Page 1

USER MANUAL

DMC-1500

Manual Rev. 2.0xf

By Galil Motion Control, Inc.

Galil Motion Control, Inc.

270 Technology Way

Rocklin, California 95765

Phone: (916) 626-0101

Fax: (916) 626-0102

Internet Address: support@galilmc.com

URL: www.galilmc.com

Rev 05-06

Page 2

Using This Manual

This user manual provides information for proper operation of the DMC-1500 controller. A separate

supplemental manual, the Command Reference, contains a description of the commands available for

use with this controller.

Your DMC-1500 motion controller has been designed to work with both servo and stepper type

motors. In addition, the DMC-1500 has a daughter board for controllers with more than 4 axes.

Installation and system setup will vary depending upon whether the controller will be used with

stepper motors, or servo motors, and whether the controller has more than 4 axes of control. To make

finding the appropriate instructions faster and easier, icons will be next to any information that applies

exclusively to one type of system. Otherwise, assume that the instructions apply to all types of

systems. The icon legend is shown below.

1580

Attention: Pertains to servo motor use.

Attention: Pertains to stepper motor use.

Attention: Pertains to controllers with more than 4 axes.

Please note that many examples are written for the DMC-1540 four-axis controller or the DMC-1580

eight axes controller. Users of the DMC-1530 3-axis controller, DMC-1520 2-axis controller or

DMC-1510 1-axis controller should note that the DMC-1530 uses the axes denoted as XYZ, the

DMC-1520 uses the axes denoted as XY, and the DMC-1510 uses the X-axis only.

Examples for the DMC-1580 denote the axes as A,B,C,D,E,F,G,H. Users of the DMC-1550 5-axis

controller, DMC-1560 6-axis controller or DMC-1570, 7-axis controller should note that the DMC1550 denotes the axes as A,B,C,D,E, the DMC-1560 denotes the axes as A,B,C,D,E,F and the DMC1570 denotes the axes as A,B,C,D,E,F,G. The axes A,B,C,D may be used interchangeably with

X,Y,Z,W.

This manual was written for the DMC-1500 firmware revision 2.0 and later. For controllers with

firmware previous to revision 2.0, please consult the original manual for your hardware. The later

revision firmware was previously specified as DMC-1500-18.

WARNING: Machinery in motion can be dangerous! It is the responsibility of the user to design

effective error handling and safety protection as part of the machine. Galil shall not

responsible for any incidental or consequential damages.

be liable or

Page 3

Firmware Updates

New feature for Rev 2.0h April 1998:

Feature Description

1. CMDERR enhanced to support multitasking: If CMDERR occurs on thread 1,2 or 3, thread will be holted.

Thread can be re-started with

XQ _ED2, _ED1, 1 for retry

XQ _ED3, _ED1, 1 for next instruction

2. _VM returns instantaneous commanded vector velocity

3. FA resolution increased to 0.25.

New feature for Rev 2.0g November 1997:

Feature Description

1. CR radius now has range of 16 million Allows for large circular interpolation radii

2. _AB returns abort input Allows for monitoring of abort input

3. CW,1 When output FIFO full application program will not

pause but data will be lost

4. List Variable (LV), List Array (LA), List app program labels

(LL)

New feature for Rev 2.0e May 1997:

Feature Description

1. ER now accepts argument < 0 Disables error output (LED and Error Output does not turn on

2. During a PR decel can now be changed on an unnatural stop Allows for monitoring of abort input

New feature for Rev 2.0d February 1997:

Feature Description

1. AP, MF, MR in stepper now uses _DE instead of _RP Trippoints based on register after buffer

2. \ now terminates QD Download array no longer requires control sequence to end

3. KS can now be fraction (down to .5) Allows for smaller stepper motor smoothing delay (due to filter)

4. New arguments for MT of 2.5 and -2.5 Reverses the direction of motion from MT 2 and MT -2

5. MG now can go to 80 characters

New feature for Rev 2.0c October 1996:

Feature Description

1. MC now works for steppers More accurate trippoint for stepper motor completion

New feature for Rev 2.0b September 1996:

Allows for output FIFO buffer to fill up without affecting the

execution of a program

Allows for the user to interrogate RAM

for that axis)

Increased message size

Page 4

Feature Description

1. Operand ‘&’ and ‘|’ for conditional statements Allows for multiple conditional statements in jump routines

IE. (A>=3) & (B<55) | (C=78)

New feature for Rev 2.0 March 1996. (This revision is also designated DMC-1500-18).

DAC resolution increased to 16-bits.

Step motor control method improved.

Command Description

KS Step Motor Smoothing

New feature for Rev 1.1

Electronic Cam

New commands:

Command Description

EA Choose ECAM master

EM Cam Cycle Command

EP Cam table interval and starting point

ET ECAM table entry

EB Enable ECAM

EG Engage ECAM cycle

EQ Disengage ECAM

New features added Jan 1995:

Allow circular array recording.

New commands added July 1994 Rev 1.4:

Command Description

RI,N N is a new interrupt mask which allows changing the interrupt

mask

QU Upload array

QD Download array

MF x,y,z,w Trippoint for motion - forward direction

MR x,y,z,w Trippoint for motion - reverse direction

MC XYZW In position trippoint

TW x,y,z,w Sets timeout for in position

VR r Sets speed ratio for VS

New commands added January 1994 Rev 1.3:

Can specify parameters with axis designator. For example:

Command Description

KPZ=10 Set Z axis gain to 10

KP*=10 Set all axes gains to 10

Page 5

(KPXZ=10 is invalid. Only one or all axes can be specified at a time).

New commands added July 1993 Rev 1.2:

Command Description

_UL Gives available variables

_DL Give available labels

@COM[n] 2's complement function

New commands added March 1993: Rev 1.2

Command Description

_CS Segment counter in LM, VM and CM modes

_AV Return distance travelled in LM and VM modes

_VPX

VP x,y<n Can specify vector speed with each vector segment Where <n

Return the coordinate of the last point in a motion sequence,

LM or VM

sets vector speed

New commands added January 1993:

Command Description

HX Halt execution for multitasking

AT At time trippoint for relative time from reference

ES Ellipse scale factor

OB n,expression Defines output n where expression is logical operation, such as

I1 & I6, variable or array element

XQ#Label,n Where n = 0 through 3 and is program thread for multitasking

DV Dual velocity for Dual Loop

Feature Description

1. Allows gearing and coordinated move simultaneously

2. Multitasking for up to four independent programs

3. Velocity Damping from auxiliary encoder for dual loop

Page 6

Page 7

Contents

Chapter 1 Overview 1

Introduction ...............................................................................................................................1

Overview of Motor Types .........................................................................................................2

DMC-1500 Functional Elements...............................................................................................2

Standard Servo Motors with +/- 10 Volt Command Signal........................................2

Stepper Motor with Step and Direction Signals..........................................................2

Microcomputer Section...............................................................................................3

Motor Interface............................................................................................................3

Communication...........................................................................................................3

General I/O..................................................................................................................3

System Elements .........................................................................................................3

Motor...........................................................................................................................4

Amplifier (Driver).......................................................................................................4

Encoder or Position Sensor.........................................................................................4

Watch Dog Timer........................................................................................................4

Chapter 2 Getting Started 7

Elements You Need...................................................................................................................7

Installing the DMC-1500...........................................................................................................8

Step 1. Determine Overall Motor Configuration.........................................................8

Step 2. Install Jumpers on the DMC-1500..................................................................8

Step 3. Configure DIP switches on the DMC-1500....................................................9

Step 4. Connect AC Power to the Controller ..............................................................9

Step 5. Install Communications Software...................................................................9

Step 6. Establish Communications with Galil Software............................................10

Step 7. Connect Amplifiers and Encoders.................................................................11

Step 8a. Connect Standard Servo Motors..................................................................13

Step 8b. Connect Step Motors...................................................................................16

Step 9. Tune the Servo System..................................................................................17

Design Examples.....................................................................................................................18

Example 1 - System Set-up.......................................................................................18

Example 2 - Profiled Move.......................................................................................18

Example 3 - Multiple Axes........................................................................................19

Example 4 - Independent Moves...............................................................................19

Example 5 - Position Interrogation............................................................................19

Example 6 - Absolute Position..................................................................................20

Example 7 - Velocity Control....................................................................................20

Example 8 - Operation Under Torque Limit.............................................................20

DMC-1500 Contents • i

Page 8

Example 9 - Interrogation..........................................................................................21

Example 10 - Operation in the Buffer Mode .............................................................21

Example 11 - Motion Programs.................................................................................21

Example 12 - Motion Programs with Loops..............................................................22

Example 13 - Motion Programs with Trippoints.......................................................22

