Galvanic applied sciences PROTECH903W OPERATION MANUAL

ProTech903W

Phosgene Analyzer

OPERATION MANUAL

Revision 2

May 27, 2015

Galvanic Applied Sciences, Inc.

7000 Fisher Road S.E.

Calgary, Alberta, T2H 0W3

Canada

Phone: (403) 252-8470

Fax: (403) 255-6287

E-mail: info@galvanic.com

World Wide Web: http://www.galvanic.com

NOTICES

This system is covered by a limited warranty. A copy of the warranty is included with this manual.

The operator is required to perform routine maintenance as described herein on a periodic basis

to keep the warranty in effect. For routine maintenance procedures, refer to Section 7.

All information in this manual is subject to change without notice and does not represent a

commitment on the part of Galvanic Applied Sciences, Inc.

No part of this manual may be reproduced or transmitted in any form or by any means without the

written permission of Galvanic Applied Sciences, Inc.

Note: Changes or modifications not expressly approved by Galvanic Applied Sciences, Inc.

could void the user's authority to operate the equipment.

© Copyright 2011, Galvanic Applied Sciences, Inc. All rights reserved.

Printed in Canada

Table of Contents

ECTION 1 PHOSGENE ANALYZER ............................................................................................... 13

S

1.1 OVERVIEW ........................................................................................................................... 13

1.2 PRINCIPLE OF OPERATION .................................................................................................... 13

1.3 FEATURES OF THE ANALYZER ............................................................................................... 14

1.4 SYSTEM OPERATING CONTROL............................................................................................. 14

1.5 CONTENTS OF THIS MANUAL ................................................................................................. 15

SECTION 2 ANALYZER COMPONENTS .............................................................................................. 16

2.1 OVERVIEW ........................................................................................................................... 16

2.2 MOTHERBOARD ................................................................................................................... 17

2.2.1 Description of the Motherboard ............................................................................ 17

2.2.2 Boards Associated with the Motherboard ............................................................. 17

2.2.3 AC and DC Power Supply .................................................................................... 17

2.3 LCD DISPLAY BOARD, KEYPAD AND LED’S ........................................................................... 17

2.3.1 User Interaction Features ..................................................................................... 17

2.3.2 Display Board Communication Ports .................................................................... 18

2.4 CHASSIS .............................................................................................................................. 18

2.5 TAPE TRANSPORT SYSTEM................................................................................................... 19

2.5.1 Supply and Take-up Reels ................................................................................... 19

2.5.2 Pulse Counter ....................................................................................................... 20

2.6 SAMPLE CHAMBER ASSEMBLY .............................................................................................. 21

2.6.1 Rate/Read Aperture Strip and the Rear Window Assembly ................................. 22

2.6.2 Read/Rate Aperture Strip ..................................................................................... 23

2.6.3 Sensor Block ........................................................................................................ 23

2.6.4 Compression Head ............................................................................................... 24

2.7 SAMPLE FLOW RELATED COMPONENTS ................................................................................ 25

2.7.1 Rotameter ............................................................................................................. 25

2.7.2 Power Vent (Eductor) ........................................................................................... 25

2.8 SAMPLE CONDITIONING SYSTEM ........................................................................................... 26

SECTION 3 INSTALLATION................................................................................................................ 28

3.1 RECEIVING THE SYSTEM ....................................................................................................... 28

3.2 INSTALLATION REQUIREMENTS ............................................................................................. 28

3.2.1 Electrical Requirements ........................................................................................ 28

3.2.2 Location of the System ......................................................................................... 28

3.2.3 Space Requirements ............................................................................................ 28

3.2.4 Area Classification Information ............................................................................. 30

3.2.5 Gas Requirements ................................................................................................ 30

3.3 UNPACKING ......................................................................................................................... 30

3.4 INSTALLATION OF THE SOFTWARE ........................................................................................ 31

3.4.1 Computer Requirements ...................................................................................... 31

3.4.2 Install the Application Software ............................................................................ 31

3.4.3 Power up the Analyzer ......................................................................................... 32

3.4.4 Connect the System to the PC via RS-232 .......................................................... 33

Revision 1 3 9/10/2019

3.4.5 Open the Application Program and Set Communication Parameters .................. 34

3.4.5.1 Com Port Direct Option ............................................................................. 35

3.4.5.2 Modem Option ........................................................................................... 35

3.4.5.3 Ethernet Option ......................................................................................... 36

3.4.5.4 Connect the Computer and the Analyzer .................................................. 37

3.5 INSTALLING THE KEYPAD AND SENSING TAPE ........................................................................ 38

3.5.1 Installing the Keypad ............................................................................................ 38

3.5.2 Installing the Sensing Tape .................................................................................. 38

3.6 CONNECTING GAS TO ANALYZER .......................................................................................... 41

3.6.1 Connecting Gas to the Analyzer ........................................................................... 41

3.6.2 Leak Testing of the Compression Head ............................................................... 41

3.6.3 Connecting the Power Eductor ............................................................................. 42

3.7 TESTING THE ANALYZER ....................................................................................................... 43

SECTION 4 OPERATING THE ANALYZER VIA THE HANDHELD KEYPAD ................................................. 44

4.1 INTRODUCTION .................................................................................................................... 44

4.2 THE FRONT PANEL LED’S .................................................................................................... 44

4.3 THE MAIN PAGE OF THE LCD DISPLAY .................................................................................. 46

4.3.1 Status Indicator Lines ........................................................................................... 47

4.3.2 Central Region ...................................................................................................... 48

4.3.3 Display Menus and Sub-menus Descriptions ....................................................... 48

4.4 USING THE HANDHELD KEYPAD ............................................................................................ 49

4.5 THE STREAMS MENU ........................................................................................................... 51

4.6 THE ALARMS PAGE ............................................................................................................ 53

4.7 THE DISPLAY MENU ............................................................................................................. 54

4.7.1 The SQNC Menu .................................................................................................. 54

4.7.2 IO Menu ................................................................................................................ 54

4.7.3 Analyzer Reading Menu ....................................................................................... 55

4.7.4 Analyzer Schedule Menu...................................................................................... 55

4.8 THE CONFIGURATION MENU ................................................................................................. 56

4.8.1 The Gen Menu ...................................................................................................... 56

4.8.2 The DIO Menu (Digital Inputs/Outputs) ................................................................ 57

4.8.3 The AIO Menu (Analog Inputs/Outputs) ............................................................... 57

4.8.4 The MSEQ Menu (Manual Sequencer) ................................................................ 58

SECTION 5 GRAPHICAL USER INTERFACE (GUI) ............................................................................... 59

5.1 OPENING THE PROGRAM ...................................................................................................... 59

5.2 COMPONENTS OF THE MAIN WINDOW ................................................................................... 61

5.2.1 Menu Bar .............................................................................................................. 61

5.2.2 The Tool Bar ......................................................................................................... 62

5.2.2.1 Communicate Toolbar ............................................................................... 62

5.2.2.2 Operation Toolbar ..................................................................................... 63

5.2.2.3 General Toolbar ........................................................................................ 64

5.2.3 Application Screens (Tabs) .................................................................................. 64

5.2.4 Status Bar ............................................................................................................. 65

5.3 COMMUNICATION BETWEEN THE COMPUTER AND THE ANALYZER ........................................... 66

5.4 THE ANALYSIS TAB .............................................................................................................. 67

5.4.1 Field Names and Explanations ............................................................................. 68

5.4.2 Analysis Data ........................................................................................................ 69

5.5 STATUS TAB ........................................................................................................................ 70

5.6 ALARMS TAB ........................................................................................................................ 71

