Page 1

USER MANUAL

DMC-1700/1800

Manual Rev. 1.2m

By Galil Motion Control, Inc.

Galil Motion Control, Inc.

3750 Atherton Road

Rocklin, California 95765

Phone: (916) 626-0101

Fax: (916) 626-0102

Internet Address: support@galilmc.com

URL: www.galilmc.com

Rev Date: 6/06

Page 2

Using This Manual

This user manual provides information for proper operation of the DMC-1700 or DMC-1800

controller. The appendix to this manual contains information regarding the accessories to these

controllers. A separate supplemental manual, the Command Reference, contains a description of the

commands available for use with the controller.

Your motion controller has been designed to work with both servo and stepper type motors.

Installation and system setup will vary depending upon whether the controller will be used with

stepper motors or servo motors. To make finding the appropriate instructions faster and easier, icons

will be next to any information that applies exclusively to one type of system. Otherwise, assume that

the instructions apply to all types of systems. The icon legend is shown below.

1X80

Attention: Pertains to servo motor use.

Attention: Pertains to stepper motor use.

Attention: Pertains to controllers with more than 4 axes.

Please note that many examples are written for the DMC-1740 and DMC-1840 four-axes controller or

the DMC-1780 and DMC-1880 eight axes controller. Users of the DMC-1730/1830 3-axis controller,

DMC-1720/1820 2-axes controller, or DMC-1710/1810 1-axis controller should note that the DMC1730/1830 uses the axes denoted as XYZ, the DMC-1720/1820 uses the axes denoted as XY, and the

DMC-1710/1810 uses the X-axis only.

17X8

Examples for the DMC-1780/1880 denote the axes as A,B,C,D,E,F,G,H. Users of the DMC1750/1850 5-axes controller, DMC-1760/1860 6-axes controller, or DMC-1770/1870 7-axes controller

should note that the DMC-1750/1850 denotes the axes as A,B,C,D and E, the DMC-1760/1860 denotes

the axes as A,B,C,D,E and F, and the DMC-1770/1870 denotes the axes as A,B,C,D,E,F and G. The

axes A,B,C,D may be used interchangeably with X,Y,Z,W for any of the DMC1700 or DMC-1800

regardless of the number of axes.

This manual was written for the DMC-1700 firmware revision 1.1 and later and all DMC-1800

firmware revisions. For a DMC-1700 controller with firmware previous to revision 1.1, please consult

the original manual for your hardware.

Attention: Pertains to a DMC-1700 1 thru 4-axes controllers with an additional 64 I/O points.

WARNING: Machinery in motion can be dangerous! It is the responsibility of the user to design

effective error handling and safety protection as part of the machine. Galil shall not

responsible for any incidental or consequential damages.

be liable or

Page 3

Contents

Contents i

Chapter 1 Overview 1

Introduction ...............................................................................................................................1

Overview of Motor Types..........................................................................................................2

Standard Servo Motor with +/- 10 Volt Command Signal ..........................................2

Brushless Servo Motor with Sinusoidal Commutation................................................2

Stepper Motor with Step and Direction Signals ..........................................................2

DMC-1700/1800 Functional Elements...................................................................................... 2

Microcomputer Section ...............................................................................................3

Motor Interface............................................................................................................ 3

Communication ........................................................................................................... 3

General I/O.................................................................................................................. 3

System Elements ......................................................................................................... 4

Motor........................................................................................................................... 4

Amplifier (Driver) ....................................................................................................... 4

Encoder........................................................................................................................4

Watch Dog Timer........................................................................................................ 5

Chapter 2 Getting Started 7

The DMC-17x0 and DMC-18x0 Motion Controllers................................................................ 7

Elements You Need ................................................................................................................... 9

Installing the DMC-1700/1800................................................................................................ 10

Step 1. Determine Overall Motor Configuration....................................................... 10

Step 2. Install Jumpers on the DMC-1700/1800........................................................11

Step 3. Install the Communications Software............................................................13

Step 4. Install the DMC-1700/1800 in the PC........................................................... 14

Step 5. Establishing Communication between the Galil controller and the host PC .14

Step 6. Determine the Axes to be Used for Sinusoidal Commutation....................... 24

Step 7. Make Connections to Amplifier and Encoder. ..............................................25

Step 8a. Connect Standard Servo Motors.................................................................. 27

Step 8b. Connect Sinusoidal Commutation Motors...................................................31

Step 8C. Connect Step Motors ..................................................................................33

Step 9. Tune the Servo System.................................................................................. 34

Design Examples .....................................................................................................................35

Example 1 - System Set-up ....................................................................................... 35

Example 2 - Profiled Move .......................................................................................35

Example 3 - Multiple Axes........................................................................................36

Example 4 - Independent Moves...............................................................................36

Example 5 - Position Interrogation............................................................................ 36

DMC-1700/1800 Contents • i

Page 4

Example 6 - Absolute Position .................................................................................. 37

Example 7 - Velocity Control....................................................................................37

Example 8 - Operation Under Torque Limit .............................................................37

Example 9 - Interrogation.......................................................................................... 38

Example 10 - Operation in the Buffer Mode............................................................. 38

Example 11 - Using the On-Board Editor ................................................................. 38

Example 12 - Motion Programs with Loops..............................................................39

Example 13 - Motion Programs with Trippoints.......................................................39

Example 14 - Control Variables................................................................................ 39

Example 15 - Linear Interpolation.............................................................................40

Example 16 - Circular Interpolation..........................................................................40

Chapter 3 Connecting Hardware 43

Overview .................................................................................................................................43

Using Optoisolated Inputs .......................................................................................................43

Limit Switch Input.....................................................................................................43

Home Switch Input.................................................................................................... 44

Abort Input ................................................................................................................44

Uncommitted Digital Inputs ...................................................................................... 45

Wiring the Optoisolated Inputs................................................................................................ 45

Using an Isolated Power Supply................................................................................46

Bypassing the Opto-Isolation: ...................................................................................47

Analog Inputs ..........................................................................................................................47

Amplifier Interface .................................................................................................................. 47

TTL Inputs............................................................................................................................... 48

TTL Outputs ............................................................................................................................ 48

Chapter 4 - Software Tools and Communications 51

Introduction .............................................................................................................................51

Galil SmartTERM.................................................................................................................... 53

Communication Settings for ISA and PCI............................................................................... 57

Windows Servo Design Kit (WSDK)...................................................................................... 61

Creating Custom Software Interfaces ...................................................................................... 62

DOS, Linux, and QNX tools....................................................................................................65

Controller Event Interrupts and User Interrupts ......................................................................65

Hardware Level Communications for ISA and PCI ................................................................67

Communications with the DMC-1700.......................................................................67

Communication with DMC-1700............................................................................... 68

Communication with DMC-1800............................................................................... 71

DMA / Secondary FIFO / DPRAM Memory Map .................................................................. 73

Explanation of Status Information and Axis Switch Information..............................76

Chapter 5 Command Basics 79

Introduction .............................................................................................................................79

Command Syntax - ASCII....................................................................................................... 79

Coordinated Motion with more than 1 axis............................................................... 80

Command Syntax - Binary ......................................................................................................80

Binary Command Format.......................................................................................... 81

Binary command table...............................................................................................82

Controller Response to DATA ................................................................................................83

Interrogating the Controller .....................................................................................................83

Interrogation Commands........................................................................................... 83

Summary of Interrogation Commands ...................................................................... 83

Interrogating Current Commanded Values................................................................ 84

ii • Contents DMC-1700/1800

Page 5

Operands....................................................................................................................84

Command Summary.................................................................................................. 84

Chapter 6 Programming Motion 85

Overview .................................................................................................................................85

Independent Axis Positioning.................................................................................................. 87

Command Summary - Independent Axis ..................................................................87

Operand Summary - Independent Axis .....................................................................87

Independent Jogging................................................................................................................89

Command Summary - Jogging.................................................................................. 89

Operand Summary - Independent Axis .....................................................................90

Position Tracking..................................................................................................................... 90

Example - Motion 2:..................................................................................................92

Example Motion 4 ..................................................................................................... 93

Trip Points ................................................................................................................. 94

Command Summary – Position Tracking Mode .......................................................95

Linear Interpolation Mode....................................................................................................... 95

Specifying Linear Segments...................................................................................... 95

Command Summary - Linear Interpolation...............................................................97

Operand Summary - Linear Interpolation..................................................................97

Example - Linear Move............................................................................................. 98

Example - Multiple Moves........................................................................................99

Vector Mode: Linear and Circular Interpolation Motion.......................................................100

Specifying the Coordinate Plane ............................................................................. 100

Specifying Vector Segments ...................................................................................100

Additional commands.............................................................................................. 101

Command Summary - Coordinated Motion Sequence............................................ 103

Operand Summary - Coordinated Motion Sequence............................................... 103

Electronic Gearing................................................................................................................. 104

Ramped Gearing .................................................................................................................... 105

Example – Electronic Gearing Over a Specified Interval........................................ 106

Command Summary - Electronic Gearing ..............................................................107

Example - Simple Master Slave ..............................................................................107

Example - Electronic Gearing ................................................................................. 107

Example - Gantry Mode .......................................................................................... 107

Example - Synchronize two conveyor belts with trapezoidal velocity correction... 108

Electronic Cam ...................................................................................................................... 108

Command Summary - Electronic CAM.................................................................. 111

Operand Summary - Electronic CAM..................................................................... 112

Example - Electronic CAM..................................................................................... 112

Contour Mode........................................................................................................................ 113

Specifying Contour Segments ................................................................................. 113

Additional Commands............................................................................................. 114

Command Summary - Contour Mode ..................................................................... 115

Stepper Motor Operation ....................................................................................................... 119

Specifying Stepper Motor Operation....................................................................... 119

Using an Encoder with Stepper Motors................................................................... 120

Command Summary - Stepper Motor Operation.....................................................120

Operand Summary - Stepper Motor Operation........................................................120

Stepper Position Maintenance Mode (SPM).......................................................................... 121

Error Limit............................................................................................................... 121

Correction................................................................................................................122

Dual Loop (Auxiliary Encoder)............................................................................................. 125

Backlash Compensation ..........................................................................................126

Motion Smoothing................................................................................................................. 127

DMC-1700/1800 Contents • iii

Page 6

Using the IT and VT Commands:............................................................................127

Using the KS Command (Step Motor Smoothing):................................................. 128

Homing .................................................................................................................................. 129

Stage 1:.................................................................................................................... 129

Stage 2:.................................................................................................................... 129

Stage 3:.................................................................................................................... 129

Command Summary - Homing Operation...............................................................132

Operand Summary - Homing Operation.................................................................. 132

High Speed Position Capture (The Latch Function).............................................................. 132

Fast Update Rate Mode .........................................................................................................133

Chapter 7 Application Programming 135

Overview ...............................................................................................................................135

Using the DMC-1700/1800 Editor to Enter Programs...........................................................135

Edit Mode Commands............................................................................................. 136

Program Format..................................................................................................................... 136

Using Labels in Programs .......................................................................................136

Special Labels..........................................................................................................137

Commenting Programs............................................................................................ 137

Executing Programs - Multitasking .......................................................................................138

Debugging Programs .............................................................................................................139

Program Flow Commands ..................................................................................................... 140

Event Triggers & Trippoints....................................................................................141

Event Trigger Examples:......................................................................................... 143

Conditional Jumps................................................................................................... 145

Using If, Else, and Endif Commands ...................................................................... 147

Subroutines.............................................................................................................. 149

Stack Manipulation..................................................................................................149

Auto-Start Routine ..................................................................................................149

Automatic Subroutines for Monitoring Conditions.................................................149

Mathematical and Functional Expressions ............................................................................ 153

Mathematical Operators ..........................................................................................153

Bit-Wise Operators.................................................................................................. 153

Functions ................................................................................................................. 154

Variables................................................................................................................................ 155

Programmable Variables ......................................................................................... 155

Operands................................................................................................................................156

Special Operands (Keywords)................................................................................. 157

Arrays ....................................................................................................................................157

Defining Arrays....................................................................................................... 157

Assignment of Array Entries................................................................................... 158

Automatic Data Capture into Arrays....................................................................... 159

Deallocating Array Space........................................................................................ 160