Example 14 - Control Variables................................................................................22

Example 15 - Linear Interpolation.............................................................................23

Example 16 - Circular Interpolation..........................................................................23

Chapter 3 Connecting Hardware

Overview..................................................................................................................................25

Using Opto-isolated Inputs......................................................................................................25

Limit Switch Input.....................................................................................................25

Home Switch Input....................................................................................................26

Abort Input................................................................................................................26

Uncommitted Digital Inputs......................................................................................27

Wiring the Optoisolated Inputs................................................................................................27

Using an Isolated Power Supply................................................................................ 28

Bypassing the Opto-Isolation:...................................................................................29

Changing Optoisolated Inputs From Active Low to Active High.............................30

Amplifier Interface ..................................................................................................................30

TTL Inputs...............................................................................................................................31

Analog Inputs...........................................................................................................................31

TTL Outputs ............................................................................................................................32

Offset Adjustment....................................................................................................................32

25

Chapter 4 Communication 33

Introduction..............................................................................................................................33

RS232 Ports.............................................................................................................................33

RS232 - Main Port {P1} DATATERM................................................................33

RS232 - Auxiliary Port {P2} DATASET..............................................................33

*RS422 - Main Port {P1}..........................................................................................33

*RS422 - Auxiliary Port {P2}...................................................................................34

Configuration...........................................................................................................................34

Baud Rate Selection ..................................................................................................34

Daisy-Chaining..........................................................................................................35

Daisy Chain Example:...............................................................................................35

Synchronizing Sample Clocks...................................................................................36

Controller Response to DATA ................................................................................................36

Galil Software Tools and Libraries..........................................................................................36

Chapter 5 Command Basics 37

Introduction..............................................................................................................................37

Command Syntax.....................................................................................................................37

Coordinated Motion with more than 1 axis...............................................................38

Program Syntax.........................................................................................................38

Controller Response to DATA ................................................................................................38

Interrogating the Controller.....................................................................................................39

Interrogation Commands...........................................................................................39

Summary of Interrogation Commands ......................................................................39

Additional Interrogation Methods.............................................................................40

Operands....................................................................................................................40

Command Summary ..................................................................................................40

ii • Contents DMC-1500

Page 9

Chapter 6 Programming Motion 41

Overview .................................................................................................................................41

Independent Axis Positioning..................................................................................................41

Command Summary - Independent Axis ..................................................................42

Operand Summary - Independent Axis.....................................................................42

Independent Jogging................................................................................................................44

Command Summary - Jogging..................................................................................44

Operand Summary - Independent Axis.....................................................................44

Linear Interpolation Mode.......................................................................................................45

Specifying Linear Segments......................................................................................45

Specifying Vector Acceleration, Deceleration and Speed:........................................46

Additional Commands...............................................................................................46

Command Summary - Linear Interpolation...............................................................47

Operand Summary - Linear Interpolation .................................................................48

Vector Mode: Linear and Circular Interpolation Motion........................................................50

Specifying Vector Segments.....................................................................................50

Specifying Vector Acceleration, Deceleration and Speed:........................................51

Additional Commands...............................................................................................51

Command Summary - Vector Mode Motion.............................................................53

Operand Summary - Vector Mode Motion................................................................53

Electronic Gearing...................................................................................................................54

Command Summary - Electronic Gearing................................................................55

Operand Summary - Electronic Gearing...................................................................55

Electronic Cam ........................................................................................................................57

Command Summary - ECAM Mode.........................................................................61

Operand Summary - ECAM Mode............................................................................61

Contour Mode..........................................................................................................................63

Specifying Contour Segments...................................................................................63

Additional Commands...............................................................................................64

Command Summary - Contour Mode.......................................................................64

Teach (Record and Play-Back)..................................................................................66

Stepper Motor Operation.........................................................................................................67

Specifying Stepper Motor Operation.........................................................................68

Using an Encoder with Stepper Motors ....................................................................69

Command Summary - Stepper Motor Operation.......................................................69

Operand Summary - Stepper Motor Operation.........................................................69

Dual Loop (Auxiliary Encoder)...............................................................................................70

Backlash Compensation ............................................................................................70

Command Summary - Using the Auxiliary Encoder.................................................72

Operand Summary - Using the Auxiliary Encoder ...................................................72

Motion Smoothing...................................................................................................................72

Using the IT and VT Commands (S curve profiling):...............................................72

Using the KS Command (Step Motor Smoothing):...................................................74

Homing....................................................................................................................................74

High Speed Position Capture (The Latch Function)................................................................77

Chapter 7 Application Programming

Overview .................................................................................................................................79

Using the DMC-1500 Editor to Enter Programs.....................................................................79

Edit Mode Commands...............................................................................................80

Program Format.......................................................................................................................81

Using Labels in Programs .........................................................................................81

Special Labels............................................................................................................81

DMC-1500 Contents • iii

79

Page 10

Commenting Programs..............................................................................................82

Executing Programs & Multitasking .......................................................................................83

Debugging Programs...............................................................................................................84

Debugging Programs...............................................................................................................86

Commands.................................................................................................................86

Operands....................................................................................................................86

Program Flow Commands.......................................................................................................87

Event Triggers & Trippoints .....................................................................................87

DMC-1500 Event Triggers........................................................................................88

Event Trigger Examples:...........................................................................................88

Conditional Jumps.....................................................................................................91

Subroutines................................................................................................................94

Stack Manipulation....................................................................................................94

Auto-Start Routine.....................................................................................................95

Automatic Subroutines for Monitoring Conditions...................................................95

Mathematical and Functional Expressions..............................................................................98

Mathematical Expressions.........................................................................................98

Bit-Wise Operators....................................................................................................99

Functions.................................................................................................................100

Variables................................................................................................................................100

Assigning Values to Variables:...............................................................................101

Operands................................................................................................................................102

Special Operands (Keywords).................................................................................103

Arrays ....................................................................................................................................103

Defining Arrays.......................................................................................................103

Assignment of Array Entries...................................................................................104

Automatic Data Capture into Arrays.......................................................................105

Command Summary - Automat ic Data Capture......................................................105

Data Types for Recording: ......................................................................................105

Operand Summary - Automatic Data Capture.........................................................106

Deallocating Array Space........................................................................................106

Input of Data (Numeric and String).......................................................................................107

Input of Data............................................................................................................107

Operator Data Entry Mode......................................................................................108

Using Communication Interrupt..............................................................................108

Output of Data (Numeric and String)....................................................................................110

Sending Messages ...................................................................................................110

Specifying the Serial Port for Messages:.................................................................111

Formatting Messages...............................................................................................111

Using the MG Command to Configure Terminals ..................................................112

Summary of Message Functions:.............................................................................112

Displaying Variables and Arrays.............................................................................112

Interrogation Commands.........................................................................................112

Formatting Variables and Array Elements..............................................................114

Converting to User Units.........................................................................................115

Programmable Hardware I/O.................................................................................................115

Digital Outputs ........................................................................................................115

Digital Inputs...........................................................................................................116

Input Interrupt Function ..........................................................................................117

Analog Inputs..........................................................................................................118

Example Applications............................................................................................................119

Wire Cutter..............................................................................................................119

X-Y Table Controller ..............................................................................................120

Speed Control by Joystick.......................................................................................122

Position Control by Joystick....................................................................................123

iv • Contents DMC-1500

Page 11

Backlash Compensation by Sampled Dual-Loop....................................................123

Chapter 8 Hardware & Software Protection 126

Introduction ...........................................................................................................................126

Hardware Protection..............................................................................................................126

Output Protection Lines...........................................................................................126

Input Protection Lines.............................................................................................126

Software Protection ...............................................................................................................127

Programmable Position Limits................................................................................127

Off-On-Error ...........................................................................................................127

Automatic Error Routine.........................................................................................128

Limit Switch Routine ..............................................................................................128

Chapter 9 Troubleshooting

Overview ...............................................................................................................................130

Installation .............................................................................................................................130

Communication......................................................................................................................131

Stability..................................................................................................................................131

Operation...............................................................................................................................131

130

Chapter 10 Theory of Operation 132

Overview ...............................................................................................................................132

Operation of Closed-Loop Systems.......................................................................................134

System Modeling...................................................................................................................135

Motor-Amplifier......................................................................................................136

Encoder....................................................................................................................138

DAC ........................................................................................................................139

Digital Filter............................................................................................................139

ZOH.........................................................................................................................139

System Analysis.....................................................................................................................140

System Design and Compensation ........................................................................................142

The Analytical Method............................................................................................142

Appendices

Electrical Specifications ........................................................................................................146

Performance Specifications...................................................................................................147

Card Level Layout.................................................................................................................148

Connectors for DMC-1500 Main Board................................................................................149

