.

Turn the potentiometer clockwise to increase amps, and anticlockwise if you wish to decrease amps. Adjustment ranges

from 0 to 50 amps.

Take the values below as an approximate reference to select

the intensity that allows reaching the requested application

temperature.

30 A 38º C 100º F

35 A 48º C 118º F

40 A 60º C 140º F

45 A 75º C 167º F

50 A 80º C 176º F

Turn the potentiometer clockwise until the screen shows the required amps for a quick preheating.

NOTE: The circuit breaker software of the transformer has a safety system to prevent

the hoses from being exposed to high temperatures during long periods of time.

If you have selected a potential over 35 amperes, after 20 minutes, the potential will

automatically regulate to 35 amperes.

This potential cannot be set above 35 amperes until the heater is disconnected from the

hoses and reconnected..

Page 14

Easy Spray-H

Service manual

14/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

3. Heaters / Calentadores

This display shows the temperatures in the isocyanate (ISO) and polyol (RESIN) heaters. To

enter new temperature settings, press the MODE button, select the desired temperature by

pressing the UP/DOWN buttons and press the MODE button again to confirm the selected

value.

The lower pushbuttons switch the heater of each product on and off. Each pushbutton

incorporates an LED which lights up when the heater is operating; a flashing LED indicates that

the heater is on but is not heating up.

The heater will temporarily stop working in the event of excess pressure in either of the heating

circuits, and will switch on again once the problem has disappeared.

If the temperature control sensor is not active, the symbol (---) will appear on the display and the

heater will switch off.

The hose heating command is not memorized by the unit and therefore it must be activated on

every power-up.

4. Mode button

Press this button to modify the different control parameters.

5. Up / Down buttons

Increase or decrease the value of each parameter.

6. Counter / Contador

This display indicates the number of cycles completed, and the number of cycles remaining.

The cycle counter is incremental and can be reset to zero by pressing the UP and DOWN

buttons simultaneously.

The system offers a certain number of work cycle pre-selects. When the unit completes the preselected number of cycles, it stops dispensing product.

To enter the desired number of cycles, press and hold the MODE button until the cycle counter

starts flashing, then select the number of cycles by pressing the UP / DOWN buttons as

required. Then press the MODE button again to confirm the number of cycles.

When the unit starts, the number of completed cycles is deducted from the number of pre-set

cycles. When all the pre-set cycles have completed, the counter displays zero and the unit

stops.

The counter display alternately shows (at intervals of two or three seconds) the number of

cycles completed (totalizer) and cycles remaining (preselector). The remaining cycles are

displayed with a minus sign (-) in front (-XXXXX).

The cycle counter display also shows alerts in the event of malfunction.

You can use the programmable counter cycles as minimum product level in the tanks, setting

the counter to 620 cycles and ensuring that the tanks are full. When the counter reaches zero

the machine stops in order not to pump air into the system and alerting the lack of product in the

tanks. Once the 620 cycles you should reset the counter and fill the tank if you want to reuse as

a low level of product tanks.

7. Control / Power button

This button controls the power switch providing electrical power to the heating circuits of the

heaters and hoses. When pressed, this button lights up. To disconnect the power supply, press

this button again. The power supply automatically cuts out in the event of an alarm for excess

temperature in the heaters (alarms 6 and 7) or an alarm for excess intensity in the hose heating

(alarm 9).

Page 15

Easy Spray-H

Service Manual

15/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

8. Motor button

This button starts and stops the hydraulic motor. When pressed, this button lights up. To switch

off the hydraulic motor, press this button again. The hydraulic motor switches off automatically

in the event of hydraulic motor overload (alarm 8). The “Motor” function is only available on

units with hydraulic drive.

9. Normal button

Press this button to activate normal operation. When pressed, this button lights up.

10. Retract button

Pressing this button sets the piston of the isocyanate proportioning pump to the retracted

position to prevent product residue from crystallizing on the piston. Press the RETRACT button

every time you stop the unit. When pressed, this button lights up.

11. Direction indicator lights

These lights indicate the direction of movement of the proportioning pumps. When there is

excess pressure in the system, both these lights go out and alarms 3 and 4 are activated. The

NORMAL and RETRACT buttons remain active.

Page 16

Easy Spray-H

Service manual

16/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

In the event of a malfunction affecting the operation of the unit, it emits an audio signal and

shows an alarm code on the COUNTER/CONTADOR display. An alarm cannot be cleared until

the problem which caused it has been resolved. After clearing the alarm, press the MODE

button.

Procedures for determining the causes of alarms are given below:

1. Operating voltage under 170V

Check the electrical power connection.

Check the transformer’s thermomagnetic protection.

2. Operating voltage above 270V

Check the electrical power connection.

3. Excess pressure ISO (solenoid valve and heating system cut-out)

Check product pressure.

Check LED no. 10 on the printed circuit board: it should be on.

Check the safety pressure switch.

4. Excess pressure POL (solenoid valve and heating system cut-out)

Check product pressure.

Check LED no. 11 on the printed circuit board: it should be on.

Check the safety pressure switch.

5. Excess temperature ISO (CONTROL/POWER cut-out)

Check the heater heating system.

Check the safety pressure switch connection and allow it to cool down so it can

automatically reset.

Check LED no. 12 on the printed circuit board: it should be on.

6. Excess temperature POL (CONTROL/POWER cut-out)

Check the heater heating system.

Check the safety pressure switch connection and allow it to cool down so it can

automatically reset.

