Galaxy Control Systems 635 Series, 600 Series, 635 CPU, 600 DPI, 635 DPI/DRM Installation/configuration Manual

...

SYSTEM GALAXY

635 & 600 HARDWARE

INSTALLATION & CONFIGURATION

SG v11.2.0

S28 11.0.3

Oct 2019

System Galaxy

635-600 Series Hardware Manual

Revised

January 2019

635-600 Series Hardware Manual

Rev. 11.1.0.2

~ 2 ~

website for the latest updates and flash compatibility information. Visit us at

Galaxy Control Systems makes every effort to provide disclosures when referencing

products that are trademarked by other companies. The publisher states that it is

System Galaxy

635-600 Series

Hardware Manual

COVERING:

600 & 635

600 & 635 DPI/DRM Rev. E/F

DIO - Rev. C / D

DSI - Rev. B/C

Relay Board – all revisions

CPU

11th Edition, Jan 2019

Revision 11.1.0.2

Information in this document is subject to change without notice.

Therefore, no claims are made as to the accuracy or completeness of this document.

Integrated applications and 3

At the time this manual is published, all 600-series Hardware is compatible with System

Galaxy 11 software. See the board compatibility section in this guide to determine oldermodel board pairing requirements and upgrade path. Check the Galaxy Tech support

www.galaxysys.com

rd

Party Technologies my have additional requirements.

Copyright © 2019 Galaxy Control Systems All rights reserved

No part of this document may be reproduced, copied, adapted, or transmitted, in any form

or by any means, electronic or mechanical, for any purpose, without the express written

consent of Galaxy Control Systems. Copyright protection claims include all forms and

matters of copyrighted material and information, including but not limited to, material

generated from the software programs, which are displayed on the screen such as icons,

look and feel, etc.

Trademarks

referencing product names solely for editorial purposes, and to the benefit of the trademark

owners with no intent to infringe upon said trademarks.

The following trademarks are referenced in this manual:

®

Microsoft

Corporation in the U.S. and other countries.

HID

Corporation.

Farpointe logo and Farpointe Data are registered trademarks of Farpointe Data, Inc.

Galaxy Control Systems

SAGEM and MORPHO logos and MORPHO

Bioscrypt

Adobe

, Windows®, MSDE® and SQL Server

®

, HID iCLASS®, and HID Corporate 1000® are registered trademarks or logos of HID Global

®

®

are trademarks of their respective owners in the U.S. and abroad.

®

and Acrobat® are registered trademarks of Adobe Systems Inc.

, MorphoAccess®, SIGMA, Sagem, Invixium,

3 North Main Street

Walkersville MD 21793

www.galaxysys.com

TM

are registered trademarks of Microsoft

~ 3 ~

Table of Contents chapter-page

1 Overview, Safeguards, Specifications, and Requirements 1-1

1.1 What’s in this Manual (you are here) 1-1

1.2 IMPORTANT: Product Safety and Precautions 1-3

1.3 Hardware Certifications & Compliances 1-4

1.4 Hardware Replacement Parts 1-6

1.4.1 ORDERING POWER TRANSFORMER & BATTERIES.......................................................................................... 1-6

1.4.2 ORDERING REPLACEMENT BOARDS .............................................................................................................. 1-6

1.5 Hardware Capability: Panel-Level (CPU) 1-7

1.5.1 Controller Capability of the 600/635 Model Access Control Panel: ................................................................ 1-7

1.6 Hardware Capability: Board-Level 1-8

1.6.1 List of Boards and Component Descriptions: ................................................................................................. 1-8

1.7 Hardware & System Descriptions 1-10

1.7.1 Description of Galaxy Access Control Panel: ................................................................................................. 1-10

ENCLOSURE DIMENSIONS: 1-10

COMPONENTS IN THE DOMESTIC 8-DOOR CONTROLLER : 1-10

1.7.2 635/600-series CPU Description: .................................................................................................................. 1-12

1.7.3 635/600 DRM (DPI) Description: .................................................................................................................. 1-13

1.7.4 600 DIO Detailed Description: ...................................................................................................................... 1-13

1.7.5 600 DSI Description: ..................................................................................................................................... 1-14

1.7.6 600 RELAY BOARD Description: .................................................................................................................... 1-14

1.7.7 The System Described: ................................................................................................................................. 1-15

1.7.8 SG System Diagram – Communication/Event Server: ................................................................................... 1-16

1.7.9 SG System Planning Notes: ........................................................................................................................... 1-17

1.8 CPU & Board Flash Requirements for 600/635-Series Hardware 1-18

1.8.1 About Factory Flash and Field-Flashing the CPU: .......................................................................................... 1-18

1.8.2 About Auto-Updating the Daughter Boards: ................................................................................................ 1-19

1.8.1 Flash Version Compatibility Chart for SG-10: ................................................................................................ 1-19

1.8.2 Version Compatibility Charts for SG-9 and SG-8: .......................................................................................... 1-21

1.9 Controller Mounting Requirements 1-22

1.10 Power Requirements 1-24

1.11 Relay Ratings and Current Draw 1-25

1.12 Hardware Wiring Specifications 1-26

1.12.1 Controller Ethernet Communications: .......................................................................................................... 1-26

1.12.2 Hardware Wiring Specifications (Type, Gauge, Distance): ............................................................................ 1-26

1.13 Board Programming Requirements 1-27

page ~ i

1.14 Network & IT Requirements for Galaxy Hardware 1-29

1.15 Communication Requirements for System Galaxy Servers 1-30

1.16 Requirements for Logins and User Privileges (SG Software) 1-31

1.17 Pinout for Ethernet Cable (Cat-5e) 1-31

1.18 General FAQs about Features of Galaxy Hardware 1-32

2. Hardware Installation Instructions 2-1

LIST OF TABLES IN THIS CHAPTER 2-2

LIST OF FIGURES FOUND IN THIS CHAPTER 2-3

STEP 1. Hardware Install ~ Site Preparation 2-5

1.1 Conducting a Site Survey................................................................................................................................... 2-5

Overall System Architecture: 2-5

Technical Certification: 2-5

Controller Power Supply and Power Sources: 2-5

1.2 Requirements and Safeguards .......................................................................................................................... 2-7

SAFEGUARDS: 2-7

REQUIREMENTS: 2-8

1.3 About Upgrading Hardware / Expanding Systems ............................................................................................. 2-9

WHEN IS UPGRADING THE HARDWARE REQUIRED? 2-9

WHEN IS UPGRADING THE SG SOFTWARE REQUIRED? 2-9

1.4 Board Compatibility and Capability (635 vs. 600 models) ................................................................................ 2-10

NOTES ABOUT REPAIR / MAINTENANCE / UPGRADE OF 600-MODEL CONTROLLERS 2-10

STEP 2. Mount the Controller Enclosure/Cabinet 2-11

2.1 Choose a good location for the Controller ....................................................................................................... 2-11

EXPOSURE 2-11

2.1.2 MOUNTING REQUIREMENTS 2-11

2.2 Running Field Wiring ........................................................................................................................................ 2-12

2.3 Mount the Controller Cabinet .......................................................................................................................... 2-13

STEP 3. Install Power Connectors inside Controller 2-14

3.1 Remove Heat Shrink (only from wires to be used) ........................................................................................... 2-14

3.2 Wire the CPU Power Connector and Tamper Switch ........................................................................................ 2-15

3.3 Wire the “A/C Fail” and “Low Battery” to Sense Connector ............................................................................. 2-16

3.4 Wire the Power Connectors for the Boards (DRM, DIO, or DSI) ........................................................................ 2-17

STEP 4. Install the CPU and Interface Boards (daughter boards) 2-18

4.1 Install the 635-CPU Board inside Controller ..................................................................................................... 2-18

4.2 Installing a 635-DRM Board (Dual Reader Module) .......................................................................................... 2-19

635-DRM - BOARD FEATURES 2-19

635-DRM - INSTALL REQUIREMENTS 2-20

635-DRM – BOARD INSTALLATION (STANDARD OPERATION) 2-21

PART 4.2.1 PRE-CONFIGURING THE SUPERVISION RESISTORS 2-21

PART 4.2.2 SETTING THE LOCK RELAY JUMPERS 2-22

PART 4.2.3 (REQUIRED) PRE-CONFIGURING THE BOARD ID 2-23

PART 4.2.4 (REQUIRED) INSTALLING THE 635 DRM BOARD IN THE CONTROLLER 2-24

4.3 Install the DIO Board in the Controller ............................................................................................................. 2-25

page ~ ii

600-DIO - BOARD FEATURES 2-25

600-DIO – BOARD INSTALLATION 2-26

4.4 Installing a 635 DSI Board (Dual Serial Interface) ............................................................................................. 2-27

635-DSI - BOARD FEATURES 2-27

635-DSI - BOARD SPECIFICATIONS 2-28

THE 635-DSI SUPPORTED TECHNOLOGIES 2-28

635-DSI MAX NO. OF DEVICES & DEVICE COUNT (per Section) 2-29

635-DSI Examples of How DSI Sections Function Independently 2-30

635-DSI – BOARD INSTALLATION 2-31

PART 4.4.1 (OPTIONAL) PRECONFIGURING THE EOL TERMINATION JUMPERS (635-DSI) 2-31

PART 4.4.2 SETTING THE PASS-THRU VOLTAGE JUMPERS 2-32

PART 4.4.3 (REQUIRED) PRE-CONFIGURING THE BOARD ID 2-33

PART 4.2 4 (REQUIRED) INSTALLING THE 635 DSI BOARD IN THE CONTROLLER 2-34

4.5 Installing a 635-Model Output Relay Board ..................................................................................................... 2-35

