Page 1

DMC-1400 Series

Command Reference

Manual Rev. 2.8

By Galil Motion Control, Inc.

DMC-1400 Series

Galil Motion Control, Inc.

3750 Atherton Road

Rocklin, California 95765

Phone: (916) 626 0101

Fax: (916) 626-0102

Internet Address: support@galilmc.com

URL: www.galilmc.com

Rev 8/06

Page 2

ARRAYS CONTROL FEEDBACK MATH PROGRAM STEPPER

DA deallocate DV dual loop AF analog feedback @ABS[n] | | BK breakpoint KS smoothing n

_DA arrays le FA accel feedfw AL arm latch @ACOS[n] arccos DL downlo

DM defin FV speed feedf _AL latch occurred? arcsin _DL labels l AV wait for arc length e wd @ASIN[n] eft

_DM space le IL integrator li configure arctan ED edit _AVS arc length ft mit CE @ATAN[n]

LA li derivative g OC output compare n] bit not ELSE if else CA 2nd vector st KD ain @COM[

QD downloa KI integral gain _OC first pulse? ] cosine EN end CR circle d @COS[n

QU print/uploa KP proportional gain RL read latch @FRAC[n] fraction ENDIF if en CS clear sequence d dif

RA reco MO motor _RL latch position @INT[n] integer HX halt thread _CS segment rd off

RC begi _MO motor o TD tell dual @RND[n] round IF conditio elliptical scale n ff? nal ES

_RC recording NB notch wid TP tell position @SIN[n] sine JP for/while loop LE linear end ? th

RD dat NF notch frequen TV tell veloc @SQR[n] x^0. JS jump subrou e _LE total arc length a cy ity 5 tin

_RD addres NZ notch ze

[ ] index F offs GA ax + add LS list LM linear axes O et es

COMMUNICAT

CC aux seri SH servo he GR ratio * multiply NO (') comment TN tangent scale al re

CF unsolicite TE tell er

CI interrup TK peak torqu DE define dual ( ) parenthesis REM fast comment VA acceleration t e

CW unsolicited b TL torque limit DP define position & an RI return interrupt VD deceleration it d

DR data recor TM sample time FE find home o | SL single step VE vector end d nly or

EO ech TT tell torq FI find index on $ hexadecimal TB tell status b VM vector axes o ue ly yte

HS handle swit

IA IP addre master ax _HM home inp > greater than UL upload VP vector point ss EA is ut

_IA Ethernet in EB enable

IH open hand count _BN serial number <= less or equal XQ execute VR VS multiplier le EC er

_IH handle in EG engage slav _BV axes >= greater or equal _XQ current li # VS speed fo e ne

IN user inpu modul ^R^V firmware rev <> not equ ZS zero stack VT s curve t EM us al

LZ leading zero master positions

MG messag EQ disengage slave @AN[x] analog in C acceleratio #AUTO; EN e A n

P2CD port 2 cod ET table @IN[x] digital in begi #AUTOERR; EN e BG n

P2CH characte

P2NM numbe ^R^S master reset AI wait for input DC deceleratio # subrouti r n ne

P2ST string BN burn AO set analog output IP increment position

PF position forma BP burn program CB clear digital out IT s curv AT wait refere t e nce

QR query record BV burn variables CN configure JG jo TIME clock g

QZ record info RS reset CO extended I/O PA position absolut WT wait e

SA send command

_SA response AB abo MB Modbus TCP PR position relativ BA ax rt e es

TH tell handles _AB abort input MW Modbus w _PR relative targe _BA 2nd DAC axis ait t

VF variable forma BL reverse soft limit OB output bit PT position trackin BB hall off t g set

WH which handle _ED program line OP output port RP desired positio BC calibration n

_WH numeric _ED1 thread SB set digital out SP speed _BC hall state

#COMINT; N1,1 ER maximum TE TI tell input b ST stop BD degre yte es

#TCPERR; RE FL forward soft limit TS tell switch ~a axis variabl BI hall inputs es e

CONTOUR

CD data _LR reverse limit #ININT; RI1 AD distance (RP) BO DAC offset

CM axes OE off on e AM complete (RP) BS setup rror

_CM buffer ful SC stop code AP position (TP) BZ find zero l

DT delta tim TC tell code AR distance (RP) _BZ distance to zero e

WC wait for buffe #CMDERR; EN1 AS at speed (SP) r

IMSWI; RE1 MC complete (TP) #L

OSERR; RE1 MF forward (TP) #P

MR reverse (TP)

TW MC timeout

#MCTIME; EN1

ft d ad

GEAR

E

PL low pas GM gantry mode - subtract LV list variables _LM buffer space

s

HOME

ECAM

HM hom < less than TR debug trace _VM velocity ch e

INFO

I/O MOTION

EEPROM

ERRORS

_LF forward limit TZ tell Ethernet I/O

@OUT[x] digital out tion? ; command delimr _BG in mo iter

II input interr A last targe

@TAN[n] tangent LL list labels LI linear point s ro

/ divide RE return e r _TN 1st position d ror rro

= assign / equ _UL variables left _VP last point fo al

_ZS stack level s EP

TIME

SINE DRIVE

MOTION WAIT

BM magnetic cy

cle

VECTOR

upt _P t

Page 3

Contents

CONTENTS ......................................................................................................................................................................... I

OVERVIEW.........................................................................................................................................................................1

CONTROLLER NOTATION ................................................................................................................... 1

ERVO AND STEPPER MOTOR NOTATION:.......................................................................................... 1

S

C

OMMAND DESCRIPTIONS ................................................................................................................. 1

Arguments..................................................................................................................................... 2

Operand Usage............................................................................................................................. 2

Usage Description ........................................................................................................................ 2

Default Description....................................................................................................................... 2

Controller Usage .......................................................................................................................... 3

SERVO UPDATE RATES ...................................................................................................................... 3

#..................................................................................................................................................... 4

$..................................................................................................................................................... 5

& | ................................................................................................................................................. 6

( )................................................................................................................................................... 7

;..................................................................................................................................................... 8

[ ] .................................................................................................................................................. 9

+ - * / .......................................................................................................................................... 10

<, >, =, <=, >=, <>.................................................................................................................. 11

=.................................................................................................................................................. 12

AB................................................................................................................................................ 13

@ABS[n]..................................................................................................................................... 14

