Page 1

INSTRUCTION MANUAL

- PH40V

- PH45V

Page 2

CONTECTS

1.! SAFETY)...............................................................................................................................)1!

2.! INTRODUCTION)..............................................................................................................)2!

3.! SPECIFICATION)&)COMPONENTS)..............................................................................)5

!

4.! INSTALLATION)INSTRUCTIONS).................................................................................)6

! A.! FEED TABLE)...........................................................................................................)6

!

B.! FOLDING)PLATES)....................................................................................................)6

!

C.! VERTICAL STACKER)..........................................................................................)6!

5.! FOLD)PRINCIPAL)AND)STYLE)GUIDE)........................................................................)

7!

6.! FOLD)SETUP)ADJUSTMENT).........................................................................................)9

!

7.! OPERATION)AND)FOLDS)............................................................................................)2

0!

8.! FOLD)CORRECTIONS)....................................................................................................)2

3!

9.! OPTIONAL)ACCESSORIES)...........................................................................................)26

!

A.! SCORING)OR)PERFORATING)WHEEL)..............................................................)2

6!

10.!FAULTS,)CAUSE)AND)REMEDY)..................................................................................)27!

Page 3

!

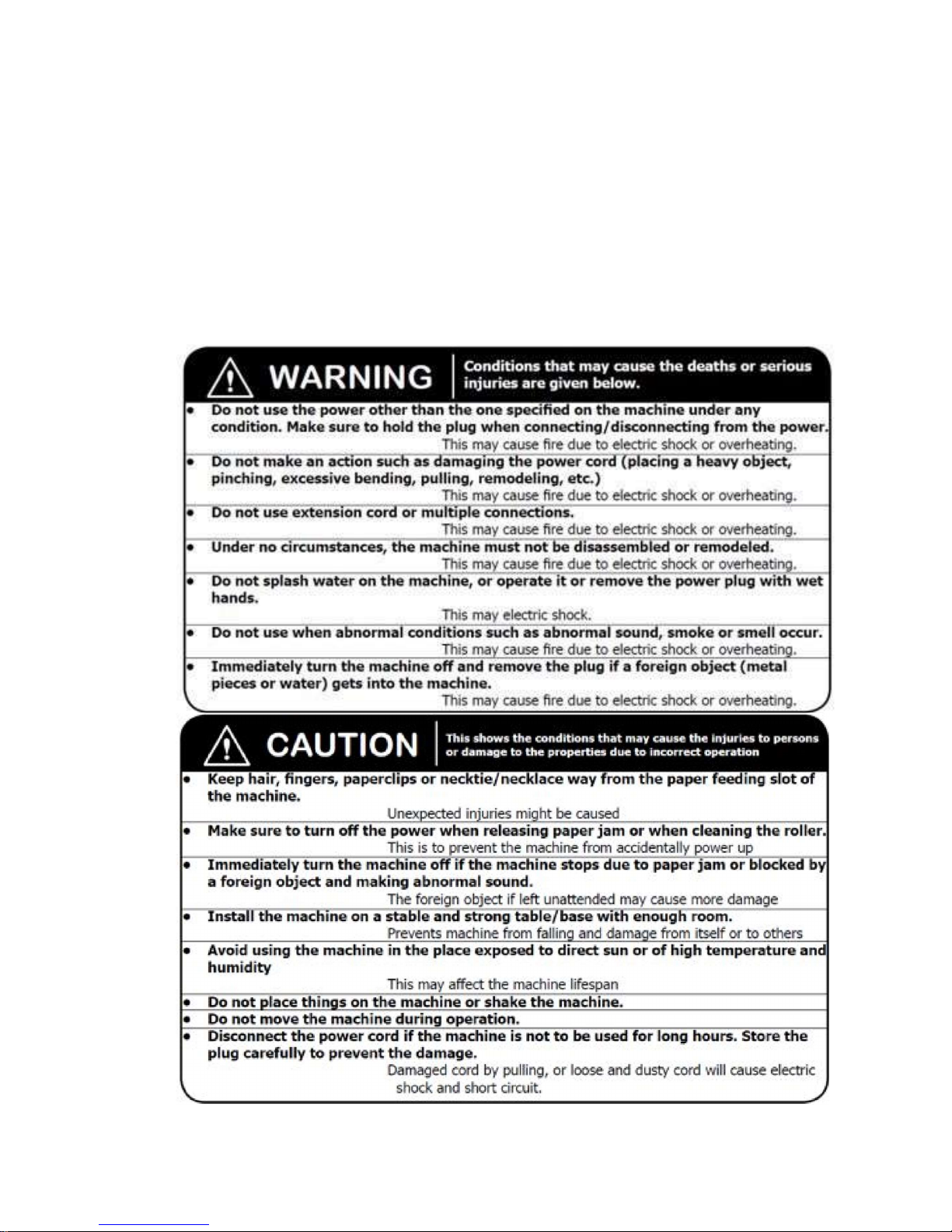

1. SAFETY

Please make sure to read this manual for safety in operation before using this

product. Take good care of this manual and keep it where you can always find it.

This manual contains cautions and warnings in order to prevent harm to the

purchaser and other persons, lives, or the damage to the properties. Attain

complete understanding before using this product.

1

Page 4

2

2. INTRODUCTION

Your new Folder is a table top automatic folding machine which will

efficiently solve all your folding problems over many years if your handle

if carefully and with care. Thanks to new advances in production

technology. The machine offers you outstanding capacity at reasonable

cost.

This manual provides a permanent record for ready reference, covering

the function of the separate units and the preparatory work for the various

folding applications. Please read this instruction in detail.

Installation of the machine should be carried out only by trained personnel

authorized by the manufactures or his representatives. Additional

instruction are provided for this purpose

Repairs and service should be carried out only by trained personnel

authorized by the manufacturers or his representatives. The interval

between inspections including safety-related function depends on the

machine usage.

Employ only trained or qualified staff and set out clearly the individual

responsibilities of the personnel for operations, set-up, maintenance and

repair.

Avoid any operational mode that might be detrimental to safety.

Machine Model

Your machine offers a wide range of applications and configurations

to suit your requirement of the folding job at hand. The machine

model number serves as a useful indication of what the configuration

of each machine is.

The components/accessories available are as follow:

• 4-Plate Folding Machine, PH40 & PH45

• Counter

• Batch-Counter

• Conveyor Belt

• Vertical Stacker with the PH40v & PH45v

Page 5

3

The model number shows the machine configuration, for example:

PH

-40

DF-30

Feed width of 300mm

4

4-

Plate Folding Machine

V

Vertical Stacker

C

Counter

DF-45

Feed width of 350mm

4

4-

Plate Folding Machine

V

Vertical Stacker

B

Batch-Counter

Note:

1. For all 4-Plate Folding Machine Unit configurations, Counter is included.

2. If the model number includes V, Vertical Stacker will be the default collecting

device.