Check LED no. 13 on the printed circuit board: it should be on.

7. Button malfunction (only active when machine is connected to the power supply)

Check the buttons.

8. Motor malfunction (motor stoppage)

Check the consumption of the hydraulic motor.

Check the electrical connections of the hydraulic motor.

Check LED no. 15 on the printed circuit board: it should be off.

NOTE: Alarm 8 (“motor malfunction”) is only included in units with hydraulic drive.

ALARMS

Page 17

Easy Spray-H

Service Manual

17/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

9. Hose heating system malfunction (CONTROL/POWER cut-out)

Replace the faulty triac.

000000 Preselected cycles completed (solenoid valve cut-out)

Press the MODE button to reset the counter.

Set the cycle selector to zero.

Disconnect the unit from the power supply before opening

the electrical console. Electrical maintenance of the machine

should only be carried out by a qualified electrician.

Page 18

Easy Spray-H

Service manual

18/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! Use suitable protective gear and follow the safety recommendations of the

suppliers of the chemical components when preparing or working with the unit.

HI-TECH provides some accessories. This set comprises the following elements:

Tube of grease, magnet holder, parts manual and service manual.

NOTE: To ensure the correct operation of the unit, the electrical power supply must

meet the specifications given on p 6 of this manual and on the unit’s rating plate.

The hoses have been subjected to a vacuum-drying treatment and are delivered with their ends

joined to prevent humidity from entering them. Do not separate them until the moment they are

to be fitted to the unit.

Proceed as follows to prepare the unit:

a) Remove the front protective covering from the pump guides

and fill the lube reservoir of the isocyanate pump with DOTP

plasticizer.

b) Connect the hose for each product to the outlet of its respective

heater (the isocyanate hose to the isocyanate heater and the

polyol hose to the polyol heater).

NOTE: The hoses are colour-coded for easy identification: red for isocyanate and blue

for polyol. To prevent connection errors, the isocyanate and polyol hose couplers are of

different sizes, which makes it impossible to connect a hose to the wrong heater.

Figure 3. Hose coupling method

PREPARING THE UNIT FOR OPERATION

Page 19

Easy Spray-H

Service Manual

19/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! To join hoses to each other, to the heaters, or to the gun, hold each hose

end in place with a spanner (1), and with a third spanner tighten or loosen the coupling

nut (2) as required (see Figure 3 18. These couplers should be tightened to a torque of 20

Nm.

c) Put 18 litres of hydraulic oil in the unit’s oil tank. The oil should comply with the

characteristics and specifications of standard DIN 51524 sections 1 and 2 (for example

ISO VG 46).

NOTE: Do not fill the tank to its maximum capacity (22

litres); the oil level should not exceed 85% of the maximum

capacity (18 litres approx.). Use the visor of the oil

thermometer to check the oil level, as this should always be

completely full (18 litres).

d) Check the oil level in the hydraulic pump by removing

the drain coupler from the pump and making sure the oil

level reaches the top of the filler neck. Add oil if

necessary and reconnect the coupler.

Preparation (units with recirculation hose)

WARNING! Use suitable protective gear and follow the safety recommendations of the

suppliers of the chemical components when preparing or working with the unit.

NOTE: To ensure the correct operation of the unit, the electrical power supply must

meet the specifications given on p 6 of this manual and on the unit’s rating plate.

After following steps a), b), c) and d) of the preparation procedure (see p.18), follow the

procedure given below to prepare the unit for recirculation:

a) Connect the recirculation hose of each product to the recirculation valves located in the

respective product tanks (the

isocyanate hose to the

isocyanate tank valve and the

polyol hose to the polyol tank

valve).

Page 20

Easy Spray-H

Service manual

20/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

b) Connect the air hose to the supply connector.

c) Connect the pressure hoses to the gun couplers, making sure the gun’s manual valves

are closed (the isocyanate hose to the isocyanate coupler and the polyol hose to the

polyol coupler).

d) Connect the recirculation hoses to the gun couplers (the isocyanate hose to the

isocyanate coupler and the polyol hose to the polyol coupler).

e) Fill the tanks with their respective product.

WARNING!

When handling chemical products, always follow the supplier’s safety and storage

instructions.

To prevent splash contamination between one tank and the other, open only the cap of

the tank being filled with product.

Never swap parts between one tank and the other, and always use the same tank for the

same product.

WARNING!

To prevent cross-contamination of products, make sure the tanks are properly closed.

To avoid spillage during transportation of the unit, never fill the tanks completely: always

leave about 20% of the tank capacity free (each tank holds 30 litres).

We recommend using small vessels (10-15 litres maximum) for pouring product into the

tanks.

Fill the tanks with the amount of product required for each application.

Purge method for hoses with recirculation

Before using the unit, all air pockets and residual oil from in-factory testing must be eliminated.

To purge the full circuit, proceed as follows:

a) Disconnect the isocyanate and polyol recirculation tubes and place them in separate

waste recipients.

b) Open the manual purge valves located under each tank.

c) Open the manual recirculation valves.

d) Rotate the power switch to the ON

position. The upper pilot light goes

on.

e) Press the CONTROL/POWER

button. The LED will light up.

f) Press the button located under the

HOSES/MANGUERAS display. The

LED inside the button will light up.

Page 21

Easy Spray-H

Service Manual

21/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

g) When the products contained in the hoses have reached working temperature, press

the ISO and RESIN buttons located under the HEATERS/CALENTADORES display.

Both LEDs will light up.