AC ............................................................................................................................................... 15

@ACOS[n].................................................................................................................................. 16

AD............................................................................................................................................... 17

AF................................................................................................................................................ 18

AI................................................................................................................................................. 19

AL................................................................................................................................................ 20

AM............................................................................................................................................... 21

@AN[n]....................................................................................................................................... 22

AO............................................................................................................................................... 23

AP................................................................................................................................................ 24

AR................................................................................................................................................ 25

AS................................................................................................................................................ 26

@ASIN[n] ................................................................................................................................... 27

AT................................................................................................................................................ 28

@ATAN[n].................................................................................................................................. 29

#AUTO........................................................................................................................................ 30

#AUTOERR................................................................................................................................. 31

AV................................................................................................................................................ 32

BA................................................................................................................................................ 33

BB................................................................................................................................................ 34

BC ............................................................................................................................................... 35

BD............................................................................................................................................... 36

BG............................................................................................................................................... 37

DMC-1400 Series Command Reference Contents ● i

Page 4

BI................................................................................................................................................. 38

BK ............................................................................................................................................... 39

BL................................................................................................................................................ 40

BM............................................................................................................................................... 41

BN ............................................................................................................................................... 42

BO............................................................................................................................................... 43

BP................................................................................................................................................ 44

BS................................................................................................................................................ 45

BV................................................................................................................................................ 46

BZ................................................................................................................................................ 47

CB ............................................................................................................................................... 48

CC............................................................................................................................................... 49

CD............................................................................................................................................... 50

CE ............................................................................................................................................... 51

CF ............................................................................................................................................... 52

CI................................................................................................................................................. 53

CM............................................................................................................................................... 54

#CMDERR .................................................................................................................................. 55

CN............................................................................................................................................... 56

CO............................................................................................................................................... 57

@COM[n]................................................................................................................................... 58

#COMINT ................................................................................................................................... 59

@COS[n].................................................................................................................................... 60

CR ............................................................................................................................................... 61

CS................................................................................................................................................ 62

CW............................................................................................................................................... 63

DA............................................................................................................................................... 64

DC............................................................................................................................................... 65

DE............................................................................................................................................... 66

DL ............................................................................................................................................... 67

DM .............................................................................................................................................. 68

DP............................................................................................................................................... 69

DT ............................................................................................................................................... 70

DV............................................................................................................................................... 71

EA................................................................................................................................................ 72

EB................................................................................................................................................ 73

EC ............................................................................................................................................... 74

ED............................................................................................................................................... 75

EG............................................................................................................................................... 76

EI................................................................................................................................................. 77

ELSE ........................................................................................................................................... 78

EM............................................................................................................................................... 79

EN ............................................................................................................................................... 80

ENDIF......................................................................................................................................... 82

EO............................................................................................................................................... 83

EP................................................................................................................................................ 84

EQ............................................................................................................................................... 85

ii • Contents DMC-1400 Series Command Reference

Page 5

ER................................................................................................................................................ 86

ES................................................................................................................................................ 87

ET................................................................................................................................................ 88

FA................................................................................................................................................ 89

FE................................................................................................................................................ 90

FI................................................................................................................................................. 91

FL................................................................................................................................................ 92

@FRAC[n].................................................................................................................................. 93

FV................................................................................................................................................ 94

GA............................................................................................................................................... 95

GN............................................................................................................................................... 96

GM .............................................................................................................................................. 97

GR............................................................................................................................................... 98

HM .............................................................................................................................................. 99

HX............................................................................................................................................. 100

IA............................................................................................................................................... 101

IF............................................................................................................................................... 102

IH .............................................................................................................................................. 103

II................................................................................................................................................ 105

IL............................................................................................................................................... 107

IN............................................................................................................................................... 108

@IN[n]...................................................................................................................................... 110

#ININT ...................................................................................................................................... 111

@INT[n] ................................................................................................................................... 112

IP............................................................................................................................................... 113

IT............................................................................................................................................... 114

IV............................................................................................................................................... 115

JG.............................................................................................................................................. 116

JP .............................................................................................................................................. 117

JS............................................................................................................................................... 118

KD............................................................................................................................................. 119

KI............................................................................................................................................... 120

KP ............................................................................................................................................. 121

KS.............................................................................................................................................. 122

LA.............................................................................................................................................. 123

LE.............................................................................................................................................. 124

_LF*.......................................................................................................................................... 125

LI............................................................................................................................................... 126

#LIMSWI................................................................................................................................... 128

LL.............................................................................................................................................. 129

LM............................................................................................................................................. 130

_LR*.......................................................................................................................................... 131

LS .............................................................................................................................................. 132

LV.............................................................................................................................................. 133

LZ.............................................................................................................................................. 134

MB............................................................................................................................................. 135

MC............................................................................................................................................. 137

#MCTIME................................................................................................................................. 138

DMC-1400 Series Command Reference Contents ● iii

Page 6

MF............................................................................................................................................. 139

MG ............................................................................................................................................ 140

MO ............................................................................................................................................ 141

MR............................................................................................................................................. 142

MT............................................................................................................................................. 143

NB ............................................................................................................................................. 144

NF ............................................................................................................................................. 145

NO............................................................................................................................................. 146

NZ.............................................................................................................................................. 147

OB............................................................................................................................................. 148

OC............................................................................................................................................. 149

OE............................................................................................................................................. 150

OF............................................................................................................................................. 151

OP............................................................................................................................................. 152

@OUT[n].................................................................................................................................. 154

P1CD P2CD............................................................................................................................. 155

P1CH P2CH............................................................................................................................. 156

P1NM P2NM............................................................................................................................ 157

P1ST P2ST............................................................................................................................... 158

#POSERR.................................................................................................................................. 159

PA.............................................................................................................................................. 160

PF.............................................................................................................................................. 161

PR.............................................................................................................................................. 162

QD............................................................................................................................................. 163

QR............................................................................................................................................. 164

QU............................................................................................................................................. 165

QZ ............................................................................................................................................. 166

RA.............................................................................................................................................. 167

RC ............................................................................................................................................. 168

RD............................................................................................................................................. 169

RE.............................................................................................................................................. 170

REM .......................................................................................................................................... 171

RI............................................................................................................................................... 172

RL.............................................................................................................................................. 173

@RND[n].................................................................................................................................. 174

RP.............................................................................................................................................. 175

