Galletti EXCELIA MXE 009M, EXCELIA MXE 009, EXCELIA MXE 014, EXCELIA MXE 011M, EXCELIA MXE 016 User Manual

...

GB

Technical manual for high efficiency heat pumps

High efficiency heat pump EXCELIA MXE series

7.3 kW -18.5 kW

R410AR410A

R410A

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

TABLE OF CONTENTS

1 The series ....................................................................................................................................................................................................... 6

2 Constructive features ...................................................................................................................................................................................... 7

3 Layout of components .................................................................................................................................................................................... 8

4 Models and configurations ............................................................................................................................................................................ 10

5 Technical characteristics ............................................................................................................................................................................... 11

5.2 Rated technical data heat pump ...................................................................................................................................................................... 11

6 Performance.................................................................................................................................................................................................. 12

6.1 MXE Cooling capacities ................................................................................................................................................................................... 12

6.2 MXE Heating capacities ................................................................................................................................................................................... 14

6.3 Integrated capacities .......................................................................................................................................................................................15

7 Sound level ...................................................................................................................................................................................................15

8 Operating limits ............................................................................................................................................................................................. 16

8.1 Cooling mode ................................................................................................................................................................................................. 16

8.2 Heating mode ................................................................................................................................................................................................. 17

8.3 Thermal carrier fluid ......................................................................................................................................................................................... 17

9 Calculation factor .......................................................................................................................................................................................... 17

9.1 Change in operating parameters with Δt other than 5°C .................................................................................................................................... 17

9.2 Water and glycol mixture ................................................................................................................................................................................. 17

10 Pressure drop ................................................................................................................................................................................................ 18

10.1 Pressure drops, water side ............................................................................................................................................................................... 18

10.2 Pressure drops of Y filter .................................................................................................................................................................................. 18

11 Available head .............................................................................................................................................................................................. 19

12 Water circuit .................................................................................................................................................................................................. 20

12.1 Water content within the system and charging of expansion tank ..................................................................................................................... 20

13 Electrical data and connections ..................................................................................................................................................................... 22

14 Overall dimensions ........................................................................................................................................................................................ 23

15 Installation clearance requirements .............................................................................................................................................................. 25

16 Siting ............................................................................................................................................................................................................. 26

16.1 Positioning of vibration dampers ...................................................................................................................................................................... 26

The technical and dimensional data provided herein may undergo changes in

connection with product improvements.

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

Galletti S.p.A via L.Romagnoli 12/a

40010 Bentivoglio (BO) Italia

Made in Italy

CATEGORIA 1

Matricola - Serial number

Codice articolo - Code

Data di produzione - Date of production

Pot.Raffreddamento - Cooling Capacity (W)

Pot.Riscaldamento - Heating Capacity (W)

Alimentazione - Power supply (kW)

Assorbimento elettrico - Power input (kW)

Peso - Weight (kg)

Max assorbimento elettrico - Max power input (kW)

Max corrente esercizio - Max running ampere (kW)

Assorbimento elettrico PdC - HP Power input (kW)

Refrigerante - Refrigerant

Max pressione refrigerante - Max refrigerant press (bar)

Max temperature refrigerant - Max refrigerant temperature (°C)

UNIT IDENTIFICATION

The unit data are reported on the rating label in this page

The label shows the following data:

- Series and size of the unit

- Date of manufacture

- Main technical data

- Manufacturer

- The label is applied on the unit, usually on the enclosing panels beside the

condenser coil.

IMPORTANT: NEVER REMOVE THE LABEL

- Serial number of the unit

- The serial number permits to identify the technical characteristics and the

components installed

- Without this datum it will be impossible to identify the unit correctly

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

Serie Grandezza Organism o Notificato N° cert ificat o Procedura di v alutazione di conf orm ità Categoria PED M arcat ura

Range Size Notified body certificate Conformit y Compl iance Module PED category Mark ing

ECH

2

O - ECH2O H

4-5-6-7

1115 Modulo D1

I

CE

MCA - MCA H 10-12-14

1115 Modulo D1

I

CE

MCA - MCA H 16-21-25-30-37-50-60

1115 Modulo D1

II

CE + PED

LCA - LCA H 045-050-060-070-080-090- 105

1115 Modulo D1

II

CE + PED

MCC - MCC H 6-7-9-12-15

1115 Modulo D1

I

CE

MCC - MCC H 18-22-25-33-37

1115 Modulo D1

II

CE + PED

MCW - MCW / H 5-7-10-12-15

1115 Modulo D1

I

CE

MCW - MCW / H 18-20-22-27-31-39

1115 Modulo D1

II

CE + PED

MPE - MPEH - MCE - M CEH 4-5-7-8 1115 Modulo D1

I

CE

MPE - MPEH - MCE - M CEH 9-10-11-13-15-18 1115 Modul o D1

I

CE

MPE - MPEH - MCE - M CEH

19-20-21-23-24-26- 27-28-31-32-34-35-39-40

1115 Modulo D1

II

CE + PED

MPE - MPEH - MCE - M CEH T30-T34-T40-T45 1115 M odulo D1

II

CE + PED

MFE 5-6-8-11-13-16-17-20-23 1115 Modulo D1

I

CE

MXE 9-11-14-16 1115 M odu lo D1

I

CE

MXE 19-21 1115 Modulo D1

II

CE + PED

LCA - LCA H 115-130- 150-180-205-220-235-250-280-300

0398 B.05.0600AP -01 - 01-01-2005

Modulo D1

II

CE + PED

N°006 rev. 4 del 06/02/2008

LCA and LCA H (115-300) units are manufactured in the plants of Hiref S.p.a - Galletti Group, Viale Spagna 31/33 Tribano (Padova)

Bentivoglio, 16/07/2008

Galletti S.p.A.

Luigi Galletti

President

DECLARATION OF CONFORMITY

Galletti S.p.A., whose head office is located at 12/a Via Romagnoli 12/a Bentivoglio (Bologna) - Italy, hereby declares, under its own responsibility, that

the water chillers and heat pumps belonging to the series:

ECHO, ECHO H, MCA, MCA H, LCA, LCA H, MCC, MCC H, MCW, MCW-H, MPE, MPEH, MCE, MCEH, MFE and MXE, units intended for applications

in civil air conditioning systems, comply with the requirements of EEC Directives 98/37/CE, 89/336/CEE, 92/31/CEE, 93/68/CEE, 2006/95/CE,

97/23/CE (PED).

These units are the result of an assembly of components [compressors, brazed plate heat exchangers, liquid receivers, pipes, control and safety

valves] which are individually provided, where required, with certification in accordance with current directives: the category to which the machines

belong is determined on the basis of an analysis of the components subject to the PED and corresponds to the highest category among the

components used.

For each series of machines, the conformity of the assembly has been assessed by notified bodies, applying the assessment procedures (forms)

pursuant to annex II of the PED - Directive 97/23, as shown in the following table:

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

1 THE SERIES

Galletti has developed this product for the production of hot water for heating

systems - especially in demand for independent homes - with the aim of

reducing primary energy consumption and operating costs compared to

conventional gas or electric systems, thanks to a high level of efficiency:

average COP 3.33 (Eurovent Energy Efficiency Class A)

average EER 3.23 (Eurovent Energy Efficiency Class A)

OPTIMISED FOR OPERATION IN THE HEATING MODE

- Plate heat exchanger with reverse-flow operation in the heating mode

(+7% increase in efficiency).

- Finned coil with wide fin spacing

- Desuperheater in the pipes at the base of the finned block heat exchanger.

- Heating cable on the base in the internal part of the finned coil.

- Facilitated condensate drainage

YEAR-ROUND OPERATION

MXE heat pumps have been designed to work in the heating mode with

outdoor air temperatures ranging from -15°C to + 30°C, producing hot water

at temperatures of up to 55°C, and in the cooling mode with air temperatures

ranging from -10 to +45°C.

The electronic expansion valve and

condensation control (under pressure)

contribute to increasing the working range.

25

30

35

40

45

50

55

60

-15 -10 -5 0 5 10 15 20 25

Air temperature (°C)

Temperature of water produced (°C)

WORKING RANGE

MXE

SMART DEFROST SYSTEM

The exclusive defrost system (optional feature available with the advanced

controller) can correctly identify an impairment of per formance in the outdoor

exchanger due to the formation of ice and minimise the process time in

relation to normal operation of the unit.

SELF-ADAPTIVE

The electronic control system allows the setpoint to be adjusted automatically

according to the outdoor temperature in order to reduce consumption and

broaden the working temperature range.

The unit can also function in systems with a low water content, even

without the use of a storage reservoir, thanks to the automatic adjustment

which limits the number of compressor starts and thus extends the life of

the compressors themselves.

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

2 CONSTRUCTIVE FEATURES

STRUCTURE

Painted galvanised sheet steel structure (RAL9002) for an attractive look and

effective resistance to corrosive agents.

Fastening devices are made of non-oxidizable materials, or carbon steel that

has undergone surface-passivating treatments.

The compressor compartment is completely sealed and may be accessed on

3 sides thanks to easy-to-remove panels that greatly simplify maintenance

and/or inspection.

Sound insulation, available on request, can further reduce the noise emissions

of the unit.

CUSTOMISED HYDRAULIC KIT

- High head pump made entirely of stainless steel, already configured for

use with mixtures of water and ethylene glycol up to 35% and provided

with internal thermal protection.

It is housed in the compressor compartment and is easy to reach thanks

to the removable perimeter panels.

- Expansion tank.

- Safety valve.

- Filling cock (included).

- Automatic vent valve.

- Water differential pressure switch and outlet water temperature probe with

anti-freeze thermostat function.

- Mechanical Y filter supplied as a standard feature on all models to protect

the evaporator (included).

- Buffer tank available on request.

COOLING CIRCUIT

- Scroll-type compressor housed in a compar tment that can be sound

insulated.

- Brazed plate heat exchangers made of STAINLESS STEEL and optimised

for use with R410A.

