Page 1

Pub. 42004-200B

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Intrinsi call y-Safe Rack-Mount

Telephone System

Confidentiality Notice

This manua l is provide d sole ly as an operatio nal, installation, and ma inte nance guide and conta ins

sensitive business and t e chnical informatio n tha t is confidentia l and pr opri et ary to GAI- Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may on ly be u sed in conn e ction with the operatio n of you r GAI-Tr onics p rodu c t or

system. This manu al may not be dis clos e d in any form, in whole or in pa rt, direct ly or i ndir ectly, to a ny

third pa r ty.

General Information

The GAI-Tronics Intrinsically-Safe Series Telephones are designed to be installed in hazardous areas.

The r ack-mount co mpone nts li ste d belo w are placed in a non- haza rdous area up t o one mil e f rom t he

telephone. This limits the energy levels going to the hazardous area to conform to all of UL’s

intrinsically safe requirements. This publication contains installation, operation, and detailed

specifications for the I.S. telephone rack-mount system.

GAI-Tronics Intrinsically-Safe (I.S.) Series Rack-Mount Telephone System configurations include the

following components:

Model Description

265 Line Card

266 Power Supply

267 Subrack Assembly

268 Patch Panel

OTE: Please refer to the Ordering Information table on page 9 for information on ordering these

N

components.

CAUTION

All det ails i n t his manual must

be followed to conform to UL req uirements for intrinsic safety.

GAI-Tronics Corporation P.O. Box 1060, Readi ng, PA 19607-1060 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 2 of 13

Installation and Setup

1. Install each Model 267 Subrack into a standard 19-inch cabinet by inserting and tightening the two

screws into the holes on each side of the subrack.

OTE: This rack is designed for M6 metric screws. Addit ional hard ware wi ll be re quired if th is

N

cabinet is to be used with 10-32 screws.

If installing multiple subrack assemblies, install one Model 268 Patch Panel between each pair of

subracks. See Figure 1 for details. The Model 268 Patch Panels are installed in the same manner as

the subrack assemblies. When installing the patch panels, install the two user-supplied 25-pair

har ness assemblies to th e rear of each patch panel.

2. Install the Model 265 Line Cards into the subrack assemblies by sliding them into the card guides.

Once fully inserted (so that the front surface of the card is flush with the subrack assembly), secure it

into place by tightening the four captive screws located on the bezel of the line card. Each subrack

assembly accommodates up to seven cards. When using less than seven cards in any one subrack

assembly, we recommend installing Part No. 14758-001 Blank Front Panel Bezels, which are

available from GAI-Tronics.

3. Install the Model 266 Power Supplies. Each subrack assembly requires one power supply.

OTE: To select 220 V power, slide the switch on the top of the Model 266 Power Supply to the

N

220 V position before installation.

Fit the supply into the guide at the left end of the subrack assembly. Insert it fully so that the front

surface of the card is flush with the subrack assembly, and secure it into place by tightening the four

captive screws located on the bezel of the power supply. Access the rear of the subrack assembly,

and locate the grounding screw at the right end of the assembly. Tighten the screw into the power

supply by turning it clockwise.

4. Packed with each Model 265 Line Card is a modular telephone line cord with a connector on each

end. Connect o ne end of th is cord is to be connected to a line card, and the other end to a jack in a

patch panel. Refer to Figure 1 to clarify the general wiring configuration.

OTE: The Model 268 Patch Panel provides 24 connectors, but for this application a maximum of 14

N

will be used. Connector selection is limited only by the length of the line cord.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 3

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 3 of 13

Figure 1. Typical Mechanical Configuration for Rack Mount System - Front View

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 4

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 4 of 13

5. Wire the central office (CO) or PBX lines to a punch-down block (66) near the cabinet. Then wire

the appropriate conductors from the 25-pair patch panel harness assembly to the punch-down block.

Refer to Figure 2. Verify that the wired pairs are from the connectors used in the patch panel. This

can be verified by checking the color coding of the harness assembly wires.

6. We recommend creating a local “base station” to aid in adjusting the telephone ring pitch and to

verify the correct operation of each line card. The base station will aid in ring pitch adjustment by

allowing personnel at the cabinet to communicate to those in the field to adjust the ring pitch level.

