Installation Note

Gallagher T12 Reader

This equipment contains components that can be damaged by electrostatic

discharge. Ensure both you and the equipment are earthed before beginning

any servicing.

Gallagher T12 Multi Tech Readers only: Using dual technology 125/Mifare

cards with Gallagher T12 Multi Tech Readers may cause both card technologies

to be read, resulting in double card badges and unusual reader feedback.

Gallagher strongly recommends against using dual technology 125/Mifare

cards with Gallagher Multi Tech Readers for sites running pre-Command Centre

v7.00 software (due for release 2nd half, 2011). From Command Centre

v7.00, a site may specify which technology a Multi Tech reader should read

off a dual technology card.

Installation Note | Gallagher T12 Reader

The Gallagher T12 Reader

The Gallagher T12 Reader is a smart card proximity reader. It can be installed

as either an entry reader or exit reader. It can be mounted on a BS 4662 British

Standard square flush box.

The reader can read Mifare DESFire EV1, Mifare Plus and Mifare Classic cards.

The Multi Tech variant can also read 125Khz cards.

R5 | Part Number: 3E2512 | 1

Installation Note | Gallagher T12 Reader

The reader sends information to the Cardax FT Controller and acts upon information

sent from the Cardax FT Controller. The reader itself does not make any access

decisions.

The Gallagher T12 Reader uses the “Cardax IV Reader” communications protocol

to communicate with the Cardax FT Controller.

Before you begin

Shipment Contents

Check the shipment contains the following items:

1 x Gallagher T12 Reader facia assembly•

1 x Gallagher T12 Reader base•

1 x M3 Torx Post Security screw•

2 x M3.5 Phillips drive fixing screws•

Power Supply

The Gallagher T12 Reader is designed to operate over a supply voltage range of

9 - 16Vdc measured at the reader terminals. The operating current draw is dependant

on the supply voltage at the reader. For the Standard variant at 12Vdc the current

draw is 89mA (standby). During card read, beeper and LED activity, the current will

momentarily reach 124mA (peak). For the Multi Tech variant at 12Vdc the current

draw is 88mA (standby) and will momentarily reach 140mA (peak).

The power source should be linear or a good quality switched-mode power supply. The

performance of the reader may be affected by a low quality, noisy power supply.

Cabling

The Gallagher T12 Reader requires a minimum cable size of 4 core 24 AWG

(0.2mm

and power (2 wires). When using a single cable to carry both power supply and

data, both the power supply voltage drop and data requirements must be considered.

Although the reader is specified to operate at 9Vdc, for good engineering design it

is recommended that the voltage at the reader should be approximately 12Vdc.

4 x 25mm No.6 self tapping, pan head, Phillips drive fixing screws•

4 x 40mm No.6 self tapping, pan head, Phillips drive fixing screws•

2

) stranded security cable. This cable allows the transmission of data (2 wires)

Examples of approved cables for connecting a single Gallagher T12 Reader to a

Controller and power supply, showing maximum cable lengths for each type of cable

and the associated circuits are:

2 | Part Number: 3E2512 | R5

Manufacturer

reference Cable format*

Installation Note | Gallagher T12 Reader

Combined

power and data

in a single cable

Data only in a

single cable

CAT5E 4 twisted pair

2

Each 2 x 0.2mm

SEC472 4 x 0.2mm

2

(24 AWG)

Not twisted pairs (24 AWG)

SEC4142 4 x 0.4mm

2

Not twisted pairs (21 AWG)

BELDEN 8723 2 twisted pair

2

Each 2 x 0.4mm

(22 AWG)

BELDEN 9842 2 twisted pair

2

Each 2 x 0.2mm

(24 AWG)

* The matching of wire sizes to equivalent wire gauges are only approximate.

Note: Grounding shielded cable may reduce the obtainable cable length by 25%

to 30%.