5.6.1 Global Alarms ....................................................................................................... 72

Revision 1 4 9/10/2019

5.6.2 Analog Input Alarms ............................................................................................. 73

5.6.3 Analysis Alarms .................................................................................................... 73

5.7 ARCHIVE TAB ....................................................................................................................... 74

5.7.1 The Table Format ................................................................................................. 74

5.7.2 The Graph Format ................................................................................................ 75

5.7.3 Filtering Data ........................................................................................................ 78

5.7.3.1 Filtering Data by Date ............................................................................... 78

5.7.3.2 Filtering Data Numerically ......................................................................... 78

5.7.3.3 Exporting Data .......................................................................................... 80

5.7.3.4 Log Setup .................................................................................................. 80

5.8 EVENTS TAB ........................................................................................................................ 83

5.9 GLOBAL TAB ........................................................................................................................ 85

5.9.1 General ................................................................................................................. 86

5.9.1.1 Tape Field ................................................................................................. 87

5.9.2 Global Alarms ....................................................................................................... 88

5.9.3 Calibration Gain Calculator................................................................................... 88

5.10 STREAMS TAB ..................................................................................................................... 89

5.10 1 Overview ............................................................................................................... 89

5.10.2 Universal Gas Run Commands ............................................................................ 91

5.10.3 The Sample Tab ................................................................................................... 91

5.10.3.1 Timing Commands .................................................................................... 91

5.10.3.2 Switching Field .......................................................................................... 93

5.10.3.3 Frequency ................................................................................................. 93

5.10.3.4 Analog Output Override ............................................................................ 93

5.10.3.5 Stream Calibration Used ........................................................................... 94

5.10.3.6 Alarms ....................................................................................................... 94

5.10.4 Calibration, Reference and Zero Gas Tabs.......................................................... 95

5.10.4.1 Calibration Tab .......................................................................................... 95

5.10.4.2 Reference Tab .......................................................................................... 96

5.10.4.3 Zero Tab .................................................................................................... 96

5.10.4.4 Differences between the Sample Tab and the

Calibration/Reference/Zero Gas Tabs ...................................................... 97

5.11 INPUTS- DRY TAB ............................................................................................................... 98

5.11.1 Discrete Input Name ............................................................................................. 99

5.11.2 Enable & Alarm Check Boxes .............................................................................. 99

5.11.3 Polarity .................................................................................................................. 99

5.11.4 Run Selector ......................................................................................................... 99

5.11.5 Action .................................................................................................................... 99

5.12 INPUTS - WET TAB ............................................................................................................ 100

5.13 OUTPUT TAB...................................................................................................................... 101

5.13.1 Digital Outputs and Solenoids ............................................................................ 102

5.13.2 Analog Outputs ................................................................................................... 102

5.14 SEQUENCER TAB ............................................................................................................... 103

5.14.1 Enables Entire Sequencer Operation Checkbox ................................................ 104

5.14.2 Available Run Types ........................................................................................... 104

5.14.3 Sequencer Items ................................................................................................ 104

5.14.4 Manual Sequencer Request Checkbox .............................................................. 105

5.14.5 Digital Input Manual Sequencer Request Enable Checkbox ............................. 105

5.14.6 Manual Sequencer # 1 - 8 .................................................................................. 106

5.15 PORTS TAB........................................................................................................................ 107

5.16 MODBUS TAB ..................................................................................................................... 108

5.16.1 Enron .................................................................................................................. 110

5.16.2 Modicon 16 ......................................................................................................... 111

Revision 1 5 9/10/2019

5.16.3 Modicon with Floating Point................................................................................ 111

5.16.4 A Typical Modbus Setup ..................................................................................... 111

5.17 ANALOG INPUT TAB ............................................................................................................ 113

5.17.1 Analog Input # .................................................................................................... 113

5.17.2 Analog Input Parameters and Controls .............................................................. 114

5.17.3 Analog Inputs Alarm ........................................................................................... 114

5.18 TIMERS TAB ....................................................................................................................... 115

5.18.1 Schedule ............................................................................................................. 116

5.18.2 Analysis .............................................................................................................. 116

5.18.3 Sequences .......................................................................................................... 116

5.19 MAINTENANCE TAB ............................................................................................................ 117

5.19.1 Entering the Calibration Mode ............................................................................ 118

5.19.2 Calibrating Analog Outputs................................................................................. 119

5.20 FACTORY TAB .................................................................................................................... 120

SECTION 6 OPERATING THE SYSTEM ............................................................................................. 121

6.1 INTRODUCTION .................................................................................................................. 121

6.2 EDITING A CONFIGURATION ................................................................................................ 121

6.2.1 Accessing the Active Configuration .................................................................... 121

6.2.2 Types of Parameters in a Configuration ............................................................. 122

6.2.3 General Guidelines for Editing Parameters ........................................................ 122

6.3 COMMONLY EDITED PARAMETERS ...................................................................................... 123

6.3.1 The Streams Tab ................................................................................................ 123

6.3.2 Sequencer Tab ................................................................................................... 124

6.4 LESS COMMONLY EDITED ANALYZER PARAMETERS ............................................................. 125

6.4.1 The Global Tab ................................................................................................... 125

6.4.2 Dry and Wet Inputs ............................................................................................. 126

6.4.3 Outputs Tab ........................................................................................................ 127

6.4.4 The Ports Tab ..................................................................................................... 128

6.4.5 Modbus Tab ........................................................................................................ 129

6.4.6 Timers Tab.......................................................................................................... 130

6.5 CALIBRATING/VALIDATING THE ANALYZER OUTPUTS ............................................................ 131

6.6 CALIBRATING/VALIDATING THE ANALYZER ............................................................................ 132

6.6.1 Manual Calibration .............................................................................................. 132

6.6.2 Manually Initiated Auto Calibration ..................................................................... 133

6.6.3 Auto Calibration .................................................................................................. 134

6.7 ANALYZING SAMPLES ......................................................................................................... 136

6.8 MONITORING SYSTEM OPERATION ...................................................................................... 138

SECTION 7 MAINTENANCE ............................................................................................................. 142

7.1 OVERVIEW ......................................................................................................................... 142

7.2. ROUTINE MAINTENANCE PROCEDURES ............................................................................... 142

7.3 CHANGING THE TAPE ......................................................................................................... 143

7.4 CHECKING THE SAMPLE SYSTEM ........................................................................................ 146

Revision 1 6 9/10/2019

SECTION 8 TROUBLESHOOTING AND SERVICE ................................................................................ 147

8.1 OVERVIEW ......................................................................................................................... 147

8.2 TROUBLESHOOTING MESSAGES AND ALERTS ...................................................................... 147

8.3 ALARMS TAB ...................................................................................................................... 149

8.4 COMMONLY OBSERVED PROBLEMS .................................................................................... 152

SECTION 9 ANALYZER Q.C. DOCUMENTATION ............................................................................... 154

SECTION 10 PHOSGENE ANALYZER WIRING BOOK ........................................................................... 157

SECTION 11 TECHNICAL SPECIFICATIONS ........................................................................................ 166

11.1 PERFORMANCE SPECIFICATIONS ........................................................................................ 166

11.2 FUNCTIONS........................................................................................................................ 166

11.3 COMMUNICATIONS / INTERFACE .......................................................................................... 167

11.4 INSTRUMENT SPECIFICATIONS ............................................................................................ 168

SECTION 12 SPARE PARTS ............................................................................................................. 169

SECTION 13 MSDS INFORMATION ................................................................................................... 172

INDEX ............................................................................................................................................. 173

Revision 1 7 9/10/2019

Revision 1 8 9/10/2019

Safety Symbols used in Manual

The Danger symbol indicates a hazardous situation that, if not

avoided will result in death or serious injury.