WARNING! To avoid excess pressure in the heating hoses, wait for the products

contained in the hoses to reach the required temperature before starting the hydraulic

system.

h) Press the MOTOR button. The LED will light up.

Once the above operations have been completed, you now have to check the direction of

rotation of the motor. Proceed as follows to make sure the motor is rotating in the clockwise

direction:

i) Rotate the hydraulic pressure regulator in the anticlockwise direction as far as it will go.

j) Rotate the power switch to the ON position. The upper pilot light goes on.

k) Press the CONTROL/POWER button.

l) Position yourself so that you can see the motor fan on the side of the unit. Press the

MOTOR button to start the motor, then press it again to stop the motor. Check that the

fan blades are turning in the clockwise direction.

m) Rotate the hydraulic pressure regulator in the anticlockwise direction as far as it will go.

n) Rotate the power switch to the ON position. The upper pilot light goes on.

o) Press the CONTROL/POWER button.

p) Press the NORMAL button. The LED will light up. One of the direction indicator lights

comes on and the proportioning pumps begin to operate.

q) If necessary, rotate the hydraulic pressure regulator to reach the required pressure, and

check the pressure of each proportioning pump on the respective pressure gauges at

the unit’s outlets.

The hydraulic circuit should be regulated to ensure that the

unit’s output pressure never exceeds the working pressure of

the product hoses fitted to the unit.

r) Allow the air and oil to escape from the recirculation tubes until there is no more

residual oil and the air has stopped gurgling.

s) Close the manual recirculation valves for each product.

t) Remove any product residue from the recirculation tubes and re-connect them to the

tanks.

u) Slowly increase the hydraulic pressure to check for any product leakage at any point in

the circuit.

v) Rotate the power switch to the OFF position. All displays will switch off.

w) Place the gun in the coupling block.

x) Rotate the power switch to the ON position. The upper pilot light goes on.

y) Press the CONTROL/POWER button. The LED will light up.

z) Press the button located under the HOSES/MANGUERAS display. The LED inside the

button will light up.

Page 22

Easy Spray-H

Service manual

22/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

aa) When the products contained in the hoses have reached working temperature, press

the ISO and RESIN buttons located under the HEATERS/CALENTADORES display.

Both LEDs will light up.

bb) Press the MOTOR button. The LED will light up.

cc) Press the NORMAL button. The LED will light up. One of the direction indicator lights

comes on and the proportioning pumps begin to operate.

The unit is now ready to operate.

Preparation (units with heated hose)

The 15 m heated hose assembly includes a power supply socket and a terminal for temperature

control.

WARNING! Use suitable protective gear and follow the safety recommendations of the

suppliers of the chemical components when preparing or working with the unit.

NOTE: To ensure the correct operation of the unit, the electrical power supply must

meet the specifications given on p 6 of this manual and on the unit’s rating plate.

After following steps a), b), c) and d) of the preparation procedure (see

p.18), follow the procedure given below to prepare the unit to work with

heated hoses:

a) Connect the hose heating temperature control cable to the

connector on the side of the electric cabinet.

WARNING! To join hoses to each other, to the heaters, or to the

gun, hold each hose end in place with a spanner (1), and with a

third spanner tighten or loosen the coupling nut (2) as required

(see Figure 3 on p. 1718. These couplers should be tightened to a

torque of 20 Nm.

NOTE: To prevent product leakage and avoid heating system malfunction, make sure

the hoses are correctly connected, electrically and mechanically.

b) Connect the air hose to the unit’s power socket and to the gun.

c) Connect the 60 cm whip hose to the gun’s coupling block connectors, making sure the

manual valves are closed.

d) Fit the temperature control sensor, with its extension nozzle, between the heated hose

and the whip hose connected to the gun. Carefully insert the sensor cable into the

heated isocyanate hose.

NOTE: Once fitted with a temperature control sensor, hoses should be handled with

care and should not be folded to excess. When coiling the hoses, make sure the winding

radius is at least one metre.

Page 23

Easy Spray-H

Service Manual

23/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

e) Insert a contact thermometer under the hose’s outer sheath so that the lower part of the

thermometer is in contact with the hoses and the upper part projects from the hose’s

outer sheath. Position the thermometer in such a way that you can see the temperature

while spraying. With hoses incorporating a temperature control sensor there is no need

to fit a contact thermometer.

f) Fill the tanks with their respective product.

WARNING!

When handling chemical products, always follow the supplier’s safety and storage

instructions.

To prevent splash contamination between one tank and the other, open only the cap of

the tank being filled with product.

Never swap parts between one tank and the other, and always use the same tank for the

same product.

WARNING!

To prevent cross-contamination of products, make sure the tanks are properly closed.

To avoid spillage during transportation of the unit, never fill the tanks completely: always

leave about 20% of the tank capacity free (each tank holds 30 litres).

We recommend using small vessels (10-15 litres maximum) for pouring product into the

tanks.

Fill the tanks with the amount of product required for each application.

Purge method for heated hoses

Before using the unit, all air pockets and residual oil from in-factory testing must be eliminated.

To purge the full circuit, proceed as follows:

a) Open the manual purge valves located under each tank.

b) Place the coupling block so that each

product drains into a separate

recipient and open the manual valves

of each product.

c) Rotate the power switch to the ON

position. The upper pilot light goes on.

d) Press the CONTROL/POWER button.

The LED will light up.

