Installation Note

Cardax Prox Plus Mifare

Reader

CAUTION

This equipment contains components that can be damaged by

electrostatic discharge. Ensure both you and the equipment

are earthed before beginning any servicing.

Before you begin

Unpack the Prox Plus Mifare reader and check that you received the

following items:

1 x Base plate

1 x Reader assembly

1 x Interconnect board

1 x Four-pin Molex 6471 crimp-terminal socket equipped with

grommet and 400 mm flexible cord

Part number 3C4480 R10 1

May 2005

4 x Self-tapping pan-head screws

4 x 10 mm plastics screw caps

1 x M4 x 12 tamper-resistant Torx-head machine screw

Power supply requirements

Each Prox Plus Mifare reader consumes 200 mA from a 13.6 V

± 15% DC supply.

Use a linear-regulator power source.

Note:

Switch mode power supplies are not recommended as they may

reduce the read range of the Prox Plus Mifare reader.

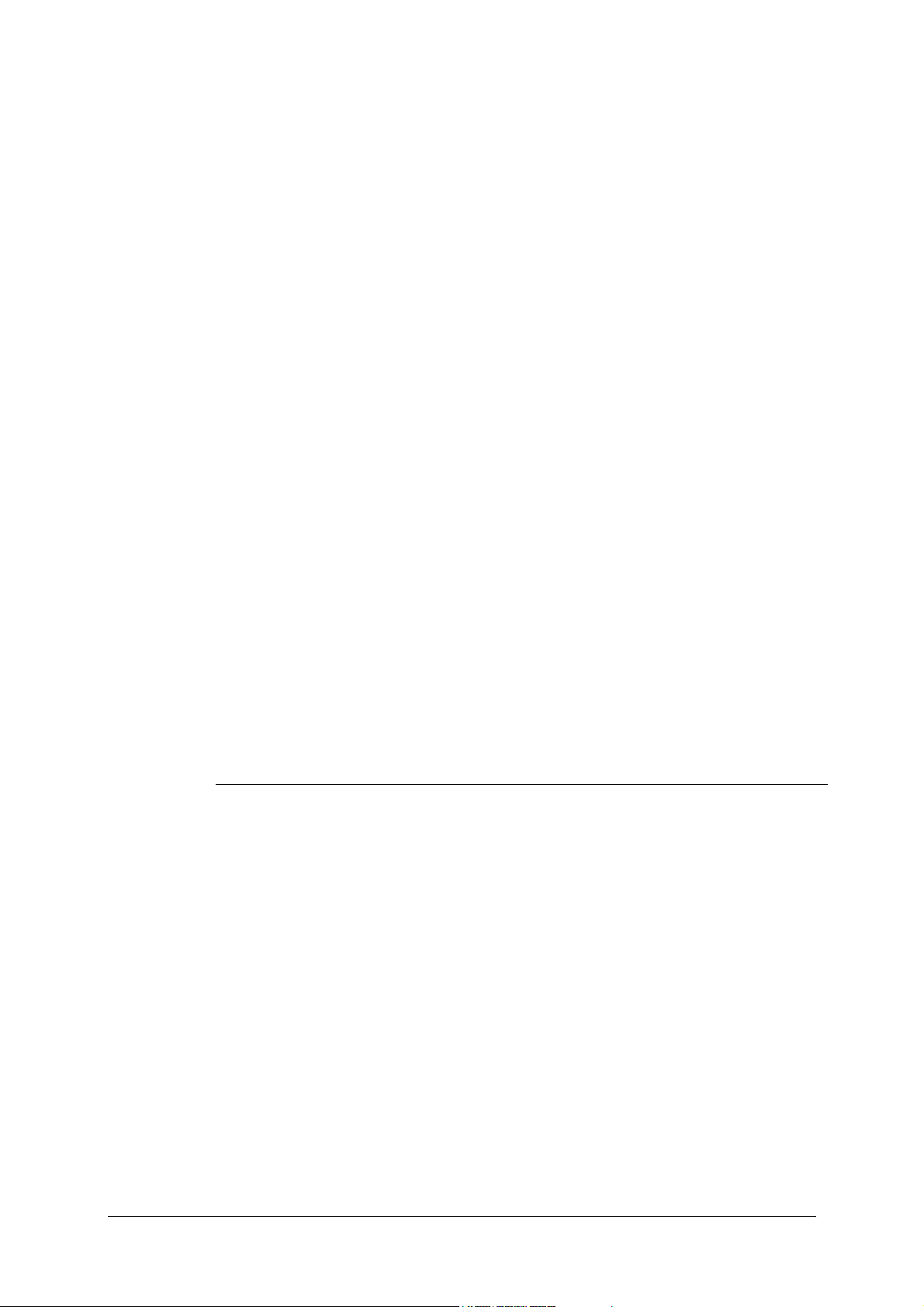

Firmware

The reader firmware has two variants. These are set out in the

table.