- Finned block condenser with 8 mm copper piping and aluminium fins,

characterised by ample heat exchange surfaces.

- Dehydrating filter.

- Flow indicator with humidity indicator.

- Electronically controlled electric thermostatic valve with dedicated driver

which controls opening according to the refrigerant pressure and

temperature downstream from the evaporator.

- Reverse cycle valve

- Single-acting valves.

- Liquid receiver.

- High and low pressure switches.

- Safety valve.

- Schrader valves for checks and/or maintenance.

- Refrigerant pressure gauges (optional)

FAN DRIVE ASSEMBLY

Electric fan with 6-pole external rotor motor directly keyed to the axial fan, with

internal thermal protection on the windings, complete with safety grille and

dedicated supporting structure.

The fan is housed in a special compartment having a profile designed to

optimise ventilation.

The use of finned block heat exchangers with 8mm diameter pipes reduces

pressure drops on the air side, thus significantly improving the noise levels of

the units.

The condensation control system continuously and automatically regulates

the fan speed, further limiting the noise emissions of the unit during nighttime

operation and under partial load conditions.

FINNED BLOCK HEAT EXCHANGER

Made of 8mm diameter copper pipes and aluminium fins, generously sized.

The special engineering of the heat exchangers allows defrost cycles to be

carried out at maximum speed in the models with heat pump operation, which

brings clear benefits in terms of the integrated efficiency of the whole cycle.

ELECTRONIC MICROPROCESSOR CONTROL

The electronic control enables the complete control of the MXE unit. It can be

easily accessed through a

polycarbonate flap with IP65 protection

rating.

The self-adaptive logic enables the unit

to operate even in systems where the

water content is low, without the use

of an inertial water storage reservoir.

By reading the outdoor air temperature, it can automatically change the setpoint to adapt it to the outdoor load

conditions or keep the unit running even in the harshest winter conditions.

The basic controller comes complete with the MODBUS protocol and enables

an immediate connection to ERGO networks.

Main functions

- Control over the temperature of water entering the evaporator.

- Defrosting management

- Control of fan speed

- Complete alarm management.

- Dynamic control of the setpoint according to the outdoor air temperature.

- Can be connected to an RS485 serial line for supervisory / teleassistance

operation;

- Option of connecting a remote terminal that duplicates the control

functions.

Devices controlled:

- Compressor

- Fans

- Reverse cycle valve

- Water circulation pump.

- Antifreeze heating elements

- Alarm signalling relay

On request, it is possible to install the advanced controller whose functions

extend to :

- LAN networks

- Smar t Defrost System

ELECTRIC CONTROL BOARD

The electric control board is constructed and wired in accordance with EEC

Directive 73/23, Directive 89/336 on electromagnetic compatibility and related

standards. Made of steel sheet, it is also protected by the enclosing panels of

the machine.

OPTIONS

Incorporable buffer tank

Low noise execution

Refrigerant pressure gauges

Antifreeze heating elements on the tank

Heat recovery 25% (chiller)

Special exchangers (hydrophilic treatment, copper-copper, cataphoresis, anticorrosion)

