Page 1

with Installation Instructions

Owner’sManual

®

Banks High-Ram

Assembly

2003-2006 Ford Power Stroke 6.0L Turbo-Diesel

F250/F350/F450/F550 Trucks

THIS MANUAL IS FOR USE WITH SYSTEMS 42750 & 42751

Gale Banks Engineering

546 Duggan Avenue • Azusa, CA 91702

43

7

1

-

9600 • F

(626) 969

Product Information & Sales: (888) 635-4565

Customer Support: (888) 839-5600

Installation Support:

bankspower.com

©2006 Gale Banks Engineering

-

ax (626) 33

888) 839-2700

(

4

10/30/06 PN 96782 v

.2.0

Page 2

Dear Customer,

f you have any questions

I

oncerning the installation of

c

your Banks Techni-Cooler, please

call our Technical Service Hotline

at (888) 839-2700 between 7:00

am and 5:00 pm (PT). If you have

any questions relating to

shipping or billing, please

ontact our Customer Service

c

Department at (888) 839-5600.

Thank you.

Tools Required:

• Drive ratchet

• Ratchet extension

• Inch and metric deep sockets

• Pliers

• Phillips and flat blade screwdrivers

• Inch and metric open end wrenches

Recommended tools:

• Foot-pound torque wrench

• Inch-pound torque wrench

General Installation

Practices

1. Before starting work, familiarize

yourself with the installation

procedure by reading all of the

instructions.

2. Throughout this manual, the left

side of the vehicle refers to the

driver’s side, and the right side to the

passenger’s side.

3. Disconnect the negative (ground)

cable from the battery (or batteries, if

there are two) before beginning

work.

4. Route and tie wires and hoses a

minimum of 6” away from exhaust

heat, moving parts and sharp edges.

”

Clearance of 8

recommended where possible.

or more is

5. When raising the vehicle, support

it on properly weight-rated safety

stands, ramps or a commercial hoist.

Follow the manufacturer’s safety

recautions. Take care to balance the

p

ehicle to prevent it from slipping or

v

alling. When using ramps, be sure

f

he front wheels are centered

t

squarely on the topsides. When

raising the front of the vehicle, put

the transmission in park (automatic)

or reverse (manual), set the parking

brake, and block the rear wheels.

When raising the back of the vehicle,

e sure the vehicle is on level ground

b

nd the front wheels are blocked

a

securely.

jacks to support the vehicle while

working under it. Do not raise the

vehicle onto concrete blocks,

masonry or any other item not

intended specifically for this use.

Caution! Do not use floor

6. During installation, keep the work

area clean. Do not allow anything to

be dropped into intake, exhaust, or

lubrication system components while

performing the installation, as foreign

objects will cause immediate engine

damage upon start-up.

