Galletti PLE TECHNICAL MANUAL

TECHNICAL MANUAL

PLE

Air-water Chillers and heat pumps with low-GWP refrigerant

50 - 160 kW

EN

RG66024439-01 10/22

R-454B refrigerant A2L gas leak

PLUS

» Refrigerant with GWP of less than 500

» High seasonal eciency values

» Electronic expansion valve

» Tandem conguration single circuit

» Remote connectivity with the most common protocols

» Possibility to congure low-noise versions

detection

Axial fan Scroll compressor Cooling only Heating/Cooling

Dear Customer,

Thank you for placing your trust in one of the products of Galletti S.p.a

This product is the result of our work and our commitment to design, research, and production and has been

made from the nest materials, employing state-of-the-art components and production technology.

The CE marking of the product ensures its compliance with the safety requirements of the following directives:

the Machinery Directive, the Electromagnetic Compatibility Directive, the Electrical Safety Directive, and the

Pressure Equipment Directive. Fulllment of the Ecodesign requirements is fully in keeping with the environmental awareness that has always guided our company.

The company certication of the Quality and Safety management system ensures that product quality is

constantly checked and improved, and that the product is manufactured in full compliance with the highest

standards.

By choosing our product, you have opted for Quality, Reliability, Safety, and Sustainability.

At your disposal, once again.

Galletti S.p.a

TRANSLATION BY ORIGINAL INSTRUCTIONS

The water chillers and heat pumps comply with directive 2014/68//EC (PED).

The technical and dimensional data reported in this manual may be modied in view of any product improvement.