Input of Data (Numeric and String)....................................................................................... 160

Input of Data............................................................................................................ 160

Output of Data (Numeric and String) .................................................................................... 161

Sending Messages ...................................................................................................161

Displaying Variables and Arrays............................................................................. 163

Interrogation Commands......................................................................................... 163

Formatting Variables and Array Elements .............................................................. 165

Converting to User Units......................................................................................... 165

Hardware I/O .........................................................................................................................166

Digital Outputs ........................................................................................................ 166

Digital Inputs........................................................................................................... 167

Input Interrupt Function ..........................................................................................167

iv • Contents DMC-1700/1800

Page 7

Analog Inputs .......................................................................................................... 168

Example Applications............................................................................................................ 169

Wire Cutter.............................................................................................................. 169

X-Y Table Controller ..............................................................................................170

Speed Control by Joystick....................................................................................... 172

Position Control by Joystick.................................................................................... 174

Backlash Compensation by Sampled Dual-Loop.................................................... 174

Chapter 8 Hardware & Software Protection 177

Introduction ...........................................................................................................................177

Hardware Protection .............................................................................................................. 177

Output Protection Lines........................................................................................... 177

Input Protection Lines ............................................................................................. 177

Software Protection ...............................................................................................................178

Programmable Position Limits ................................................................................ 178

Off-On-Error ...........................................................................................................179

Automatic Error Routine ......................................................................................... 179

Limit Switch Routine ..............................................................................................179

Chapter 9 Troubleshooting 181

Overview ...............................................................................................................................181

Installation ............................................................................................................................. 181

Communication......................................................................................................................182

Stability.................................................................................................................................. 182

Operation ............................................................................................................................... 183

Chapter 10 Theory of Operation 185

Overview ...............................................................................................................................185

Operation of Closed-Loop Systems.......................................................................................187

System Modeling................................................................................................................... 188

Motor-Amplifier...................................................................................................... 189

Encoder....................................................................................................................191

DAC ........................................................................................................................192

Digital Filter ............................................................................................................ 192

ZOH......................................................................................................................... 193

System Analysis.....................................................................................................................193

System Design and Compensation.........................................................................................195

The Analytical Method............................................................................................ 195

Appendices 199

Electrical Specifications ........................................................................................................199

Servo Control ..........................................................................................................199

Stepper Control........................................................................................................199

Input/Output ............................................................................................................ 199

Power....................................................................................................................... 200

Performance Specifications ...................................................................................................200

Connectors for DMC-1700/1800 Main Board ....................................................................... 201

Pin-Out Description for DMC-1700/1800............................................................................. 203

Setting Addresses for the DMC-1700.................................................................................... 206

Standard Addresses .................................................................................................206

Plug and Play Addresses .........................................................................................209

Accessories and Options........................................................................................................ 210

PC/AT Interrupts and Their Vectors...................................................................................... 211

DMC-1700/1800 Contents • v

Page 8

ICM-1900 Interconnect Module ............................................................................................ 211

ICM-1900 Drawing ...............................................................................................................215

AMP-19X0 Mating Power Amplifiers...................................................................................215

ICM-2900 Interconnect Module ............................................................................................ 216

Opto-Isolated Outputs ICM-1900 / ICM-2900 (-Opto option).............................................. 219

Standard Opto-isolation and High Current Opto-isolation:..................................... 219

64 Extended I/O of the DMC-17x8/1700/1800 Controller.................................................... 219

Configuring the I/O of the DMC-17x8 (and DMC-1750 to DMC-1780 & DMC-

1810 to 1880, with DB-14064)................................................................................

Configuring the 64 Extended I/O of the DMC-1750 to 1780 and 1850 to 1880 using

the DB-14064 ..........................................................................................................

Connector Description:............................................................................................ 221

IOM-1964 Opto-Isolation Module for Extended I/O Controllers.......................................... 224

Description: .............................................................................................................224

Overview .................................................................................................................225

Configuring Hardware Banks.................................................................................. 226

Digital Inputs........................................................................................................... 227

High Power Digital Outputs .................................................................................... 229

Standard Digital Outputs ......................................................................................... 230

Electrical Specifications ..........................................................................................231

Relevant DMC Commands......................................................................................232

Screw Terminal Listing........................................................................................... 232

Coordinated Motion - Mathematical Analysis....................................................................... 234

DMC-1700/DMC-1000 Comparison.....................................................................................237

List of Other Publications...................................................................................................... 238

Training Seminars.................................................................................................................. 239

Contacting Us ........................................................................................................................240

WARRANTY ........................................................................................................................240

219

221

Index 241

vi • Contents DMC-1700/1800

Page 9

Chapter 1 Overview

Introduction

The DMC-1700 series motion control cards install directly into the ISA bus while the DMC-1800 series motion

controllers install directly into a PCI slot. These controller series offers many enhanced features including highspeed communications, non-volatile program memory, faster encoder speeds, and improved cabling for EMI

reduction.

The DMC-1700/1800 provides two channels for high speed communication. Both controllers use a high speed main

FIFO for sending and receiving commands. Additionally, the DMC-1700 provides a DMA channel which places a

data record directly into PC memory or a secondary polling FIFO for instant access to controller status and

parameters. The DMC-1800 provides either Dual Port RAM (DPRAM) or a secondary polling FIFO for instant

access to controller status and parameters. The controllers allow for high-speed servo control up to 12 million

encoder counts/sec and step motor control up to 3 million steps per second. Sample rates as low as 62.5μsec per

axis are available.

A 4 meg Flash EEPROM provides non-volatile memory for storing application programs, parameters, arrays, and

firmware. New firmware revisions are easily upgraded in the field without removing the controller from the PC.

The DMC-1700 is available with up to eight axes on a single ISA card. The DMC-1710, 1720, 1730, 1740 one thru

four axes controllers are on a single 10.25” x 4.8” card and the DMC-1750, 1760, 1770, 1780 five thru eight axes

controllers are on a single 13.25” x 4.8” card.

The DMC-1800 is available from one to eight axes on a single PCI card. The DMC-1810, 1820, 1830, 1840,

covering from one to four axes, are on a single 8.2” x 4.2” card and the DMC-1850, 1860, 1870, 1880 five thru eight

axes controllers are on a single 12.28” x 4.2” card.

Designed to solve complex motion problems, the DMC-1700/1800 can be used for applications involving jogging,

point-to-point positioning, vector positioning, electronic gearing, multiple move sequences and contouring. The

controller eliminates jerk by programmable acceleration and deceleration with profile smoothing. For smooth

following of complex contours, the DMC-1700/1800 provides continuous vector feed of an infinite number of linear

and arc segments. The controller also features electronic gearing with multiple master axes as well as gantry mode

operation.

For synchronization with outside events, the DMC-1700 and DMC-1800 provide uncommitted I/O, including 8

digital inputs (24 inputs for DMC-1750 thru DMC-1780 and DMC-1850 thru DMC-1880), 8 digital outputs (16

outputs for DMC-1750 thru DMC-1780 and DMC-1850 thru DMC-1880), and 8 analog inputs for interface to

joysticks, sensors, and pressure transducers. The DMC-1718, 1728, 1738, and 1748 controllers are also available

for an additional 64 I/O. Dedicated optoisolated inputs are provided on all DMC-1700/1800 controllers for forward

and reverse limits, abort, home, and definable input interrupts. The DMC-1800 has plug and play capabilities to ease

the setup process. Commands can be sent in either Binary or ASCII. Additional software is available to autotune,

view trajectories on a PC screen, translate CAD.DXF files into motion, and create powerful, application-specific

operator interfaces with Visual Basic. Drivers for WIN98SE, ME, NT4.0, 2000 and XP are available.

DMC-1700/1800 Chapter 1 Overview • 1

Page 10

Overview of Motor Types

The DMC-1700/1800 can provide the following types of motor control:

1. Standard servo motors with +/- 10 volt command signals

2. Brushless servo motors with sinusoidal commutation

3. Step motors with step and direction signals

4. Other actuators such as hydraulics - For more information, contact Galil.

The user can configure each axis for any combination of motor types, providing maximum flexibility.

Standard Servo Motor with +/- 10 Volt Command Signal

The DMC-1700/1800 achieves superior precision through use of a 16-bit motor command output DAC and a

sophisticated PID filter that features velocity and acceleration feedforward, an extra pole filter, and integration

limits.

The controller is configured by the factory for standard servo motor operation. In this configuration, the controller

provides an analog signal (+/- 10Volt) to connect to a servo amplifier. This connection is described in Chapter 2.

Brushless Servo Motor with Sinusoidal Commutation

The DMC-1700/1800 can provide sinusoidal commutation for brushless motors (BLM). In this configuration, the

controller generates two sinusoidal signals for connection with amplifiers specifically designed for this purpose.

Note: The task of generating sinusoidal commutation may be accomplished in the brushless motor amplifier. If the

amplifier generates the sinusoidal commutation signals, only a single command signal is required and the controller

should be configured for a standard servo motor (described above).

Sinusoidal commutation in the controller can be used with linear and rotary BLMs. However, the motor velocity

should be limited such that a magnetic cycle lasts at least 6 milliseconds*. For faster motors, please contact the

factory.

To simplify the wiring, the controller provides a one-time, automatic set-up procedure. The parameters determined

by this procedure can then be saved in non-volatile memory to be used whenever the system is powered on.

The DMC-1700/1800 can control BLMs equipped with or without Hall sensors. If hall sensors are available, once

the controller has been setup, the controller will automatically estimates the commutation phase upon reset. This

allows the motor to function immediately upon power up. The hall effect sensors also provides a method for setting

the precise commutation phase. Chapter 2 describes the proper connection and procedure for using sinusoidal

commutation of brushless motors.

* 6 Milliseconds per magnetic cycle assumes a servo update of 1 msec (default rate).

Stepper Motor with Step and Direction Signals

The DMC-1700/1800 can control stepper motors. In this mode, the controller provides two signals to connect to the

stepper motor: Step and Direction. For stepper motor operation, the controller does not require an encoder and

operates the stepper motor in an open loop fashion. Chapter 2 describes the proper connection and procedure for

using stepper motors.

DMC-1700/1800 Functional Elements

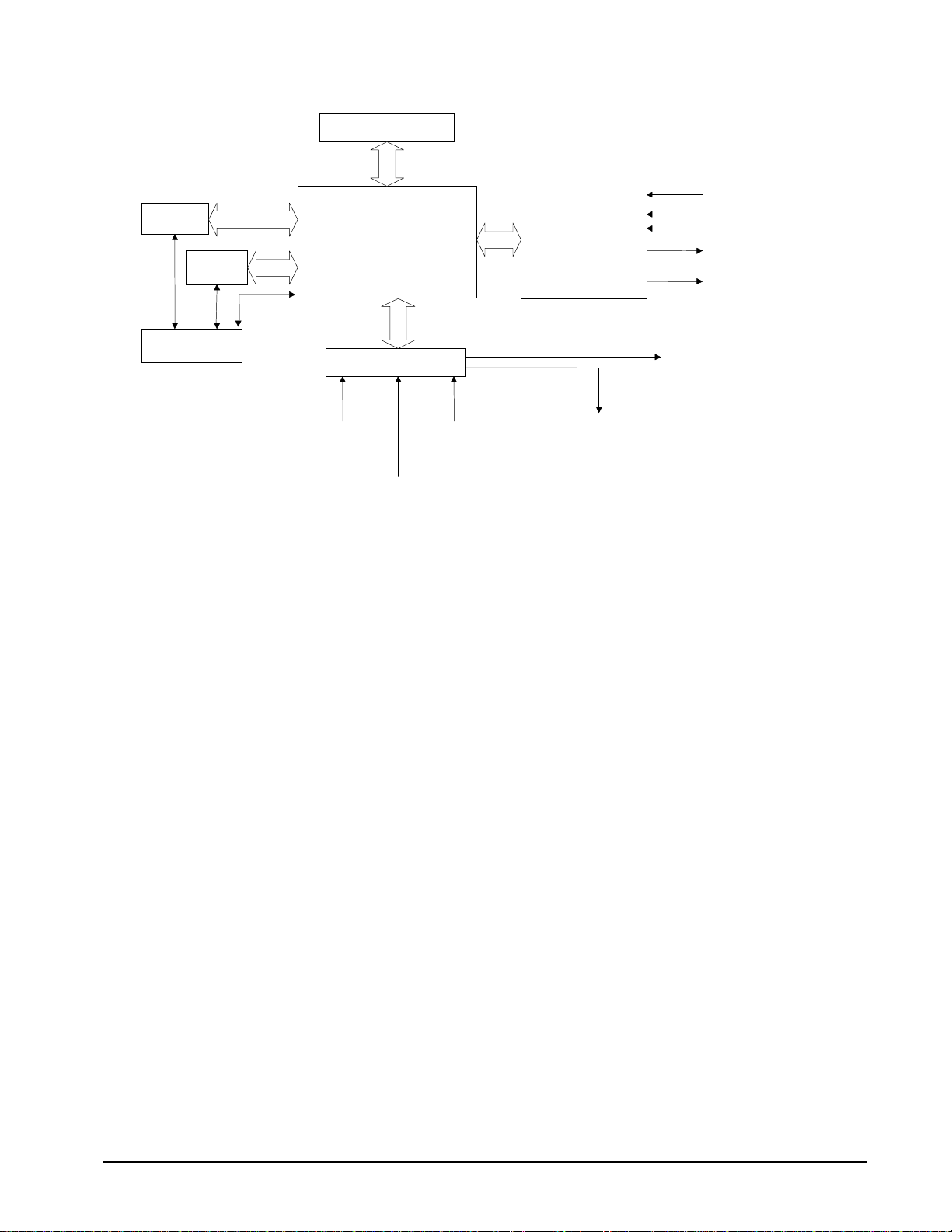

The DMC-1700/1800 circuitry can be divided into the following functional groups as shown in Figure 1.1 and

discussed below.