Page 24

Easy Spray-H

Service manual

24/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

e) Press the button located under the HOSES/MANGUERAS display. The LED inside the

button will light up.

f) When the products contained in the hoses have reached working temperature, press

the ISO and RESIN buttons located under the HEATERS/CALENTADORES display.

Both LEDs will light up.

WARNING! To avoid excess pressure in the heating hoses, wait for the products

contained in the hoses to reach the required temperature before starting the hydraulic

system.

g) Press the MOTOR button. The LED will light up.

Once the above operations have been completed, you now have to check the direction of

rotation of the motor. Proceed as follows to make sure the motor is rotating in the clockwise

direction:

h) Rotate the hydraulic pressure regulator in the anticlockwise direction as far as it will go.

i) Rotate the power switch to the ON position. The upper pilot light goes on.

j) Press the CONTROL/POWER button.

k) Position yourself so that you can see the motor fan on the side of the unit. Press the

MOTOR button to start the motor, then press it again to stop the motor. Check that the

fan blades are turning in the clockwise direction.

l) Rotate the hydraulic pressure regulator in the anticlockwise direction as far as it will go.

m) Rotate the power switch to the ON position. The upper pilot light goes on.

n) Press the CONTROL/POWER button.

o) Press the MOTOR button. The LED will light up.

p) Press the NORMAL button. The LED will light up. One of the direction indicator lights

comes on and the proportioning pumps begin to operate.

q) If necessary, rotate the hydraulic pressure regulator to reach the required pressure, and

check the pressure of each proportioning pump on the respective pressure gauges at

the unit’s outlets.

The hydraulic circuit should be regulated to ensure that the

unit’s output pressure never exceeds the working pressure of

the product hoses fitted to the unit.

r) Open the coupling block manual valves.

s) Allow the materials to escape via the coupling block until there is no more residual oil

and the air has stopped gurgling.

t) Close the manual valves for each product and remove residual product from the

coupling block.

u) Rotate the power switch to the OFF position. All displays will switch off.

v) Place the gun in the coupling block.

w) Rotate the power switch to the ON position. The upper pilot light goes on.

x) Press the CONTROL/POWER button. The LED will light up.

Page 25

Easy Spray-H

Service Manual

25/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

y) Press the button located under the HOSES/MANGUERAS display. The LED inside the

button will light up.

z) When the products contained in the hoses have reached working temperature, press

the ISO and RESIN buttons located under the HEATERS/CALENTADORES display.

Both LEDs will light up.

aa) Press the MOTOR button. The LED will light up.

bb) Press the NORMAL button. The LED will light up. One of the direction indicator lights

comes on and the proportioning pumps begin to operate.

The unit is now ready to operate.

Page 26

Easy Spray-H

Service manual

26/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Follow the recommended procedure, in the sequence given, to power-up the unit:

WARNING! Do not start the power-up procedure described below until all necessary

prior adjustments have been made correctly.

a) Check the condition of the DOTP plasticizer contained in the isocyanate pump’s lube

reservoir. Change the oil if it is discoloured or shows signs of solidification, and tighten

the packing nut to make the seal tight.

b) Make sure the product tanks are full or have the minimum content for application to

begin.

c) Check the product intake filters. Clean them if necessary.

d) Open the manual purge valves located under each tank.

e) Open the manual recirculation valves (hoses with recirculation).

NOTE: Only perform this step if you wish to recirculate the products.

NOTE: Recirculation of products enables heater temperature settings to be reached

quicker, heating both the hoses and the gun. For more efficient heating during

recirculation, fill the tanks with the minimum amount of product necessary for the

application.

WARNING! The product tanks are made of a plastic material which can withstand a

maximum temperature of 80ºC. The temperature of the products inside the tanks must

never exceed this limit.

WARNING! Never recirculate when the tanks are completely full, as this can cause

abnormally high pressure in the tanks.

f) Check the hydraulic oil level. Add oil if the level is low.

g) Make sure the products are at the minimum required temperature for their delivery to

the unit via the transfer pumps. Contact your supplier for information on the minimum

delivery temperature.

h) Check the product intake filters. Clean them if necessary.

i) Rotate the power switch to the ON position. The upper pilot light goes on.

j) Press the CONTROL/POWER button. The LED will light up.

k) Press the button located under the HOSES/MANGUERAS display. The LED inside the

button will light up.

l) When the products contained in the hoses have reached working temperature, press

the ISO and RESIN buttons located under the HEATERS/CALENTADORES display.

Both LEDs will light up.

POWER-UP PROCEDURE

Page 27

Easy Spray-H

Service Manual

27/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! To avoid excess pressure in the heating hoses, wait for the products

contained in the hoses to reach the required temperature before starting the hydraulic

system.

m) Press the MOTOR button. The LED will light up.

n) Press the NORMAL button. The LED will light up. One of the direction indicator lights

comes on and the proportioning pumps begin to operate.

o) Rotate the hydraulic pressure regulator to reach the required pressure, and check the

pressure of each proportioning pump on the respective pressure gauges at the unit’s

outlets.

The hydraulic circuit should be regulated to ensure that the

unit’s output pressure never exceeds the working pressure of

the product hoses fitted to the unit.

p) Set the isocyanate heater temperature.

q) Set the polyol heater temperature.

r) Set the hose heating temperature and intensity.

For hoses with recirculation:

s) Close the recirculation valves if open and open each product’s manual valves on the

gun. Perform a test spray and check the pressure readings on each product’s pressure

gauge. If the test spray is satisfactory and the pressure readings remain identical,

proceed with application.