The Warning symbol indicates a hazardous situation that, if not

avoided could result in death or serious injury.

The Caution symbol with the safety alert symbol indicates a

hazardous situation that, if not avoided could result in minor or

moderate injury.

The Notice symbol is used to highlight information that will

optimize the use and reliability of the system.

Revision 1 9 9/10/2019

Important Safety Guidelines for the Model 903W Phosgene

Analyzer

Please read the following warnings and cautions carefully before using the 903W Phosgene

Analyzer

This equipment must be used as specified by the manufacturer or overall safety

will be impaired.

Access to this equipment should be limited to authorized, trained personnel ONLY.

Observe all warning labels on the analyzer enclosures.

The analog outputs and alarm relay contacts may be powered by a source separate from the

one (s) used to power the analyzer system. Disconnecting the main power source may not

remove power from the analog output signals.

Any safety recommendations or comments contained herein are suggested guidelines only.

Galvanic Applied Sciences Inc. bears no responsibility and assumes no liability for the use and/or

implementation of these suggested procedures.

This system, when operating in its normal mode, and/or when it is being serviced, maintained,

installed and commissioned contains items which may be hazardous to humans if handled or

operated incorrectly or negligently. These items include, but are not limited to:

• High Voltage Electrical Energy

• Toxic and Explosive Gases

The 903W Phosgene Analyzer is designed to be safely operated in a Class 1, Div.2, Group B, C

and D,T3 area.

Revision 1 10 9/10/2019

Manufacturer’s Warranty Statement

Galvanic Applied Sciences Inc. (“Seller”) warrants that its products will be free from defects in

materials and workmanship under normal use and service in general process conditions for 12

months from the date of Product start-up or 18 months from the date of shipping from Seller’s

production facility, whichever comes first (the “Warranty Period”). Products purchased by Seller

from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond

making a reasonable commercial effort to arrange for procurement and shipping of the Resale

Products. Buyer must give Seller notice of any warranty claim prior to the end of the Warranty

Period. Seller shall not be responsible for any defects (including latent defects) which are reported to

Seller after the end of the Warranty Period.

THIS WARRANTY AND ITS REMEDIES ARE IN LIEU OF ALL OTHER WARRANTIES OR

CONDITIONS EXPRESSED OR IMPLIED, ORAL OR WRITTEN, EITHER IN FACT OR BY

OPERATION OF LAW, STATUTORY OR OTHERWISE, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, WHICH SELLER SPECIFICALLY DISCLAIMS.

Seller’s obligation under this warranty shall not arise until Buyer notifies Seller of the defect.

Seller’s sole responsibility and Buyer’s sole and exclusive remedy under this warranty is, at

Seller’s option, to replace or repair any defective component part of the product upon receipt of

the Product at Seller’s production facility, transportation charges prepaid or accept the return of

the defective Product and refund the purchase price paid by Buyer for that Product. If requested

by Buyer, Seller will use its best efforts to perform warranty services at Buyer’s facility, as soon as

reasonably practicable after notification by the Buyer of a possible defect provided that Buyer

agrees to pay for travel time, mileage from the Seller’s facility or travel costs to the airport / train

station closest to Buyer’s facility plus all other travel fees, hotel expenses and subsistence.

Except in the case of an authorized distributor or seller, authorized in writing by Seller to extend

this warranty to the distributor’s customers, the warranty herein applies only to the original

purchaser from Seller (“Buyer”) and may not be assigned, sold, or otherwise transferred to a third

party. No warranty is made with respect to used, reconstructed, refurbished, or previously owned

Products, which will be so marked on the sales order and will be sold “As Is”.

Limitations

These warranties do not cover:

• Consumable items such as lamps.

• Analyzer components which may be damaged by exposure to contamination or fouling

from the process fluid due to a process upset, improper sample extraction techniques or

improper sample preparation, fluid pressures in excess of the analyzer’s maximum rated

pressure or fluid temperatures in excess of the analyzer’s maximum rated

temperature. These include but are not limited to sample filters, pressure regulators,

transfer tubing, sample cells, optical components, pumps, measuring electrodes,

switching solenoids, pressure sensors or any other sample wetted components.

• Loss, damage, or defects resulting from transportation to Buyer’s facility, improper or

inadequate maintenance by Buyer, software or interfaces supplied by Buyer, operation

Revision 1 11 9/10/2019

outside the environmental specifications for the instrument, use by unauthorized or

untrained personnel or improper site maintenance or preparation.

• Products that have been altered or repaired by individuals other than Seller personnel or

its duly authorized representatives, unless the alteration or repair has been performed by

an authorized factory trained service technician in accordance with written procedures

supplied by Seller.

• Products that have been subject to misuse, neglect, accident, or improper installation.

• The sole and exclusive warranty applicable to software and firmware products provided

by Seller for use with a processor internal or external to the Product will be as follows:

Seller warrants that such software and firmware will conform to Seller’s program manuals

or other publicly available documentation made available by Seller current at the time of

shipment to Buyer when properly installed on that processor, provided however that

Seller does not warrant the operation of the processor or software or firmware will be

uninterrupted or error-free.

The warranty herein applies only to Products within the agreed country of original end destination.

Products transferred outside the country of original end destination, either by the Seller at the

direction of the Buyer or by Buyer’s actions subsequent to delivery, may be subject to additional

charges prior to warranty repair or replacement of such Products based on the actual location of

such Products and Seller’s warranty and/or service surcharges for such location(s).

Repaired Products

Repaired products are warranted for 90 days with the above exceptions.

Limitation of Remedy and Liability

IN NO EVENT SHALL SELLER BE LIABLE TO BUYER FOR ANY INDIRECT,

CONSEQUENTIAL, INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES, OR FOR ANY LOSS OF

USE OR PRODUCTION, OR ANY LOSS OF DATA, PROFITS OR REVENUES, OR ANY

CLAIMS RAISED BY CUSTOMERS OF BUYER OR ANY ENVIRONMENTAL DAMAGE OR ANY

FINES IMPOSED ON BUYER BY ANY GOVERNMENTAL OR REGULATORY AUTHORITIES,

WHETHER SUCH DAMAGES ARE DIRECT OR INDIRECT, AND REGARDLESS OF THE

FORM OF ACTION (WHETHER FOR BREACH OF CONTRACT OR WARRANTY OR IN TORT

OR STRICT LIABILITY) AND WHETHER ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES OR NOT.

Revision 1 12 9/10/2019

Section 1 Phosgene Analyzer

1.1 Overview

The Galvanic Applied Sciences Model 903W Phosgene analyzer is designed to measure

Phosgene (PH

1.2 Principle of Operation

The analyzer relies on the chemical reaction between phosgene and 4-(4Nitrobenzyl)pyridine and N-Benzyl Aniline to form a red color complex.

When a paper tape that has been impregnated with and 4-(4-Nitrobenzyl)pyridine and NBenzyl Aniline is exposed to phosgene, a red color complex will be formed on the tape. The

rate of colour change on the tape is directly proportional to the concentration of phosgene in

the gas stream. When the rate of colour change is measured, the concentration of phosgene

in the gas stream can be determined.

.

The analyzer can use two different analysis algorithms to determine the concentration of

phosgene in the sample.

Standard Analysis (Peak Detect) - In the standard analysis method, the rate of stain

formation on the tape is monitored. The point at which the rate of stain is at a maximum

represents the concentration of phosgene in the sample gas.

Timed Analysis. In the timed analysis algorithm the average rate of stain on the tape is

calculated over a fixed period of time.