RS.............................................................................................................................................. 176

<control>R<control>S............................................................................................................ 177

<control>R<control>V............................................................................................................ 178

SA.............................................................................................................................................. 179

SA n........................................................................................................................................... 180

SB.............................................................................................................................................. 181

SC.............................................................................................................................................. 182

SH.............................................................................................................................................. 183

@SIN[n].................................................................................................................................... 184

SL .............................................................................................................................................. 185

SP.............................................................................................................................................. 186

iv • Contents DMC-1400 Series Command Reference

Page 7

@SQR[n] .................................................................................................................................. 187

ST .............................................................................................................................................. 188

@TAN[n] .................................................................................................................................. 189

TB.............................................................................................................................................. 190

TC.............................................................................................................................................. 191

#TCPERR.................................................................................................................................. 193

TD ............................................................................................................................................. 194

TE.............................................................................................................................................. 195

TH ............................................................................................................................................. 196

TI............................................................................................................................................... 197

TIME*....................................................................................................................................... 198

TL.............................................................................................................................................. 199

TM............................................................................................................................................. 200

TP.............................................................................................................................................. 201

TR.............................................................................................................................................. 202

TS .............................................................................................................................................. 203

TT.............................................................................................................................................. 204

TV.............................................................................................................................................. 205

TW............................................................................................................................................. 206

UI .............................................................................................................................................. 207

UL ............................................................................................................................................. 208

VA.............................................................................................................................................. 209

VD............................................................................................................................................. 210

VE.............................................................................................................................................. 211

VF.............................................................................................................................................. 212

VM............................................................................................................................................. 213

VP.............................................................................................................................................. 214

VR.............................................................................................................................................. 215

VS.............................................................................................................................................. 216

VT.............................................................................................................................................. 217

WC............................................................................................................................................. 218

WH ............................................................................................................................................ 219

WT............................................................................................................................................. 220

XQ............................................................................................................................................. 221

ZR.............................................................................................................................................. 222

ZS .............................................................................................................................................. 223

INDEX..............................................................................................................................................................................225

DMC-1400 Series Command Reference ● v

Page 8

Page 9

Overview

Controller Notation

This command reference is a supplement to the Galil Motion Control User Manual. For proper

controller operation, consult the Users Manual. This manual describes commands to be used with the

Galil Econo Series Motion Controllers: DMC-1410, DMC-1411, DMC-1412, DMC-1414, DMC1415, DMC-1416, DMC-1417, and DMC-1425. Commands are listed in alphabetical order.

This command summary includes all executable commands, which can be used with the DMC-1400

series motion controller. These commands are common to all the controllers in that series with certain

exceptions. These exceptions are noted on each corresponding command as “Controller Usage”. An

example is Ethernet commands for the DMC-1415, DMC-1416, and DMC-1425.

Servo and Stepper Motor Notation:

Your motion controller has been designed to work with both servo and stepper type motors.

Installation and system setup will vary depending upon whether the controller will be used with stepper

motors, or servo motors. To make finding the appropriate instructions faster and easier, icons will be

next to any information that applies exclusively to one type of system. Otherwise, assume that the

instructions apply to all types of systems. The icon legend is shown below.

Attention: Pertains to servo motor use.

Attention: Pertains to stepper motor use.

Command Descriptions

Each executable instruction is listed in the following section in alphabetical order. Below is a

description of the information, which is provided for each command.

The two-letter Opcode for each instruction is placed in the upper left corner. Below the Opcode is a

description of the command and required arguments.

DMC-1400 Series Command Reference ● 1

Page 10

Arguments

As arguments, some commands require actual values to be specified following the instruction. These

commands are followed by lower case n where n is replaced by an actual value.

A “?” returns the specified value for that axis. For example, AC? returns the acceleration of the axis.

Other commands require action on the axis to be specified. These commands do not have an operand

action for the axis or are specified by writing the command only, such as BG or ST. When

downloading commands to the DMC-141X, do not insert a space prior to any command. For example,

ST; AM is invalid because there is a space after the semicolon.

The DMC-1425 is the only controller in the DMC-1400 Econo Series that supports two axes. For this

controller, arguments are specified for the X and Y axis.

Operand Usage

Most commands have a corresponding operand that can be used for interrogation. The Operand Usage

description provides proper syntax and the value returned by the operand. Operands must be used

inside of valid DMC expressions. For example, to display the value of an operand, the user could use

the command:

MG ‘operand’

All of the command operands begin with the underscore character (_). For example, the value of the

current position on the motor can be assigned to the variable ‘V’ with the command:

V=_TP

Usage Description

The Usage description specifies the restrictions on proper command usage. The following provides an

explanation of the command information provided:

"While Moving" states whether or not the command is valid while the controller is performing a

previously defined motion.

"In a program" states whether the command may be used as part of a user-defined program.

"Command Line" states whether the command may be used other than in a user-defined program.

"Can be Interrogated" states whether or not the command can be interrogated by using the “?” as a

command argument.

"Used as an Operand" states whether the command has an associated operand.

Default Description

In the command description, the DEFAULT section provides the default values for controller setup

parameters. These parameters can be changed and the new values can be saved in the controller's nonvolatile memory by using the command, BN. If the setup parameters are not saved in non-volatile

memory, the default values will automatically reset when the system is reset. A reset occurs when the

power is turned off and on, when the reset button is pushed, or the command, RS, is given.

When a master reset occurs, the controller will always reset all setup parameters to their default values

and the non-volatile memory is cleared to the factory state. A master reset is executed by the

command, <ctrl R> <ctrl S> <Return> OR

jumper or dip switch on.

by powering up or resetting the controller with the MRST

For example, the command KD is used to set the Derivative Constant for each axis. The default value

for the derivative constant is 64. If this parameter is not set by using the command KD, the controller

will automatically set this value to 64 for each axis. If the Derivative Constant is changed but not

saved in non-volatile memory, the default value of 64 will be used if the controller is reset or upon

2 ● Overview DMC-1400 Series Command Reference

Page 11

power up of the controller. If this value is set and saved in non-volatile memory, it will be restored

upon reset until a master reset is given to the controller.

The default format describes the format for numerical values, which are returned when the command is

interrogated. The format value represents the number of digits before and after the decimal point.