The base sta t ion ca n a lso be connected to each diode barr ier t ermi na l st rip to check for th e corr ect

operation of that circuit. See Step 7 to assure the correct connection of the base station to a line card.

7. Install the I.S. Series Telephones and wire them back to the central cabinet. The wires will terminate

at the back of the Model 267 Subrack on terminal strips provided on the diode barriers (one terminal

strip per telephone). Follow the wiring instructions in Pub. 42004-380.

N

OTE: The wiring on this drawing must be followed to maintain intrinsic safety.

8. Plug a user-supplied power cord with a type IEC 320 connector into the socket located on the rear

right side of the subrack assembly. Be sure to select the appropriate cord for the voltage selected on

the power supply (110 V or 220 V). Connect the power cord to a power source.

9. Use the base station to assist in adjusting the ring pitch of each telephone. Several calls must be

placed from the base station to the remote telephone to complete each adjustment. When all the

telephones are properly adjusted, remove the base station, and install it at the desired location.

10. Perform any necessary troubleshooting. See the Troubleshooting section on page 6.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 5

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 5 of 13

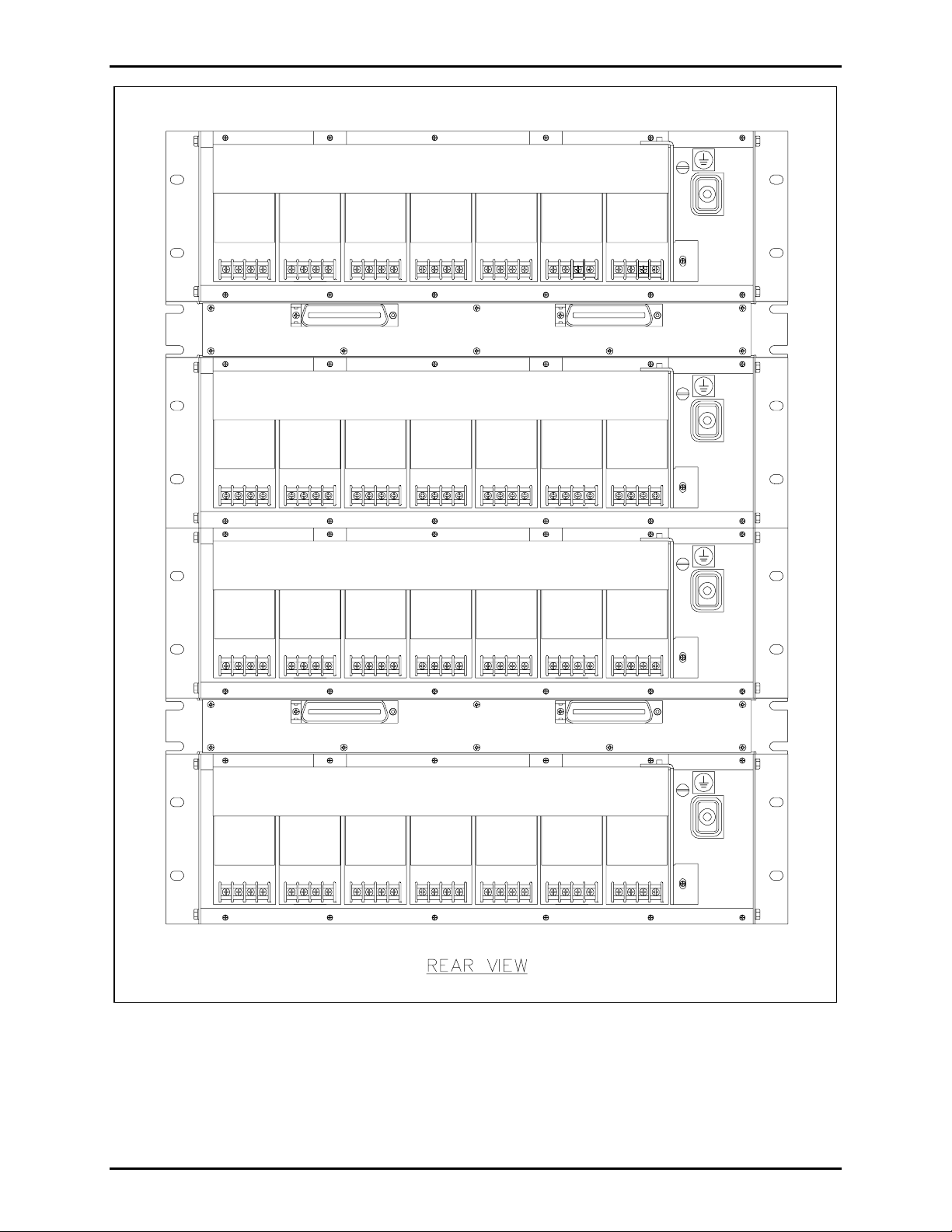

Figure 2. Typical Mechanical Configuration for Rack Mount System - Rear View

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 6

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 6 of 13

Troubl eshooting

This section inclu des two trou bles hooting c harts desi gned t o quickly p inpoint the sou rce o f problems.

N

OTE: It may be advantageous to temporarily connect an I.S. telephone panel directly to the output

terminals of the Model 267 Subrack when troubleshooting. Then, using the charts below, the cause of the

problem should be more easily determined.

Non-E quipment Rel ated Problems

Problem Solution

The I.S. phone is inactive with

no light s on the IBU when t he

phone is off-hook.

The power light is on only when

the phone is off hook.

The I.S. phone has no dial tone.

1. Check the ac power to the Model 266 Power Supply.

2. Check the ac fuse F1 at the Model 266 Power Supply.

Check for I.S. telephone wiring open.

1. If there is a problem with the ac power to the

Model 266 Power Supply, the IBU lights will be lit in the

following pattern: O =

ISLOOP O LOCK

On, P = Off

P

HOOK

P

TELCO

P

2. If the I.S. telephone has a wiring short, the IBU lights will be lit

in the following pattern: O =

On, P = Off

(Short may be between conductors, or either/both conductor(s) to

ground/shield.)

ISLOOP O LOCK

P

HOOK P TELCO

P