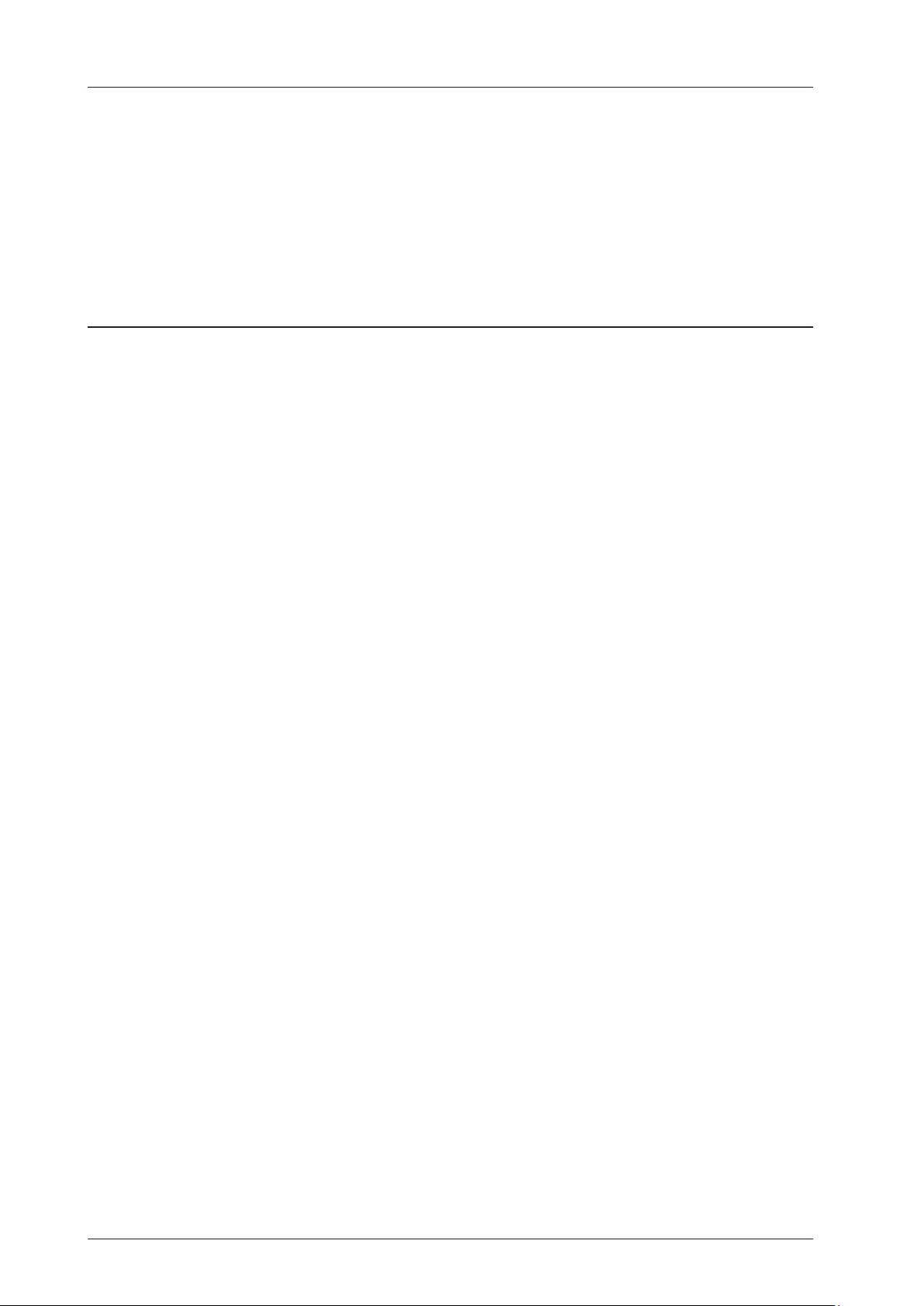

Distance between Proximity Readers

The distance separating any two proximity readers must not be less than 200mm

(8 inches) in all directions.

100m (330ft) 300m (1000ft)

100m (330ft) 250m (800ft)

150m (500ft) 150m (500ft)

100m (330ft) 150m (500ft)

100m (330ft) 200m (650ft)

200mm

When mounting a proximity reader on an internal wall, check that any reader fixed

to the other side of the wall is not less than 200mm (8 inches) away.