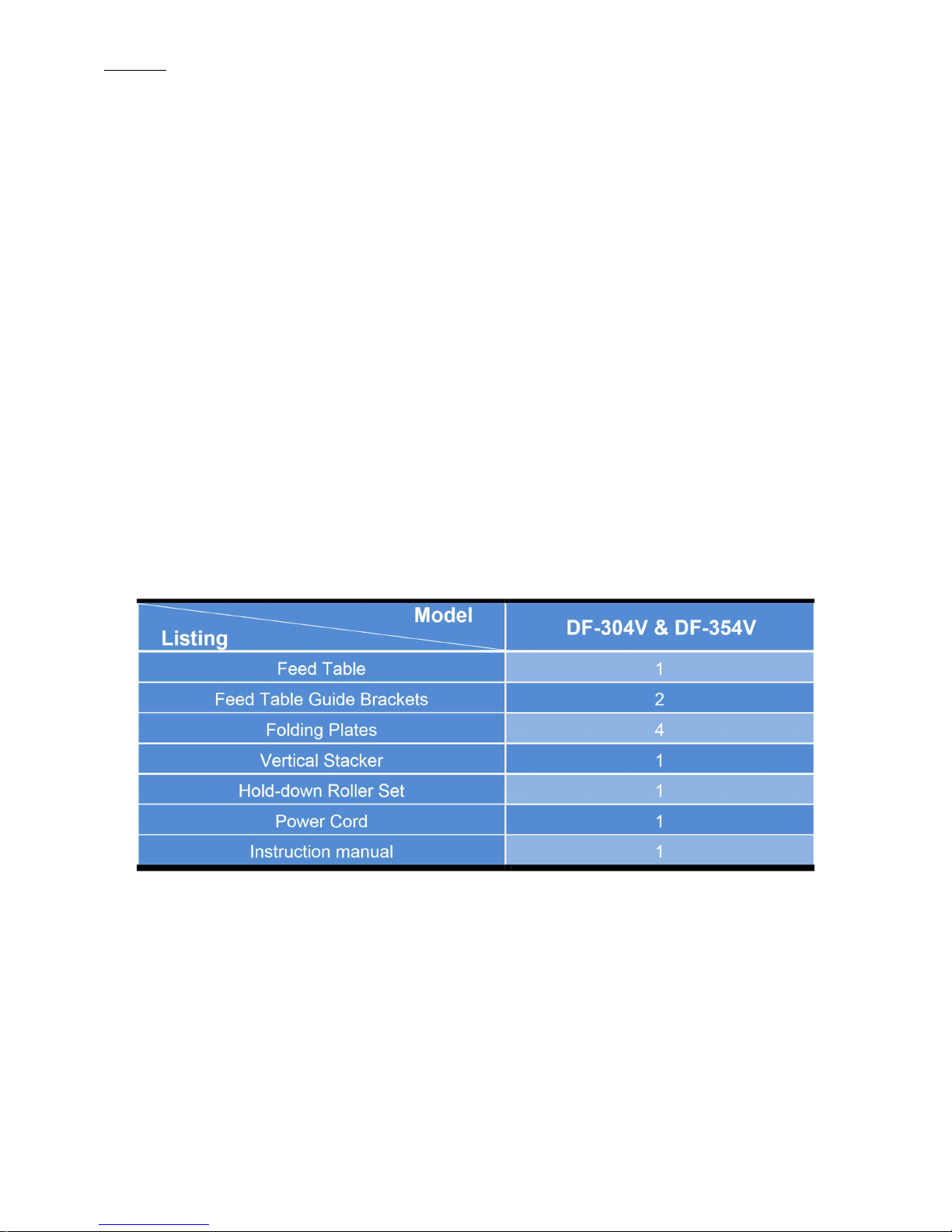

Machine Check List

Check completeness of the accompanying accessories:

Page 6

4

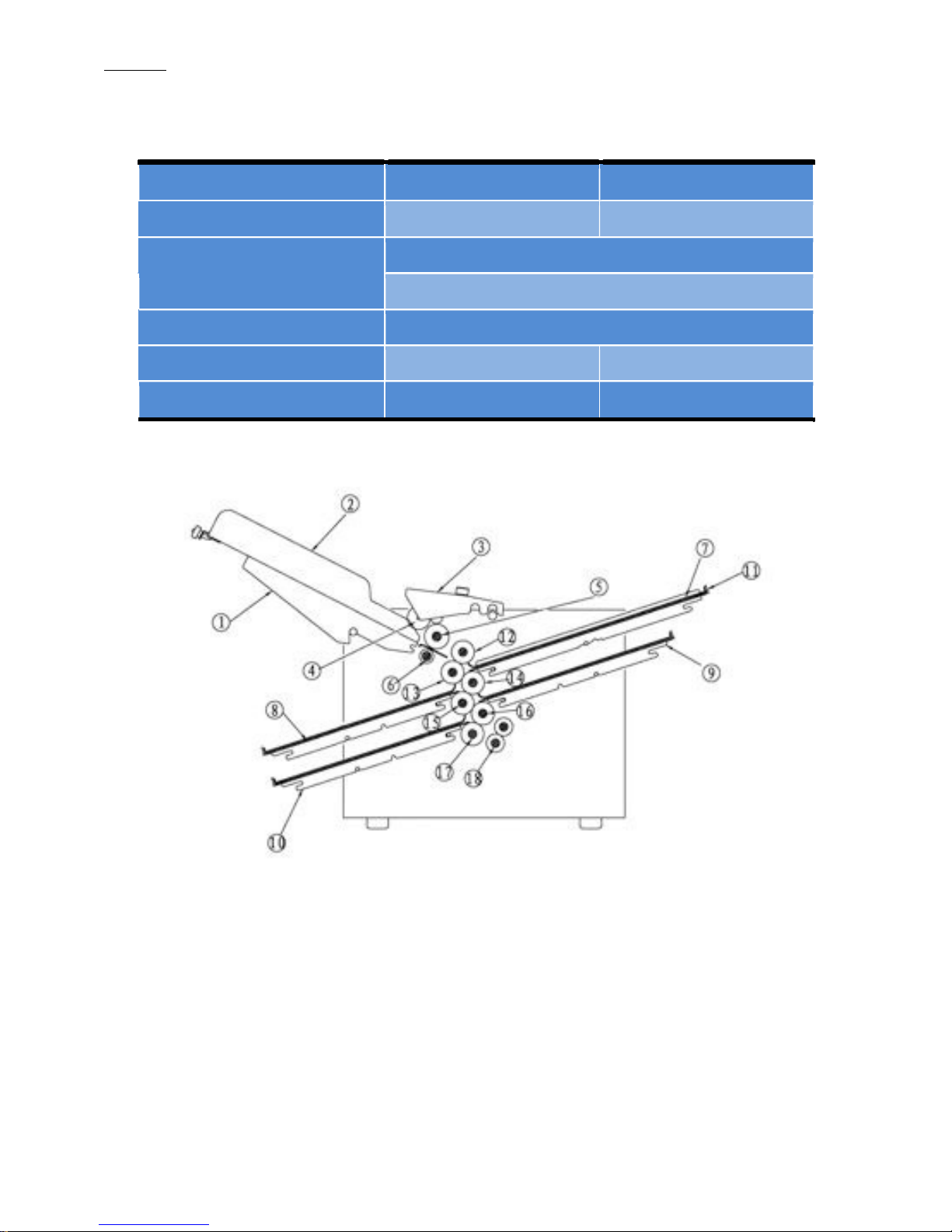

3. SPECIFICATION & COMPONENTS

Model

PH40

V

PH45

V

Max. paper size (mm) 300(W)x 500(L) 350(W)x 540(L)

Min. paper size (mm) 80(W) x 100(L)

Folding paper weight (gsm) 45 to 150

Min. folding size (mm) 24

Dimension (LxWxH in mm) 1100x525x510 1100x570x510

Weight (kg) 68kg 71kg

1 Feed table 2 Feed guide Bracket 3 Feeder

4 Infeed Roller 5 Feed Roller 6 Pressure Roller

7 Folding plate 1 8 Folding plate 2 9 Folding plate 3

10 Folding plate 4 11 Deflector Bar 12 Fold Roller 1

13 Fold Roller 2 14 Fold Roller 3 15 Fold Roller 4

16 Fold Roller 5 17 Fold Roller 6 18 Ejector Rollers

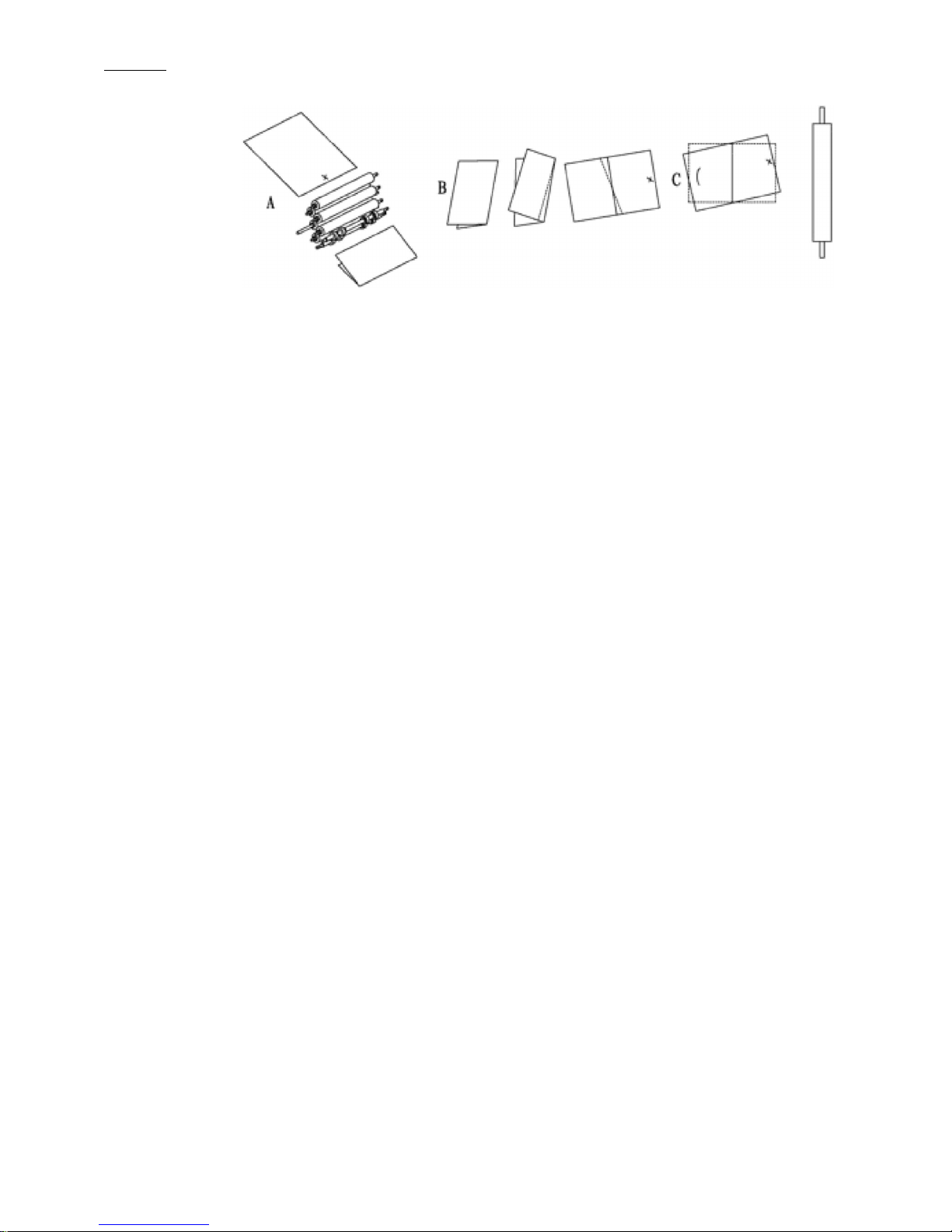

4. INSTALLATION INSTRUCTIONS

First, mount the machine on a sufficiently strong table or similar base.

Page 7

5

A. Feed Table

Hook in the Feed table. First place it on the support shaft, slide it down at

an angle until the lower slots engage with the pins on the side panels. The

upper slots must engage with the support shaft. After which, install the

two bracket guides.

B. Folding Plates

Hook the folding plates according to their designated slots into position

like the feed table. You will note that the plate has a deflector bar on one

side, while the other is formed as an open “pocket”. Hook in the plates as

dictated by the desired type of fold (refer to Folding Style Guide). To do

so, place the plate on the two-front pins in the side panels of the machine,

then slide it towards the folding rollers until you can clearly hear all four

pins clicking into engagement. You may turn the handwheel to ensure

that the folding plate is properly engaged and there is no hindrance.