ACCESSORIES AVAILABLE

Remote control boards

Base vibration dampers

Metal grilles to protect exchangers

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

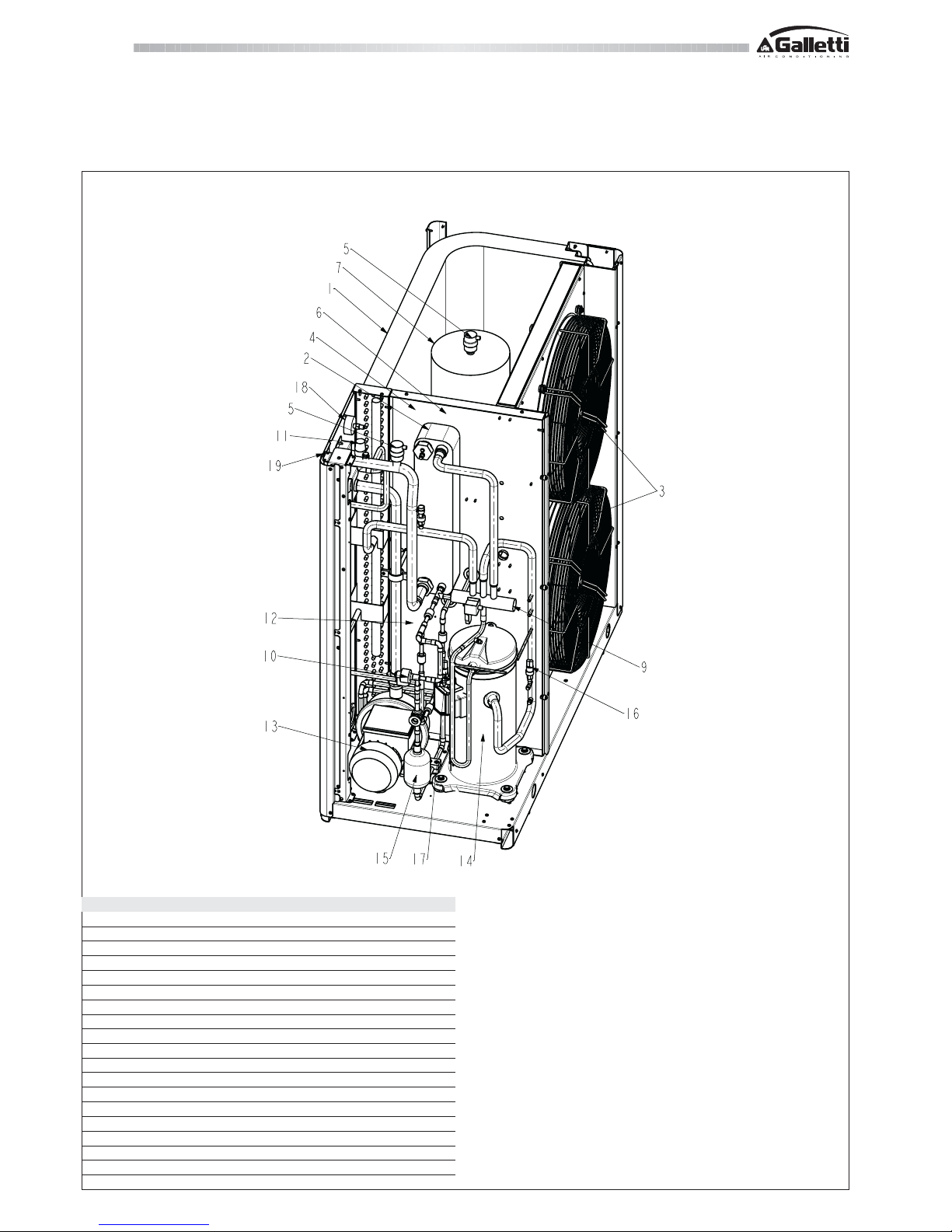

3 LAYOUT OF COMPONENTS

MXE 09 ÷ 16

LEGEND Description

1 R410A - air exchanger

2 R410A - water exchanger

3 Fans

4 Water differential pressure switch (fan compartment)

5 Automatic air vent valve

6 Expansion tank (fan compartment)

7 Buffer tank (accessory)

9 4-way valve

10 Thermostatic valve

11 Water safety valve

12 Liquid receiver (fan compartment)

13 Circulation pump

14 Compressor

15 Refrigerant filter

16 Low pressure switch and charge inlet

17 High pressure switch and charge inlet

18 Water pressure gauge

19 Water filling point

MXE 09 - 16

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

3 LAYOUT OF COMPONENTS

MXE 19 ÷ 21

LEGEND Description

1 R410A - air exchanger

2 R410A - water exchanger

3 Fans

4 Water differential pressure switch (fan compartment)

5 Automatic air vent valve

6 Expansion tank (fan compartment)

7 Buffer tank (accessory)

9 4-way valve

10 Thermostatic valve

11 Water safety valve

12 Liquid receiver (fan compartment)

13 Circulation pump

14 Compressor

15 Refrigerant filter

16 Low pressure switch and charge inlet

17 High pressure switch and charge inlet

18 Water pressure gauge

19 Water filling point

MXE 19 - 21

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

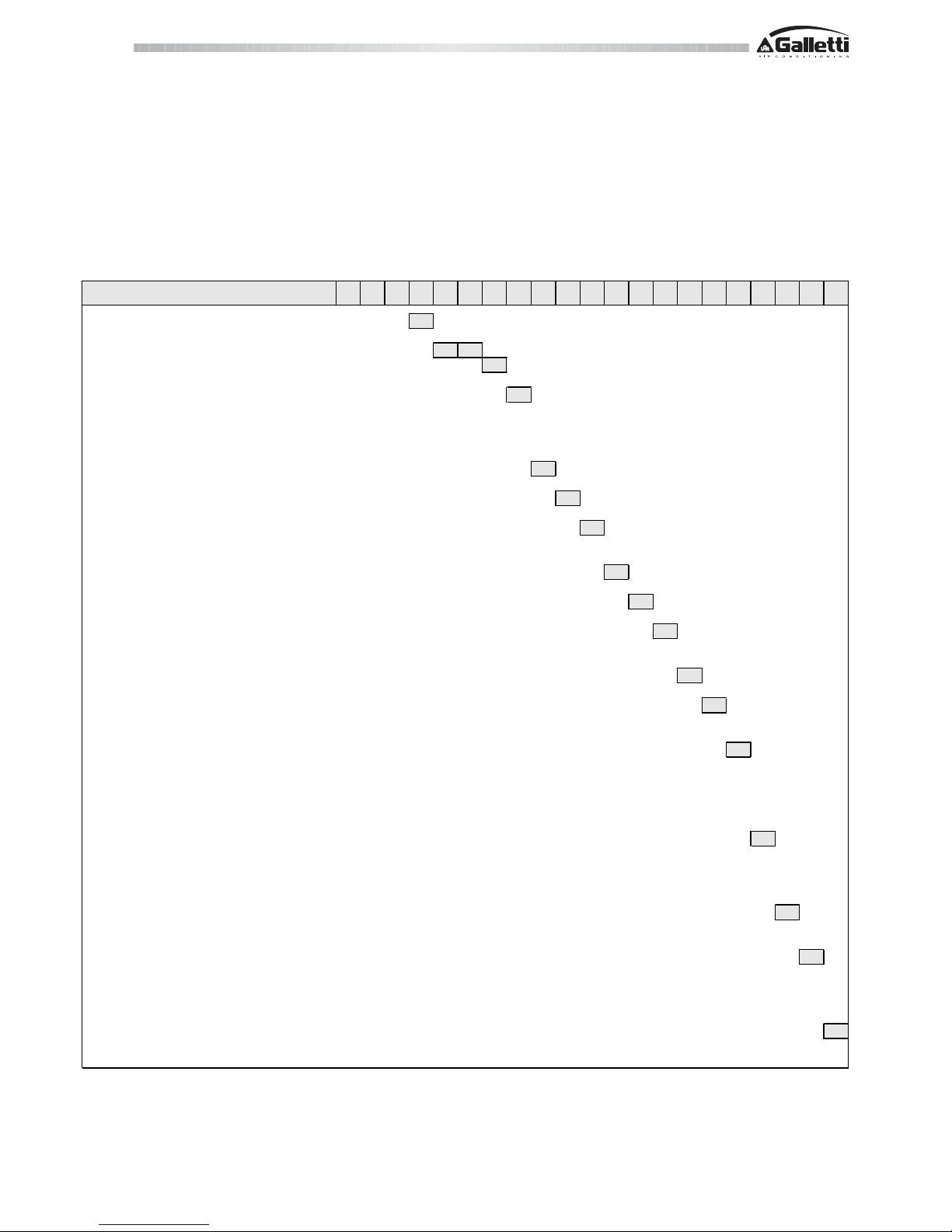

4 MODELS AND CONFIGURATIONS

FIELD OF APPLICATION

MXE heat pumps have been designed to heat water for air conditioning and heating systems intended for residential or commercial use.

MODELS AND VERSIONS

The MXE series features 6 models of varying capacity equipped with heat pump.

All models are charged with R410A refrigerant.

N.B. The choice of some options may preclude the choice of others or make some other fields become mandatory. Contact Galletti S.p.A. for verification

MX E 009H0A100CP1000001

0

0

09

H

H

0

0

M

2

4

A

A

1

1

0

0

S

0

0

C

C

P

P

S

1

1

0

0

M

0

0

2

S

M

X

0

O

R

C

B

0

0

G

Complete Unit Code

Operation

Single phase

400 - 3N - 50

Model (size)

Version

Single compressor

Heat pump

Powe r Suppl y

Single Phase + thermalmagnetic

400 - 3N - 50 + the rmal magnetic

Expansion Valve

Elect ronic expa nsi on valve

Not present

Condensing control

Present

Heat Recover

Pump and accessories

Pump - ves sel - wate r charge valve

Buffer tank

Not present

With modulating air flow

Antifreeze kit

Present, unit with pump and vessel

Present, unit with pump, vessel and tank

Acoustic insulation

Sound proofing insulation for compressor housing

Refrigerant ci rcuit accessoires

Not present

Refrigerant gauge

Protection grille

Not present

Remote control

Special coil

Standard

Copper / copper heat exchanger

Not present

RS485 port (modbus + carel protocol)

Simplified

Base microprocessor remote control (modbus excluded )

ADVANCED microprocessor remote control

Present

Cat ap hore sis

"Blygold"

0

0

1

2

3

1

1

2

Advanced microprocessor

Soft starter

Power factor correction capacitors + soft starter

Control panel

Basic microprocessor

Compressor options

Not present

Power factor correction capacitors

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

5 TECHNICAL CHARACTERISTICS

5.1 RATED TECHNICAL DATA OF HEAT PUMPS

* Weights refer to model with pump and storage reservoir

- Cooling capacity: outdoor air temperature 35°C, water temperature 12°C / 7°C

- Heating capacity: outdoor air temperature 7°C dry bulb and 6.2°C wet bulb, water temperature 40°C/45°C

- Sound power measured according to standards ISO 3741 - ISO 3744 and EN 29614-1

- Sound pressure measured at a distance of 10 m and a height of 1.5 m above the ground in a clear field (fan side).

- The maximum electrical input is the mains electricity that must be available in order for the unit to work.

- The maximum current absorption refers to the current that will trigger the internal safety devices of the unit. It is the maximum current allowed in the unit.

This value may never be exceeded; it must be used as a reference for determining the size of the power supply line and the related safety devices (refer to the

wiring diagram supplied with the units).

MXE

009 M 009 011 M 011 014 016 019 021

Pow er s upply V-ph-H z 230-1-50 400-3-50 230-1-50 400-3-50 400-3-50 400-3-50 400-3-50 400-3-50

Cooling capacity kW 7,33 7,46 9,34 9,34 12,20 14,40 16,05 18,50

Total power input

kW 2,83 2,71 3,58 3,38 4,30 5,24 5,54 6,21

EER 2,98 3,19 2,91 3,10 3,10 2,96 3,10 3,17

ESEER 3,92 3,62 3,73 3,31 3,77 3,59 3,67 3,79

Heating capacity kW 8,54 8,46 10,82 10,51 13,66 15,84 18,53 20,64

Total power input in hea ti ng mode kW 3,15 2,99 3,72 3,47 4,47 5,24 5,71 6,31

COP 3,07 3,21 3,23 3,39 3,33 3,25 3,47 3,47

Ma ximum power i nput A 22,3 9,3 26,3 11,3 13,3 16,3 19,6 20,0

Starting absorbed current A 84 37 98 50 66 72 77 103

n° of scroll compressor / circuits 1/1 1/1 1/1 1/1 1/1 1/1 1/1 1/1

Low/high pr essure switch bar 0,7 / 42 0,7 / 42 0,7 / 42 0,7 / 42 0,7 / 42 0,7 / 42 0,7 / 42 0,7 / 42

n° of axial fan 22222244

Air flow

m

3

/h

7.705 7.705 7.705 7.705 7.355 7.355 12.679 12.679

Water fl ow in cooling mode l/ h 1.261 1.283 1.606 1.606 2.098 2.477 2.761 3.182

Water fl ow in he at pum p l/ h 1.469 1.454 1.861 1.821 2.442 2.853 3.211 3.605

Di ame te r of hydrualic connections " 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/ 4 1 1/4

Avai l able pressure head (cooling) kP a 130 130 132 132 115 111 154 157

Avai l able pressure head (he ating) kPa 118 118 121 125 103 98 143 148

Expansion tank

dm

3

55555555

Buffer tank

dm

3

30 30 30 30 30 30 30 50

Height

mm 1250 1250 1250 1250 1250 1250 1275 1275

Length mm 1220 1220 1220 1220 1220 1220 1590 1590

Depth mm 550 550 550 550 550 550 600 600

Sound powe r lev el dB(A) 69 69 69 69 69 69 72 72

Sound pr ess ur e lev el dB(A) 41 41 41 41 41 41 44 44

Transport we ight * kg

212 212 215 215 219 220 273 273

Operating weight * kg

237,5 237,5 240,5 240,5 244,5 245,5 309,3 309,3

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

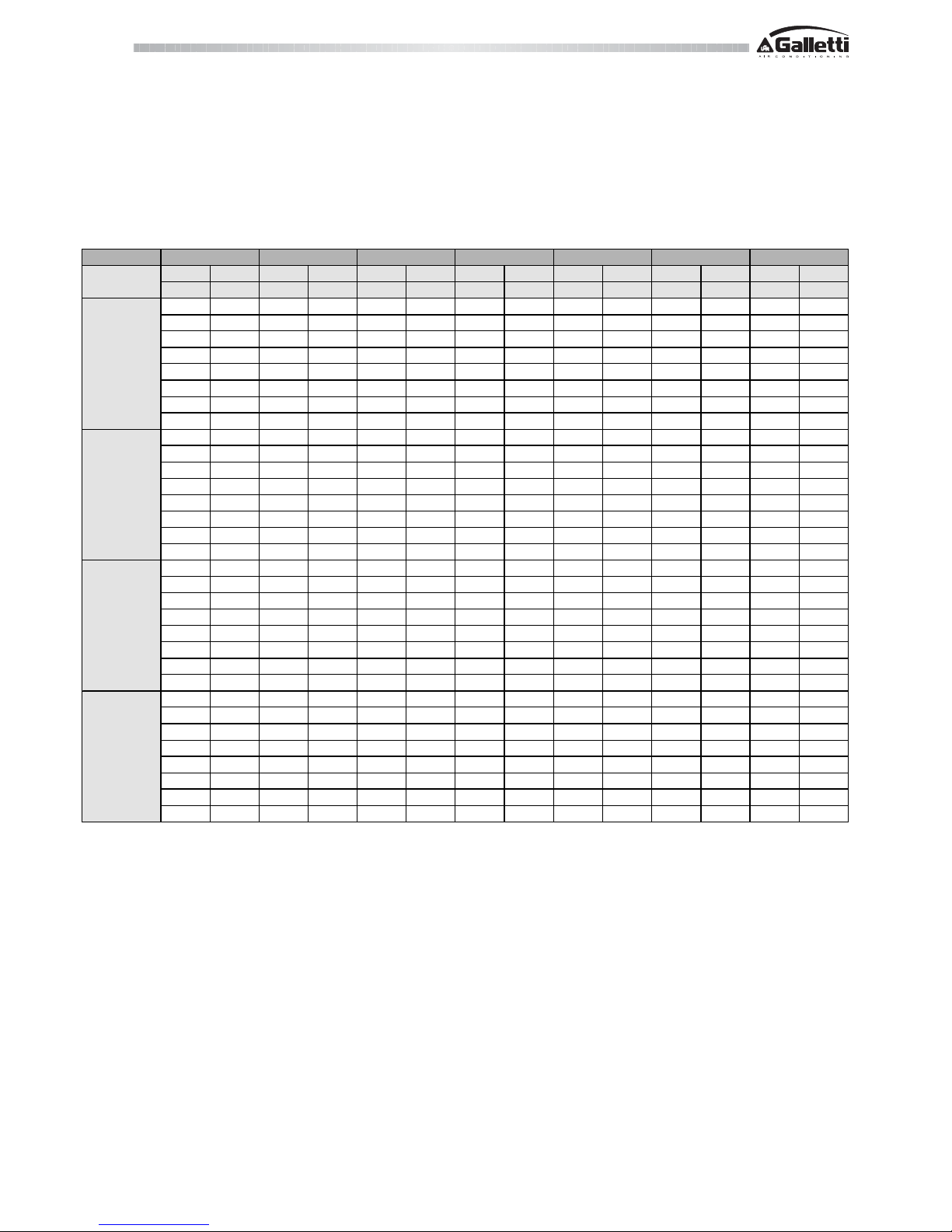

6 PERFORMANCE

6.1 MXE COOLING CAPACITIES

Tbs

1

Air inlet temperature (dry bulb)

