Page 1

Pub. 42004-600L2C

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 12580-001

Amplifier Distribution/Monitor Module

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

Introduction

This document discusses installing, operating, and maintaining the 12580-001 Amplifier Distribution/

Monitor Module (ADM), which provides the following features:

• Distributes audio to central amplifiers

• Verifies the integrity of speaker loops

• Monitors amplifier failure contacts

• Communicates with the Master Control Unit

How to Use the Assembly

This section describes applications for the Amplifier Distribution/Monitor Module, its hardware

configuration, block diagram, interfaces, and installation. Because this assembly is controlled by a 69254

Series or 69440 Series Master Control Unit (MCU) and is set up in the MCU’s configuration software,

there are no operating controls or software configuration for the ADM. Refer to the MCU Configuration

details in your system manual for all operation information.

Application

The Amplifier Distribution/Monitor Module is used to distribute audio to up to six central amplifiers. It

is also used to verify the integrity of the related speaker loops and to monitor up to six amplifier failure

contacts, reporting their status to the MCU. The ADM’s speaker loop inputs allow it to detect various

fault conditions on any of up to six speaker loops. These fault conditions include ground faults, cable

breaks*, wire-to-wire short circuits*, and amplifier failures.

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 2 of 17

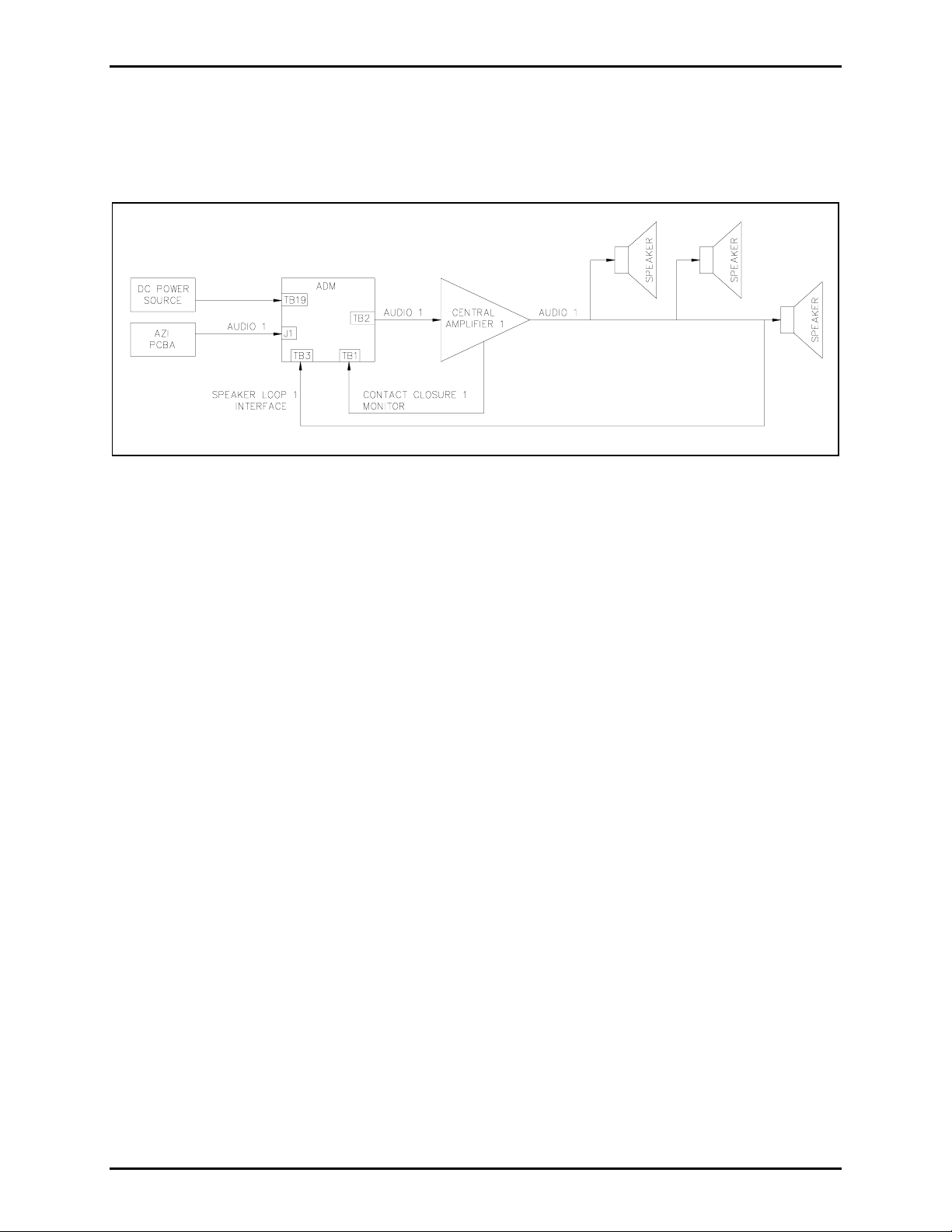

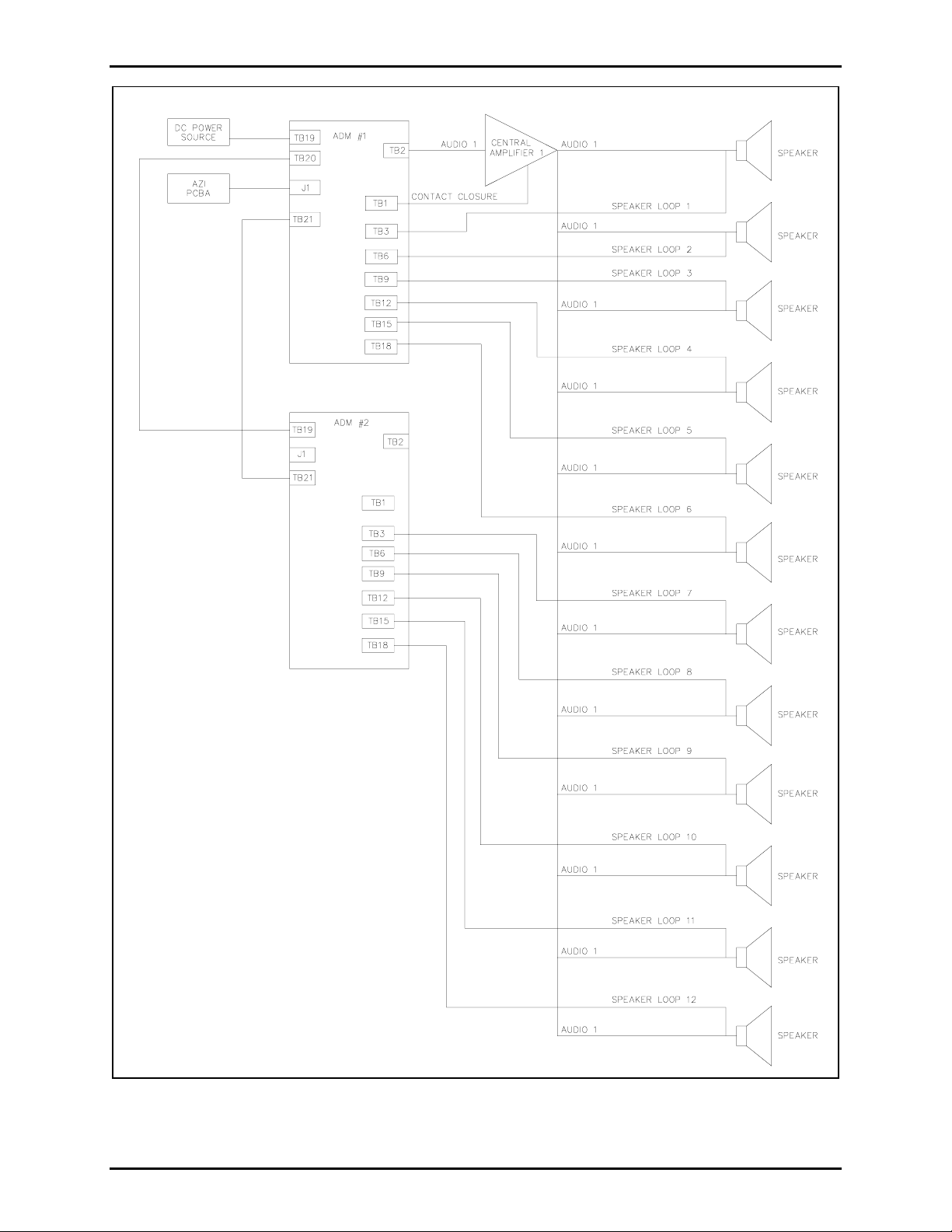

The ADM’s contact closure inputs are typically used to monitor the amplifier failure contacts of the

central amplifiers to determine amplifier failure. Figure 1 illustrates a typical application for one paging

zone. Figure 2 illustrates an alternate application for one central amplifier and twelve speaker loops.

OTE: (*) indicates that fault detection occurs only while the associated amplifier is not in use.