2 • Chapter 1 Overview DMC-1700/1800

Page 11

DMA/DPRAM

2ND FIFO

Primary

FIFOS

Interrupts

WATCHDOG TIMER

68331

MICROCOMPUTER

WITH

4 Meg RAM

4 Meg FLASH EEPROM

HIGH-SPEED

MOTOR/ENCODER

INTERFACE

FOR

X,Y,Z,W, etc.

ISOLATED LIMITS AND

HOME INPUTS

MAIN ENCODERS

AUXILIARY ENCODERS

+/- 10 VOLT OUTPUT FOR

SERVO MOTORS

PULSE/DIRECTION OUTPUT

FOR STEP MOTORS

ISA/PCI BUS

I/O INTERFACE

8 UNCOMMITTED

ANALOG INPUTS

HIGH-SPEED LATCH FOR EACH AXIS

8 PROGRAMMABLE,

OPTOISOLATED

8 PROGRAMMABLE

OUTPUTS

INPUTS

HIGH SPEED ENCODER

COMPARE OUTPUT

Figure 1.1 - DMC-1700/1800 Functional Elements

Microcomputer Section

The main processing unit of the controller is a specialized 32-bit Motorola 68331 Series Microcomputer with 512K

byte RAM and 512K byte Flash EEPROM. The RAM provides memory for variables, array elements, and

application programs. The flash EEPROM provides non-volatile storage of variables, programs, and arrays. The

Flash also contains the firmware of the controller, which is field upgradeable.

Motor Interface

Galil’s GL-1800 custom, sub-micron gate array performs quadrature decoding of each encoder at up to 12 MHz.

For standard servo operation, the controller generates a +/-10 Volt analog signal (16 Bit DAC). For sinusoidal

commutation operation, the controller uses 2 DACs to generate 2

operation the controller generates a step and direction signal.

+/-10Volt analog signals. For stepper motor

Communication

The communication interface with the host PC contains a primary and secondary communication channel. The

primary channel uses a bi-directional FIFO and includes PC interrupt handling circuitry. The secondary channel can

be set as DMA or DPRAM where data is placed in PC memory or as a Polling FIFO where data is placed into the

controller’s FIFO buffer. The DMA is available on the DMC-1700 and, DPRAM is only available on the DMC1800 (1810-1840 Rev H and greater, DMC-1850-1880 Rev E and greater), whereas the Polling FIFO is available on

both the DMC-1700 and DMC-1800.

General I/O

The controller provides interface circuitry for 8 bi-directional, optoisolated inputs, 8 TTL outputs, and 8 analog

inputs with 12-Bit ADC (16-bit optional). The general inputs can also be used for triggering a high-speed positional

latch for each axis.

Each axis on the controller has 2 encoders, the main encoder and an auxiliary encoder. Each unused auxiliary

encoder provides 2 additional inputs available for general use (except when configured for stepper motor operation).

DMC-1700/1800 Chapter 1 Overview • 3

Page 12

17X8

1X80

The DMC-1718, 1728, 1738, 1748 controllers have 64 additional general I/O points. The user can

configure these I/O points as inputs or outputs in blocks of 8.

The DMC-1750 through DMC-1780 and DMC-1850 through DMC-1880 controllers provide interface

circuitry for 16 optoisolated inputs, 8 TTL inputs, 16 TTL outputs, and 8 analog inputs with 12-bit

ADC (16-bit optional).

System Elements

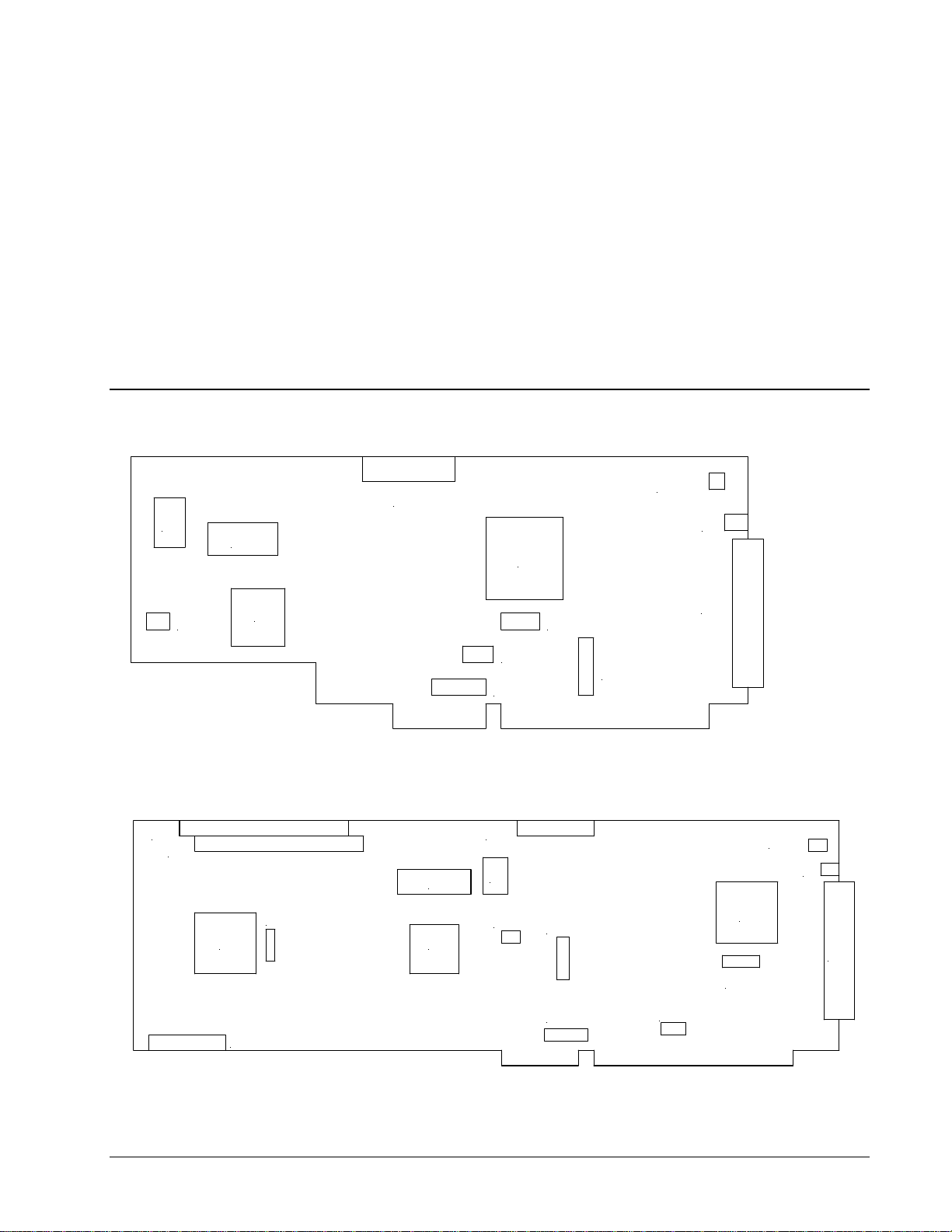

As shown in Fig. 1.2, the DMC-1700/1800 is part of a motion control system which includes amplifiers, motors, and

encoders. These elements are described below.

Power Supply

Computer

Figure 1.2 - Elements of Servo systems

DMC-1700/1800

Controller

Encoder Motor

Driver

Motor

A motor converts current into torque, which produces motion. Each axis of motion requires a motor sized properly

to move the load at the required speed and acceleration. (Galil’s “Motion Component Selector” software can help

you with motor sizing). Download at

The motor may be a step or servo motor and can be brush-type or brushless, rotary or linear. For step motors, the

controller can operate full-step, half-step, or microstep drives. An encoder is not required when step motors are

used.

www.galilmc.com/support/download, select “MCS”.

Amplifier (Driver)

For each axis, the power amplifier converts a +/-10 Volt signal from the controller into current to drive the motor.

For stepper motors, the amplifier converts step and direction signals into current. The amplifier should be sized

properly to meet the power requirements of the motor. For brushless motors, an amplifier that provides electronic

commutation is required or the controller must be configured to provide sinusoidal commutation. The amplifiers

may be either pulse-width-modulated (PWM) or linear. They may also be configured for operation with or without

a tachometer. For current amplifiers, the amplifier gain should be set such that a 10 Volt command generates the

maximum required current. For example, if the motor peak current is 10A, the amplifier gain should be 1 A/V. For

velocity mode amplifiers, 10 Volts should run the motor at the maximum speed.

Encoder

An encoder translates motion into electrical pulses which are fed back into the controller. The DMC-1700/1800

accepts feedback from either a rotary or linear encoder. Typical encoders provide two channels in quadrature,

known as CHA and CHB. This type of encoder is known as a quadrature encoder. Quadrature encoders may be

4 • Chapter 1 Overview DMC-1700/1800

Page 13

either single-ended (CHA and CHB) or differential (CHA, CHA-, CHB, CHB-). The controller decodes either type

into quadrature states or four times the number of cycles. Encoders may also have a third channel (or index) for

synchronization.

The DMC-1700/1800 can also interface to encoders with pulse and direction signals. Refer to the “CE” command in

the command reference for details.

There is no limit on encoder line density; however, the input frequency to the controller must not exceed 3,000,000

full encoder cycles/second (12,000,000 quadrature counts/sec). For example, if the encoder line density is 10,000

cycles per inch, the maximum speed is 300 inches/second. If higher encoder frequency is required, please consult

the factory.

The standard encoder voltage level is TTL (0-5v), however, voltage levels up to 12 Volts are acceptable. (If using

differential signals, 12 Volts can be input directly to the DMC-1700/1800. Single-ended 12 Volt signals require a

bias voltage input to the complementary inputs).

The DMC-1700/1800 can accept analog feedback (+/-10v) instead of an encoder for any axis. For more information

see the command AF in the command reference.

To interface with other types of position sensors such as absolute encoders, Galil can customize the controller and

command set. Please contact Galil to talk to one of our applications engineers about your particular system

requirements.

Watch Dog Timer

The DMC-1700/1800 provides an internal watchdog timer which checks for proper microprocessor operation. The

timer toggles the Amplifier Enable Output (AEN), which can be used to switch the amplifiers off in the event of a

serious controller failure. The AEN output is normally high. During power-up and if the microprocessor ceases to

function properly, the AEN output will go low. The error light for each axis will also turn on at this stage. A reset

is required to restore the controller to normal operation. Consult the factory for a Return Materials Authorization

(RMA) Number if your DMC-1700/1800 is damaged.