Tw in/out Water inlet/outlet temperature

PF Cooling capacity

PA Total power input including pump

Tw inTw outPFPAPFPAPFPAPFPAPFPAPFPA

[°C] [°C] kW kW kW kW kW kW kW kW kW kW kW kW

10 5 8,1 2,15 7,8 2,29 7,32 2,53 6,84 2,82 6,34 3,15 5,82 3,52

11 6 8,4 2,15 8,1 2,30 7,57 2,54 7,08 2,82 6,56 3,15 6,02 3,53

12 7 8,7 2,14 8,3 2,30 7,8 2,54 7,32 2,82 6,79 3,15 6,23 3,53

13 8 9,0 2,13 8,6 2,30 8,1 2,54 7,57 2,83 7,02 3,16 6,44 3,54

14 9 9,3 2,13 8,9 2,31 8,4 2,55 7,8 2,83 7,25 3,17 6,66 3,54

15 10 9,7 2,12 9,2 2,31 8,6 2,55 8,1 2,84 7,49 3,17 6,88 3,55

16 11 10,0 2,12 9,5 2,32 8,9 2,56 8,3 2,85 7,74 3,18 7,11 3,55

17 12 10,3 2,12 9,8 2,32 9,2 2,57 8,6 2,86 7,99 3,19 7,34 3,56

10 5 8,6 2,08 8,2 2,21 7,62 2,43 7,03 2,70 6,40 3,01 5,74 3,36

11 6 8,8 2,07 8,4 2,21 7,85 2,44 7,24 2,70 6,60 3,01 5,93 3,36

12 7 9,1 2,06 8,7 2,21 8,1 2,44 7,45 2,70 6,81 3,01 6,12 3,36

13 8 9,4 2,06 8,9 2,22 8,3 2,44 7,67 2,71 7,01 3,02 6,31 3,37

14 9 9,6 2,05 9,1 2,22 8,5 2,45 7,9 2,71 7,20 3,02 6,50 3,37

15

10

9,9 2,04 9,3 2,22 8,7 2,45 8,1 2,72 7,40 3,03 6,69 3,37

16 11 10,2 2,04 9,6 2,23 8,9 2,46 8,3 2,73 7,59 3,03 6,87 3,38

17 12 10,4 2,04 9,8 2,24 9,2 2,47 8,5 2,73 7,78 3,04 7,05 3,38

10 5 10,5 2,81 9,9 3,05 9,3 3,34 8,7 3,69 8,00 4,10 7,31 4,57

11 6 10,8 2,82 10,2 3,06 9,6 3,36 9,0 3,71 8,27 4,12 7,55 4,59

12 7 11,2 2,83 10,6 3,07 9,9 3,37 9,3 3,73 8,5 4,14 7,80 4,62

13 8 11,6 2,84 10,9 3,08 10,3 3,39 9,6 3,75 8,8 4,16 8,05 4,64

14 9 11,9 2,85 11,3 3,10 10,6 3,40 9,9 3,76 9,1 4,19 8,30 4,67

15 10 12,3 2,86 11,6 3,11 10,9 3,42 10,2 3,78 9,4 4,21 8,56 4,69

16 11 12,7 2,87 12,0 3,12 11,3 3,43 10,5 3,80 9,7 4,23 8,8 4,72

17 12 13,1 2,88 12,4 3,14 11,6 3,45 10,8 3,82 10,0 4,26 9,1 4,75

10 5 10,6 2,52 10,0 2,76 9,4 3,04 8,7 3,36 8,0 3,72 7,3 4,12

11 6 11,0 2,53 10,3 2,77 9,7 3,05 9,0 3,38 8,3 3,74 7,6 4,14

12 7 11,3 2,54 10,7 2,78 10,0 3,07 9,3 3,39 8,6 3,76 7,8 4,16

13 8 11,7 2,55 11,0 2,80 10,3 3,08 9,6 3,41 8,8 3,78 8,1 4,19

14 9 12,0 2,56 11,4 2,81 10,6 3,10 9,9 3,43 9,1 3,80 8,3 4,21

15 10 12,4 2,57 11,7 2,82 11,0 3,12 10,2 3,45 9,4 3,82 8,6 4,23

16 11 12,8 2,58 12,1 2,84 11,3 3,13 10,5 3,47 9,7 3,84 8,9 4,25

17 12 13,2 2,59 12,4 2,85 11,7 3,15 10,8 3,49 10,0 3,86 9,1 4,28

45

MXE 009 M

MXE 009

MXE 011 M

Tbs

1

25 3020 35 40

MXE 011

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

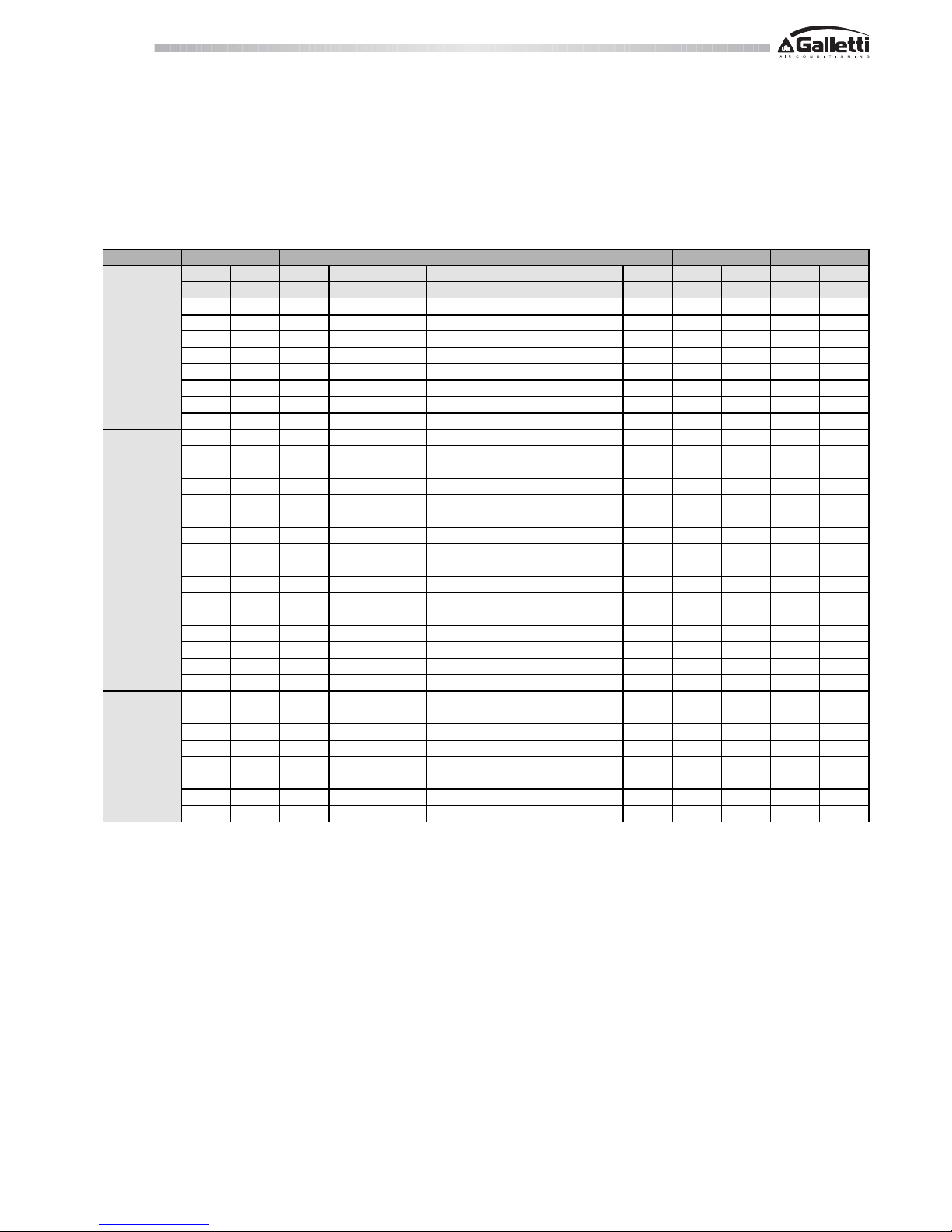

6 PERFORMANCE

6.1 MXE COOLING CAPACITIES

Tbs

1

Air inlet temperature (dry bulb)