Controller Usage

The controller usage indicates which models within the DMC-1400 Econo Series line support the

current command. Controllers referenced in this manual are the DMC-1410, DMC-1411, DMC-1412,

DMC-1414, DMC-1415, DMC-1416, DMC-1417 and DMC-1425. ALL indicates that all Econo

controllers support the specific command.

Servo Update Rates

The standard servo update period on all E-Series Motion Controllers is 1msec. To change the servo

update, use the command, TM. The controller firmware will allow operation down to 250 usec per

sample.

Fast Firmware (DMC-1415/1416/1425)

The DMC-1415, DMC-1416 and DMC-1425 motion controllers can operate in ‘fast mode’ that allows

operation down to 125 usec per sample.

In order to run the motion controller in fast mode, the fast firmware must be uploaded. This can be

done through the Galil terminal software such as DMCTERM and WSDK. Use the menu option,

"Update Flash EEPROM" to change the controller firmware. The fast firmware is included with the

controller utilities.

When operating in fast mode, there are functions that are disabled and/or altered.

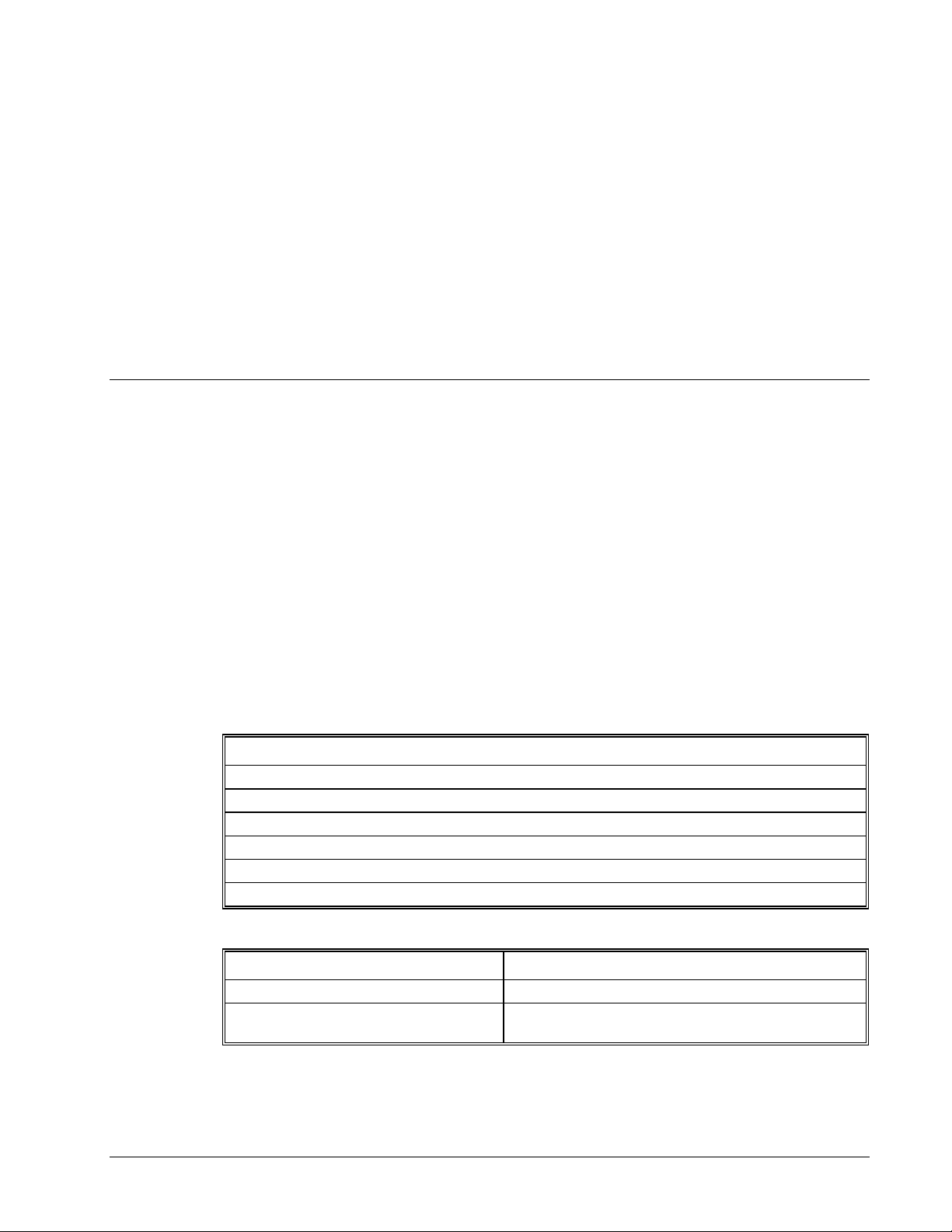

Commands which are not Allowed when Operating in Fast Mode:

Command

Gearing Mode

Ecam Mode

Analog Feedback (AF)

Stepper Motor Operation (MT 2, -2, 2.5, -2.5)

Trippoints allowed only in thread 0

Tell Velocity Interrogation Command (TV)

Commands which are Altered when Operating in Fast Mode:

Command Modification

MT Command argument 2, 2.5, -2, -2.5 not valid

AD, AI, AM, AP, AR, AS, AT, AV, MC,

MF, MR, WC

Commands not allowed in thread 1

DMC-1400 Series Command Reference Overview ● 3

Page 12

#

FUNCTION: Label (subroutine)

DESCRIPTION:

The # operator denotes the name of a program label (for example #Move). Labels can be up

to seven characters long and are often used to implement subroutines or loops. Labels are

divided into (a) user defined and (b) automatic subroutines. User defined labels can be

printed with LL and the number of labels left available can be queried with MG _DL.

The automatic subroutines include #CMDERR, #LIMSWI, #POSERR, #ININT, #AUTO,

and #MCTIME.