) in a gaseous stream.

3

Revision 1 13 9/10/2019

1.3 Features of the Analyzer

The analyzer provides the following capabilities:

• Rapid response

• 5-14 week tape life (dependent on gas concentration), which is up to 2 times greater than

that of traditional tape analyzers. Optical tape counter ensures exact spacing of stains and

keep track of tape consumption

• Low operation and maintenance costs

• Uninterrupted operation with dual redundant AC and DC power supply

• Ethernet communication and USB port with easy to use Windows

• Enhanced data logging allows for up to ten months of data storage for complete audit trail

and trouble shooting and report generation.

• Built-in MODBUS communications / RTU capabilities and a large number of outputs and

inputs with sensor auto-calibration on each analysis and dual redundant power supply.

TM

based PC software

1.4 System Operating Control

The analyzer is controlled by a dedicated data acquisition system which provides supervisory

control, performs all calculations and provides the user interface.

The system includes an onboard computer system which provides full screen display of the

phosgene concentration, key system control parameters and their status.

A hand held key pad is provided for user interface with the analyzer. Operation of the system

with the keypad is described in Section 4. As an alternative, a PC based Graphical User

Interface (GUI) which can be used to view and enter information on a remote basis is

described in Section 5.

Revision 1 14 9/10/2019

1.5 Contents of this Manual

This manual contains the following information:

• Section 1: Model 903W Phosgene Analyzer presents introductory information about the

system and the mode of operation.

• Section 2: Analyzer Components describes the design of the major components of the

system

• Section 3: Installation describes unpacking the analyzer, installing it in the facility and

interfacing with other devices.

• Section 4: Operating the Analyzer via the Handheld Keypad describes how the user enters

data and views system parameters using the hand help controller module and on board

display panel.

• Section 5: The Graphical User Interface presents a detailed discussion of the various

aspects of the application program on the personal computer.

• Section 6: Operating the System discusses the role of the various tabs of the how the

various tabs of the Graphical User Interface are employed

• Section 7: Maintenance includes a discussion of activities which should be performed on a

routine bases to optimize operation

• Section 8: Troubleshooting and Service presents information that is useful in diagnosing

problems with the analyzer and describes how various components are replaced.

• Section 9: Quality Control includes the test documentation material used to test the

analyzer

• Section 10: Wiring includes diagrams to assist the operator in interfacing auxiliary

components such as relays, solenoids, etc. to the controller module.

• Section 11: Specifications presents the specifications for the analyzer.

• Section 12: Spare Parts lists a number of items which may be required to maintain

operation of the analyzer.

• Section 13: MSDS contains the Manufacturers Safety Data Sheets for chemical materials

items used in the system.

Revision 1 15 9/10/2019

Section 2 Analyzer Components

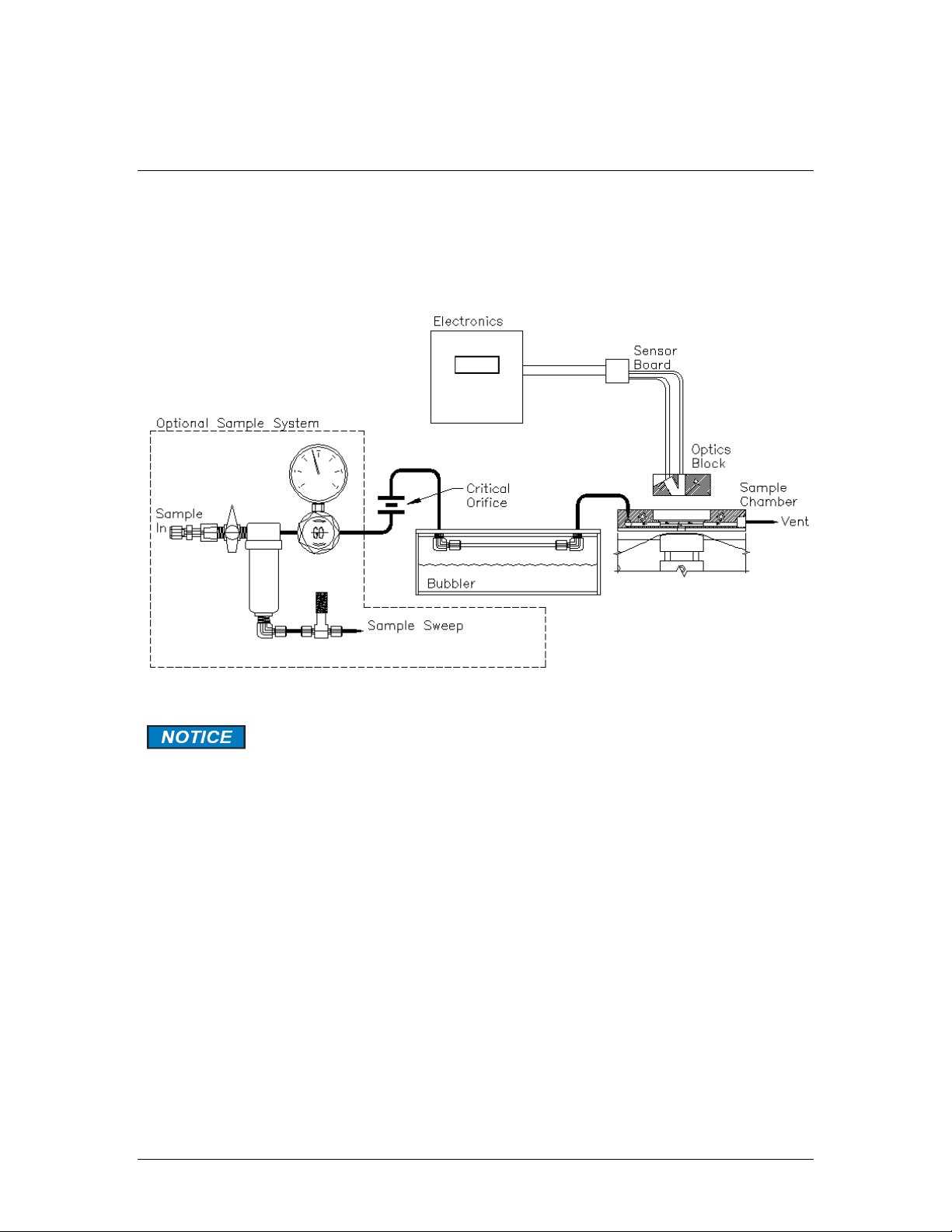

2.1 Overview

The 903W Phosgene analyzer is an integrated system designed to monitor the concentration

of phosgene in a gaseous stream using the method described in Section 1. An overview of

the major components of the analyzer is presented in Figure 2-1.

Figure 2-1: Schematic of Flow Path

The phosgene application does not use the bubbler shown in Figure 2-1.

The system includes the following major components:

• Motherboard (Section 2.2)

• Display Board, Keyboard, LED’s (Section 2.3)

• Chassis (Section 2.4)

• Tape Transport System (Section 2.5)

• Sample Chamber Assembly (Section 2.6)

• Sample Flow Related Components (Section 2.7)

An external sample conditioning system is available as an option (Section 2.9).

Revision 1 16 9/10/2019

2.2 Motherboard

2.2.1 Description of the Motherboard

The motherboard is housed in an enclosure and consists of a large main board which houses

the system memory, system’s clock battery, the AC and DC power supplies, 6 isolated

analog outputs, 6 relays, 8 solenoids, 4 (Wet contact) discrete inputs and 4 (Dry contact)

discrete inputs. The type of enclosure the electronics is housed in will depend on the area

classification certification of the analyzer.

