Page 1

Pub. 42004-716L2C

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 12579-003

Monitored Relay Module (MRM)

Confidentiality Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains sensitive

business and technical information that is confidential and proprietary to GAI-Tronics. GAI-Tronics

retains all intellectual property and other rights in or to the information contained herein, and such

information may only be used in connection with the operation of your GAI-Tronics product or system.

This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any third party.

How to Use the Assembly/Model

Application

The Model 12579-003 Monitored Relay Module (MRM) is a Snaptrack module designed for use in the

SmartSeries systems. GAI-Tronics uses the MRM to provide a maximum of eight independently

controlled relay-contact outputs. Each of the eight relay-contact outputs has an associated LED to

indicate its current status. These relay-contact outputs are typically used to switch power to signaling

devices, such as beacons, on command from the 69254 Series or 69440 Series Master Control Unit

(MCU).

The MRM also provides the capability of supervising the cable runs to these signaling devices for such

abnormal conditions as open-circuit conditions, ground faults, and wire-to-wire short circuit conditions.

In addition, if fewer than eight relay-contact outputs are needed for a particular application, then the

MRM may also be used to receive inputs from field devices. The MRM is comprised of three main

components: the 69613-001Central Processing Unit (CPU) printed circuit board assembly (PCBA), the

69252-001 Power Relay Module, and the 69251-201 Monitored-In-8 PCBA.

The MRM is designed to be mounted in a Snaptrack that is installed in an enclosure. Snaptrack is a

grooved plastic channel designed to allow PCBAs to securely ‘snap’ into the groove. The Snaptrack

provides flexible installation because the track may be installed inside an enclosure wherever it is

convenient.

The MRM communicates with the MCU via the 69613-001 CPU PCBA over a FSK modem intended for

use in GAI-Tronics SmartSeries systems. This FSK link (page line) is periodically monitored by the

MCU for any interruptions in communication. The MCU uses this communication channel to control

activation/de-activation of the MRM’s relay-contact outputs. In turn, the MRM uses this communication

channel to report to the MCU any cable run fault conditions that are detected. The MCU identifies a

particular MRM on this FSK link by its module address. This module address is set by rotary hex switch

S1 and S2 of the MRM (located on the CPU PCBA.) The range of valid settings is from 05 to FE (hex).