Connectors for Auxiliary Board (Axes E,F,G,H)..................................................................152

146

Servo Control ..........................................................................................................146

Stepper Control .......................................................................................................146

Input/Output............................................................................................................146

Power.......................................................................................................................147

J2 - Main (60 pin IDC)............................................................................................149

J5 - General I/O (26 pin IDC) .................................................................................150

J3 - Aux Encoder (20 pin IDC)...............................................................................150

J4 - Driver (20 pin IDC)..........................................................................................151

J6 - Daughter Board Connector (60 pin )................................................................151

J7 - 10 pin................................................................................................................151

JD2 - Main (60 pin IDC).........................................................................................152

JD5 - I/O (26 pin IDC)...........................................................................................153

JD3 - 20 pin IDC - Auxiliary Encoders...................................................................153

DMC-1500 Contents • v

Page 12

JD4 - 20 pin IDC - Amplifiers.................................................................................154

JD6 - Daughterboard Connector (60 pin)................................................................154

Cable Connections for DMC-1500........................................................................................154

Standard RS-232 Specifications..............................................................................154

DMC-1500 Serial Cable Specifications...................................................................155

Pin-Out Description for DMC-1500......................................................................................157

Configuration Description for DMC-1500............................................................................159

Jumpers....................................................................................................................159

Address Configuration Jumpers..............................................................................159

Front Panel Baud Rate Switches .............................................................................159

Adjustment Pots.......................................................................................................160

Dip Switch Settings ...............................................................................................................160

Offset Adjustments for DMC-1500.......................................................................................160

Accessories and Options........................................................................................................161

ICM-1100 Interconnect Module............................................................................................162

AMP/ICM-1100 Connections................................................................................................162

J2 - Main (60 pin IDC)............................................................................................165

J3 - Aux Encoder (20 pin IDC)...............................................................................165

J4 - Driver (20 pin IDC)..........................................................................................165

J5 - General I/O (26 pin IDC)..................................................................................165

JX6, JY6, JZ6, JW6 - Encoder Input (10 pin IDC).................................................165

ICM-1100 Drawing ...............................................................................................................166

AMP-11x0 Mating Power Amplifiers...................................................................................167

TERM-1500 Operator Terminal............................................................................................167

DB-15072 OPTO-22 Expansion Option................................................................................175

Configuring the I/O for the DB-15072....................................................................175

Connector Description of the DB-15072.................................................................176

Coordinated Motion - Mathematical Analysis.......................................................................179

DMC-700/DMC-1500 Comparison.......................................................................................182

List of Other Publications......................................................................................................184

Contacting Us ........................................................................................................................184

WARRANTY ........................................................................................................................185

Index 191

vi • Contents DMC-1500

Page 13

Chapter 1 Overview

Introduction

The DMC-1500 Series are packaged motion controllers designed for stand-alone operation. Features

include coordinated motion profiling, uncommitted inputs and outputs, non-volatile memory for

stand-alone operation and RS232/RS422 communication. Extended performance capability over the

previous generation of controllers includes: fast 8 MHz encoder input frequency, precise 16-bit motor

command output DAC, +/-2 billion counts total travel per move, faster sample rate, and multitasking

of up to four programs. The controllers provide increased performance and flexib ility and yet are

smaller in size and lower in cost than the previous generation. The DMC-1500 is also available as a

cost-effective, card-level product making it ideal for OEM applications.

Designed for maximum system flexibility, the DMC-1500 is available for one to eight axes and can be

interfaced to a variety of motors and drives including step motors, servo motors and hydraulics.

Each axis accepts feedback from a quadrature linear or rotary encoder with input frequencies up to 8

million quadrature counts per second. For dual-loop applications that require one encoder on both the

motor and the load, auxiliary encoder inputs are included for each axis.

The powerful controller provides many modes of motion including jogging, point-to-point positioning,

linear and circular interpolation with infinite vector feed, electronic gearing and user-defined path

following. Several motion parameters can be specified including acceleration and deceleration rates,

and slew speed. The DMC-1500 also provides S-curve acceleration for motion smoothing.

For synchronizing motion with external events, the DMC-1500 includes 8 opto-isolated inputs, 8

programmable outputs and 7 analog inputs. For controllers with 5 or more axes, the DMC-1500 has

an additional 8 opto-isolated inputs and 8 TTL inputs. I/O expansion boards provide additional inputs

and outputs or interface to OPTO 22 racks. Event triggers can automatically check for elapsed time,

distance and motion complete.

Despite its full range of sophisticated features, the DMC-1500 is easy to program. Instructions are

represented by two letter commands such as BG for Begin and SP for Speed. Conditional Instructions,

Jump Statements, and arithmetic functions are included for writing self-contained applications

programs. An internal editor allows programs to be quickly entered and edited, and support software

such as the Servo Design Kit allows quick system set-up and tuning.

To prevent system damage during machine operation, the DMC-1500 provides several error handling

features. These include software and hardware limits, automatic shut-off on excessive error, abort

input, and user-definable error and limit routines.

DMC-1500 Chapter 1 Overview • 1

Page 14

Overview of Motor Types

The DMC-1500 can provide the following types of motor control:

Standard servo motors with +/- 10 volt command signals

Step motors with step and direction signals

Other actuators such as hydraulics - For more information, contact Galil.

The user can configure each axis for any combination of motor types, providing maximum flexibility.

Standard Servo Motors with +/- 10 Volt Command Signal

The DMC-1500 achieves superior precision through use of a 16-bit motor command output DAC and

a sophisticated PID filter that features velocity and acceleration feedforward, an extra pole filter and

integration limits.

The controller is configured by the factory for standard servo motor operation. In this configuration,

the controller provides an analog signal (+/- 10Volt) to connect to a servo amplifier. This connection

is described in Chapter 2.

Stepper Motor with Step and Direction Signals

The DMC-1500 can control stepper motors. In this mode, the controller provides two signals to

connect to the stepper motor: Step and Direction. For stepper motor operation, the controller does not

require an encoder and operates the stepper motor in an open loop fashion. Chapter 2 describes the

proper connection and procedure for using stepper motors.