200mm

R5 | Part Number: 3E2512 | 3

Installation Note | Gallagher T12 Reader

Installation

The Gallagher T12 Reader is designed to be mounted on a standard British electrical

flush box, or any solid flat surface. However installation on metal surfaces, particularly

those with a large surface area will reduce read range. The extent to which the range

is reduced will depend upon the type of metal used.

The recommended mounting height for the reader is 1.1m (3.6ft) from the floor level

to the centre of the reader device. However this may vary in some countries and you

should check local regulations for variations to this height.

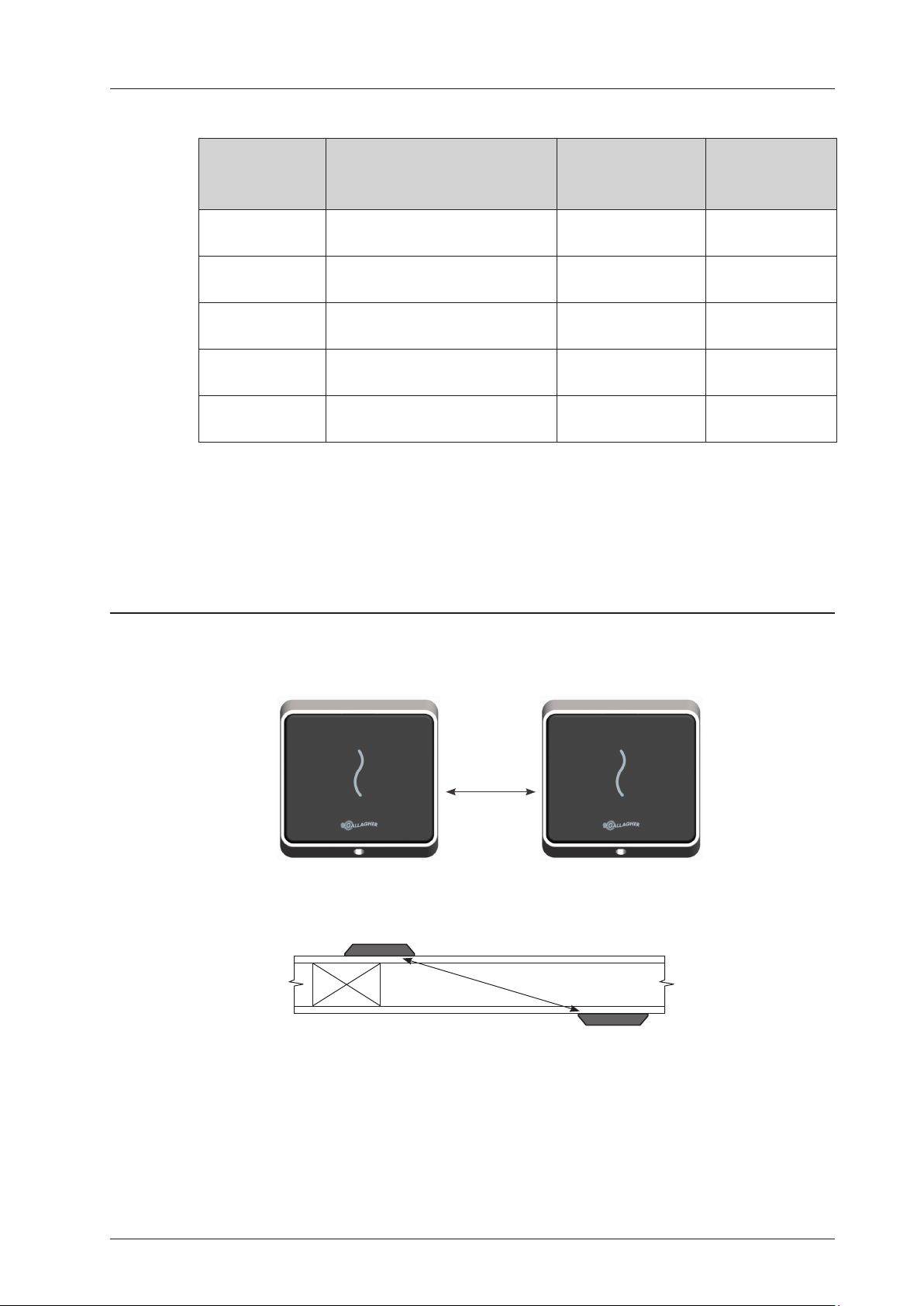

Ensure the building cable has been run out through the flush box.1.