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

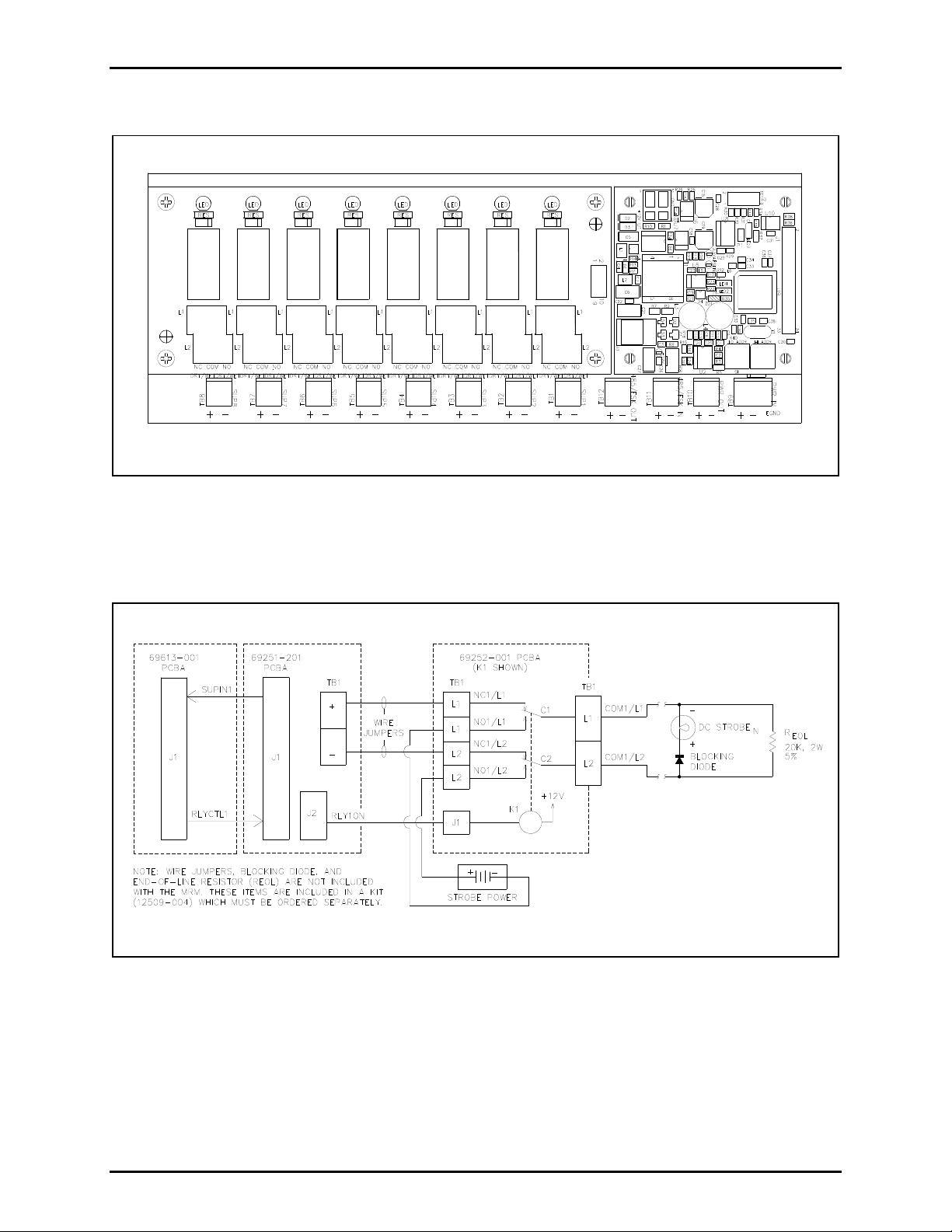

Hardware Configuration

2 of 16

Block Diagram

Figure 1. Monitored Relay Module

Figure 2. MRM Block Diagram

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 3

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

3 of 16

Interfaces

The Model 12579-003 MRM interfaces to a Page/Party® Interface (PPI) card in the ADVANCE control

cabinet via the system page line (FSK link).

Installation Safety Guidelines

Please adhere to all warnings, safety, and operating instructions on the unit and in the installation manual.

WARNING

1. Disconnect power before servicing. Do not disconnect the equipment while circuit is energized.

2. Avoid servicing the unit during electrical storms.

3. Do not touch uninsulated wires.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 4

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

4 of 16

Installation Guidelines

1. Notify plant personnel of a system shutdown prior to servicing the unit.

2. Disconnect power before installing or removing the MRM.

Mounting

To install the module into the Snaptrack, slide either the right or left edge of the module into the top

groove on the track. On the opposite side, press firmly on the top and bottom corners of the module until

they snap into the groove. Carefully press from each corner toward the center and simultaneously snap

the edges firmly into place.

Power

After the MRM is installed onto the Snaptrack, 12 V dc power is brought in from the auxiliary power

supply and terminated on TB9 (PWR IN). The positive leg is connected to TB9-1(+) and the return leg is

landed on TB9-2(−). An earth ground is connected to TB9-3 (EGND). TB9 is paralleled with TB10.

TB10 (PWR OUT) may be used to distribute power to additional Snaptrack modules.

OTES:

N

Although power may be daisy-chained between MRMs and other Snaptrack modules, the preferred

method of delivering power to these modules is by providing a dedicated cable run between each

module and the auxiliary power supply.

The auxiliary power supply return leg must be connected to earth ground for proper operation. The

physical connection should be made at the auxiliary power supply terminals.

The ground reference for this assembly must be identical to that of the enclosure.

The MRM does not contain any current-limiting for power. It is recommended that an external fuse

be provided with the appropriate voltage and current ratings. The selected fuse should be of the

slo-blo variety.