635-OUTPUT RELAY BOARD - FEATURES 2-35

635-RELAY BOARD – INSTALLATION OF BOARD IN CONTROLLER 2-36

PART 4.5.1 PREP STEPS - BEFORE INSTALLING THE RELAY BOARDS 2-36

PART 4.5.2 CONFIGURE THE RELAY BOARD IDs (REQUIRED) 2-38

PART 4.5.3 INSTALLING THE BOARDS IN THE PANELS (REQUIRED) 2-39

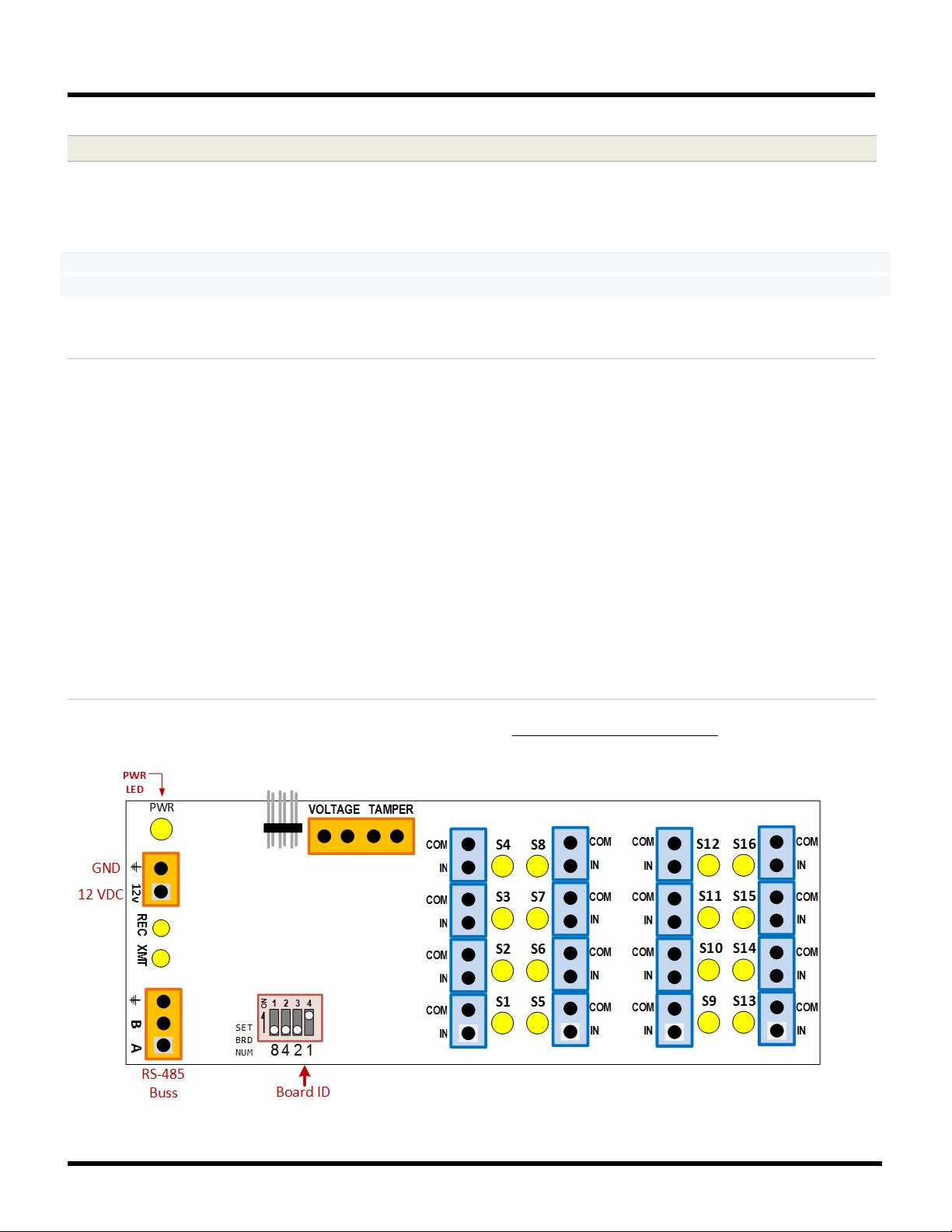

4.6 Installing 635-Model Input Module .................................................................................................................. 2-43

635-INPUT MODULE - FEATURES 2-43

635-INPUT MODULE – INSTALLATION OF BOARDS IN CONTROLLER PANELS 2-44

PART 4.6.1 PREP STEPS - BEFORE INSTALLING THE INPUT BOARDS 2-44

PART 4.6.2 CONFIGURE THE BOARD IDs (REQUIRED) 2-46

PART 4.6.3 INSTALLING THE BOARDS IN THE PANELS (REQUIRED) 2-47

STEP 5. Applying Power to the Controller 2-52

5.1 Pull all field wiring into the controller .............................................................................................................. 2-52

5.2 Connecting Back-up Battery and Power Transformer to the Power Supply ...................................................... 2-52

5.3 About adding an Auxiliary Power Supply inside the Controller ....................................................................... 2-53

5.4 About External Power Supplies outside the Controller .................................................................................... 2-53

5.5 Installing Suppression Diodes at the Door Locks .............................................................................................. 2-53

STEP 6. Program the 635 CPU Board 2-54

6.1 Connecting to the CPU Board via Putty® or HyperTerminal® ............................................................................ 2-54

6.1 Programming the 635-Model CPU Board via Web Page ................................................................................... 2-55

STEP 7. Set the Interface Board ID’s (DPI/DIO/DSI) 2-60

7.1 Apply power to the “Daughter” Boards (DPI/DIO/DSI) .................................................................................... 2-60

7.2 Verify Board ID is Correct for Daughter Board(s) (DRM/DIO/DSI) .................................................................... 2-61

7.3 Verify Flash Version is Correct for Daughter Board(s) (DRM/DIO/DSI) ............................................................. 2-61

7.4 Flash Version Chart .......................................................................................................................................... 2-62

STEP 8. Connect the Controller CPU to the Network 2-63

8.1 Connect the CPU to the Ethernet LAN .............................................................................................................. 2-63

8.2 Verify Connection to the Event Server ............................................................................................................. 2-64

STEP 9. Test the Controller (recommended) 2-66

9.1 SOFTWARE PROGRAMMING QUICK NOTES: .................................................................................................... 2-66

9.2 TESTING PANELS with WEB PAGE OR SOFTWARE COMMANDS: ...................................................................... 2-66

page ~ iii

STEP 10. Wiring Field Devices to all Interface Boards 2-67

10.1 Field Wiring Standard Readers to the 635 DRM Board ................................................................................... 2-68

10.2 Field Wiring the SIGMA Morpho to the 635 DRM........................................................................................... 2-70

10.3 Field Wiring the 635 DRM for ANTI PASSBACK .............................................................................................. 2-71

10.4 Field Wiring the DIO - Digital Input/Output board ......................................................................................... 2-72

10.5 About setting up Supervision & Hypervision of Inputs ................................................................................... 2-73

SUPERVISION OF INPUTS: 2-73

HYPERVISION OF INPUTS: 2-74

10.6 Field Wiring the 635-Input Modules to the 635-DSI Board ............................................................................. 2-75

10.7 Field Wiring Output Relay Boards to the 635-DSI Board ................................................................................. 2-76

10.7 Field Wiring Schlage AD PIMs to the 635-DSI Board ....................................................................................... 2-77

10.8 Field Wiring 635-DRM Remote Door Module to the 635 DSI Multidrop ......................................................... 2-78

10.9 Field Wiring Cypress Clock to 635-DSI Board .................................................................................................. 2-79

10.10 Field Wiring LCD Display Unit to 635-DSI Board - ......................................................................................... 2-80

STEP 11. Walk-Test the System (recommended) 2-81

11.1 Quick Steps to Software Setup ....................................................................................................................... 2-81

11.2 Quick Steps to creating a Test Card ................................................................................................................ 2-82

3 Communication /Event Server Overview 3-1

3.1 Description of the Communication Server 3-1

3.2 IP Connections between Services 3-2

3.3 Opening the GCS Event Service window: 3-3

3.4 Managing the 600 Controller Connections: 3-3

3.5 Managing the TCP/IP Service Connections: 3-4

3.6 About the Status of Connections: 3-5

3.7 Configuring the Controller Connection Settings: 3-6

3.8 Configuring the TCP/IP Client Server Settings: 3-7

3.9 Configuring the ODBC Settings: 3-8

4 Hardware Troubleshooting 4-1

4.1 Troubleshooting Connectivity and Red-X on Loops 4-2

4.2 Verifying connections between Services 4-3

4.3 Verifying settings in SG Properties Screens 4-6

4.4 Verifying settings at the Controller (CPU) 4-7

A – Appendix : Programming Templates A-1

A.1 DPI - Reader port programming A-1

A.2 DIO port programming A-2

page ~ iv

A.3 DSI port programming A-3

B – Appendix: Resetting ODBC Connections B-1

B.1 : Configure your SG Data Sources B-1

C – Appendix : View panel settings in Web Browser C-1

D – Appendix : Checking Loop Programming D-1

E – Appendix : Checking Controller Programming E-1

F – Appendix : Starting & Stopping GCS Services F-1

G – Appendix : Opening the Event Service G-1

H – Appendix : Putty/HyperTerminal Commands H-1

I – Appendix : Finding IP Address of Event Server I-1

J – Appendix : Ping Controller from Event Server J-1

K – Appendix : Wiring DPI Emergency Release K-1

L – Appendix : List of Terms L-1

M – Appendix: 635 & 600 Series Boards M-1

M.1 635 CPU Board – Central Process Unit M-1

M.2 600 CPU Board – Central Process Unit M-2

M.3 600 DPI Reader Board - Dual Port Interface Board M-3

M.4 DIO Board – Digital Input/Output Board M-4

M.5 DSI Board– Dual Serial Interface board M-5

M.6 Relay board (General Output or Elevator Control) M-6

N – Appendix : 600 Relay Panels 1

N.1 General Output Relay Panel (First Panel) 1

N.2 General Output Relay Panel (Second Panel) 2

N.3 Elevator Control Panel (First Panel ) 3

N.4 Elevator Control Panel (Second/Additional Panel) 4

O – Appendix : Output Relay Board Help 1

O.1 Relay board (General Output or Elevator Control) 1

O.2 Relay Board Power and Data Wiring 2

O.3 Relay Board Dipswitch Settings for board numbers 3

O.4 Relay Number Chart 4

O.5 Software Setup of the Output Relay board 5

page ~ v

Q – Appendix: Replacing a 600 DPI with 635 DRM Q-1

Q.1 Specifications for the 635 DPI Board Q-1

INSTALL REQUIREMENTS ......................................................................................................................................... Q-2

Q.2 QUICK STEPS for installing a 635 DPI Q-4

[STEP 1] FLASH / LOAD THE CPU .............................................................................................................................. Q-5

[STEP 2] FIND A VALID BOARD ID (via the software programming).......................................................................... Q-6

[STEP 3] SET THE DPI DIPSWITCH (Board ID Addressing) .......................................................................................... Q-7

[STEP 4] 635-DPI PREP: READER VOLTAGE ............................................................................................................... Q-8

[STEP 5] 635-DPI PREP: DOOR SUPERVISION (resistors & settings) .......................................................................... Q-8

[STEP 6] 635 DPI PREP: SETTING JUMPERS FOR LOCK RELAYS .................................................................................. Q-9

[STEP 7] MOUNT THE 635 DPI BOARD IN THE CONTROLLER CARD SLOT ................................................................ Q-10

[STEP 8] WIRING TO EXISTING FIELD DEVICES ........................................................................................................ Q-11

[STEP 9] LAND WIRING for POWER ........................................................................................................................ Q-16

[STEP 10] CONNECT DPI POWER ............................................................................................................................ Q-16

[STEP 11] CONNECT DPI RIBBON CABLE ................................................................................................................. Q-17

[STEP 12] DPI FLASHING AND LOADING DATA ....................................................................................................... Q-18

[STEP 13] CONNECT FIELD DEVICES ........................................................................................................................ Q-20