2.2.2 Boards Associated with the Motherboard

The main processor daughter board and an optional Ethernet card are associated with the

motherboard.

2.2.3 AC and DC Power Supply

The motherboard houses the AC and DC power supplies. The working AC voltage range is

100-240 VAC and the DC voltage range is 10-32 VDC.

If an AC supply is used, the analyzer uses the AC solenoid drivers which are Black in colour.

If a DC supply is used, the analyzer uses the DC solenoid drivers which are Red in colour.

The analyzer can operate in a dual redundant power mode in which the DC power supply is

the backup if the AC power supply fails. It is important to note that in this mode the DC

solenoid drivers would be used.

2.3 LCD Display Board, Keypad and LED’s

2.3.1 User Interaction Features

The system presents the system status to the operator via a 128 x 64 LCD display on the

front panel. In addition, there are ten LED indicators which provide information about the

status of the system.

A hand held keypad is used to communicate with the system. Operation of the system via the

keypad is described in Section 4.

A detailed application program for a personal computer is provided to monitor the system,

view archived data and establish input and output protocols from/to external devices. A

detailed discussion of the user interface is presented in Chapter 5.

Revision 1 17 9/10/2019

2.3.2 Display Board Communication Ports

The system has two distinct communications ports housed on the display board. A USB/RS232 port is located on the right side of the display board. A pair of switches that can be set for

USB or RS232 communications is located on the reverse side of this board on the bottom left

hand corner. By default, the switch is set for USB usage.

A RJ-9/22 jack that can also be used for RS232 communications is located directly under the

LCD Display. There are jumpers located on the bottom left hand corner of the CPU board that

need to be set if this jack is to be used or if the Ethernet card is used. The Ethernet Card

option and the RJ-9/22 jack cannot be used simultaneously.

2.4 Inner Swing Panel

The inner swing panel contains all of the mechanical parts of the system including the tapeadvance motor, the pulse counter used to accurately advance the tape, the sensing tape

spool, and the components related to the actual flow of sample gas and the measurement of

the concentration of phosgene in the sample gas stream. A photo of the swing panel is

shown in Figure 2-2.

Figure 2-2: Swing Panel

Revision 1 18 9/10/2019

2.5 Tape Transport System

The tape transport system is responsible for advancing the tape and ensuring that the

analyzer has a fresh section of white tape available at the commencement of every analysis

cycle. The tape transport system is shown in Figure 2-3.

Figure 2-3: Tape Transport System

The tape transport system consists of the supply and take-up reels, the drive motor, the

compression head, the pulse counter, and the optional low-tape sensor.

2.5.1 Supply and Take-up Reels

The supply and take-up reels are the key components in the tape transport system.

• The supply reel, which has a small screw-on retaining disk, is found on the bottom of the

chassis, and can hold reels of tape up to 350 feet in length. The tape is threaded over the

lower tape guide, past the sample chamber assembly and compression head, over the two

upper tape guides, and finally over the pulse counter pulley before reaching the take-up

reel.

• The take-up reel, which has a large screw-on retaining disk, is driven by the motor, and is

responsible for advancing the tape at the end of every cycle.

A small electric motor that is controlled by the main processor of the system turns the take-up

reel to advance the tape at the beginning of every analysis cycle to ensure that the next

analysis has a section of unreacted reagent to react with the phosgene.

The motor is either installed inside the chassis. The length of time that the motor runs is

controlled by the system processor in conjunction with the pulse counter.

Revision 1 19 9/10/2019

2.5.2 Pulse Counter

The pulse counter is used to ensure even spacing of stains on the sensing tape. The pulse

counter is shown in Figure 2-4.

Figure 2-4: Pulse Counter

The left and centre pictures show the pulse counter as it appears when not installed in the

chassis and the right picture shows how the pulse counter appears in the tape transport

system. The black aluminum (or grey plastic) capstan is mounted on the silver nub seen in

the left picture, and it rotates when the tape moves over it.

The pulse counter produces a specific amount of pulses for every revolution. By measuring

the number of pulses produced by the movement of the tape while the motor is running, the

system processor can ensure that the tape is advanced exactly the same distance before

every analysis cycle, regardless of the quantity of tape on the take-up reel. This ensures that

the stain spacing on the tape is even; further, by reducing the amount of white space

between subsequent stains, tape wastage is minimized, and tape life is maximized.

When the motor advances the take-up reel, causing the tape to move, the movement of the

tape causes the capstan on the pulse-counter to rotate, producing pulses. These pulses are

read by the sensor block, which then sends the pulse count to the system processor. When

the processor receives a number of pulses equal to the number of pulses per advance set in

the application program; typically around 40 pulses, or a little less than one sixth of a

revolution, it sends a signal to the motor to stop turning, and the tape stops advancing.

The pulse counter also allows the system to accurately indicate the quantity of tape

remaining on the supply reel, as long as the initial length is set correctly in the application

program or through the keypad. This value is displayed on the LCD in the upper right corner,

and can be output through an analog output. The quantity of tape remaining is calculated

after every analysis cycle, using the formula outlined in Section 5.9.1.1. This value can also

be used to trigger a low-tape alarm when the quantity of tape goes below a user-set value,

set up through the application program.

Revision 1 20 9/10/2019

2.6 Sample Chamber Assembly

The sample chamber assembly is the key component in the measurement of the phosgene

concentration in the gas. The sample chamber assembly allows the sample gas to pass onto

the sensing tape, and also contains the detector assembly, (sensor block). An exploded view

of the sample chamber assembly is shown in Figure 2-5.

Figure 2-5: Sample Chamber Assembly (Exploded View)

Revision 1 21 9/10/2019

2.6.1 Rate/Read Aperture Strip and the Rear Window Assembly

The Rate/Read Aperture strip and the Rear Window are made of a clear plastic to allow the

light from the sensor block to pass through to the tape to correctly measure the rate of color

change on the tape. The sensor block is held onto the sample chamber via clips; by

tightening the screws on the clips, the rear window is pressed into the rear window rubber

gasket and sealed to the sample chamber by pressure from the sensor block above it. The

rate/read aperture strip is sealed to the inside of the sample chamber using silicone grease.