C. Vertical Stacker

Due to tension from the paper materials, if the paper has been folded into

very small dimension or has been folded several times, the paper will

spring back out of the fold. If conveyor belt system was used, the paper

might not be nicely fanned out. Thus, it is advisable for the user to fit the

machine with a vertical stacker (especially for collecting paper less than

30mm or perform up to 3folds).

Insert the vertical stacker into the support shaft in the rear of folding

machine using the groove provided.

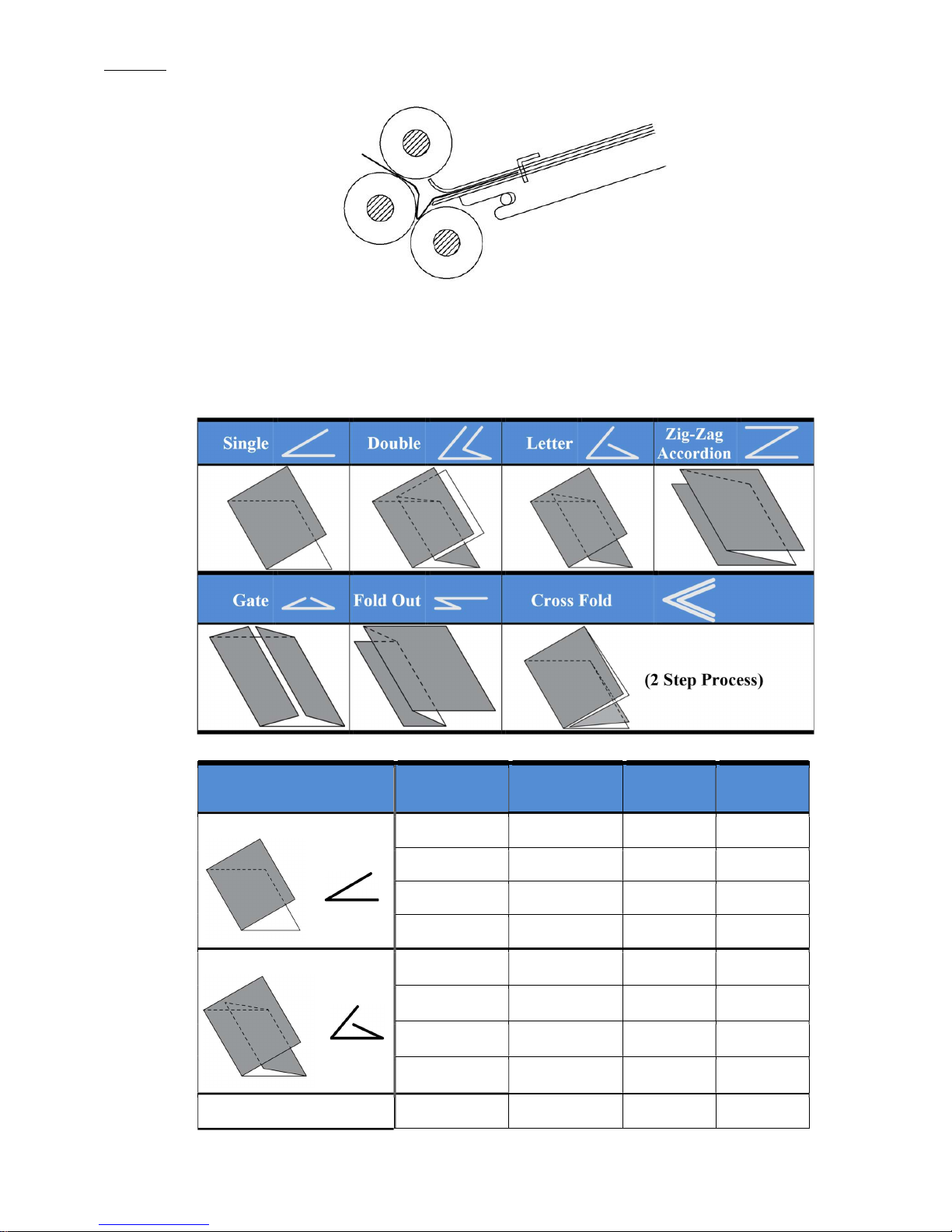

5. FOLD PRINCIPAL AND STYLE GUIDE

Folding is carried out by folding plates. This section will provide a brief

description on the folding process and the fold styles. These will enable

you to carry out settings for any desired style without extensive trial runs.

Fold Principal

The feeder takes the sheet between the first pair of fold rollers which

drives it into the first folding plate until it comes up against the adjustable

stop. But as the rear of the sheet is still advanced by the fold roller, a loop

is formed. As the loop gets bigger, the paper is seized by the second pair of

roller, creating a fold line and carried to second folding plate. The process

is repeated.