Firmware identification Capability

vR1.06 and earlier Reads Philips Mifare 1K cards.

vR2.05 and later Reads Philips Mifare 1K cards

Depending on the type of firmware, there is a difference in the

sequence displayed on the reader's screen after power has been

applied.

Reads all sectors of Philips Mifare 4K cards

2 Part number 3C4480 R10

May 2005

vR1.nn vR2.nn

After power has been applied,

the reader:

Beeps

Displays each of its icons in

sequence

Displays the secure icon

After power has been applied,

the reader:

Beeps

Displays each of its icons in

sequence

Displays each of its icons in

.

sequence a second time

Displays all icons

simultaneously

Displays a blank screen for

about two seconds

Displays the secure icon

.

The version of firmware used by the reader is shown on a label

attached to the central processor integrated circuit. The diagrams

below show the location of the label for both variants of the reader.

(MFCM 200)

(MFRC500)

Part number 3C4480 R10 3

May 2005

Cabling

The Prox Plus Mifare reader uses the Cardax IV communications

system. It can be connected to the following equipment:

Cardax FT Controller 3000

Cardax FT Reader I/O Interface

Cardax FT URI

Use 4 core, 0.2 mm² (AWG 24) cabling with a maximum nominal

capacitance of 120 pF/m.

With this type of cable, the maximum distance between the Prox

Plus Mifare reader and the device to which it connects is 200 m

(650 ft).