[STEP 14] LOAD DATA TO THE PANEL .................................................................................................................... Q-20

[STEP 15] WALK TEST YOUR DEVICES ..................................................................................................................... Q-20

Table of Tables:

Table 1: RELATED DOCUMENTS 1-2

Table 2: REPLACEMENT BOARDS AND PARTS 1-6

Table 3: CPU COMPONENTS (635 vs 600) 1-8

Table 4: DRM COMPONENTS (635 vs 600) 1-8

Table 5: FLASH VERSION CHART 1-19

Table 6: BOARD COMPATIBILITY CHART for SG10 (Tables 7 & 8 for SG-9 or lower ) 1-20

Table 7: FLASH VERSION CHART for SG-9 (and older) 1-21

Table 8: SG 9/8 Software Compatibility for 600-series Board Revisions 1-21

Table 9: Ratings for Relays for Galaxy Hardware 1-25

Table 10: Board Current Draw for Galaxy Hardware 1-25

Table 11: DEVICE WIRING SPECIFICATIONS 1-26

Table 12: ETHERNET WIRING SPECIFICATIONS 1-26

Table 13: WIRING SPECIFICATIONS 2-8

Table 14: BOARD COMPATIBILITY CHART for SG10 2-10

Table 15: 635-CPU PINOUT 2-15

Table 16: DRY-CONTACT RELAY OPERATION = (NORMAL OPERATION) 2-22

Table 17: WET-CONTACT RELAY OPERATION = JUMPERS INSTALLED 2-22

page ~ vi

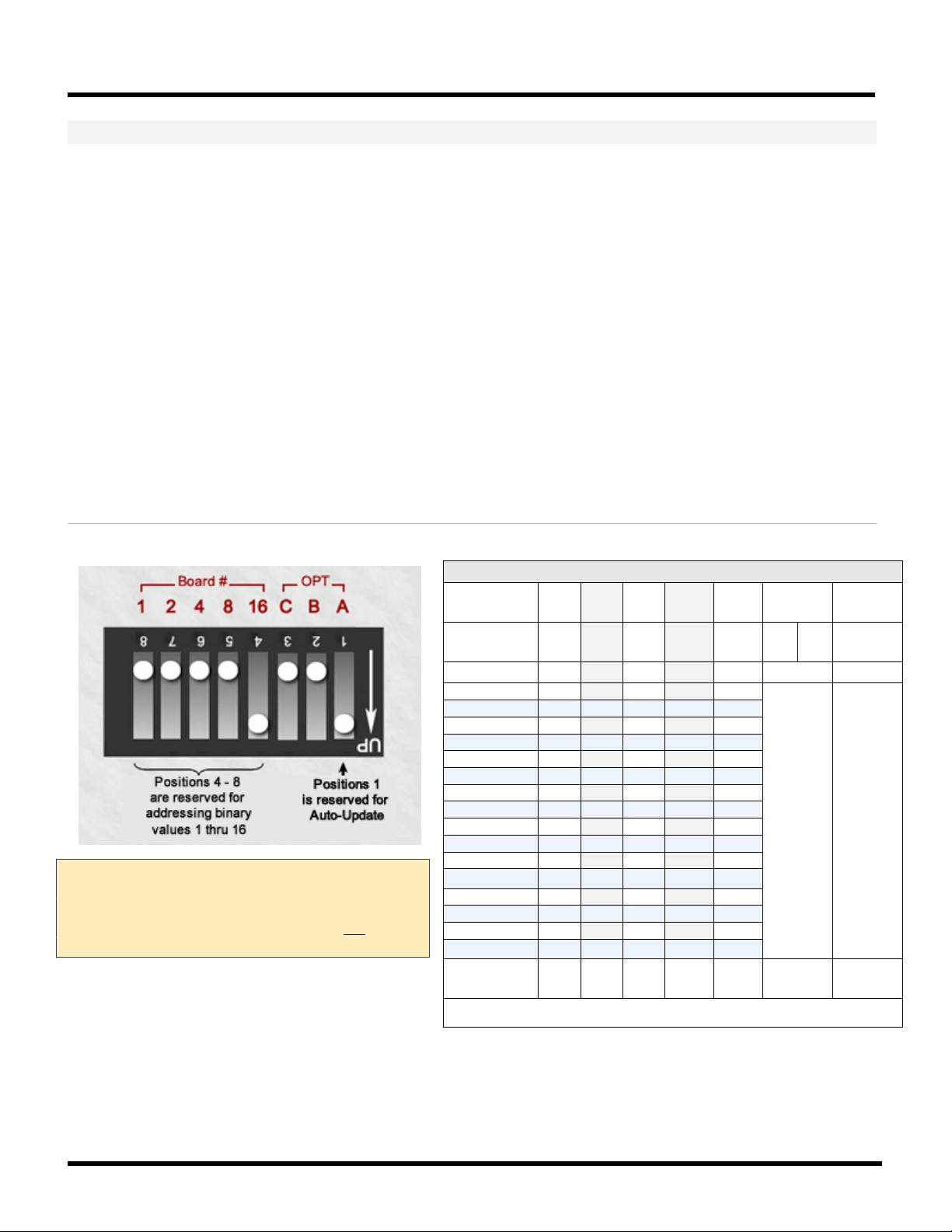

Table 18: BINARY ADDRESS TABLE FOR 635-DRM 2-23

Table 19: DSI Max. Number of Devices and Device Count for each Section 2-29

Table 20: Examples of DSI Sections Functioning Independently 2-30

Table 21: Mapping the DSI “Section Use” in the SG Software 2-30

Table 22: SET THE TERMINATION JUMPERS FOR EACH SECTION 2-31

Table 23: SET THE PASS-THRU JUMPERS FOR EACH SECTION 2-32

Table 24: BINARY ADDRESS TABLE FOR 635-DRM 2-33

Table 25: BINARY ADDRESS TABLE FOR OUTPUT RELAY BOARD 2-38

Table 26: WIRING PINOUT FROM 635-DSI TO FIRST RELAY BOARD 2-42

Table 27: WIRING PINOUT FROM ONE RELAY BOARD TO NEXT RELAY BOARD 2-42

Table 28: BINARY DIPSWITCH SETTINGS FOR INPUT BOARD 2-46

Table 29: WIRING PINOUT FROM THE 635-DSI TO FIRST INPUT BOARD 2-51

Table 30: WIRING PINOUT FROM ONE INPUT BOARD TO NEXT INPUT BOARD 2-51

Table 31: FLASH VERISON CHART 2-62

Table 32: WIRING DISTANCES FOR HARDWARE 2-67

Table 33: Software Setup - Process for 600 Loops are as follows 2-81

page ~ vii

Table of Figures: chap-page

Figure 1 – 600/635 Model Controller (Access Control Panel) Basic 1-11

Figure 2 – CPU BOARD EDGE COMPONENTS: 635 CPU (Upper) & 600 CPU (Lower) 1-12

Figure 3 - Concept Diagram showing how Global Events use the GCS Event Service 1-15

Figure 4 - System Diagram of 600-series Loop/Clusters connecting to Event Server 1-16

Figure 5 – 6XX-Series Controller Mounting Requirements: 1-22

Figure 6 – 6xx-series Medium Controller Dimensions & Knockout Diagram: 1-23

Figure 7 – 600/635-Model Controller Configuration Example: 1-28

Figure 8 – Illustration of UL-Listed Power Supply and Transformer 2-6

Figure 9 – 6xx-series Controller Mounting Diagram 2-13

Figure 10 – Controller Wiring Harness: 2-14

Figure 11 – Diagram of CPU Power and Tamper Connectors: 2-15

Figure 12 – 635 CPU Warning Circuits: “A/C Fail”, “Low Battery”, and “Tamper” 2-16

Figure 13 – Wiring Power Connector on 635 DRM: 2-17

Figure 14 – Installing CPU (with bracket against back of cabinet) 2-18

Figure 15 – 635 DRM Board Features: 2-19

Figure 16 – BINARY DIPSWITCH for DRM Board ID 2-23

Figure 17 – Installing a DRM Board with bracket against back of cabinet: 2-24

Figure 18 – 600 DIO Board Features: 2-25

Figure 19 – Installing a DIO Board with bracket against back of cabinet: 2-26

Figure 20 – 635 DSI Board Features: 2-27

Figure 21 – Examples using Termination Resistance with the 635 DSI Board: 2-31

Figure 22 – Using Pass-thru Jumpers on the 635 DSI Board: 2-32

Figure 23 – BINARY DIPSWITCH for DSI Board ID 2-33

Figure 24 – Installing a DSI Board with bracket against back of cabinet: 2-34

Figure 25 – 635 Output Board Features: 2-35

Figure 26 – Example of Relay Boards in Main Panel for General Purpose Output Relay (ORM) 2-