N

Figure 1. Single Page Zone - Typical Application

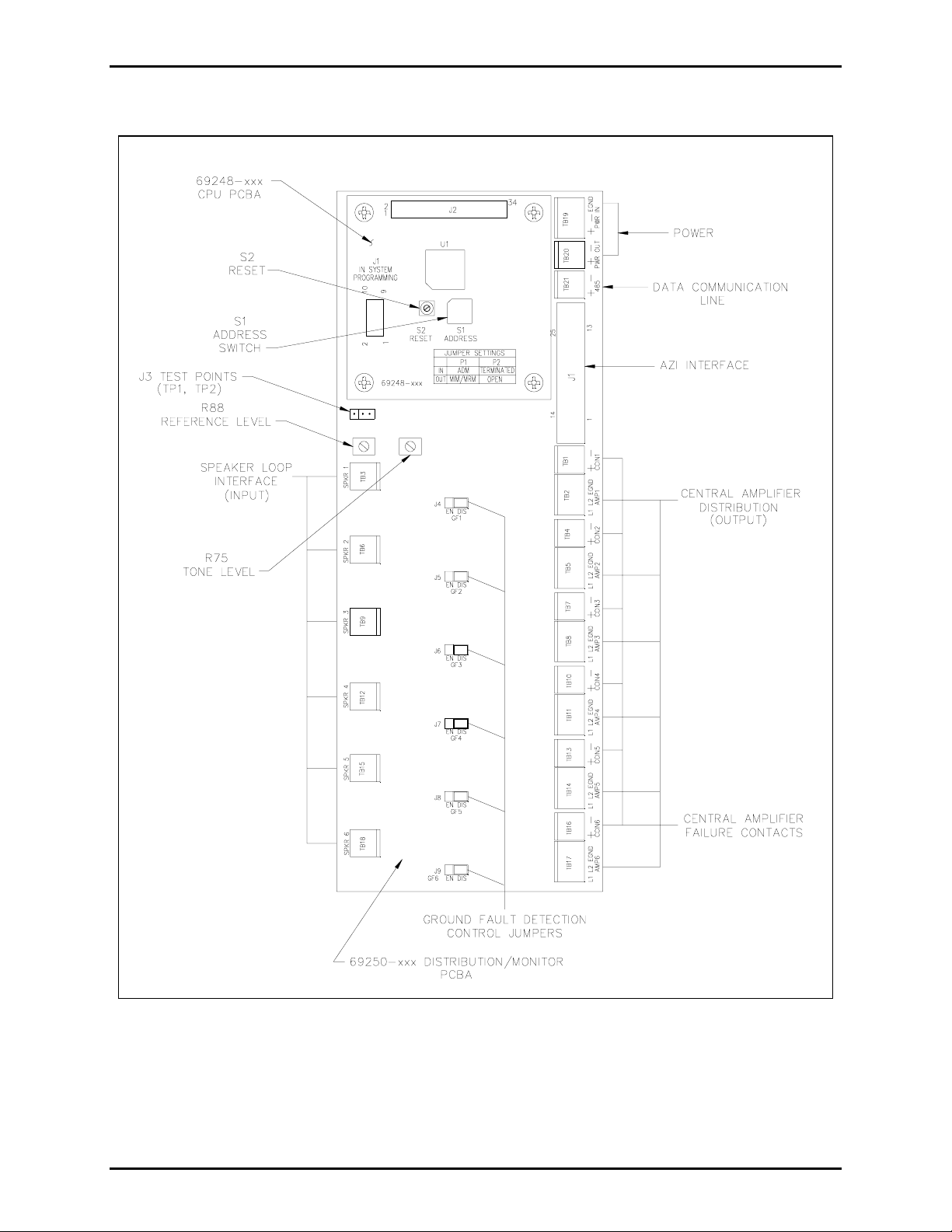

The ADM is comprised of two subassemblies: the 69250-xxx Distribution/Monitor printed circuit board

assembly (PCBA) and the 69248-xxx Central Processing Unit (CPU) PCBA. The ADM mounts in a

Snaptrack™, a grooved plastic channel that allows a PCBA to securely ‘snap’ into place. The

Snaptrack™ provides flexible installation because it may be installed in an equipment rack wherever it is

convenient.

The ADM communicates with the MCU via the CPU PCBA over a bi-directional RS-485 link. The CPU

PCBA monitors the status of the module’s contact clo sure inputs and speaker loop inputs and reports

them to the MCU via this communication link.

The MCU periodically interrogates the ADM to determine its status. The MCU identifies a particular

module on this RS-485 link by its address. (The ADM’s module address is set by rotary hex switch S1,

located on the CPU PCBA.)

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 3

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 3 of 17

Figure 2. Single Amplifier with 12 Speaker Loops - Alternate Application

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 4

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 4 of 17

Hardware Configuration

Figure 3. Hardware Configuration

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 5

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 5 of 17

Interfaces

The Model 12580-001 Amplifier Distribution/Monitor Module provides a number of external interfaces,

all of which are located on the Distribution/Monitor PCBA.