Page 8

6

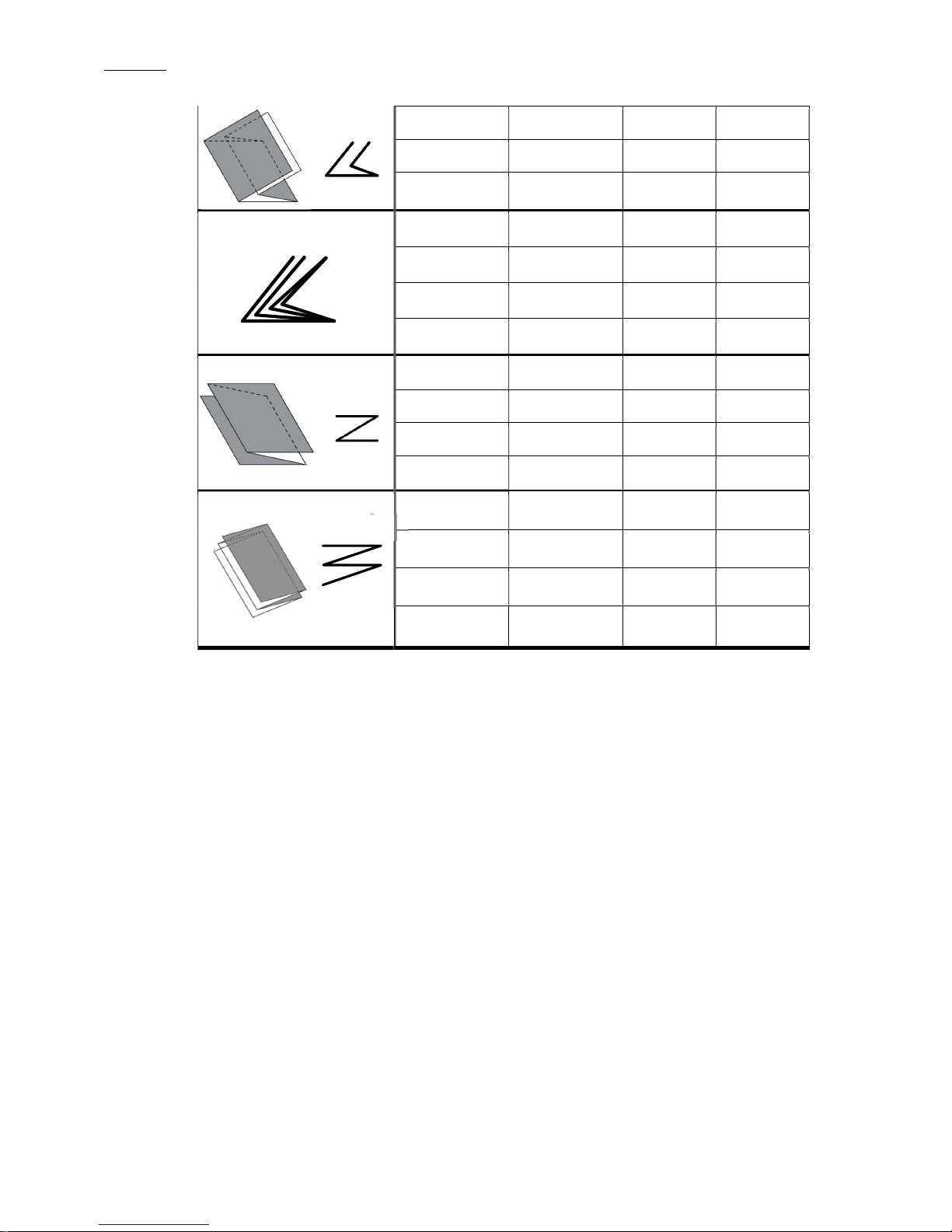

Below are some of the common folds and setup guide that you will come

across during your folding. With the 4-plate machine, there more

combinations essentially based on these principal and setup.

Basic Fold Style

Fold Style Setting Guide

Type of fold Fold Plate

Set To Paper

Length

A4 A3

Single

1 1/2 148 210

2 -* - -

3 - - -

4 - - -

Letter

1 2/3 198 280

2 1/3 99 140

3 - - -

4 - - -

Double Parallel 1 1/2 148 210

Page 9

7

2 1/4 74 105

3 - - -

4 - - -

Triple Parallel (8-Page)

1 1/2 148 210

2 1/4 74 105

3 - - -

4 1/8 37 52

Zig-Zag/Accordion**

1 1/3 99 140

2 1/3 100 140

3 - - -

4 - - -

1 1/4 74 105

2 1/4 75 105

3 1/4 76 105

4 - - -

* The dash line – means to insert the fold plate with the paper deflector side into the

machines.

**For Accordion Fold, fold plate stops should be set so they increase by 1 mm from one

plate to the next.

6. FOLD SETUP ADJUSTMENT

Controls and Accessories

• Main Start/Stop Switch

• Speed control:

Varies speed while machine is running or stopped.

• Counter (model C & B)

• Feed Switch (model B)

• Feed Table: adjustable to different paper format and right-angle

feed of paper into machine.

8 - Page

Accordi

on **

Page 10

8

• Paper Thickness Adjusting Knob:

Variable adjustment for thickness of papers between 45-150 gsm.

• Feeder:

With adjustable infeed pressure roller.

• Folding plates:

With micro-adjust for length and angle setting, fitted with scales.

• Vertical Stacker:

Adjust the stacker wheels according to the paper size.

• Hand wheel:

Turns machine when motor is switched off.

Hand Wheel

With the interest to protect the machine operator and also compliance with

the safety regulation, the hand wheel is now detachable.

You may attach the hand wheel when you need to adjust for paper

thickness or remove paper jam.

Page 11

9

Please remove the hand wheel before switching on the machine.

Adjust Paper Thickness

Paper thickness is to be adjusted so that the feeder only feeds one piece of

paper at a time. By adjusting to the pressure roller, you can limit the

passage gap to any paper thickness.

Set the gap between feed roller and pressure roller to paper thickness by

turning the knob (1) at the machine side. To reduce the gap, turn knob (1)

clockwise. Once you can feel the rollers lightly pulling the sheet, stop the

adjustment. Do not set the gap too small as it will result in abnormal

wear on the feeder wheels.

You can double check the thickness setting by trying to feed two pieces of

paper together. If the feeder is able to separate the sheets, the thickness is

set correctly.

Page 12

10

Adjust Feed Guide

First align the left feed bracket guide (1) so that the sheet is fed centered

on the table as far as possible. A notch (2) in the table under the

removable center panel marks table center, but you can also align the

sheet using the feed or pressure roller as gauge.

To shift the guide, firstly loosen the knurled nut (3), pull away the clip

lightly. Shift and align the guide, then fasten the nut.

After finish setting the left guide, then adjust the right guide (4). Put the

paper on the feed table; align the paper with the left guide, then move the

right guide to the edge of the paper, leaving a gap around 0.5mm. Do not

press the guide too tightly close to the paper. Fasten the nut to fix the right

guide. Check again whether the paper is in the middle between the left

and right guide and ensure the guide is not too tightly or loose placed

against the paper.

Displace the hold-down disks in such a way that they serve as guides

which is placed about 2-3 cm from the edge of the sheet.

Page 13

11

Paper Stack

It is important to fan the paper stack before placing it on the feed table:

Grip the left end of the paper with your left hand and bend it towards the

right.

Press on the right side of the paper with your right hand, and then release

your left hand. The paper stack will snap back and will be fanned out

slightly. Repeat the process once or twice more until the stack if fanned

out properly.

Place the fanned out stack on the feed table in such a way that the

uppermost sheet is located under the feed roller.

Page 14

12

Feeder Pressure

To adjust the feed pressure, first place the feeder unit at its rest position

(Infeed roller raised). Set the pressure of roller on feeder with the knurled

nut (1).

For paper weight from 60gsm to 90gsm, place the nut in the middle,

neutral position.

For over 90gsm paper, loosen the nut and push it towards the paper stack,

thus applying more pressure.

For the paper less than 60gsm, shift the nut at the opposite direction

(towards the delivery direct).

If the paper pressure is adjusted not properly, the paper will be pressed too

tightly and will leave crease on the paper.

Page 15

13

When the pressure is set, place the feeder to its work position.

To sum up, set paper feed in the following steps:

• Set gap between feed and pressure roller approximately to paper

thickness.

• Align guides.

• Set infeed roller contact pressure with the knurled nut on the feeder.

Setting the Folding Table

According to the folding type, adjust the folding plate.