DMC-1700/1800 Chapter 1 Overview • 5

Page 14

THIS PAGE LEFT BLANK INTENTIONALLY

6 • Chapter 1 Overview DMC-1700/1800

Page 15

Chapter 2 Getting Started

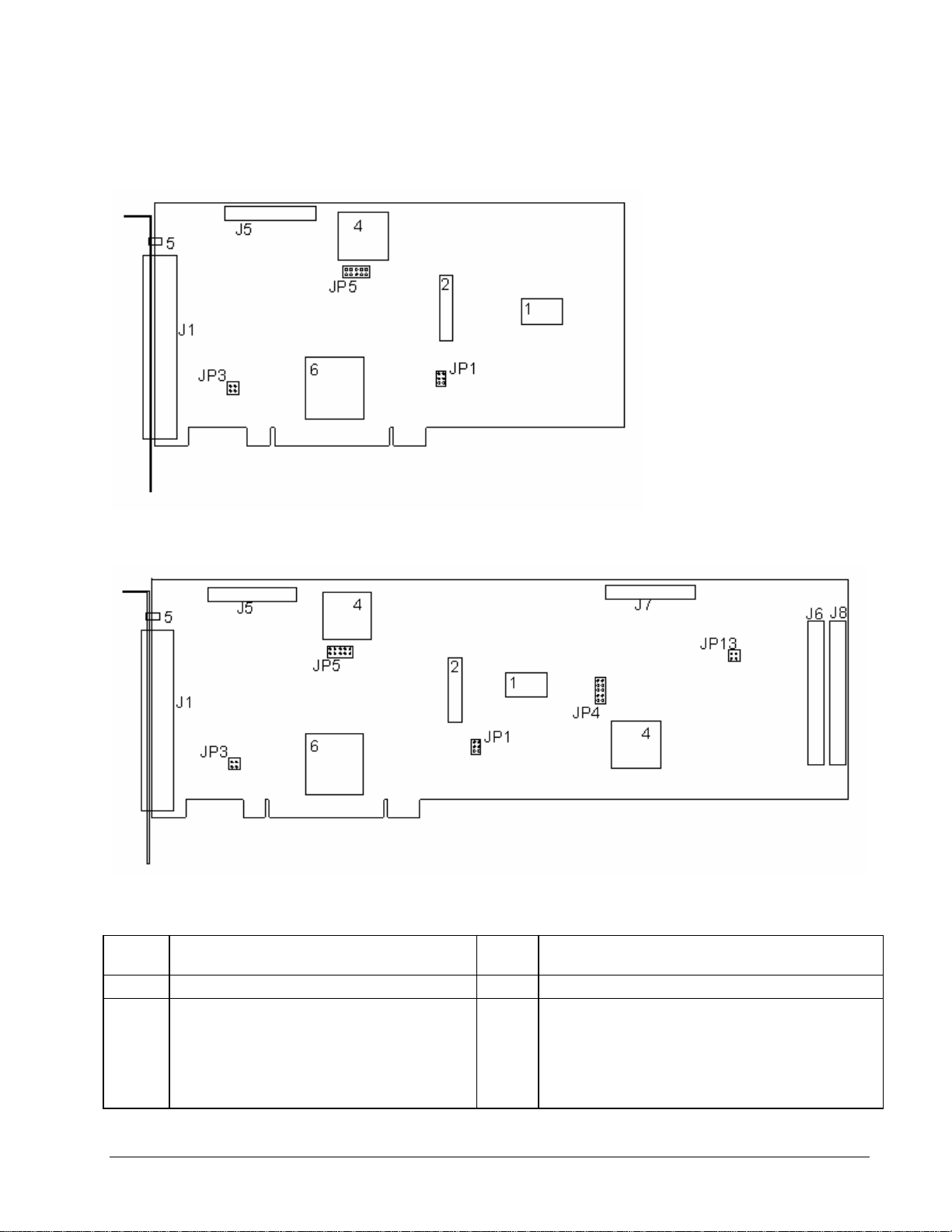

The DMC-17x0 and DMC-18x0 Motion Controllers

J5

JP3

1

5

2

4

J1

JP1

3

JP5

JP4

JP8

JP9

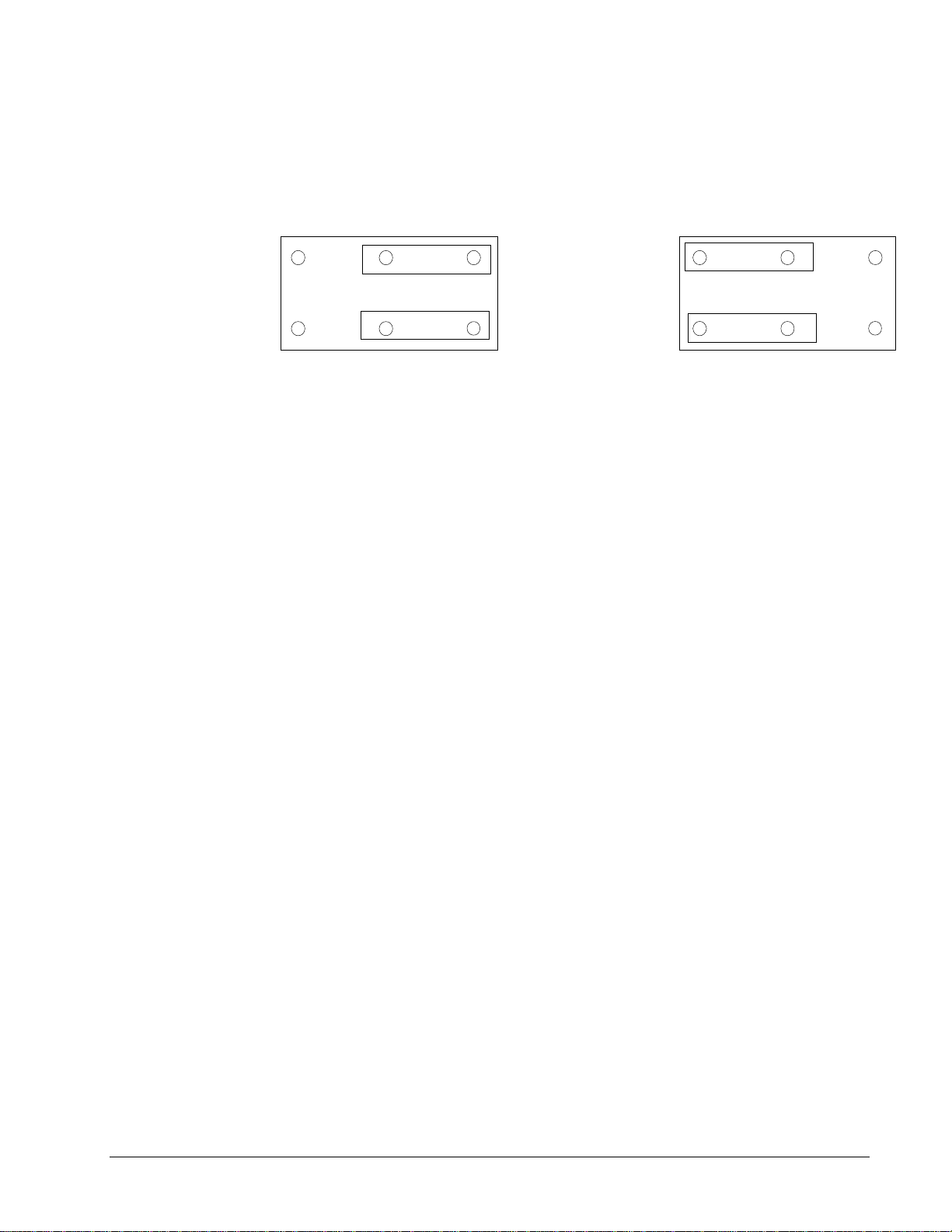

Figure 2-1 - Outline of the DMC-1710 through DMC-1740

J6

J8

4

2

JP4

3

J5

1

JP1

JP3

5

4

JP8

J1

JP5

JP9

J7

Figure 2-2 - Outline of the DMC-1750 through DMC-1780

DMC-1700/1800 Chapter 2 Getting Started • 7

JP6

Page 16

Figure 2-3 - Outline of the DMC-1810 through DMC-1840

Figure 2-4 - Outline of the DMC-1850 through DMC-1880

1 Flash EEPROM J8

2 RAM JP1 Master Reset & UPGRD jumpers

3 Motorola 68331 microprocessor JP3

8 • Chapter 2 Getting Started DMC-1700/1800

50-pin header connector corresponding to pins 1

through 50 of connector for axes 5-8

INCOM & LSCOM jumpers. Used for bypassing optoisolation for the limit, home, and abort switches and the

digital inputs IN1 - IN8. See section “Bypassing OptoIsolation”, Chap3.

DMC-1850/1880 – 1 thru 4 axis only

Page 17

4 Galil GL-1800 custom gate array JP4

5 Error LED JP5

6 Xilinx for PCI bus communications JP6

J1 100-pin high density connector for axes 1-4.

(Part number Amp #2-178238-9)

J5

J6 / J8

J7

26-pin header connector for the auxiliary encoder

cable. (Axes 1-4)

Two 50-pin headers connecting corresponding

signals for axes 5-8

26-pin header connector for the auxiliary encoder

cable. (Axes 5-8)

JP8 Address jumpers A2 – A8

JP9 IRQ jumper.

JP13

Jumpers used for configuring stepper motor operation

on axes 5-8 (DMC-1750/1780 and DMC-1850/1880

only).

Jumpers used to select DMA channel 0 or 1 (DMC1710/1740 only).

Jumpers used for configuring stepper motor operation

on axes 1-4.

Jumpers used to select DMA channel 0 or 1 (DMC1780 only).

INCOM & LSCOM jumpers. Used for bypassing optoisolation for the limit, home, and abort switches and the

digital inputs IN9 – IN16. See section “Bypassing

Opto-Isolation”, Chap3. (DMC-1850/1880 only)

Note: Above layouts are for the most current controller revisions. For older revision boards, please

refer to Appendix.

Elements You Need

Before you start, you must get all the necessary system elements. These include:

1a. DMC-1710/1810, 1720/1820, 1730/1830, or DMC-1740/1840 Motion Controller, (1)

100-pin cable, and (1) ICM-1900 interconnect module.

or

1b. DMC-1750/1850, 1760/1860, 1770/1870 or DMC-1780/1880, (2) 100-pin cables and (2)

ICM-1900s. CB 50-100 connector board and included two 50-pin ribbon cables which

converts the two 50-pin ribbon cables into a single 100-pin connector.

or

1c. DMC-1718, 1728, 1738, 1748, (1) 100-pin cables and (1) ICM-1900s. Connection to the

extended I/O can be made through the IOM-1964 opto-isolation module. Using the IOM1964 requires (1) IOM-1964, (1) CB-50-100 and (1) 100 pin cable.

2. Servo motors with Optical Encoder (one per axis) or step motors.

3. Power Amplifiers.

4. Power Supply for Amplifiers.

5. PC (Personal Computer - ISA bus or PCI bus).

6. Galil SmartTerm (from CD ROM or download at www.galilmc.com)

7. WSDK is optional but recommended for first time users.

The motors may be servo (brush type or brushless) or steppers. The amplifiers should be suitable for the motor and

may be linear or pulse-width-modulated. An amplifier may have current feedback, voltage feedback or velocity

feedback

.

DMC-1700/1800 Chapter 2 Getting Started • 9

Page 18

For servo motors in current mode, the amplifiers should accept an analog signal in the +/-10 Volt range

as a command. The amplifier gain should be set such that a +10V command will generate the

maximum required current. For example, if the motor peak current is 10A, the amplifier gain should

be 1 A/V. For velocity mode amplifiers, a command signal of 10 Volts should run the motor at the

maximum required speed. Set the velocity gain so that an input signal of 10V, runs the motor at the

maximum required speed.

The WSDK software is highly recommended for first time users of the DMC-1700/1800. It provides step-by-step

instructions for system connection, tuning and analysis.

For step motors, the amplifiers should accept step and direction signals. For start-up of a step motor

system refer to Step 8c “Connecting Step Motors”.