Pressure readings should be practically identical and should remain constant. One

direction indicator light should remain on and the other off. The light which is on

indicates the direction of movement of the pumps.

If the pressures oscillate with each movement, consult the Malfunctions section before

continuing.

t) Connect the air supply to the gun, open the manual valves for each product, perform a

test spray and check the readings on the pressure gauges of each product. If the test

spray is satisfactory and the pressure readings remain identical, proceed with

application.

Page 28

Easy Spray-H

Service manual

28/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Follow the recommended procedure, in the sequence given, to power-down the unit when you

have finished using it:

a) Press the RETRACT button. The LED will light up.

b) Operate the gun, spraying into a waste recipient until the isocyanate proportioning

pump is in the retracted position and the spray angle begins to decrease.

WARNING! To prevent product leakage and premature deterioration of the pump’s seal

rings, do not reduce the pressure to zero. We recommend keeping the system at a

minimum pressure of 30 bars to prolong the life of the seal rings.

c) Press the MOTOR button. The LED will go out.

d) Press the ISO and RESIN buttons located below the heater temperature display. Both

LEDs will go out.

e) Press the button located under the HOSES/MANGUERAS display. The LED will go out.

f) Press the CONTROL/POWER button. The LED will go out.

g) Rotate the power switch to the OFF position. The upper pilot light goes out.

h) Close the stop valves controlling intake of the products.

i) Close the manual valves on the coupling block and dismount the gun for carrying out

the necessary maintenance.

POWER-DOWN

Page 29

Easy Spray-H

Service Manual

29/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! This unit includes parts which reach temperatures likely to cause burns. Do

not touch or handle the hot parts of the unit until they have cooled down.

To avoid possible contamination, all of the unit’s circuits (pumps, heaters and hoses) must be

cleaned before applications which require a change of components.

Follow the steps given below to clean the unit before changing any of its components:

NOTE: Save reusable products to suitable recipients, following the instructions of the

manufacturer.

a) Open the manual purge valves located under each tank.

b) Place the tubs containing the DOTP cleaning agent near the unit.

c) Dismount the gun and leave the coupling block joined to the hoses.

d) Place a recipient below the coupling block to collect the products contained in the tanks

and inside the unit.

e) Rotate the power switch to the ON position.

f) Open the taps on the coupling block and press the CONTROL/POWER, MOTOR and

NORMAL buttons to start the proportioning pumps.

g) Let the materials drain into their recipients from the coupling block until the tanks are

completely empty.

h) Press the NORMAL, MOTOR and CONTROL/POWER buttons to stop the proportioning

pumps. The displays on the temperature regulators will go out.

i) Rotate the power switch to the OFF position.

j) Close the manual valves located below each product tank.

k) Close the taps on the coupling block

l) Fill the product tanks with DOTP cleaning agent (approx. 5 litres).

m) Rotate the power switch to the ON position.

n) Open the manual purge valves located under each tank.

o) Open the taps on the coupling block and press the CONTROL/POWER, MOTOR and

NORMAL buttons to start the proportioning pumps.

p) Let the DOTP cleaning agent drain into the recipient from the coupling block until the

tanks are completely empty.

q) Press the NORMAL, MOTOR and CONTROL/POWER buttons to stop the proportioning

pumps. The displays on the temperature regulators will go out.

r) Rotate the power switch to the OFF position.

s) Close the manual valves located below each product tank.

t) Close the taps on the coupling block.

u) Proceed as indicated in the instructions for preparing the unit.

CLEANING PROCEDURE (HEATED HOSES)

Page 30

Easy Spray-H

Service manual

30/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! This unit includes parts which reach temperatures likely to cause burns. Do

not touch or handle the hot parts of the unit until they have cooled down.

To avoid possible contamination, all of the unit’s circuits (pumps, heaters and hoses) must be

cleaned before applications which require a change of components.

Follow the steps given below to clean the unit before changing any of its components:

a) Disconnect the isocyanate and polyol recirculation tubes and place them in separate

waste recipients.

NOTE: Save reusable products to suitable recipients, following the instructions of the

manufacturer.

b) Open the manual purge valves located under each tank.

c) Open the manual recirculation valves.

d) Place the tubs containing the DOTP cleaning agent near the unit.

e) Dismount the gun and leave the coupling block joined to the hoses.

f) Put the recirculation hose end in a recipient to collect the products contained in the

tanks and inside the unit.

g) Rotate the power switch to the ON position.

h) Check that the taps on the coupling block are closed and press the

CONTROL/POWER, MOTOR and NORMAL buttons to start the proportioning pumps.

i) Check that the product pumps are working.

j) Let the materials drain into the recipient from the recirculation hoses until the tanks are

completely empty.

k) Press the NORMAL, MOTOR and CONTROL/POWER buttons to stop the proportioning

pumps. The displays on the temperature regulators will go out.

l) Rotate the power switch to the OFF position.

m) Close the manual valves located below each product tank.

n) Fill the product tanks with DOTP cleaning agent (approx. 5 litres).

o) Open the manual purge valves located under each tank.

p) Close the recirculation valves for each product.

q) Reconnect the recirculation hoses to their respective tanks and re-open the recirculation

valves.

r) Rotate the power switch to the ON position.

s) Press the CONTROL/POWER, MOTOR and NORMAL buttons to start the proportioning

pumps.