For any information , please contact the company: info@galletti.it

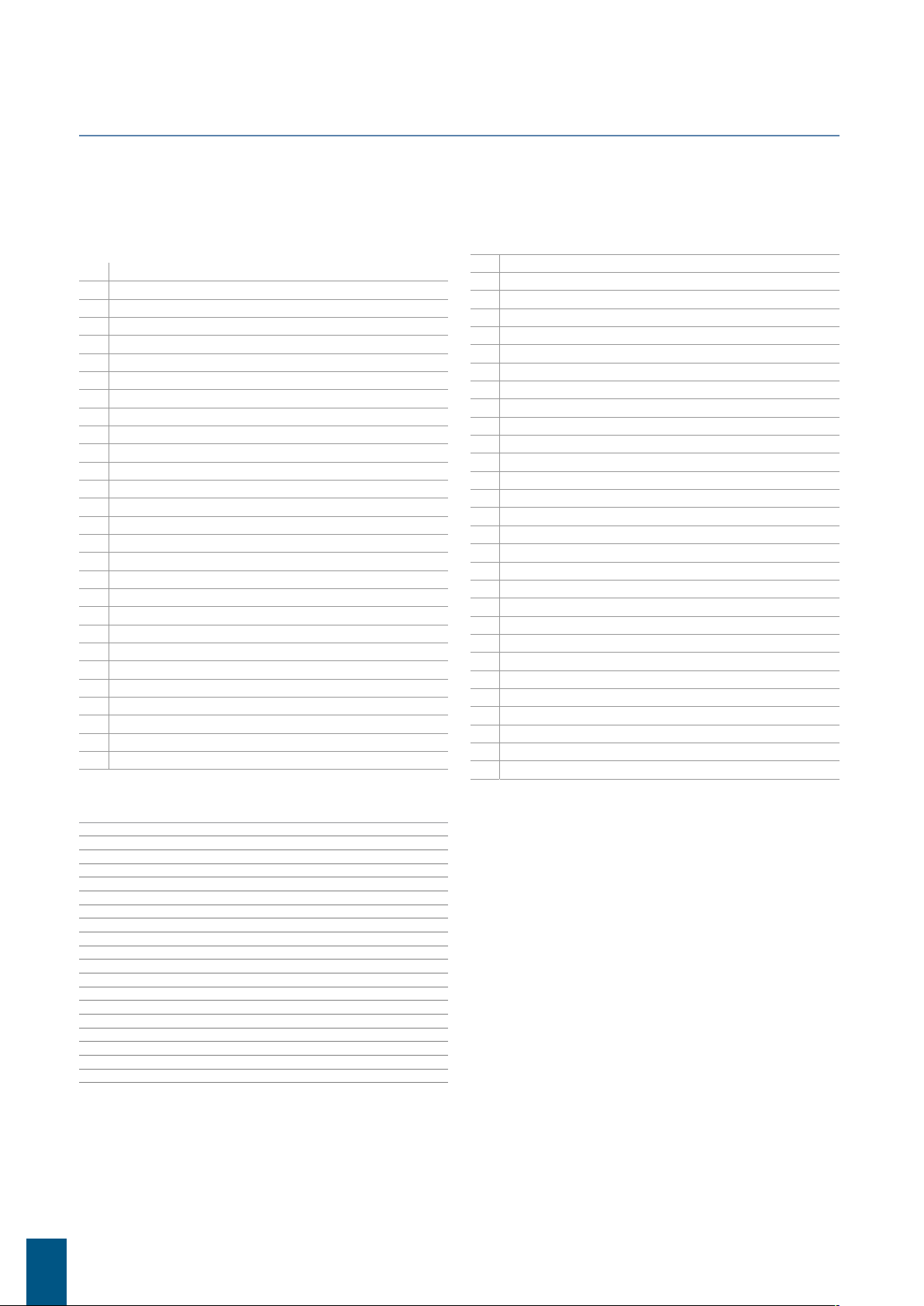

TABLE OF CONTENTS

1 SERIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.4

2 CONSTRUCTIVE FEATURES . . . . . . . . . . . . . . . . p.4

2.1 STRUCTURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.4

2.2 CUSTOMISED HYDRAULIC KIT. . . . . . . . . . . . . . . . . p.4

2.3 COOLING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.4

2.4 REFRIGERANT WITH LOW GWP . . . . . . . . . . . . . . . . p.4

2.5 ELECTRONIC VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . p.4

2.6 ELECTRONIC MICROPROCESSOR CONTROL . . . p.4

2.7 GAS LEAK DETECTION SYSTEM . . . . . . . . . . . . . . . . p.5

2.8 MICROCHANNELS FINNED COIL. . . . . . . . . . . . . . . p.5

3 CONFIGURATION OPTIONS. . . . . . . . . . . . . . . . p.6

4 TECHNICAL FEATURES . . . . . . . . . . . . . . . . . . . . . p.7

4.1 WATER CHILLERS RATED TECHNICAL DATA

PLE C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.7

4.2 HEAT PUMPS RATED TECHNICAL DATA PLE H

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.8

5 PED CATEGORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.8

6 PERFORMANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . p.9

6.1 CORRECTION OF THE HEATING CAPACITIES . . p.10

11 INSTALLATION CLEARANCE

REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . p.21

12 SITING AND DAMPERS . . . . . . . . . . . . . . . . . . . p.22

13 DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.23

14 WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.26

15 ELECTRICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . p.29

7 SOUND LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.10

7.1 ACOUSTIC INSULATION VERSIONS . . . . . . . . . . . p.10

8 OPERATING LIMITS. . . . . . . . . . . . . . . . . . . . . . . . p.11

8.1 OPERATING LIMITS IN CHILLER MODE . . . . . . . . p.11

8.2 OPERATING LIMITS IN HEAT PUMP MODE . . . . p.12

8.3 THERMAL CARRYING FLUID . . . . . . . . . . . . . . . . . . p.13

9 WATER PRESSURE DROP . . . . . . . . . . . . . . . . . . p.14

9.1 Y FILTER PRESSURE DROPS . . . . . . . . . . . . . . . . . . . p.14

10 WATER CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.15

10.1 WATER CONTENT AND CHARGING OF

EXPANZION TANK SYSTEM . . . . . . . . . . . . . . . . . . . p.16

10.2 WATER CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.16

10.3 DESUPERHEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . p.19

1 SERIES

The PLE range units are designed for heating and cooling the

water to be used in ari-conditioning or process system, for residential, commercial or industrial. The PLE range units are intended for outdoor installation (IP24 protection degree), in a position

2 CONSTRUCTIVE FEATURES

STRUCTURE

Galvanised sheet steel structure treated with a polyester powder

coating (RAL9002) suitable for outdoor applications, for an attractive look and eective resistance to corrosive agents.