1 Plate Stop

2 Angle Adjustment Screw

3 Vertical Adjustment Knob

4 Plate Stop Setting Knob

5 Adjustment Shaft

6 Deflector

You can firstly fold one paper by hand, then refer to the folded size, shift

plate stop (1) or refer to the Fold Style Guide.

First loosen the Plate Stop Setting Knob (4), then shift the stop plate to

the designated place and fasten the screw. When the folding plate is not

Page 16

14

needed, take it out and fit it reversely with the deflector (6) end into the

machine. When the setting is completed, please test folding several papers

first.

You can fine-tune the stops for length and angle with the knurled screws.

Angle Micro-Adjustment (2) Vertical Micro-Adjustment (3)

Connect the Counter (for model number C & B only)

The counter will work only when combined with the sensor. Before using the

counter, please connect the sensor in advanced.

Please note that there are three metallic contacts in one side of the power

cord of the sensor. The sensor MUST BE connected with the flat side

with NO Metallic Contact Side on top (picture A). Do not connect the

sensor with this side on top (picture B),

Page 17

15

Vertical Stacker

Installation of the vertical stacker

Insert the vertical stacker into the support shaft in the rear of folding

machine using the groove (1) provided.

Adjustment of the Vertical Stacker Belts

Adjust the belts according to the width of the folded paper. The belt should

have at least 10 to 15mm gap to the edge of the paper.

Minimum Fold Size Adjustment

Position the minimum size folded

paper at the center of the stacker.

Adjust the belt to the size of the

paper, leaving around 10~15mm

space to the edge of the paper.

Page 18

16

Maximum Fold Size Adjustment

Position the maximum size folded

paper at the center of the stacker.

Adjust the upper outer belt to space

1/4 of the paper length from the

centre.

The lower outer belt should be

positioned as such that it leaves

around 10~15mm to the edge of the

paper.

Adjustment of the Vertical Stacker Guides Ensure

that a gap of 1 to 2mm is kept between the two

paper guides located after the belt system. This can

be done by adjusting the screw of shaft (2).

The right and left paper guides (3) are adjusted

according to the width of the paper.

Put the stop board (4) after the folded paper.

Start the vertical stacker:

After above steps, switch on the power switch and adjust the speed (5)

of the vertical stacker. As a general rule, the speed of the stacker should

be faster than the speed of the machine.

The Folder is now ready to run. But before you switch on, please note the

following important points:

A change of speed while the machine is running may change the fold style

applied. This may happen as you start the machine, since it needs a little

time to run up to speed.

Page 19

17

For this reason, it is advisable to place your left hand on the stack before

switching on the power. Release the paper only when the machine has run

up to the selected speed (you will hear the steady hum).

The same applies when you switch the machine off with sheets of paper

remain on the feed table. Again, hold them down to stop the feed, when the

motor is running at steady speed, release the grip.

In the way, the whole run from first to last sheet will be evenly folded.

Page 20

18

7. OPERATION AND FOLDS

1. Choice between Auto/Manual for Counter Mode

2. Choice between increment or decrement count

3. Set batch count quantity

Enter Button

Once setting is completed under Count Mode, press enter to

store memory

In Count Mode

• Press to increase the display number

• Select Auto Mode for counter

• Select incremental counting for counter

In Speed Mode (when machine stops)

• Press to increase the speed of machine

In Count Mode

• Press to decrease the display number

• Select Manual Mode for counter

• Select decremental counting for counter

In Speed Mode (when machine stops)

• Press to decrease the speed of machine

Select Button

–

Select “ Count ”

Mode

In Count

Safety Caution

Mode Selection

Start/Stop

Quantity Se tting and Counter Screen

Increase/Decrease,

Left/Right

Enter

and Test

Page 21

19

In Count Mode

• Press to move left for digit position

• Digit flashes indicating the current position

In Count Mode

• Press to move right for digit position • Digit flashes indicating

the current position

When the counter is set and machine at the stop position, press

Right button to perform test fold (3 sheets).

In Count Mode

displays the counter number to set with flashing digit

indicating the position In

Speed Mode

displays the speed of the machine to be set

When Machine is running displays the

current sheet count When Machine stops

displays the total sheet folded

When the preset counter quantity has not complete and feed

table runs out of paper, displays E2 (with Buzzer alarm)

When sensor detects no infeed of paper, displays E1 (with

Buzzer alarm)

Feeder When Feeder safety lights lid up, indicates feed table

has no paper, displays E2 in counter

screen with buzzer alarm

Start/Stop Button

Press once to start(green light), press again to stop (red light)

When the machine stops, Speed light lid up

able to adjust the speed of the machine

1. When machine stops and displays the total

paper count, long press for 3 secs to reset to zero

2. Press once to deactivate the buzzer alarm

Operation Example

Counter Set with number of sheets to fold

Auto mode and decrement counting for Counter Setting

Page 22

20

1. Press to enter Count Mode.

Auto and Manual LED will blink. Press to select Auto mode.

Add and Sub LED will blink. Press to select Sub for decrement

count style

Use the direction buttons to set the number of sheets to fold.

2. Press to store setting

3. Press to determine machine speed

4. Press to test fold. 3 sheets will be folded.

5. When the test fold result is okay, press to start the machine

With the above setting, when the machine is running:

The display panel will:

1. Indicates the paper count

Under ADD method (increment style) the displays starts from 0 to the

preset value

Under SUB method (decrement style) the displays starts from the preset

value and counts down to 0

2. Under Auto mode, once it reaches the preset value, the batch light will

blink with a buzzer sound, stops feeding for 3 sec and continue another

cycle

3. Under Manual mode, when the preset value is reached, the machine runs

for 3 sec and then stops. Press to resume folding.

When the counter value is set to 000000, no counting will be made. Press

to operate the machine. However, this mode is not recommended

8. FOLD CORRECTIONS

Eliminating a diagonal fold

Page 23

21

Mark the first sheet you run through the machine with a cross on the top

side, so that you know in which direction it has been fed. If it leaves the

machine with the fold diagonally shifted from the straight line, first fold it

by hand to an even more acute diagonal offset from the straight, then

place it again on the feed table in the correct running direction. Since the

fold always runs parallel to the spindles, you must now turn the sheet (and

adjust the guides correspondingly) until the next trial fold runs exactly

parallel to the spindles. The next sheet will already show an improvement.

Possibly, you may have to make another trial fold, continuing with the

sheet alignment until the diagonal shift is completely corrected.

Setting to pointed tips or out-of-square paper

Where the sheet end has pointed tips (diagonal cuts) or out-of-square, use

the angle micro-adjust to adjust to the correct angle.

