Galaxy 65 User Guide

Part No. 43061-02A

Issue 2-0

January 13, 2004

Galaxy 65 User Guide

Notices

The information in this document is subject to change without notice.

While every effort has been made to ensure that all information in this document is accurate, the Authors

accept no liability for any errors that may arise.

No part of this document may be transmitted or copied in any form, or by any means, for any purpose,

without the written permission of the Authors.

Issue 2-0 January 13, 2004 Part No. 43061-02A

Acknowledgments

ii

Contents

Contents

Preface .................................................................................................................................................. ix

International Standards .......................................................................................................................... ix

Potential for Radio Frequency Interference ........................................................................................... ix

European Regulations ............................................................................................................................ x

Safety ...................................................................................................................................................... x

Battery Safety ....................................................................................................................................... xii

Laser Safety .......................................................................................................................................... xii

Rack System Precautions ..................................................................................................................... xiii

ESD Precautions .................................................................................................................................. xiii

Data Security ....................................................................................................................................... xiv

Special Tools and Equipment .............................................................................................................. xiv

Related Documentation ....................................................................................................................... xiv

Conventions .......................................................................................................................................... xv

Revision History ................................................................................................................................... xvi

1 Introduction ..................................................................................................................................... 1

1.1 The Galaxy 65 System ................................................................................................................ 1

1.2 The Enclosure Core Product ....................................................................................................... 2

1.2.1 Enclosure Chassis .............................................................................................................. 2

1.2.2 Tower Option ...................................................................................................................... 3

1.3 The Plug-in Modules ................................................................................................................... 4

1.3.1 Power Supply/Cooling Module ........................................................................................... 4

1.3.2 Operators Panel ................................................................................................................. 5

1.3.3 Loop Resiliency Circuit Input/Output Module (FC-AL) ....................................................... 6

1.3.4 Drive Carrier Module .......................................................................................................... 9

1.3.5 Dummy Carrier Modules .................................................................................................. 10

1.4 Visible and Audible Alarms ........................................................................................................ 10

1.5 Installing your Galaxy 65 Subsystem ........................................................................................ 11

1.6 Galaxy 65 Technical Specification ............................................................................................11

1.6.1 Dimensions ....................................................................................................................... 11

1.6.2 Weight .............................................................................................................................. 11

1.6.3 AC Power (450W PSU) .................................................................................................... 11

1.6.4 PSU Safety and EMC Compliance ................................................................................... 12

1.6.5 Power Cord ...................................................................................................................... 12

iii

Galaxy 65 User Guide

1.6.6 Environment ..................................................................................................................... 12

1.6.7 Interfaces ......................................................................................................................... 13

1.6.8 Drive Carrier Module Specification .................................................................................. 13

1.6.9 Galaxy 65 FC-AL LRC I/O Module Specification ............................................................. 14

1.6.10 RAID Card ........................................................................................................................ 14

1.6.11 Software Enclosure Services (SES) Support ................................................................... 14

2 Operation ....................................................................................................................................... 15

2.1 Before You Begin ...................................................................................................................... 15

2.2 Power On .................................................................................................................................. 15

2.2.1 Power Supply/Cooling Module LEDs ............................................................................... 16

2.3 Ops Panel LEDs ........................................................................................................................ 16

2.4 Starting the Drives ..................................................................................................................... 18

2.4.1 Disk Drives LEDs ............................................................................................................. 18

2.5 Power Up/Down ........................................................................................................................ 18

3 Galaxy 65 RAID Management ......................................................................................................19

3.1 Managing Arrays and Partitions Using SAM ............................................................................. 19

3.2 Managing Arrays ....................................................................................................................... 20

3.3 Viewing Array and Drive Status Information ............................................................................. 20

3.3.1 Viewing Array and Partition Statistics .............................................................................. 21

3.3.2 Verifying an Array ............................................................................................................ 22

3.3.3 Changing Array Ownership .............................................................................................. 23

3.3.4 Changing an Array Name ................................................................................................ 23

3.3.5 Trusting an Array ............................................................................................................. 23

3.3.6 Deleting an Array ............................................................................................................. 24

3.4 Managing Partitions .................................................................................................................. 25

3.4.1 Viewing Partition Status Information ................................................................................ 25

3.4.2 Changing a Partition Name .............................................................................................. 25

3.4.3 Changing a Partition LUN ............................................................................................... 26

3.4.4 Controlling Partition Access ............................................................................................. 27

3.4.5 Changing the Read-Ahead Cache Size ........................................................................... 30

3.4.6 Deleting a Partition ........................................................................................................... 31

4 System Status ............................................................................................................................... 33

4.1 Monitoring System Status Using SAM ...................................................................................... 33

4.2 Setting Up Remote Notification ................................................................................................. 33

4.2.1 Starting and Stopping Remote Notification ...................................................................... 34

4.2.2 Setting Up the Events to be Monitored ............................................................................ 34

4.2.3 Setting Up the E-mail Addresses ..................................................................................... 34

4.3 Saving Log Information to a File ............................................................................................... 35

4.4 Displaying Overall Statistics ...................................................................................................... 36

4.4.1 Resetting the All Statistics ...............................................................................................37

5 Configuring the Galaxy 65 System ............................................................................................. 39

5.1 Configuring the LAN-related Settings ........................................................................................ 40

5.1.1 Configuring the Telnet Timeout ........................................................................................ 40

5.1.2 Configuring the SNMP Settings ....................................................................................... 40

5.1.3 Configuring the System Information ................................................................................. 41

5.1.4 Setting Passwords ........................................................................................................... 41

5.1.5 Configuring the Security Options ..................................................................................... 42

iv

Contents

5.2 Changing the Date and Time .................................................................................................... 43

5.3 Understanding LUNs and Viewing LUN Information ................................................................. 43

5.3.1 Viewing LUN Information .................................................................................................. 44

5.4 Changing Management LUNs ................................................................................................... 44

5.5 Changing the Alarm Mute Setting ............................................................................................. 44

5.6 Controlling Host Access to the Galaxy 65’s Write-back Cache Setting ..................................... 45

5.7 Enabling and Disabling the Battery ...........................................................................................46

5.8 Changing the Utility Priority ....................................................................................................... 46

5.9 Rescanning All Ports ................................................................................................................. 47

5.10 Pausing I/O ................................................................................................................................ 47

5.11 Saving and Restoring a Configuration File ................................................................................ 48

5.11.1 Saving a Configuration File .............................................................................................. 48

5.11.2 Restoring a Configuration File .......................................................................................... 48

5.12 Viewing and Restoring Default Settings .................................................................................... 50

5.12.1 Viewing Default Settings ..................................................................................................50

5.12.2 Restoring Default Settings ................................................................................................50

5.13 Updating Software .................................................................................................................... 51

6 Managing Disk Drives & Enclosures ........................................................................................... 53

6.1 Managing Disk Drives ............................................................................................................... 53

6.1.1 Displaying Disk Drive Information .................................................................................... 53

6.1.2 Clearing Metadata from a Disk Drive ............................................................................... 54

6.1.3 Enabling and Disabling Write-back Cache ....................................................................... 55

6.1.4 Displaying Disk Drive Cache Status ................................................................................. 55

6.1.5 Enabling and Disabling SMART Changes ........................................................................ 55

6.1.6 Blinking a Drive LED ........................................................................................................ 56

6.1.7 Taking Down a Disk Drive ................................................................................................ 56

6.1.8 Testing a Disk Drive ......................................................................................................... 57

6.2 Managing Enclosures ................................................................................................................ 57

6.2.1 Setting the EMP LUN ....................................................................................................... 57

6.2.2 Changing the Additional EMP Setting ............................................................................. 58

7 Troubleshooting and Problem Solving ....................................................................................... 59

7.1 Overview ................................................................................................................................... 59

7.1.1 Initial Start-up Problems ................................................................................................... 59

7.2 LEDs .......................................................................................................................................... 60

7.2.1 Power Supply/Cooling Module ......................................................................................... 60

7.2.2 Ops Panel ......................................................................................................................... 60

7.3 Audible Alarm ............................................................................................................................ 61

7.3.1 Audible Alarm Mute .......................................................................................................... 61

7.4 Troubleshooting ......................................................................................................................... 62

7.4.1 System Faults ................................................................................................................... 63

7.4.2 Power Supply/Cooling Faults ........................................................................................... 63

7.4.3 Thermal Control ................................................................................................................ 64

7.4.4 Thermal Alarm .................................................................................................................. 65

7.5 Drive Carrier Module Faults ...................................................................................................... 65

7.5.1 Dummy Carrier Modules ................................................................................................. 65

7.5.2 Auto Start Failure ............................................................................................................. 66

7.6 Dealing with Hardware Faults ................................................................................................... 66

7.7 Continuous Operation During Replacement .............................................................................. 66

7.8 Problems Accessing the Galaxy 65 Subsystem Using the Ethernet Port ................................. 66

v

Galaxy 65 User Guide

7.9 Host Fibre Channel Problems ................................................................................................... 67

7.10 Array Problems ......................................................................................................................... 68

7.10.1 Changing the Backoff Percent Using SAM ...................................................................... 68

7.10.2 Changing the Backoff Percent Using the Disk Array Administrator ................................. 68

7.11 Galaxy 65 Subsystem Problems ............................................................................................... 69

7.12 Replacing a Module .................................................................................................................. 69

7.12.1 Power Supply/Cooling Modules ....................................................................................... 69

7.12.2 Ops Panel ........................................................................................................................ 72

7.12.3 Storage Manager Module ................................................................................................ 72

7.12.4 Insertion/Removal of SFP Modules ................................................................................. 74