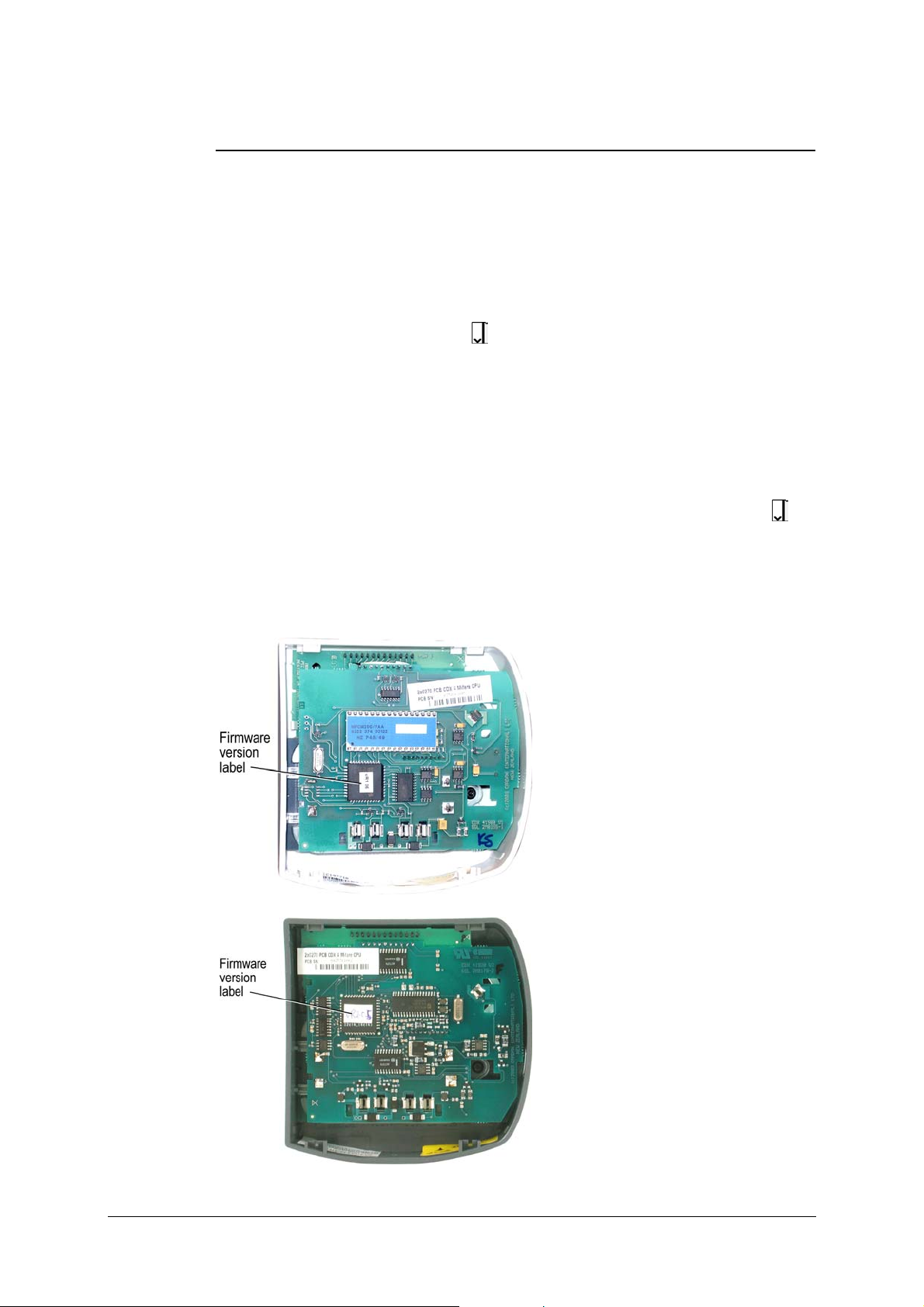

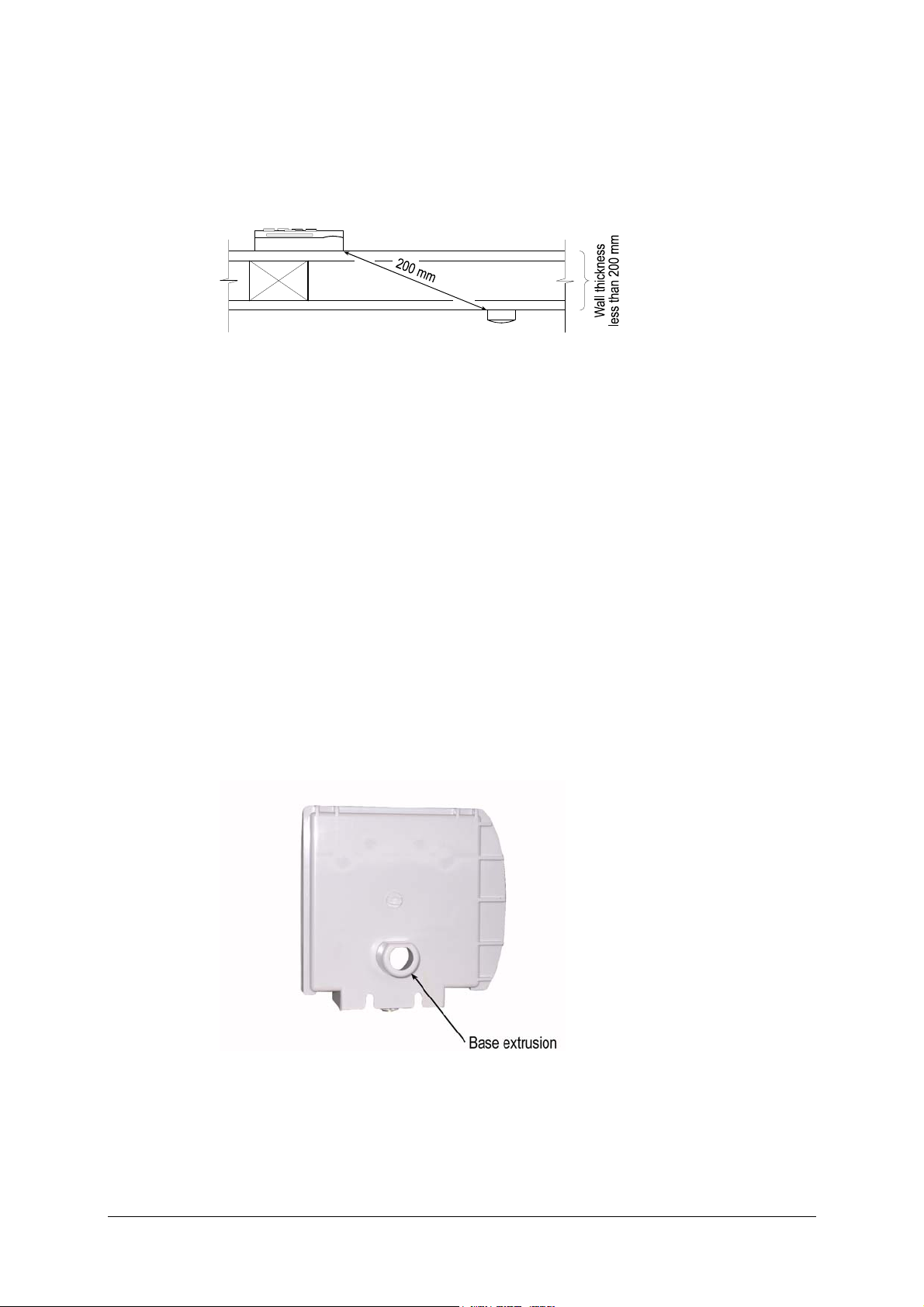

Distance between proximity readers

The distance separating any two proximity readers must not be less

than 200 mm in all directions.

200 mm

4 Part number 3C4480 R10

May 2005

When mounting a proximity reader on an internal wall, check that

any reader fixed to the other side of the wall is not less than

200 mm away.

Attaching the base plate

Note:

The Prox Plus Mifare reader has been designed to metric

specifications. Any imperial measurements shown in this document

are approximate.

The Prox Plus Mifare reader is designed to be mounted on any solid

flat surface including metal surfaces.

The recommended mounting height for the Prox Plus Mifare reader

is 1100 mm from floor level to the centre of the reader device.

However this may vary in some countries and you should check

local regulations for variations to this height.

Drill a 20 mm (3/4 inch) diameter hole for the base extrusion

through or into the mounting surface to a minimum depth of 40 mm

(1½ inches).

Run the building cabling through the base.

Part number 3C4480 R10 5

May 2005

Press the base extrusion into the 20 mm (3/4 inch) hole and secure

the base to the mounting surface using the four fixing screws.

Fit the screw caps over each fixing screw. The screw caps prevent

water from entering the reader via the fixing holes. The caps must

be installed for the Prox Plus Mifare reader to comply with the

environmental specification.

Note:

It is very important that the base of the reader is flush with and tight

against the mounting surface. If you are mounting the Prox Plus

Mifare reader on a rough surface you should make the surface as

smooth as possible under the reader and up to 25 mm (1 inch)

around the reader.

Note:

The grommet through which the cables feed into the base of the

