Page 1

Pub. 42004-687L2B

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 703-007 SmartSeries RTU

Enclosure

Confidentiality Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

The Model 703-007 RTU (Remote Terminal Unit) Enclosure is designed to be a component in

GAI-Tronics SmartSeries system. It mates with a SmartSeries handset or speaker amplifier to form a

SmartSeries station.

®

When connected to a SmartSeries system, the station operates as a standard multi-party Page/Party

device. In addition, it supports supervised input circuits and a relay output (supervision optional). The

following configurations are possible:

• One supervised input circuit and one supervised relay output (factory setting)

• Two supervised input circuits and no relay output

• Two supervised input circuits and one non-supervised relay output

OTE: The relay output circuit is intended for use with GAI-Tronics-approved equipment. The circuit

N

may not support supervision of equipment that is not approved by GAI-Tronics.

How to Use the Assembly/Model

This section describes applications for the Model 703-007 SmartSeries RTU Enclosure, its hardware,

software configuration, interfaces and operation.

Application

The SmartSeries Station RTU is designed for use with the SmartSeries amplifiers and handsets in a

standard multi-party Page/Party

and deactivating a single relay circuit located in the SmartSeries station enclosure. This circuit is

referred to as a relay output. Terminal block TB3, located on the rear panel of the station enclosure,

provides an interface with this relay.

®

system. It is also possible to control an external device by activating

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 2 of 12

In addition to the relay output capability, the RTU also provides two inputs. These circuits provide an

interface to dry contact switches, (e.g., a pull box) that are monitored within the SmartSeries station. The

SmartSeries station reports any switch activation to the Master Control Unit (MCU).

The relay output is factory-set to be supervised through input #1. Refer to Figure 1. However, you may

elect to use input #1 by disconnecting supervision for the relay output.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Figure 1.

Page 3

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 3 of 12

Hardware Configuration

The SmartSeries RTU allows three choices of operational configurations. Select the configuration that

best suits your need for circuits. The following table lists the RTU configurations:

Configuration Inputs Outputs

1

2

3

Configuration 1

One supervised input One supervised relay output (factory setting)