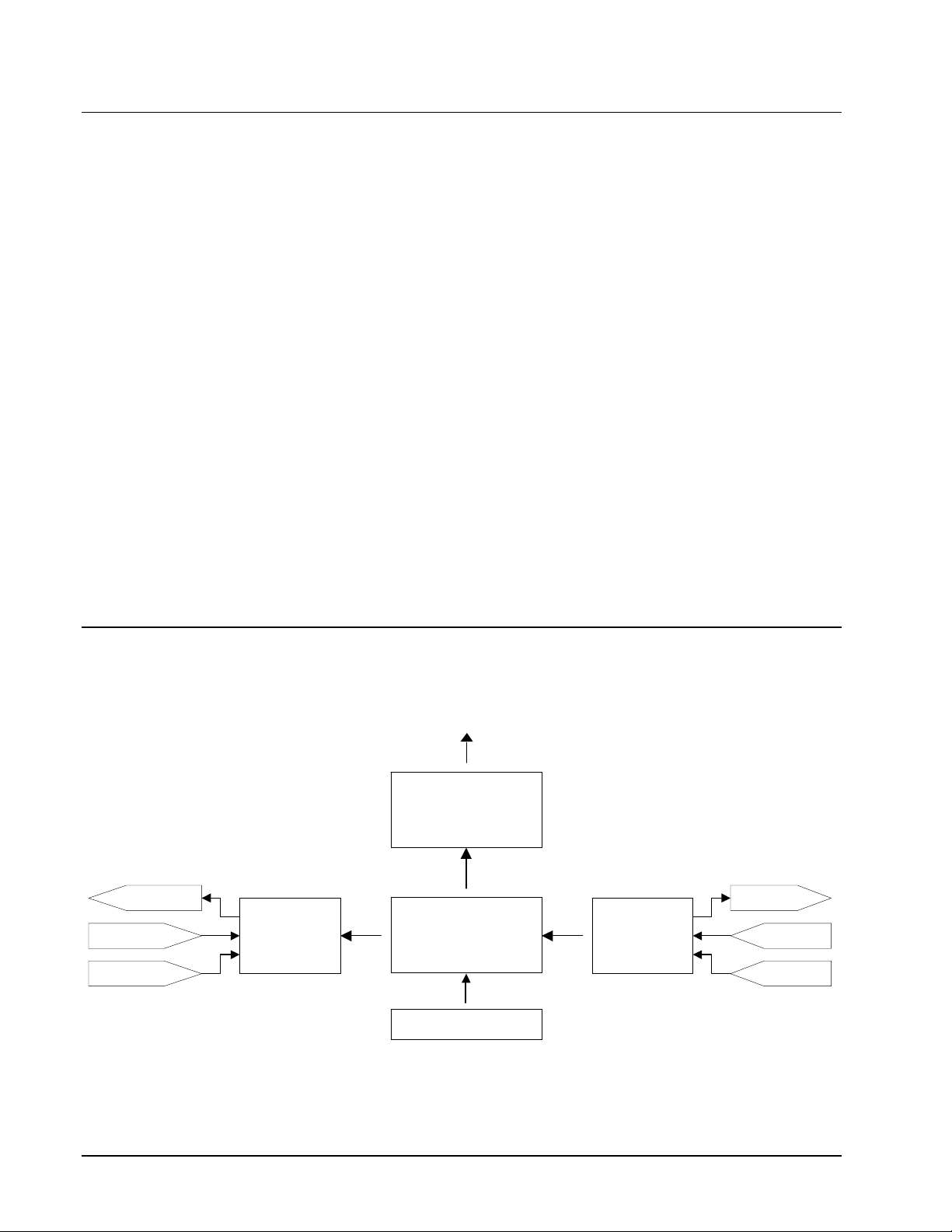

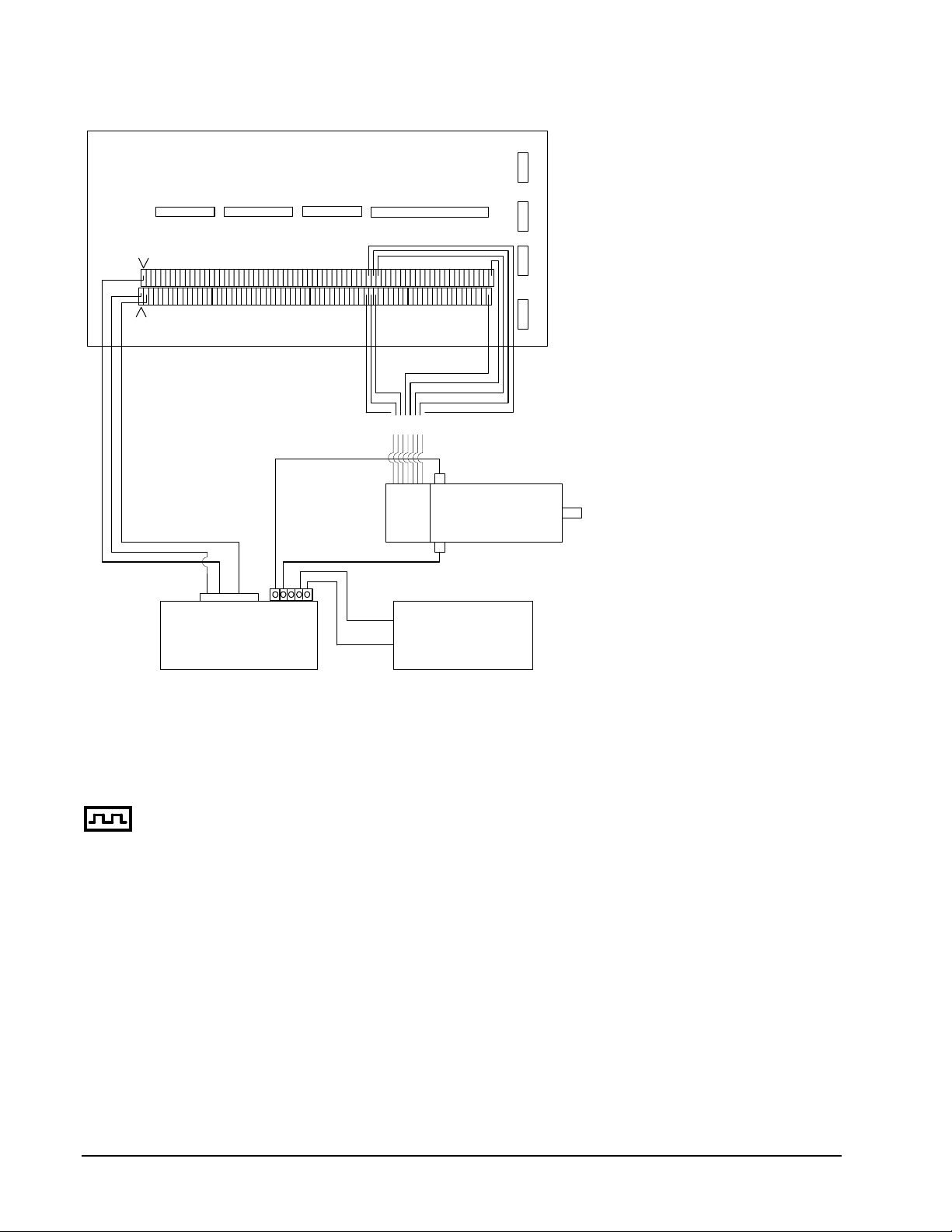

DMC-1500 Functional Elements

The DMC-1500 circuitry can be divided into the following functional groups as shown in Figure 1.1

and discussed in the following.

To

RS-232 / RS-422

Communication

80

8 Digital

8 Analog

8 TTL

I/

Interfac

Figure 1.1 - DMC-1500 Functional Elements

6834

Microcompute

256K

64K

128K EEPROM

Watch

Timer

To

GL-

4-

Motor/Encode

Interfac

Fro

Limit

Fro

Encoder

2 • Chapter 1 Overview DMC-1500

Page 15

Microcomputer Section

The main processing unit of the DMC-1500 is a specialized 32-bit Motorola 68340 Series

Microcomputer with 256K RAM, 64 K EPROM and 128 K bytes EEPROM. The RAM provides

memory for variables, array elements and application programs. The EPROM stores the firmware of

the DMC-1500. The EEPROM allows parameters and programs to be saved in non-volatile memory

upon power down.

Motor Interface

For each axis, a GL-1800 custom gate array performs quadrature decoding of the encoders at up to 8

MHz, generates the +/-10 Volt analog signal (16 Bit DAC) for input to a servo amplifier, and

generates step and direction signal for step motor drivers.

Communication

Communication to the DMC-1500 is via two separately addressable RS232 ports. The ports may also

be configured by the factory for RS422. The serial ports may be daisy-chained to other DMC-1500

controllers.

General I/O

The DMC-1500 provides interface circuitry for eight optoisolated inputs, eight general outputs and

seven analog inputs (12 Bit ADC with option for 16 Bit ADC).

1580

An auxiliary board, the DB-15072 provides interface to up to three OPTO 22 racks with 24 I/O

modules each. 24 bits can be configured for interface to output or input modules and the remaining 48

for input modules.

Controllers with 5 or more axes provide 24 inputs and 16 outputs.