Prox Plus Mifare reader helps to keep the device waterproof.

6 Part number 3C4480 R10

May 2005

Connections

INTERCONNECT BOARD

(VIEWED FROM

CABLE SI DE OF CONNECTOR)

READER

INTERCONNECT BOARD

12 34

READER SIDE OF CONNECTOR)

1234

1

1

2

2

3

3

4

4

(VIEWED FROM

MOLEX 6471

CRIMP TERMINAL SOCKET

4321

(VIEWED FROM

CABLE SIDE OF SOCKET)

RED

1

2

WHITE

3

BLUE

BLACK

4

+12V

DATA OUT

DATA IN

-12V

FT CONTROLLER 3000;

FT READER I/O INTERFACE; OR

FT URI

You can connect the building cable to the reader in either of two

ways:

use the four-pin socket and cord supplied with the reader and

join the cord to the building cabling; or

provide your own Molex 6471 crimp terminal socket and

terminate the building cable directly to it.

In either case, ensure that you use the socket grommet supplied with

the reader.

If you supply your own socket, use the cable terminating tool. The

tool has a head (Part No. C861145) and handle (Part No. C861115).

Pin number 4 of the socket feeds into the cable terminating tool

first.

The other end of the building cable connects to one of the

following:

Cardax FT Controller 3000

Cardax FT Reader I/O Interface

Cardax FT URI

Part number 3C4480 R10 7

May 2005

Connecting to the Cardax FT Controller 3000

The Cardax FT Controller 3000 interfaces the following types of

reader into the Cardax FT Command Centre system:

Cardax IV readers, including Prox Plus Mifare readers

Wiegand readers

Each Cardax FT Controller 3000 can interface up to eight Prox Plus

Mifare readers into the Cardax FT Command Centre system.

The ports to which the Prox Plus Mifare reader can connect are set

up as four distinct groups (numbered 1 to 4). Each group provides

connection for two Prox Plus Mifare readers or other Cardax IV

readers. Refer to the following diagram for the location of the ports

on the Cardax FT Controller 3000.