2 96782 v.2.0

Page 3

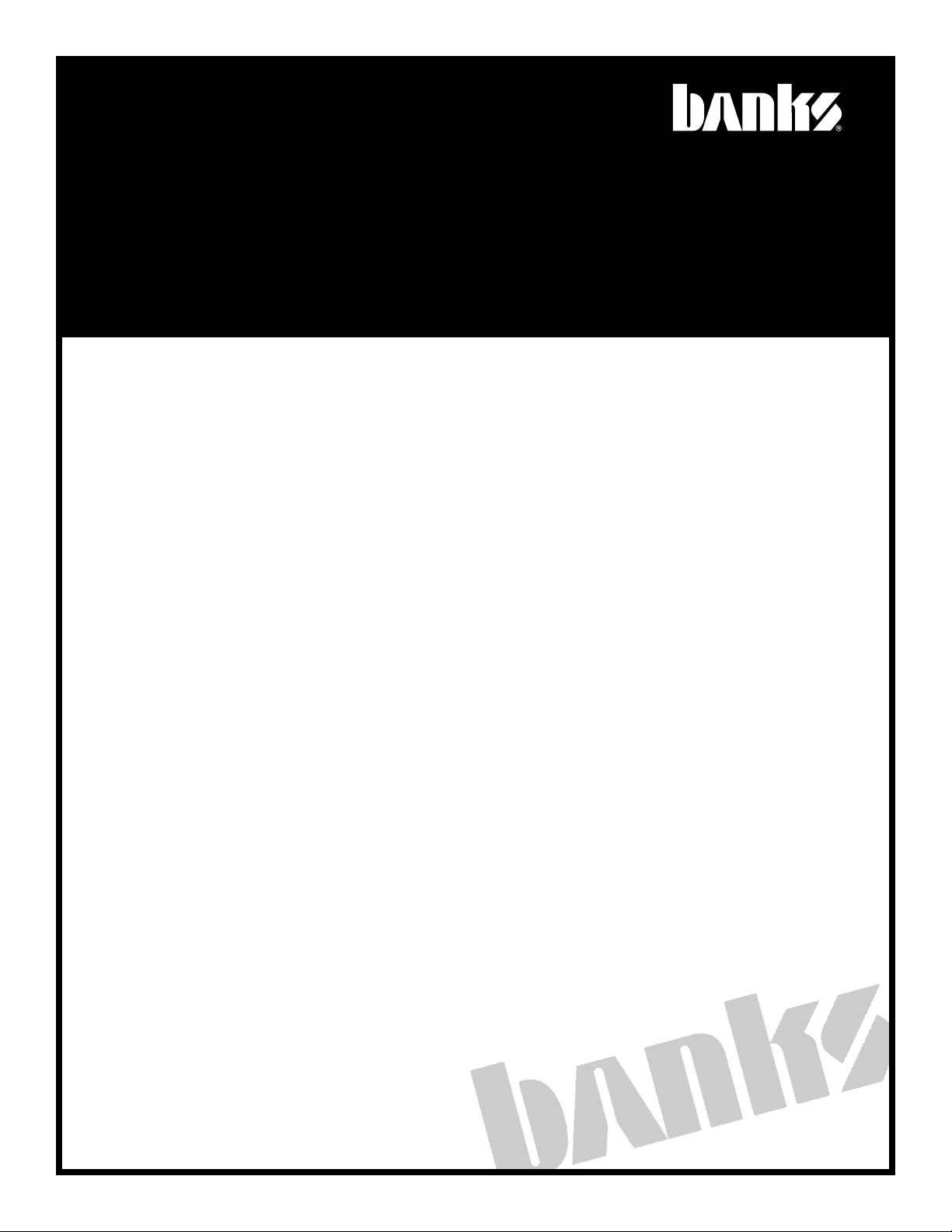

Figure 1. Electronic module near the driver side battery on 2005-06 4-wheel

drive equipped vehicles

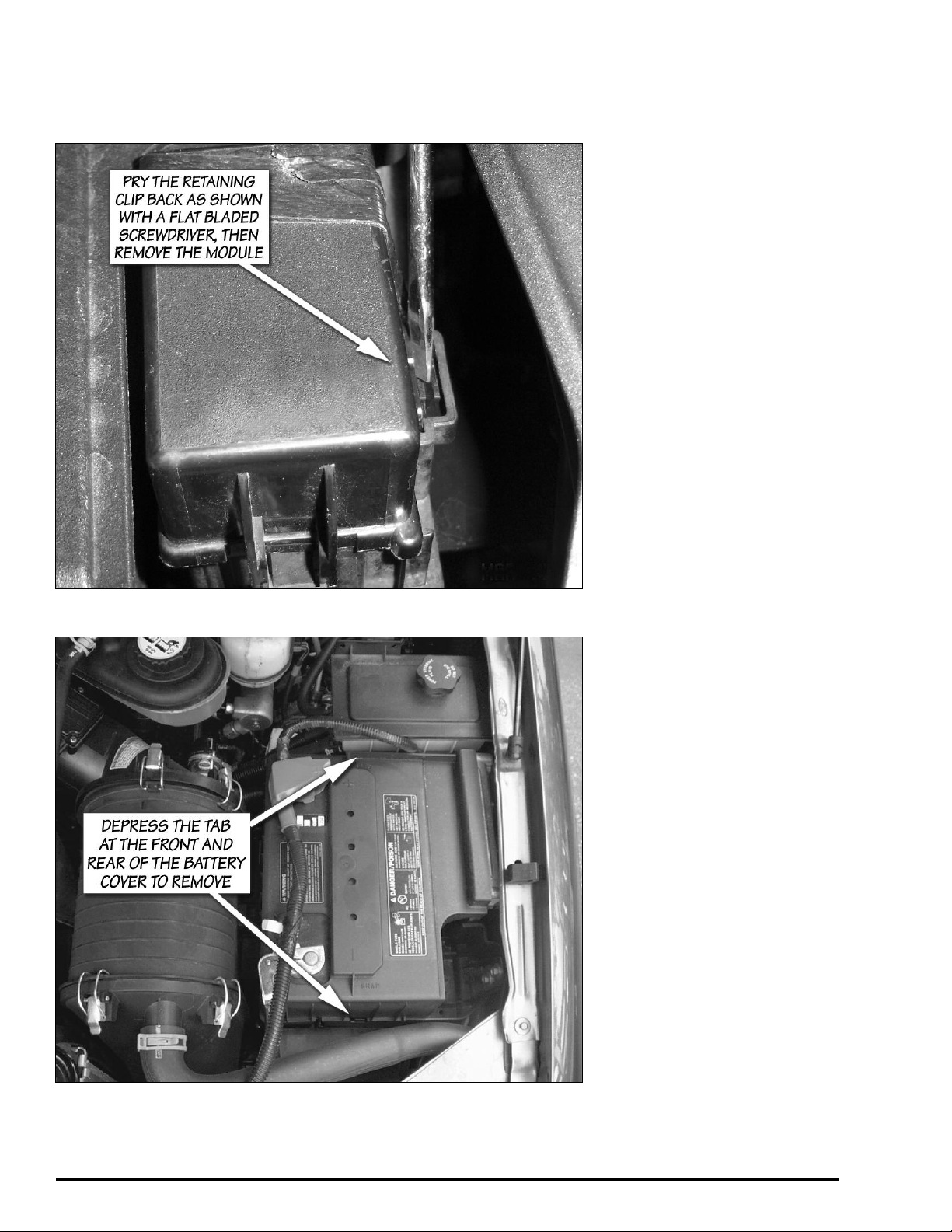

Figure 2

emove Stock Components

R

1. Remove the (+) and (-) battery

cables from both the drivers and

assenger side batteries.

p

2. Undo the two toggle clamps at

the rear of the air box assembly.

3. Disengage the two tabs on the

lower backside of the air box

assembly from the slots on the rear

cover.

4. Remove the air box assembly and

air box front cover from the vehicle.

5. For 2005-06 4-wheel drive

equipped vehicles only:

electronics module near the driver

side battery shown in

retaining tab for the module can be

pried back with a flat blade

screwdriver as shown in the figure.

After the tab is depressed, the

module can easily be pulled away

from it's mounting bracket.

Remove the

Figure 1. The

6. Remove driver’s side plastic

battery cover. There are tabs at the

front and back of the cover that need

to be depressed to remove the cover,

as shown in

careful not to break the plastic box,

as it will be re-installed later.

Figure 2. Note: Be

7. Remove the driver’s side battery

hold down clamp (8mm socket).

8. Remove the driver’s side battery.

WARNING: When lifting a battery,

excessive pressure on the end

walls could cause acid to spew

through the vent caps, resulting in

personal injury. Lift with a battery

carrier or with hands on opposite

corners. Failure to follow these

instructions may result in

personal injury.