Tw in/out Water inlet/outlet temperature

PF Cooling capacity

PA Total power input including pump

Tw inTw outPFPAPFPAPFPAPFPAPFPAPFPA

[°C] [°C] kW kW kW kW kW kW kW kW kW kW kW kW

10 5 13,6 3,12 13,0 3,43 12,2 3,81 11,4 4,27 10,5 4,81 9,6 5,43

11 6 14,1 3,13 13,4 3,44 12,6 3,83 11,8 4,29 10,9 4,83 9,9 5,45

12 7 14,5 3,14 13,8 3,46 13,0 3,85 12,1 4,32 11,2 4,86 10,2 5,47

13 8 15,0 3,16 14,2 3,48 13,4 3,88 12,5 4,34 11,6 4,88 10,5 5,49

14 9 15,4 3,17 14,7 3,50 13,8 3,90 12,9 4,37 11,9 4,91 10,9 5,51

15 10 15,9 3,19 15,1 3,53 14,2 3,93 13,3 4,40 12,3 4,93 11,2 5,54

16 11 16,4 3,21 15,5 3,55 14,6 3,96 13,7 4,43 12,6 4,96 11,6 5,56

17 12 16,9 3,23 16,0 3,58 15,0 3,99 14,1 4,46 13,0 5,00 11,9 5,59

10 5 16,4 3,82 15,5 4,19 14,5 4,63 13,5 5,12 12,4 5,67 11,2 6,28

11 6 16,9 3,84 16,0 4,22 15,0 4,66 13,9 5,16 12,8 5,71 11,6 6,33

12 7 17,5 3,87 16,5 4,26 15,5 4,70 14,4 5,20 13,2 5,75 12,0 6,37

13 8 18,0 3,90 17,0 4,29 16,0 4,73 14,8 5,24 13,6 5,80 12,4 6,42

14 9 18,5 3,93 17,5 4,32 16,4 4,77 15,3 5,28 14,1 5,84 12,8 6,46

15 10 19,1 3,97 18,1 4,36 16,9 4,81 15,7 5,32 14,5 5,89 13,2 6,51

16 11 19,7 4,00 18,6 4,40 17,4 4,85 16,2 5,36 14,9 5,93 13,6 6,56

17 12 20,2 4,04 19,1 4,44 17,9 4,89 16,7 5,41 15,4 5,98 14,0 6,61

10 5 17,9 4,20 17,1 4,53 16,1 4,96 15,0 5,46 14,0 6,03 12,8 6,67

11 6 18,5 4,21 17,6 4,55 16,6 4,99 15,5 5,49 14,4 6,06 13,3 6,71

12 7 19,2 4,22 18,2 4,58 17,1 5,01 16,0 5,52 14,9 6,10 13,7 6,75

13 8 19,8 4,24 18,8 4,61 17,7 5,04 16,6 5,55 15,4 6,14 14,1 6,79

14 9 20,4 4,27 19,4 4,63 18,3 5,07 17,1 5,59 15,9 6,17 14,6 6,83

15 10 21,1 4,29 20,0 4,66 18,8 5,11 17,6 5,62 16,3 6,21 15,0 6,87

16 11 21,7 4,32 20,6 4,69 19,4 5,14 18,2 5,66 16,9 6,25 15,5 6,92

17 12 22,4 4,35 21,2 4,73 20,0 5,17 18,7 5,70 17,4 6,29 15,9 6,96

10 5 20,8 4,57 19,7 4,99 18,6 5,49 17,4 6,08 16,1 6,74 14,8 7,5

11 6 21,5 4,60 20,4 5,03 19,2 5,53 17,9 6,12 16,6 6,79 15,3 7,5

12 7 22,2 4,64 21,0 5,07 19,8 5,58 18,5 6,17 17,2 6,84 15,8 7,6

13 8 22,9 4,68 21,7 5,11 20,4 5,62 19,1 6,21 17,7 6,9 16,3 7,6

14 9 23,6 4,72 22,4 5,15 21,1 5,67 19,7 6,26 18,3 6,9 16,8 7,7

15 10 24,3 4,76 23,1 5,20 21,8 5,71 20,4 6,31 18,9 7,0 17,4 7,7

16 11 25,1 4,81 23,8 5,24 22,4 5,76 21,0 6,36 19,5 7,0 17,9 7,8

17 12 25,8 4,86 24,5 5,29 23,1 5,81 21,7 6,41 20,1 7,1 18,5 7,9

MXE 019

MXE 021

MXE 014

MXE 016

Tbs

1

20 25 30 35 40 45

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

6 PERFORMANCE

6.2 MXE HEATING CAPACITIES

Tbs

1

Air inlet temperature (dry bulb)

Tw in/out Water inlet/outlet temperature

PT Heating capacity

PA Total power input including pump

RH Relative humidity

Tw inTw outPTPAPTPAPTPAPTPAPTPAPTPA

[°C] [°C] kW kW kW kW kW kW kW kW kW kW kW kW

25 30 3,65 2,45 5,62 2,37 7,43 2, 32 9,2 2,29 10,3 2,28 11,1 2,27

30 35 3,64 2,72 5,58 2,63 7,29 2, 57 8,9 2,53 10,0 2,51 10,8 2,50

35 40 3,65 3,02 5,57 2,93 7,18 2, 86 8,7 2,81 9,7 2,79 10,5 2,78

40 45 - - 5,58 3,28 7,08 3,20 8,5 3,14 9,5 3,12 10,1 3,10

4550------8,33,519,23,489,83,47

5055--------9,03,909,63,88

25 30 3,18 2,35 5,67 2,31 7,77 2, 25 9,5 2,21 10,5 2,19 11,1 2,18

30 35 3,11 2,60 5,49 2,55 7,49 2, 48 9,1 2,43 10,1 2,41 10,7 2,40

35 40 3,01 2,87 5,30 2,83 7,22 2, 75 8,8 2,69 9,7 2,67 10,3 2,66

40 45 - - 5,11 3,16 6,95 3,07 8,5 3,00 9,3 2,97 9,9 2,96

4550------8,13,368,93,329,53,30

5055--------8,63,709,03,67

25 30 4,62 2,92 7,15 2,89 9,50 2, 88 11,8 2,88 13,3 2, 88 14,3 2,87

30 35 4,59 3,21 7,05 3,16 9,29 3, 15 11,5 3,14 12,9 3, 13 13,9 3,13

35 40 4,50 3,47 6,96 3,47 9,11 3, 46 11,2 3,45 12,5 3, 45 13,4 3,44

40 45 - - 6,89 3,81 8,95 3,82 10,9 3,82 12,1 3, 82 13,0 3,81

4550------10,64,2511,84,2412,64,24

5055--------11,44,7312,24,73

25 30 4,46 2,54 6,96 2,61 9,29 2, 61 11,6 2,60 13,0 2, 59 14,0 2,58

30 35 4,35 2,78 6,81 2,86 9,04 2, 86 11,2 2,85 12,6 2, 84 13,5 2,84

35 40 4,34 3,04 6,70 3,13 8,80 3, 14 10,9 3,14 12,1 3, 14 13,1 3,14

40 45 - - 6,62 3,45 8,59 3,47 10,5 3,47 11,7 3, 47 12,6 3,47

4550------10,23,8511,33,8512,23,85

5055--------11,04,2611,74,26

25 30 5,94 3,23 9,12 3,26 11,94 3,24 14,7 3,23 16,4 3, 23 17,6 3,24

30 35 5,91 3,63 9,04 3,64 11,74 3,59 14,3 3,57 16,0 3, 57 17,1 3,59

35 40 6,03 4,07 8,99 4,09 11,54 4,03 14,0 3,99 15,5 3, 99 16,7 4,00

40 45 - - 8,97 4,61 11,34 4,54 13,7 4,48 15,1 4,47 16,2 4,48

4550------13,35,0614,75,0315,75,02

5055--------14,35,6615,25,63

25 30 6,83 3,70 10,58 3,83 14,03 3,89 17,4 3,93 19,5 3,96 21,0 3,99

30 35 6,77 4,11 10,35 4,22 13,70 4,28 16,9 4,32 19,0 4,36 20,4 4,38

35 40 6,62 4,53 10,11 4,66 13,36 4,73 16,5 4,78 18,4 4,81 19,8 4,83

40 45 - - 9,86 5,14 13,02 5,23 16,0 5,29 17,9 5,32 19,2 5,35

4550------15,55,8617,35,9018,55,9

5055--------16,76,5317,96,6

25

30 7,96 4, 23 12,47 4,31 16,53 4, 37 20,4 4,43 23,0 4,48 24,8 4,51

30 35 7,83 4,62 12,26 4,73 16,14 4,79 19,8 4,84 22,3 4,88 24,0 4,92

35 40 7,74 5,03 12,06 5,19 15,75 5,26 19,3 5,33 21,6 5,37 23,2 5,40

40 45 - - 11,86 5,70 15,38 5,80 18,7 5, 9 20,9 5,9 22,4 6, 0

4550------18,16,520,26,621,66,6

5055--------19,57,320,87,3

25 30 8,00 4,36 13,60 4,53 18,17 4,63 22,6 4,74 25,3 4,8 27,4 4,9

30 35 7,95 4,86 13,30 5,02 17,68 5,11 21,9 5,2 24,6 5,3 26,5 5, 3

35 40 7,90 5,38 13,05 5,56 17,23 5,65 21,3 5,7 23,8 5,8 25,7 5, 9

40 45 - - 12,83 6,16 16,82 6,28 20,6 6, 4 23,1 6,4 24,8 6, 5

4550------20,07,122,37,124,07,2

5055--------21,67,923,27,9

MXE 009

MXE 011 M

MXE 019

MXE 016

MXE 014

MXE 011

20°C / 70 %7 °C / 88 % 15 °C / 80 %

MXE 021

Tbs

1

/ RH -5 °C / 90 % 0 °C / 90 %-10 °C

MXE 009 M

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

6 PERFORMANCE

6.3 INTEGRATED CAPACITIES

In the heat pump operation (heating mode), the actual heating capacities of units may be lower than the values shown in the table, due to defrosting

cycles. To obtain the actual heating capacity, multiply the capacity values by the corrective coefficients given below.