36

Figure 27 – Example of Relay Boards Installed in a Separate Panel 2-37

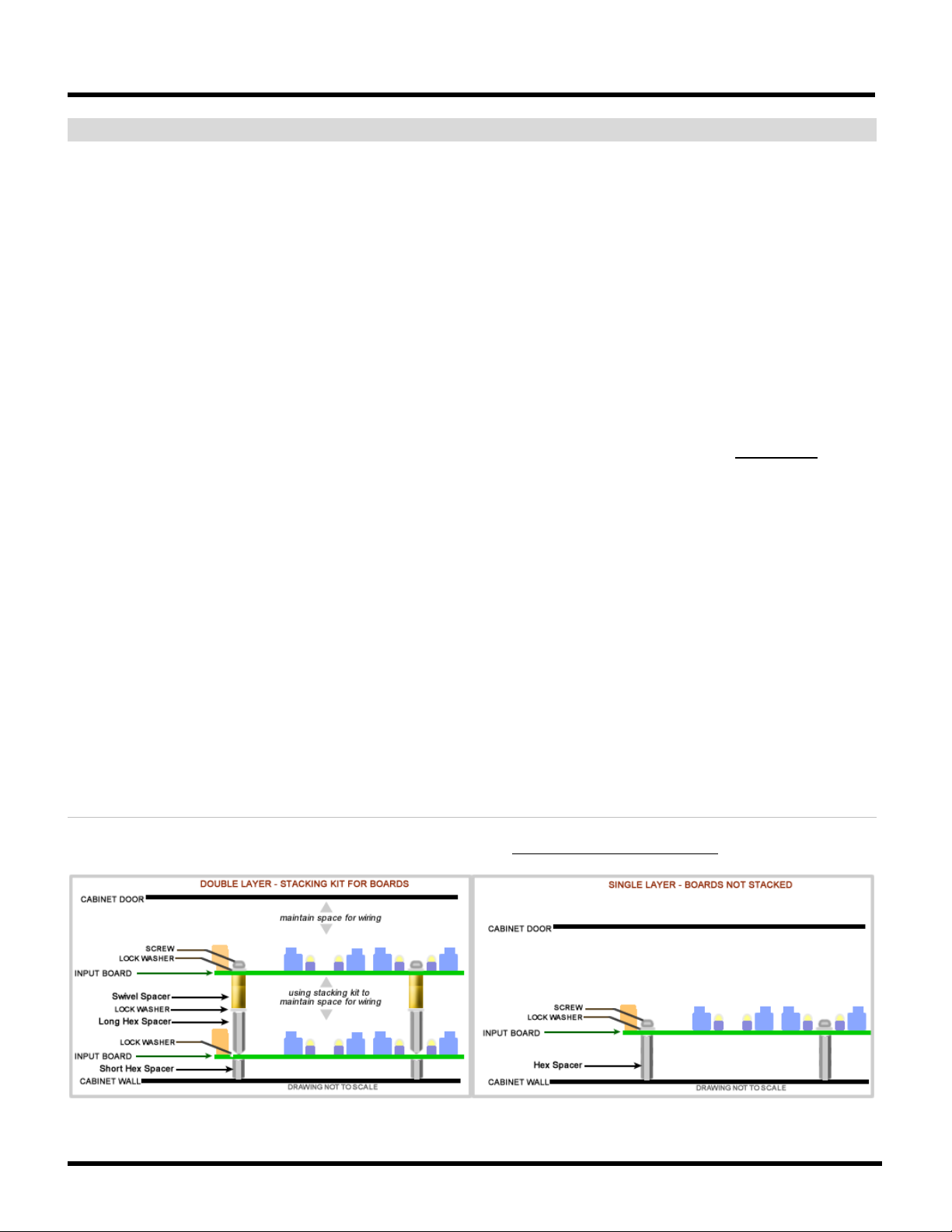

Figure 28 – Example of Single Layer vs. Stacked Install (SEE PART 4.5.3 FOR EXACT

INSTRUCTIONS) 2-37

Figure 29 – Relay Board Installation Options (Single Layer vs. Stacked) 2-39

Figure 30 – 635-Relay Board: Wiring the Relay Terminals 2-40

Figure 31 – 635-Relay Board: Wiring the Power Input 2-40

Figure 32 – Relay Board Installation (on the 635-DSI Board’s RS-485 Multidrop) 2-41

Figure 33 – 635-Input Module Features 2-43

Figure 34 – Basic Example of Input Boards Installed in the Main Panel 2-44

Figure 35 – Basic Example of Input Boards Installed in a Separate Panel 2-45

Figure 36 – Example of Single Layer vs. Stacked Install (SEE PART 4.6.3 FOR EXACT

INSTRUCTIONS) 2-45

page ~ viii

Figure 37 – Input Board Installation Options (Single Layer vs. Stacked) 2-47

Figure 38 – Input Board Component Designations and Connector Pinouts 2-48

Figure 39 – Input Board: Voltage-monitoring and Tamper-switch Wiring 2-48

Figure 40 – Input Board: Power Input Wiring 2-49

Figure 41 – Input Board Installation (wiring 635 Input Boards to the 635-DSI RS485-Multidrop)2-

50

Figure 42 – Installing a Surge Suppression Diode for Door Lock 2-53

Figure 43 – Example of 635 Web Config Tool Screen 2-55

Figure 44 – Example of ‘All Panel Summary’ screen – LIST OF DETECTED PANELS 2-56

Figure 45 – Example of ‘Network Configuration’ Screen – CPU NETWORK SETTINGS 2-57

Figure 46 – Example of ‘Panel Status’ screen – (CPU STATUS / CURRENT SETTINGS) 2-58

Figure 47 – Example of ‘Panel Configuration’ screen – ( CPU PROGRAMMING ) 2-59

Figure 48 – Example of Bringing Daughter Boards online - Panel Status screen 2-61

Figure 49 – 635 CPU: Power, Ethernet, Tamper and Data connections 2-63

Figure 50 – Example of Controller’s Embedded Web Report: 2-65

Figure 51 – 635-DRM Reader Board Edge Connectors (component-side up) 2-68

Figure 52 – DRM BOARD: Reader Wiring Template – for typical reader technologies. 2-69

Figure 53 – DRM board: Reader Wiring Template for the SIGMA Reader. 2-70

Figure 54 – DPI board: Reader Wiring Template for Anti-Passback. 2-71

Figure 55 – 600-DIO Board: Component Designation and Connector wiring pinout 2-72

Figure 56 – Diagram of the end of line resistors for input supervision: 2-73

Figure 57 – Wiring the 635-Input Board to a 635-DSI Board: 2-75

Figure 58 – Wiring a 600-Relay Board to a 635-DSI Board: 2-76

Figure 59 – Wiring a Schlage AD PIM to a 635-DSI Board: 2-77

Figure 60 – Wiring a 635-DRM (for Remote Door Modules) to a 635-DSI Board: 2-78

Figure 60 – Wiring a Cypress Clock (1201) to a 635-DSI Board: 2-79

Figure 61 – Wiring a Galaxy LCD Display Unit to a 635-DSI Board: 2-80

Figure 29 - Block Diagram of core GCS Services: 3-2

Figure 30 - Event Service Controller Connections screen: 3-3

Figure 31 - Event Service TCP/IP Service Connections screen: 3-4

Figure 32 - Event Service Status Messages screen: 3-5

Figure 33 - Event Service Settings > Controller Connection Settings screen: 3-6

Figure 34 - Event Service Settings > TCP/IP Client Server Settings screen: 3-7

Figure 35 - Event Service Settings > Database Settings screen: 3-8

Figure 36 - Programming at the Software must match the Controller: 4-8

page ~ ix

page ~ x

635/600-SERIES HARDWARE INSTALL GUIDE

1 Overview, Safeguards, Specifications, and Requirements

This chapter covers general safeguards and hardware requirements.

Requirements are organized by topic (listed below) so that technicians, installers, planners, administrators

and can easily find the pertinent information.

1.1 What’s in this Manual (you are here)

CHAPTER-1 OUTLINE

1.1 What’s in this Manual (you are here) ...................................................................... 1-1

1.2 IMPORTANT: Product Safety and Precautions ...................................................... 1-3

1.3 Hardware Certifications & Compliances ................................................................. 1-4

1.4 Hardware Replacement Parts ................................................................................. 1-6

1.5 Hardware Capability: Panel-Level (CPU) .............................................................. 1-7

1.6 Hardware Capability: Board-Level ......................................................................... 1-8

1.7 Hardware & System Descriptions ......................................................................... 1-10

1.8 CPU & Board Flash Requirements for 600/635-Series Hardware ........................ 1-18

1.9 Controller Mounting Requirements ....................................................................... 1-22

1.10 Power Requirements ............................................................................................ 1-24

1.11 Relay Ratings and Current Draw .......................................................................... 1-25

1.12 Hardware Wiring Specifications ............................................................................ 1-26

1.13 Board Programming Requirements ...................................................................... 1-27

1.14 Network & IT Requirements for Galaxy Hardware ................................................ 1-29

1.15 Communication Requirements for System Galaxy Servers .................................. 1-30

1.16 Requirements for Logins and User Privileges (SG Software) ............................... 1-31

1.17 Pinout for Ethernet Cable (Cat-5e) ....................................................................... 1-31

1.18 General FAQs about Features of Galaxy Hardware ............................................. 1-32

CHAPTER-2 COVERS

Step-by-step installation instructions for installing the hardware and field devices are in Chapter-2.

CHAPTER-3 COVERS

The Event Server and GCS Services are covered briefly in Chapter-3

CHAPTER-4 COVERS

Hardware Trouble-shooting information is found in Chapter-4

Chapter-Page 1-1

635/600-SERIES HARDWARE INSTALL GUIDE

MANUAL NAM E

DESCRIPTION

System Galaxy Software Installation

installing/upgrading the software/database.

Also in HTML which can be started from the GalSuite Install splash screen ( IE 6 or later).

SG Software Requirements Manual

for PC’s / Servers that run software/services.

System Galaxy Software Manual

features, programming and use.

Appendixes as follows

Appendix A ~ Hardware programming templates / tables that help installer and system owner

record facts about the hardware configuration that will be used when setting up

the software correctly.

Appendix B ~ How to … connect to HyperTerminal

Appendix C ~ How to … read the panel settings shown through the embedded web page

Appendix D ~ How to … validate the Loop Programming

Appendix E ~ How to … validate the controller programming

Appendix F ~ How to … start and stop services

Appendix G ~ How to … open the Event Service

Appendix H ~ List of HyperTerminal Commands

Appendix I ~ How to … find the IP Address of Event Server

Appendix J ~ How to … ping controller from the event server

Appendix K ~ How to … wire DPI boards for Emergency Release

Appendix L ~ List of Terms used in the document

Appendix M ~ Board diagrams and components listed

Appendix N ~ Panel Configurations for General Output and Elevator Control panels

Appendix O ~ Relay Board Help: dipswitch settings, board ID / relay # chart

Additional Supporting Documentation

This hardware manual provides software programming tips to aid installer in walk testing the hardware

during the installation process. The following documents provide extensive instructions on the System and

Software Installations.

Table 1: RELATED DOCUMENTS

Chapter-Page 1-2

635/600-SERIES HARDWARE INSTALL GUIDE

!

1.2 IMPORTANT: Product Safety and Precautions

These notes apply to 635-model & 600-model Controllers (and their boards). Please read and follow.

WARNING - Failure to obey safety warnings could result in serious bodily injury, death, and/or

damage to equipment, and/or loss of data, and/or undesirable equipment/system operation.

1. Installation and Maintenance: Installation and maintenance of System Galaxy hardware and software

must be performed by an authorized/certified dealer. Always use best practices when installing and

operating Galaxy equipment and peripheral hardware devices.

2. Controller Power Supply: The 635/600-Series Controller uses a power transformer 110 volts alternating

current (110 VAC), however the circuit boards are low-voltage 12 VDC from the internal power supply.

ALWAYS use the power transformer provided with the controller cabinet and the specified power source.

3. Multiple power supplies: Door Locks should have a separate power supply. If wiring more than 4

proximity readers on a single controller, technician should install a second power supply to avoid

undesirable operation.

4. Controller Power Source: controller must be connected to a non-switchable power circuit.

5. Power Hazards: this equipment should be installed and operated only with the type of power source

indicated in the instructions (or labels). Serious bodily injury or equipment damage could result.

6. Power Cord Protection: route power cords and other wires/cables wisely. Avoid trampling, straining,

pinching or chafing. Electrical shock or equipment damage could occur.

7. Overloading Hazards: Do not overload the power supplies or equipment.

8. 5-V Reader Voltage Regulation: Do not connect 5v Reader directly to a 635-DRM. You must install

voltage regulator at reader end. (With 600-DRM/DPIs, install onboard voltage-jumpers in 5-volt position.)

9. Grounding: Do not ground the controller to cold water ground/earth ground.

10. Moisture & Water Hazards: This equipment is non-condensable and must be mounted in a dry and

protected area. Do not install or use this equipment in or near sources of moisture such as exposure to

weather, rain, pools, car washes, air conditioners, or moisture. Serious bodily injury, death, or

equipment damage could occur.