Fastening devices are made of non-oxidizable materials, or carbon steel that has undergone surface-passivating treatments.

On request acoustic insulation can reduce the unit noise

emissions

Fastening devices are made of non-oxidizable materials, or carbon steel that has undergone surface-passivating treatments.

CUSTOMISED HYDRAULIC KIT

The hydronic kit is fully congurable, and as an option the

pumping unit can be requested with silicon carbide/ silicon carbide/viton seals to handle ethylene glycol and propylene glycol

concentrations of up to 35% with minimum product mixture

temperatures of -10 °C. With standard pumps the maximum

ethylene glycol concentrations is: for frame 1: 25% and 30% for

others.

COOLING CIRCUIT

Scroll type compressors in a tandem conguration that can

be sound insulated. The adopted components’ eciency, reliability, and noise emission levels represent the state of the

art for scroll compressors.

Brazed plate heat exchangers made of stainless steel and op-

timised for use with R454B.

Finned block condenser with 8 mm copper piping and al-

uminium ns, characterised by circuits for optimize the operation both as evaporator and as condenser and to reduce

refrigerant charge (PLE H).

Microchannel condenser with low refrigerant charge (PLE C).

Dehydrating lter.

Flow indicator with humidity indicator.

Cycle reversing valve (only PLE H)

Check valve (PLE H)

Liquid receiver (PLE H)

High and low pressure switch

Schrader valves for checks and/or maintenance

Electronic expansion valve for liquid injection: available on

conguration, expands a little quantity of liquid in com-

pressors intake for reduce discharge overheating during the

DHW production in cold climates.

Electronic expansion valve: this standard feature expands

the liquid refrigerant towards the plate heat exchanger

during operation in chiller mode and towards coils in heat

pump mode.

Low-pressure relief valve: it limits the maximum pressure of

the low-pressure circuit in order to maintain the PED catego-

ry of the compressor. (Only for model 142-152)

not accessible to the public.

WARNING: Do not install the unit in environments with gas

A

or ammable dusts.(ATEX zone)

Liquid separator (PLE H): this congurable accessory pro-

vides greater protection to the compressors against the return of liquids, especially during cycle reversals and defrosting. It is strongly recommended on all heat pumps operating

in harsh and/or variable climates and in the areas indicated

by the operating range. It is always combine with liquid injection.

PLE H): this congurable accessory provides greater pro-

tection to the compressors against the return of liquids, especially during cycle reversals and defrosting. It is strongly

recommended on all heat pumps operating in harsh and/or

variable climates and in the areas indicated by the operating

range

REFRIGERANT WITH LOW GWP

Use of R454B refrigerant with low environmental impact. R454B

is a next-generation A2L refrigerant with a GWP of only 467,

one of the lowest on the market. This GWP value ensures that

the PLE range complies with the gradual reduction of quotas of

greenhouse refrigerants in the European market required by the

F-GAS regulation, down to the stricter limits foreseen for 2030

ELECTRONIC VALVE

It is standard on the entire range and oers greater responsiveness during transients. The electronics also manage the synergistic operation of the compressors and the valve, thereby making it possible to vary overheating and maximize eciency at

partial loads.

ELECTRONIC MICROPROCESSOR CONTROL

The electronic control enables the complete control of the PLE

unit. It can be easily accessed through a polycarbonate ap with

IP65 protection rating.

By reading the outdoor air temperature, it can automatically

change the setpoint to adapt it to the outdoor load conditions

or keep the unit running even in the harshest winter conditions.