7 SOUND LEVEL

LEGEND:

LpATotal sound pressure level, weighted A, measured in an open field, at a distance of 10 m, with a directivity factor of 2.

Lw Sound power level by octave band, not weighted

LwATotal sound power level, weighted A

-5 0 5 >5

P

chiller2 0,91 0,9 0,95 1

PCO XS 0,92 0,97 0,95 1

Control

Air temperature dry bulb (°C)

Lw

A

Lp

A

125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz Total Total

dB dB dB dB dB dB dB dB (A) dB (A)

MXE 009M 74,8 68,5 67,9 63,8 56,6 51,6 47,8 69 41

MXE 009 74,8 68,5 67,9 63,8 56,6 51,6 47,8 69 41

MXE 011M 74,8 68,5 67,9 63,8 56,6 51,6 47,8 69 41

MXE 011 74,8 68,5 67,9 63,8 56,6 51,6 47,8 69 41

MXE 014 75,3 69,0 68,4 64,3 57,1 52,1 48,3 69 41

MXE 016 75,3 69,0 68,4 64,3 57,1 52,1 48,3 69 41

MXE 019 77,8 71,5 70,9 66,8 59,6 54,6 50,8 72 44

MXE 021 78,3 72,0 71,4 67,3 60,1 55,1 51,3 72 44

Model

Lw

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

8 OPERATING LIMITS

The graphs below illustrate the operating limits of MXE (in the case of continuous operation) in relation to the outlet water temperature and outdoor air temperature.

1 For transitory periods (e.g. equipment start up) values up to 25 °C are allowed

2 Value that may be reached only for outdoor air temperatures exceeding 0°C.

3 With condensation control: outdoor air T min - 15°C

Warning!

The units are designed to work with water and air temperatures falling within the range defined by the operating limits.

Attempting to operate the units beyond these limits could cause irreparable damage to the units themselves.

8.1 OPERATING LIMITS IN CHILLER MODE

TBS1Outdoor temperature (dry bulb)

Tw

2

Outlet water temperature

OPERATING LIMITS CHILLER HEAT PUMP

MIN MAX MIN MAX

Inlet water temperature (°C) 12 24 39 51

Outlet water temperature (°C) 7 19 27 57

Thermal differential of water (°C) 5836

Outdoor air temperature (°C) -10 48 -15 22

-15

-10

-5

0

5

10

15

20

25

30

35

40

45

50

6 8 10 12 14 16 18 20

TW2 (°C)

Tbs

1

(°C)

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

6.3 THERMAL CARRIER FLUID

The units belonging to the MxE series can work with mixtures of water and up

to 30% ethylene glycol.

9 CALCULATION FACTORS

9.1 CHANGE IN OPERATING PARAMETERS WITH ΔT OTHER THAN

5°C

After identifying the unit’s per formance in the terms of the desired outlet water

temperature, correct the value by multiplying it by the following corrective

coefficients.

DT

W

C

PF/PT

C

PA

C

Qw

C

Dpw1

3 0,975 1 1,63 2,64

4 0,99 1 1,24 1,53

51111

6 1,015 1 0,85 0,72

7 1,03 1 0,74 0,54

8 1,04 1 0,65 0,42

LEGEND

DTWDifference between water inlet temperature and water outlet temperature

C

PF/PT

Corrective coefficient of cooling/heating capacity

C

PA

Correction coefficient of electrical input

C

Qw

Correction coefficient of water flow rate

C

Dpw1

Correction coefficient of pressure drop

8 OPERATING LIMITS

8.2 OPERATING LIMITS IN HEAT PUMP MODE

TBS1Outdoor temperature (dry bulb)

Tw

2

Outlet water temperature

9.2 WATER AND GLYCOL MIXTURE

Based on the minimum outlet water temperature, you can derive the percentage

of ethylene glycol and the corrective coefficient using the table below.

Percentage of ethylene glycol 0% 10% 20% 30 % 40%

Minimum temp. of water produced 5°C 2°C -5°C -10°C -15°C

Mixture freezing temp. (°C) 0°C -4°C -14°C -18°C -24°C

Capacity correction factor 1,000 0,998 0,994 0,989 0,983

Water flow rate correction factor 1,000 1,047 1,094 1,140 1,199

Pressure drop correction factor 1,000 1,157 1,352 1,585 1,860

WARNING:

The use of propylene glycol is not admitted with standard pumps.

For further information, contact the manufacturer.

20

25

30

35

40

45

50

55

60

-20-15-10-5 0 5 10152025

Tbs1 (°C)

TW

2

(°C)

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

10 PRESSURE DROPS

The diagram shows the evaporator pressure drops (Dp) as a function of the

water flow rate (Qw), assuming an average water temperature of 10°C.

10.1 PRESSURE DROPS ON THE WATER SIDE

10.2 PRESSURE DROPS OF Y FILTER

The diagram shows the Y filter pressure drops (Dp) as a function of the water

flow rate (Qw), assuming an average water temperature of 10°C.

MXE 09 ÷ 21

MXE 09 ÷ 21

4Z>OK@

'

S>N3D@

0;(

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

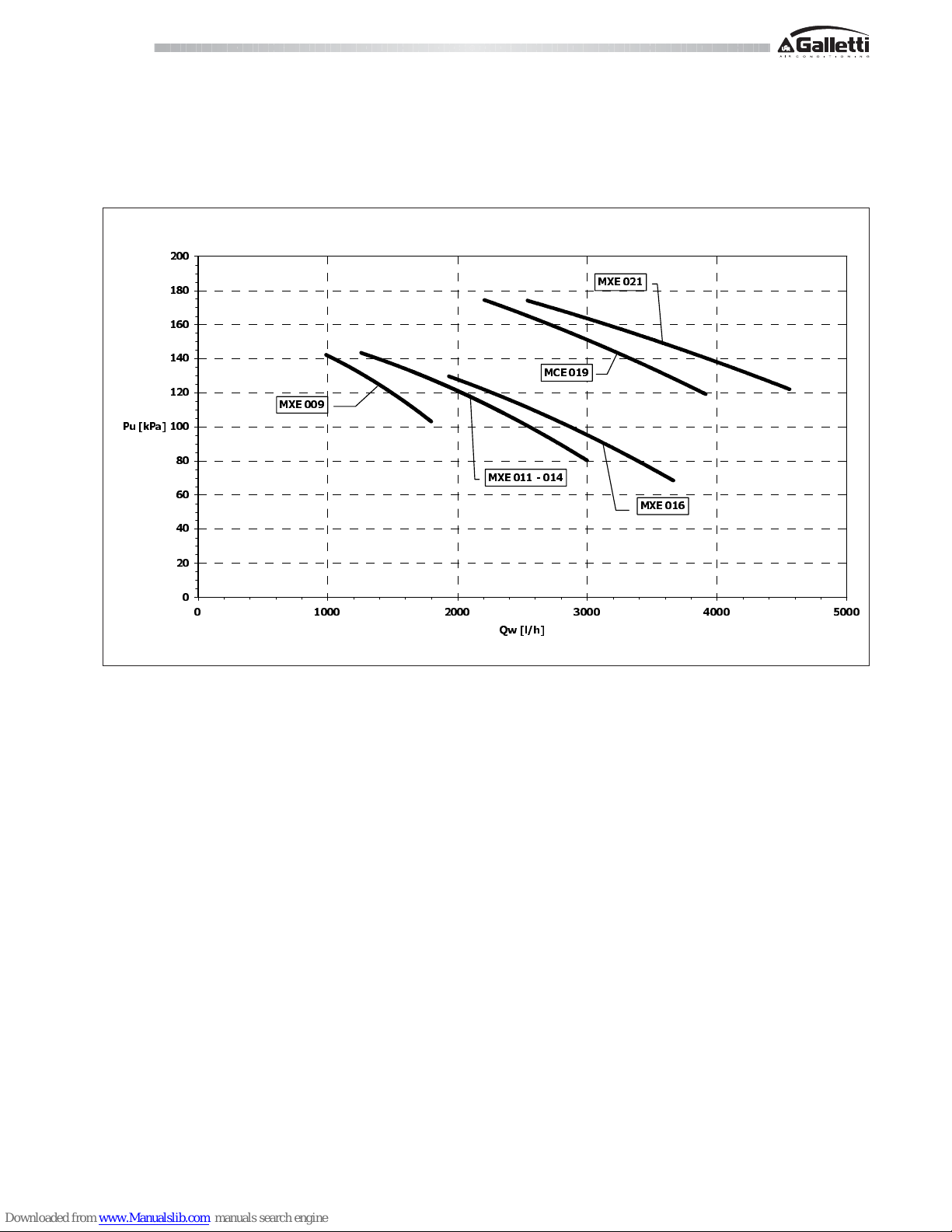

11 AVAILABLE HEAD OF THE UNIT

The diagram below shows the available head (Pu) of the unit as a function of

the water flow rate (Qw), assuming an average water temperature of 10°C, net

of pressure drops.

Pressure drops of the Y filter are not counted.

MXE 09 ÷ 21

4Z>OK@

3X>N3D@

0&(

0;(

0;(

0;(

0;(

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

12 WATER CIRCUIT

When setting up the water circuit of the unit, it is advisable to follow the directions

below and in any case comply with local or national regulations.

Connect the pipes to the chiller using flexible couplings to prevent the

transmission of vibrations and to compensate thermal expansions.

It is recommended to install the following components on the pipes:

- Temperature and pressure indicators for routine maintenance and monitoring of the unit. Checking the pressure on the water side will enable you to

verify whether the expansion tank is working efficiently and to promptly detect

any water leaks within the equipment.

- Traps on incoming and outgoing pipes for temperature measurements,

which can provide a direct reading of the operating temperatures.

- Regulating valves (gate valves) for isolating the unit from the water circuit.

- Metal mesh filter (supplied), with a mesh size no greater than 1 mm,

to be fitted on the inlet pipe to protect the exchanger from scale or

impurities present in the pipes.