11. Object & Liquid Penetration Hazards: Do not insert (or use) objects in the equipment that are not

approved, as they could touch voltage points or short out parts. Never spill, pour or apply any liquid

substance on the equipment. Failure to heed could result in electrical shock or equipment damage.

12. Cleaning: Do not clean equipment with water or liquid. Electrical shock or equipment damage could occur.

13. Heat Hazards: this equipment has -10º C to +60º C (14 º F to 140 º F) temperature specs. Avoid mounting

close to heat sources or uncontrolled climates. Equipment failure could result.

14. Static Electricity: Take standard precautions to avoid static shock if handling the circuit boards.

15. Mounting Safety: This equipment is designed to be wall mounted. Never place or install this equipment in a

location or manner that is unstable to avoid personal injury or equipment damage.

16. Burden: do not place or rest any heavy object on this unit – the unit could fall or become detached from its

mounting and result in personal injury or equipment damage.

Chapter-Page 1-3

635/600-SERIES HARDWARE INSTALL GUIDE

12VDC / 8Ah Battery

1.3 Hardware Certifications & Compliances

The 600-Series & 635-Series Access Control Panel (ACP) is listed as follows:

REGULATORY STANDARDS

UL 294, Fifth Edition, Access Control System Units

UL 1076, Fifth Edition, Proprietary Burglar Alarm Units and Systems

CSA C22.2, No. 205-M1983, First Edition, Signal Equipment

CE EN-50133

RoHS Compliant

Installation and Service for Galaxy Hardware:

Installation and service of Galaxy hardware / components must be performed by a Galaxy-certified Technician.

Power Source for Galaxy Access Control Panel (ACP):

The Galaxy Controller requires a continuous power source from a 110VAC non-switched outlet that is less than

25 feet from the control panel. (Do not connect the power adapter to an outlet that is controlled by a switch.)

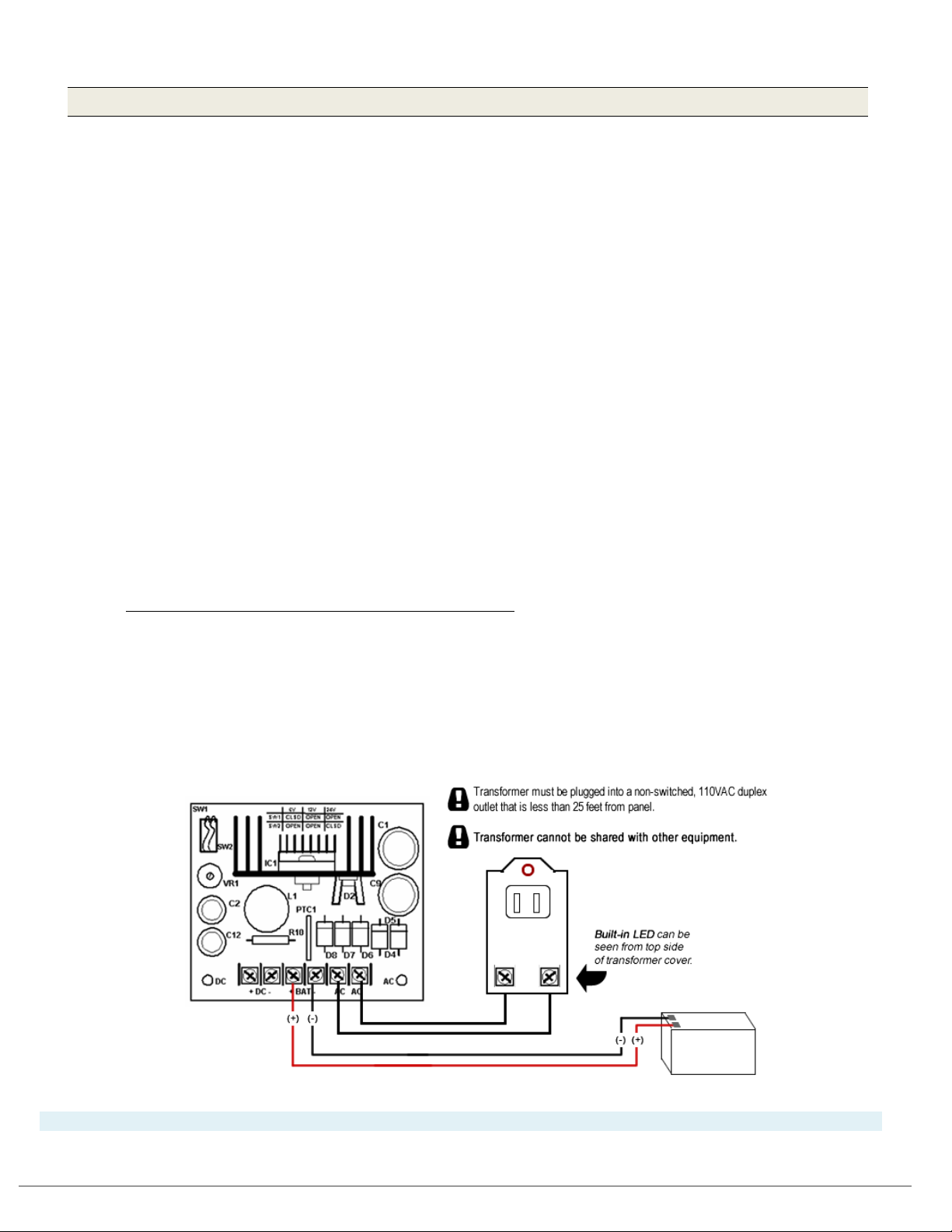

AC Power Transformer, Class-2, Plug-in Type (shown with Altronix Power Supply):

The AC Power Transformer, used by Galaxy controllers, must meet following requirements:

• Must be a Class-2 Plug-in Transformer with fused secondary.

• AC Transformer must be plugged into the 110VAC non-switched, duplex outlet.

• Transformer must not be shared by any other equipment.

• Requires 1 pair of 18 AWG wire (minimum).

• Input-rated at 120 VAC / 48 VA at 60 Hz,

• Output-rated 16.5 VAC / 40VA at 60 Hz.

• Must be UL-Listed and CSA-Certified.

Galaxy access control panels that require AC transformers are only intended for use with a UL Listed, Class-2

transformers, like the one manufactured by Universal Power Group No. UB1640WR.

- - - See NEXT PAGE for LifeSafety Power Supply - - -

Chapter-Page 1-4

635/600-SERIES HARDWARE INSTALL GUIDE

Power Supply (LifeSafety FPO75) for Controller (no transformer needed / for US or International):

The LifeSafety FPO75 (75 Watt) Power Supply does not use a plug-in transformer. LifeSafety Power Supply is

compatible for international installations.

CAUTION: Power Input Jumper (JP1) is set 120 VAC/ 60 HZ (Factory Default; i.e. JP1 is closed/not cut).

You must correctly configure the power input JP1 jumper wire – see FlexPower install manual that is shipped

with the power supply. Failure to correctly configure JP1 will cause equipment damage or hazard.

• For 120 VAC / 60 Hz input power = JP1 CLOSED (Factory Default) Do not cut JP1 Jumper Wire.

• For 230 VAC / 50 Hz input power = JP1 OPEN Cut the JP1 Jumper Wire (at red dot).

• Only use 12VDC Output switch position SW1. Galaxy Controllers do not support 24VDC.

1) JP1 - AC Input Voltage Jumper (120/230VAC):

For 120VAC = JP1 is UNCUT (Factory Default)

For 230 VAC = JP1 Wire must be CUT

2) J9 - AC Input Connector (3-prong)

3) LED - AC Power LED (ON/OFF)

4) JP2 - Earth-Ground Jumper (enable/disable) = DISABLED (position 2)

5) JP3 - Battery Jumper (enable/disable) = ENABLED (position 1)

6) J2/J3 - Battery Connections for back up battery (+/-)

7) TB1 - Terminal Block for DC Voltage Output Lugs (DC1)

8) LED - DC Power LED (

9) J1 (or SW1) - DC Output Voltage Jumper = must be set to the 12V position!

Also: SYSTEM FLT LED - Can indicate a missing battery when JP3 is “enabled” and AC power is applied/on.

ON/OFF)

Chapter-Page 1-5

635/600-SERIES HARDWARE INSTALL GUIDE

635 BOARDS

600 BOARDS

OTHER PARTS

20-0635-30

20-0600-60

+3V Lithium Battery: 53-2035-00

20-0235-10

20-0268-40

12V / 8Ah Sealed, Lead-Acid Battery: 90-0714-53

1.4 Hardware Replacement Parts

The 600-series and 635-series Access Control Panels use the following replacement parts:

1.4.1 ORDERING POWER TRANSFORMER & BATTERIES

+3V Lithium Battery – Panasonic CR2354

• Galaxy PN 53-2035-00

• Installs on-board, for the 600-CPU, 635-CPU. Observe polarity when installing.

12V / 8Ah (or equivalent) Sealed, Lead-Acid battery – Universal Power Group UB1280

• Galaxy PN 90-0714-53

• Installs inside the 600- or 635-series controller cabinet.

• Replacement every 3-5 years.

• Do not short-circuit; observing polarity when installing.

• Avoid total discharging (deep discharging).

• WARNING: risk of fire, explosion, or burns. Do not open, disassemble, incinerate or heat above 65°C.

16.5 / 40VA AC Transformer; Class-2 Plug-in - Universal Power Group UB1640RW

• Galaxy PN 90-0714-52

• Input rated 120 VAC / 48 VA at 60 Hz

• Output rated 16.5 VAC / 40VA at 60 Hz

• Must be plugged into a 110VAC, non-switched outlet. Install at distance less than 25 feet from panel.

• DO NOT connect controller power adapter to an outlet that is controlled by a switch.

• Transformer cannot be shared with any other equipment.

1.4.2 ORDERING REPLACEMENT BOARDS

Table 2: REPLACEMENT BOARDS AND PARTS

635 CPU:

635 DPI/DRM:

16.5 / 40VA AC Transformer: 90-0714-52

600 CPU:

600 DPI:

(Class-2 Plug-in)

Chapter-Page 1-6

635/600-SERIES HARDWARE INSTALL GUIDE

1.5 Hardware Capability: Panel-Level (CPU)

1.5.1 Controller Capability of the 600/635 Model Access Control Panel:

TCP/IP (CPU on-board) Ethernet Network Communication:

• 635 MODEL CPU = 10/100 MB / Full Duplex Auto-sensing Ethernet Network capable

(600 Model CPU = 10MB Full Duplex Ethernet Network capable)

• 600/635 models auto-detect/auto-connect to the System Galaxy GCS Event Service after the CPU is

correctly configured for the field settings (provided the Communication Server is installed/online).

• CPUs and daughter boards must be configured* with correct field settings by the installer.