Two supervised inputs No relay output

Two supervised inputs One non-supervised relay output

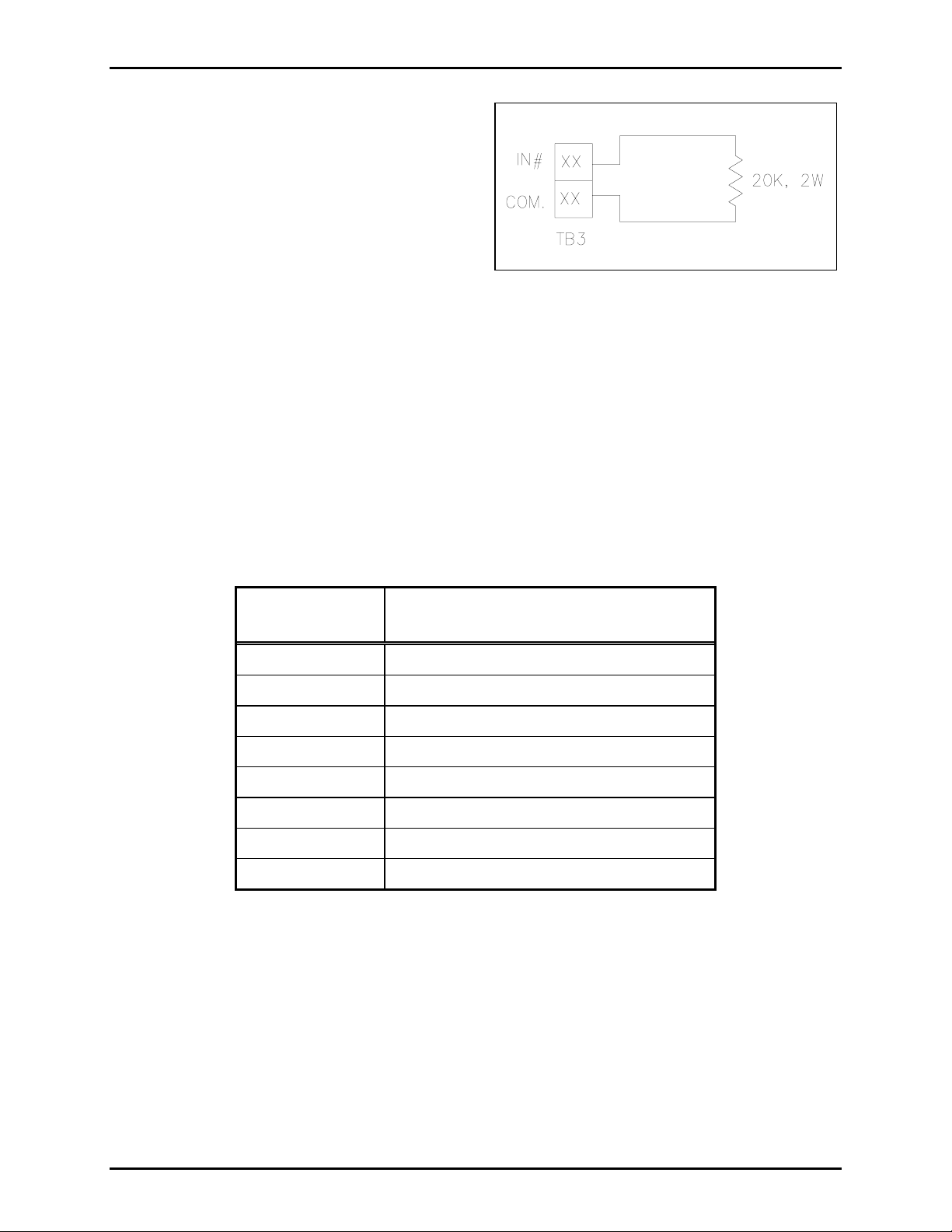

In the first configuration, the relay output is supervised to continually ensure the integrity of the external

circuit. The first input, IN 1, is used to support supervision of the relay output circuit. This wiring

method requires the use of a 20 k-ohm, 2-watt resistor placed in parallel to the relay output device (e.g. a

beacon or strobe) as shown in Figure 2.

Figure 2. Beacon or Strobe

Wire the terminating resistor as close as possible to the beacon. Supervision is performed during nonactivation of the relay output using IN 1. The second input, IN 2, remains available for detecting switch

activations. The following section describes switch wiring choices. The RTU provides 120 V ac for

beacon power on pins TB3-28, TB3-29, and TB3-30.

N

OTE: This configuration is hardwired at the factory.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 4

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 4 of 12

Configuration 2

The second configuration uses two supervised input

circuits and does not make use of the single relay

output. This configuration is accomplished by

interfacing to terminal block TB3-23 and TB3-24 for

IN 1 and TB3-25 and TB3-26 for IN 2.

The external dry contact switch, either normally open

or normally closed respectively, should be in parallel to

a 15 k-ohm resistor as shown in Figure 3.

A 5.1 k-ohm resistor should be in series to the 15

K-ohm resistor. This provides a voltage divider

network used to detect a short or open across the

external circuit’s cabling.

This configuration requires that the orange wire from

TB3-23 going to the relay output circuit be

disconnected so as not to interfere with supervised

operation.

Another method of performing supervision using

multiple switches is shown in Figure 4. This method

requires only one 20 k-ohm resistor that is placed in

parallel to multiple normally open dry contact switches

at the end of line (EOL).

Figure 4. Input Line Supervision Multiple Switch - Example

Figure 3. PLC or Switch Box

Normally Open and Normally Closed - Example

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 5

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 5 of 12

Configuration 3

In the third configuration, the relay output circuit is

non-supervised. This means the RTU can command

a system device to activate or deactivate without the

integrity of the external circuit being verified. In

this configuration, both inputs are available.

N

OTE: Unused inputs must be terminated at

terminal block TB3 with a 20 k-ohm, 2-watt resistor.

Resistors are supplied with the units. See Figure 5.

Figure 5. Unused Input

Software Configuration

The software configuration of the RTU is accomplished through the use of the System Start-up Tool

(SST). The type of RTU is dependent on the hardware configuration. Before setting up the software, it

is important to know how the inputs and outputs will be used.

Interface

Use the ribbon connector supplied with the unit to connect the SmartSeries relay circuit to the connector

at the base of the SmartSeries station. Wiring to the RTU is performed by connecting the external

circuits to the appropriate lugs on the TB3 terminal block located on the rear panel on the enclosure. The

following table shows the wiring for TB3:

Terminal Block

Lug No.

Label

TB3-23 IN 1

TB3-24 Common

TB3-25 IN 2

TB3-26 Common

TB3-27 Spare

TB3-28 Line (hot) 120 V ac 50/60 Hz, 2.5 amps max.