ARGUMENTS: #nnnnnnn where

nnnnnnn is a label name up to seven characters

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line No

Controller Usage

RELATED COMMANDS:

LL List labels

_

UL Labels left

JP Jump statement

JS Jump subroutine

ALL

EXAMPLES:

#Loop; JP#Loop, x=10 ;’wait until x becomes 10

#Move

PRX=1000

BGX

AMX

EN

;’define a subroutine to move the x axis

4 ● # DMC-1400 Series Command Reference

Page 13

$

FUNCTION: Hexadecimal

DESCRIPTION:

The $ operator denotes that the following string is in hexadecimal notation

ARGUMENTS: $nnnnnnnn.mmmm

n is up to eight hexadecimal digits (denoting 32 bits of integer)

m is up to four hexadecimal digits (denoting 16 bits of fraction)

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

* Multiply (shift left)

/ Divide (shift right)

MG {$8.4} Print in hexadecimal

EXAMPLES:

x = $7fffffff.0000 ;’store 2147483647 in x

y = x & $0000ffff.0000 ;’store lower 16 bits of x in y

z = x & $ffff0000.0000 / $10000 ;’store upper 16 bits of x in z

ALL

DMC-1400 Series Command Reference $ ● 5

Page 14

& |

FUNCTION: Bitwise Logical Operators AND and OR

DESCRIPTION:

The operators & and | are typically used with IF, JP, and JS to perform conditional jumps;

however, they can also be used to perform bitwise logical operations.

ARGUMENTS: n & m or n | m where

n and m are signed numbers in the range -2147483648 to 2147483647.

For IF, JP, and JS, n and m are typically the results of logical expressions such as (x > 2)

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@COM[n] Bitwise complement

IF If statement

JP Jump statement

JS Jump subroutine

ALL

EXAMPLES:

IF (x > 2) & (y = 4)

MG “true”

ENDIF

:MG 1 | 2

3.0000

:

;x must be greater than 2 and y equal to 4 for the message to print

;'Bitwise operation: 01 OR 10 is 11 = 3

6 ● & | DMC-1400 Series Command Reference

Page 15

( )

FUNCTION: Parentheses (order of operations)

DESCRIPTION:

The parentheses denote the order of math and logical operations. Note that the controller

DOES NOT OBEY STANDARD OPERATOR PRECEDENCE. For example,

multiplication is NOT evaluated before addition. Instead, the controller follows left-toright precedence. Therefore, it is recommended to use parenthesis as much as possible.

ARGUMENTS: (n) where

n is a math (+ - * /) or logical (& |) expression

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

+ - * / Math Operators

& | Logical Operators

EXAMPLES:

:MG 1 + 2 * 3

9.0000

:MG 1 + (2 * 3)

7.0000

:

ALL

DMC-1400 Series Command Reference ( ) ● 7

Page 16

;

FUNCTION: Semicolon (Command Delimiter)

DESCRIPTION:

The semicolon operator allows multiple Galil commands to exist on a single line. It is used

for the following three reasons:

(1) To put comments on the same line as the command (BGX ;’begin motion)

(2) To compress DMC programs to fit within the program line limit (Note: use a

compression utility to do this. Do not program this way because it is hard to read.)

(3) To give higher priority to a thread. All commands on a line are executed before the

thread scheduler switches to the next thread.

ARGUMENTS: n; n; n; … where

n is a Galil command

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

NO or ‘ comment

ALL

EXAMPLES:

BGX ;’comment

PRX=1000;BGX;AMX ;’Save program line space

#High

a = a + 1; b = b + 1

JP#High

#Low

c = c + 1

d = d + 1

JP#Low

;’#High priority thread executes twice as fast as #Low when run in

;’parallel

8 ● ; DMC-1400 Series Command Reference

Page 17

[ ]

FUNCTION: Square Brackets (Array Index Operator)

DESCRIPTION:

The square brackets are used to denote the array index for an array, or to denote an array

name.

ARGUMENTS: mmmmmmmm[n] where

mmmmmmmm is the array name

n is the array index and is an integer between 0 and 7999

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

DM Dimension Array

QU Print/Upload Array

EXAMPLES:

DM A[100] ;’define a 100 element array

A[0] = 3 ;’set first element to 3

MG A[0] ;’print element 0

QU A[] ;’print entire array

ALL

DMC-1400 Series Command Reference [ ] ● 9

Page 18

+ - * /

FUNCTION: Math Operators

DESCRIPTION:

The addition, subtraction, multiplication, and division operators are binary operators (they

take two arguments and return one value) used to perform mathematical operations on

variables, constants, and operands.

ARGUMENTS: (n + m) or (n – m) or (n * m) or (n / m) where

n and m are signed numbers in the range -2147483648 to 2147483647

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

( ) Parenthesis

EXAMPLES:

x = ((1 + (2 * 3)) / 7) - 2 ;’assign -1 to x

ALL

10 ● + - * / DMC-1400 Series Command Reference

Page 19

<, >, =, <=, >=, <>

FUNCTION: Comparison Operators

DESCRIPTION:

The comparison operators are as follows:

< less than

> greater than

= equals

<= less than or equal

>= greater than or equal

<> not equals

These are used in conjunction with IF, JP, JS, ( ), &, and | to perform conditional jumps. The

result of a comparison expression can also be printed with MG or assigned to a variable.

ARGUMENTS: (n < m) or (n > m) or (n = m) or (n <= m) or (n >= m) or (n <> m) where

n and m are signed numbers in the range -2147483648 to 2147483647

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

ALL

RELATED COMMANDS:

( ) Parentheses

IF If statement

JP Jump

JS Jump subroutine

EXAMPLES:

IF (x > 2) & (y = 4)

MG “true”

ENDIF

;x must be greater than 2 and y equal to 4 for the message to print

DMC-1400 Series Command Reference <, >, =, <=, >=, <> ● 11

Page 20

=

FUNCTION: Equals (Assignment Operator)

DESCRIPTION:

The assignment operator is used for three reasons:

(1) to define and initialize a variable (x = 0) before it is used

(2) to assign a new value to a variable (x = 5)

(3) to print a variable or array element (x= which is equivalent to MG x). MG is the

preferred method of printing.

ARGUMENTS: mmmmmmmm = n where

mmmmmmmm is a variable name and n is a signed number in the range -

2147483648 to 2147483647

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

MG Print Message

EXAMPLES:

:x=5

:x=

5.0000

:MG x

5.0000

:

ALL

;’define and initialize x to 5

;’print x two different ways

12 ● = DMC-1400 Series Command Reference

Page 21

AB

FUNCTION: Abort

DESCRIPTION:

AB (Abort) stops a motion instantly without a controlled deceleration. If there is a program

operating, AB also aborts the program unless a 1 argument is specified. The command,

AB, will shut off the motors for any axis in which the off-on-error function is enabled

(see command "OE").