Correcting minor fold variations

Once you have accurately set the plate stops to the desired style of fold by

the scales, it should not normally be necessary to equalize minor fold

variation, provided the running speed is not changed drastically after

setting up.

Placing and replenishing the paper stack

When feed table, automatic-paper feed, plates and delivery have been set to

the required fold, place the first paper stack on the table - between 100 and

300 sheets, depending on paper grade, evenly fanned out. Align the stack

at the sides. To avoid the last sheets of a stack being drawn together under

rollers and spindles, it is advisable to stick a single sheet with adhesive

Page 24

22

tape to the table. Place the fanned stack on top, holding it in position with

your left hand and guiding it with the right. Cautiously slide the stack up to

the feed roller working range so that the fanning will not collapse again. As

the top sheet must be seized first, slide it closest to the feeder.

Replenishing the stack

You can top up the stack while the machine is running in two ways:

a) When only a few sheets are left, slide the new stack under the last sheet

and the machine can run on without a break.

b) Alternatively, you can let the last sheet be drawn in and then place a

newly prepared stack on the table. This briefly breaks the machine run,

but the negligible time loss will not reduce average output

Adjusting Roller Pressure

Depending on the weight of the paper, sometimes it is necessary to adjust

the roller pressure according to ensure a smooth and accurate fold.

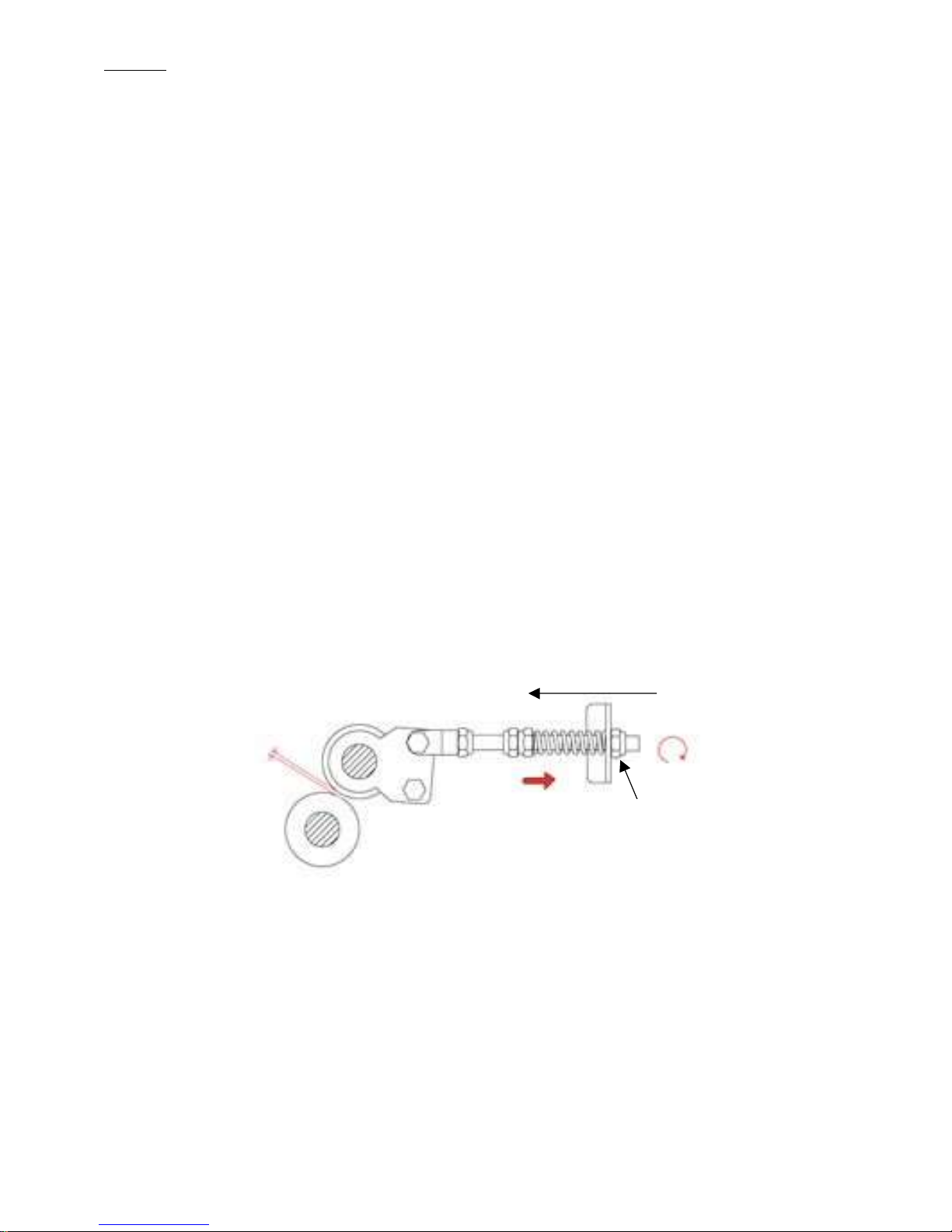

The roller pressure can be adjusted by turning on the nut (1) clockwise or

anti-clockwise to achieve the desire pressure. The direction/point of rotation

reference is always the view from the nut looking towards the roller.

Turn the adjustment nut (1) Clockwise:

This action will pull the rod and create a gap between the rollers. This

step is to release pressure on the fold rollers.