TB3-29 Neutral 120 V ac 50/60 Hz

TB3-30 Earth ground

The SmartSeries RTU is pre-wired from the factory to support one supervised input and one supervised

relay output. To disable the supervision of the relay output circuit by IN 1, disconnect the orange wire

going to the relay circuit card located at TB3-23. This is the only wiring modification necessary for any

of the three RTU configurations.

Operation

The supervised input and relay output functions are supported by the ADVANCE system.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 6

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 6 of 12

Installation

CAUTION

indicated on the approval listing in the “Specifications” section of this manual. Such installation

may cause a safety hazard and consequent injury or property damage.

WARNING

Do not disconnect equipment while energized.

Insure proper grounding to protective earthing.

When installing an add-on station, consult the appropriate system connection diagram. When used in

conjunction with the station installation information and cable layout guide, it should provide all the

information necessary to install additional Page/Party< stations.

Do not install this equipment in hazardous areas or areas other than those

Enclosure Placement

All GAI-Tronics Page/Party® units are wired in parallel. Good system layout design minimizes the cable

required for each installation. GAI-Tronics multi-conductor cable, designed especially for this

application, is recommended. The number, size, and color-coding of conductors are listed in the

appropriate system connection diagram.

System layout and power cable length are very important when installing Page/Party< equipment.

Although it varies for different systems, the general guideline is that the total power cable length should

not exceed one mile (5280 feet) for 120 V ac systems. The total cable length is the most important

consideration while cable length between the stations is generally not a factor.

Mounting

The Model 703-007 RTU Enclosure is not supplied with conduit or cable openings. Drill or punch these

openings using Figure 6 before mounting the enclosure. Whenever possible, do not enter an enclosure

from the top: side or bottom entry helps to prevent moisture from dripping onto the terminals or PCBAs.

The entry holes should be placed on the enclosure per Figure 6.

Plain entry holes must maintain the following:

• The plain hole shall be no larger than 0.7 mm above the major diameter of the entry thread.

• The gland or stopping plug is secured internally by a locknut, such that the gland or stopping plug

will be not dislodged by a 7 N-m impact.

• The enclosure will be maintained at IP 66 by a suitable sealing washer under the shoulder of the

cable gland or conduit hub.

The customer may drill plain entry holes in the enclosure providing they are in accordance with the

relevant code of practice and comply with the details shown in Figure 6. When mixed entries are

accommodated on a face they must be in the positions shown in this manual for the largest gland entry on

that face. For complex mixed entries, contact GAI-Tronics Technical Sales. Entries into the enclosure

must be via a suitable approved entry device. All unused entry holes must be fitted with a stopping plug

with a certification equal to that of the enclosure’s ATEX certification. The stopping plug shall be held

in place by a locknut.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 7

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 7 of 12

Figure 6. Acceptable Entry Locations

N

OTE: It is recommended that no more than two M40 glands be installed on the bottom face of the