9. Remove the wire harness plastic

retaining clip on the back of the

plastic battery box.

10. Remove the plastic battery box

[(4x) 13mm socket].

4-wheel drive equipped vehicles only:

A small bracket used to mount an

electronic module will also be

removed with the plastic battery tr

For 2005-06

ay.

96782 v.2.0 3

Page 4

11. Locate the driver side boost

tube. Loosen the hose clamps and

remove the boost tube, hose clamps

and hose (if applicable) from engine

compartment and set aside. These

arts will not be reused.

p

12. Remove the four allen head

bolts that attach the stock intake

elbow. The intake elbow is the 90

degree transition from the driver

side boost tube to the intake

anifold.

m

13. Remove the stock intake elbow

and gasket.

14. Cover the inlet to the intake

manifold to prevent debris from

getting into this area.

Modifications to make room for

the Banks Techni-Cooler System

15. For 2005-06 4-wheel drive

equipped vehicles only:

two retaining clips that attach the

wire harness to the metal battery

tray.

Remove the

16. Remove the driver’s side metal

battery tray [(3x) 13mm socket].

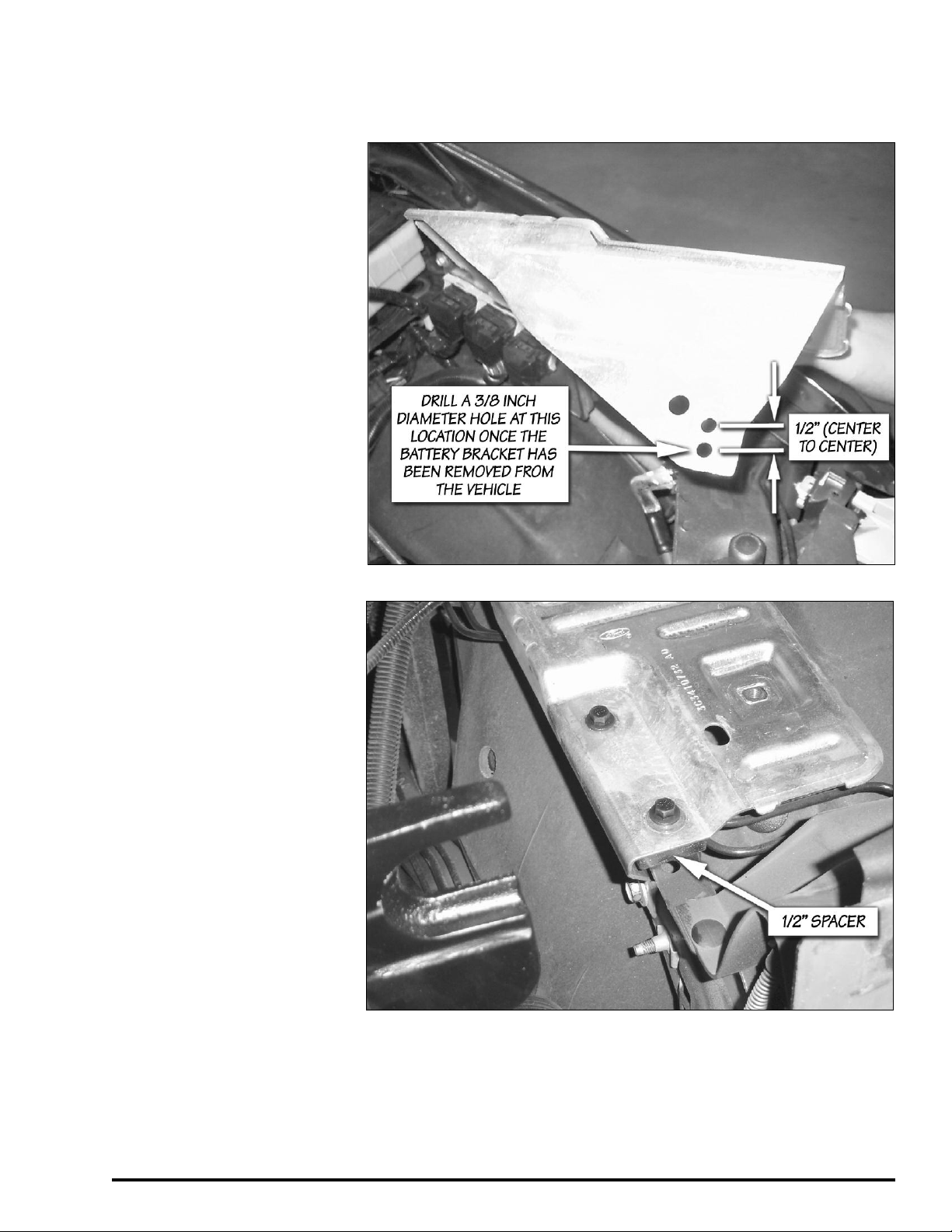

17. Drill a

Figure 3.

3

⁄8 inch hole as shown in

18. Reinstall the battery tray as

shown in

1

⁄2" spacer and longer supplied 8mm

bolts. Torque the bolts to 12 ft-lbs

Figure 4 with the supplied

Figure 3

Figure 4

4 96782 v.2.0

Page 5

igure 5

F

19. Trim the fan shroud as shown in

Figure 5 using Template 1 on page

9, to clear the Banks High Ram.

Note: 2005-06 vehicles require a

different trim to fan shroud, use

appropriate template. See

Template 1.