P4

P4

RS485

P2

PF4

PF3

PF2

PF1 PE1

P3

DETECTOR

LED

PE4

PE3

PE2

PC1 to PC4

Inputs

pin 1 = Input 1

pin 2 = Ground

pin 3 = Input 2

PC4

PD4

PC4PD4

PC3

PD3

PC3

PD3

PC2

PD2

PD2

PC2

PC1

PD1

PD1

PC1

PB1 to PB4

2 x Cardax IV Readers

per connector

Reader 1 = pins 1 & 3

Reader 2 = pins 2 & 4

Pin 1 = Reader 1 t ransmit

Pin 2 = Reader 2 t ransmit

Pin 3 = Reader 1 rece ive

Pin 4 = Reader 2 rece ive

P1

RS485

J1 to J4

terminating resistors

PA4

PB4

PA4

POWER

OUT

PA3

PB3

PA3

POWER

OUT

PA2

PB2

PA2

POWER

OUT

PA1

PB1

PA1

POWER

OUT

Group 4

Group 3

Group 2

Group 1

PA1 to PA4

Power Out

pin 1 = power out

pin 2 = 0 V

Make the connections from the Prox Plus Mifare reader to the

Cardax FT Controller 3000 as shown:

8 Part number 3C4480 R10

May 2005

Controller 3000

Group (x4)

PB1 and PA1... to... PB4 and PA4

4 3 2 1

Prox Plus Mifare

Reader 2

PB

Prox Plus Mifare

Reader 1

PA

2 1

Note:

Within each group, you cannot mix Cardax IV readers with

Wiegand Readers. This is because connecting one Wiegand reader

requires all four pins on plug PB. For example, if you connect a

Prox Plus Mifare reader to Port 1 of Group 1, Port 2 of Group 1 can

only connect to another Cardax IV reader.

The terminating resistors (J1 for Group 1, J2 for Group 2, etc.) must

NOT be fitted for those groups to which Prox Plus Mifare readers

are connected.

Connecting to the Cardax FT Reader I/O Interface

The Cardax FT Reader I/O Interface has connections for up to

sixteen Prox Plus Mifare readers or other Cardax IV readers.

The Prox Plus Mifare reader connects to either plug PA or PB in

Groups 1 to 8.

Make the connections from the Prox Plus Mifare reader to the

Reader I/O interface as shown:

Part number 3C4480 R10 9

May 2005

Prox Plus Mifare Readers

Red

1

White

2

Blue

3

Black

4

Red

1

White

2

Blue

3

Black

4

Reader I/O Interface

Group (x8)

IN

Reader A

OUT

IN

OUT

(PA)

Reader B

(PB)

+V

Power

0

(PD)

For the location of the plugs on the Reader I/O Interface, refer to

the component layout diagram:

10 Part number 3C4480 R10

May 2005

Connecting to the Cardax FT URI

Connect the cables to the socket as shown.

Cardax FT Universal Reader Interface

P2 Non-CardaxFT

Reader 2

pin 1 = 5/12 V power

pin 2 = DataA

pin 3 = DataB

pin 4 = Card detect

pin 5 = LED output

pin 6 = Beeper output

pin 7 = Ground

Prox Plus Mifare Connector

Black

4

Blue

3

White

2

Red

1

Plug P1 or P2

GND

OUTPUTS

OUTPUTS

DET

COMMS

COMMS

5/12V

Connect the Prox Plus Mifare reader connector to either the P1 or

P2 plug on the Cardax FT URI. Refer to the Cardax FT URI

component layout diagram, next, for the location of the plugs.

T1

D17

NC NO

COIL

COMM

D21

NC NO

COIL

RLY2

COMM

D18

P5

Power & Comms

pins 1 & 2 = RS485

pin 3 = 13.6 V ± 15%

pin 4 = 0V

JP1

Reader Voltage select

D17 and D21

Relay state indicators

LED on = Energised

LED off = De-energised

P7

Relay Outputs

R1 p1 = Normally closed

R1 p2 = Normally open

R1 p3 = Common

R2 p4 = Normally closed

R2 p5 = Normally open

R2 p6 = Common

p7 = Ground

= 12V (1A total)