CLEANING PROCEDURE (HOSES WITH

RECIRCULATION)

Page 31

Easy Spray-H

Service Manual

31/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

t) Let the unit recirculate for 2-3 minutes to clean the hoses and tanks. For better tank

cleaning results, heat the cleaning agent with the heaters.

u) Press the NORMAL, MOTOR and CONTROL/POWER buttons to stop the proportioning

pumps. The displays on the temperature regulators will go out.

v) Rotate the power switch to the OFF position.

w) Close the recirculation valves located under each product tank.

x) Disconnect the recirculation tubes from the isocyanate and polyol tanks and place them

in separate waste recipients.

y) Open the recirculation valves located under each product tank and make sure the taps

on the coupling block are closed.

z) Rotate the power switch to the ON position.

aa) Press the CONTROL/POWER, MOTOR and NORMAL buttons to start the proportioning

pumps.

bb) Check that the product pumps are working.

cc) Let the cleaning agent drain from the recirculation tubes until the tanks are empty.

dd) Press the NORMAL, MOTOR and CONTROL/POWER buttons to stop the proportioning

pumps. The displays on the temperature regulators will go out.

ee) Rotate the power switch to the OFF position.

ff) Close the manual valves located below each product tank.

gg) Close the manual recirculation valves.

hh) Proceed as indicated in the instructions for preparing the unit.

Page 32

Easy Spray-H

Service manual

32/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

WARNING! This unit includes parts which reach temperatures likely to cause burns. Do

not touch or handle the hot parts of the unit until they have cooled down.

When the unit is to be out of service for over five weeks, you must replace the products

contained in the unit with DOTP plasticizer.

Follow the steps given below to replace the products with DOTP plasticizing agent:

NOTE: If the products contained in the unit can be reused, save them to suitable

recipients, following the instructions of the supplier.

a) Perform the cleaning procedure for hoses with recirculation (see p.30) or heated hoses

(see p.29), as appropriate.

b) Fill the product tanks with DOTP cleaning agent (approx. 5 litres).

c) Open the manual purge valves located under each tank.

d) Make sure the taps on the coupling block (in the case of heated hoses) or the

recirculation taps (in the case of hoses with recirculation) are closed.

e) Rotate the power switch to the ON position.

f) Press the CONTROL/POWER and MOTOR buttons.

g) Press the RETRACT button and wait for the proportioning pumps to descend into the

retract position.

h) Press the RETRACT, MOTOR and CONTROL/POWER buttons to stop the

proportioning pumps.

i) Rotate the power switch to the OFF position.

j) Reduce product pressure by opening the taps on the coupling block (in the case of

heated hoses) or the recirculation taps (in the case of recirculation hoses) and then

closing them.

To prevent product leakage and the premature wear of pump packing seals, do not

reduce pressure to zero. We recommend keeping the system at a minimum pressure of

30 bars to prolong the service life of packing seals.

Proportioning pumps, heaters and hoses should always be filled with DOTP plasticizer when the

unit is not in use. Never leave the unit or its hoses empty of product or DOTP plasticizer.

TEMPORARY LAYOFF OF THE UNIT

Page 33

Easy Spray-H

Service Manual

33/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

The Easy Spray-H unit has been designed and built to operate in severe working conditions. It

will work with a high degree of reliability on condition that it is used and maintained correctly.

This section contains information on the possible causes of malfunctions in the unit. Most

problems with the unit can be detected and resolved using the information provided in this

section. Please refer to this information before requesting technical assistance from your

authorized dealer or HI-TECH technical services. Feel free to contact the technical assistance

service of HI-TECH SPRAY EQUIPMENT, S.A. at any time. Our team of qualified technicians is

on hand to help and advise you when necessary.

NOTE: Repairs by unqualified personnel or the use of non-original replacement parts

can damage the unit and endanger the safety of the operator.

To avoid bodily damage caused by the incorrect handling of the

substances and solvents used in the spraying process, read carefully the

safety information provided by suppliers.

Dispose of waste as required by applicable legislation.

Disconnect the unit from the power supply before opening the electrical

console.

Electrical maintenance should only be carried out by a qualified

electrician.

To avoid exposure to pressurized fluids, do not release any connectors or

perform maintenance work on parts subjected to pressure until the

pressure has been completely eliminated.

Use suitable protection when using or performing maintenance on the

unit, or when in its vicinity. This protection includes, but is not limited to,

the use of masks, protective goggles, gloves, safety footwear and safety

clothing.

This unit includes parts which reach temperatures likely to cause burns.

Do not touch or handle the hot parts of the unit until they have cooled

down.

To avoid the risk of crushing or amputation, only use this unit when its

moving parts are fitted with correctly installed safety guards. Make sure

all safety guards are correctly mounted after completing repair or

maintenance work.

MALFUNCTION

Page 34

Easy Spray-H

Service manual

34/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Heaters

WARNING! Before attempting to fix any kind of malfunction, make sure that no buttons

are lit on the electrical panel, that the power switch is in the OFF position and that the

unit is disconnected from the power supply. Never open the electrical console when the

unit is connected to the power supply. Heaters can reach high temperatures. Always wait

until they have cooled down before handling them.

NOTE: The thermostat is a safety device which is in contact with the heater. If the

temperature exceeds 120ºC (248º) the

thermostat will cut off the power supply to the

temperature regulator. The thermostat will not

start working again until the temperature of the

heater falls below 120ºC (248ºF).

If the temperature of either heater (isocyanate or

polyol) exceeds 90ºC (194ºF) an alarm will

activate and the corresponding number will appear

on the control panel (5 for isocyanate and 6 for

polyol).