Installing the DMC-1700/1800

Installation of a complete, operational DMC-1700/1800 system consists of 9 steps.

Step 1. Determine overall motor configuration.

Step 2. Install Jumpers on the DMC-1700/1800.

Step 3. Install the communications software.

Step 4. Install the DMC-1700/1800 in the PC.

Step 5. Establish communications with the Galil Communication Software.

Step 6. Determine the Axes to be used for sinusoidal commutation.

Step 7. Make connections to amplifier and encoder.

Step 8a. Connect standard servo motors.

Step 8b. Connect sinusoidal commutation motors

Step 8c. Connect step motors.

Step 9. Tune the servo system

Step 1. Determine Overall Motor Configuration

Before setting up the motion control system, the user must determine the desired motor configuration. The DMC1700/1800 can control any combination of standard servo motors, sinusoidally commutated brushless motors, and

stepper motors. Other types of actuators, such as hydraulics can also be controlled, please consult Galil.

The following configuration information is necessary to determine the proper motor configuration:

Standard Servo Motor Operation:

The DMC-1700/1800 has been setup by the factory for standard servo motor operation providing an analog

command signal of +/- 10V. No hardware or software configuration is required for standard servo motor operation.

Sinusoidal Commutation:

Sinusoidal commutation is configured through a single software command, BA. This configuration causes the

controller to reconfigure the number of available control axes.

Each sinusoidally commutated motor requires two DAC’s. In standard servo operation, the DMC-1700/1800 has

one DAC per axis. In order to have the additional DAC for sinusoidal commutation, the controller must be

designated as having one additional axis for each sinusoidal commutation axis. For example, to control two

10 • Chapter 2 Getting Started DMC-1700/1800

Page 19

standard servo axes and one axis of sinusoidal commutation, the controller will require a total of four DAC’s and the

controller must be a DMC-1740 or DMC-1840.

Sinusoidal commutation is configured with the command, BA. For example, BAX sets the X axis to be sinusoidally

commutated. The second DAC for the sinusoidal signal will be the highest available DAC on the controller. For

example: Using a DMC-1740, the command BAX will configure the X axis to be the main sinusoidal signal and the

‘W’ axis to be the second sinusoidal signal.

The BA command also reconfigures the controller to indicate that the controller has one less axis of ‘standard’

control for each axis of sinusoidal commutation. For example, if the command BAX is given to a DMC-1740

controller, the controller will be re-configured to a DMC-1730 controller. By definition, a DMC-1730 controls 3

axes: X,Y and Z. The ‘W’ axis is no longer available since the output DAC is being used for sinusoidal

commutation.

Further instruction for sinusoidal commutation connections are discussed in Step 6.

Stepper Motor Operation:

To configure the DMC-1700/1800 for stepper motor operation, the controller requires a jumper for each stepper

motor and the command, MT, must be given. The installation of the stepper motor jumper is discussed in the

following section entitled “Installing Jumpers on the DMC-1700/1800”. Further instruction for stepper motor

connections are discussed in Step 8c.

Step 2. Install Jumpers on the DMC-1700/1800

Master Reset and Upgrade Jumpers

JP1 contains two jumpers, MRST and UPGRD. The MRST jumper is the Master Reset jumper. With

MRST connected, the controller will perform a master reset upon PC power up or upon the reset input

going low. Whenever the controller has a master reset, all programs, arrays, variables, and motion

control parameters stored in EEPROM will be ERASED.

The UPGRD jumper enables the user to unconditionally update the controller’s firmware. This jumper

is not necessary for firmware updates when the controller is operating normally, but may be necessary

in cases of corrupted EEPROM. EEPROM corruption should never occur, however, it is possible if

there is a power fault during a firmware update. If EEPROM corruption occurs, your controller may

not operate properly. In this case, install the UPGRD Jumper and use the update firmware function on

the Galil Terminal to re-load the system firmware.

Opto Isolation Jumpers

The inputs and limit switches are optoisolated. If you are not using an isolated supply, the internal

+5V supply from the PC may be used to power the optoisolators. This is done by installing jumpers on

JP3 and/or JP13.

For each axis that will be used for stepper motor operation, the corresponding stepper mode (SM)

jumper must be connected. The stepper motor jumpers, labeled JP5 for axes X through W and JP4 for

axes E through H, are located directly beside the GL-1800 IC’s on the main board (see the diagram for

the DMC-1700/1800). The individual jumpers are labeled SMX, SMY, SMZ and SMW for axes 1

through 4 and SME, SMF, SMG and SMH for axes 5 through 8.

Stepper Motor Jumpers

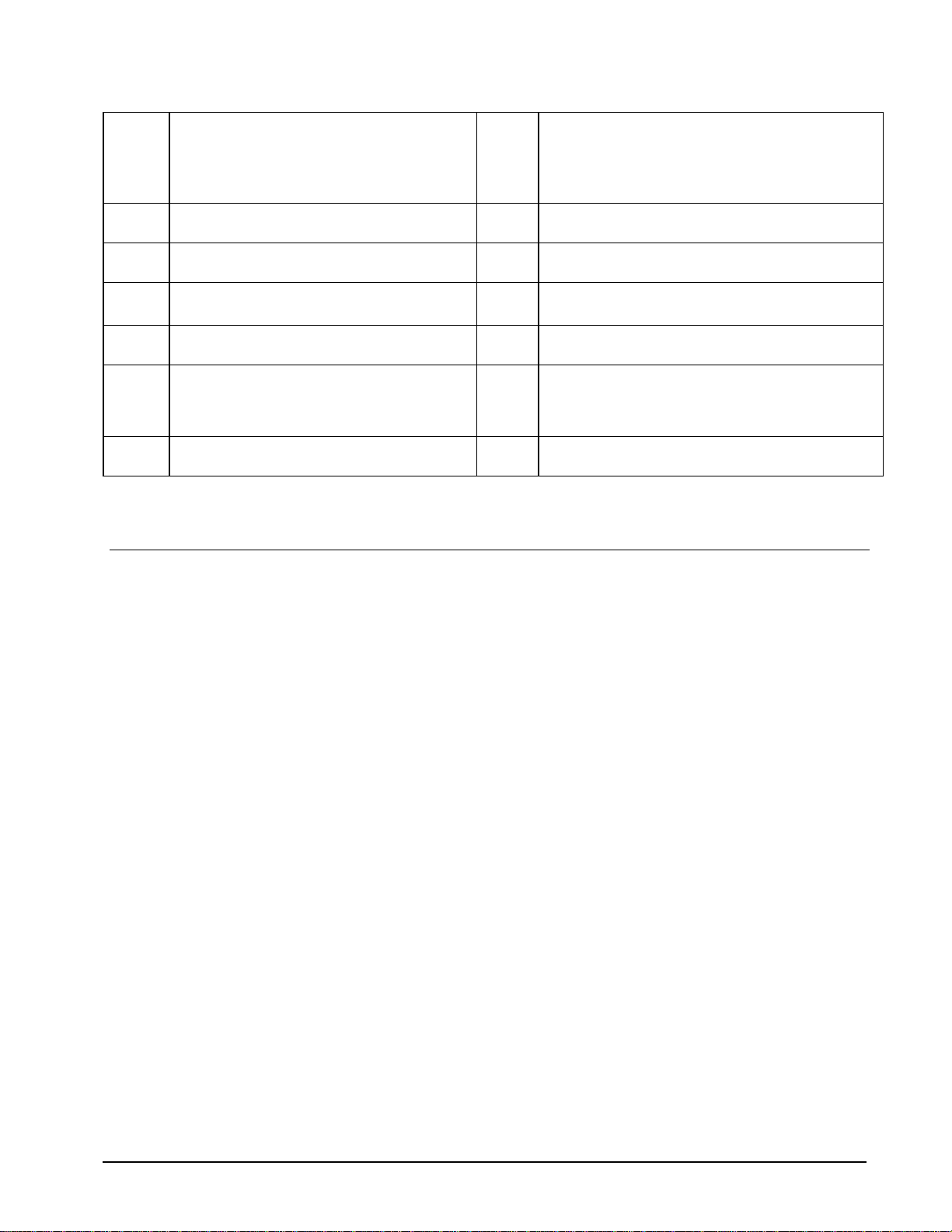

(Optional) DMA Jumpers

The DMA channel is only available with the DMC-1700 controller. The DMC-1700 controller allows

either DMA channel 0 or 1 to be selected. The jumper location JP4 on the DMC-1740 and JP6 on the

DMC-1700/1800 Chapter 2 Getting Started • 11

Page 20

DMC-1780 allows the user to select which channel will be used. The DMA channel chosen should be

Q

K

Q

K

reflected within the Galil software registry. 2.5 illustrates these settings.

Please note earlier controller revisions (Rev. E and earlier for DMC-1740, Rev. C and earlier for

DMC-1780) did not have hardware jumpers for DMA channel selection.

0

DR

1

DAC

Setting for DMA channel 1 Setting for DMA channel 0

Figure 2.5 - Jumper settings for DMC-1700 DMA

DR

DAC

(Optional) IRQ (Interrupt) Jumpers

IRQ jumpers are not necessary for communication with the Galil controllers. Rather, they are an

option that may be used for notifying the PC of events that occur on the motion controller. The

selectable IRQ jumpers are only available on the DMC-1700. The PCI drivers for the DMC-1800 will

automatically assign it an IRQ based on system availability.

On the DMC-1700, select which IRQ line will be used when the controller needs to notify the PC of an

interrupt. You will need to select an IRQ line which is open on your PC, meaning not shared with any

other device. Within the Galil Software Registry, the corresponding IRQ line should be entered into

the controller registry information.

NOTE: For Version 7 Drivers and ISA/PC-104 controllers with new firmware, a jumper MUST

be installed on one of the IRQ jumper pins in order to use Interrupt Communicati on (the default

method of communication). Match the IRQ jumper on the board with an IRQ Setting that

displays “No Conflicts” in the Device Manager.

1 0

If No IRQ lines are available or Interrupt Communication is not desired, the user must go to the

“Controller Registration” menu and uncheck the “Interrupt Communication” method. Stall or

Delay methods of communication will then be used. A Communication Timeout error will occur

if this is not done.

(Optional) Motor Off Jumpers

The state of the motor upon power up may be selected with the placement of a hardware jumper on the

controller. With a jumper installed at the MO location, the controller will be powered up in the ‘motor

off’ state. The SH command will need to be issued in order for the motor to be enabled. With no

jumper installed, the controller will immediately enable the motor upon power up. The MO command

will need to be issued to turn the motor off.

The MO jumper is always located on the same block of jumpers as the stepper motor jumpers (SM).

This feature is only available to newer revision controllers (Rev. F and later for DMC-1740, Rev. D

and later for DMC-1780, Rev. C and later for DMC-1840). Please consult Galil for adding this

functionality to older revision controllers.

12 • Chapter 2 Getting Started DMC-1700/1800

Page 21

Configuring the Address Jumpers on the DMC-1700

The DMC-1700 address, N, is selectable by setting the address jumpers labeled A2, A3, A4, A5, A6,

A7 and A8 where each jumper represents a digit of the binary number that is equivalent to N minus

512. Jumper A2 represents the 2

digit (the 4th binary digit from the right) and so on up to the most significant digit, which is represented

by jumper A8. The 2 least significant (rightmost) digits are not represented. A location with a jumper

placed on the board means the value of the digit represented by that jumper is 0. If the jumper is open,

the digit is 1.

Because the least significant digit represented by the Address Jumpers is the 2

addresses divisible by 4 are configurable on the DMC-1700. The DMC-1700 can be configured for

th

address between 512 and 1024. To configure an address you must do the following:

any 4

1. Select an address, N, between 512 and 1024, divisible by 4. Example: 516

2. Subtract 512 from N. Example: 516 – 512 = 4

3. Convert the resultant number into a 9-digit binary number being sure to represent all

leading zeros. Using our example: Converting 4 to binary results in 100. As a 9-digit

binary number, this is represented by 000000100.

4. Truncate the 2 least significant (rightmost) digits. Example: 0000001.

5. Set the jumpers as described above. Again, jumper at the location is represented by a 0,

while no jumper at the location represents a 1.