7.12.5 Battery Replacement .......................................................................................................74

7.12.6 Drive Carrier Module ........................................................................................................ 75

7.13 Problems During Startup (When Using the Disk Array Administrator) ...................................... 75

7.14 Terminal Emulator and COM Port Problems ............................................................................. 76

7.15 Warning and Error Events ......................................................................................................... 77

7.15.1 Warnings .......................................................................................................................... 78

7.15.2 Errors ............................................................................................................................... 80

7.16 Setting Up and Viewing the Debug Log .................................................................................... 81

7.16.1 Summary of Debug Log Capabilities ............................................................................... 81

7.16.2 Collecting Debug Logs .....................................................................................................81

7.16.3 Configuring Debug Logs .................................................................................................. 82

7.16.4 Using SAM to Set Up and View the Debug Log ............................................................... 83

7.16.5 Using the Disk Array Administrator to Set Up Debug Logging ......................................... 83

7.17 Using the Loader Diagnostics Menu ......................................................................................... 83

7.18 Using the Loader Utility Menu ................................................................................................... 84

7.19 Understanding Disk-related Errors ............................................................................................ 84

7.19.1 Disk Errors ....................................................................................................................... 84

7.19.2 Disk Channel Errors ......................................................................................................... 85

7.19.3 Voltage and Temperature Errors and Warnings .............................................................. 86

7.20 Slow Write Performance ........................................................................................................... 86

7.21 Spare Parts and Ancillary Items ............................................................................................... 87

7.22 Upgrading Your LRC I/O Modules ............................................................................................ 87

A Array Basics .................................................................................................................................. 89

A.1 Array Types ............................................................................................................................... 90

A.1.1 RAID 0 (Striped Disks) .....................................................................................................90

A.1.2 RAID 1, RAID 10 (Mirrored Disks) ................................................................................... 90

A.1.3 RAID 3 ............................................................................................................................. 90

A.1.4 RAID 4 ............................................................................................................................. 91

A.1.5 RAID 5 ............................................................................................................................. 91

A.1.6 RAID 50 ........................................................................................................................... 91

A.1.7 Volume Sets ..................................................................................................................... 91

A.2 Comparing RAID Levels ............................................................................................................ 92

A.3 Mixing Disks from Different Manufacturers or with Different Capacities ................................... 93

B Accessing Disk Array Administrator Software .......................................................................... 95

B.1 Accessing the Disk Array Administrator Using the RS-232 Serial Port ..................................... 96

B.2 Accessing the Disk Array Administrator Using the Ethernet Port .............................................. 98

B.2.1 Using the Ethernet Port for the First Time ....................................................................... 98

B.2.2 Accessing the Disk Array Software Using the Ethernet Port ........................................... 99

B.3 Navigating the Disk Array Administrator Software .................................................................. 101

vi

Contents

B.3.1 Changing the Screen Display ......................................................................................... 102

B.3.2 Disk Array Administrator Menu Tree .............................................................................. 103

C Creating and Managing Arrays & Partitions ............................................................................. 105

C.1 Creating Arrays ....................................................................................................................... 105

C.1.1 Creating a Single-Partition Array .................................................................................... 106

C.1.2 Creating a Multiple-Partition Array ................................................................................. 111

C.2 Managing Arrays ..................................................................................................................... 116

C.2.1 Viewing Array and Drive Status Information ................................................................... 117

C.2.2 Stopping the Array Initialization Process ........................................................................ 120

C.2.3 Adding a Partition ........................................................................................................... 121

C.2.4 Verifying an Array ........................................................................................................... 123

C.2.5 Reconstructing an Array ................................................................................................. 126

C.2.6 Expanding Array Capacity .............................................................................................. 126

C.2.7 Changing an Array Name ............................................................................................... 129

C.2.8 Changing Array Ownership ............................................................................................ 130

C.2.9 Trusting an Array ............................................................................................................ 130

C.2.10 Deleting an Array ............................................................................................................ 131

C.3 Managing Partitions ................................................................................................................. 133

C.3.1 Understanding Partitions ................................................................................................ 133

C.3.2 Viewing Partition Status Information .............................................................................. 134

C.3.3 Expanding a Partition ..................................................................................................... 139

C.3.4 Changing a Partition Name ............................................................................................ 140

C.3.5 Changing a Partition LUN .............................................................................................. 141

C.3.6 Changing the Read-Ahead Cache Size ......................................................................... 142

C.3.7 Enabling or Disabling Write-back Cache ........................................................................ 143

C.3.8 Controlling Partition Access ........................................................................................... 144

C.3.9 Deleting a Partition ......................................................................................................... 151

D Monitoring System Status .......................................................................................................... 153

D.1 Introduction .............................................................................................................................. 153

D.2 Displaying the Event Log ......................................................................................................... 154

D.2.1 Viewing the Most Recent Event ..................................................................................... 154

D.2.2 Viewing One Event at a Time ......................................................................................... 155

D.2.3 Viewing a Whole Screen of Events ................................................................................ 156

D.2.4 Capturing the Event Log ................................................................................................ 157

D.3 Displaying Module Status Information ..................................................................................... 158

D.4 Displaying Hardware and Configuration Information ............................................................... 159

D.5 Capturing the Event Log, Hardware, and Configuration Information ....................................... 164

D.6 Displaying Drive Errors and Resetting Error Statistics ............................................................ 164

D.7 Displaying Overall Statistics .................................................................................................... 165

D.7.1 Resetting Overall Statistics ............................................................................................ 166

E Managing Spares ........................................................................................................................ 167

E.1 Managing Dedicated Spares ................................................................................................... 168

E.1.1 Adding a Dedicated Spare ............................................................................................. 168

E.1.2 Deleting a Dedicated Spare ........................................................................................... 168

E.2 Enabling Dynamic Spares ....................................................................................................... 169

E.3 Managing the Spare Pool ........................................................................................................ 170

E.3.1 Adding a Spare to the Spare Pool .................................................................................. 171

E.3.2 Deleting a Spare from the Spare Pool ............................................................................ 171

vii

Galaxy 65 User Guide

E.3.3 Displaying the Spare Pool .............................................................................................. 171

F Managing Disk Drives and Enclosures ..................................................................................... 173

F.1 Managing Disk Drives ............................................................................................................. 173

F.1.1 Displaying Drive Information .......................................................................................... 173

F.1.2 Clearing Metadata from a Drive ..................................................................................... 177

F.1.3 Enabling and Disabling Write-back Cache ..................................................................... 177

F.1.4 Displaying Disk Cache Status ........................................................................................ 179

F.1.5 Enabling and Disabling SMART Changes ..................................................................... 181

F.1.6 Blinking a Drive LED ...................................................................................................... 182

F.1.7 Taking Down a Drive ...................................................................................................... 182

F.1.8 Testing a Drive ............................................................................................................... 183

F.2 Managing Enclosures .............................................................................................................. 183

F.2.1 Setting the EMP LUN ..................................................................................................... 184

F.2.2 Changing the Additional EMP Setting ........................................................................... 187

G Configuring the Galaxy 65 Subsystem ..................................................................................... 189

G.1 Shutting Down and Restarting the Storage Manager Module ................................................. 190

G.1.1 Shutting Down and Restarting the Current SM Module ................................................. 190

G.1.2 Shutting Down the Other SM Module ............................................................................ 191

G.1.3 Shutting Down Both SM Modules .................................................................................. 192

G.1.4 Other Controller Menu ................................................................................................... 192

G.2 Changing the Date and Time .................................................................................................. 192

G.3 Configuring the Host Channels ............................................................................................... 195

G.4 Understanding LUNs and Viewing LUN Information ............................................................... 196

G.4.1 Viewing LUN Information ............................................................................................... 197

G.5 Configuring the FC Disk Channels .......................................................................................... 198

G.6 Changing the Alarm Mute Setting ........................................................................................... 200

G.7 Locking the Cache Setting ...................................................................................................... 203

G.8 Enabling and Disabling the Battery ......................................................................................... 204

G.9 Changing the Utility Priority ..................................................................................................... 205

G.10Rescanning All Channels ........................................................................................................ 206

G.11Pausing I/O ............................................................................................................................. 207

G.12Restoring Default Settings ...................................................................................................... 208

G.13Updating Firmware ................................................................................................................. 209

G.13.1 Updating the SM, SM Loader and Memory Controller Firmware .................................. 209

G.13.2 Updating LAN Firmware ................................................................................................. 210

viii

H LAN Configuration ...................................................................................................................... 213

H.1 Configuring the SM for TCP/IP ................................................................................................213

H.2 Configuring the LAN Settings .................................................................................................. 214

H.2.1 Configuring the IP Settings ............................................................................................ 214

H.2.2 Configuring the FTP Settings ......................................................................................... 215

H.2.3 Configuring the Telnet Settings ...................................................................................... 215

H.2.4 Configuring the SNMP Settings ..................................................................................... 216

H.2.5 Configuring the Contact Settings ................................................................................... 217

H.2.6 Configuring the HTTP Settings ...................................................................................... 218

H.2.7 Configuring the Security Options ................................................................................... 218

H.2.8 Resetting the LAN Subsystem ...................................................................................... 219

Glossary ............................................................................................................................................. 221

Contents

Index ................................................................................................................................................... 229

ix

Galaxy 65 User Guide

x

Preface

Preface

What is in this guide

This user guide gives you step-by-step instructions on how to install, configure and connect the Galaxy

65 storage Subsystem to your host computer system, and how to use and maintain the system.