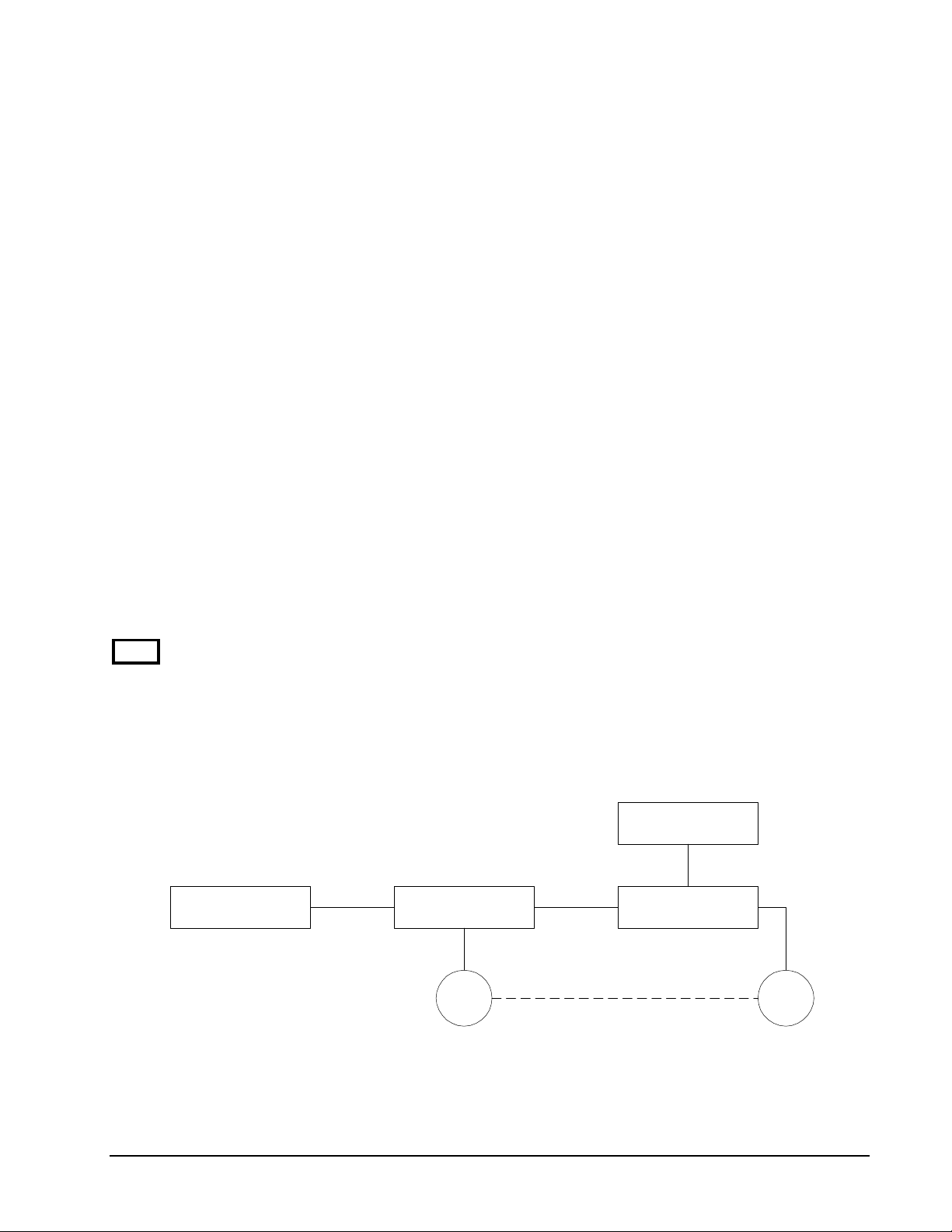

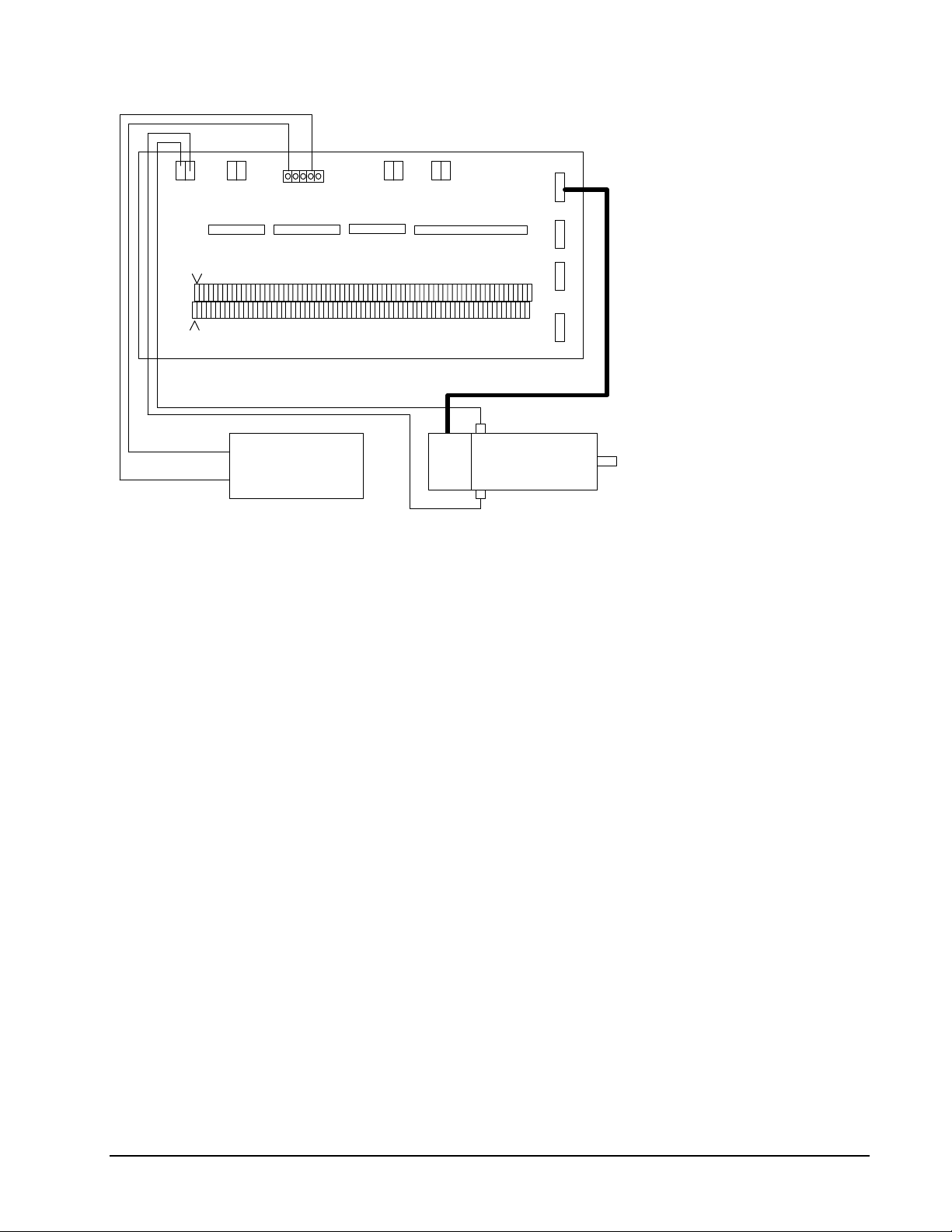

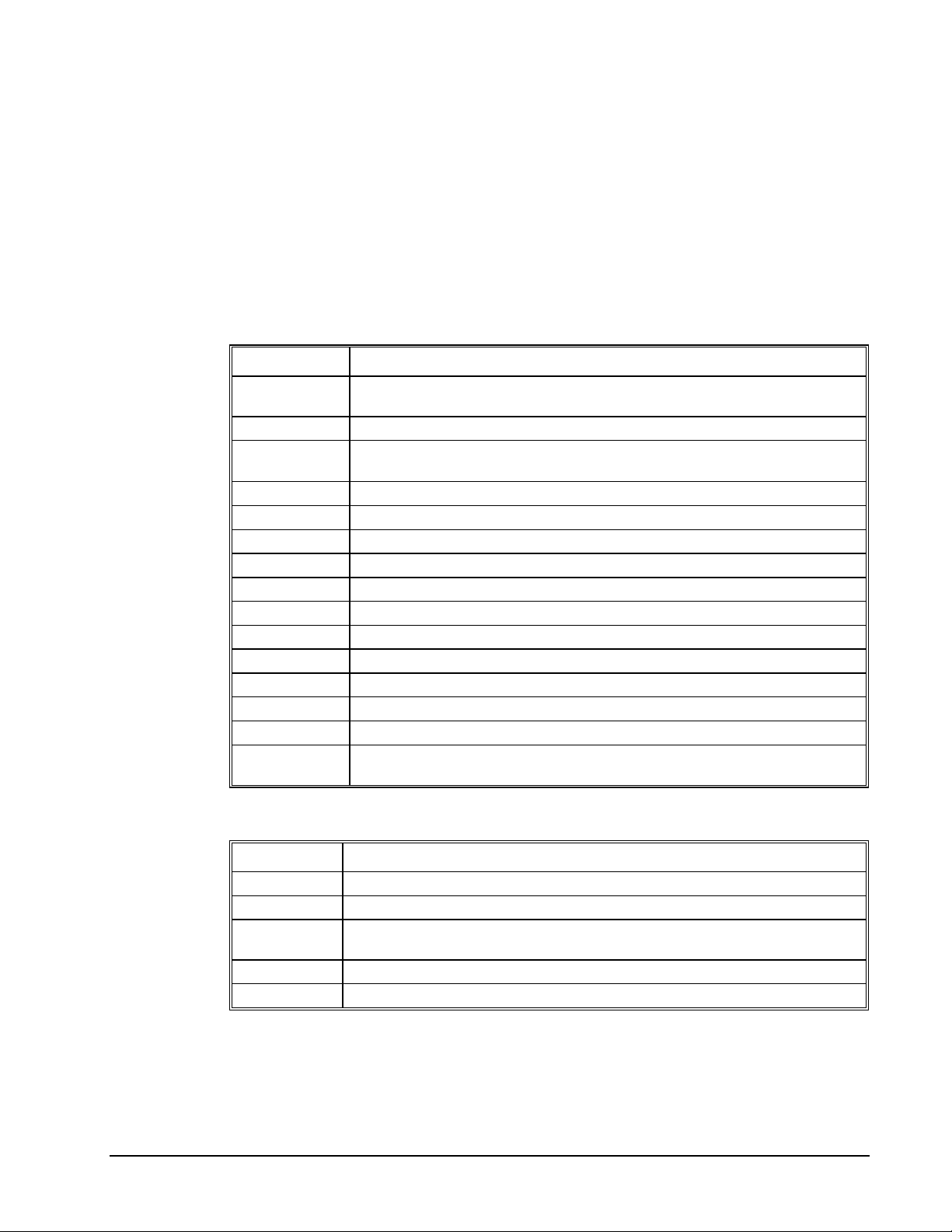

System Elements

As shown in Fig. 1.2, the DMC-1500 is part of a motion control system which includes amplifiers,

motors and encoders. These elements are described below

Power Supply

Computer DMC-1500 Controller Driver

Encoder Motor

Figure 1.2 - Elements of Servo systems

DMC-1500 Chapter 1 Overview • 3

Page 16

Motor

A motor converts current into torque which produces motion. Each axis of motion requires a motor

sized properly to move the load at the desired speed and acceleration. Galil's Motion Component

Selector software can help you calculate motor size and drive size requirements. Contact Galil at 800377-6329 if you would like this product.