Main functions:

Control of water returning from the system’s temperature

With modulating pump, control of the ow temperature to

the unit or the Delta T

Possibility of adapting the set-point to the outside load con-

ditions or to the outside temperature

Control of the electronic valve

Complete alarm management, including history

An RS485 serial port is available for monitoring

Possibility of connecting a second remote terminal (display)

Management of multiple units connected to a LAN network

Devices controlled

Compressor

PLE

TECHNICAL MANUAL4

Reverse cycle valve (PLE H)

Alarm signalling relay

LAN networks for controlling 6 units in parallel and manag-

ing BACNET and LON communication protocols

GAS LEAK DETECTION SYSTEM

As a standard feature, the units are equipped with leak detection

sensors near the cooling circuit. The microprocessor manages

the procedures for securing and shutting down the unit in case

of refrigerant leakage, also making it possible to divert the power supply of the control unit that collects the information from

the leak sensors on a low-voltage emergency line. This function

allows the complete disconnection of the power to the unit during maintenance operations, while leaving all the safety systems

enabled.

MICROCHANNELS FINNED COIL

The entire Chiller range has microchannel coils as a standard feature. The large heat exchange surface, the absence of a

copper-aluminum interface, and the perfect ow of air make it

possible to achieve the same performance while reducing the

refrigerant charge by up to 40%, with obvious benets from an

ecological point of view. Galletti microchannel coils are made of

Long Life Alloy, an aluminium alloy that oers maximum safety

in urban and industrial environments.

For heat pumps there is a nned-coil exchanger with 8mm copper tubes and alluminium ns.

RG66024439-01

All copying, even partial, of this manual is strictly forbidden 5

3 CONFIGURATION OPTIONS

The range PLE consists of 10 models with cooling capacities

from 50 to 160 kW, available as cooling only and reversible heat

pump mode, charged with R454B uid classied like A2L (slightly ammable)

» Conguration options

1 Expansion valve

A Electronic

2 Water pump and accessories

0 Absent

1 LP pump + expansion vessel

2 LP run and standby double pump + expansion vessel

3 HP pump + expansion vessel

4 HP run and standby double pump + expansion vessel

A LP inverter pump + expansion vessel

B LP run and standby double inverter pump + expansion vessel

C HP inverter pump + expansion vessel

D HP run and standby double inverter pump + expansion vessel

3 Water buer tank

0 Absent

S Selected

4 Partial heat recovery

0 Absent

D Desuperheater with water pump free contact

5 Air ow modulation

A Condensation control with high-head EC electronically controlled fans

C Condensation control by phase-cut fans

E Condensing control with electronic EC fans

6 Antifreezing kit

0 Absent

E Evaporator

P Evaporator and water pump

S Evaporator, water pump and water buer tank

7 Acoustic insulation and attenuation

NOTE: The choice of some options can make the choice of some

others forbidden or make some selection (elds) mandatory.

Please contact Galletti for verication.

0 Absent

3 Compressor soundproof insulations and compressor compartment acoustic insulation

8 Refrigerant pipework accessories

0 Absent

2 Operation limit extension low T air (Liquid separator in compressor intake + liquid injection)

9 Remote control / Serial communication

0 Absent

2 RS485 serial board (Carel / Modbus protocol)

B BACNET IP / PCOWEB serial board (advanced controller required)

G BACNET IP / PCOWEB + SUPERVISOR SOFTWARE (GWeb)

S Remote simplied user panel

X Remote user panel for advanced controller

10 Special coils / Protective treatments

0 Copper-aluminium (standard heat pump only)

C Cataphoresis

E Microchannel in Long Life Alloy (standard for chiller)

I Hydrophilic

M Microchannels coil with e- coating treatment

P Pre-painted ns with epoxy painting

R Copper-copper

11 Anti vibration shock mounts

0 Absent

G Rubber anti vibration shock mounts

M Spring anti vibration shock mounts

12 Outdoor coil trace heater

0 Absent

1 Selected

13 Onboard controller

1 Advanced

» Accessories

A Outdoor nned coil heat exchanger protection lters

B Outdoor nned coil heat exchanger protection grille

C Pair of couplings Victaulic

D ON/OFF status of the compressors

E Remote control for step capacity limit (advanced controller required)