To simplify this task, there is a complete list of jumper settings for the DMC-1700 found in the

appendix in the section Setting Addresses for the DMC-1700.

2

digit (the 3rd binary digit from the right), jumper A3 represents the 2

2

digit (jumper A2), only

3

Step 3. Install the Communications Software

Before installing the controller in the PC, Galil communications software terminal and drivers should

be loaded. Installing the Galil software prior to installing the card will allow most operating system to

automatically install the DMC-1800 (PCI) controller into both the Windows and Galil registries.

Install the Galil Software Products CD-ROM into your CD drive. A Galil .htm page should

automatically appear with links to the software products. Select “DMCSmartTerm” and click

“Install…” Follow the installation procedure as outlined.

Using the Galil Software CD-ROM, go to the directory, D:\July2000 CD\DMCDOS\Disk1. Type

"INSTALL" at the DOS prompt and follow the directions.

Using the Galil Software CD ROM, go to the directory, D:\July2000 CD\DMCWIN. Select

DMCWIN16.exe and follow the directions.

Using Win98SE, ME, NT4.0, 2000, and XP

Using DOS:

Using Windows 3.x (16 bit versions):

Using Windows 95, 98(first edition):

Using the Galil Software CD ROM, go to the directory, D:\July2000 CD\DMCWIN. Select

DMCWIN32.exe and follow the directions.

DMC-1700/1800 Chapter 2 Getting Started • 13

Page 22

1X80

Note: Galil software is also available for download at: http://www.galilmc.com/support/download.html

Step 4. Install the DMC-1700/1800 in the PC

The DMC-1700 is installed directly into the ISA expansion bus. The DMC-1800 is installed directly

into the PCI expansion bus. The procedures are outlined below.

Step A. Make sure the PC is in the power-off condition.

Step B. Remove unit cover.

Step C. Remove the metal plate covering the expansion bus slot where the DMC-1700/1800

will be inserted.

Step D. Insert DMC-1700/1800 card in the expansion bus and secure with screw.

Step E. Attach 100-pin cable to your controller card. If you are using a Galil ICM-1900 or

AMP-19X0, this cable connects into the J2 connection on the interconnect module. If

you are not using a Galil interconnect module, you will need to appropriately terminate

the cable to your system components, see the appendix for cable pin outs. The auxiliary

encoder connections are accessed through the 26-pin IDC connector, J5.

If you are using a controller with more than 4 axes you will need a CB-50-100 converter board, which

brings out a second 100-pin cable to be attached to the second ICM-1900. Two 50-pin ribbon cables

attach the CB-50-100 to the DMC-1780.

DMC-1700 Install:

The DMC-1700 is addressed manually, with a default address of 1000. Earlier controller revisions

(Rev. E and earlier for DMC-1740, Rev. C and earlier for DMC-1780) had Plug-and-Play utilities,

which have been removed on the most current revisions. Please refer to the appendix if your controller

has the Plug-and-Play functionality. If an address other than 1000 is necessary for your controller,

refer to Step-2.

DMC-1800 Install:

The installation of the DMC-1800 will vary with operating systems due to how the PCI is handled

within that operating system. For Win98SE, ME, NT4.0, 2000 and XP, the OS will automatically

install the drivers. With Windows 95 or 98, upon power up your computer should recognize the DMC1800 as a new device and will prompt you for an “Installation Disk”. The computer will ask you to

point towards the DMC1800.INF file on your PC. This file will automatically configure the controller

for your computer’s available resources. The installation will also automatically add this information

to the Galil Registry (see Step 5 below).

Step 5. Establishing Communication between the Galil controller and the host PC

Using Galil Software for DOS (DMC-1700 only)

To communicate with the DMC-1700, type DMCTERM at the prompt. You will need to provide

information about your controller such as controller type (DMC-1700), address, and IRQ. Once you

have established communication, the terminal display should show a colon “:”. If you do not receive a

colon, press the carriage return.

If you still do not receive a colon, the most likely cause is an address conflict in your computer. If the

default of address 1000 causes a conflict, Galil recommends the addresses of 816 and 824, since they

are likely to avoid conflict. Please refer to Step-2 Configuring the Address Jumpers on the DMC-1700

to change the address.

14 • Chapter 2 Getting Started DMC-1700/1800

Page 23

Using Galil Software for Windows 3.x, 95 and 98 First Edition (DMC-1700

only)

In order for the Windows software to communicate with a Galil controller, the controller must be

registered in the Windows Registry. To register a controller, you must specify the model of the

controller, the communication parameters, and other information. The registry is accessed through the

Galil software, such as WSDK and DTERM (DTERM is installed with DMCWIN and installed as the

icon “Galil Terminal”). From WSDK, the registry is accessed under the FILE menu. From the

DTERM program, the registry is accessed from the REGISTRY menu.

The registry window is equipped with buttons to Add, Change, or Delete a controller. Pressing any of

these buttons will bring up the Set Registry Information window.

Use the Add button to add a new entry to the Registry. You will need to supply the Galil Controller

type. The controller model number must be entered and if you are changing an existing controller, this

field will already have an entry. Pressing the down arrow to the right of this field will reveal a menu of

valid controller types. Choose the corresponding controller (DMC-1700).

The registry information for the DMC-1700 will show a default address of 1000. This information

should be changed as necessary to reflect any changes to the controllers address jumpers. Hardware

interrupts may also be set in the registry, although for initial communication these are not necessary.

The default is no interrupt. Driver information is also listed, in which Galil recommends using the

standard Galil Drivers.

The registry entry also displays timeout and delay information. These are advanced parameters that

should only be modified by advanced users (see software documentation for more information).

Once you have set the appropriate Registry information for your controller, Select OK and close the

registry window. You will now be able to communicate with the DMC-1700. Once the entry has been

selected, click on the OK button. If the software has successfully established communications with the

controller, the registry entry will be displayed at the top of the screen.

If you are not properly communicating with the controller, the program will pause for 3-15 seconds.

The top of the screen will display the message “Status: not connected with Galil motion controller” and

the following error will appear: “STOP - Unable to establish communication with the Galil controller.

A time-out occurred while waiting for a response from the Galil controller.” If this message appears,

you must click OK. In this case, there is most likely an address conflict.

If you receive this error, the most likely cause is an address conflict in your computer. If the default of

address 1000 causes a conflict, Galil recommends the addresses of 816 and 824, since they are likely to

avoid conflict. Please refer to Step-2 Configuring the Address Jumpers on the DMC-1700 to change

the address.

Once you establish communications, click on the menu for terminal and you will receive a colon

prompt. Communicating with the controller is described in later sections.

Using Galil Software for Windows 98 SE, ME, XP, and 2000

In order for the Windows software to communicate with a Galil controller, the controller must be

entered in the Windows Registry. In Windows 98 SE, 2000 and XP operating systems (OS), the

DMC-1800 is plug and play. This means that on power up the computer will automatically detect the

card and install the appropriate device driver. A ‘Found New Hardware’ dialog box may appear

during installation of the device driver. The controller will be identified by model name and entered

into the Galil Registry. Now the user can communicate to the controller using DMCSmartTERM.

Note: In order for the PC to recognize the plug and play controller as a Galil device, the Galil

software must be loaded prior to installing the card.

DMC-1700/1800 Chapter 2 Getting Started • 15

Page 24

DMC-1800 and DMC-1417 in the Galil Registry

Using a DMC-1700 card in a plug and play OS (Win 98 SE, 2000, ME, XP) will require adding the

controller to the system in the Windows Device Manager. In Win 98 SE and ME this feature is

accessed through the Start\Settings\Control Panel\Add New Hardware shortcut. In Win 2000 and XP

it can be accessed through My Computer\Properties\Hardware\Hardware Wizard. The procedures on

the two operating systems are nearly identical, but the dialog boxes may look a little different.