The motor may be a step or servo motor and can be brush-type or brushless, rotary or linear. For step

motors, the controller can be configured to control full-step, half-step, or microstep drives.

Amplifier (Driver)

For each axis, the power amplifier converts a +/-10 Volt signal from the controller into current to

drive the motor. The amplifier should be sized properly to meet the power requirements of the motor.

For brushless motors, an amplifier that provides electronic commutation is required. The amplifiers

may be either pulse-width-modulated (PWM) or linear. They may also be configured for operation

with or without a tachometer. For current amplifiers, the amplifier gain should be set such that a 10

Volt command generates the maximum required current. For example, if the motor peak current is

10A, the amplifier gain should be 1 A/V. For velocity mode amplifiers, 10 Volts should run the motor

at the maximum speed.

For stepper motors, the amplifier converts step and direction signals into current.

Encoder or Position Sensor

An encoder translates motion into electrical pulses which are fed back into the controller. The DMC1500 accepts feedback from either a rotary or linear encoder. Typical encoders provide two channels

in quadrature, known as CHA and CHB. This type of encoder is known as a quadrature encoder.

Quadrature encoders may be either single-ended (CHA and CHB) or differential (CHA,CHA,CHB,CHB-). The DMC-1500 decodes either type into quadrature states or four times the number of

cycles. Encoders may also have a third channel (or index) for synchronization.

The DMC-1500 can also interface to encoders with pulse and direction signals.

There is no limit on encoder line density, however, the input frequency to the controller must not

exceed 2,000,000 full encoder cycles/second or 8,000,000 quadrature counts/sec. For example, if the

encoder line density is 10,000 cycles per inch, the maximum speed is 200 inches/second.

The standard voltage level is TTL (zero to five volts), however, voltage levels up to 12 Volts are

acceptable. If using differential signals, 12 Volts can be input directly to the DMC-1500. Singleended 12 Volt signals require a bias voltage input to the complementary inputs.

The DMC-1500 can accept analog feedback instead of an encoder for any axis. Note: the DMC-1580

controller must be modified by the factory to allow for analog feedback on axis H. For more

information see description of analog feedback in Chapter 2 under section entitled "Test the encoder

operation".

To interface with other types of position sensors such as resolvers or absolute encoders, Galil can

customize the controller and command set. Please contact Galil to talk to one of our applications

engineers about your particular system requirements.

Watch Dog Timer

The DMC-1500 provides an internal watch dog timer which checks for proper microprocessor

operation. The timer toggles the Amplifier Enable Output (AEN) which can be used to switch the

amplifiers off in the event of a serious DMC-1500 failure. The AEN output is normally high. During

power-up and if the microprocessor ceases to function properly, the AEN output will go low. The

4 • Chapter 1 Overview DMC-1500

Page 17

error light for each axis will also turn on at this stage. A reset is required to restore the DMC-1500 to

normal operation. Consult the factory for a Return Materials Authorization (RMA) Number if your

DMC-1500 is damaged.

DMC-1500 Chapter 1 Overview • 5

Page 18

THIS PAGE LEFT BLANK INTENTIONALLY

6 • Chapter 1 Overview DMC-1500

Page 19

Chapter 2 Getting Started

Elements You Need

Before you start, you will need the following system elements:

1. DMC-1500 Motion Controller and included cables, RS232, 60 pin ribbon cable and 26-pin

ribbon cable.

1a. For stepper motor operation, you will need an additional 20-pin ribbon cable, J4.

2. Servo motors with Optical Encoder (one per axis) or step motors

3. Power Amplifiers for motors

4. Power Supply for Amplifiers

5. PC (Personal Computer with RS232 port)

Software from Galil (Optional - but strongly recommended for first time users)

Communication Disk (COMMdisk)

-AND WSDK-16 Servo Design Software for Windows 3.1, and 3.11 for Workgroups

-OR WSDK-32 for Windows 95 or NT

ICM-1100 Interface Module (Optional, but strongly recommended). The Galil ICM-1100 is an

interconnect module with screw type terminals that directly interfaces to the DMC-1500 controller.

Note: An additional ICM-1100 is required for the DMC-1550 through DMC-1580.

The motors may be servo (brush type or brushless) or steppers. The amplifiers should be suitable for

the motor and may be linear or pulse-width-modulated. An amplifier may have current feedback or

voltage feedback.

For servo motors, the amplifiers should accept an analog signal in the +/-10 Volt range as a command.

The amplifier gain should be set so that a +10V command will generate the maximum required

current. For example, if the motor peak current is 10A, the amplifier gain should be 1 A/V. For

velocity mode amplifiers, a command signal of 10 Volts should run the motor at the maximum

required speed.

For step motors, the amplifiers should accept step and direction signals.

The WSDK software is highly recommended for first time users of the DMC-1500. It provides stepby-step instructions for system connection, tuning and analysis.

DMC-1500 Chapter 2 Getting Started • 7

Page 20

Installing the DMC-1500

Installation of a complete, operational DMC-1500 system consists of 9 steps.

Step 1. Determine overall motor configuration.

Step 2. Install jumpers on the DMC-1500.

Step 3. Configure the DIP switches on the DMC-1500.

Step 4. Connect AC power to controller

Step 5. Install communications software.

Step 6. Establish communications with Galil Software.

Step 7. Connect amplifiers and Encoders.

Step 8a. Connect standard servo motors.

Step 8b. Connect step motors.

Step 9. Tune the servo system

Step 1. Determine Overall Motor Configuration

Before setting up the motion control system, the user must determine the desired motor configuration.

The DMC-1500 can control any combination of standard servo motors, and stepper motors. Other

types of actuators, such as hydraulics can also be controlled, please consult Galil.

The following configuration information is necessary to determine the proper motor configuration:

1580

Standard Servo Motor Operation:

The DMC-1500 has been setup by the factory for standard servo motor operation providing an analog

command signal of +/- 10V. No hardware or software configuration is required for standard servo

motor operation.

Stepper Motor Operation:

To configure the DMC-1500 for stepper motor operation, the controller requires a jumper for each

stepper motor and the command, MT, must be given. The installation of the stepper motor jumper is

discussed in the following section entitled "Installing Jumpers on the DMC-1500". Further

instruction for stepper motor connections are discussed in Step 8b.

Step 2. Install Jumpers on the DMC-1500

The DMC-1500 has jumpers inside the controller box which may need to be installed. To access these

jumpers, the cover of the controller box must be removed. The following describes each of the

jumpers.

WARNING: Never open the controller box when AC power is applied to it.

For each axis that will be driving a stepper motor, a stepper mode (SM) jumper must be connected.

If you using a controller with more than 4 axis, you will have two pc-cards inside the controller box.

In this case, you will have 2 sets of stepper motor jumpers, one on each card. The jumpers on the

bottom card will be for axes X,Y,Z and W (or A,B,C, and D) and the top will be E,F,G and H. To

access the bottom card, the top card must be carefully removed.

8 • Chapter 2 Getting Started DMC-1500

Page 21

The stepper mode jumpers are located next to the GL-1800 which is the largest IC on the board. The

jumper set is labeled JP40 and the individual stepper mode jumpers are labeled SMX, SMY, SMZ,

SMW. The fifth jumper of the set, OPT, is for use by Galil technicians only.

The jumper set, J41, can be used to connect the controllers internal power supply to the optoisolated

inputs. This may be desirable if your system will be using limit switches, home inputs digital inputs,

or hardware abort and optoisolation is not necessary for your system. For a further explanation, see

section Bypassing the Opto-Isolation in Chapter 3.

Step 3. Configure DIP switches on the DMC-1500

Located on the outside of the controller box is a set of 5 DIP switches.