3. If the TELCO line has an open, the IBU lights will be lit in the

following pattern: O =

ISLOOP O LOCK

O

HOOK O TELCO

P

The lights on the IBU flash

randomly.

The I.S. telephone has an intermittent wiring short. The short may be

between the conductors or either/both conductor(s) to ground/shield.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

On, P = Off

Page 7

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 7 of 13

Equipm ent-rel ated Probl ems

Problem Solution

There is no incoming ring tone. 1. Check the I.S. telephone panel.

2. Check the Model 265 Line Card.

There i s no receiver audio, no

1. Check the I.S. telephone panel.

side tone, and no touch tones

when pressed.

2. Check the Model 265 Line Card.

3. Check for an ope n or s hort in the connec tin g c abl e.

Ca nnot dial out , but c an hear

touch tones when pressed.

1. Check the Model 265 Line Card.

2. Check the TELCO line c onnec tion. It may be bad or there ma y

be no connection.

I.S. telephone is inactive. 1. Check the I.S. telephone panel.

2. Check the Model 265 Line Card.

3. Check for an ope n or s hort in the connec tin g c abl e.

No power lights are on. Check the Model 266 Power supply.

CAUTION

Any field repa irs on the intrinsically-safe des ign of the phone are st rictly prohi b ited. Any such

cha nge will void ALL hazardous app rovals . Please co nta c t the GAI - Tr onics F ield Service Department a t

800-492-1212 inside the USA or 610-777-1374 outside the USA for the Regional Service Center closest

to you.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 8

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 8 of 13

Lightning Protecti on

Telephone lines are susceptible to lightning strikes and must be properly protected and maintained. Onpremise line protection is usually provided at the building entrance by the responsible telephone company

when it is installed. T his protection is o f ten n e g lected after installatio n.

Degradation of conventional protection, such as carbon blocks or gas discharge types, will occur with

each lightni ng strike. To ensure sa fe operat ion, p rotec tive e lemen ts should be replaced freque ntly and

checked for proper connection and grounding. Gas discharge types are by far the most robust, costeffective mea ns of protectio n.

The registered I.S. equipment meets all isolation and safety requirements of FCC, Part 68 and UL 913.

However, lightning strikes are not predictable or considered to be a condition of fault likely to occur in

practice as defined by the guidelines for intrinsic safety. Therefore, it is imperative that the user employ

and ma inta in a proper lightning p rotec tion sche me. Thi s is tr ue for a ll haza rdous area equipment and all

telecommunications equipment subject to lightning.