enclosure.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 8

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 8 of 12

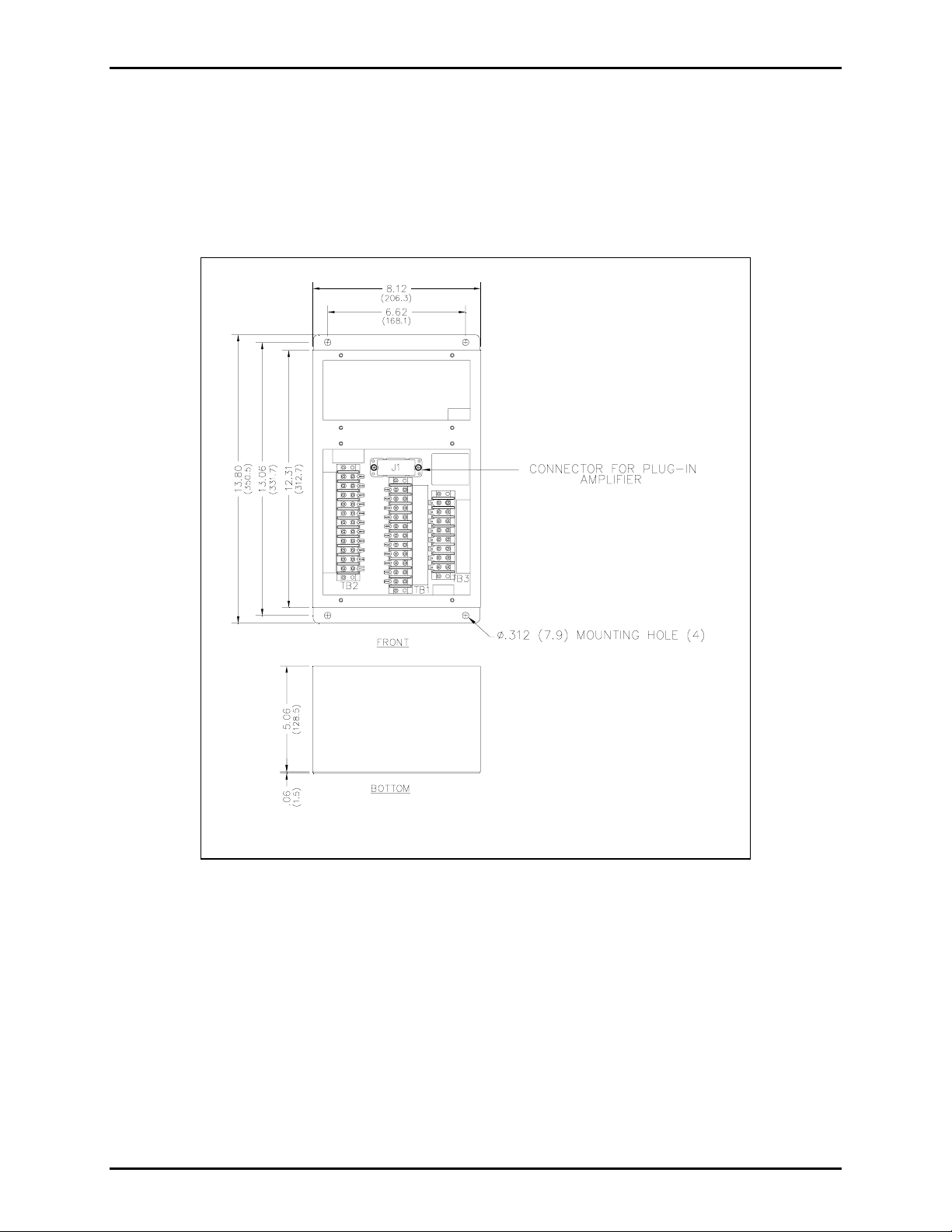

For specific mounting details, refer to Figure 7. There are four 0.312-inch diameter mounting holes in

the corners of the amplifier enclosure. The suggested mounting height for all station enclosures is 54

inches (137 cm) up to the centerline of the enclosure.

For continued IP 66 protection, torque setting for securing the amplifier to the enclosure should be 10 to

12 in-lbs. or 1.13 to 1.36 N-m.

Figure 7. Model 703-007 SmartSeries RTU Enclosure

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 9

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 9 of 12

Wiring

Refer to the appropriate system layout diagram. Follow the wire colors carefully because the colors

correspond to GAI-Tronics multi-party cable. The wires must be spade-lugged and connected carefully

and completely to the terminal block. An improper termination may result in diminished station

performance.

CAUTION

For safe operation, connect terminal 3 of TB1 to system ground. See Figure 1.

Local Muting

The appropriate system layout diagram illustrates local speaker muting when stations are completely

assembled and paging operation occurs. Normally, when the station button is pressed, the paging speaker

connected to that station is silenced (muted) to prevent acoustic feedback to the handset microphone.

However, while the handset is in use for party line conversations, the paging speaker is “live” to enable

paging calls from other stations.

To disable the mute feature, follow these instructions:

1. Locate the lugged violet wire attached to terminal point 7 (Mute) on the terminal block within the

enclosure.

2. Transfer the lugged violet wire to terminal point 8 (Page L1).

After any muting changes are made, unpack the station amplifier and install.

Mutual Muting

In the event that feedback occurs within an area and repositioning of the system speakers does not help,

mutual muting may be used to correct this problem.

Perform the following steps to mutually mute adjacent amplifiers/handsets within a zone.

1. Ensure that the purple lugged wire is connected to terminal 7 of TB1.

2. Connect terminal TB1-7 of the handset station to TB1-7 of the station within the zone that is causing

feedback. This is done by using the spare system wire (orange conductor) from within the system

cable that runs between the stations.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 10

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 10 of 12

Maintenance

Regular inspection and a good preventive maintenance program will increase the reliability of your

GAI-Tronics station. The GAI-Tronics Field Service Department can formulate a service contract suited

to your facility’s specific need for preventive maintenance.

®

In addition, the following procedure can be used to keep Page/Party

systems operating effectively.

WARNING

Before performing any of the following preventive maintenance steps,

remove all power from the station.