F Congurable digital alarm board (advanced controller required)

G Soft starter

H Power factor capacitors

I Refrigerant sensors

L Water pipes additional insulation

M 0-10 V signal for external user pump control (on-board pump excluded)

N Compressor tandem/trio isolation valves

O Night-time low-noise

Q Temperature probe for pump shutdown on the primary circuit

R Enabling 2nd set-point / external alarm signaling via digital input

S Hot-wire electronic ow switch

T Mains power analyzer for monitoring and reducing power consumption

U Unit lifting pipes

V Set-point modication with 4-20mA signal

PLE

TECHNICAL MANUAL6

4 TECHNICAL FEATURES

4.1 WATER CHILLERS RATED TECHNICAL DATA PLE C

» Water chillers rated technical data PLE C

PLE 052 062 072 082 092 102 122 132 142 152

Power supply V-ph-Hz 400 / 3+N / 50

Cooling capacity (1) kW 53,0 59,0 66,0 72,0 88,0 97,0 108 122 135 145

Total power input (1) kW 17,4 20,1 23,0 26,3 30,2 34,3 39,9 42,2 49,0 56,1

EER (1) 3,03 2,92 2,87 2,73 2,91 2,82 2,72 2,89 2,74 2,59

SEER (2) 4,42 4,23 4,15 4,12 4,45 4,25 4,26 4,25 4,18 4,11

Air ow rate (1) m³/h 22600 22600 22600 22600 32200 32200 32200 42700 42700 42700

Water ow (1) l/h 9069 10116 11365 12318 15112 16625 18648 20981 23169 25009

Water pressure drop (1) k Pa 22 27 27 31 33 39 35 43 44 50

Available pressure head - LP pumps (1) k Pa 164 155 150 140 124 115 115 156 148 135

Available pressure head - HP pumps (1) k Pa 213 204 198 188 183 173 174 177 170 157

Maximum current absorption A 48,0 52,0 58,0 64,0 78,0 85,0 94,0 105 116 127

Start up current A 163 170 184 224 254 304 304 308 376 376

Startup current with soft starter A 128 133 144 174 200 239 239 243 296 296

Compressors / circuits 2/1

no. of axial fans 4 4 4 4 6 6 6 8 8 8

Buer tank volume dm³ 125 125 125 125 190 190 190 295 295 295

Refrigerant charge (3) kg 6,60 6,70 6,90 7,00 11,5 11,8 12,5 13,0 13,5 14,0

Height mm 1731 1731 1731 1731 1731 1731 1731 1731 1731 1731

Depth mm 1176 1176 1176 1176 1176 1176 1176 1176 1176 1176

Length mm 2088 2088 2088 2088 2576 2576 2576 3186 3186 3186

Sound power level (4) dB(A) 80 81 81 81 84 84 85 88 88 89

Sound power level, low-noise version (4) dB(A) 77 78 78 78 81 81 82 85 85 87

Sound pressure level (5) dB(A) 52 53 53 53 56 56 57 60 60 61

Weight without options kg 462 465 469 476 590 591 642 750 808 858

Maximum transport weight kg 520 523 529 536 682 683 733 906 962 1012

(1) O utdoor air temperature 35°C, water temperature 12°C / 7°C (EN14511:2018)

(2) η eciency values for heating and cooling are respectively calculated by the following formulas: [η = SCOP / 2,5 - F(1) - F(2)] e [η = SEER / 2,5 - F(1) - F(2)]. For further information, please refer to the technical document “ErP 2009/125/EC

DIRECTIVE” in the catalogue introducing pages, or to the EN14825:2017 regulation.

(3) Kg gas value is estimated. For the exact value refer to the plate data on the unit.