ARGUMENTS: AB n where

n = no argument or 1

1 aborts motion without aborting program, 0 aborts motion and program

AB aborts motion on all axes in motion and cannot stop individual axes.

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand Yes

Controller Usage

ALL

OPERAND USAGE:

_AB gives the state of the Abort Input

RELATED COMMANDS:

SH Turns servos back on if they were shut-off by Abort and OE1.

EXAMPLES:

AB Stops motion

OE 1,1,1,1 Enable off-on-error

AB Shuts off motor command and stops motion

#A Label - Start of program

JG 20000 Specify jog speed on X-axis

BGX Begin jog on X-axis

WT 5000 Wait 5000 msec

AB1 Stop motion without aborting program

WT 5000 Wait 5000 milliseconds

SH Servo Here

JP #A Jump to Label A

EN End of the routine

Hint: Remember to use the parameter 1 following AB if you only want the motion to be aborted.

Otherwise, your application program will also be aborted.

DMC-1400 Series Command Reference AB ● 13

Page 22

@ABS[n]

FUNCTION: Absolute value

DESCRIPTION:

Takes the absolute value of the given number. Returns the value if positive, and returns -1

times the value if negative.

ARGUMENTS: @ABS[n] where

n is a signed number in the range -2147483647 to 2147483647

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@SQR Square Root

EXAMPLES:

:MG @ABS[-2147483647]

2147483647.0000

:

ALL

14 ● @ABS[n] DMC-1400 Series Command Reference

Page 23

AC

FUNCTION: Acceleration

DESCRIPTION:

The Acceleration (AC) command sets the linear acceleration rate for independent moves, such

as PR, PA and JG moves. The parameters input will be rounded down to the nearest

factor of 1024. The units of the parameters are counts per second squared. The

acceleration rate may be changed during motion. The DC command is used to specify

the deceleration rate.

ARGUMENTS: AC n where

n is an unsigned number in the range in the range 1024 to 67107840

“?” returns the acceleration value

USAGE:

While Moving Yes Default Value 256000

In a Program Yes Default Format 8.0

Command Line Yes

Can be Interrogated Yes

Used as an Operand Yes

Controller Usage

OPERAND USAGE:

_ACx contains the value of acceleration.

ALL

RELATED COMMANDS:

DC Specifies deceleration rate.

FA Feedforward Acceleration.

IT Smoothing constant

EXAMPLES:

AC 150000 Set acceleration to 150000

AC ? Request the current Acceleration setting

0149504 Return Acceleration

(resolution, 1024)

V=_AC Assigns the current acceleration setting to the variable V

HINTS: Specify realistic acceleration rates based on your physical system such as motor torque

rating, loads, and amplifier current rating. Specifying an excessive acceleration will cause large

following error during acceleration and the motor will not follow the commanded profile. The

acceleration feedforward command FA will help minimize the error.

DMC-1400 Series Command Reference AC ● 15

Page 24

@ACOS[n]

FUNCTION: Inverse cosine

DESCRIPTION:

Returns in degrees the arc cosine of the given number.

ARGUMENTS: @ACOS[n] where

n is a signed number in the range -1 to 1.

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@ASIN Arc sine

@SIN sine

@ATAN Arc tangent

@COS Cosine

@TAN Tangent

EXAMPLES:

:MG @ACOS[-1]

180.0000

:MG @ACOS[0]

90.0000

:MG @ACOS[1]

0.0001

:

ALL

16 ● @ACOS[n] DMC-1400 Series Command Reference

Page 25

AD

FUNCTION: After Distance

DESCRIPTION:

The After Distance (AD) command is a trippoint used to control the timing of events. This

command will hold up the execution of the following command until one of the following

conditions have been met:

1. The commanded motor position crosses the specified relative distance from the start

of the move.

2. The motion profiling on the axis is complete.

3. The commanded motion is in the direction which moves away from the specified

position.

The units of the command are quadrature counts. The motion profiler must be on or the

trippoint will automatically be satisfied.

Note: AD will be affected when the motion smoothing time constant, IT, is not 1. See IT

command for further information.

ARGUMENTS: ADn where

n is an unsigned integer in the range 0 to 2147483647, with no commas.

USAGE:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

ALL

RELATED COMMANDS:

AR After distance for repetitive triggering

EXAMPLES:

#A;DP0,0,0,0 Begin Program

PR 10000 Specify positions

BG Begin motion

AD 5000 After motor travels 5000 units

MG "Halfway" ;TP Send message

EN End Program

Hint: The AD command is accurate to the number of counts that occur in 2 servo samples (2 msec for

TM 1000). Multiply your speed by 2 msec to obtain the maximum position error in counts. Remember

AD measures incremental distance from start of move on one axis.

DMC-1400 Series Command Reference AD ● 17

Page 26

AF

FUNCTION: Analog Feedback

DESCRIPTION:

The Analog Feedback (AF) command is used to set an axis with analog feedback instead of

digital feedback (quadrature/pulse dir). As the analog feedback is decoded by a 12-bit

A/D converter, an input voltage of 10 volts is decoded as a position of 2047 counts and a

voltage of -10 volts corresponds to a position of -2048 counts. When using Analog

Feedback mode, X axis feedback must be wired to analog input 1 and Y axis feedback

must be wired to analog input 2.

ARGUMENTS: AF x,y AFX=x AF a,b where

x,y are integers

1 = Enables analog feedback

0 = Disables analog feedback and switches to digital feedback

"?" returns a 0 or 1 which states whether analog feedback is enabled for the specified axes.

USAGE:

While Moving No Default Value 0,0,0,0

In a Program Yes Default Format -

Command Line Yes

Can be Interrogated Yes

Used as an Operand Yes

Controller Usage

DMC-1415/1416/1425 only

OPERAND USAGE:

_AFx contains the value of acceleration for the specified axis.

RELATED COMMANDS:

CE Configure Encoder

EXAMPLES:

AF 1,0 Analog feedback on X axis

V1 = _AFX Assign feedback type to variable

AF ? Interrogate feedback type

18 ● AF DMC-1400 Series Command Reference

Page 27

AI

FUNCTION: After Input

DESCRIPTION:

The AI command is used in motion programs to wait until after the specified input has

occurred. If n is positive, it waits for the input to go high. If n is negative, it waits for n

to go low.