If you are not mounting to a flush box, use the drill template at the back of this

installation note as a guide, to drill all five holes. Drill the 13mm (1/2 inch)

diameter centre hole (this is the centre hole for which the building cable will

exit the mounting surface) and the four fixing holes.

Run the building cabling through the reader base.2.

Secure the base to the flush box using the two M3.5 screws provided. It is 3.

important the base of the reader is flush with and tight against the mounting

surface.

If you are not mounting to a flush box, secure the base to the mounting surface

using the four fixing screws provided.

Base

Building

cable

M3.5 screw

M3.5 screw

Connect the reader tail extending from the facia assembly to the building cable. 4.

Connect the wires shown below.

Note: Do not cut the ‘Reserved’ wires, as these may be used for future functions.

4 | Part Number: 3E2512 | R5

Installation Note | Gallagher T12 Reader

Positive Red

Negative Black

Reserved Orange

Reserved Green

Reserved Brown

CDXIV TX White

Cardax IV Reader

CDXIV RX Blue

Fit the facia assembly into the base by clipping the small lip, into the top of 5.

the base and holding the top, press the bottom of the facia assembly down

into the base.

Insert the M3 Torx Post Security screw (using a T10 Torx Post Security screwdriver) 6.

through the hole at the bottom of the base to secure the facia assembly.

Note: The recommended torque for the security screw is 0.7Nm (0.5 lb/ft). It

is important not to exceed the maximum torque of 1.5Nm (1.1 lb/ft).

Facia

Connections

A Gallagher T12 Reader can connect to one of the following devices using the

“Cardax IV Reader” communications protocol:

Reader tail

Connection

Fit screw to secure

facia to base

Removal of the facia assembly is a simple reversal of these steps.7.

Cardax FT Reader Module (for the Controller 6000)•

Cardax FT GBUS Universal Reader Interface (Cardax FT GBUS URI)•

Cardax FT Controller 3000-4R or 3000-8R•

Cardax FT Universal Reader Interface (Cardax FT URI)•

Cardax FT Reader I/O Interface•

R5 | Part Number: 3E2512 | 5

Installation Note | Gallagher T12 Reader

Connecting to the Cardax FT Reader Module (for the Controller 6000)

Connect the wires to the sockets as shown:

Positive Red

Negative Black

Reserved Orange

Reserved Green

Reserved Brown

Cardax IV Reader 2

Cardax IV Reader 1

CDXIV TX White

CDXIV RX Blue

Positive Red

Negative Black

Reserved Orange

Reserved Green

Reserved Brown

CDXIV TX White

CDXIV RX Blue

-

+

R1 Out

R1 In

R2 Out

R2 In

C12

Cardax FT Reader Module

Connecting to the Cardax FT GBUS Universal Reader Interface

Connect the wires to the sockets as shown in either of the following diagrams:

Pin 15

RLY 2 COM

RLY 2 NO

Cardax FT GBUS URI

Reader

RLY 2 NC

DATA 0

DATA 1

OUT 1

OUT 2

Top Row

Pin 1

COM A

COM B

TAMPER

GND

VOUT

GND

VIN

GND

Pin 15

RLY 2 COM

RLY 2 NO

Cardax FT GBUS URI

Reader

RLY 2 NC

DATA 0

DATA 1

3

OUT 1

C45

OUT 2

6

Top Row

Pin 1

COM A

COM B

TAMPER

GND

VOUT

GND

VIN

GND

6 | Part Number: 3E2512 | R5

Positive Red

Negative Black

Reserved Orange

Reserved Green

Cardax IV Reader

Reserved Brown

CDXIV TX White

CDXIV RX Blue

Positive Red

Negative Black

Reserved Orange

Reserved Green

Cardax IV Reader

Reserved Brown

CDXIV TX White

CDXIV RX Blue

Installation Note | Gallagher T12 Reader

Connecting to the Cardax FT Controller 3000-4R or 3000-8R

The ports to which the Gallagher T12 Reader can connect are set up as groups, as

follows:

Two groups (numbered 1 and 2) on the Controller 3000-4R, and•

Four groups (numbered 1 to 4) on the Controller 3000-8R•

Each group provides connection for two Gallagher T12 Readers. Refer to the following

diagram for the location of the ports on the Cardax FT Controller 3000-8R.

R5 | Part Number: 3E2512 | 7

Installation Note | Gallagher T12 Reader

Make the connections from the Gallagher T12 Reader to either the Cardax FT

Controller 3000-4R or 3000-8R as shown:

Cardax FT Controller 3000-4R or 3000-8R

Group

PB1 and PA1... to... PB2 and PA2 (3000-4R)

PB4 and PA4 (3000-8R)

1 DATA 0

2 DATA 1

Positive Red

Cardax IV Reader

PA

2 0 V

Negative Black

1 V OUT

Reserved Orange

Reserved Green

Reserved Brown

CDXIV TX White

CDXIV RX Blue

Positive Red

Negative Black

Reserved Orange

Reserved Green

Cardax IV Reader

4 OUT 2

Reserved Brown

CDXIV TX White

PB

3 OUT 1

CDXIV RX Blue

Note: Within each group, you cannot mix Cardax IV readers with Wiegand Readers.

This is because connecting one Wiegand reader requires all four pins on plug PB. For

example, if you connect a Cardax IV reader to Port 1 of Group 1, Port 2 of Group

1 can only connect to another Cardax IV reader.

8 | Part Number: 3E2512 | R5

Technical Specications

Technical Specications

Routine maintenance: Not applicable for this reader

Cleaning: This reader should only be cleaned with a clean, lint

Power required: Voltage: 9Vdc - 16Vdc

Environmental: Temperature Range: -30°C to +70°C

Installation Note | Gallagher T12 Reader

free, damp cloth

Current (at 12Vdc): 89mA (standby) Standard variant

124mA (peak) Standard variant

88mA (standby) Multi Tech variant

140mA (peak) Multi Tech variant

Note: Direct sunlight may increase the internal reader

temperature above the ambient temperature level.

Humidity: 95% non-condensing

Approvals and Standards

This product complies with the environmental regulations for the

Restriction of Hazardous Substances in electrical and electronic

equipment (RoHS). The RoHS directive prohibits the use of

electronic equipment containing certain hazardous substances in

the European Union.

This symbol on the product or its packaging indicates that this

product must not be disposed of with other waste. Instead, it is

your responsibility to dispose of your waste equipment by handing

it over to a designated collection point for the recycling of waste

electrical and electronic equipment. The separate collection and

recycling of your waste equipment at the time of disposal will

help conserve natural resources and ensure that it is recycled in a

manner that protects human health and the environment. For more

information about where you can drop off your waste equipment

for recycling, please contact your local city recycling office or the

dealer from whom you purchased the product.

Environmental Protection: IP68

Impact Rating: IK07

ACN 002 132 943

R5 | Part Number: 3E2512 | 9

Installation Note | Gallagher T12 Reader

FCC

This device complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

Note: Changes or modifications not expressly approved by

Gallagher Group Limited could void the user’s authority to operate

this equipment.

10 | Part Number: 3E2512 | R5

Drill Template

15mm

25mm (1 inch)

(0.59 inches)

13mm (1/2 inch)

diameter

hole for cable

26mm (1 inch) 29mm (1.41 inches)

22.3mm

(0.88 inches)

40mm (1.57 inches)

35mm (1.38 inches)

86mm (3.39 inches)

86mm (3.39 inches)

25mm (1 inch)

Loading...

Loading...