Who should use this guide

This user guide assumes that you have a working knowledge of the Fibre Channel environment into

which you are installing the Galaxy 65 system. If you do not have these skills, or are not confident with

the instructions in this guide, do not proceed with the installation.

International Standards

The Galaxy 65 storage system complies with the requirements of the following agencies and standards:

• CE to IEC 950/EN60950

• UL 60950

•cUL

Potential for Radio Frequency

Interference

USA Federal Communications Commission (FCC)

Note This equipment has been tested and found to comply with the limits for a class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. The supplier is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Note

FCC approval only applies when using the supplied screened Ethernet cable.

ix

Galaxy 65 User Guide

European Regulations

This equipment complies with European Regulations EN 55022 Class A: Limits and Methods of

Measurement of Radio Disturbance Characteristics of Information Technology Equipments and

EN50082-1: Generic Immunity.

Safety

All plug-in modules are part of the fire enclosure and must only be removed when a replacement can be

immediately added. The system must not be run without all units in place.

Drive Carrier Module

Caution Label:

• Do not operate with

modules missing

• Spin down time 30

seconds

Permanently unplug the unit if you think that it has become damaged in any way and before you move it.

• A Galaxy 65 enclosure can weigh up to 37kg (81lb). Do not try to lift it by yourself.

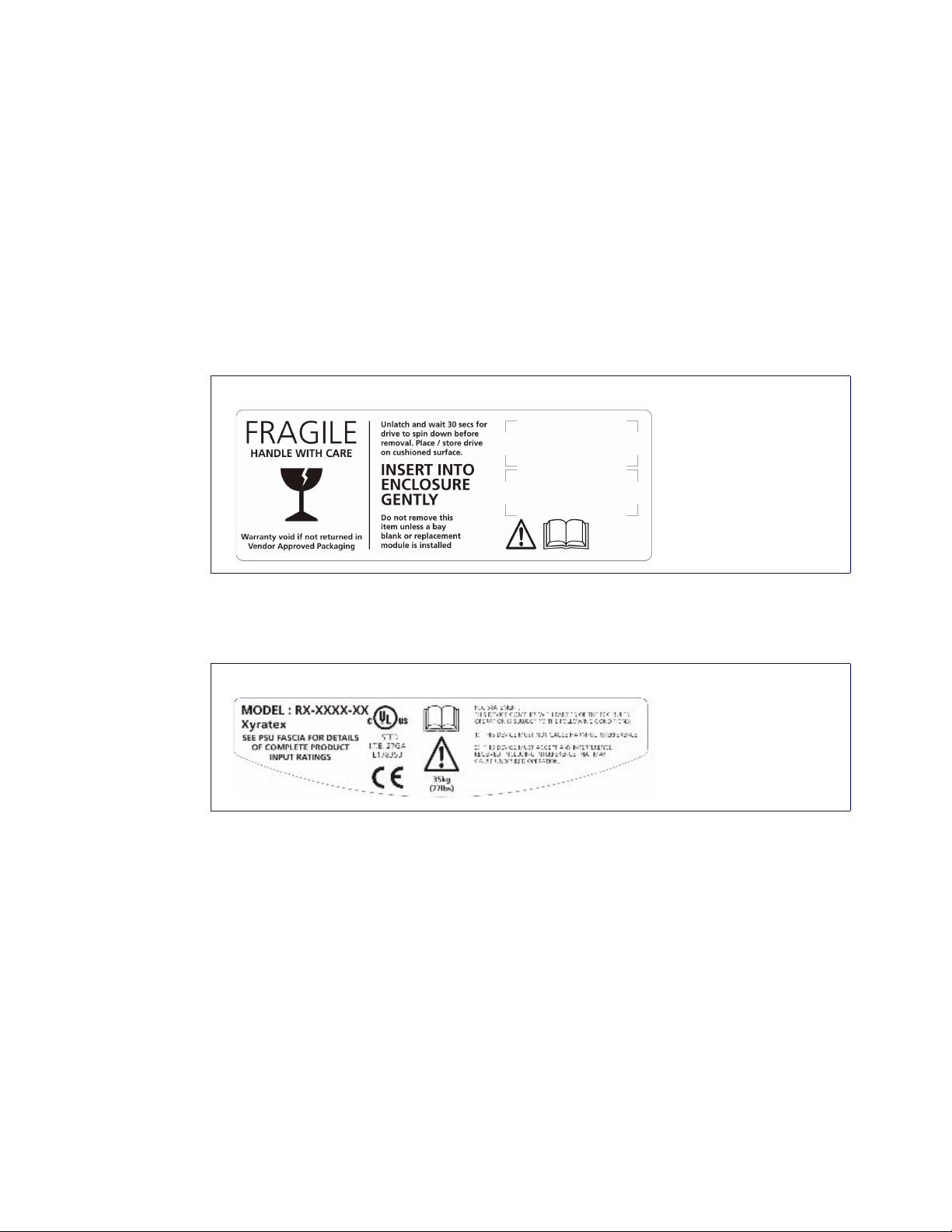

Chassis Warning Label:

Weight Hazard

• Do not attempt to lift the enclosure by means of the extended LRC module or by the handles on the

PSU/Cooling module as they are not designed to support the weight of the populated enclosure.

• In order to comply with applicable safety, emission and thermal requirements no covers should be

removed and all bays must be fitted with plug-in modules.

x

LRC Module Caution

Label:

Do not operate with

modules missing

PSU/Cooling Module Caution Label:

Do not operate with modules missing

Preface

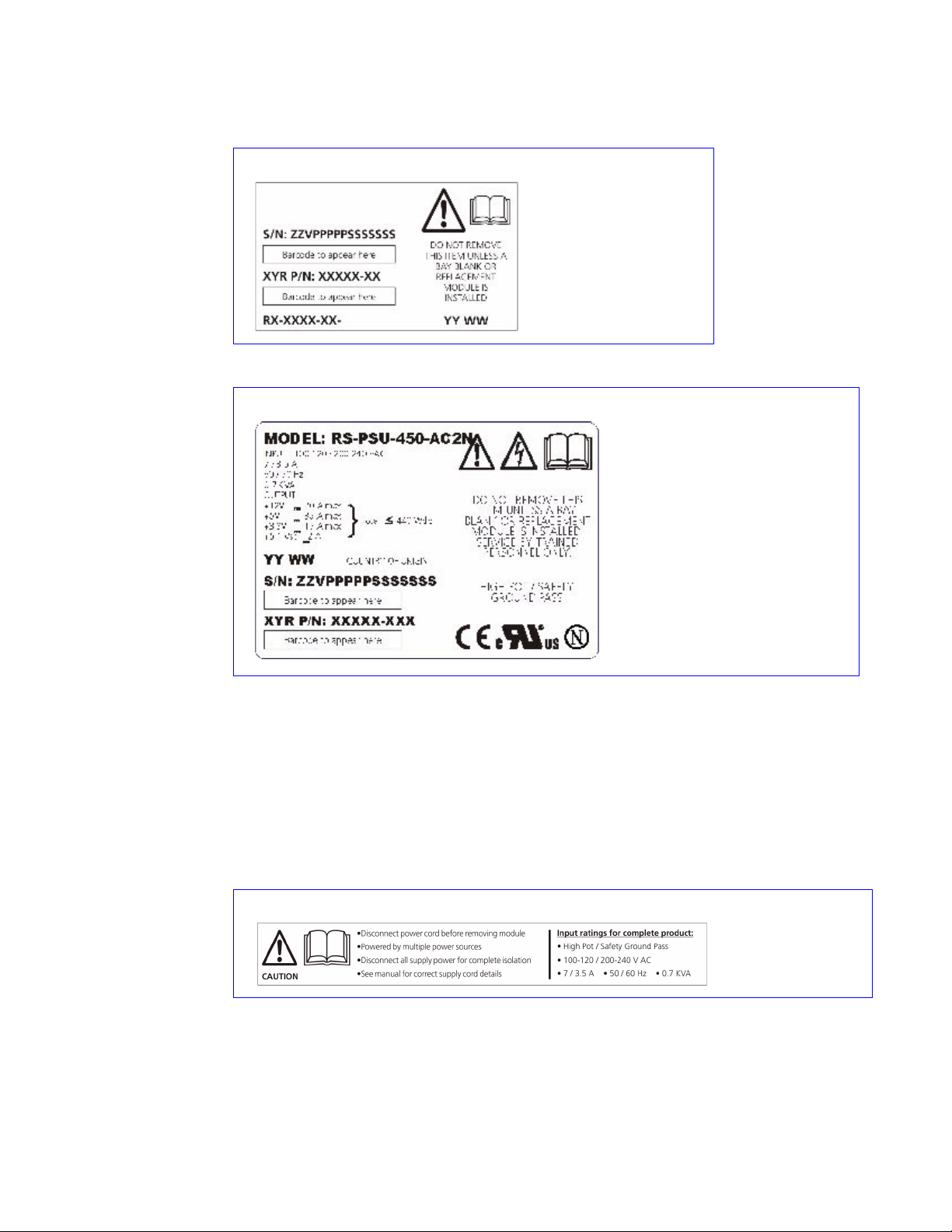

• The Galaxy 65 unit must only be operated from a power supply input voltage range of 100 -120VAC

or 200-240 VAC.

• The plug on the power supply cord is used as the main disconnect device. Ensure that the socket

outlets are located near the equipment and are easily accessible.

• This equipment is intended to operate with two working PSUs.

• If powered by multiple AC sources, disconnect all supply power for complete isolation

PSU Warning Label:

Power Hazards

• The power connection must always be disconnected prior to removal of the Power Supply/Cooling

module from the enclosure.