Figure 3. Example of L ightnin g Protection D esign

Proper grounding is the most critical consideration in any intrinsically-safe system. Unsafe energy levels

are limited by the protective diode barrier with reference to the I.S. ground terminals.

It is imperative

to make good mechanical and electrical ground connections to maintain intrinsic safety

(for low impedance ground connections, less than 1 ohm required; less than 0.1 ohms is recommended).

Use the latest National Electrical Code (NEC) published by NFPA to ensure that proper ground

connections are made.

References: UL 913 NEC, Article 504

N

OTE: Do not connect the intrinsically-safe ground directly to the ac power ground terminals.

WARNING

Installation must be in accordance with GAI-Tronics Pub. 42004-380 to ensure intrinsic safety.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 9

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 9 of 13

Ordering Information

Quantity of

Stations Desired

1-7 1-7 (same as

Number of Model

265 Line Cards

Required

Number of Model

266 Powe r

Supplies Requi red

1 1 1

Number of

Model 267 Card

Cage s Required

quantit y of st a t ions )

8-14 8-14 (same as

2 2 1

quantit y of st a t ions )

15-21 15-21 (same as

3 3 2

quantit y of st a t ions )

22-28 22-28 (same as

4 4 2

quantit y of st a t ions )

29-35 29-35 (same as

5 5 3

quantit y of st a t ions )

For 36 or more tele phones, follow the s ame r atio as demo nstr ated above.

Number of Model

268 Patch Panels

Required

Service Information

Per UL requirement, no replacement parts are available for this unit. Please contact the GAI-Tronics

Field Service Department at 800-492-1212 inside the USA or 610-777-1374 outside the USA for the

Regi onal Serv ice Ce nter c l osest to you.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 10

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 10 of 13

User Instructions

This equipment complies with Part 68 of the FCC Rules. On the side of the Model 265 Line Card is a

label that contains, among other information, the FCC Registration Number and Ringer Equivalence

Number (REN) for this equipment. If requested, this information must be provided to the telephone

company.

This equipment uses the RJ11C USOC ja ck.

The REN is used to determine the quantity of devices that may be connected to the telephone line.

Excessive RENS on the telephone line may result in the devices not ringing in response to an incoming

call. In most, but not all areas, the sum of the RENS should not exceed five (5.0). To be certain of the

number of devices that may be connected to the line, contact the telephone company to find out the

maximum REN for the calling area.

If this equipment causes harm to the telephone network, the telephone company will notify you in

advance. If advance notice is not practical, the telephone company will notify the customer as soon as

possible. Also, you will be advised of your right to file a complaint with the FCC if you believe it is

necessary.

The telephone company may mak e chan g es in it s fac i lities, e quip m e nt, opera tions, or p rocedu res that

could affect the operation of the equipment. If this happens, the telephone company will provide advance

notice for you to make the necessary modifications to maintain uninterrupted service.

If trouble is experienced with this equipment please contact GAI-Tronics at 800-492-1212 (if calling from

outside Pennsylvania), or 610-777-1374 (within Pennsylvania and outside the US) for repair and/or

warranty information. If the trouble is causing harm to the telephone network, the telephone company

may request you remove the equipment until the problem is resolved.

This equipment cannot be used on telephone company-provided coin service. Connection to party-line

service i s subj ect to sta te tari ffs.

When making test calls to emergency numbers:

• Remain on the line and briefly explain to the dispatcher the reason for the call.

• Perform such a ct ivit i es i n the off-peak hours, s u ch as ear ly mornin g or la t e ev enings.

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 11

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 11 of 13

Specification s

General/Environmental

Location (rack-mounted IBU)..................................................... Ordinary (non-classified) indoor/outdoor

FCC Registration Number .................................................................................... ADGUSA-65066-TE-E

Ringer Equivalence Number (REN)................................................................................................... 0.4B

Operating temperatur e ra n ge

I.S. Series Telephones......................................................... -40° F to +140° F (-40° C to +60° C)

Rack equipment..................................................................... +32° F to +104° F (0° C to +40° C)

Relative humidity.................................................................................. 95% (non-condensing) maximum

Maximum safe wiring distance between IBU and I.S. Series telephon es

Standard wire types......................................................................................................................... 1 mile

Using GTC 60059-001 conductor............................................................................................... 1.5 miles

Using GTC 60021-301 conductor............................................................................................... 1.5 miles

Wiring

Construction.......................................................................................................................... Twiste d pair

Type.......................................................................................................................................... Shielded*

Conductor size (minimum)......................................................................................................... 24 AWG

Wiring loop resistance (maximum)............................................................................................ 275 ohms

Wiring capacitance (maximum).................................................................................................. 0.316 uF

*Shielded cable is required where multiple I.S. telephone wires are routed together.