Switch 1 is the Master Reset switch. When this switch is on, the controller will perform a master reset

upon PC power up. Whenever the controller has a master reset, all programs and motion control

parameters stored in EEPROM will be ERASED. During normal operation, this switch should be off.

Switch 2,3 and 4 are used to configure the baud rate of the main RS232 serial port. See section

Configuration in Chapter 4.

Switch 5 is used to configure both serial ports for hardware handshake mode. Set this switch on for

handshake mode. Please note that the Galil communication software requires that hardware handshake

mode be enabled.

Step 4. Connect AC Power to the Controller

Before applying power, connect the 60-pin and 26-pin ribbons between the DMC-1500 and ICM-1100

interconnect module. The DMC-1500 requires a single AC supply voltage, single phase, 50 Hz or 60

Hz. from 90 volts to 260 volts.

WARNING: Dangerous voltages, current, temperatures and energy levels exist in this product

and in its associated amplifiers and servo motor(s). Extreme caution should be exercised in the

application of this equipment. Only qualified individuals should attempt to install, set up and

operate this equipment.

WARNING: Never open the controller box when AC power is applied to it.

Applying power will turn on the green light power indicator.

Step 5. Install Communications Software

After you have installed the DMC-1500 controller and turned the power on to your computer, you

should install software that enables communication between the controller and PC. There are several

ways to do this. The easiest way is to use the communication disks available from Galil

(COMMDISK VOL1 FOR DOS AND VOL2 FOR WINDOWS).

Using the COMMdisk Vol1 for Dos:

To use this disk, insert the COMMDISK VOL 1 in drive A. Type INSTALL and follow the

directions.

Using the COMMdisk Vol2 for Windows (16 bit and 32 bit versions):

For Windows3.x, run the installation program, setup16.exe. For Windows 95 or Windows NT, run

the installation program, setup32.exe.

DMC-1500 Chapter 2 Getting Started • 9

Page 22

Step 6. Establish Communications with Galil Software

Use the supplied 9-pin RS232 ribbon cable to connect the MAIN DMC-1500 serial port to your

computer or terminal at COMPORT 1. The DMC-1500 main serial port is configured as DATASET.

Your computer or terminal must be configured as a DATATERM for full duplex, no parity, 8 bits

data, one start bit and one stop bit.

Select the baud rate switches for 19.2 KB, 9600 B or 1200 B. The default setting is 19.2 KB.

Your computer needs to be configured as a "dumb" terminal which sends ASCII characters as they are

typed to the DMC-1500. The COMMdisk from Galil provides a terminal emulator program for your

computer. Follow the steps below to install and run the terminal emulator.

Dos Users:

To communicate with the DMC-1500, type TALK2DMC at the prompt. Once you have established

communication, the terminal display should show a colon, :. If you do not receive a colon, press the

carriage return. If a colon prompt is not returned, there is most likely an incorrect setting of the serial

communications port. The user must ensure that the correct communication port and baud rate are

specified when attempting to communicate with the controller. Please note that the serial port on the

controller must be set for handshake mode for proper communication with Galil software. The user

must also insure that the proper serial cable is being used, see appendix for pin-out of serial cable.

Windows Users:

In order for the windows software to communicate with a Galil controller, the controller must be

registered in the Galil Registry. The Galil Registry is simply a list of controllers. Registration consists

of telling the software the model of the controller, the address of the controller, and other information.

To do this, run the program DMCREG16 for Windows 3.x or DMCREG32 for Windows 95 and NT.

The DMCREG window will appear. Select Registry from the menu.

Note: If you are using DMCREG for the first time, no controllers will exist in the Ga lil Register. This

is normal.

The registry window is equipped with buttons to Add, Change, or Delete a controller. Pressing any

of these buttons will bring up the Set Registry Information window. (It should be noted that if you

wish to change information on any existing controller, it should be selected before clicking Change,

even if it is the only controller listed in the Registry.)

Use the Add button to add a new entry to the Registry. You will need to supply the Galil Controller

type. For any address changes to take effect, a model number must be entered. If you are changing an

existing controller, this field will already have an entry. If you are adding a controller, it will not.

Pressing the down arrow to the right of this field will reveal a menu of valid controller types. You

should choose DMC-1500. The registry information will show a default comm port of 2 and a default

baud rate of 9600 appears. This information should be changed as necessary to reflect the computers

comm port and the baud rate as set by the controller's DIP switches. The registry entry also displays

timeout and delay information. These are advanced parameters which should only be modified by

advanced users (see software documentation for more information).

Once you have set the appropriate Registry information for your controller, exit from the DMCREG

program. You will now be able to run communication software.

If you are using Windows 3.x, run the program DTERM16.EXE and if you are using Windows 95 or

Windows NT, run the program DTERM32.EXE. From the file menu, select Startup. You will now

see the registry information. Select the entry for your controller. Note: If you have only one entry,

you still must select this controller for the software to establish communications. Once the entry has

been selected, click on the OK button. If the software has successfully established communications

with the controller, the registry entry will be displayed at the top of the screen.

10 • Chapter 2 Getting Started DMC-1500

Page 23

If you are not properly communicating with the controller, the program will pause for 3-15 seconds.

The top of the screen will display the message “Status: not connected with Galil motion controller”

and the following error will appear: “STOP - Unable to establish communication with the Galil

controller. A time-out occurred while waiting for a response from the Galil controller.” If this

message appears, you must click OK. In this case, there is most likely an incorrect setting of the serial

communications port. The user must ensure that the correct communication port and baud rate are

specified when attempting to communicate with the controller. Please note that the serial port on the

controller must be set for handshake mode for proper communication with Galil software. The user

must also insure that the proper serial cable is being used, see appendix for pin-out of serial cable.

Once you establish communications, click on the menu for terminal and you will receive a colon

prompt. Communicating with the controller is described in later sections.

Sending Test Commands to the Terminal:

After you connect your terminal, press <carriage return> or the <enter> key on your keyboard. In

response to carriage return (CR), the controller responds with a colon, :

Now type

TPX (CR)

This command directs the controller to return the current position of the X axis. The controller should

respond with a number such as

0000000

The RS232 communication is established.

1580

Step 7. Connect Amplifiers and Encoders.

Once you have established communications between the software and the DMC-1500, you are ready

to connect the rest of the motion control system. The motion control system typically consists of an

ICM-1100 Interface Module, an amplifier for each axis of motion, and a motor to transform the current

from the amplifier into torque for motion. Galil also offers the AMP-11X0 series Interface Modules

which are ICM-1100’s equipped with servo amplifiers for brush type DC motors.

If you are using an ICM-1100, connect the 100-pin ribbon cable to the DMC-1500 and to the

connector located on the AMP-11X0 or ICM-1100 board. The ICM-1100 provides screw terminals

for access to the connections described in the following discussion.

Motion Controllers with more than 4 axes require a second ICM-1100 or AMP-11X0 and second 100pin cable.

System connection procedures will depend on system components and motor types. Any combination

of motor types can be used with the DMC-1500.

Here are the first steps for connecting a motion control system:

Step A. Connect the motor to the amplifier with no connection to the controller. Consult the

amplifier documentation for instructions regarding proper connections. Connect and

turn-on the amplifier power supply. If the amplifiers are operating properly, the motor

should stand still even when the amplifiers are powered up.

Step B. Connect the amplifier enable signal.

Before making any connections from the amplifier to the controller, you need to verify

that the ground level of the amplifier is either floating or at the same potential as earth.

WARNING: When the amplifier ground is not isolated from the power line or when it has a different

potential than that of the computer ground, serious damage may result to the computer controller

and amplifier.

DMC-1500 Chapter 2 Getting Started • 11

Page 24

If you are not sure about the potential of the ground levels, connect the two ground

signals (amplifier ground and earth) by a 10 KΩ resistor and measure the voltage across

the resistor. Only if the voltage is zero, connect the two ground signals directly.

The amplifier enable signal is used by the controller to disable the motor. It will disable

the motor when the watchdog timer activates, the motor-off command, MO, is given, or

the position error exceeds the error limit with the "Off-On-Error" function enabled (see

the command OE for further information).

The standard configuration of the AEN signal is TTL active high. In other words, the

AEN signal will be high when the controller expects the amplifier to be enabled. The

polarity and the amplitude can be changed if you are using the ICM-1100 interface

board. To change the polarity from active high (5 volts = enable, zero volts = disable) to

active low (zero volts = enable, 5 volts = disable), replace the 7407 IC with a 7406. Note

that many amplifiers designate the enable input as ‘inhibit’.

To change the voltage level of the AEN signal, note the state of the resistor pack on the

ICM-1100. When Pin 1 is on the 5V mark, the output voltage is 0-5V. To change to 12

volts, pull the resistor pack and rotate it so that Pin 1 is on the 12 volt side. If you

remove the resistor pack, the output signal is an open collector, allowing the user to

connect an external supply with voltages up to 24V.