• A safe electrical earth connection must be provided to the power cord. Check the grounding of the

enclosure before applying power.

xi

Galaxy 65 User Guide

Warning Do not remove covers from the power supply unit. Danger of electric shock inside. Return the PSU

Caution Caution: If this equipment is used in a manner not specified by the manufacturer, the protection provided

• Provide a suitable power source with electrical overload protection to meet the requirements laid

down in the technical specification.

• A faulty power supply/cooling module must be replaced with a fully operational module within 24

hours.

to your supplier for repair.

PSU Safety Label:

Electric Shock Hazard Inside

by the equipment may be impaired.

Battery Safety

The battery is user replaceable, please refer to the Battery Replacement Procedure.

Warning There is a danger of explosion if the battery is incorrectly replaced.

• Dispose of used batteries in accordance with the manufacturer’s instructions and National

regulations.

Laser Safety

Class 1 Laser Product

When the Galaxy 65 Subsystem is supplied with optical modules they contain a laser that complies with

Laser Class 1, US 21 CFR (J) and EN 60825-1.

If optical modules are to be provided and fitted by the end user, lasers must comply with the standards

listed above.

xii

Rack System Precautions

The following safety requirements must be considered when the unit is mounted in a rack.

• The rack design should incorporate stabilizing features suitable to prevent the rack from tipping or

being pushed over during installation or in normal use.

• When loading a rack with the units, fill the rack from the bottom up and empty from the top down.

• The rack should comply with the airflow requirements detailed in the technical specification.

• The rack design should take into consideration the maximum operating ambient temperature for the

unit, which is 40°C when dual cooling modules are fitted.

• The rack should have a safe electrical distribution system. it must provide overcurrent protection for

the unit and must not be overloaded by the total number of units installed in the rack. Consideration

of the electrical power consumption rating shown on the nameplate should be used when

addressing these concerns.

• The electrical distribution system must provide a reliable earth for each unit and the rack.

Preface

• Each power supply in each unit has an earth leakage current of 0.65mA. The design of the electrical

distribution system must take into consideration the total earth leakage current from all the power

supplies in all the units. The rack will require labelling with "HIGH LEAKAGE CURRENT. Earth

connection essential before connecting supply".

• The rack when configured with the units must meet the safety requirements of UL1950 and IEC

60950.

ESD Precautions

Caution It is recommended that you fit and check a suitable anti-static wrist or ankle strap and observe all

conventional ESD precautions when handling Galaxy 65 plug-in modules and components. Avoid contact

with backplane components and module connectors, etc.

xiii

Galaxy 65 User Guide

Data Security

• Power down your host computer and all attached peripheral devices before beginning installation.

• Each enclosure contains up to 16 removable disk drive modules. Disk units are fragile. Handle them

with care, and keep them away from strong magnetic fields.

• All the supplied plug-in modules and blanking plates must be in place for the air to flow correctly

around the enclosure and also to complete the internal circuitry.

• If the Subsystem is used with modules or blanking plates missing for more than a few minutes, the

enclosure can overheat, causing power failure and data loss. Such use may also invalidate the

warranty.

• If you remove any drive module, you may lose data.

– If you remove a drive module, replace it immediately. If it is faulty, replace it with a drive module

of the same type and capacity

• Ensure that all disk drives are removed from the enclosure before attempting to manhandle or move

the rack installation.

• Do not abandon your backup routines. No system is completely foolproof.

Special Tools and Equipment

There are no special tools required but in order to complete the assembly of some configurations you may

need the following (not supplied):

• Security keys (one of these should be included with your Galaxy 65 enclosure for use with the drive

locks).

Related Documentation

• Galaxy 65 Getting Started Manual (P/N 44521-01A), Issue 1.0

• Galaxy 65 Quick Installation Guide (P/N 43062-01A), Issue 1.0

• Galaxy 65 Series Rack Installation Guide (P/N 43638-01A), Issue 1.0

xiv

Conventions

This Getting Started guide uses several conventions to help explain how to use the X24.

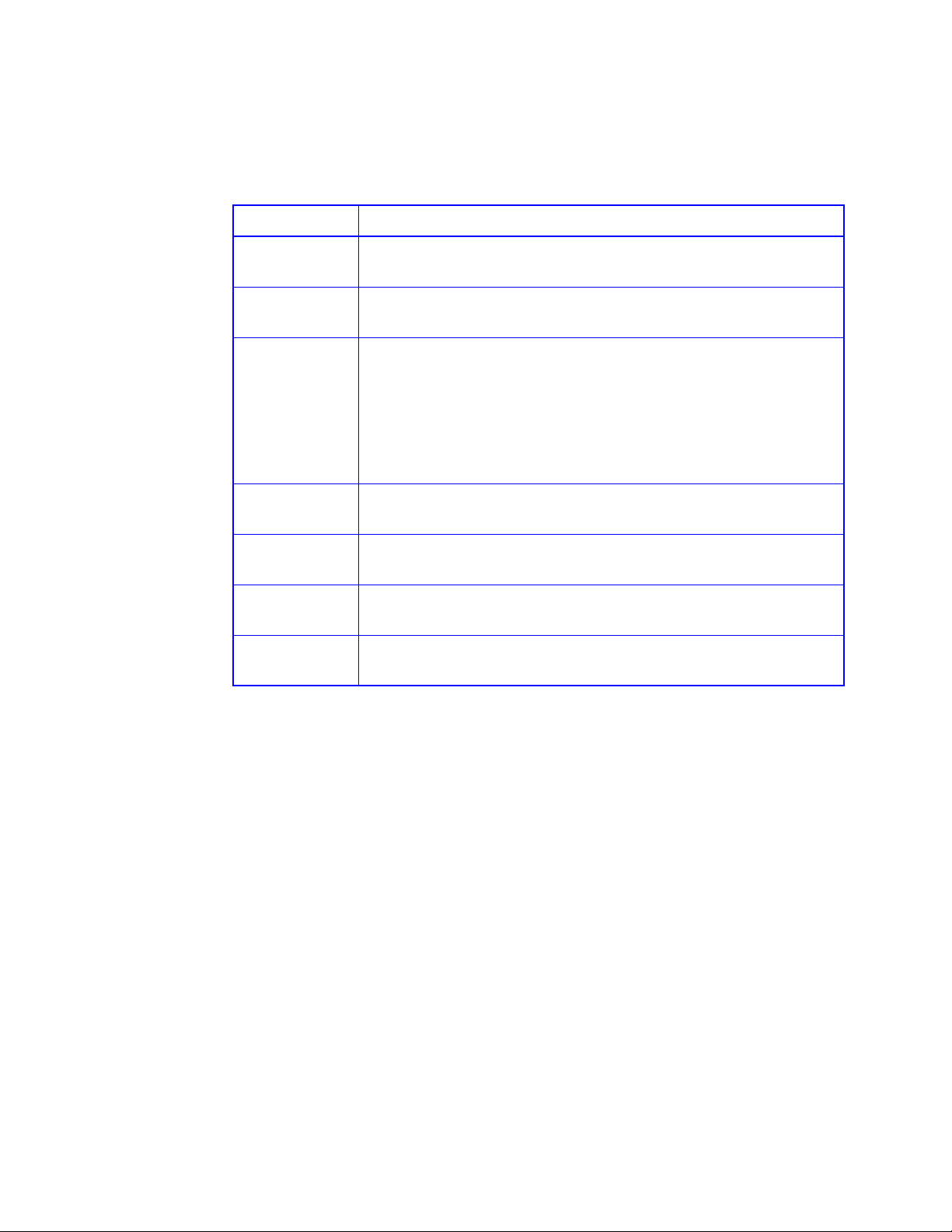

Convention Definition

Bold Words in bold indicate items to select such as menu items or command

buttons.

CTRL-R Keys you press simultaneously. In this example, hold down the Ctrl key and

press the r key.

Preface

MB

Note Notes

Important Important

Caution Cautions warn you about actions that may permanently delete data or cause

Warning Warnings warn you about actions that may be hazardous to personnel,

The abbreviation MB is used for megabytes in all situations. However, the

amount of data represented by MB differs as follows:

For disk drives, arrays, partitions, and data rate statistics, 1 MB equals

1,000,000 using the International System of Units (SI) standard.