ARGUMENTS: AI +/-n where

n is an integer in the range 1 to 7 decimal for DMC-1410/1411/1417/1415/1416 and 0 to 3

decimal for the DMC-1425.

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

RELATED COMMANDS:

@IN[n] Function to read input 1 through 7 or 1 through 3 for DMC-1425

II Input interrupt

#ININT Label for input interrupt

ALL

EXAMPLES:

#A Begin Program

AI 7 Wait until input 7 is high

SP 10000 Speed is 10000 counts/sec

AC 20000 Acceleration is 20000 counts/sec2

PR 400 Specify position

BG Begin motion

EN End Program

HINT: The AI command actually halts execution until specified input is at desired logic level. Use the

conditional Jump command (JP) or input interrupt (II) if you do not want the program sequence to

halt.

DMC-1400 Series Command Reference AI ● 19

Page 28

AL

FUNCTION: Arm Latch

DESCRIPTION:

The AL command enables the latching function (high speed position capture) of the

controller. When the AL command is used to arm the position latch, the encoder position

of the main encoder input will be captured upon a low going signal on Input 1. The

command RL returns the captured position value. When interrogated or used in an

operand the AL command will return a 1 if the latch is armed or a zero after the latch has

occurred. The CN command will change the polarity of the latch.

ARGUMENTS: ALn where

n is X (or Y for the DMC-1425) or

n is SX for the aux encoder on DMC-1415/16

USAGE:

While Moving Yes Default Value 0

In a Program Yes Default Format 1.0

Command Line Yes

Can be Interrogated No

Used as an Operand Yes

Controller Usage

ALL

OPERAND USAGE:

_ALx contains the state of the latch. 0 = not armed, 1 = armed.

RELATED COMMANDS:

RL Report Latch

EXAMPLES:

#START Start program

AL Arm latch

JG 50000 Set up jog at 50000 counts/sec

BG Begin the move

#LOOP Loop until latch has occurred

JP #LOOP,_AL=1

RL Transmit the latched position

EN End of program

20 ● AL DMC-1400 Series Command Reference

Page 29

AM

FUNCTION: After Move

DESCRIPTION:

The AM command is a trippoint used to control the timing of events. This command will hold

up execution of the following commands until the current move on the specified axis or

axes is completed. AM occurs when the profiler is finished generating the last position

command. However, the servo motor may not be in the final position. Use TE to verify

position error for servos, or use the MC trippoint to wait until final actual position is

recorded.

ARGUMENTS: AM

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

RELATED COMMANDS:

BG (_BG returns a 0 if motion complete)

MC Actual Motion Complete (In-Position)

ALL

EXAMPLES:

#MOVE Program MOVE

PR 5000 Position relative moves

BG Start

AM After the move is complete

EN End of Program

#F;DP 0 Program F

PR 5000 Position relative moves

BG Start

AM After motion complete on all axes

MG "DONE";TP Print message

EN End of Program

HINT: AM is a very important command for controlling the timing between multiple move sequences.

For example, if the motor is in the middle of a position relative move (PR) you cannot make a position

absolute move (PA, BG) until the first move is complete. Use AM to halt the program sequences until

the first motion is complete. AM tests for profile completion. The actual motor may still be moving.

Another method for testing motion complete is to query the operand, _BG. This is equal to 1 du ring

motion, and 0 when motion profiling is complete.

DMC-1400 Series Command Reference AM ● 21

Page 30

@AN[n]

FUNCTION: Read analog input

DESCRIPTION:

Returns the value of the given analog input in volts

ARGUMENTS: @AN[n] where

n is an unsigned integer in the range 1 to 8

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@IN Read digital input

@OUT Read digital output

SB Set digital output bit

CB Clear digital output bit

OF Set analog output offset

ALL

EXAMPLES:

:MG @AN[1] ;'print analog input 1

1.7883

:x = @AN[1] ;'assign analog input 1 to a variable

22 ● @AN[n] DMC-1400 Series Command Reference

Page 31

AO

FUNCTION: Analog Out

DESCRIPTION:

The AO command sets the analog output voltage of Modbus Devices connected via Ethernet.

ARGUMENTS: AO m, n where

m is the I/O number calculated using the following equations:

m = (SlaveAddress*10000) + (HandleNum*1000) + ((Module-1)*4) + (Bitnum-1)

Slave Address is used when the Modbus device has slave devices connected to it and specified as

Addresses 0 to 255. Please note that the use of slave devices

for Modbus are very rare and this number will usually be 0.

HandleNum is the handle specifier from A to F (1 to 6).

Module is the position of the module in the rack from 1 to 16.

BitNum is the I/O point in the module from 1 to 4.

n = the voltage which ranges from 9.99 to –9.99

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Controller Usage

DMC-1415/1416/1425

RELATED COMMANDS:

SB Set Bit

CB Clear Bit

EXAMPLES:

DMC-1400 Series Command Reference AO ● 23

Page 32

AP

FUNCTION: After Absolute Position

DESCRIPTION:

The After Position (AP) command is a trippoint used to control the timing of events. This

command will hold up the execution of the following command until one of the following

conditions have been met:

1. The commanded motor position crosses the specified absolute position.

2. The motion profiling on the axis is complete.

3. The commanded motion is in the direction which moves away from the specified

position.

The units of the command are quadrature counts. The motion profiler must be on or the

trippoint will automatically be satisfied.

ARGUMENTS: APn where

n is a signed integer in the range -2147483648 to 2147483647 decimal

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

ALL

RELATED COMMANDS:

AD Trippoint for relative distances

EXAMPLES:

#TEST Program B

DP0 Define zero

JG 1000 Jog mode (speed of 1000 counts/sec)

BG Begin move

AP 2000 After passing the position 2000

V1=_TP Assign V1 X position

MG "Position is", V1= Print Message

ST Stop

EN End of Program

HINT: The accuracy of the AP command is the number of counts that occur in 2 samples (2 msec for

TM 1000). Multiply the speed by the time period of 2 samples to obtain the maximum error. AP tests

for absolute position. Use the AD command to measure incremental distances.

24 ● AP DMC-1400 Series Command Reference

Page 33

AR

FUNCTION: After Relative Distance

DESCRIPTION:

The After Relative (AR) command is a trippoint used to control the timing of events. This

command will hold up the execution of the following command until one of the following

conditions have been met:

1. The commanded motor position crosses the specified relative distance from either

the start of the move or the last AR or AD command.