96782 v.2.0 5

Page 6

Figure 6 General Assembly Banks Techni-Cooler

9

9

8

10

1

5

6

7

12

13

3

2

4

15

14

11

Item Description P/N Qty

1 High-Ram Intake Manifold

2003-04 42745 1

2005-06 42746 1

2 Boost tube, left 41326 1

3 Hose, 3.5”x 3.25”, Black 94215 1

4 Hump Hose, 3” x 3”, Blue 94510 1

5 Gasket, High-Ram Intake 93038 1

6 Stud, High-Ram Air Intake M6-1.0 x 1⁄4-20 x 4.365 91534 3

7 Stud, High-Ram Air Intake M6-1.0 x 1⁄4-20 x 6.725 91535 1

Nut, Nylock

8

9 Washer, SAE Flat, Zinc 1⁄4” 91102 4

10 Washer, Thread Sealing 1⁄4”-20 91106 2

11 O-Ring. High-Ram 93606 2

12 Hose Clamp, 3.5” Spring Loaded 92897 2

13 Hose Clamp, 3.0” Spring Loaded 92860 2

14 Spacer, Battery Box 91890 1

15 Hex-Bolt, Washer Head, Black 8mm-1.25 x 30mm 91810 2

1

⁄4”

-20

1110 4

9

6 96782 v.2.0

Page 7

igure 7

NYLOCK NUT

STANDARD WASHER

THREAD SEALING

WASHER

BANKS HIGH RAM

O-RING

STUD

F

Figure 8

High-Ram Installation

pply the supplied thread locker

20. A

o the M6 threaded side of the High

t

Ram studs. The M6 thread length is

shorter than the

the opposite ends of the studs.

sing the two

21. U

provided, tighten the High Ram studs

into the intake manifold by threading

both nuts onto the stud. Tighten the

nuts against each other using two

open end wrenches, then tighten the

stud by turning the wrench on the top

nut. The stud should be torqued to 2-3

ft-lbs. Reverse the process to remove

the nut and repeat for each stud.

1

⁄4"-20 threads on

1

-20 nuts

⁄4"

22. 2003 to 2004 vehicles only.

Remove 0.75" of the split loom near the

connector shown in

provide additional clearance for the

High-Ram.