For memory, 1 MB equals 1,048,576 using the memory industry standard.

give you information that can help you improve the performance of your

system.

gives you important information that may affect how you decide to

set up your system.

damage to your system.

resulting in injury or death

xv

Galaxy 65 User Guide

Revision History

Version Date Description of Change

Issue 1.0 June, 2003 Initial (Beta) Release

Issue 2.0 January, 2004 Chapter 1, Page 14 amended:

Section 1.6.10: “(planned)” deleted.

xvi

Preface

xvii

Galaxy 65 User Guide

xviii

Chapter 1

Introduction

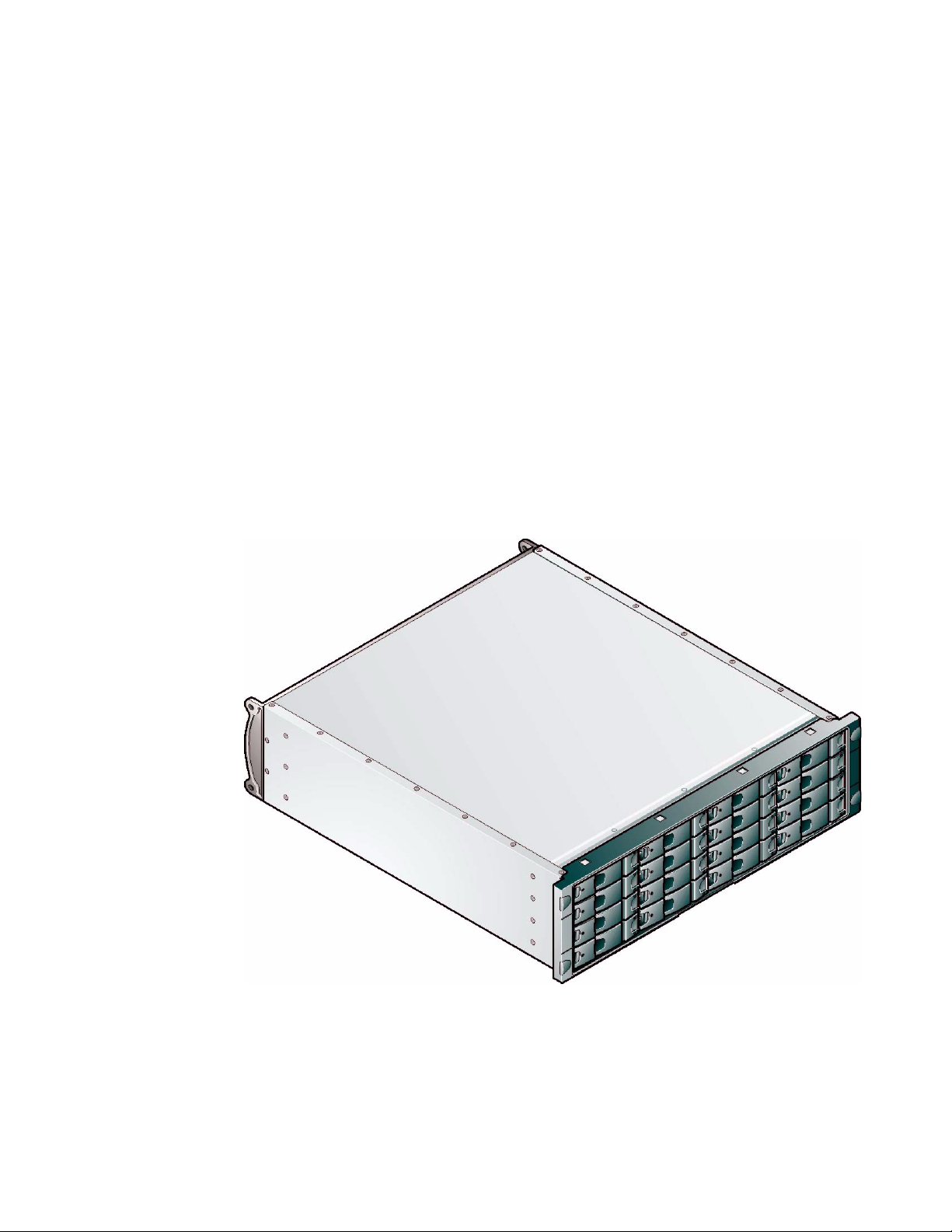

1.1 The Galaxy 65 System

.

Introduction

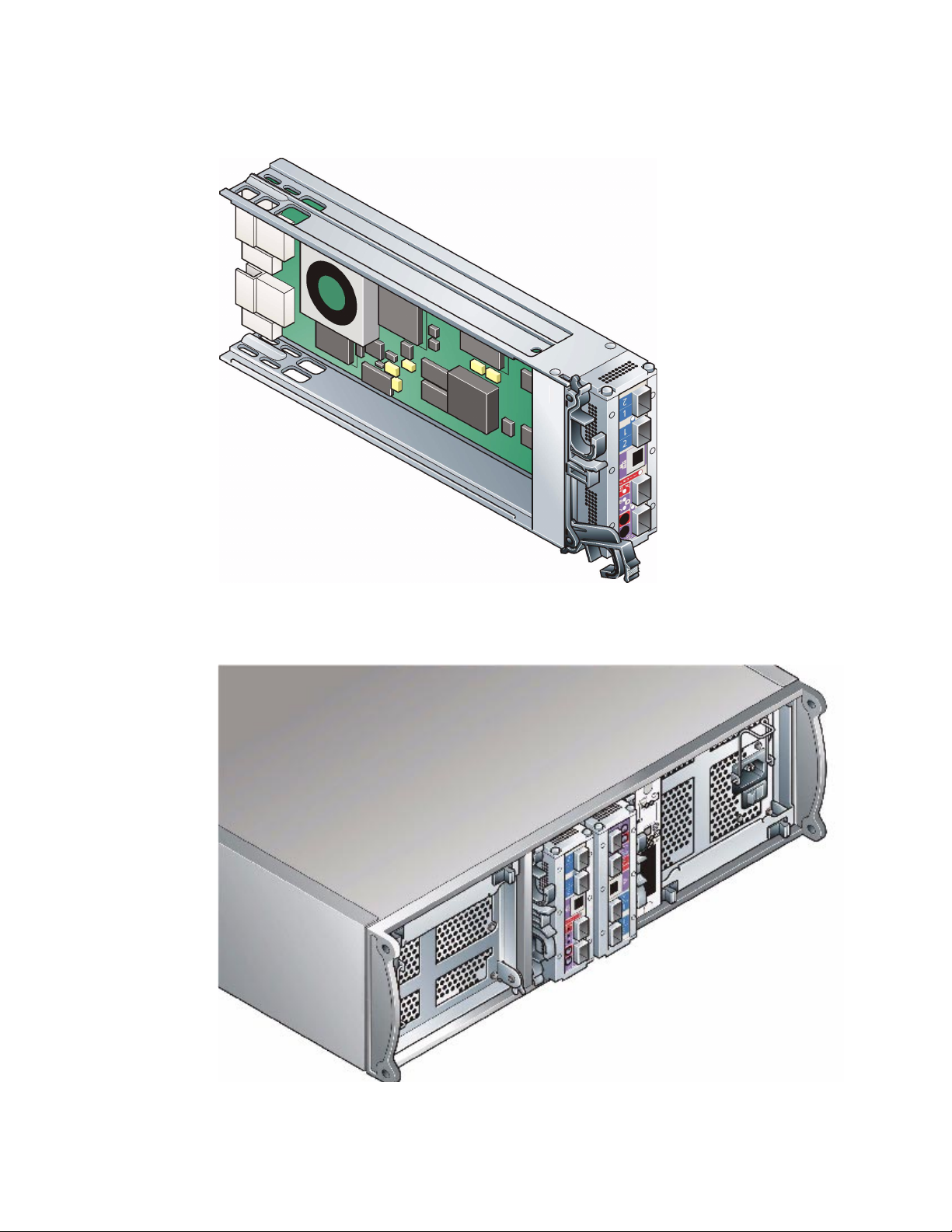

Figure 1–1

The Galaxy 65 (FC-AL) System

1

Galaxy 65 User Guide

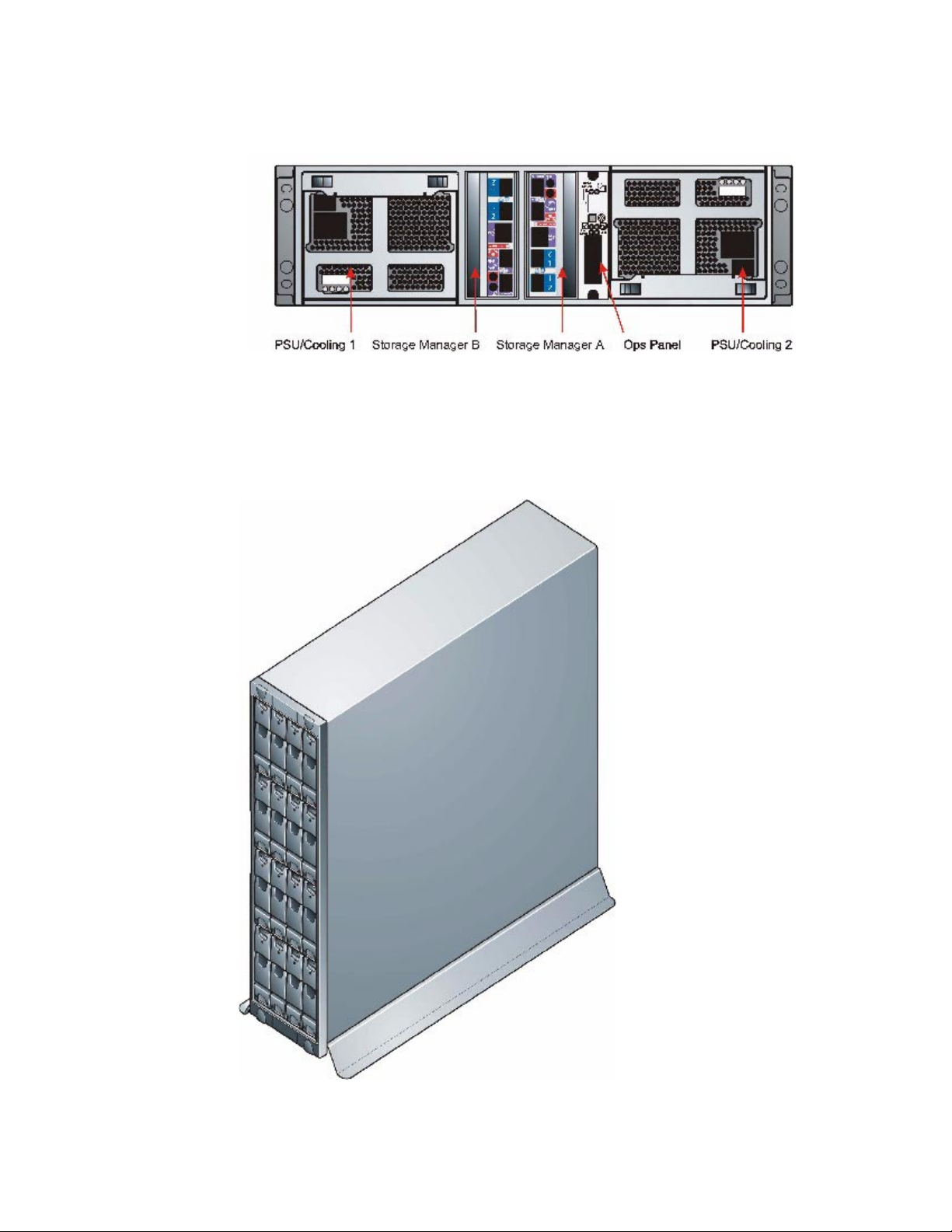

1.2 The Enclosure Core Product

1.2.1 Enclosure Chassis

The Galaxy 65 design concept is based on a Subsystem together with a set of plug-in modules. The

Galaxy 65 Subsystem as supplied comprises:

• Chassis and Backplane with integral Operators Panel.