Data Communication Line

Terminal blocks TB11 and TB12 are for the page line connection (FSK data communication) from the

PPI card to additional MIM and MRM modules.

FSK Signal Gain

The FSK Signal Gain, R8, adjusts the FSK transmit signal strength. It is set at the factory and should not

be adjusted by the installer.

Relay - Contact Outputs

The MRM contains eight individually configurable relay-contact outputs, allowing it to control field

devices such as beacons. Connections with these field devices are made at connectors TB1 through TB8

of the 69252-001 Power Relay Module.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 5

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

5 of 16

Each connector corresponds to a single output (TB1 is used for output #1, TB2 is used for output #2,

etc.). If fewer than eight supervised relay-contact outputs are required, the unused outputs may be used to

receive inputs (dry contact closures or non-supervised 24 V dc wet contact closures) from field devices.

In this case, connections with these field devices are made at connectors TB1 through TB8 of the 69251201 Monitored-In-8 PCBA. Each of these outputs may be configured to operate in one of six modes.

Two of these six modes are used to control signaling devices, while the remaining four modes are used to

receive inputs (contact closures) from field devices.

Each mode requires a unique connection scheme between the external field devices and the

appropriate connector on the MRM. The connection scheme for each mode is described below.

Since the connection scheme is independent of which output is used, only Output #1 will be

discussed.

To ensure proper termination, ferrules must be crimped on the ends of all conductors that are terminated

on the terminal blocks. The size of the ferrule is dependent upon the size of the conductor used and can

be sourced from any supplier such as Phoenix, Altec or Weidmuller. The terminals accept a maximum

conductor size of No. 12 AWG and a minimum conductor size of No. 28 AWG.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 6