Power

The ADM uses 3-position terminal block TB19 (labeled PWR

IN) to deliver dc power (12 V dc) to the

PCBAs and to provide an earth ground connection for them. Two-position terminal block TB20 (labe led

OUT) brings out the dc power from TB19, allowing additional Snaptrack™ modules to receive

PWR

power. The pinout for TB19

WARNING

is shown in Table 1 and the pinout for TB20 is shown in Table 2.

Incorrect connection of the power source to TB19 or TB20 may cause damage to this assembly.

Table 1. Power Input - TB19 Pinout

Pin No. Function Description

1

2

3

PWR

PWR

PWR

IN +

IN −

IN EGND

Connects to the positive lead of the power supply (input)

Connects to the negative (ground) lead of the power supply (input)

Connects to earth ground (input)

Table 2. Power Output - TB20 Pinout

Pin No. Function Description

1

PWR

OUT +

Connects the positive lead of the power supply to other Snaptrack™

modules (output)

2

PWR

OUT −

Connects the negative (ground) lead of the power supply to other

Snaptrack™ modules (output)

AZI Interface

DB-25 style connector J1 interfaces the Amplifier Zone Interface (AZI) PCBA to the ADM. J1 connects

the six central amplifier input lines, the RS-485 data communication line, and earth ground of the AZI

PCBA to the ADM. The six central amplifier input lines are connected to the following 3-position

terminal blocks: TB2, TB5, TB8, TB11, TB14, and TB17.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 6

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 6 of 17

The RS-485 data communications line is connected to J2 (to interface with the CPU PCBA) and to 2position terminal block, TB21. Earth ground is connected to TB19 pin 3. The pinout for AZI interface

connector J1 is shown in Table 3.

Table 3. AZI Interface J1 Pinout

Pin

No. Function

RS485+

1

Passes the positive leg of the

Description

Pin

No. Function

RS485−

14

RS-485 interface from the AZI

PCBA to TB21 (

485 +) (I/O)

2 Not used 15 Not used

3 Not used 16 Not used

4 Not used 17 Not used

5

AMP1_L1

Passes one leg of audio input

18

AMP1_L2

for central amplifier 1 from the

AZI PCBA to TB2 (

AMP1 L1)

(input)

6

AMP2_L1

Passes one leg of audio input

19

AMP2_L2

for central amplifier 2 from the

AZI PCBA to TB5 (

AMP2 L1)

(input)

7

AMP3_L1

Passes one leg of audio input

20

AMP3_L2

for central amplifier 3 from the

AZI PCBA to TB8 (

AMP3 L1)

(input)

Description

Passes the negative leg of the

RS-485 interface from the

AZI PCBA to TB21 (

485 −)

(I/O)

Passes the other leg of audio

input for central amplifier 1

from the AZI PCBA to TB2

AMP1 L2) (input)

(

Passes the other leg of audio

input for central amplifier 2

from the AZI PCBA to TB5

(AMP2 L2) (input)

Passes the other leg of audio

input for central amplifier 3

from the AZI PCBA to TB8

AMP3 L2) (input)

(

8

9

10

AMP4_L1

AMP5_L1

AMP6_L1

Passes one leg of audio input

for central amplifier 4 from the

AZI PCBA to TB11 (

AMP4 L1)

(input)

Passes one leg of audio input

for central amplifier 5 from the

AZI PCBA to TB14 (

AMP5 L1)

(input)

Passes one leg of audio input

for central amplifier 6 from the

AZI PCBA to TB17 (

AMP6 L1)

(input)

21

22

23

AMP4_L2

AMP5_L2

AMP6_L2

Passes the other leg of audio

input for central amplifier 4

from the AZI PCBA to TB11

(AMP4 L2) (input)

Passes the other leg of audio

input for central amplifier 5

from the AZI PCBA to TB14

AMP5 L2) (input)

(

Passes the other leg of audio

input for central amplifier 6

from the AZI PCBA to TB17

AMP6 L2) (input)

(

11 not used 24 not used

12 not used 25 not used

13

EGND

Passes earth ground to the AZI

PCBA (output)

NOTE: Connector J1 of the ADM is connected to the AZI PCBA via a DB25 cable assembly. This

cable assembly is not included with the ADM and must be purchased separately.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 7

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 7 of 17

Data Communication Line

Terminal block, TB21 is provided to enable the RS-485 signal to be daisy-chained to additional

Snaptrack™ modules. The pinout for the data communications line is shown in Table 4.

Table 4. Data Communications Line - TB21 Pinout

Pin

No. Function

1

485

+

Daisy-chains the positive leg of the RS-485 interface to other Snaptrack™ modules

Description

(I/O)

2

485

−

Daisy-chains the negative leg of the RS-485 interface to other Snaptrack™ modules

(I/O)

NOTE: The conductors terminated on this terminal block should be a twisted pair.