* 635 CPUs have embedded Web Configuration page which is auto-detected when the browser and

CPU are on the same network segment and port 80 is open. All CPUs and daughter boards can be

configured with the Web Configuration Tool or with a terminal emulator such as HyperTerminal.

Some daughter boards use dipswitch and jumpers to set certain features. See Chapter-2.

50,000 card/user capacity/per cluster: expands to unlimited cards if ‘Card Lookup’ feature enabled.

• Supports all card technologies: Prox 125KHz, Barcode, Magnetic Stripe; HID

DESFire™, MIFARE DESFire™ EVI;

®

iClass®; MIFARE®, MIFARE

• Supports Government-compliant Readers/card data: HSPD-12 & FIPS 201; PIV, PIV2, FASC-N 200bit, 75bit

CHUID; TWIC; CAC-Legacy, Transition, Endpoint; PKI challenge to Personal Certificate(PAK)

• Supports Biometric Identification/Authentication Readers: Sagem 2/300, Sagem 100/110, Sagem520;

L-1 Identity (Bioscrypt) 4G-Series Readers; Morpho MA SIGMA (Legacy mode), MA SIGMA 5G Mode*

* SIGMA 5G mode is supported on systems where System Galaxy 10.4.8 (or higher) is integrated

with the MorphoManager/BioBridge software for enrollment of biometric credentials. The SIGMA

reader must be added to the MorphoManager software and the system supports Biometric (finger

only – 1:many) and Prox+Biometric (card+finger – 1:1) . See SG SIGMA with MorphoManager Guide.

Note: SIGMA Legacy mode is supported on SG with the traditional biometric enrollment and does

not depend on MorphoManager or BioBridge module.

254 user-definable Time Schedules per cluster: plus 2 fixed schedules (“Always” and “Never”)

256 user-definable I/O Groups per cluster

256/Unlimited Access Control Groups: 254 user-definable access groups, plus 2 fixed (“Always”/“Never”) and

expands to unlimited with the Personal Doors feature enabled.

10,000-event memory buffer/per CPU (i.e. controller):

NON-DEGRADED OPERATION - Galaxy Panels remain fully operational even when the system or database server is “offline”.

Full functionality is maintained because all users, cards, access rules, schedules and hardware operational settings are stored

in the CPU memory. If the Communication (Event) Server or Database servers are offline, the panel stores its log events in

memory until the CPU is able to reconnect. Upon reconnection, the CPU returns to live event logging and transmits all offline

events to the database. The “offline” events are available via system reports. Any programming changes made at the

software will be stored in the database until the panel comes back online and the data is loaded via the DataLoader service

or GCS Load Utility.

Chapter-Page 1-7

635/600-SERIES HARDWARE INSTALL GUIDE

635 MODEL CPU

600 MODEL CPU

coldstart jack (“park” to warm-reset)

reset switch (1 sec. warm reset/10 sec. cold reset)

RJ-45 Ethernet jack

HFJ-11 Ethernet Jack (Auto-sensing 10/100MB)

Serial Port and programming cable

(option: or use the serial programming port/cable)

635 MODEL DRM

600 MODEL DPI/DRI

(not applicable) install a voltage regulator

if using 5V readers

Board ID is set using CPU RS232 Serial Port (directly

running HyperTerminal® or similar emulator.

Enable/Disable section-2 via SW2

the DRM on an RS485 Multidrop

Power Input terminal for “wet lock

Relays (2 relays each section/port)

“Wet-Lock-Relay” Jumpers to

each section)

1.6 Hardware Capability: Board-Level

1.6.1 List of Boards and Component Descriptions:

This is the list of CPU & Daughter Boards as of System Galaxy v10 Software.

1. CPU Board (600 model & 635 model ) - Central Processing Unit

Supports up to 64 Devices (readers, inputs, etc.) per CPU board/panel

Factory installed 3V lithium backup battery.

Pre-loaded (factory-default) s28 Flash – may require field update to match site system version

9-pin D-Shell, RS232 Serial Port – for configuring CPU with a serial programming cable via Laptop/PC

Table 3: CPU COMPONENTS (635 vs 600)

Configure the IP Address using the RS232

Configure the IP Address using the embedded web tool

2. DPI/DRM Board (600/635) - Dual Port Reader Interface / Dual Reader Module

Supports 2 readers per board

2 surge suppression diodes (to suppress lock surge)

2 supervision resistor/sockets (and 4.7K resistors factory default)

4 Form C SPDT Relays (2 relays each section/port)

SW1 reset switch

Table 4: DRM COMPONENTS (635 vs 600)

12v/5v reader port voltage jumpers

Board ID is set using the SW2 dipswitch

1 RS-485 Communication Port (not applicable)

Dipswitch Option-B; only used for the

RS485 Comm. Port if remotely installing

connecting a PC using a programming cable and

(not applicable)`

relay operation” 4 Form C SPDT

enable/disable the option (for relay-1 on

Chapter-Page 1-8

(not applicable)

(not applicable)

635/600-SERIES HARDWARE INSTALL GUIDE

3. 600 DIO Board - Digital Input / Output Board–

Supports maximum 8 inputs per board

Supports maximum 4 outputs per board

SW1 Reset Switch

4. DSI Board - Dual Serial Port Interface –

2 RS485 Communication Ports per board (Section-1/Section-2)

SW1 Reset Switch

120 K ohm termination resistors included with board (only install resistor near the RS485

connector if the board is at the end-of-line for the 485 Section (channel) you are wiring. Treat each

section independently; one section could be at EOL when the other section is not.

5. 600/635-model Relay Board - for General Output or Elevator Control

Supports 8 outputs per board

Uses Form-A SPST Relays.

RS485 Communication Port (3-pin A/B/GND)

Board ID is addressed via dipswitch

6. 635-model Input Board

Supports 16 Inputs per board (normally open/normally closed must be set in the software screen)

RS485 Communication Port (3-pin A/B/GND)

Termination Jumper (2-pin black) – installer must install jumper only if the board is at the end-of-line.

Voltage / Tamper input terminal provided

Board ID is addressed via dipswitch

Chapter-Page 1-9

635/600-SERIES HARDWARE INSTALL GUIDE

1.7 Hardware & System Descriptions

1.7.1 Description of Galaxy Access Control Panel:

ENCLOSURE DIMENSIONS:

• 18 GAUGE ELECTRICAL CABINET, HINGED

• 8-DOOR/MEDIUM = 18

ADDITIONAL PANEL SIZES OFFERED:

• 2-DOOR/SMALL = 12 X 12 X 4 in.

• 16-DOOR/LARGE = 32

• 8-DOOR/RACK MOUNT = 7

COMPONENTS IN THE DOMESTIC 8-DOOR CONTROLLER :

Factory-installed Power wiring harness for board power (pre-stripped wire tips are

covered with shrink-tubing to prevent shorts)

Factory-installed power supply

harness, with jumpers preset to factory default (see manufacturer’s specifications for your power needs) Additional power supplies may be needed for readers and field devices.

X 13.75 X 6.25 in.

X 13.75 X 6.25 in.

X 19 X 18.75 in. (18 x 49 x 48 c1m) (Std. 4 Rack Units)

(1)

for powering CPU and daughter boards (prewired to

See Power Requirements Section of this guide as well as installation instructions – and the original

manufacturer’s instructions for the reader or device)

Factory-installed tamper switch (prewired to wiring harness)

1 ribbon cable for IC2 Data Bus (with board connectors crimped in place)

1 power transformer 110VAC / 60Hz and AC Cable

1 battery for back up power (12VDC / 8 A-hr – individually wrapped/boxed)

1 pair of battery wires (pre-installed on the power supply)

1 set of keys for the door lock on the enclosure

1 Serial Programming Cable that connects the CPU to a PC Com port for 600 model.

635 CPU and Daughter Boards

* Some Daughter Boards require setting the Board ID and other options using the SW2

dipswitch BEFORE mounting boards inside the enclosure.

Also any on-board jumpers (all models) must be set BEFORE mounting boards.

* are configurable via web interface using port 80.

Note:

CPU & Daughter boards are shipped individually per the Dealer’s purchase order.

NOTE: This list represents a standard, domestic 8-Door Panel. Components may vary for other

domestic and international panels and other sizes

See diagram on next page for example of controller cabinet.

Chapter-Page 1-10

635/600-SERIES HARDWARE INSTALL GUIDE

Figure 1 – 600/635 Model Controller (Access Control Panel) Basic

Chapter-Page 1-11

635/600-SERIES HARDWARE INSTALL GUIDE

1.7.2 635/600-series CPU Description:

See Appendix M for complete list of CPU components

The CPU Board is the brains of the controller and holds the S28 Flash Code in its memory.

635 CPUs are compatible with all 635 and 600 series daughter boards.

• CPU must run the correct version S28 that matches the software (see instructions in chapter 2)

• CPU provides on-board Ethernet (TCP/IP 100 MB full duplex) ; LEDs indicate connection / transmission

• 635 & 600 CPUs provide board programming options via the on board connections via TCP/IP using the Galaxy

Configuration Tool (635) or (RS-232 at J4 (600 only) using HyperTerminal or Putty Tool

• The 635 & 600 CPUs CPU initiate the IP connection to the System Galaxy Event Server.

• 10,000 event buffer per CPU . During operation, the CPU Board processes events locally (at the panel).

Figure 2 – CPU BOARD EDGE COMPONENTS: 635 CPU (Upper) & 600 CPU (Lower)

Chapter-Page 1-12

635/600-SERIES HARDWARE INSTALL GUIDE

voltage regulator in line – preferably at the reader end.

1.7.3 635/600 DRM (DPI) Description:

See Appendix M for complete component list of 600 DPI

The DRM (DPI) Board controls the readers, door contacts, request to exit, door lock, and offers an

additional output relay for both reader/door ports. 600 and 635 DPI’s are interchangeably

compatible with either a 635 or 600-series CPU.

635-DRM WARNING – Do not connect a 5v Reader directly to a 635-DRM. You must install a 5-VDC

635-DRM NOTICE – See Appendix-Q of this guide for installation instructions including wiring

Lock Relays for wet relay operation.

• Controls two (2) Reader ports (sections) per board, including contacts for Door Contacts, REX devices.

• Controls two (2) Lock Relays per board (one relay per reader port/section); Form C SPDT DRY RELAY.

» 600/635 Lock Relays support either Fail-safe or Fail-secure wiring; Dry relay Fail-safe or Fail-

secure wiring is shown in Chapter 2 (see 600 DPI board layout in Appendix M;). All 635 Wet Relay

wiring is shown in Appendix Q).

» 600/635 Lock Relays a support Dry Relay operation by default,

» 635 only supports wet relay operation for Lock Relays; wet/dry operation is independent per

section. See Appendix Q for 635 instructions.

• Controls two (2) Output Relays per board (one relay per port/section); Form C SPDT DRY RELAY. Relay-2

supports either Normally Open or Normally Closed device wiring.