P3

Keypad

pin 1 = Row1

pin 2 = Row 2

pin 3 = Row 3

pin 4 = Row 4

pin 5 = Column1

pin 6 = Column2

pin 7 = Column3

pin 8 = Ground

P2

P6

13.6 V ± 15% out

pin 1 = 13.6 V ± 15%

pin 2 = Ground

3A fused

F2 3A

13.6 V ± 15%out

F1 500mA

13.6 V ± 15%in

D10 Comms

LED flashing =

communicating with

FT Controller

D10

E

5V

JP1

12V

D18

Run LED

P1

(c)1999 PEC(New Zealand) Ltd

Non-CardaxFT

P1

Reader 1

pin 1 = 5/12 V power

pin 2 = DataA

pin 3 = DataB

pin 4 = Card detect

pin 5 = LED output

pin 6 = Beeper output

pin 7 = Ground

210

1

P8

Diagnostic port

P8

9

SW1

Device address

Set device number

SW1

22825V2 Assy 22826

P4

Balanced Inputs

pin 1 = Input1

pin 2 = Input 2

pin 3 = Input 3

pin 4 = Input 4

pin 5 = Input 5

pin 6 = Input 6

pin 7 = Ground

REV[A][B][C]

Part number 3C4480 R10 11

May 2005

Fitting the facia

1. Press the Molex 6471 socket onto the four pin plug on the

interconnect board.

2. Push the interconnect board into the base plate so that the

Molex 6471 socket beds into the grommet.

3. Push the interconnect board further until it is captured by the

clips on the base plate.

4. Slide the facia attachment lugs into the guides at the rear of the

base plate.

5. On the front of the facia, press down on the Cardax label until

the security screw hole lines up with the M4 threaded hole

underneath the base plate.

6. Pass the M4 security screw through the hole in the facia and use

a tamper-resistant Torx-head tool to drive it into the threaded

hole in the base plate.

Removing the facia

1. Using a tamper-resistant Torx-head tool, remove the M4

security screw from the underside of the facia.

2. Pull the base of the facia away from the base plate.

3. Slide the facia's attachment lugs out of the guides at the rear of

the base plate.

12 Part number 3C4480 R10

May 2005

Initialisation

Initialising with the Cardax FT Controller 3000

Refer to the Cardax FT Controller 3000 Installation Note (Part

number 3E1089) for initialisation instructions.

Initialisation of the Cardax FT Controller 3000 does not require

prior connection to the Prox Plus Mifare reader. The Prox Plus

Mifare reader will be operational as soon as it is:

connected to a Cardax FT Controller 3000, and

configured as a Cardax IV reader within the Cardax FT

Command Centre system.

Initialising with the Cardax FT Reader I/O Interface

Refer to the Cardax FT Reader I/O Interface Installation Note

(Gallagher Part number 3E1016) for initialisation instructions.

Initialisation of the Cardax FT Reader I/O Interface does not require

prior connection to the Prox Plus Mifare reader. The Prox Plus

Mifare reader will be operational as soon as it is:

connected to a Cardax FT Reader I/O Interface, and

configured as a Cardax IV reader within the Cardax FT

Command Centre system.

Initialising with the Cardax FT URI

Refer to the Cardax FT Universal Reader Interface Installation

Note (Gallagher Part number 3C4518) for initialisation instructions.

Initialisation of the Cardax FT URI does not require prior

connection to the Prox Plus Mifare reader. The Prox Plus Mifare

reader will be operational as soon as it is:

connected to a Cardax FT URI, and

configured as a Cardax IV reader within the Cardax FT

Command Centre system.

Part number 3C4480 R10 13

May 2005

Icons

The Prox Plus Mifare reader displays the following icons on the

liquid crystal display (LCD) to indicate the access status of the zone

controlled by the reader.

14 Part number 3C4480 R10

May 2005

Approvals and Standards

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for

help.

Note: Changes or modifications not expressly approved by

Gallagher Security Management Systems could void the

user's authority to operate the equipment.

ACN: 002132943

Part number 3C4480 R10 15

May 2005

PUBLISHED BY

Gallagher Group Limited

Kahikatea Drive, Private Bag 3026

Hamilton, New Zealand

Copyright© Gallagher Group Limited 2004.

All rights reserved. Patents Pending.

3C4480

R10

May 2005

DISCLAIMER Whilst every effort has

been made to ensure accuracy, neither

Gallagher Group Limited nor any

employee of the company, shall be liable

on any ground whatsoever to any party in

respect of decisions or actions they may

make as a result of using this information.

In accordance with the Gallagher policy of

continuing development, design and

specifications are subject to change

without notice.

Developed and manufactured by

Gallagher Group Limited, an ISO

9001:2000 Certified Supplier.

Loading...

Loading...