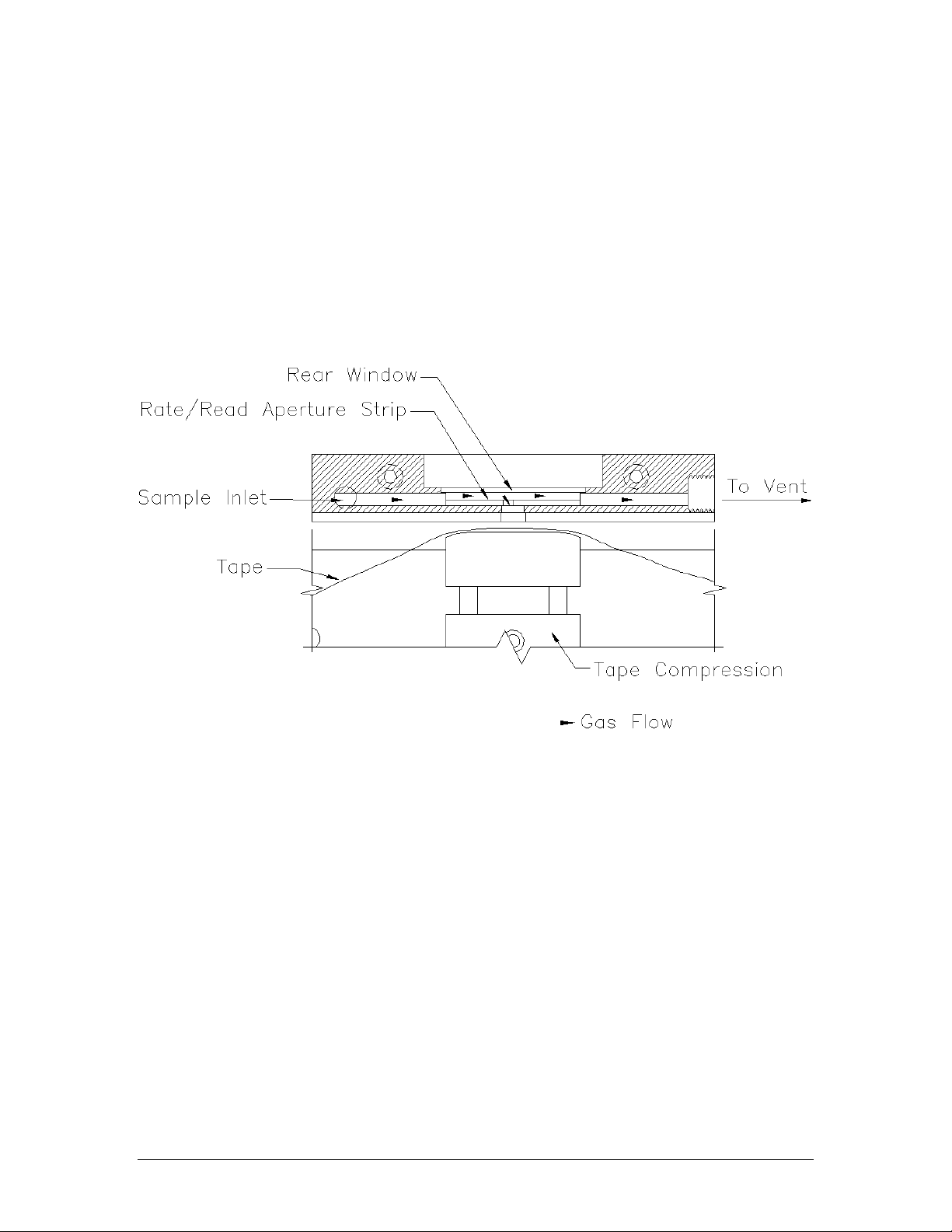

The sample flow through the sample chamber assembly is shown in Figure 2-6.

Figure 2-6: Sample Flow

Clean, humidified, and flow-regulated sample enters the sample chamber from the sample

inlet and passes over the Rate/Read Aperture strip, behind the rear window. Some of the gas

passes through the aperture strip and onto the sesning tape, causing a measurable color

change. The tape is held firmly against the sample chamber by the compression head. The

amount of gas that passes onto the tape is dependent on the size of the aperture strip. After

the gas passes over the tape, it is vented.

Revision 1 22 9/10/2019

Maximum Range (ppm)

Aperture Strip Size

Part Number

<300 ppb

Wedge

MC1136

>300 ppb

Wide Open

N/A

2.6.2 Read/Rate Aperture Strip

The Read/Rate aperture strip is used to control the quantity of gas that is actually passes

onto the sensing tape. If the phosgene concentration in the sample gas is high, it may be

necessary to reduce the quantity of gas that passes onto the tape to react with the reagent on

the tape, otherwise the rate of color change will be too fast for the system to correctly analyze

the sample and poor results will be obtained. Likewise, if the phosgene concentration in the

sample gas is low, it is necessary to allow more sample gas to pass onto the tape to allow the

rate of colour change to be high enough to produce reliable results. The size of the aperture

in the read/rate aperture strip is small for high concentrations, and for low concentrations it is

large. Certain ranges do not even require an aperture strip.

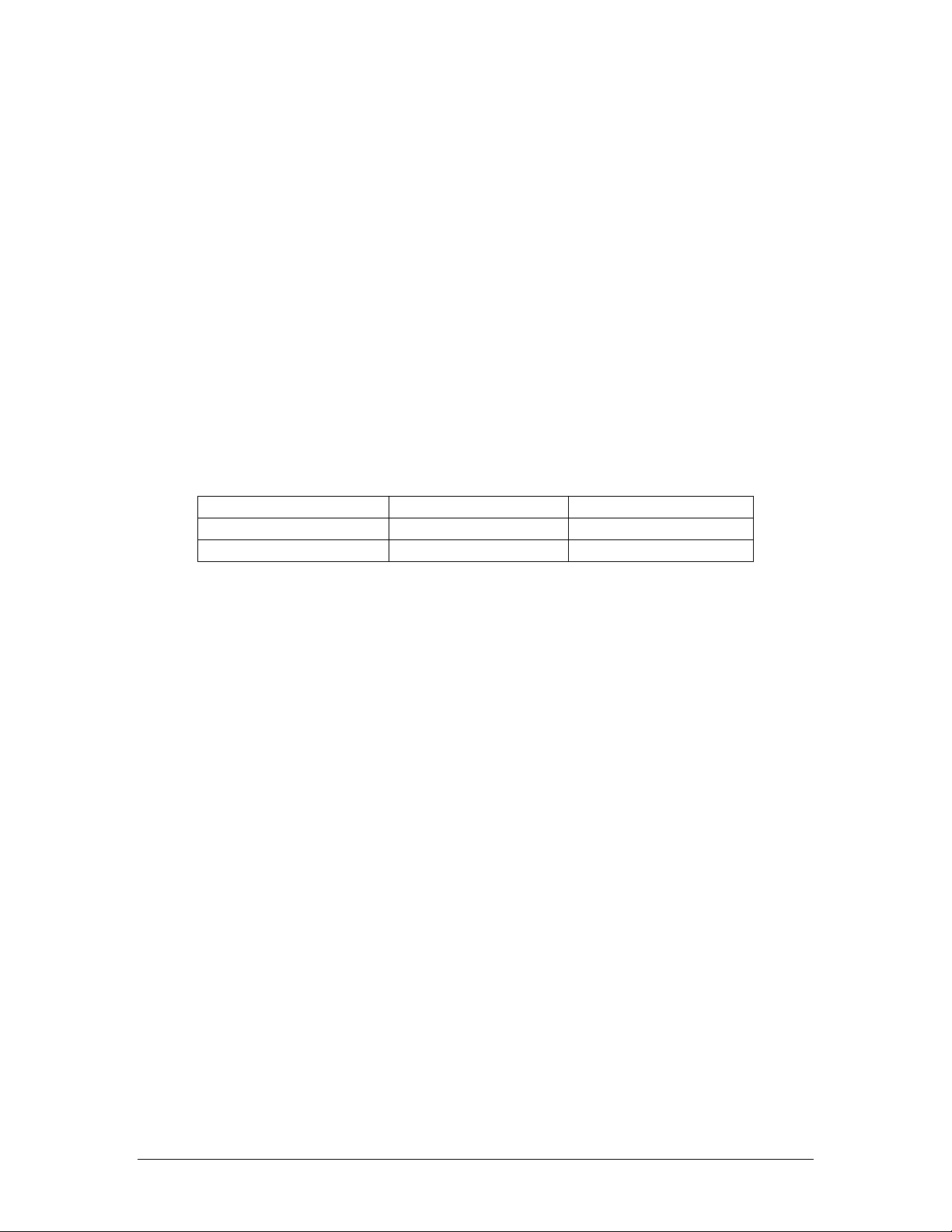

Galvanic Applied Sciences provides a broad range of read/rate aperture strip sizes. The most

common aperture strip sizes are listed in Table 2-1 along with the maximum ranges they are

capable of measuring and their correct part numbers. For other ranges, please contact

Galvanic Applied Sciences.