2. The motion profiling on the axis is complete.

3. The commanded motion is in the direction which moves away from the specified

position.

The units of the command are quadrature counts. The motion profiler must be on or the

trippoint will automatically be satisfied.

ARGUMENTS: ARn where

n is unsigned integer in the range 0 to 2147483647 decimal.

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

ALL

RELATED COMMANDS:

AP Trippoint for after absolute position

EXAMPLES:

#A;DP 0 Begin Program

JG 50000 Specify speed

BG Begin motion

#B Label

AR 25000 After passing 25000 counts of relative distance on X-axis

MG "Passed_X";TP Send message

JP #B Jump to Label #B

EN End Program

HINT: AR is used to specify incremental distance from last AR or AD command. Use AR if multiple

position trippoints are needed in a single motion sequence.

DMC-1400 Series Command Reference AR ● 25

Page 34

AS

FUNCTION: At Speed

DESCRIPTION:

The AS command is a trippoint that occurs when the generated motion profile has reached the

specified speed. This command will hold up execution of the following command until

the speed is reached. The AS command will operate after either accelerating or

decelerating. If the speed is not reached, the trippoint will be triggered after the speed

begins diverging from the AS value.

ARGUMENTS: AS

USAGE:

While Moving Yes Default Value ---

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

EXAMPLES:

#SPEED Program A

PR 100000 Specify position

SP 10000 Specify speed

BG Begin

AS After speed is reached

MG "At Speed" Print Message

EN End of Program

ALL

WARNING: The AS command applies to a trapezoidal velocity profile only with linear acceleration.

AS used with smoothing profile will be inaccurate.

26 ● AS DMC-1400 Series Command Reference

Page 35

@ASIN[n]

FUNCTION: Inverse sine

DESCRIPTION:

Returns in degrees the arc sine of the given number.

ARGUMENTS: @ASIN[n] where

n is a signed number in the range -1 to 1.

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@ACOS Arc cosine

@SIN sine

@ATAN Arc tangent

@COS Cosine

@TAN Tangent

EXAMPLES:

:MG @ASIN[-1]

-90.0000

:MG @ASIN[0]

0.0000

:MG @ASIN[1]

90.0000

:

ALL

DMC-1400 Series Command Reference @ASIN[n] ● 27

Page 36

AT

FUNCTION: At Time

DESCRIPTION:

The AT command is a trippoint which is used to hold up execution of the next command until

after the specified time has elapsed. The time is measured with respect to a defined

reference time. AT 0 establishes the initial reference. AT n specifies n msec from the

reference. AT -n specifies n msec from the reference and establishes a new reference

after the elapsed time period.

ARGUMENTS: AT n where

n is a signed integer in the range 0 to 2 Billion

n = 0 defines a reference time at current time

positive n waits n msec from reference

negative n waits n msec from reference and sets new reference after elapsed time period

(AT -n is equivalent to AT n; AT 0)

USAGE:

While Moving Yes Default Value 0

In a Program Yes Default Format ---

Command Line Yes

Can be Interrogated No

Used as an Operand No

Controller Usage

ALL

EXAMPLES:

The following commands are sent sequentially

AT 0 Establishes reference time 0 as current time

AT 50 Waits 50 msec from reference 0

AT 100 Waits 100 msec from reference 0

AT –150 Waits 150 msec from reference 0 and sets new reference at 150

AT 80 Waits 80 msec from new reference (total elapsed time is 230 msec)

28 ● AT DMC-1400 Series Command Reference

Page 37

@ATAN[n]

FUNCTION: Inverse tangent

DESCRIPTION:

Returns in degrees the arc tangent of the given number.

ARGUMENTS: @ATAN[n]

n is a signed number in the range -2147483647 to 2147483647

USAGE: DEFAULTS:

While Moving Yes Default Value -

In a Program Yes Default Format -

Command Line Yes

Controller Usage

RELATED COMMANDS:

@ASIN Arc sine

@SIN sine

@ACOS Arc cosine

@COS Cosine

@TAN Tangent

EXAMPLES:

:MG @ATAN[-10]

-84.2894

:MG @ATAN[0]

0.0000

:MG @ATAN[10]

84.2894

:

ALL

DMC-1400 Series Command Reference @ATAN[n] ● 29

Page 38

#AUTO

FUNCTION: Subroutine to run automatically upon power up

DESCRIPTION:

#AUTO denotes code to run automatically when power is applied to the controller, or after

the controller is reset. When no host software is used with the controller, #AUTO and the

BP command are required to run an application program on the controller.

USAGE:

While Moving Yes

In a Program Yes

Command Line No

Controller Usage

RELATED COMMANDS:

BP Burn program

EXAMPLES:

#AUTO ;'move the x axis upon power up

PRX=1000 ;'move 1000 counts

BGX ;'begin motion

AMX ;'wait until motion is complete

EN

NOTE: Use EN to end the routine

ALL

30 ● #AUTO DMC-1400 Series Command Reference

Page 39

#AUTOERR

FUNCTION: Automatic subroutine for notification of EEPROM checksum errors

DESCRIPTION:

#AUTOERR will run code upon power up if data in the EEPROM has been corrupted. The

EEPROM is considered corrupt if the checksum calculated on the bytes in the EEPROM

do not match the checksum written to the EEPROM. The type of checksum error can be

queried with _RS

USAGE:

While Moving Yes

In a Program Yes

Command Line No

Controller Usage

RELATED COMMANDS:

_RS Checksum error code

EXAMPLES:

#AUTO

WT 2000

MG "AUTO"

JP#AUTO

EN

#AUTOERR

WT500

MG "AUTOERR ", _RS

EN

NOTE: An application program must be executing for the automatic subroutine to fun c tion, which

runs in thread 0.

NOTE: Use EN to end the routine

DMC-14x5 / 6 ONLY

DMC-1400 Series Command Reference #AUTOERR ● 31

Page 40

AV

FUNCTION: After Vector Distance

DESCRIPTION:

The AV command is a trippoint which is used to hold up execution of the next command

during coordinated moves such as VP,CR or LI. This trippoint occurs when the path

distance of a sequence reaches the specified value. The distance is measured from the

start of a coordinated move sequence or from the last AV command. The units of the

command are quadrature counts.

ARGUMENTS: AV s,t where