• Power Supply/Cooling plug-in modules, auto-ranging, 475W, AC (see Figure 1–5)

• FC-AL Drive Carrier Modules and associated dummy carrier modules (See Figure 1–10).

• FC-AL LRC 2Gb/s Input/Output Modules with integrated Rorke Data Galaxy 65 RAID controllers,

known as Storage Managers.(See Figure 1–8).

The chassis consists of a sheet metal enclosure assembly containing a Backplane PCB and module

runner system. This chassis assembly also includes an integral Operators (Ops) Panel mounted at the

rear.

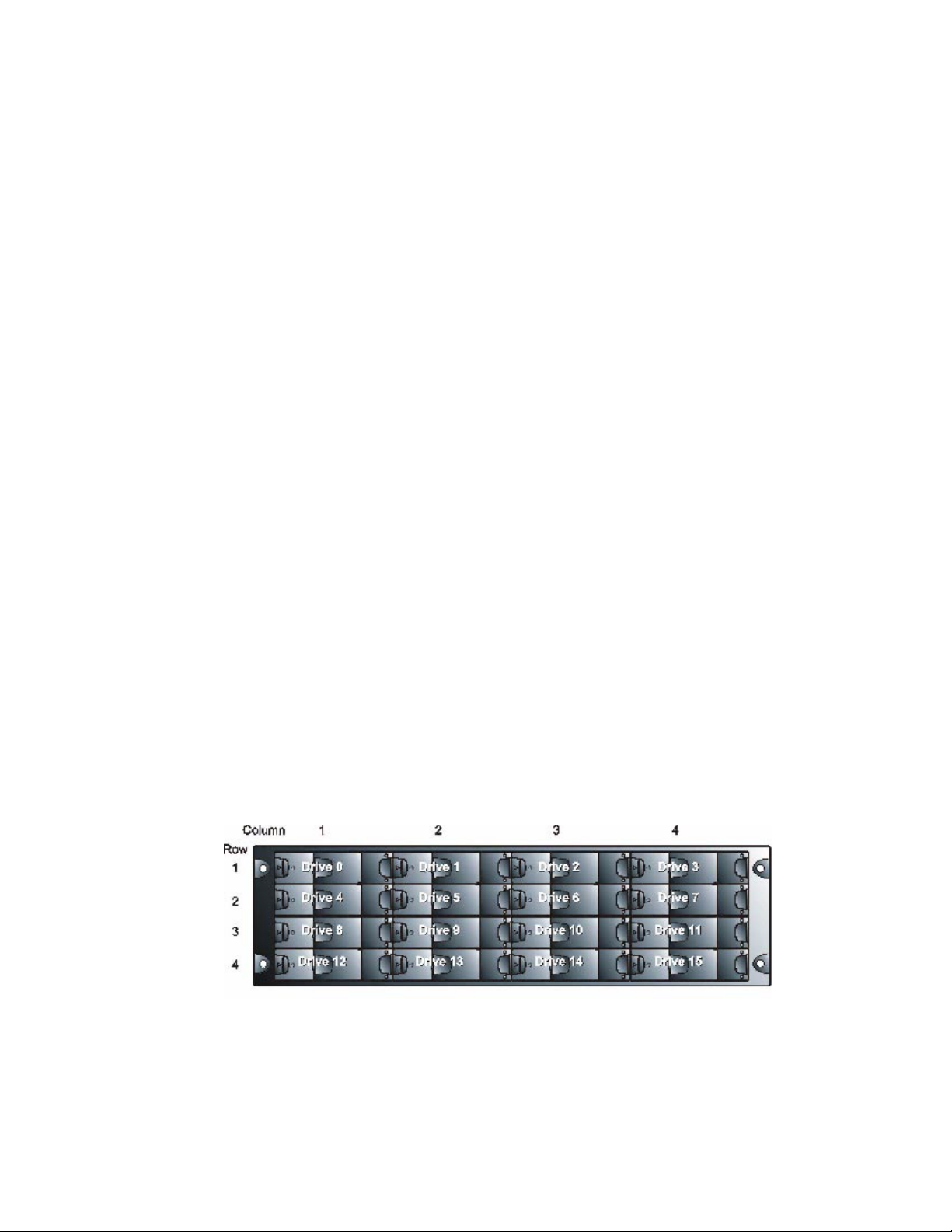

The chassis assembly contains 16 drive bays at the front, each of which accommodates a plug-in drive

carrier module. The 16 drive bays are arranged in 4 rows of 4 drives. At the rear, the chassis assembly

contains 5 module bays to house two Power Supply/Cooling modules, two LRC I/O modules and the

integral Ops panel.

The Backplane PCB provides logic level signal and low voltage power distribution paths. Figure 1–2 and

Figure 1–3 show front and rear views of an Galaxy 65 chassis respectively.

The 4 x 4 chassis is fitted with 19 inch Rack mounting features which enables it to be fitted to standard

19 inch racks and uses 3EIA units of rack space.

• A Bay is defined as the space required to house a single 1.0" high 3.5 inch disk drive in its carrier

module. e.g. a 1 x 4 bay module would take the space of 1 drive width by 4 drive bays high (in rack

mount configuration).

.

Figure 1–2 Galaxy 65 Enclosure Chassis (Front)

2

Figure 1–3 Galaxy 65 Enclosure Chassis (Rear)

1.2.2 Tower Option

An optional tower kit is available, which can be fitted to the rack chassis described here.

Introduction

Figure 1–4

.

Galaxy 65 Tower Option

3

Galaxy 65 User Guide

1.3 The Plug-in Modules

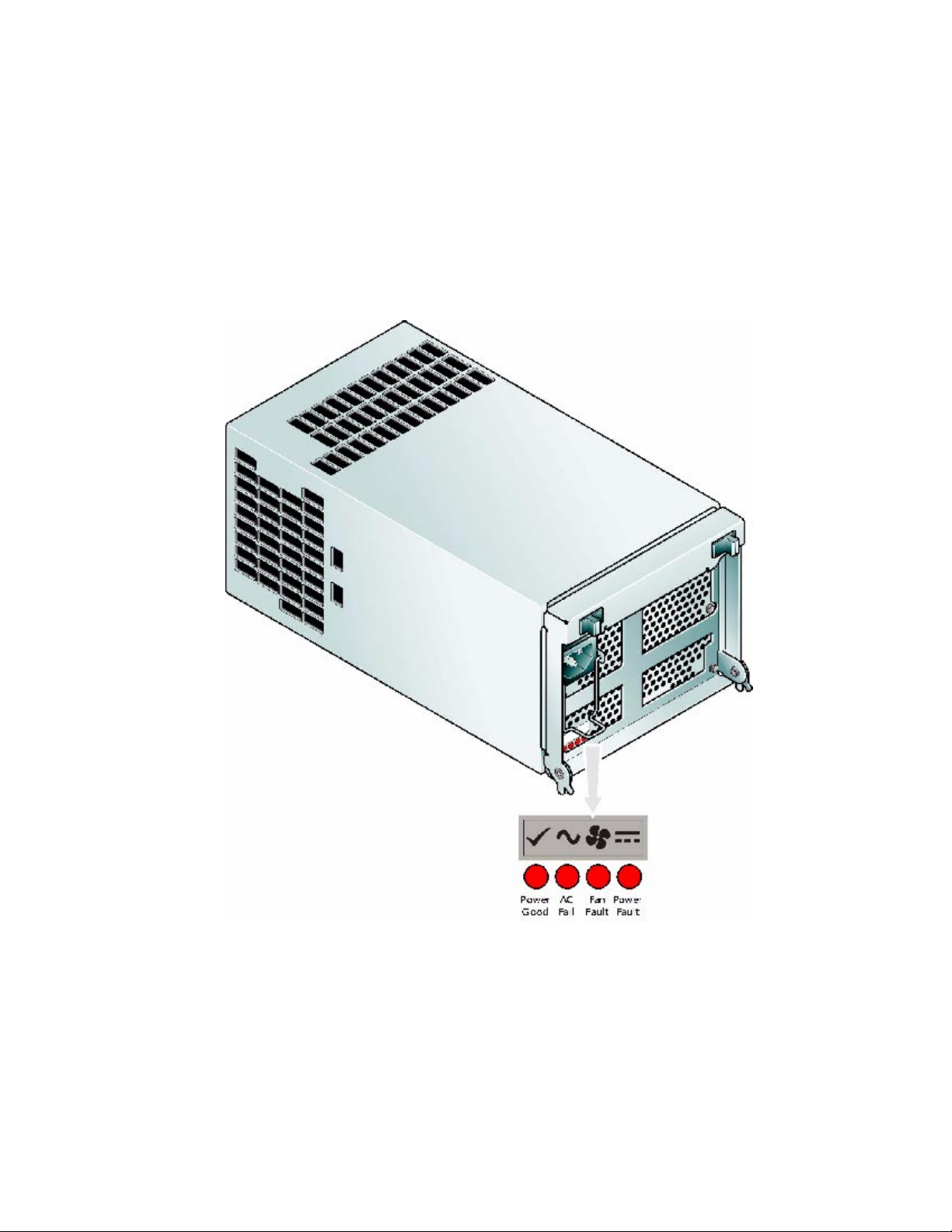

1.3.1 Power Supply/Cooling Module

A Galaxy 65 Enclosure requires one or more of the following modules for normal operation:

Two Power Supply/Cooling modules (Figure 1–5) are supplied mounted in the rear of the enclosure as

part of the Subsystem core product.