Figure 7 to

23. Install the supplied o-rings on

the two driver side studs as shown in

the exploded view in

Figure 8. Slide

96782 v.2.0 7

Page 8

he o-rings down to the base of the

t

ntake manifold.

i

24. For 2003 to 2004 vehicles,

install the factory replacement intake

manifold gasket in the groove on the

intake manifold.

ehicles,

v

eplacement intake manifold gasket

r

on the High Ram.

For 2005-06

nstall the factory

i

25. Slide the High-Ram over the

nstalled studs.

i

26. Place the thread sealing washers

on the two driver side studs. Use a

twisting motion to thread the sealing

washers over the threaded portion of

the studs to avoid tearing the seals.

Install standard flat washers on the

passenger side studs and on top of

the thread sealing washers, as shown

Figure 8.

in

27. Secure the High Ram with (4x)

1

⁄4"-20 Nylon locking nuts. Torque to

9 ft-lbs.

NOTE: Before slipping the boost tube

and the corresponding hose, into

position, ensure that all connection

ends are clean and free of any oil

residue and contaminates. Clean all

connection points with a

based solvent

Mineral Spirits, Denatured Alcohol or

Lacquer Thinner. Read and follow the

manufactures operation instruction

for non-oil based solvent cleaner.

such as Acetone,

non-oil

28. Locate the Banks boost tube,

connection hose, hump hose and

supplied hose clamps. Install hoses,

hose clamps and Banks boost tube

as shown in

Note: the connection hose should be

slid firmly against the hose stops

provided on the High Ram. Allow a

minimum

High Ram and boost tubes.

Figure 6.

1

⁄8” air gap between CAC,

igure 9

F

On 2003 to 2004 vehicles: The brake

line on the driver side may need to

be slightly bent to provide additional

clearance for the boost tube.

On 2005-06 vehicles: One of the

power steering fluid lines may need

to be bent to provide clearance for

the driver side boost tube.

29. The hose clamps on the High

Ram must be positioned as shown in

Figure 9 to avoid contact with the

hood.

30. Tighten the hose clamps to 75

inch-lbs (

not ft-lbs!).

31. Re-install the plastic driver side

battery box. Torque the attachment

bolts to 12 ft-lbs.

On 2005-06 4-wheel drive vehicles

only:

Reinstall the electronic module

mounting bracket that was removed

with the plastic battery tray.

32. Re-install the driver’s side

battery, battery hold down clamp,

and plastic battery cover. Torque the

hold down clamp retaining bolt to 89

WARNING: When lifting a

in-lbs.

battery, excessive pressure on the

end walls could cause acid to

spew through the vent caps,

resulting in personal injury. Lift

with a battery carrier or with

hands on opposite corners. Failure

to follow these instructions may

result in personal injury.

33. For 2005-06 4-wheel drive

equipped vehicles only:

electronic module near the driver

side battery

Figure 1.

The module is shown in

.

Re-install the

34. Re-install the air filter assembly

box and air box front cover.

35. Re-install the driver and

passenger (+) and (-) battery cables.

8 96782 v.2.0

Page 9

ALIGN WITH

SHROUD EDGE

03-04 SHROUD

SUPP

ORT PIN

2005-06 SHROUD

SUPP

ORT PIN

HIGH RAM

FAN

SHROUD TEMPLA

TE

SHROUD

SUPP

ORT PIN

2003-04

AREA TO T

RIM

2005-06

AREA TO T

RIM

Template 1

(fan shroud, step 19)

96782 v.2.0 9

Page 10

Notes

10 96782 v.2.0

Page 11

Notes

96782 v.2.0 11

Page 12

Gale Banks Engineering

546 Duggan Avenue • Azusa, CA 91702

(626) 969-9600 • Fax (626) 334 -1743

roduct Information & Sales: (800) 438-7693

P

Customer Support: (888) 839-5600

Installation Support: (888) 839-2700

bankspower.com

Loading...

Loading...