1

Direction of

View

Page 25

23

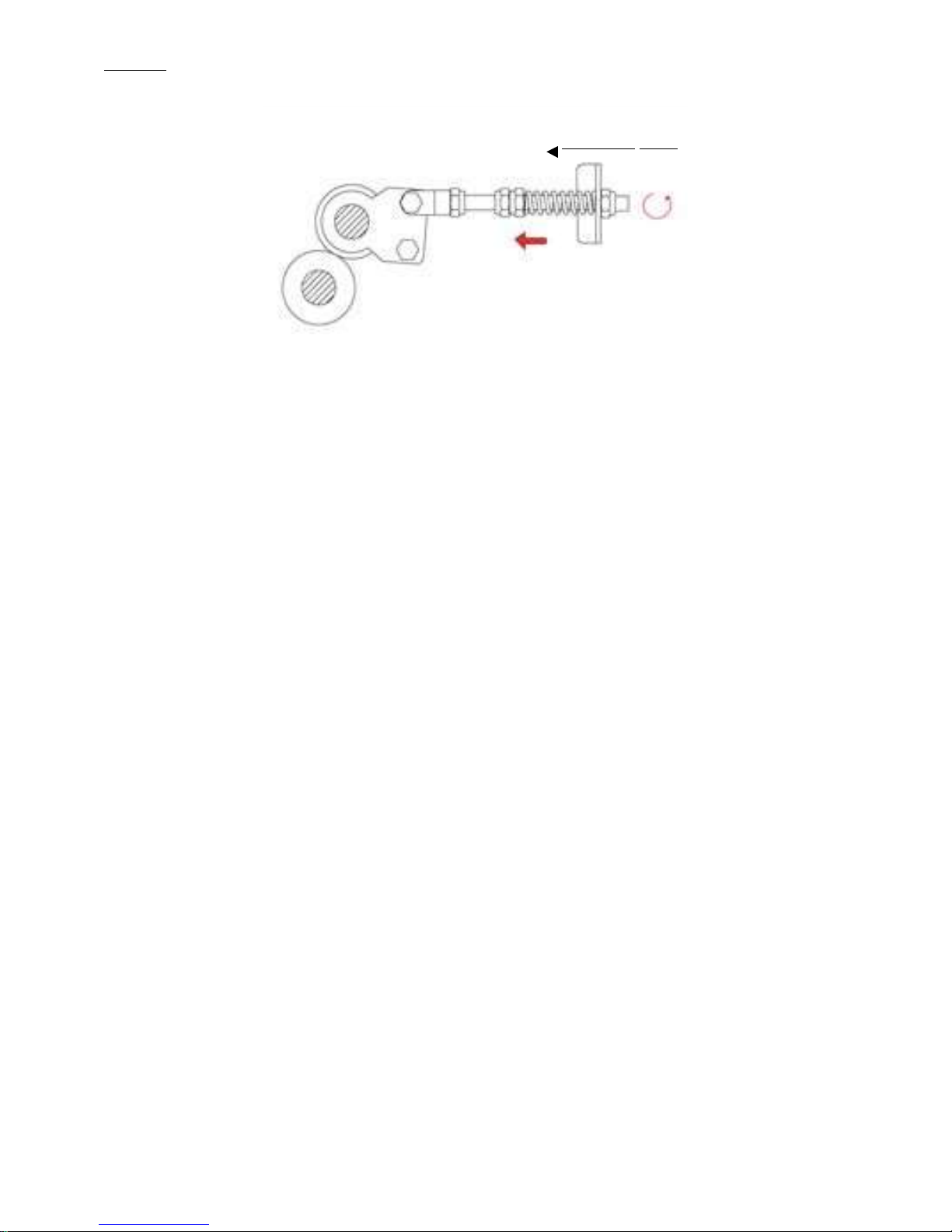

Turn the adjustment nut (1) Anti-Clockwise:

This action will push the rod and close the gap between the rollers. This

step is to increase pressure on the fold rollers

9. OPTIONAL ACCESSORIES

A. Scoring!or!Perforating!Wheel!

First, mark the scoring position on a test paper then adjust the ejector roller

to the paper edge. Roll out the paper to the ejector shafts by turning the

handwheel. Adjust the scoring wheel to the required position. After which,

adjust the upper wheels towards the scoring wheel. This will create the

score line when the paper is run through. Please test the depth of the score.

In general, for thin paper, set the distance between the scoring wheel is

closer. For thicker paper, set the distance further apart.

This set-up and principle also applies to perforation wheel.

When the scoring/perforating wheels are not in use, loosen the roller

and move it 1cm away from the cam.

D

irection of

View

Page 26

24

10. FAULTS,

CAUSE AND

REMEDY

Perforating Stripper

Perforating stripper eliminates the

tendency of paper sticking on the

perforating wheel, which might cause a

jam during the output. Install perforating

stripper on the hold - down roller shaft.

Page 27

25

(

Fault Cause Remedy

Intermittent(and(

irregular(feed(

1.(Feed(bracket(set(too(narrow(

2.(Gap(between(feed(and(

pressure(roller(too(narrow(

3.(Infeed(roller(pressure(

insufficient(or(roller(worn(out(

4.(Feeder(Shaft(drive(belt(worn(

1.(Loosen(the(bracket(by(a(little(

2.(Increase(gap(with(setting(knob((

(

3.(Increase(feed(on(the(feeder(or(

replace(infeed(roller(

4.(Replace(belt(

Very(lightDweight(

paper(grade(

becomes(creased(

1.(Infeed(roller(pressure(too(

strong(

2.(Gap(between(feed(and(

pressure(roller(too(narrow(

3.(Speed(too(high(

4.(Paper(runs(at(an(angle(

5.(Pressure(of(first(pair(of((fold(

rollers(too(strong(our(uneven(

1.(Reduce(feed(pressure(with(

knurled(nut(

2.(Increase(gap(with(setting(knob((

(

3.(Reduce(speed(

4.(Correct(with(feed(brackets(

5.(Have(pressure(and(parallel(fold(

roller(alignment(set(by(our(

service(engineer(((fold(roller(

arrangement(is(suitable(for(all(

paper(grades(in(general(use,(but(

for(some(very(thin(papers,(fold(

roller(pressure(can(be(altered()(

Two(or(more(sheets(

drawn(in(together(

The(folding(machine(

has(stopped(

1.(Gap(between(feed(and(

pressure(roller(too(wide(

2.(Paper(jam,(the(blocking(

prevention(has(switched(off(

the(folder(

1.(Narrow(gap(with(setting(knob(

(

2.(Clear(paper(jam.(To(restart(the(

machine,(it(has(to(be(switched(off

and(then(switched(on(again.(

Folded(sheets(slide(

one(inside(the(other(

Gap(betw

een(ejector(roller(and(

holdDdown(rollers(too(wide(or(

too(short(

Correct(the(holdDdown(wheel(

distance(

Sheets(jam(between(

ejector(roller(and(

holdDdown(rollers(

1.(Gap(between(ejector(spindles(

and(holdDdown(rollers(too(

short(

2.(Ejector(rollers(not(evenly(

spaced(over(sheet(width(

(

3.(Ejector(rollers(worn(

1.(Correct(the(holdDdown(wheel(

distance(

(

2.(Reposition(the(rollers,(together(

with(the(scoring(wheels,(so(that(

they(will(guide(the(paper(evenly(

3.(Replace(rollers(

Sheets(not(evenly(

fanned(on(delivery(

1.(Paper(feed(irregular(

(

2.(Ejector(rollers(worn(or(not(

evenly(set(

3.(Delivery(belt(is(slack(

(

4.(Drive(belt(of(delivery(belt(worn(

1.(Correct(setting(((see(section(on(

“paper(feed”()(

2.(Replace(or(reposition(rollers(

(

3.(Tension(belt(or(replace(it,(if(

necessary(

4.(Fit(new(drive(belt(

Page 28

26

Loading...

Loading...