Figure 1–5 AC Power Supply/Cooling Module

.

PSU voltage operating ranges are nominally 115V or 230V AC, selected automatically.

.

Four LEDs mounted on the front panel of the Power Supply/Cooling Module indicate the status of the PSU

and the fans.

Warning The Power Supply/Cooling module is not an operator removable part. It should only be removed

by a technician who has knowledge of the hazards present within the module.

4

1.3.1.1 Multiple Power Supply/Cooling Modules

The Galaxy 65 system must always be operated with two Power Supply/Cooling modules fitted. The two

Power Supply/Cooling modules operate together so that if one fails the other maintains the power supply

and cooling while you replace the faulty unit.

Module replacement should only take a few minutes to perform but must be completed within 5 minutes

from removal of the failed module.

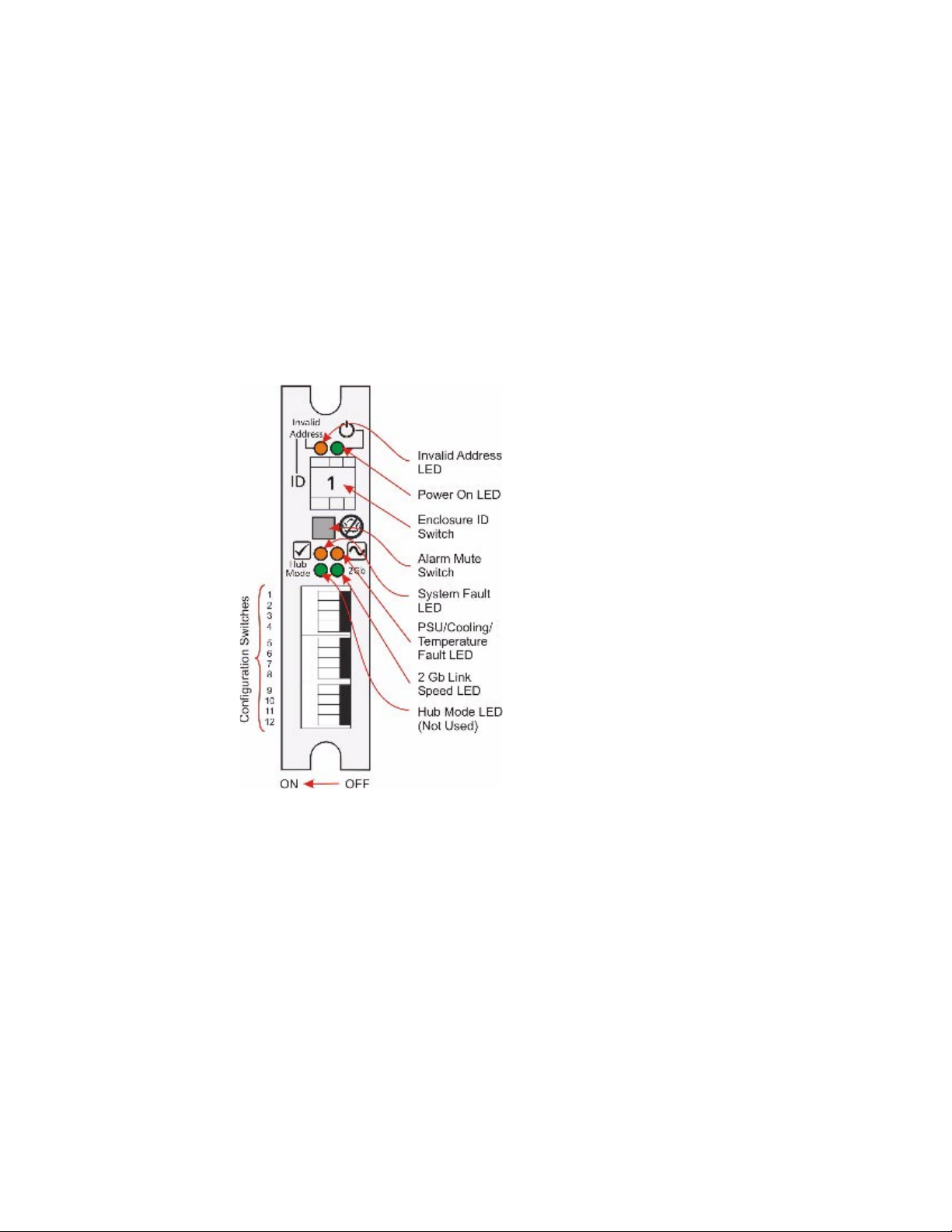

1.3.2 Operators Panel

Supplied as an integral part of the Enclosure core product, a typical Operators (Ops) Panel is shown in

Figure 1–6.

Introduction

Figure 1–6 Operators (Ops) Panel

The Ops Panel provides the enclosure with a micro controller which is used to monitor and control all

elements of the Enclosure.

1.3.2.1 Ops Panel Indicators and Switches

The Ops Panel includes Light Emitting Diodes (LEDs) which show the status for all modules, an Audible

Alarm which indicates when a fault state is present, a push-button Alarm Mute switch and a thumb wheel

SEL_ID address Range selector switch.

The Ops Panel switch functions are shown in Table 1–1.

Important Switch settings are only read at Power On.

The Galaxy 65 enclosure ID must always be set to select ID1.

5

Galaxy 65 User Guide

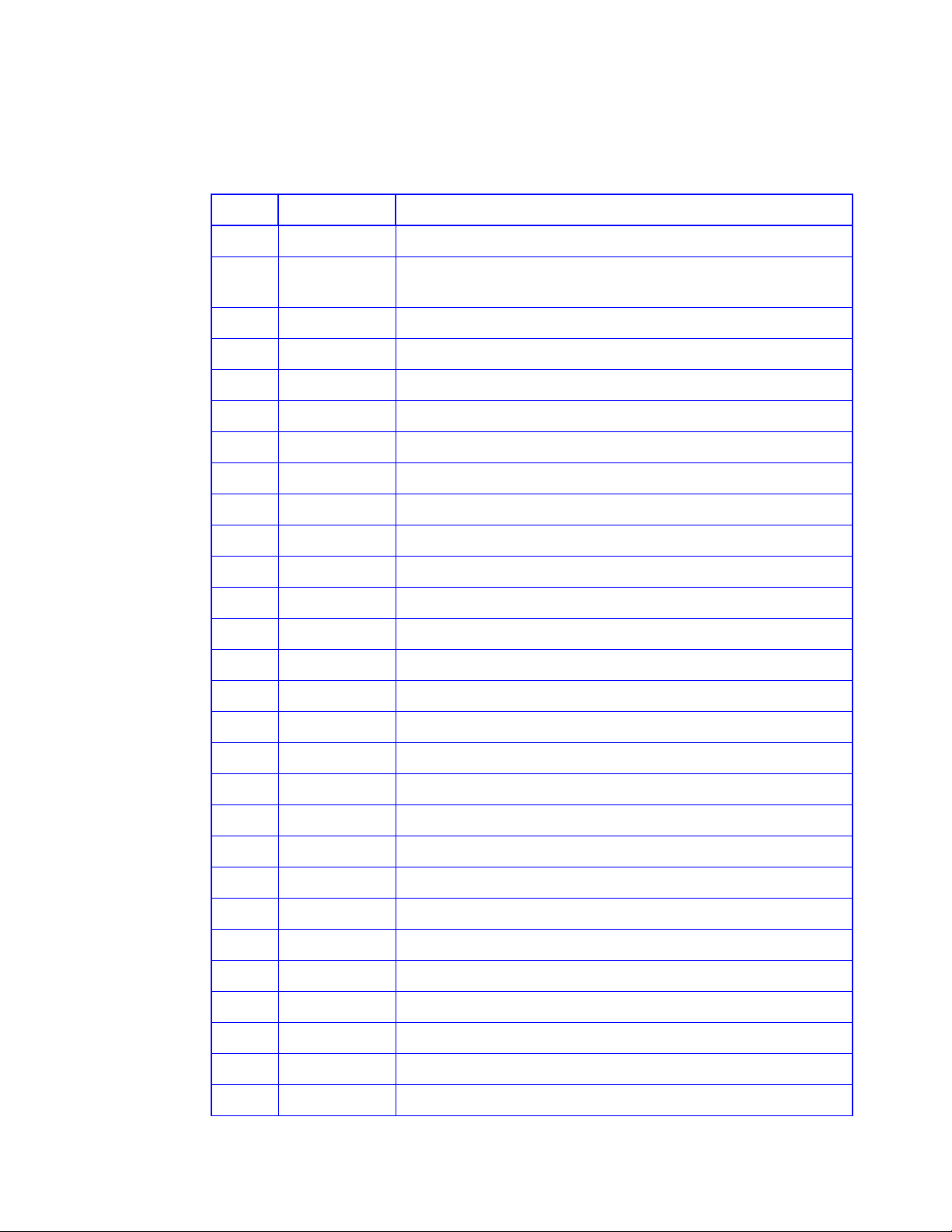

Table 1–1 Ops Panel Switch Functions (Default settings for Galaxy 65 LRC usage at 2Gb/s)

Switch

Number

1 Loop Select,

2 Not Used Note: on Galaxy 65-FC2 enclosures this must be set On.

3 Not Used

4 Not Used

5 & 6 Not Used

7 & 8 Drive Loop Speed

9 & 10 Drive Addressing

11 SOFT SELECT On Select Functions using the hardware

12 Not Used

Function Recommended

Dual (2x8)

Sw7 Sw8

Select

Mode Selection

On Off Force 2Gb/s

Off Off Force 1Gb/s

Sw9 Sw10

On Off Mode 2, 2x8 mode. Mandatory

Definition

Setting

Off LRC operates on two loops of 8 drives

Mandatory

switches

Caution All mandatory settings must be observed in order for the Galaxy 65 system to function correctly.