1. Remove the amplifier from the enclosure.

2. Visually check the interior of the enclosure for signs of contamination such as dust, condensation or

process liquid.

3. Using the No. 10440-002 Maintenance Cable, plug the amplifier into the connector in the enclosure.

Check, and if necessary, adjust the amplifier to maximize performance.

4. Reinstall the amplifier in the enclosure. Ensure that all gaskets and hardware are in place. Failure to

install the gaskets, which also act as spacers, can result in damage to the connectors on the amplifiers

and inside the enclosures and can cause system faults.

It may become necessary to re-terminate some or all of the enclosures in a system. If so, strip the wires

back to clean copper and connect only one wire to each connector to allow for easier future

troubleshooting.

To maintain system operations, we recommend keeping one SmartSeries RTU per every ten installed

units in the site maintenance inventory.

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with the return authorization number and a

purchase order number. If the equipment is under warranty, repairs will be made without charge. Please

include a written explanation of all defects to assist our technicians in their troubleshooting efforts. Call

800-492-1212 for help in identifying the Regional Service Center closest to you.

Fuse

WARNING

Do not remove fuse when energized. Replace with the same type and size fuse.

RTU fuse = T2.5A, 250V, 5×20mm, IEC60127-2

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 11

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 11 of 12

Troubleshooting

The following table lists some hints to aid technicians in troubleshooting.

Problem Solution

Station responds to polling

messages but the relay output

does not respond.

Check for trouble report from station if the output is being supervised.

The report will indicate what type of trouble has occurred. If the

message, “Supervised Output Circuit” is reported, check relay circuit

and supervision path.

Station does not respond to poll

message.

The following device fault

message received at the MCU:

“Supervised Input Circuit”

Check and replace fuse on the back panel of the enclosure as well as

fuses on the SmartSeries device.

Check that the input circuit is properly terminated.

Check the external circuit connected to either input of the RTU for a

short or open. The input circuit number is identified on the device

fault message.

Device fault message is not

received but the input circuits

Verify that the SST configuration is set up to report the alarm.

Remove and replace the SmartSeries Handset or Amplifier.

do not activate an alarm.

A device fault is not reported to

Check and replace the SmartSeries station relay circuit card.

the MCU but the output circuit

does not respond to an

activation command.

Relay output does not engage. Ensure the ribbon cable from the J3 connector to the RTU board is

attached correctly.

Feedback occurs during page

only.

1. If a speaker is close to the station, try using the muting feature in

amplifier enclosure at terminal blocks by connecting the violet

wire at terminal 8 to terminal 7. See wiring diagram and refer to

the mutual muting section of this manual.

2. Check line terminations.

3. Check location and orientation of speakers in the area. Feedback

may be caused feedback by adjacent stations.

4. Call GAI-Tronics service for details.

Cross talk occurs. One or more system cable pairs may be improperly terminated.

Visually inspect the system cable for accidental crossing of cable

pairs or grounds.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 12

Pub. 42004-687L2B

Model 703-007 SmartSeries RTU Enclosure Page 12 of 12

Specifications

Construction/finish ................................................. 16-gauge cold-rolled steel; textured gray polyurethane

Mounting............................................................................ Wall or column, four 5/16-inch mounting holes

Connections ............................................................................... Internal screw-type barrier terminal blocks

External controls........................................................................................................ Rotary selector switch

Dimensions .............................................................. 13.8 H × 8.1 W × 5.1 D inches (350 × 206 × 129 mm)

Temperature range (operating and storage)........................................ −22º F to +158º F (−30º C to +70º C)

Shipping weight .................................................................................................................... 7.5 lbs. (3.4 kg)

Approvals

Model 703-007.............................................................................................................. II 3G EEx nA IIC T6

Temperature: −30º C to 70º C

Location Zone 2

IP 66 when installed with a Model 701-305, 751-005, 701-905, or 751-905 Amplifier

NRTL listed .............................Suitable for use in hazardous locations Class I, Div. 2, Groups A, B, C, D;

Class II, Div. 2, Groups F, G;

Class III, Div. 2

when used with listed 701-305, 701-905, 751-005 or 751-905 Amplifier

Enclosure environmental rating: Type 13

CE Mark

Certificate No. DEMKO 04 ATEX 0424225X

Notified Body Id No. 0539

UL International DEMKO A/S

Lyskear 8

DK-2730 Herlev

Denmark

Replacement Parts

Contact GAI-Tronics for replacement part information.

f:\standard ioms - current release\42004 instr. manuals\42004-687l2b.doc

11/10

Page 13

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...