- Air vent valves, to be placed at the highest points of the water circuit for the

purpose of bleeding air. (The internal pipes of the unit are fitted with small

air vent valves for bleeding the unit itself: this operation may only be carried

out when the unit is disconnected from the power supply).

- Drainage valve and, where necessary, a drainage tank for emptying out the

equipment for maintenance purposes or when the unit is taken out of service

at the end of the season. (A 1” drainage valve is provided on the optional

water buffer tank: this operation may only be carried out when the unit is

disconnected from the power supply).

It is of fundamental importance that the incoming water supply is hooked up

to the connection marked “Water Inlet”.

Otherwise the evaporator would be exposed to the risk of freezing since the

antifreeze thermostat would not be able to perform its function; moreover the

reverse cycle would not be respected in the cooling mode, resulting in additional

risks of malfunctioning.

The dimensions and position of plumbing connections are shown in the

dimension tables at the end of the manual.

The water circuit must be set up in such a way as to guarantee that the nominal

flow rate of the water supplied to the evaporator remains constant (+/- 15%)

in all operating conditions.

A standard feature of MXE units is a device for controlling the flow rate (flow

switch or differential pressure switch) in the water circuit in the immediate

vicinity of the evaporator.

12.1 SYSTEM WATER CONTENT AND CHARGING OF

EXPANSION TANK

In models without a water storage tank it is necessary to assure that the content

of water within the system does not fall below 4.5 litres/kW. This level is

necessary to prevent the water temperature from falling below the indoor unit

enabling threshold during defrost cycles.

N.B kW in reference to rated capacity

The expansion tank is pre-charged to a pressure of 1.5 bars, sufficient for

systems with a maximum height difference (H in the figure at the side) of 13

metres.

For greater height differences, refer to the table below in order to adjust the

charging pressure of the expansion tank accordingly.

In no case should you exceed the maximum height difference Hmax = 35 m.

Hmax=35 m

LEGEND

H Height difference of system

p

i

Charging pressure of expansion tank

C

max

Maximum system water content

Models

H

(m)

p

i

(bar)

C

max

(l)

<13 1,5 145

15 1,7 133

20 2,2 105

25 2,7 77

30 3,1 49

MXE 009-021

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

12 WATER CIRCUIT

MXE (EVAPORATOR AND PUMP)

PLUMBING DIAGRAMS

MXE (EVAPORATOR, PUMP AND TANK)

OPZIONALE

OPTIONAL

OPZIONALE

OPTIONAL

LEGEND

VS Safety valve

EV Evaporator

PD Differential pressure switch

MA Water pressure gauge

VAS Air vent valve

SA Buffer tank

VE Expansion tank

P Pump

RS Drainage valve

RC Water filling cock

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

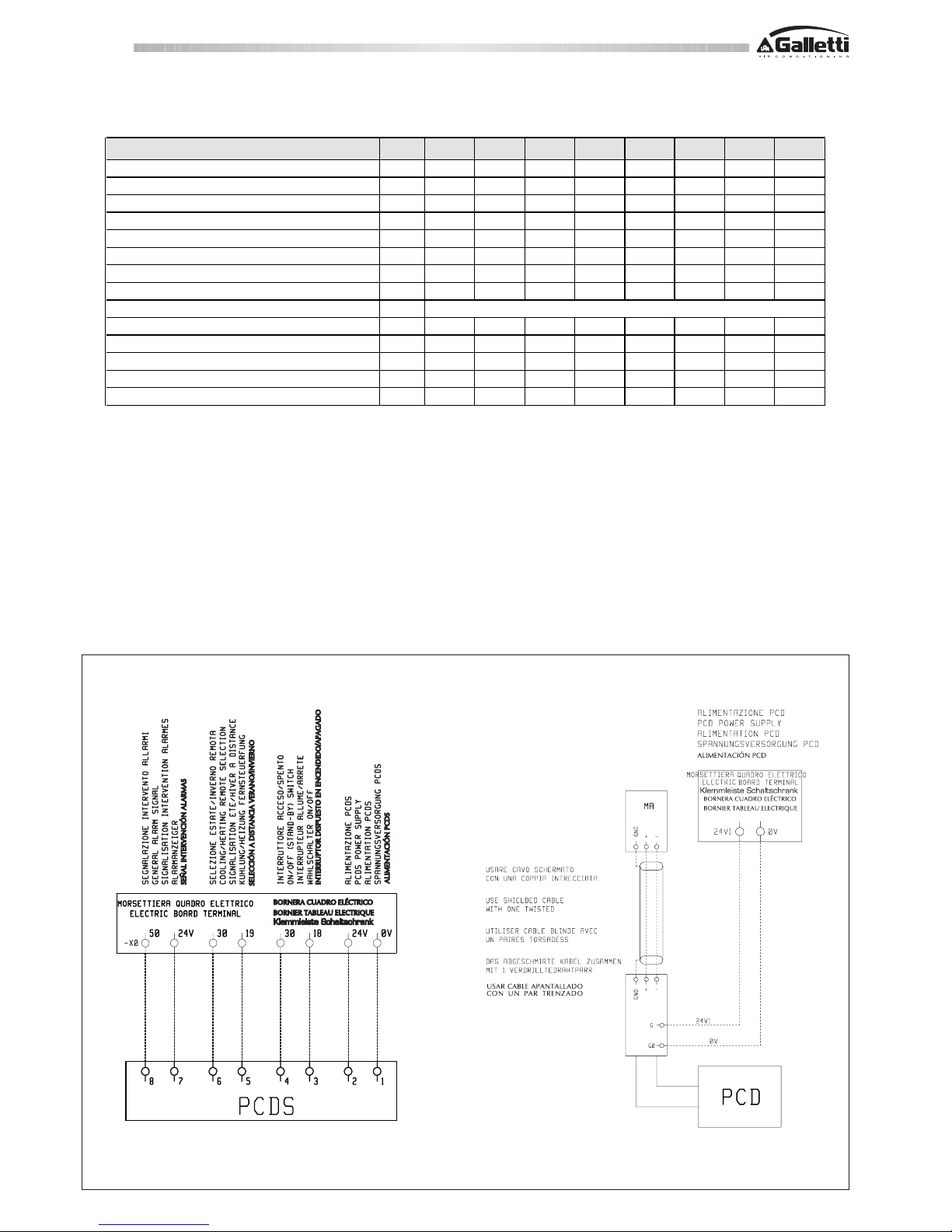

13 ELECTRICAL DATA AND CONNECTIONS

- The maximum electrical input is the mains electricity that must be available in order for the unit to work.

- The maximum current absorption refers to the current that will trigger the internal safety devices of the unit.

It is the maximum current allowed in the unit. This value may never be exceeded; it must be used as a reference for determining the size of the power supply

line and the related safety devices (refer to the wiring diagram supplied with the units).

Cross-section area of cables: 4 A/mm2 approx.

DIAGRAM SHOWING ELECTRICAL CONNECTIONS BETWEEN MXE AND PCDS / PCD REMOTE CONTROL PANEL

Use cabo blindado com

um par trançado

Alimentação PCD

Placa de bornes do quadro eléctrico

Sinalização intervenção alarmes

Selecção verão/inverno remota

Interruptor aceso/apagado

Alimentação PCDS

Note: Should the unit go into an alarm status, a voltage of 24V will be present

on the terminals of the electric control panel; where an interface with a voltagefree contact is desired, a relay must be fitted by the installer.