Note To set Host 1Gb use the Ethernet connected configurator.

1.3.3 Loop Resiliency Circuit Input/Output Module (FC-AL)

The Galaxy 65 storage Subsystem includes an enclosure with rear facing bays which house two Loop

Resiliency Circuit (LRC) I/O modules with integrated Rorke Data

Storage Managers (SM) modules. (see Figure 1–3)

The FC-AL Backplane incorporates two independent loops formed by Port Bypass Circuits within the LRC

I/O modules.

The plug-in SM modules have been designed for integration into a Galaxy 65 storage Subsystem, utilizing

FCAL interfacing with the host computer system.

Processors housed on the LRC modules provide enclosure management and interface to devices on the

Backplane, PSU, LRC and Ops Panel, to monitor internal functions. These processors operate in a

master slave configuration to allow failover.

The module incorporates the following LED indicators, shown in Figure 1–7:

• Host Port 0 Signal Good (Green)

• Host Port 1 Signal Good (Green)

• Expansion Port 0 Rx Good (Green)

Galaxy 65 RAID controller, known as

6

• Expansion Port 1 Rx Good (Green)

• ESI/LRC module fault LED (Amber)

• Cache Active (Green)

• RAID Controller Activity

– Ready (Green)

Host Activity of either host channels (Flash off)

–

• Battery Fault (Amber)

Introduction

Figure 1–7 LRC Panel Layout

Important Fitting of a RAID controller to the LRC module is a factory only operation.

7

Galaxy 65 User Guide

Figure 1–8

Warning Do not attempt to lift the enclosure by means of the extended SM module

..

Galaxy 65 LRC (Storage Manager) I/O Module

Figure 1–9

Galaxy 65 Enclosure with Storage Manager Modules and PSUs Installed

8

Introduction

The Storage Manager module operates at 1 or 2 Gb.

• Two external ports for expansion to further enclosures are provided by SFP connectors

• Two external ports to the host controllers are provided from SM module all Form Factor (SFP) GBIC

modules, auto-bypass at the output ports is provided.

• An RJ45 10/100 Base T Ethernet controller management port is provided on the LRC board,

interfacing to the controller through 2 RS232 serial and GPIO lines.

Caution The RJ45 Ethernet connector on the LRC module must not be connected to telecommunications

networks.

• The SM module also incorporates a standby Li-ion battery pack, 72 hours cache hold up time

(512Mb). The battery cell has thermal protection and is connected to the RAID controller by flying

lead.

Note The Galaxy 65 product range is available in 1Gb, 2Gb, JBOD or RAID variants, by changing the LRC

modules. Please contact your supplier for details.

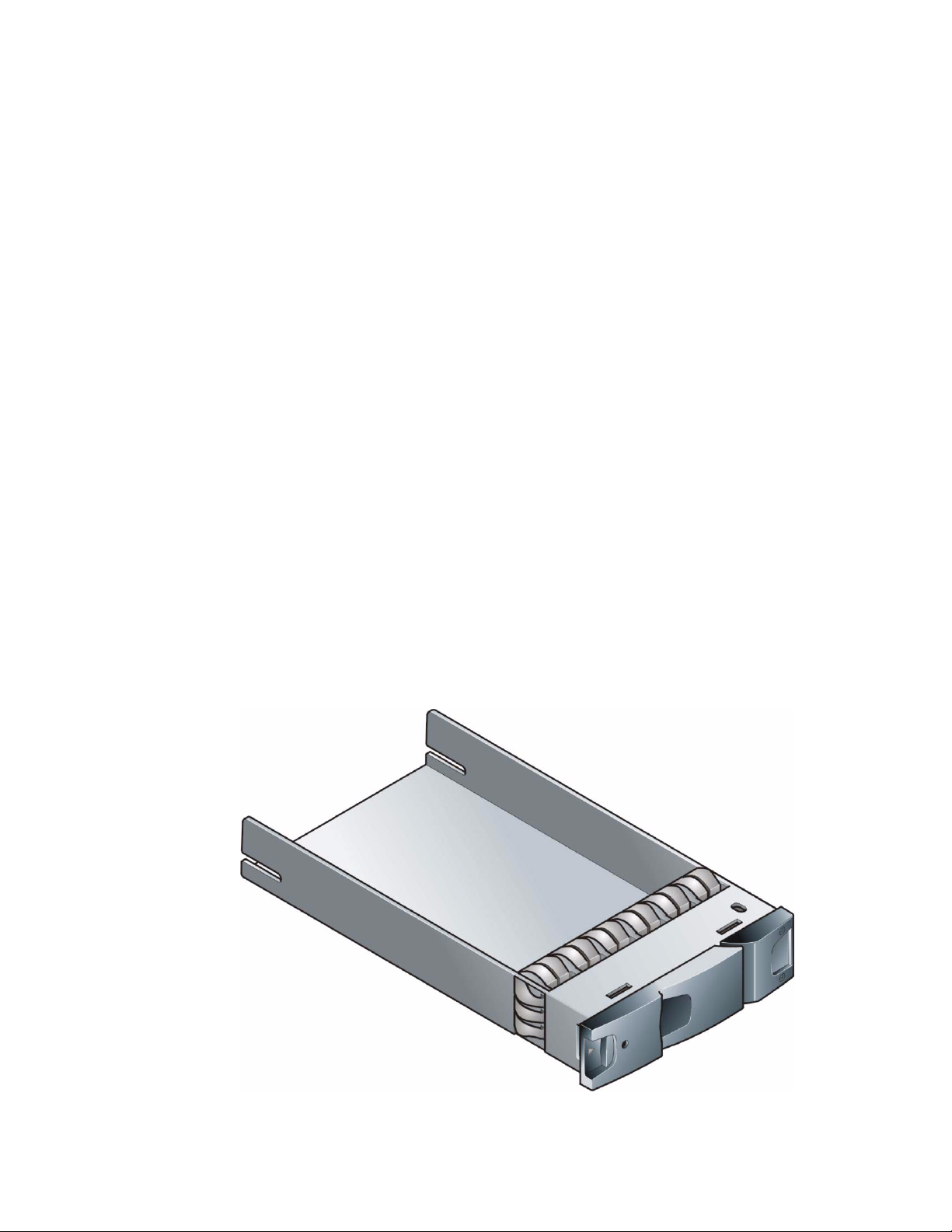

1.3.4 Drive Carrier Module

The Drive Carrier module comprises a hard disk mounted in a carrier. Each drive bay will house a single

1.0 inch high, 3.5 inch disk drive in its carrier.

Each disk drive is enclosed in a die-cast aluminum carrier which provides excellent thermal conduction,

radio frequency and electro-magnetic induction protection and affords the drive maximum physical

protection.

The front cap also supports an ergonomic handle which provides the following functions:

• Camming of carrier into and out of drive bays.

• Positive 'spring loading' of the drive/backplane connector.

• An anti-tamper lock operated by a torx socket type key.

Figure 1–10

Drive Carrier Module

9

Galaxy 65 User Guide

1.3.4.1 Drive Status Indicators

1.3.4.2 Anti-tamper Locks

Each drive carrier incorporates two indicators, an upper (Green) and lower (Amber). In normal operation

the green indicator will be ON and will flicker as the drive operates.

Anti-tamper locks are fitted in the drive carrier handles (Figure 1–11) and are provided to disable the

normal ‘pinch' latch action of the carrier handle.

Figure 1–11

Anti-tamper Lock

1.3.5 Dummy Carrier Modules

Dummy carrier modules are provided for fitting in all unused drive bays. They are designed as integral

drive module front caps with handles and must be fitted to all unused drive bays to maintain a balanced

airflow.

Warning Operation of the Enclosure with ANY modules missing will disrupt the airflow and the drives will

not receive sufficient cooling. It is ESSENTIAL that all apertures are filled before operating the

unit. Dummy Carriers are available for this purpose.

1.4 Visible and Audible Alarms

The functional modules have associated status LEDs. The Ops Panel shows a consolidated status for all

modules.

LEDs show constant green for good or positive indication. Constant Amber LEDs indicate there is a fault

present within that module.

The Ops Panel also incorporates an Audible Alarm to indicate when a fault state is present and also an

Alarm Mute push-button.

Warning The Ops Panel is an integral part of the enclosure chassis assembly and can only be replaced by

trained personnel.

10

Loading...

Loading...