Central Amplifier Audio Distribution

Terminal blocks TB2, TB5, TB8, TB11, TB14, and TB17are provided to connect audio from the AZI to

the six central amplifier inputs. The audio signals are differential, so a 2-connductor cable is required for

each input. An additional termination point (EGND) has been provided for an earth ground connection.

The pinout for TB2, TB5, TB8, TB11, TB14, and TB17 is shown in Table 5.

Table 5. Central Amplifier Audio Distribution - TB2, TB5, TB8, TB11, TB14, and TB17 Pinout

Pin

No. Function

Description

1

2

3

AMP

AMP

AMP

L1

L2

EGND

Connects one leg of audio to a central amplifier’s input (output)

Connects the other leg of audio to a central amplifier’s input (output)

Connects earth ground to a central amplifier (output)

NOTE: For optimum audio quality, the conductors terminated on pins 1 and 2 of these terminal blocks

should be twisted pairs.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 8

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 8 of 17

Central Amplifier Failure Inputs

The ADM contains six 2-position terminal blocks (TB1, TB4, TB7, TB10, TB13, and TB16) to receive

central amplifier failure contacts. A normally open or normally closed dry contact closure input is

provided for each amplifier. The pinout for the central amplifier failure inputs is shown in Table 6.

Table 6. Central Amplifier Failure Inputs - TB1, TB4, TB7, TB10, TB13, and TB16 Pinouts

Pin

No. Function

1

2

CCIN

CCIN

+

−

Connects to one leg of a central amplifier’s contact closure (input)

Connects to the other leg of a central amplifier’s contact closure (input)

Description

Speaker Loop Interfaces

The ADM contains six 2-position terminal blocks (TB3, TB6, TB9, TB12, TB15, and TB18) to enable

termination of the six central am pli fier s peak er loops. The ADM monitors the speaker loops for ground

faults, cable breaks*, wire-to-wire shorts*, and amplifier failures. The pinout for TB3, TB6, TB9, TB12,

TB15, and TB18

OTES:

N

is shown in Table 7.

• (*) indicates that fault detection occurs only while the associated amplifier is not in use.

• Only one voltage type (25 V, 70 V, etc.) may be supervised at a time.

Table 7. Speaker Loop Interfaces TB3, TB6, TB9, TB12, TB15, and TB18 Pinouts

Pin

No. Function

Description

1

2

SPKR

SPKR

Connects to one leg of a central amplifier’s speaker loop (input)

Connects to the other leg of a central amplifier’s speaker loop (input)

NOTE: The conductors terminated on these terminal blocks should be twisted pairs. These connections

are not polarity-sensitive.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 9

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 9 of 17

Installation

This section contains installation instructions for the Amplifier Distribution/Monitor Module. Notify

plant personnel of a system shutdown prior to servicing the unit.

Precautions

Adhere to all warnings and all safety and operating instructions on the unit and in this manual.

WARNING

Disconnect power to the ADM and central amplifiers before installing, removing, or servicing the

module.

Do not touch bare wires.

Avoid servicing the unit during electrical storms.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 10

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 10 of 17

Hardware Configuration

Before installing a new ADM, set S1 on the CPU PCBA to the module address and set the jumper

settings (J4-J9) as shown in the system manual. Valid address settings are (5 to E). Jumper settings

(J4–J9) allow ground fault detection to be enabled or disabled. See Table 8 for the jumper setting details.

OTES:

N

• To ensure proper termination, crimp a ferrule on the end of any conductor that is to be terminated on

a terminal block. The size of the ferrule depends on the size of the conductor used and may be

obtained from suppliers such as Phoenix, Altec, or Weidmuller. The terminals accept a maximum

conductor size of No. 12 AWG and a minimum conductor size of No. 28 AWG.

• Ground fault detection can be enabled only when one speaker loop from each amplifier is being

monitored.

Table 8. Ground Fault Control Jumpers J4 through J9

Reference

Designator

J4

(GF1)

J5

(GF2)

J6

(GF3)

J7

(GF4)

J8

(GF5)

J9

(GF6)

Speaker loop 1 ground

fault detection control

Speaker loop 2 ground

fault detection control

Speaker loop 3 ground

fault detection control

Speaker loop 4 ground

fault detection control

Speaker loop 5 ground

fault detection control

Speaker loop 6 ground

fault detection control

Description

NOTE: (*) indicates the factory default setting.

Valid Settings

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

• Pins 1 and 2 (EN) shorted: enabled

• Pins 2 and 3 (DIS) shorted: disabled*

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 11

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 11 of 17

Mounting

To install the module into the Snaptrack ™, slide ei the r the right or left edge of the module into the top

groove on the track. On the opposite edge of the module, press firmly on the top and bottom corners of

the module until they snap into the groove. Carefully press from each corner toward the center and

simultaneously snap the edge firmly into place.