Shipping weight

Model 265 Line Card.................................................................................................... 2.88 lbs. (1.31 kg)

Model 266 Power Supply ............................................................................................. 4.88 lbs. (2.22 kg)

Model 267 Subrack Assembly...................................................................................... 8.42 lbs. (3.83 kg)

Model 268 Patch Panel................................................................................................. 1.56 lbs. (0.71 kg)

Dimensions

Model 265 Line Card....................................... 5.06 H × 2 W × 12.9 D; inches (128.6 × 50.8 × 327.6 mm)

Model 266 Power Supply ............................. 5.06 H × 3.8 W x 12.1 D; inches (128.6 × 96.5 × 307.3 mm)

Model 267 Subrack Assembly..................... 5.25 H × 19 W × 14.5 D; inches (133.3 × 482.6 × 368.3 mm)

Model 268 Patch Panel........................... 1.75 H × 19.75 W × 1.25 D; inches (44.5 × 501.65 × 31.75 mm)

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 12

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 12 of 13

Electrical /Acoustical

Rack-mounted IBU consisting of......................................................... One Model 267 Subrack Assembly

One Model 266 Power Supply

Up to seven Model 265 Line Cards

Telephone Network Interface

2-wire........................................................................................... BELL PUB 61100 Compatible

4-wire............................................................................... See the 4-Wire Option Interface below

AC power input

Voltage (selectable) ....................................................................................... 90-130V/180-240V

Frequency...................................................................................................................... 47-63 Hz

Current ....................................................................................................... 0.5 amps (maximum)

Ringer pitch adjust ................................................................................................. 1 kHz-8 kHz (nominal

Intrinsically-Safe Interface

Voltage (maximum).............................................................................................................. 18 V

Resistance (minimum).................................................................................................... 66 ohms

Current Limited (maximum) ............................................................................................ 136 mA

IBU Indicators

I.S. Loop Current.......................................................................................................... I.S. LOOP (GRN)

I.S. Lock Detect............................................................................................................ I.S. LOCK (GRN)

Telephone Line Loop Current.............................................................................................T ELCO (YEL)

Hook...................................................................................................................................HOOK (YEL)

Model 265 4-Wire Option Interface

Receive (TB2-1, 2).............................................................................................................. DRY (No dc)

Signal Level................................................................................................................... 0 dBm (nominal)

+3 dBm (maximum)

Transmit (TB2-3, 4)..........................................................................................................................WET

DC loop current ................................................................................................... 20 mA - 70 mA

Signal level........................................................................................................ 0 dBm (nominal)

Ring voltage input.............................................................................................. 40 V - 150 Vrms

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 13

Pub. 42004-200B

Intrinsically Safe Rack-Mount Telephone System Page: 13 of 13

I.S. Series Telephones

Electrical specifications (nominal)......................................................................................... 12 V, 12 mA

Ringer performance (typical)............................................................................................98 dB @ 10 feet

Frequency (adjustable at IBU)................................................................. 1 kHz - 8 kHz (nominal)

Ring signal loss (18 AWG)...........................................................................................-4 dB/mile

Signaling........................................................................................................................................ DTMF

Transmission path (2-conductor) ..............................................................................................Full du plex

Microphone...................................................................................................................... Noise-canceling

Earpiece................................................................................................................Hearing aid compatible

Output (0 dBm @ IBU TELCO Line) ..........................................................105 dB SPL @ 1 kHz

Audio signal loss (18 AWG)......................................................................................-1.3 dB/mile

N

OTE: Must be connected in accordance with GAI-Tronics publication 42004-380.

Approvals

When connected according to GAI-Tronics Pub. 42004-380:

......................................................................................................Class I, Div. 1, Groups A, B, C, and D;

Class II, Div. 1, Groups E, F, a nd G; Clas s III;

\\s_eng\gtc proddoc s \st andard iom s - current release\42004 instr. manuals \ 42004-200b. doc

02/06

Page 14

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...