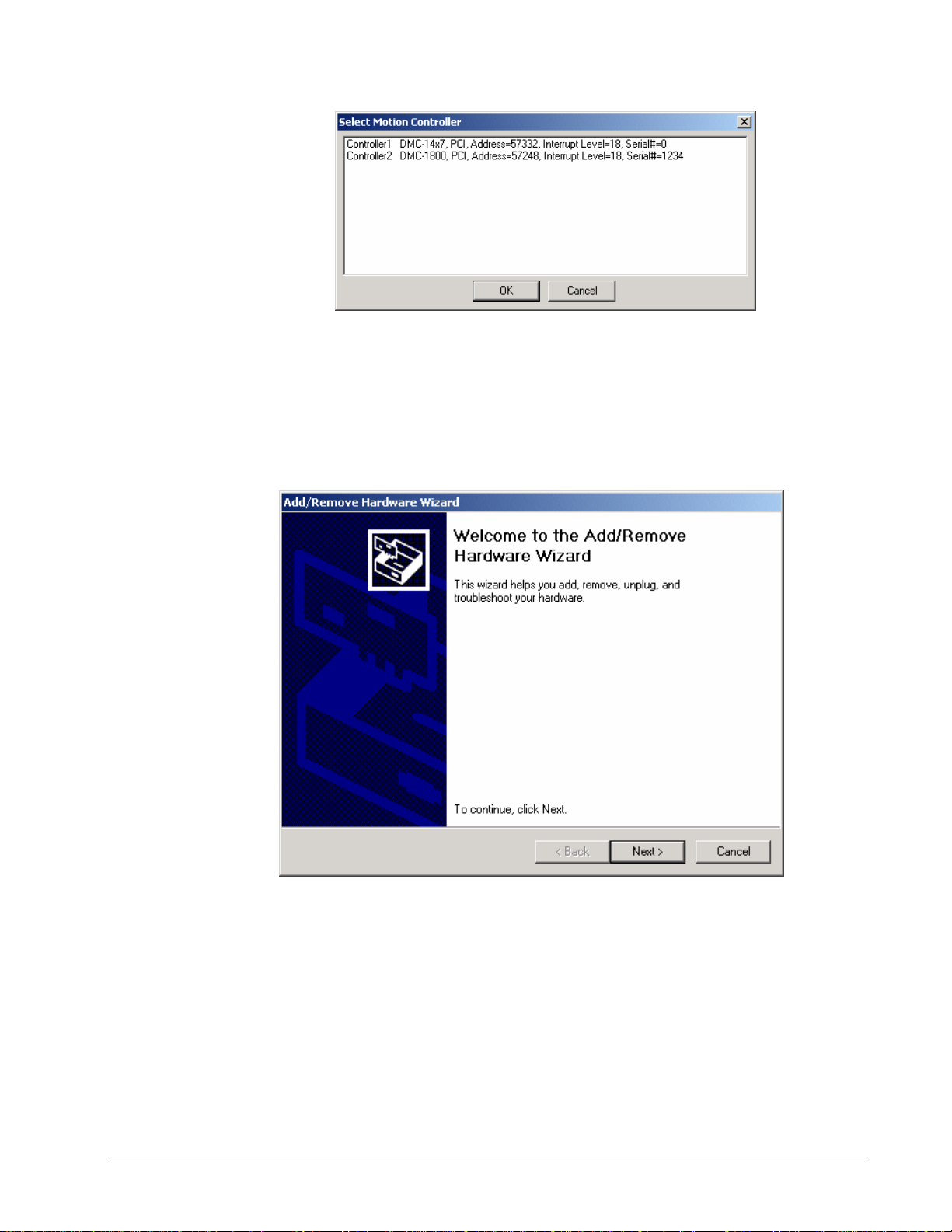

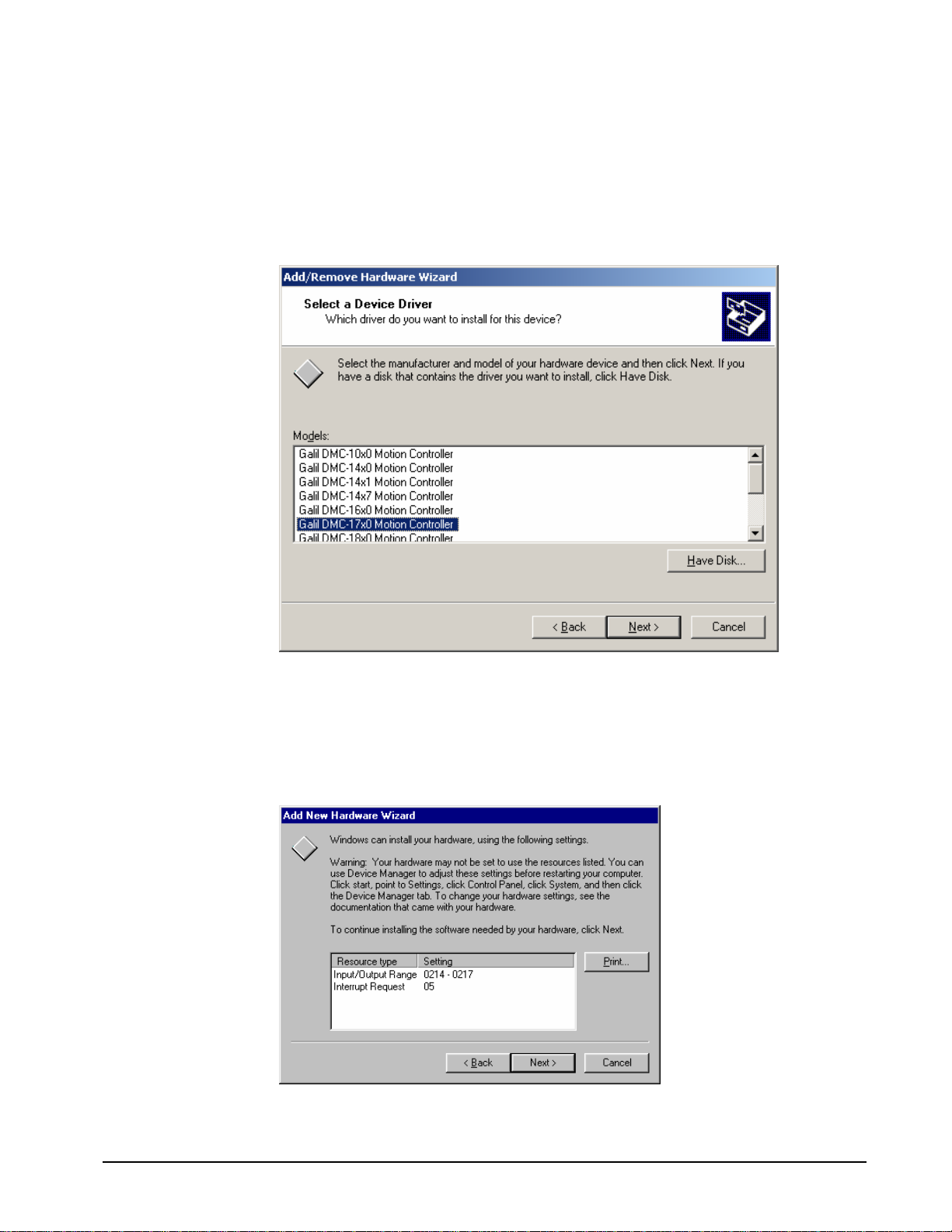

Windows 2000 Hardware Wizard

Note: All the pictures in this Hardware Wizard section are from Windows 2000 unless specified

otherwise.

1. On the first dialog, select Add/Troubleshoot

16 • Chapter 2 Getting Started DMC-1700/1800

Page 25

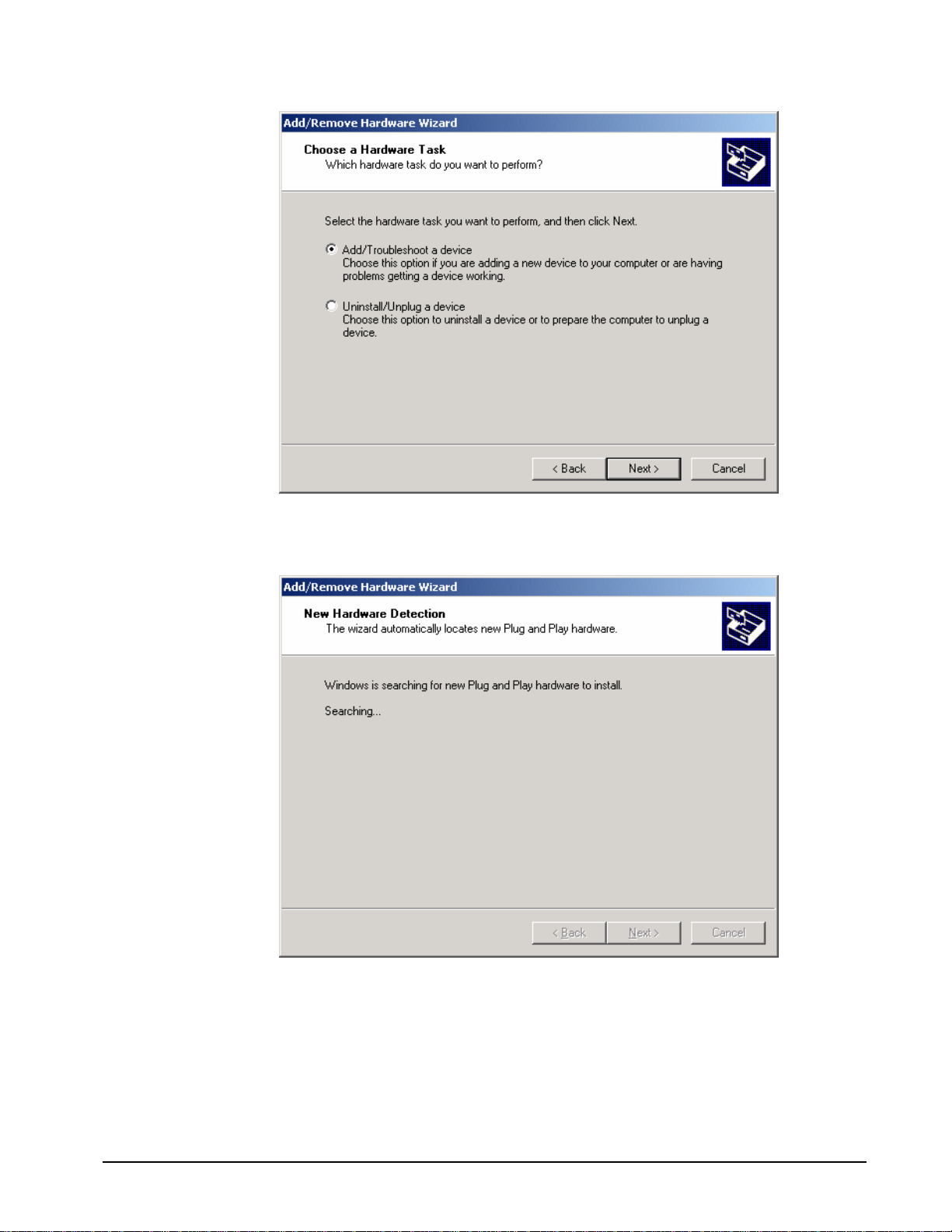

Let the Hardware Wizard try to detect a new Plug and Play device.

2.

3. If a device is found, the Hardware Wizard will then ask if the device is on a list of found

devices. Say no and proceed to the next dialog box. In Win 2000, the next window will

display a list of devices. Select “Add a new device” from the top of the list.

DMC-1700/1800 Chapter 2 Getting Started • 17

Page 26

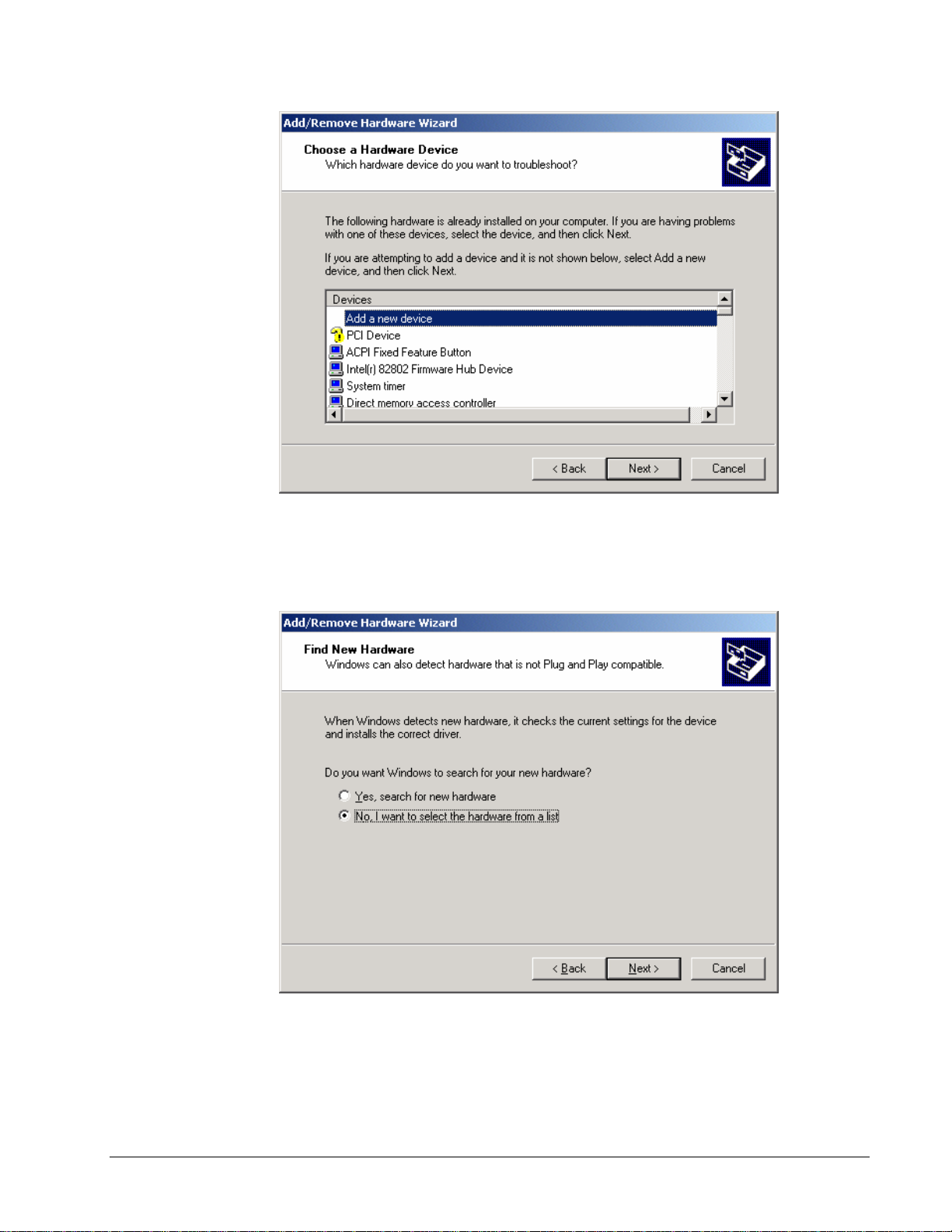

4. The Hardware Wizard prompts for Windows to search for the new device. This feature is for

devices such as modems that can be found by ‘random’ queries of all available

communication ports. Select, ‘No’ and proceed to the next dialog.

With DMCWIN32 or DMCTERM already installed, the following window will say, “Select

5.

the type of hardware you want to install”. Click on the Diamond with either “Galil” or “Galil

Motion Control” written to the side of it, and the list of Galil controllers will be displayed.

Select the DMC-1700 card from the list.

18 • Chapter 2 Getting Started DMC-1700/1800

Page 27

Note: If this is the first time a 1700 card has been installed on the machine, then the Galil

diamond may not be present. If there is no Galil diamond on the Hardware Type window,

click on Other Devices instead. At that point, the list of Galil ISA and PC/104 cards will

appear.

6. With the device selected, the OS then needs to allocate any required resources.

6a. In Win 98 SE and ME the OS automatically assigns resources that are most likely

incompatible.