Power

After installing the ADM in the Snaptrack™, bring 12 V dc power from the auxiliary power supply to

(labeled PWR IN). Connect the positive leg to terminal 1 (+) and the negative or return leg to

TB19

terminal 2 (−). Connect earth ground to terminal 3 (EGND). TB20

with TB19

so that power may be distributed to additional Snaptrack™ modules.

(labeled PWR OUT) is paralleled

WARNING

Incorrect connection of the power source to TB19 or TB20 may cause damage to this assembly.

N

OTES:

• Although power may be daisy-chained between Snaptrack™ modules, the preferred method of

delivering power to these modules is to provide a dedicated cable run from the power supply to each

module.

• The auxiliary power supply is not part of the 10457 Series Card Rack Assembly nor does the card

rack assembly power supply provide power to Snaptrack™ modules. An additional power supply

must be included in the cabinet to support these modules.

• For proper operation, connect the auxiliary power supply return leg to earth ground at the auxiliary

power supply.

• The ground reference for this assembly must be identical to that of the card rack assembly.

• The ADM does not provide any current-limiting for input power. An external fuse of the Slo-Blo

variety, with the appropriate voltage and current ratings, should be provided.

®

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 12

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 12 of 17

AZI Interface

Connect a DB25 cable assembly (sold separately) from the AZI PCBA to the J1 connector of the ADM.

J1 connects the six central amplifier input lines, the RS-485 data communication line, and earth ground of

the AZI PCBA to the ADM.

Data Communication Line

Terminal block TB21 has been provided to distribute the RS-485 data communication line to additional

Snaptrack™ modules. If there are no additional Snaptrack™ modules, connect a 150-ohm, ½ watt

terminating resistor (sold separately) across TB21 of the 69250-xxx, or install a jumper across the pins of

P2 on the 69248-xxx CPU PCBA.

CAUTION

The RS-485 line is polarity-sensitive. Be sure to maintain circuit polarity throughout installation.

OTES:

N

1. The conductor terminated on TB21

should be a twisted pair.

2. Only one termination is to be applied to an RS-485 circuit - either a 150-ohm resistor across TB21, or

a jumper across the pins of P2.

Central Amplifier Audio Distribution

Connect terminal blocks TB2, TB5, TB8, TB11, TB14, and TB17

OTE: For optimum audio quality, the conductors terminated on pins 1 and 2 of TB2, TB5, TB8, TB11,

N

to the associated central amplifiers.

TB14, and TB17 should be twisted pairs.

Central Amplifier Failure Inputs

Connect the central amplifier failure contacts to the ADM at terminal block connectors TB1, TB4, TB7,

TB10, TB13, and TB16. These dry contact closures ty pically orig ina te from the associa ted cen tra l

amplifiers.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 13

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 13 of 17

Speaker Loop Return Lines

Terminate the central am plifie r speaker loops to be monitored by the ADM on connectors TB3, TB6,

TB9, TB12, TB15, and TB18. Typically, this connection is made to the last speaker on the circuit so

that the entire loop is monitored. These connections are not polarity-sensitive.

OTE: The conductors terminated on TB3, TB6, TB9, TB12, TB15, and TB18 should be twisted pairs.