MXE

009 M 009 011 M 011 014 016 019 021

Maximum power input kW

4,0 3,9 4,9 4,6 6,0 6,6 7,3 8,2

Maximum current absorption A

22,0 9,0 26,0 11,0 13,0 16,0 20,0 21,0

Starting absorbed current A

84 37 99 50 66 72 77 103

Fan motor rated power kW

0,14 0,14 0,14 0,14 0,14 0,14 0,14 0,14

Fan motor rated current A

0,6 0,6 0,6 0,6 0,6 0,6 0,6 0,6

Pump motor rated power kW

22222222

Pump motor rated current A

230-1-50 400-3N -50 230-1-50 400-3N-50 400-3N -50 400-3N -50 400-3N-50 400-3N-50

Power supply V/f/Hz

230-1-50 400-3N -50 230-1-50 400-3N-50 400-3N -50 400-3N -50 400-3N-50 400-3N-50

Auxiliary powe r supply V/f/Hz

Power cables

mm

2

64644466

PCD connecting cables

mm

2

AWG22 AWG22 AWG22 AWG22 AWG22 AWG22 AWG22 AWG22

PCDS connecting cables

mm

2

11111111

Safety fuse F A

25 16 32 16 20 20 25 25

Circuit breaker IL A

25 16 32 16 20 20 25 25

230-1-50

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

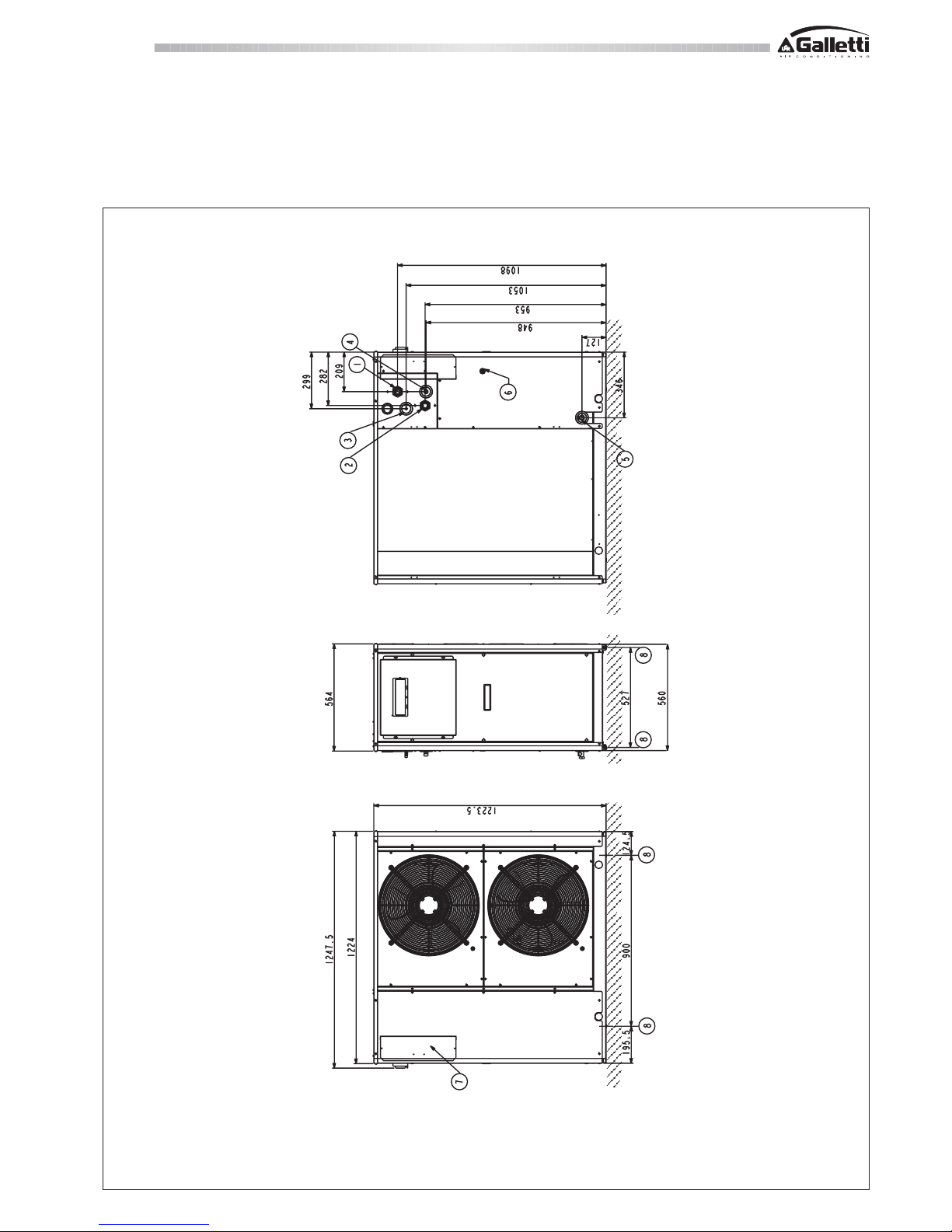

14 OVERALL DIMENSIONS MXE 09 ÷ 16

Legend:

1 Water inlet 1" ¼ female

2 Water outlet 1" ¼ female

3 Safety valve discharge outlet provided with rubber ring holder

4 Water supply ½” male (optional tap)

5 Water drainage ½” female

6 Power supply Ø 28 mm

7 Electric control board

8 Fastening points for vibration dampers (accessory)

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

14 OVERALL DIMENSIONS MXE 19 ÷ 21

Legend:

1 Water inlet 1" ¼ female

2 Water outlet 1" ¼ female

3 Safety valve discharge outlet provided with rubber ring holder

4 Water supply ½” male (optional tap)

5 Water drainage ½” female

6 Power supply Ø 28 mm

7 Electric control board

8 Fastening points for vibration dampers (accessory)

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

15 INSTALLATION CLEARANCE REQUIREMENTS

To guarantee the proper functioning of the unit and access for maintenance

purposes, it is necessary to comply with the minimum installation clearance

requirements shown in figures 1 and 2.

There must be no obstacles blocking the path of the air flow from the fans.

Avoid any and all situations of backflow of hot air between air outlet and inlet

of the unit.

If even only one of the above conditions is not fulfilled, please contact the

manufacturer to check for feasibility.

1

MXE 09 ÷ 16

In the design of the MXE series, special care has been taken to minimise noise

and vibrations transmitted to the ground.

Even greater insulation may be obtained, however, by using vibration damping

base supports (available as optional accessories).

If vibration damping base supports are adopted, it is strongly recommended

also to use vibration damping couplings on the water pipes.

Whenever the unit is to be sited on unstable ground (various types of soil,

gardens, etc.) it is a good idea to provide a supporting base of adequate

dimensions.

Warning:

heat pump units produce condensation while operating

in the heating mode.

QUADRO ELETTRICO

ELECTRICAL BOX

LATO BATTERIA

EXCHANGER SIDE

LATO ATTACCHI IDRAULICI BATTERIA

HEAT EXCHANGER WATER CONNECTION SIDE

1 m

1,5 m

1,5 m

MXE 19 ÷ 21

LATO ATTACCHI IDRAULICI BATTERIA

HEAT EXCHANGER WATER CONNECTION SIDE

QUADRO ELETTRICO

ELECTRICAL BOX

LATO BATTERIA

EXCHANGER SIDE

1 m

1,5 m

1,5 m

2

RG66004088 - Rev 00

MXE

All copying, even partial, of this manual is strictly forbidden.

16 SITING

It is important to bear in mind the following aspects when choosing the best

site for installing the unit:

- size and origin of water pipes;

- location of the power supply;

- solidity of the supporting surface;

- avoid obstacles to the outflow of air from the fan which could cause back

suction (see section on “installation clearance requirements”);

- direction of prevalent winds: (position the unit so that prevalent winds do

not alter the fan air flow).

A prevalent wind blowing from a direction opposite to the fan air flow will

reduce the maximum air temperature to a lower value than specified in the

operating limits,

a wind blowing in the same direction as the fan air flow will increase the minimum

air temperature to a higher value than specified in the operating limits.

Also in the heat pump mode, wind may have the effect of reducing the unit’s

operating range.

- avoid the possible reverberation of sound waves (do not install the unit in

narrow or cramped spaces).

- ensure adequate accessibility for maintenance or repairs (see section on

“installation clearance requirements”).

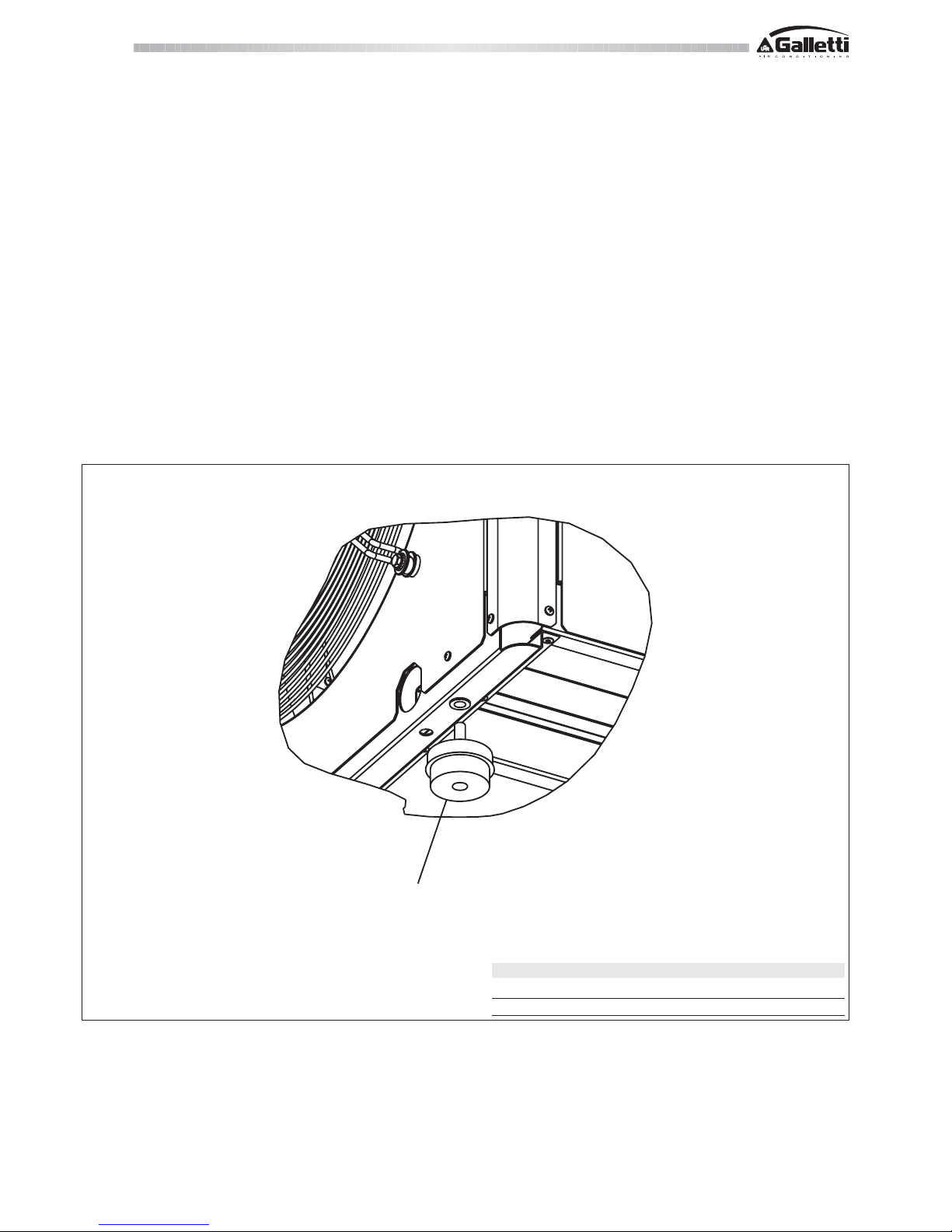

16.1 POSITIONING OF VIBRATION DAMPERS (ACCESSORY)

Dampers

MXE CODE NO. OF VIBRATION DAMPERS

09 -16 RYPAMCA10 4

19 - 21 RYPAMCA10 4

RG66004088 - Rev 00

All copying, even partial, of this manual is strictly forbidden.

MXE

Loading...

Loading...