Automatically Assigned resources in Win 98 SE

DMC-1700/1800 Chapter 2 Getting Started • 19

Page 28

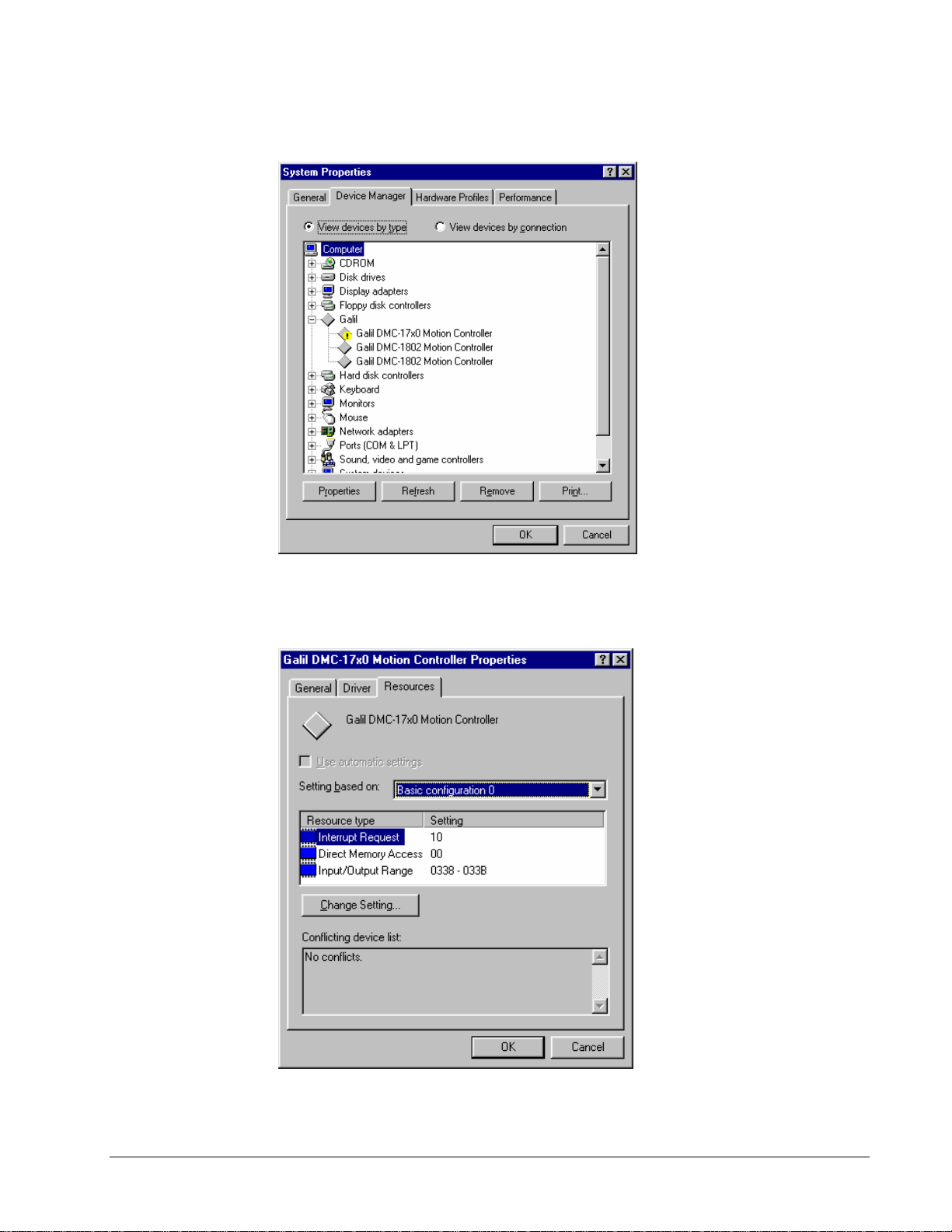

At this point the user must reboot and go to the Device Manager under My Computer\Properties.

Device Manager in Win 98 SE

Select the device from the list, go to the resource tab, and reassign the resources to those that match the

address and interrupt (IRQ) jumpers on the controller (see the appendix for ‘Address Settings’ and

Step 3 for installing jumpers).

Changing the Resources in Win 98 SE

20 • Chapter 2 Getting Started DMC-1700/1800

Page 29

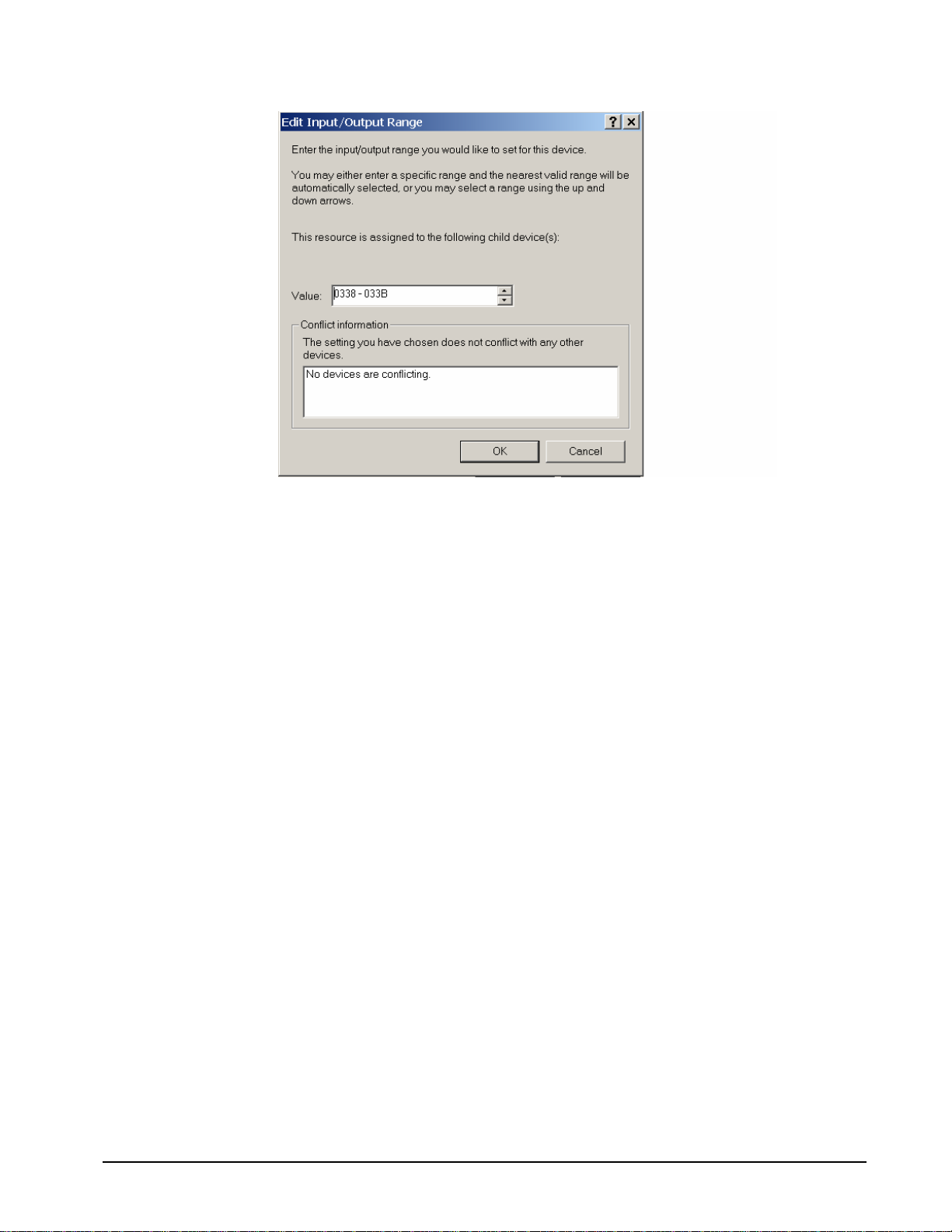

Edit Input/Output Range in Win 98 SE

When changing the settings, the operating system will inform the user of any resource conflicts. If

there are resource conflicts, it is necessary to compare the available resources to those on the jumpers,

and select a configuration that is compatible. If all configurations have a resource conflict, then the

user will have to reconfigure or remove another card to free up some resources. This is most likely to

happen with IRQs, as they can be scarce.

Note: The “Input/Output Range” is used to assign a communication address to the controller. This

address is given in hexadecimal, which means the user should use the scientific calculator in

Start\Programs\Accessories to convert the decimal address desired into its hexadecimal equivalent.

The user can just enter a single hexidecimal number into the ‘Value:’ box and the OS will assign an

I/O range to it.

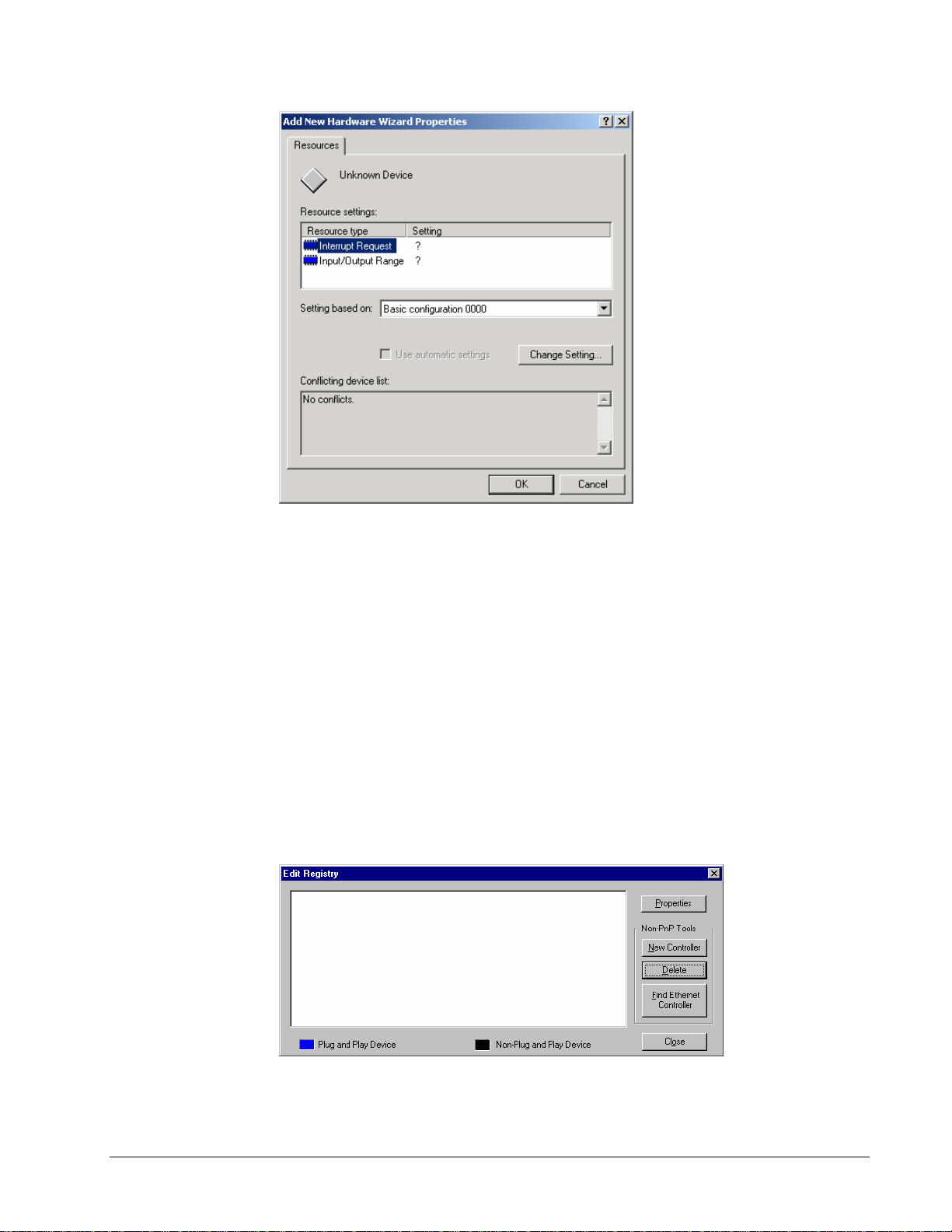

6b. In Win 2000, the procedure is the same except the user has the opportunity to set

resources/examine conflicts without rebooting first. Highlight the “Interrupt Request” and

“Input/Output Range” individually and select ‘Change Setting…’ to make the appropriate adjustments.