N

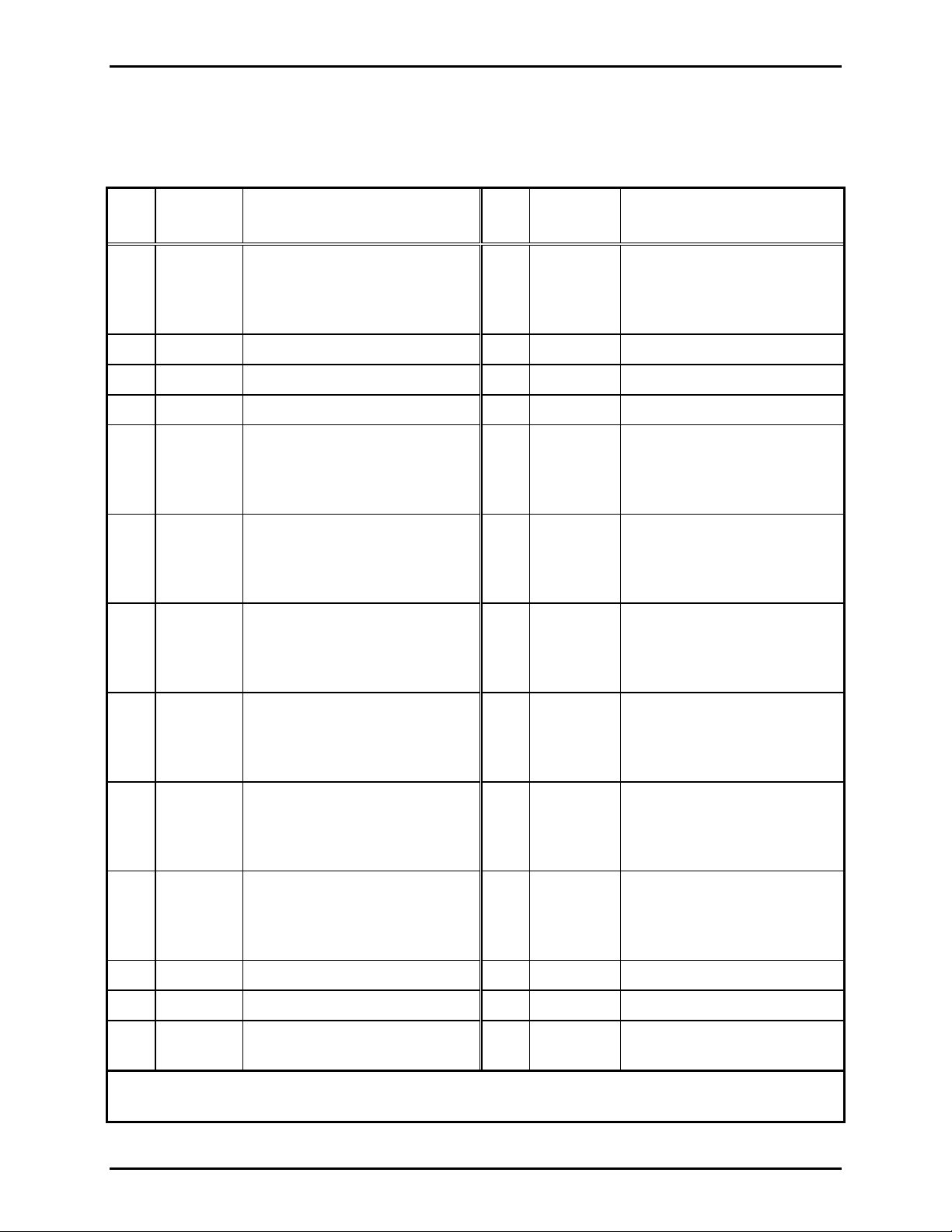

Table 9. Circuit Relationships

Function →

Ckt. No. ↓

1 TB2-1 (AMP1 L1)

2 TB5-1 (AMP2 L1)

3 TB8-1 (AMP3 L1)

4 TB11-1 (AMP4 L1)

5 TB14-1 (AMP5 L1)

6 TB17-1 (AMP6 L1)

Central Amplifier

Audio Distribution

TB2-2 (AMP1

TB5-2 (AMP2

TB8-2 (AMP3

TB11-2 (AMP4

TB14-2 (AMP5

TB17-2 (AMP6

L2)

L2)

L2)

L2)

L2)

L2)

Speaker Loop

Interfaces

TB3 (SPKR

TB6 (SPKR

TB9 (SPKR

1) J4 (GF1) TB1 (CCIN1)

2) J5 (GF2) TB4 (CCIN2)

3) J6 (GF3) TB7 (CCIN3)

TB12 (SPKR

TB15 (SPKR

TB18 (SPKR

Ground Fault

Detection Control

4) J7 (GF4) TB10 (CCIN4)

5) J8 (GF5) TB13 (CCIN5)

6) J9 (GF6) TB16 (CCIN6)

Central Amplifier

Failure Contact

Table 9 shows the relationship between the connectors and headers for each of the six circuits the ADM

supports. It includes the component’s desig na tion and the labe l prin ted on the Distribu ti on/ Mon ito r

PCBA, where applicable.

For example: audio for circuit 1’s am plifier input is passed from the AZI PCBA to terminal block TB2

(labeled AMP1

SPKR

1) and it includes ground fault detection control via header J4 (l abe led GF1). The related contact

closure input is via TB1

L1 and AMP1 L2). The speaker loop return line for this circuit is via TB3 (la bel ed

(labeled CCIN1).

After all terminations have been made, apply power to the equipment, and adjust referenc e lev el

tone level

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

R75 as described in the “Maintenance” section.

R88 and

Page 14

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 14 of 17

How to Diagnose Assembly Faults

Table 10 describes possible solutions for some common problems.

Table 10. Fault Diagnosis

Problem Possible Solution

General malfunction

Ground fault detector does

not respond to ground

faults on one or more

speaker loop interfaces

• Verify that power is properly connected to TB19.

• Verify proper polarity and dc voltage range (+9 to +15 V dc) at

TB19 (PWR

IN).

• Verify that the address (S1) matches the system configuration and

the unit is enabled.

• Verify that all Snaptrack™ modules are set to a unique address.

• Verify the power supply negative terminal is connected to earth

ground.

• Verify the proper polarity of the RS-485 data line for all Snaptrack™

modules connected to this unit.