Table 2-1: Read/Rate Aperture Strip Sizes and Associated Ranges

The range for each read/rate aperture strip size is the range between the maximum range of

the next largest aperture strip size and the maximum range of the given aperture strip size. In

addition, the system is capable of measuring ranges outside those listed in this table; please

contact Galvanic Applied Sciences for more details.

2.6.3 Sensor Block

The Sensor Block consists of two electronics boards, a microprocessor board, and a

colorimetric detector. The sensor block is shown in Figure 2-7.

Figure 2-7: Sensor Block (From Left: Top View, Side View, and Installed View)

Revision 1 23 9/10/2019

The sensor block measures the intensity of light reflected off of the sensing tape. The light

emitting diode emits a beam of green light that passes through the rear window and the

rate/read aperture strip and is reflected off of the sensing tape. The reflected light then

passes back through the aperture strip and rear window to reach the photodiode detector,

where it is measured. As the stain on the tape gets darker and darker while exposed to

phosgene, the amount of light reflected back to the photodiode detector is reduced. The

change in the amount of light reflected back to the photodiode detector is directly proportional

to the concentration of phosgene in the sample gas.

The sensor block communicates with the electronics assembly via an RS-485 connection. If

the connection between the sensor block and the electronics assembly is broken for any

reason, a Sensor Communication Alarm will be triggered and the analyzer is considered to be

in a Fail State.

The sensor block contains a temperature sensor that measures the ambient temperature

near the sensor block. This temperature sensor can be used to trigger alarms should the

ambient temperature rise above or drop below set amounts, values that can be set in the

GUI.

The sensor block plays a key role in the tape advance algorithm. While the tape advance

motor is running, the sensor block receives pulses from the pulse counter. When the sensor

block receives the number of pulses set in the GUI it sends a message to the system’s main

processor. The processor then sends a message to the motor to stop advancing the tape.

2.6.4 Compression Head

The compression head is the component in the tape transport system that seals the sensing

tape up against the sample chamber. The compression head is shown in Figure 2-8.

Figure 2-8: Compression Head

The compression head is comprised of a black low-friction plastic held up against the tape

and sample chamber by means of two springs. The low-friction plastic construction ensures

that the tape moves smoothly past the compression head, preventing tape breakage.

The compression head creates a seal between the tape and the sample chamber and it

ensures that the stains on the tape are even and have sharp edges, which produces much

better results. In addition, because the low friction plastic is black, it prevents stray light from

being detected by the photodiode on the sensor block. This in turn prevents inadvertent

Revision 1 24 9/10/2019

triggering of high concentration alarms, as stray light could make the system report that it was

analyzing a much higher concentration gas than it actually is.

2.7 Sample Flow Related Components

The system contains a number of components that control the flow of the sample and

condition it

It is essential to have a consistent flow rate because the concentration reading is dependent

on sample flow rate. The higher the flow rate, the more sample gas comes into contact with

the sensing tape in a given period time, and thus the faster reaction and higher concentration

reading.

2.7.1 Rotameter

The rotameter is a device that controls and indicates the flow rate through the system. It is

mounted on the right side of the 903W enclosure.

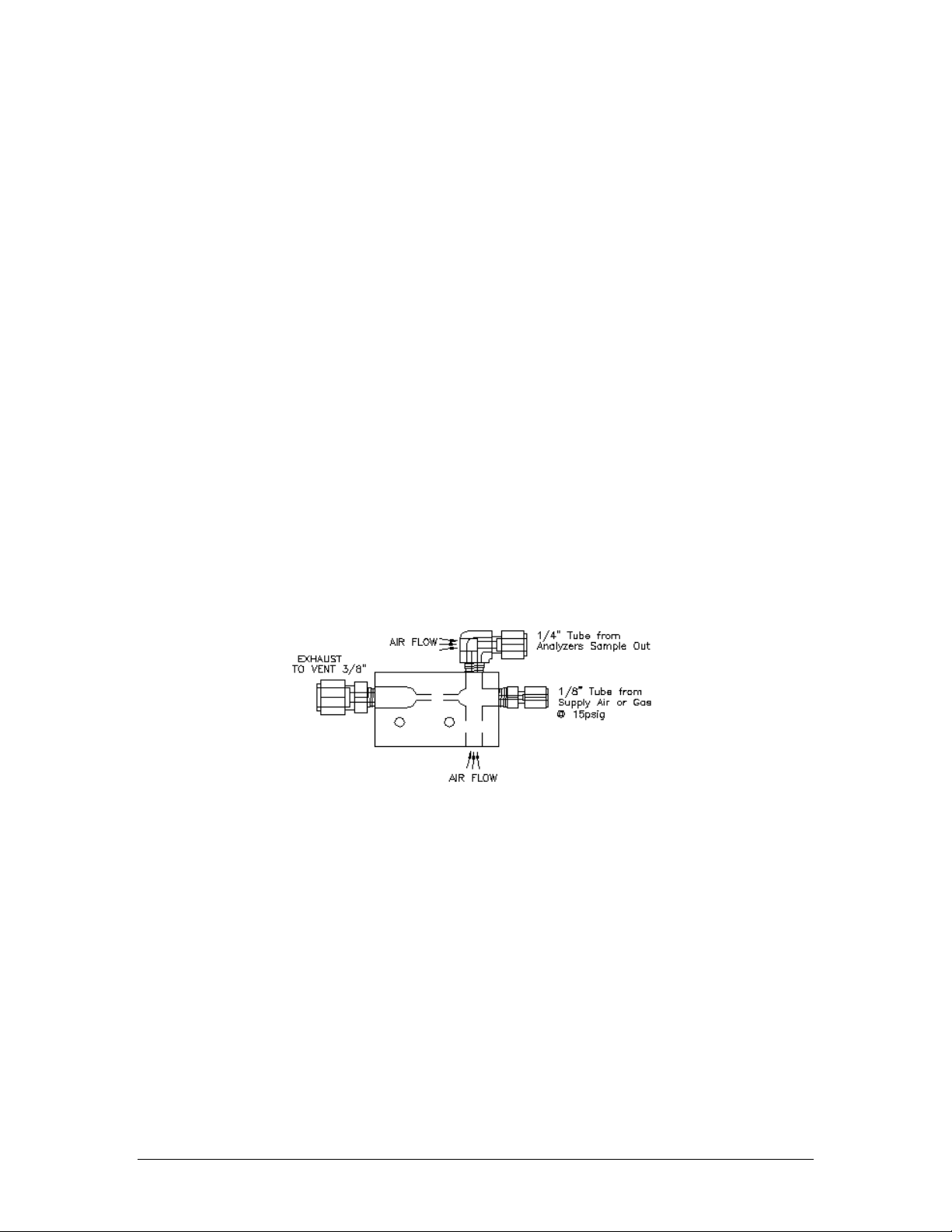

2.7.2 Power Vent (Eductor)

The power vent (eductor) produces a positive pressure at the exhaust while allowing the

analyzer vent to remain at ambient pressure. An eductor is shown in Figure 2-1.

Figure 2-10: Eductor

The eductor has two purposes:

• Changes in ambient pressure can affect the results produced by the system. If the system

is inside a building where there is a fluctuating static pressure in comparison to the outside

ambient pressure, the power vent will eliminate any influence on the tape staining.

Static pressure changes inside the building are normally caused by building vent fans

coming on and off which will change the differential pressure across the sample chamber.

Pressure can also be affected by a strong wind blowing across the vent. When this happens,

a slight change in the pressure of the sample between the tape and the sample chamber

occurs.