(4) S ound power level measured according to ISO 9614

(5) S ound pressure measured at a distance of 10 m in a free eld with a directivity factor of 2

RG66024439-01

All copying, even partial, of this manual is strictly forbidden 7

4.2 HEAT PUMPS RATED TECHNICAL DATA PLE H

» Heat pumps rated technical data PLE H

PLE 052 062 072 082 092 102 122 132 142 152

Power supply V-ph-Hz 400 / 3+N / 50

Cooling capacity (1) kW 50,1 54,9 62,5 70,5 83,8 92,5 107 120 132 142

Total power input (1) kW 18,5 21,3 24,0 27,0 30,8 36,1 41,0 44,8 49,7 56,3

Absorbed rated current (1) A 34,0 38,0 42,0 46,0 56,0 62,0 69,0 78,0 86,0 95,0

EER (1) 2,71 2,58 2,60 2,61 2,72 2,56 2,61 2,68 2,66 2,53

SEER (2) 4,40 4,21 4,11 3,93 4,40 4,02 4,22 4,23 4,15 3,93

Heating capacity (3) kW 59,0 66,0 75,0 84,0 99,0 111 125 138 157 172

Total power input (3) kW 18,3 20,6 23,5 26,0 30,7 34,7 39,1 43,1 48,4 53,8

Absorbed rated current (3) A 34,0 39,0 43,0 48,0 56,0 65,0 73,0 81,0 89,0 99,0

COP (3) 3,21 3,20 3,20 3,24 3,23 3,20 3,20 3,21 3,24 3,20

SCOP (2) 3,61 3,66 3,77 3,90 3,61 3,61 3,84 3,73 3,79 3,73

Energy eciency 142 144 148 153 142 142 150 146 149 146

Heating energy eciency class (4) A+

Maximum current absorption A 48,0 52,0 58,0 64,0 78,0 85,0 94,0 105 116 127

Start up current A 163 170 184 224 254 304 304 308 376 376

Startup current with soft starter A 128 133 144 174 200 239 239 243 296 296

Compressors / circuits 2/1

no. of axial fans 4 4 4 4 6 6 6 8 8 8

Air ow rate (1) m³/h 24400 24400 23900 23500 34900 34900 33900 46700 46700 45500

Water ow (1) l/h 8624 9446 10758 12140 14418 15927 18419 20699 22745 24516

Water pressure drop (1) k Pa 21 24 25 31 28 36 34 42 38 44

Available pressure head - LP pumps (1) k Pa 168 160 151 138 129 116 115 158 156 138

Available pressure head - HP pumps (1) k Pa 218 210 200 186 187 175 173 179 177 160

Air ow rate (3) m³/h 24400 24400 24000 23500 35200 35200 34200 46700 46700 45900

Water ow (3) l/h 10193 11420 13026 14577 17208 19221 21658 23996 27204 29845

Water pressure drop (3) k Pa 28 34 35 43 36 51 46 55 51 60

Available pressure head - LP pumps (3) k Pa 160 150 138 118 119 101 96 140 136 111

Available pressure head - HP pumps (3) k Pa 209 199 185 164 177 159 154 162 158 132

Buer tank volume dm³ 125 125 125 125 190 190 190 295 295 295

Refrigerant charge (5) kg 9,50 10,0 13,0 16,1 17,5 18,0 23,0 25,0 28,3 28,6

Height mm 1731 1731 1731 1731 1731 1731 1731 1731 1731 1731

Depth mm 1176 1176 1176 1176 1176 1176 1176 1176 1176 1176

Length mm 2088 2088 2088 2088 2576 2576 2576 3186 3186 3186

Sound power level (6) dB(A) 80 81 81

Sound power level, low-noise version (6) dB(A) 77 78 78 78 81 81 82 85 85 87

Sound pressure level (7) dB(A) 52 53 53 53 56 56 57 60 60 61

Weight without options kg 502 505 517 532 646 647 711 828 906 956

Maximum transport weight kg 560 563 577 592 739 739 801 983 1059 1109

(1) O utdoor air temperature 35°C, water temperature 12°C / 7°C (EN14511:2018)

(2) η eciency values for heating and cooling are respectively calculated by the following formulas: [η = SCOP / 2,5 - F(1) - F(2)] e [η = SEER / 2,5 - F(1) - F(2)]. For further information, please refer to the technical document “ErP 2009/125/EC

DIRECTIVE” in the catalogue introducing pages, or to the EN14825:2017 regulation.