Follow the procedure below, in the sequence

given, to rectify the problem and avoid expensive

repairs. Check that all automatic switches are in

the correct working position before proceeding to

locate faults.

PROBLEM SOLUTIONS

The heater does not heat up, although the LED in the heater button is lit.

1-2-3

The symbol (---) appears on the heater display.

4

SOLUTIONS

1. Heating elements

Each heater contains two 900 W heating elements, connected in parallel and delivering a total

heating power of 1800 W (Easy Spray-H model). If a heater fails to reach the required

temperature after two or three minutes, it’s possible that one of its two elements is faulty.

To check the elements, proceed as follows:

With the power switch in the OFF position, use a tester to check the total resistance of the

heater, which should be 30 Ohms. A higher reading may indicate that one or more elements are

faulty.

Page 35

Easy Spray-H

Service Manual

35/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Disconnect the elements and check that the individual resistance of each element is 60 Ohms.

Extreme environmental conditions may affect the operation of the heaters, preventing them from

reaching the required temperature. In such circumstances, try moving the unit to a warmer

location or use an auxiliary heating system.

2. Static relay

If the above checks have not revealed any problems, check the static relay.

3. Automatic switch

The automatic switch protects the heating elements against voltage surges. With the power

disconnected, open the control panel and make sure the switch is primed (see circuit diagram).

If not, prime it.

4. Temperature sensor

Temperature sensor malfunctions are automatically displayed on the control panel. In the event

of a malfunction, replace the sensor, being careful not to damage it during installation. The

sensor should be in contact with the element.

Hose heating

WARNING! Before attempting to fix any kind of malfunction, make sure that no buttons

are lit on the electrical panel, that the power switch is in the OFF position and that the

unit is disconnected from the power supply. Never open the electrical console when the

unit is connected to the power supply. Hoses can reach high temperatures. Always wait

until they have cooled down before handling them.

Follow the procedure below, in the sequence given, to rectify the problem and avoid expensive

repairs. Check that all automatic switches are in the correct working position before proceeding

to locate faults.

PROBLEMS SOLUTIONS

The hose heats up but does not reach the programmed temperature.

1-2-8

The hose does not heat up but the LED is lit.

3-4-5-6

The symbol (---) appears on the hose display.

7

The automatic switch trips.

3

Page 36

Easy Spray-H

Service manual

36/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

SOLUTIONS

1. Hoses without product or air pockets in hoses

Purge the air from the hoses.

2. The ISO heater is not delivering the required temperature

See the section on heater problems.

3. Hose connector

Check the hose connector’s electrical connection on the left hand side of the console.

4. Heating element disconnected

Check that the resistance reading in the hose is 33Ω ± 2Ω

5. F4 automatic switch

Protects against current spikes in the hose circuit. This switch is located inside the control

panel. Check that it is set to the ON position. If the switch is not working properly, replace it with

one of equal amperage.

WARNING! Replacing the automatic switch with another of different characteristics can

damage the unit and endanger the safety of the operator.

6. Triac

If the other checks have not revealed any problems, check the triac. Replace the triac if it is not

working properly.

7. TCS temperature control sensor

Temperature sensor malfunctions are automatically displayed on the control panel. To

determine whether the fault is caused by the sensor itself or by a defective electrical connection,

perform the following check: unscrew the temperature control sensor’s electrical connector from

the end of the hose, and without removing any other connection connect it directly to the unit’s

electrical outlet. If the control function reappears, check the electrical connections of the

temperature control sensors at both ends of the hose, and if necessary replace the temperature

control sensors.

8. Adjusting the hose heating temperature

The purpose of the hose heating system is to keep the temperature of the products in the hose

at the same temperature as they left the heaters. Therefore, the maximum hose temperature

setting (80ºC) is the same as the maximum setting on the heaters display.

Page 37

Easy Spray-H

Service Manual

37/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Proportioning pumps

WARNING! Before attempting to fix any kind of malfunction, make sure the power

switch is in the OFF position and that the unit is disconnected from the power supply.

Never open the electrical console when the unit is connected to the power supply.

Proportioning pumps work under pressure. Do not release any connection or perform

repair or maintenance work on components subjected to pressure until all pressures

have been completely eliminated.

PROBLEMS SOLUTIONS

The pumps lose pressure when the unit is stopped.

1

The pressure readings in the proportioning pumps are different.

1-2-3

There is cavitation in the proportioning pump.

1-2-3

The proportioning pumps do not reverse direction.

4

The proportioning pumps do not move.

4

The movement of the proportioning pumps is erratic.

4-5

SOLUTIONS

1. Pressure loss in ball valves

Observe the pressure gauges to identify which pump is losing pressure. To determine which

ball valve is faulty, check in which direction of movement the pump loses pressure. If pressure is

lost in the upward stroke, check the discharge (upper) ball valve. If pressure is lost on the

downward stroke, check the intake (lower) ball valve.

Proceed as follows to check the ball valves:

a) Disconnect the unit from the power supply and shut the stop valves controlling product

intake underneath the tanks.

b) Depressurize the proportioning pump and dismount the faulty ball valve.

c) Pressure loss in ball valves is usually caused by foreign particles which prevent the ball

from coupling perfectly with the seat in the upper part of the closing bushing. Clean the

ball and the surface of the bushing seat and check there are no nicks, marks or

scratches on the bushing or the ball. If cleaning does not resolve the problem, or if any

defects are detected, replace the bushing and the ball.