The slight change in differential pressure across the tape can cause a reduction in the seal

between the tape and the sample chamber, resulting in poorly shaped stains that give poor

Revision 1 25 9/10/2019

results. It can also cause more air to be introduced into the sample chamber, diluting the

sample gas and producing lower-than-expected results.

• If the system is located in a cold climate, the humidified sample gas passing out of the vent

can freeze, blocking off the flow through the sample system. By using a power vent, the

residence time of the sample gas within the system is reduced, making it less likely that the

moist air will freeze inside the analyzer.

2.8 Sample Conditioning System (Optional)

The sample conditioning system is an optional accessory that filters the sample gas and

lowers it to a pressure suitable for use in the system. A typical sample conditioning system is

seen in Figure 2-14.

Figure 2-14: Typical Sample Conditioning System

The sample conditioning system generally consists of a filter, a pressure regulator to regulate

the sample down to 15 psig, and a valve to switch between calibration and sample gas to

allow the system to be calibrated.

The type of filter is dependent on the nature of the gas and generally has a sample sweep

associated with it. Sample gas is usually taken off the bottom of the regulator to drive the

Revision 1 26 9/10/2019

power vent. The calibration valve can be either a manual 2-way valve or a solenoid controlled

by the system.

Revision 1 27 9/10/2019

Section 3 Installation

3.1 Receiving the System

When the system arrives, inspect the packaging for external signs of damage. If there is any

obvious physical damage, contact the shipping agent and Galvanic Applied Sciences to

report the damage and request that the carrier's agent be present when the unit is unpacked.

It is recommended that you retain the shipping container so that it may be used for future

shipment of the unit, if necessary.

3.2 Installation Requirements

3.2.1 Electrical Requirements

The analyzer can be powered by 100-240 VAC or 10-32 VDC sources. The power

requirement is 10 W.

If desired, it is possible to connect both AC and DC power supplies. In this manner, the DC

power supply as a backup power. When choosing a power source, the type of solenoid

drivers need to be considered (AC or DC).

3.2.2 Location of the System

The system is designed to be operated at ambient temperatures from 10 - 50

Applied Sciences offers complete analyzer shelters from sun shades to complete buildings,

please contact Galvanic Applied Sciences, Inc. (or your local representative) for additional

information.

The system should be mounted in a location where it is not exposed to excessive vibration.

In addition, it should be mounted in a location where the ambient pressure remains relatively

consistent over the course of a day

The vent line cannot have any backpressure on it, as backpressure can seriously impact

readings. The vent line should be as short as possible at a slight continuous downward slope.

o

C. Galvanic

3.2.3 Space Requirements

The size of the analyzer is 17” H x 19” W x 9” D (43 cm x 48 cm x 23 cm). Mounting

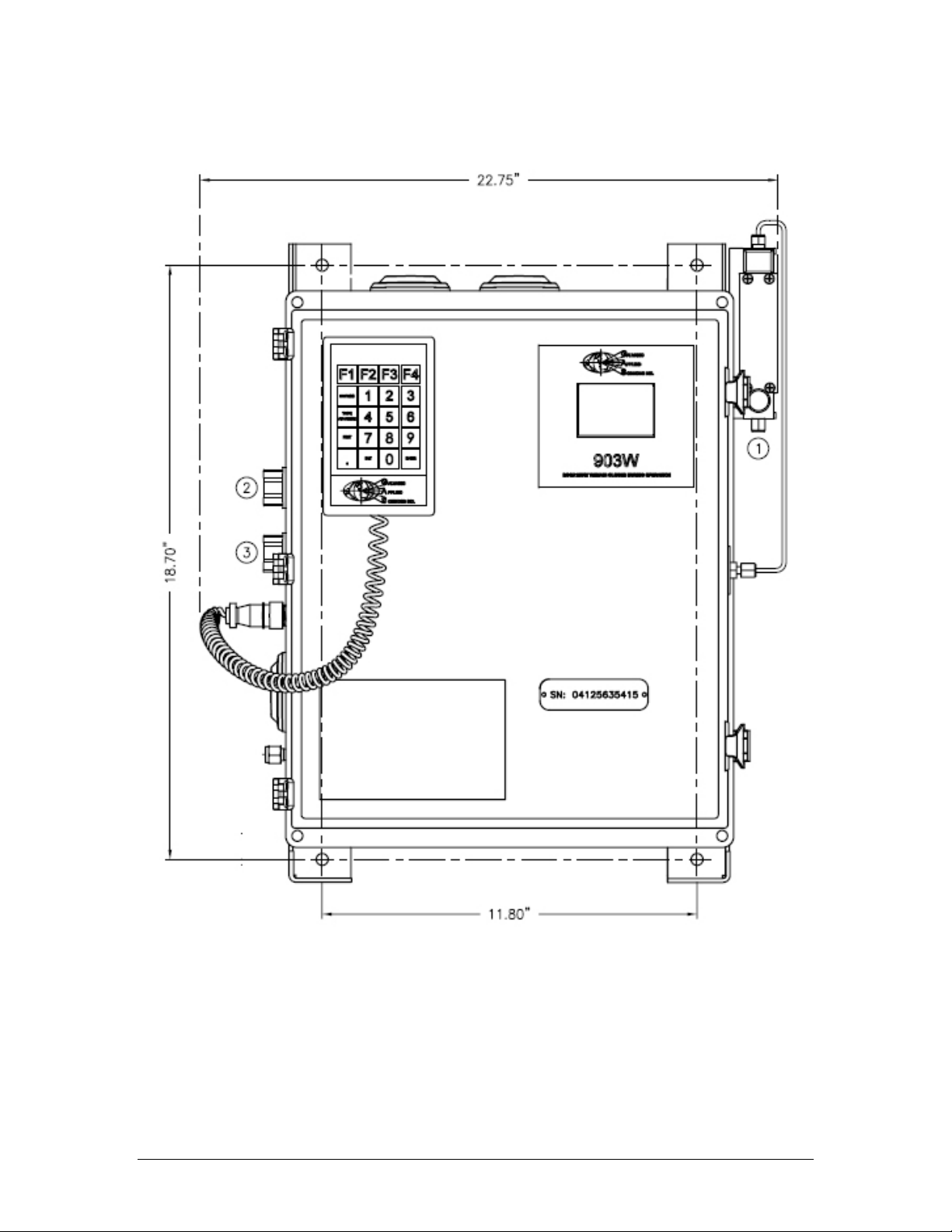

information is provided in Figure 3-1.

Revision 1 28 9/10/2019

Figure 3-1: Analyzer Dimensions

If the system is mounted on a panel, allow approximately 15” on the left hand side of to allow

the removal of the tape cover on the side of the chassis, and to allow easy access for tape

installation and removal.

If the system is installed in a cabinet, allow 6” on the left side for the installation of a vent line.

Revision 1 29 9/10/2019

The optional sample conditioning system is typically mounted on the sample panel to the right

of the analyzer.

3.2.4 Area Classification Information

Class 1, Division 2, Groups B, C & D, T3

3.2.5 Gas Requirements

If the analyzer is not provided with a sample conditioning system, the sample gas needs to be

clean and regulated at 15-20 psig.

3.3 Unpacking

To unpack the system:

a) Open the shipping container and remove all packing material and boxes. Visually inspect

the system and accessories package(s) to ensure that no damage has occurred. If

damage has occurred, save all packing material and contact the shipping company as

well as Galvanic Applied Sciences.

If any damage is visible, do not proceed with the system installation. Do not attempt to

facilitate repairs yourself as this will negate and/or invalidate any possible insurance

claims or equipment warranty.

b) Place the small packages aside in a safe, secure storage area as they are not needed at

this stage of the system installation.

Revision 1 30 9/10/2019

Loading...

Loading...