(3) O utdoor air temperature dry bulb 7°C / wet bulb 6°C, water temperature 40°C / 45°C (EN14511:2018)

(4) S easonal energy eciency class for LOW TEMPERATURE room heating under AVERAGE climatic conditions [EUROPEAN REGULATION No 811/2013]

(5) Kg gas value is estimated. For the exact value refer to the plate data on the unit.

(6) S ound power level measured according to ISO 9614

(7) S ound pressure measured at a distance of 10 m in a free eld with a directivity factor of 2

81 84 84 85 88 88 89

5 PED CATEGORY

The water chillers and heat pumps comply with directive 2014/68//EC (PED).

Series Size Notied body PED Category Marking

F1 0476 III CE + PED

PLE

PLE

TECHNICAL MANUAL8

F2 0476 III CE + PED

F3 0476 III CE + PED

6 PERFORMANCES

Galletti has developed on its www.galletti.com web-area the

new ON-LINE integrated platform for product selection, conguration and the making of the economic oer.

The software, whose use is easy and intuitive, allows the identication of the desired products by calculating their performances

Product selection:

Filters to make the identication of the requested product easier

Performance calculation and saving of results

Performance comparison between products belonging to dierent series

Conguration and project history

Wizard conguration of accessories and options for chillers, heat pumps and

hydronic units

Creation of a project which collects all products of interest

Complete management of the storaged history projects

based on real working conditions and their conguration helping the user in choosing options and accessories. It also allows to

obtain a detailed report which includes performances, dimensional drawings, tender specications and the economic oer.

Report:

Generation of a detailed list report in pdf format

Choice of the sections to be included in the print:

Products performances

Dimensional drawings

Tender specications

RG66024439-01

All copying, even partial, of this manual is strictly forbidden 9

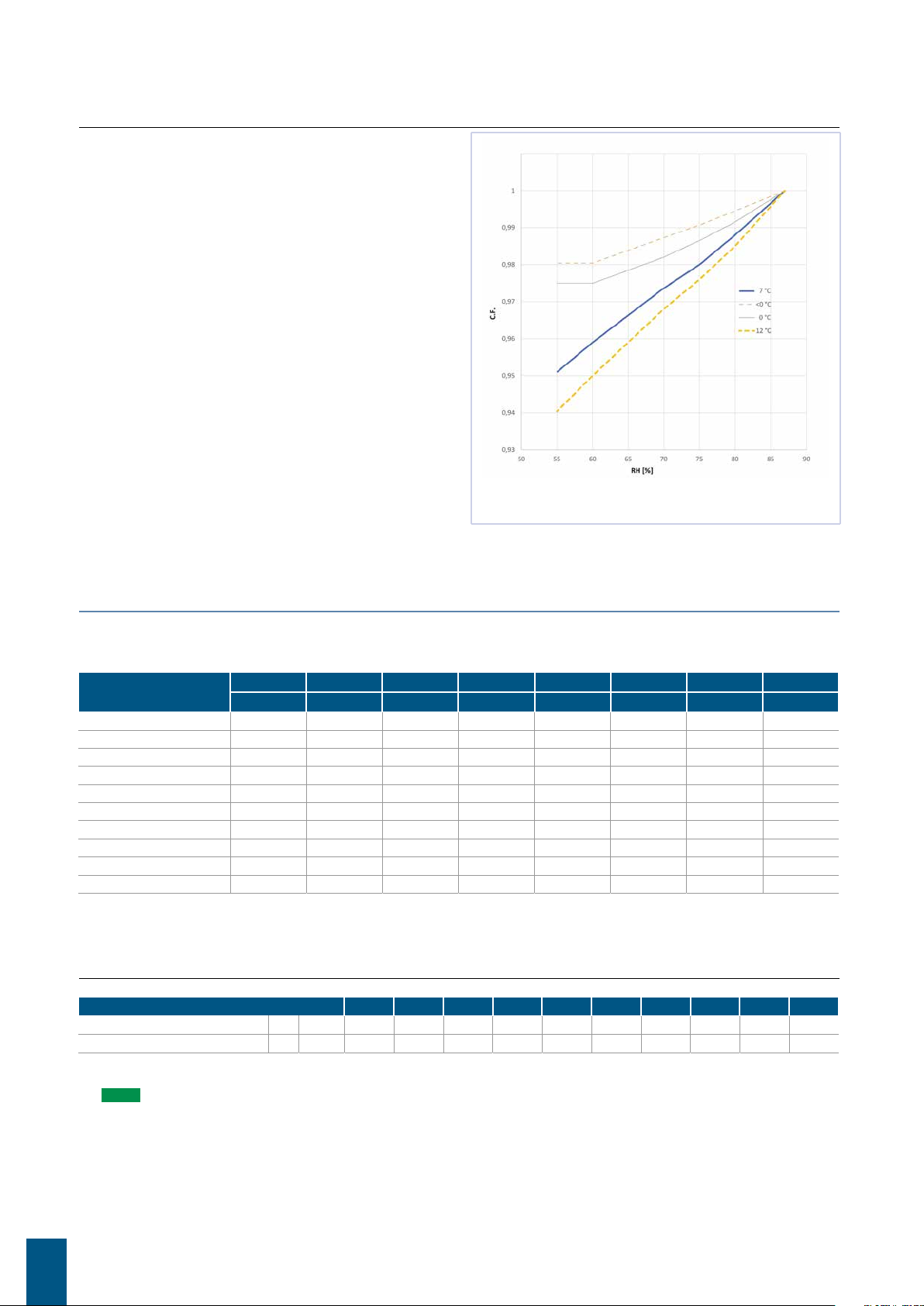

6.1 CORRECTION OF THE HEATING CAPACITIES

In the heat pump operation (heating mode), the actual heating

capacities of units may be lower than the values shown in the

technical data table, due to the dierent values of the relative

humidity of the external air. To obtain the actual heating capacity, multiply the capacity values by the corrective coecients

given in graphic.

C.F Correction coecient

RH Relative humidity

7 SOUND LEVELS

» Standard sound level

Mod.

PLE152CS 89 84,3 90,7 81,8 80,6 74,2 67,0 66,0

PLE142CS 88 84,3 90,7 81,8 80,6 74,2 67,0 66,0

PLE132CS 88 84,3 90,7 81,8 80,6 74,2 67,0 66,0

PLE122CS 85 84,3 90,7 81,8 80,6 74,2 67,0 66,0

PLE102CS 84 84,3 90,7 81,8 80,6 74,2 67,0 66,0

PLE092CS 84 83,3 89,7 80,8 79,6 73,2 66,0 65,0

PLE082CS 81 77,7 82,5 76,5 75,9 69,0 62,7 62,1

PLE072CS 81 77,7 81,5 75,5 74,9 68,0 61,7 60,2

PLE062CS 81 77,7 81,5 75,5 74,9 68,0 61,7 60,2

PLE052CS 80 77,7 81,5 75,5 74,9 68,0 61,7 60,2

1. Total sound power level, weighted A

2. Sound power level by octave band, not weighted

7.1 ACOUSTIC INSULATION VERSIONS

PLE 052 062 072 082 092 102 122 132 142 152

Sound power level (1) dB(A) 80 81 81 81 84 84 85 88 88 89

Sound power level, low-noise version (1) dB(A) 77 78 78 78 81 81 82 85 85 87

(1) S ound power level measured according to ISO 9614

LwA (1) 125 Hz (2) 250 Hz (2) 500 Hz (2) 1000 Hz (2) 2000 Hz (2) 4000 Hz (2) 8000 Hz (2)

dB(A) dB dB dB dB dB dB dB

NOTE: Low noise sound power level = standard + com-

C

pressor silencing housings.

PLE

TECHNICAL MANUAL10

Loading...

Loading...