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

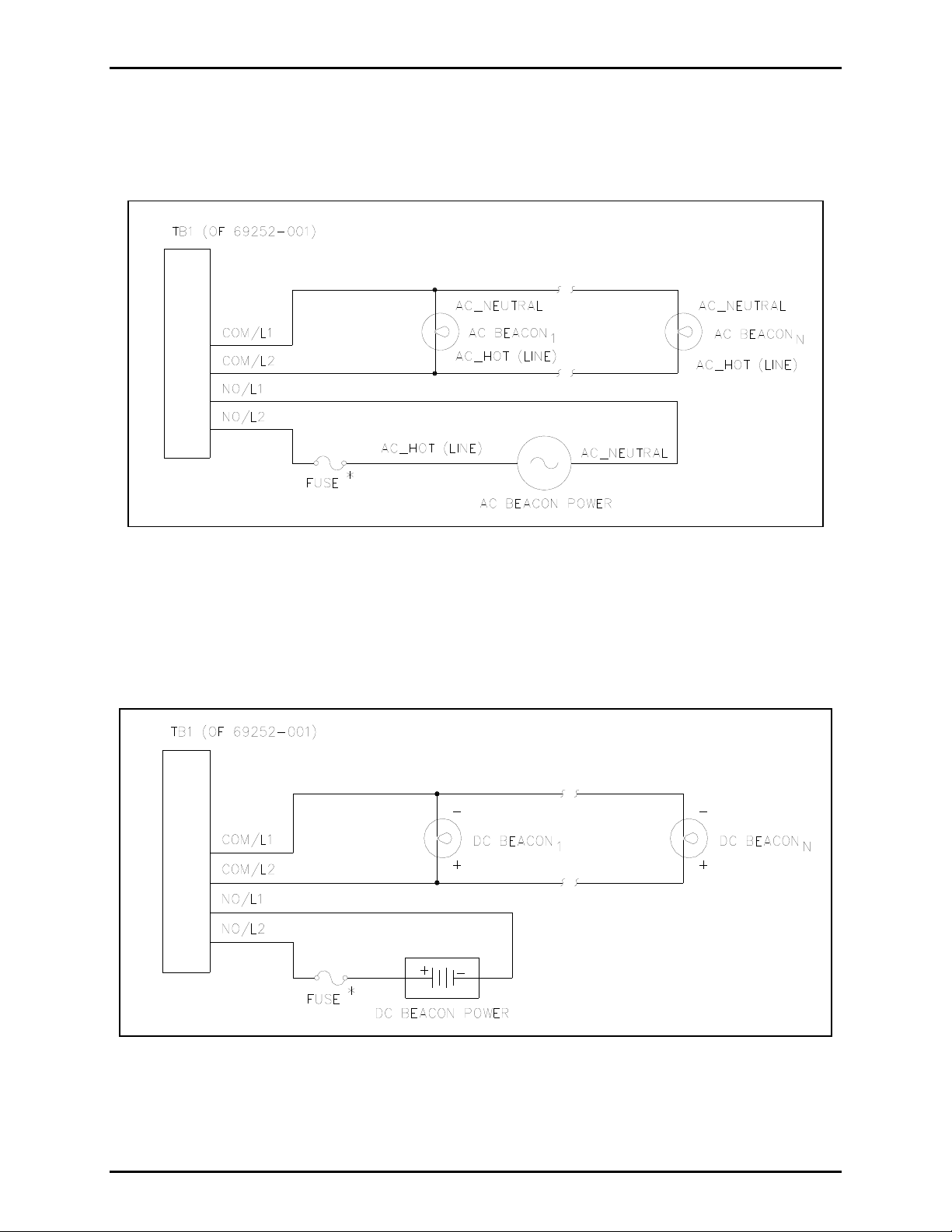

Mode 0: Deactivate Circuit

6 of 16

In Mode 0, outputs may be used to control several signaling devices by connecting/disconnecting power

to these devices. In this mode, no supervision of the loop is supported. This mode supports both ac- and

dc-powered signaling devices.

Figure 3. Deactivate Circuit - AC-Powered Beacons

Figure 3 shows the recommended wiring diagram for ac-powered signaling devices, while Figure 4 shows

the recommended wiring diagram for dc-powered signaling devices (using Output #1 as an example.)

OTE: The MRM does not contain any current-limiting for the signaling device power. It is

*N

recommended that an external fuse be provided for each output circuit with the appropriate voltage and

current ratings. The selected fuse should be of the slo-blo variety.

Figure 4. Deactivate Circuit - DC-Powered Beacons

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 7

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Mode 1: IDC Line Supervision Multiple Switch

7 of 16

In this mode any number of normally-open dry contact closures may be installed on the line. The loop is

monitored for ground faults and open circuits in Mode 1. The end-of-line device is a 20 k, 5% tolerance

resistor.

Figure 5. IDC Line Supervision Multiple Switch

OTE: The 20 k, 5% tolerance resistor is not included with the MRM. The resistor is included in a kit

N

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 8

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Mode 2: IDC Single Normally-Open (N.O.) Switch

8 of 16

In this configuration, only one normally-open dry contact closure may be installed per supervised line. In

this mode, the loop is monitored for open circuits, wire-to-wire short circuits (across + and −), and ground

faults. When the contact closure is not active (open), the loop appears as 20.1 k load (15 k in series

with 5.1 k). This appears on the input to the MIM and indicates a healthy loop. When the contact

closure is active (closed), the 15 k resistor is bypassed.

Figure 6. IDC Single Normally-Open Switch

When the contact closure is active (closed), the 15 k resistor is bypassed. In this case, output #1 only

sees a 5.1 k load. When this occurs, it indicates to the MRM that the contact closure is active. If there

is a short across L1 and L2, if either leg is grounded, or if a break occurs on either leg, the MRM indicates

that a fault has occurred.

OTE: The terminating resistors are not included with the MRM. These resistors are included in a kit

N

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 9

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Mode 3: IDC Single Normally-Closed (N.C.) Switch

9 of 16

In this configuration, only one normally-closed dry contact closure may be installed per supervised line.

In this mode, the loop is monitored for open circuits, wire-to-wire short circuits (across + and -), and

ground faults. When the contact closure is not active (closed), the 15 k is bypassed and the circuit sees

only the 5.1 k load.