• LEDs are provided on the edge of board to indicate when a Relay is activated (LED = solid on) or deactivated

(LED = off).

1.7.4 600 DIO Detailed Description:

See Appendix M for complete component list of 600 DIO

The DIO Board controls eight (8) input devices and four (4) output devices per board. The board comes with

built-in supervision and Hypervision capability that is turned on from the System Galaxy software after end-

of-line supervision resistors have been installed. The Output Relays are

be wired Normally Open or Normally Closed based on they type of device being used (see diagram of DIO

in Appendix M).

Dry Form-C SPDT relays that can

Chapter-Page 1-13

635/600-SERIES HARDWARE INSTALL GUIDE

1.7.5 600 DSI Description:

See Appendix M for complete component list of 600 DSI

The DSI Board controls two (2) RS-485 serial ports per board for the following devices:

PERIPHERALS

Cypress Clock (Time Clock model 1201)

Galaxy LCD custom message display (displays time and custom messages upon card swipes)

OUTPUT RELAYS

Galaxy Output Relay Board (Elevator Control or General Output Relay control)

WIRELESS READERS

IR Schlage RS-485 PIM for Wireless Readers (Legacy)

Schlage AD300 Hard-wired Readers

Schlage AD400 Wireless Readers

Assa Abloy Aperio Wireless Readers

Salto Salis Wireless Readers

Other wireless readers – see www.galaxysys.com

1.7.6 600 RELAY BOARD Description:

See Appendix M for complete component list of 600 RELAY BOARD

The Relay Board controls eight (8) Form-A SPST relays per board. The board supports General Output control

or Elevator Relay Control. The Relay Board is daisy-chained to the RS-485 port of the DSI board – rules

apply (see Chapter-2 for details; and diagram in Appendix M).

In General Mode, output relays can be triggered by DIO inputs or by certain alarm events (reader &

controller) using I/O Groups (mapped in the software). General relays can also be directly controlled from a

software (i.e. hardware tree, device status, or graphic screen).

Elevator Control mode is also set up in the software after the Relay board have been installed. See

Chapter 2 for hardware installation instructions.

Chapter-Page 1-14

635/600-SERIES HARDWARE INSTALL GUIDE

1.7.7 The System Described:

The hardware side of the system includes controllers (panels) and all field hardware (readers, locks, REXs, etc.) that

make up the access control system. The panels interoperate with the System Galaxy Software by sending

event messages over a LAN/WAN network to the Event Server (i.e. Communication Server/PC). GCS

Services are involved – see figure-2.

The event messages are handled by the GCS Event Service (running on the Event Server) and are logged to the SG

database and SG monitoring software. Core GCS Services are involved in routing the messages properly -

see figure-2. Also see diagram of core services in Chapter 3 Figure 26). The GCS Event Service is described

in Chapter 3 of this manual. GCS Services are explained in-depth Chapter 11 of SG Software Manual.

600-series controllers initiate the connection to the Event Server. The panels are grouped into (assigned to)

Clusters, which are equivalent to a Loop in the software, but there is no primary panel in a cluster. Each panel

initiates its own connection to the Event Server. NOTE: A cluster can be thought of as a TCP/IP loop (or

virtual loop); not a hard-wired 422 loop. A panel can send global events to other panels in the same

loop/cluster.

below for example of global events).

The GCS Event Service must be running to support global events within the cluster (see Figure 1

Figure 3 - Concept Diagram showing how Global Events use the GCS Event Service

Chapter-Page 1-15

635/600-SERIES HARDWARE INSTALL GUIDE

1.7.8 SG System Diagram – Communication/Event Server:

In the diagram (below) you can see how the GCS Services are connected and transmit

messages to the System Galaxy Database and to the System Galaxy Software/Monitoring

screen. Likewise, messages go from the software to the panels via the GCS Services.

Figure 4 - System Diagram of 600-series Loop/Clusters connecting to Event Server

This diagram shows a stand-alone installation (all Software and Services on one server).

Chapter-Page 1-16

635/600-SERIES HARDWARE INSTALL GUIDE

1.7.9 SG System Planning Notes:

While the installer can begin installing the Galaxy Hardware before the software and database are installed,

keep in mind that the SG Database & Communication Server (software/database &GCS services) must be

installed before the panels can connect to the system and be walk-tested.

1. Basic hardware tests can be performed using the Web Configuration Tool / Embedded Web

Page of the CPU before the system walk-through is performed.

2. A full walk-test can be performed after all hardware has been installed, configured and is

programmed into the SG Software/Database, and panels are connected to the GCS Event Service

(system is online).

Tips on Planning an Installation:

1. Obtain and use site plans, blueprints and drawings (as needed).

2. Use the Programming Templates (from Appendix A of this Guide) to record information about the

exact hardware configuration

Helps installer keep track of the hardware during the hardware installation & configuration process

Helps installer correctly identify all hardware during basic hardware tests, troubleshooting & walk-tests

Helps installer correctly configure the hardware into the SG Software/Database

Helps the customer’s IT Administrator understand how to support the Hardware on the LAN/Network

. This information is valuable in the following ways:

3. Determine how many panels and boards you will need to install. .

4. Determine the types and quantity of field devices you will need (readers, locks, contacts, input and

output devices, clocks, separate power supplies, wiring and other field equipment).

5. Determining the Location of controller(s) and field devices. Remember to follow Safety, Mounting,

Wiring and Distance Specifications (see other sections in Chapter 1 for these specifications).

6. Use the correct type of wiring for field devices. Be sure to consider the type of ceiling (plenum vs. non-

plenum). (Reference Chapter 1 Wiring Specifications)

7. Contact the Network Administrator to get network access on the LAN/WAN network.

Chapter 1 – Network Requirements covers LAN network requirements for Galaxy hardware.

Chapter 1 later sections that cover software & system requirements for connecting to Galaxy GCS

Services. This is necessary for logging data to the database and event screen. This information is also

helpful for troubleshooting connections.

Chapter-Page 1-17

635/600-SERIES HARDWARE INSTALL GUIDE

1. First the CPU must be upgraded to the current “stepstone” file version.

3. Finally all daughter boards must be updated to the flash “release” version.

1.8 CPU & Board Flash Requirements for 600/635-Series Hardware

1.8.1 About Factory Flash and Field-Flashing the CPU:

CPU boards come with a pre-installed, factory flash code.

Factory flash allows the boards to start up (boot up) and be configured before they have been field-flashed. This lets

the installer configure network parameters and other settings. The boards must still be field-flashed to the correct

flash version if the factory flash doesn’t match the System Galaxy software, in order to operate correctly.

• IMPORTANT: All CPUs and daughter boards must be running the correct S28 version of flash (i.e. field flash

code) that is compatible with the System Galaxy software operating at the field install site. You may need to

upgrade or downgrade your boards in order to match the system version in a repair scenario.

• IMPORTANT: Field-flashing a controller CPU can be done using the GCS Loader Utility, after configuring the CPU

board settings and IP/network parameters, AND Event Server IP Address.

• NOTE: If the factory flash already matches the field flash version, the installer does not need to flash the board.

NOTICE: When downgrading a factory CPU to older site flash code v5.0 (or older), it is advisable to keep the I2C Ribbon Cable

disconnected from the CPU to prevent daughter boards from prematurely updating to the factory-flash. Reconnect the CPU to the

I2C Bus after the CPU flash has been correctly updated (including validate & burned). See Chapter-2.

IMPORTANT UPGRADE INFORMATION FOR ALL SYSTEMS

A. For systems upgrading from 5.00 Flash or lower - panels must be upgraded in a three-step process:

• If panels are running v5.00 /4.77 Flash (or lower), you cannot go straight up to 10.4.x (or current

flash) – the flash process will not complete, although it will not damage the board. Drop back and run the

“stepstone” file and then run the “release” file.

• Remember: CPU flash version must match the SG Software Version. Reference Flash Version Table in

Chapter 1 or 2 to confirm which flash versions are needed.

2. Then the CPU must be upgraded to the flash “release” file version.

B. For systems upgrading from 5.04 Flash or higher – follow the information below:

• If site is at 5.04 you must disconnect all 635-DSI boards. This does not affect 600 DSI boards.

• This does not affect later versions after 5.04.

• To find out if you have any 635-DSI Boards, send a [Get Board Info] from the Controller Programming

screen in the System Galaxy software (or look up Panel Summary via the CPU’s embedded web page).

1.

First disconnect the 635 DSI’s from the Data ribbon cable.

Upgrade the CPU flash . Then upgrade the other daughter boards as normal.

2.

Finally upgrade each 635-DSI Board individually.

3.

To do this, connect one DSI board to the ribbon cable and upgrade it before connecting and upgrading the

next one. To trigger a flash update, click [Allow Board Flash Update] button in GCS Loader or webpage.

CPU’s and daughter boards can be flashed using the GCS Loader Utility from the System Galaxy software: Launch the GCS Loader Utility

from the software by right-clicking on a loop/cluster name in the Hardware Tree. Use the *_stepstone.s28 and the *_release.s28.

CPU’s and daughter boards can be flashed using the embedded webpage (browser): Launch the panel’s embedded webpage by using the

635 Config Tool or by entering the panel’s IP Address into the browser url. Use the *_stepstone.bin and the *_release.bin. Browser/PC

must be on the same network segment as panel.

SUPPORT: Consult Galaxy Technical Support if you any questions.

Chapter-Page 1-18

635/600-SERIES HARDWARE INSTALL GUIDE

1.8.2 About Auto-Updating the Daughter Boards:

Daughter boards come with a pre-installed factory version of flash code that allows the boards to boot

up even though they have not been field-flashed.

• All daughter boards (DPI, DRM, DIO, DSI) must be running the correct field flash.

• Daughter boards auto-update on the I2C bus (ribbon cable), based on the flash version in the CPU.

• With flash v 5.0 or lower, the CPU imposed a 10-Minute Flash Timer, that delayed the auto-update of

daughter boards for 10-minutes. This timer can be bypassed with the ‘clear auto’ command.

• With flash v 5.04 or higher, the CPU does not impose a 10-Minute Flash Timer. The installer must

manually invoke the flashing of the daughter boards.

WARNING: DO NOT INTERRUPT POWER TO THE PANEL OR TO ANY BOARDS UNTIL ALL BOARDS HAVE COMPLETED

FLASH UPDATES. Interrupting power during flashing can damage the board memory.

1.8.1 Flash Version Compatibility Chart for SG-10:

This section covers Flash Version Compatibility for SG 10/11 and 635-600 Board Compatibility for SG10/11.