• Verify that the cable assembly is properly connected between the

ADM (on J1) and the AZI PCBA.

• Verify that the CPU PCBA is properly seated on the

Distribution/Monitor PCBA.

• Verify that the ground fault detection control header for the

corresponding speaker loop interface (refer to Table 9) is set to the

enable position (EN).

• Verify the ground fault detection is enabled in the system

configuration.

• Call for service.

Supervisory tone detector

does not respond to tone on

one or more speaker loop

• Check the input and output cabling between the central amplifier and

the ADM.

• Verify that the central am plif ier is op erat iona l.

interfaces

• Check the Tone Level

adjustment.

• Verify the speaker loop supervision is enabled in the system

configuration.

• Call for service.

Central amplifier fa ilu re

contacts are not reported.

• Check cabling between the central amplifier and the ADM.

• Verify the amplifier failure contacts are enabled in the system

configuration.

• Call for service.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

R75, and Reference Level, R88 for proper

Page 15

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 15 of 17

How to Maintain the Assembly

This section describes maintenance for the Amplifier Distribution/Monitor Module and lists its

specifications and replacement parts.

Maintenance

WARNING

Disconnect power to the ADM and central amplifiers before servicing.

1. Inspect and replace frayed or cracked wiring.

2. Secure/replace loose wires and spade terminals.

3. Remove corrosion from terminals.

Adjustments

The ADM contains two adjustable controls; a Reference Level adjustment, and a Tone Level adjustment.

• The Reference Level adjustment,

R88, sets a reference point (trip point). The Tone Level must exceed

the reference level to enable detection of the Superv is o ry Tone.

• The Tone Level Adjustment,

R75, controls the Supervisory Tone signal level applied to the detector.

These adjustments are set at the factory for a 70.7 V central amplifier system. Additional adjustments

may be required during installation to meet the requirements of your system. Use a straight blade

screwdriver and a dc voltmeter to make adjustments.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 16

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 16 of 17

Reference Level Adjustmen t

1. Set the dc voltmeter to the 20 V scale.

2. Connect the dc voltmeter between (J10 pin 2) ground and test point 2 (TP2-J10 pin 3).

3. Adjust the

R88 Reference Level to one of the following set points:

Speaker Loop

Input Voltage

Reference Level

Setting

Tone Level

Setting

10 V 50 mV 200 mV or higher

25 V 350 mV 500 mV or higher

70.7 V 1.85 V factory setting 2.0 V or higher

100 V 2.35 V 2.5 V or higher

141 V 2.35 V 2.5 V or higher

Tone Level Adjustment

1. Set the dc voltmeter to the 20 V scale.

2. Connect the dc voltmeter between ground (J10 pin 2) and test point 1 (TP1-J10 pin 1).

3. While the Supervisory Tone is active (active approximately every 90 seconds), adjust

R75 Tone

Level until the dc voltage exceeds the Reference Level by at least 150 mV dc (factory setting), or

rotate

R75 fully clockwise.

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 17

Pub. 42004-600L2C

Model 12580-001 Amplifier Distribution/Monitor Module Page: 17 of 17

Specification s

Electrical

Power requirements ............................................................................... +9 to +15 V dc (+12 V dc nominal)

Current draw.....................................................................48 mA (min.), 70 mA (nominal), 132 mA (max.)

Input/output.......................................................................................................................................Power in

Power out

RS-485

Six audio outputs (for use with external amplifiers)

Six contact closure inputs

Six speaker loop interfaces (for fault detection)

RS-485 termination.............................................................................On board when P2 jumper is installed

Speaker loop ground fault detection...............................................................Less than 5 kilohms to ground

Supervisory tone detect ion sens itivity ................. 10 V

Speaker loop interface maximum voltage................................................................................ 141 V

Speaker loop input impedance.................................................................................20 kilohms min. (1 kHz)

Contact closure on-resistance....................................................................................................10 ohms max.

min. @ speaker loop interface (fin = 19.394 kHz)

RMS

RMS

max.

Terminals

Minimum conductor size..........................................................................................No. 28 AWG (0.5 mm

Maximum conductor size..........................................................................................No. 12 AWG (3.0 mm

2

2

Environmental

Temperature range (operating/storage).................................................. +32° F to +122° F (0° C to +50° C)

Humidity............................................................................95% non-condensing relative humidity (+50° C)

Mechanical

Unit dimensions........................................................4.0 H × 10.5 W × 1.50 D inches (102 × 267 × 38 mm)

Unit weight.......................................................................................................................1.0 lb. (454 g) max.

Approval

CE Mark

Replac ement Parts

Model Number Description

69248-xxx CPU PCBA

)

)

69250-xxx Distribution/Monitor PCBA

f:\standard ioms - current release\42004 instr. manuals\42004-600l2c.doc

10/11

Page 18

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...