Figure 7. IDC Single Normally-Closed Switch

This change is sensed by the MRM and indicates to the MRM that the contact closure is active. If there is

a short across L1 and L2, if either leg is grounded, or if a break occurs on either leg, the MRM indicates

that a fault has occurred.

OTE: The terminating resistors are not included with the MRM. These resistors are included in a kit

N

(12509-004), which must be ordered separately.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 10

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Mode 4: IAC Line Supervision

10 of 16

In Mode 4, outputs can be used to control several dc-powered signaling devices by connecting/

disconnecting power to these devices. In addition, this loop is monitored for open circuits, wire-to-wire

short circuits (across + and −), and ground faults. If any of these three conditions are detected by the

MRM, the MRM indicates that a fault has occurred. Please note that monitoring of the loop only occurs

while the loop is inactive (signaling devices are off).

Figure 8. IAC Line Supervision – DC-Powered Beacons

It is recommended that Mode 4 only be used with dc-powered signaling devices. In Mode 4, one

blocking diode must be provided for every signaling device connected to the loop. Note that some

signaling devices already include a blocking diode in the unit - in this case, no additional blocking diode

is required. The end-of-line device is a 20 k, 2-watt, 5% tolerance resistor. Please observe all polarities

as indicated in Figure 8 above.

OTE: The blocking diodes, the wire jumpers, and the 20 k, 2-watt, 5% tolerance resistor are not

N

included with the MRM. These components are included in a kit (12509-004), which must be ordered

separately.

OTE: The MRM does not contain any current-limiting for the signaling device power. It is

*N

recommended that an external fuse be provided for each output circuit with the appropriate voltage and

current ratings. The selected fuse should be of the slo-blo variety.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 11

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

11 of 16

CAUTION

If ac-powered signaling devices are being used on an output loop configured for Mode 4 (Figure 9),

observe the following limitations necessary for reliable operation for the loop monitoring feature:

The dc-resistance measured across the loop (with both end-of-line device and the MRM

removed from the loop) must be at least 100 k

Do NOT use blocking diodes in this loop.

Figure 9. IAC Line Supervision – AC-Powered Beacons

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 12

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Mode 5: IDC Non-supervision Multiple Switch (Dry Contact)

12 of 16

In this mode, any number of normally-open dry contact closures can be installed on the line. The loop

will not

be monitored for any faults in Mode 5.

Figure 10. IDC Non-Supervision Multiple Switch (Dry Contact)

Mode 5: IDC Non-Supervision (Wet Contact)

In this wet contact mode, shorting jumpers for each input must be moved from the factory default of

“dry” to “wet” contact mode. When in “wet” contact mode, the input can be activated during a 0 V

condition or a 24 V condition. The factory default setting is “24 V dc input when active” (position 2-3).

If “0 V dc input when active” is desired, move jumper from position 2-3 to position 1-2. The loop will

be monitored for any faults in Mode 5. Ensure the polarity of input connection is correct as it is

not

polarity sensitive.

Figure 11. IDC Non-Supervision (Wet Contact)

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 13

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Table 1. Jumper Settings for Mode 5 Input Operation