Table 5: FLASH VERSION CHART for SG 10/11

SG SOFTWARE FLASH VERSION CPU DPI DIO DSI

(new) SG 11.2.0 Flash v 11.0.3 11.0.3 (all boards)*

SG 10.5.6 Flash v 10.5.6 10.5.6 (all boards)*

SG 10.5.1 Flash v 10.5.3 10.5.3 (all boards)*

SG 10.4.9 Flash v 10.4.15 10.4.15 (all boards)*

SG 10.4.8 Flash v 10.4.8 10.4.8 (all boards)*

SG 10.4.1 Flash v 10.4.1 10.4.1 (all boards)*

SG 10.4 Flash v 10.4 10.4 (all boards) *

SG 10.3.x Flash v 5.04 5.04 (all boards) *

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1) (2)

SG 10.2.0 Flash v 5.00 5.0 (all boards)

SG 10.1.x Flash v 4.77 4.77 (all boards)

SG 10.0.0 Flash v 4.60 4.60 (all boards)

the new RS485 Input Module or RS485 Door Module are not compatible the 600-CPU.

* -

(1) the CPU no longer uses a 10-min Flash Timer delay. You must manually start daughter board flash updates via GCS

Loader.

(2)

NOTICE FOR 635-DSI Boards (only): To upgrade from 5.04 Intermediate Flash to 10.4 (or higher), you must disconnect all 635-DSI

Boards from the I2C Data Bus – then connect one board at a time and complete the flash update before connecting the next one. This

does not affect the 600 DSI.

SEE THE NEXT TABLE SHOWING BOARD COMPATIBILITY AND SYSTEM VERSION.

See the next page for the Compatibility Charts for SG 10 releases

Chapter-Page 1-19

635/600-SERIES HARDWARE INSTALL GUIDE

635-SERIES CONTROLLER

600-SERIES CONTROLLER

635 CPU Board - Processor

600 CPU Board – Processor

635 DAUGHTER BOARDS

600 DAUGHTER BOARDS

635 DAUGHTER BOARDS

600 DAUGHTER BOARDS

600 DIO Board

600 DIO Board

635 DRM Reader Board

600 DPI Reader Board

635 DRM Reader Board

600 DPI Reader Board

635 DSI Serial Board

600 DSI Serial Board

635 DSI Serial Board

600 DSI Serial Board

Schlage PIM 485 ODT (legacy)

Schlage PIM 485 ODT (legacy)

Schlage PIM 485 ODT (legacy)

Schlage PIM 485 ODT (legacy)

Assa Abloy Aperio (SG 10.1)

Assa Abloy Aperio (SG 10.1)

<< Not supported on 600-CPU

<< Not supported on 600-CPU

Salto Salis Wireless (SG 10.2)

Salto Salis Wireless (SG 10.2)

<< Not supported on 600-CPU

<< Not supported on 600-CPU

or Mix AD-300/AD-400 (10.2)

or Mixed AD-300/AD-400 (10.2)

635 Input Module (SG 10.4)

<< Not supported on 600-DSI

• 635 Remote Door DRM (10.4)

<< Not supported on 600-DSI

COMPATIBLE MODULES (RS-485 multi-drop)

COMPATIBLE MODULES (RS-485 multi-drop)

635 Door Module (using 635 CPU & DSI, SG 10.3)

Table 6: BOARD COMPATIBILITY CHART for SG 10/11 (Tables 7 & 8 for SG-9 or lower )

WHEN IS UPGRADING SG SOFTWARE REQUIRED ?…

if an SG version is noted, then that is the minimum version of SG required to support that board/feature

if the no version is listed, then any version of SG 10 supports the feature.

WHEN IS UPGRADING HARDWARE REQUIRED ?…

Installing Wireless Readers, IP Readers – you must upgrade to 635 CPU and 635-DSI

Installing 635-Input Module – you must upgrade to 635 CPU and 635-DSI

Installing a Galaxy 485 Remote Door Module – You must upgrade to 635-CPU, 635-DRM, and 635-DSI.

Installing newer destination-driven elevator systems, then you must install all 635-model hardware.

• 600-model boards can interoperate with 635-model boards in the same system and within the same control panel.

• You can replace older 600-model boards with new 635-model boards as needed.

• The older 600-model boards do not support the newer hardware interfaces and features supported by the 635.

• Operates in same loop /system with 600 CPUs

• Supports all 635 & 600 daughter boards

• Supports all 635-series RS 485 Modules

• Supports all 600-series RS 485 Modules – restrictions apply*

• Supports Destination-driven elevator systems

• Supports Card Tour Board

• 600 Output Module (general

output or elevator control)

• LCD Clock unit

•

•

•

• Schlage AD-300 (SG 10.2)

• Schlage AD-400 Wifi (10.2)

•

• Assa IP Readers (SG 10.4) • Assa IP Readers (SG 10.4)

•

• 600 Output Module (general

output or elevator control)

• LCD Clock unit

•

•

•

• Schlage AD-300 (SG 10.2)

• Schlage AD-400 Wifi (10.2)

•

• Operates in same loop /system with 635 CPUs

• Compatible/Supports all 600 daughter boards

• Supports 635 DRM (Reader board)

• Supports 600 Output/Elevator Modules on 600 DSI

• Destination-driven elevator systems and Card Tour are not supported.

• 600 Output Module (general

output or elevator control)

• LCD Clock unit

•

• 600 Output Module (general

output or elevator control)

• LCD Clock unit

•

600 Elevator/Output Module ( using DSI )

Chapter-Page 1-20

635 Input Module (using 635 CPU & DSI, SG 10.4) << 635 Input Module not supported on 600 CPU

<< 635 Door Module not supported on 600 CPU

600 Elevator/Output Module ( using DSI )

635/600-SERIES HARDWARE INSTALL GUIDE

FLASH VERSION

CPU

DPI

DIO

DSI

SOFTWARE VERSION

V4.57 Flash

4.57

4.57

4.57

4.57

SG 9.0.5

V4.51 Flash

4.51

4.51

4.51

4.51

SG 9.0.4

V4.50 Flash

4.50

4.50

4.50

4.50

SG 9.0.0

V2.30e Flash

2.30e

1.71d

1.61b

2.31f

SG 8.3.0

v1.74d Flash

1.74d

1.60h

1.40b

2.12a

SG 8.2.3

v1.60 Flash

1.61j

1.60e

1.40b

2.2b

SG 8.2.2

v1.60 Flash

1.60n

1.60e

1.40b

2.2b

SG 8.2.0

v1.40 Flash

1.40d

1.40c

1.40c

not used

SG 8.1.1

to a recent version of SG 10 or 11. Contact Technical Support for assistance.

Software Compatibility

Hardware Compatibility

Factory Revisions

Board

1.8.2 Older Flash Version Compatibility Charts (SG-9 / SG-8):

Table 7: FLASH VERSION CHART for SG-9 (and older)

IMPORTANT: you may need to step up the flash to interim versions to make the upgrade all the way

Table 8: SG 9/8 Software Compatibility for 600-series Board Revisions

SG Software S28 Flash

SG 9.X

SG 8.X

See Table above

for correct Flash

Version

(1)

600 CPU Board - Processor Board

Board Models

(A, B, C … E, F, etc.)

All CPU revisions are compatible with all

daughter-board revisions.

600 DIO Board - Input/Output Board

600 DPI Board - Reader Interface

All daughter-board revisions are compatible

with all CPU revisions.

600 DSI Board - RS-485 Serial Board

(1) All CPUs and daughter boards should be running the correct flash code that was released with the SG Software that is installed

on the jobsite. Find the correct flash version by opening the software help window or by opening the Loader Utility. If you replace

a board you must flash it to the correct version issued with the installed SG version. If you upgrade the SG Software system, then

you must reflash all your panels and daughterboards to the version of flash that is issued with the new SG Software. The flash

running in the panel/boards must be in sync with the SG Software version installed. Obey any stepped upgrade flashing

instructions mentioned in the prior section. Always contact Tech Support to ensure you have the complete information for

upgrading flash.

Chapter-Page 1-21

635/600-SERIES HARDWARE INSTALL GUIDE

1.9 Controller Mounting Requirements

1. The controller enclosure must be wall mounted using tear-drop shaped mounting holes.

2. Panel can be mounted horizontally (typical) or vertically

Non-condensable: do not mount in or near water, liquid, moisture or rain/weather

Clean, reasonably dust-free environment.

Temperature should be between -10° C and +60° C.

Location should have limited access for security purposes.

Do not mount to metal studs or brackets.

Do not connect Chassis to Cold Water Ground.

Avoid power transformers and high voltage and high frequency devices.

Figure 5 – 6XX-Series Controller Mounting Requirements:

Applies to both 635- and 600- model controllers. Medium controller shown.

Chapter-Page 1-22

635/600-SERIES HARDWARE INSTALL GUIDE

Figure 6 – 6xx-series Medium Controller Dimensions & Knockout Diagram:

This diagram shows a facing (inside) view of the back and inside views of sides for a medium

controller enclosure.

Drawing is shown rotated 90 degrees to fit on page.

Dimensions shown in inches.

Chapter-Page 1-23

635/600-SERIES HARDWARE INSTALL GUIDE

1.10 Power Requirements

1. A Power Transformer 16VAC @ 40 VA (transformer included if purchased with panels).

• Power transformer must be plugged into a 110VAC/60Hz outlet that is less than 25 feet from the

controller.

• The 110VAC outlet cannot be controlled by a switch.

• Transformer cannot be shared with other equipment.

2. The controller comes with a 12VDC 2.5 amps Power Supply for powering CPU and daughter boards (power

supply included as purchased with panel).

The 12 VDC Power Supply must be connected to the controller’s wiring harness inside the panel by the

installation technician.

3. Do not power relay boards on the same power supply as CPU, DPI or DSI. If 635/600 Model Output or

Elevator Relay Boards are in the same panel with a CPU and DSI, they will need a separate power supply;

Output Rated at 12 VDC 2.5 amps.

4. When using more than four proximity readers on one controller, it is necessary to use an additional power

supply to power the additional readers. You must common the grounds between the power supplies in the

panel (readers only).

5. When using biometric readers: biometric readers must be powered separately. Do not power Biometric

readers from the DRM board or from the controller power supply.

6. Powering door locks: An additional DC Power Supply is required. Do not power door locks from the DRM

board or from the controller power supply.

7. IMPORTANT: Do NOT use the same power supply for Locks and Readers. Use a separate power supply for

locks.

8. IMPORTANT: additional power supplies must be purchased for any field devices or equipment that will

require it (e.g. Sagem Readers, Cypress Clocks, input or output devices, etc.). Follow the device manufacturer’s

guidelines for type of power supply to use.

9. IMPORTANT: DO NOT Common the Ground of the Lock Power to the controller power supply or to the

reader power supplies.

10. Surge Suppression Diodes should be installed parallel to lock to suppress kickback surge. Diodes should be

located at the lock and as far away from the controller as possible.

Chapter-Page 1-24

635/600-SERIES HARDWARE INSTALL GUIDE

Board

Relay Type

Port Output =

See Appendix Q for details.

Output Control

Control

Current draw for a single board

Current draw with relays energized

CPU = 0.07 amps (70 mA)

n/a