On the ICM-1100, the amplifier enable signal is labeled AENX for the X axis. Connect

this signal to the amplifier (figure 2.3) and issue the command, MO, to disable the motor

amplifiers - often this is indicated by an LED on the amplifier.

Step C. Connect the encoders

For stepper motor operation, an encoder is optional.

For servo motor operation, if you have a preferred definition of the forward and reverse

directions, make sure that the encoder wiring is consistent with that definition.

The DMC-1500 accepts single-ended or differential encoder feedback with or without an

index pulse. If you are not using the AMP-11X0 or the ICM-1100 you will need to

consult the appendix for the encoder pinouts for connection to the motion controller. The

AMP-11X0 and the ICM-1100 can accept encoder feedback from a 10-pin ribbon cable

or individual signal leads. For a 10-pin ribbon cable encoder, connect the cable to the

protected header connector labeled X ENCODER (repeat for each axis necessary). For

individual wires, simply match the leads from the encoder you are using to the encoder

feedback inputs on the interconnect board. The signal leads are labeled XA+ (channel

A), XB+ (channel B), and XI+. For differential encoders, the complement signals are

labeled XA-, XB-, and XI-.

Note: When using pulse and direction encoders, the pulse signal is connected to CHA

and the direction signal is connected to CHB. The controller must be configured for

pulse and direction with the command CE. See the command summary for further

information on the command CE.

Step D. Verify proper encoder operation.

Start with the X encoder first. Once it is connected, turn the motor shaft and interrogate

the position with the instruction TPX <return>. The controller response will vary as the

motor is turned.

At this point, if TPX does not vary with encoder rotation, there are three possibilities:

1. The encoder connections are incorrect - check the wiring as necessary.

2. The encoder has failed - using an oscilloscope, observe the encoder signals. Verify that both channels

A and B have a peak magnitude between 5 and 12 volts. Note that if only one encoder channel fails,

12 • Chapter 2 Getting Started DMC-1500

Page 25

the position reporting varies by one count only. If the encoder failed, replace the encoder. If you

cannot observe the encoder signals, try a different encoder.

3. There is a hardware failure in the controller- connect the same encoder to a different axis. If the

problem disappears, you probably have a hardware failure. Consult the factory for help.

Step 8a. Connect Standard Servo Motors

The following discussion applies to connecting the DMC-1500 controller to standard servo motor

amplifiers:

The motor and the amplifier may be configured in the torque or the velocity mode. In the torque

mode, the amplifier gain should be such that a 10 Volt signal generates the maximum required current.

In the velocity mode, a command signal of 10 Volts should run the motor at the maximum required

speed.

Step by step directions on servo system setup are also included on the WSDK (Windows Servo Design

Kit) software offered by Galil. See section on WSDK for more details.

Step A. Check the Polarity of the Feedback Loop

It is assumed that the motor and amplifier are connected together and that the encoder is

operating correctly (Step B). Before connecting the motor amplifiers to the controller,

read the following discussion on setting Error Limits and Torque Limits. Note that this

discussion only uses the X axis as an examples.

Step B. Set the Error Limit as a Safety Precaution

Usually, there is uncertainty about the correct polarity of the feedback. The wrong

polarity causes the motor to run away from the starting position. Using a terminal

program, such as DMCTERM, the following parameters can be given to avoid system

damage:

Input the commands:

ER 2000 <CR> Sets error limit on the X axis to be 2000 encoder counts

OE 1 <CR> Disables X axis amplifier when excess position error exists

If the motor runs away and creates a position error of 2000 counts, the motor amplifier

will be disabled. Note: This function requires the AEN signal to be connected from the

controller to the amplifier.

Step C. Set Torque Limit as a Safety Precaution

To limit the maximum voltage signal to your amplifier, the DMC-1500 controller has a

torque limit command, TL. This command sets the maximum voltage output of the

controller and can be used to avoid excessive torque or speed when initially setting up a

servo system.

When operating an amplifier in torque mode, the voltage output of the controller will b e

directly related to the torque output of the motor. The user is responsible for determining

this relationship using the documentation of the motor and amplifier. The torque limit

can be set to a value that will limit the motors output torque.

When operating an amplifier in velocity or voltage mode, the voltage output of the

controller will be directly related to the velocity of the motor. The user is responsible for

determining this relationship using the documentation of the motor and amplifier. The

torque limit can be set to a value that will limit the speed of the motor.

For example, the following command will limit the output of the controller to 1 volt on

the X axis:

DMC-1500 Chapter 2 Getting Started • 13

Page 26

TL 1 <CR>

Note: Once the correct polarity of the feedback loop has been determined, the torque limit

should, in general, be increased to the default value of 9.99. The servo will not operate

properly if the torque limit is below the normal operating range. See description of TL in

the command reference.

Step D. Connect the Motor

Once the parameters have been set, connect the analog motor command signal (ACMD)

to the amplifier input.

To test the polarity of the feedback, command a move with the instruction:

PR 1000 <CR> Position relative 1000 counts

BGX <CR> Begin motion on X axis

When the polarity of the feedback is wrong, the motor will attempt to run away. The

controller should disable the motor when the position error exceeds 2000 counts. If the

motor runs away, the polarity of the loop must be inverted.

Note: Inverting the Loop Polarity

When the polarity of the feedback is incorrect, the user must invert the loop polarity and

this may be accomplished by several methods. If you are driving a brush-type DC motor,

the simplest way is to invert the two motor wires (typically red and black). For example,

switch the M1 and M2 connections going from your amplifier to the motor. When

driving a brushless motor, the polarity reversal may be done with the encoder. If you are

using a single-ended encoder, interchange the signal CHA and CHB. If, on the other

hand, you are using a differential encoder, interchange only CHA+ and CHA-. The loop

polarity and encoder polarity can also be affected through software with the MT, and CE

commands. For more details on the MT command or the CE command, see the

Command Reference section.

Note: Reversing the Direction of Motion

If the feedback polarity is correct but the direction of motion is opposite to the desired

direction of motion, reverse the motor leads AND the encoder signals.

When the position loop has been closed with the correct polarity, the next step is to adjust the PID

filter parameters, KP, KD and KI. It is necessary to accurately tune your servo system to ensure

fidelity of position and minimize motion oscillation as described in the next section .

14 • Chapter 2 Getting Started DMC-1500

Page 27

ICM-1100

J4

J5

J3

J2

Pin 2

Pin 1

red wire

black wire

+

CPS Power Supply

-

Screw Terminals

Encoder Ribbon Cable

(Typically Black Connector)

-

Galil

DC Servo Motor

Encoder

(Typically Red Connector)

+

W Encoder Z Encoder Y Encoder X Encoder

Figure 2-2 - System Connections with the AMP-1100Amplifier. Note: this figure shows a Galil Motor and

Encoder which uses a flat ribbon cable to connect to the AMP-1100 unit.

DMC-1500 Chapter 2 Getting Started • 15

Page 28

ICM-1100

ACMDX

GND

AENX

Pin 2

Pin 1

J4

J5

Screw Terminals

Encoder Wire Connections

Encoder: ICM-1100:

Channel A(+) XA+

Channel B(+) XB+

Channel A- XAChannel B- XBIndex Pulse XI+

Index Pulse - XI-

+Ref In 4

Inhibit* 11

Signal Gnd 2

MSA 12-80

Motor + 1

Motor - 2

Power Gnd 4

High Volt 5

J3

XI+ (81)

XB+ (79)

XA+ (77)

Encoder Wires

black wire

red wire

J2

+5V (103)

GND (104)

XI- (82)

XB- (80)

XA- (78)

(Typically Red Connector)

+

DC Servo Motor

Encoder

(Typically Black Connector)

-

-

CPS Power Supply

+

W Encoder Z Encoder Y Encoder X Encoder

Figure 2-3 System Connections with a separate amplifier (MSA 12-80). This diagram shows

the connections for a standard DC Servo Motor and encoder.

Step 8b. Connect Step Motors

In Stepper Motor operation, the pulse output signal has a 50% duty cycle. Step motors operate open

loop and do not require encoder feedback. When a stepper is used, the auxiliary encoder for the

corresponding axis is unavailable for an external connection. If an encoder is used for position

feedback, connect the encoder to the main encoder input corresponding to that axis. The commanded

position of the stepper can be interrogated with RP or DE. The encoder position can be interrogated

with TP.

The frequency of the step motor pulses can be smoothed with the filter parameter, KS. The KS

parameter has a range between 0.5 and 8, where 8 implies the largest amount of smoothing. See

Command Reference regarding KS.