2. Pressure reading imbalances

Pressure reading imbalances occur when an obstruction in the hose or gun prevents one of the

spray components from exiting the nozzle during spraying, or when a problem in the pumping

system prevents one of the components from reaching the gun in the required quantities.

Identifying which component is causing the imbalance is relatively easy, as the component

chemical products used in the polyurethane foam spray system are of different colours. By

observing the colour of the component coming out of the gun you can determine which

component is missing.

Page 38

Easy Spray-H

Service manual

38/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

To ascertain whether the pressure imbalance is caused by an obstruction or by a problem in the

pumping system, operate the spray gun and check the reading on the pressure gauge of the

missing component. Compare this reading with the pressure indicated on the other component’s

pressure gauge: if the pressure of the missing component is higher, the pressure imbalance is

caused by an obstruction; if it is lower, the imbalance is due to a problem in the pumping

system.

3. Cavitation

Cavitation occurs when the proportioning pump requires a greater volume of material than the

feed system is supplying, giving rise to the formation of voids in the proportioning pump. There

are three possible causes of cavitation:

a) High viscosity. Polyurethane foam spray systems normally require a minimum transfer

temperature of 12ºC: at lower temperatures, the viscosity of the component products

increases and it is more difficult to pump them. When ambient conditions do not allow

the component products to be kept at the minimum temperature of 12ºC, auxiliary

heating equipment must be used to keep the component products at the minimum

required transfer temperature.

b) The product intake filter is clogged (see Maintenance).

c) The intake ball valve is leaking as a result of wear or defects in the ball or the closing

surface of the bushing, which causes some of the material to return to the tank.

Therefore the volume of material delivered by the proportioning pump in the discharge

cycle is lower than required, giving rise to an incorrect product ratio.

4. Fault in the direction change sensor

The hydraulic cylinder which drives the proportioning pumps is fitted with two inductive sensors

which control its change of direction. Accidental displacement from the detection position will

mean the pumps do not change direction, and so the sensor has to be returned to it correct

position.

The only way to adjust the position of the sensors is by inserting them to a greater or lesser

degree in the cylinder body.

5. Tank empty

As there is no way of visually checking the level of product in the tanks during the normal

operation of the unit, there is a risk that air will enter the circuit if the level in one tank is too low.

This will cause the pumping system to malfunction.

If this problem occurs, purge the air from the circuit as described in the corresponding section

on p.20 (hoses with recirculation) or p.23 (heated hoses).

Page 39

Easy Spray-H

Service Manual

39/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

Hydraulic drive

WARNING! Before attempting to fix any kind of malfunction, make sure that no lights

are lit on the control panel, the power switch is set to the OFF position, and the unit is

disconnected from the power supply. Never open the electrical console when the unit is

connected to the power supply. The hydraulic motor operates under pressure. Do not

release any connection or perform repair or maintenance work on components subjected

to pressure until all pressures have been completely eliminated.

Follow the procedure below, in the sequence given, to rectify the problem and avoid expensive

repairs. Check that all automatic switches are in the correct working position before proceeding

to locate faults.

PROBLEMS SOLUTIONS

The electric motor does not start, or stops during operation.

1

The hydraulic pump delivers no pressure.

2

Little or no pressure, with chirps.

2-3

SOLUTIONS

1. Automatic switch

The electric motor is protected by an automatic safety switch which trips when too much current

is delivered to the motor. Disconnect the unit from the power supply and allow the motor to cool

down. Open the control panel and re-prime the automatic switch. The motor should now work

normally. If too much current is being delivered to the motor it is important to identify why this is

happening, for in the event of failure by the automatic switch the electric motor may be

damaged by overheating.

2. Little or no pressure

The most likely cause of lack of pressure is that the hydraulic pump is not delivering enough

pressure due to mis-priming, caused by a lack of oil or a clogged intake filter. Check these

points to ensure correct operation.

3. Noise

A chirping noise is a common symptom of cavitation. This noise is normal upon power-up and

normally disappears after about thirty seconds.

If the chirping continues, stop the unit to protect the hydraulic pump and check that the hose

couplings are properly tightened and that the pump is correctly primed. Remove the pump drain

coupler and fill the pump if necessary.

Another cause of pump noise is excessive temperature of the hydraulic oil. Make sure the oil is

being delivered in the correct quantity, and if necessary improve ventilation to allow greater

dissipation of heat from the hydraulic tank.

Page 40

Easy Spray-H

Service manual

40/48 Issue 1.9 Ref. NR-00088-ENG

http://www.gamapur.com/

To obtain optimum performance from the Easy Spray-H unit you must perform certain

maintenance operations on a daily or regular basis.

To avoid bodily damage caused by the incorrect handling of the

substances and solvents used with this unit, read carefully the safety

information provided by their suppliers.

Dispose of waste as required by applicable legislation.

Disconnect the unit from the power supply before opening the electrical

console.

Electrical maintenance should only be carried out by a qualified

electrician.

To avoid exposure to pressurized fluids, do not release any connectors or

perform maintenance work on parts subjected to pressure until the

pressure has been completely eliminated.

Use suitable protection when using or performing maintenance on the

unit, or when in its vicinity. This protection includes, but is not limited to,

the use of masks, protective goggles, gloves, safety footwear and safety

clothing.

This unit includes parts which reach temperatures likely to cause burns.

Do not touch or handle the hot parts of the unit until they have cooled

down.

To avoid the risk of crushing or amputation, only use this unit when its

moving parts are fitted with correctly installed safety guards. Make sure