13 of 16

Input No. Dry Contact

Input Selection

1 P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 & 3

2 P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

3 P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

4 P10 – Pins 2 & 3

P11 – Pins 2 & 3

24 V DC Wet Contact Input

Selection

P1 – Pins 1 & 2

P2 – Pins 1 & 2

0 V dc – Active: P3 – Pins 1 & 2

24 V dc – Active: P3 – Pins 2 & 3

P4 – Pins 1 & 2

P5 – Pins 1 & 2

0 V dc – Active: P6 – Pins 1 & 2

24 V dc – Active: P6 – Pins 2 & 3

P7 – Pins 1 & 2

P8 – Pins 1 & 2

0 V dc – Active: P9 – Pins 1 & 2

24 V dc – Active: P9 – Pins 2 & 3

P10 – Pins 1 & 2

P11 – Pins 1 & 2

Factory Default

Setting

P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 & 3

P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

P10 – Pins 2 & 3

P11 – Pins 2 & 3

P12 – Pins 2 & 3

5 P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

6 P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

7 P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

8 P22 – Pins 2 & 3

P23 – Pins 2 & 3

0 V dc – Active: P12 – Pins 1 & 2

24 V dc – Active: P12 – Pins 2 & 3

P13 – Pins 1 & 2

P14 – Pins 1 & 2

0 V dc – Active: P15 – Pins 1 & 2

24 V dc – Active: P15 – Pins 2 & 3

P16 – Pins 1 & 2

P17 – Pins 1 & 2

0 V dc – Active: P18 – Pins 1 & 2

24 V dc – Active: P18 – Pins 2 & 3

P19 – Pins 1 & 2

P20 – Pins 1 & 2

0 V dc – Active: P21 – Pins 1 & 2

24 V dc – Active: P21 – Pins 2 & 3

P22 – Pins 1 & 2

P23 – Pins 1 & 2

P12 – Pins 2 & 3

P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

P22 – Pins 2 & 3

P23 – Pins 2 & 3

P24 – Pins 2 & 3

0 V dc – Active: P22 – Pins 1 & 2

P24 – Pins 2 & 3

24 V dc – Active: P22 – Pins 2 & 3

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 14

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

Operation

All operation is controlled by the MCU and is set up in the configuration software. See the MCU

Configuration details in the system manual for all operation information.

How to Diagnose Assembly Faults

Symptom Action

14 of 16

MRM does not

communicate with

MCU.

MRM does not

recognize dry

inputs.

MRM does not

activate an alarm

with 24 V dc

applied to input

terminal. (Wet

contact mode

ONLY)

Verify power is applied to the MRM

Verify page line is connected to the MRM

Verify address of MRM agrees with the setup configuration

Ensure CPU PCBA is correctly connected via J1

Call for service of the MRM

Verify power is applied to the MRM

Verify page line is connected to the MRM

Verify end-of-line resistor(s) properly installed on each input circuit

Verify total loop resistance is less than 100

Call for service of the MRM

Verify that the jumper that selects the proper “__ V dc when active” mode is in

the correct position for the desired mode. Refer to Mode 5: IDC NonSupervision (Wet Contact) on page 12.

Verify that the input jumpers have been repositioned for “wet” operation.

Verify that input is within the acceptable dc voltage range (20–30 V dc).

Verify that the proper voltage polarity has been observed for external

connections to the input terminals.

Call for service of the MRM.

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 15

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

15 of 16

Specifications

Electrical

Power requirements ................................................................................................................. 12 V dc 10%

Current draw ................................................. 1 amp maximum @ 12 V dc (does not include beacon power)

Number of output/input loops ..............................................................................................................8 loops

Maximum devices on output/input loop ................................. Limited by maximum current draw (Mode 0)

Unlimited (Mode 1)

One (Mode 2)

One (Mode 3)

Limited by maximum current draw (Mode 4)

Unlimited (Mode 5) (dry)

One (Mode 5) (wet)

Input/output ....................................................................................................................................... Power in

Power out

Page line (FSK) in

Page line (FSK) out

Eight field outputs/inputs

Data communications .............................................................................................................................. FSK

End-of -line device ............................................................................................................... 20 k (Mode 1)

5.1 k in series with 15 k across contact (Mode 2)

5.1 k in series with 15 k across contact (Mode 3)

20 k, 2-watt resistor (Mode 4 - up to 132 V ac/V dc)

None (Mode 5)

Field Outputs/Inputs

Mode 0

Maximum current draw (per output) ............................................................. 5 amps @ 24 V dc or 240 V ac

Maximum dc switching voltage ........................................................................................................ 150 V dc

Maximum ac switching voltage ........................................................................................................ 240 V ac

Mode 1

Contact closure resistance (activated) ................................................................................... 1 k maximum

Open fault detection ............................................................................................................ Minimum 65 k

Ground fault detection ......................................................................................... Less than 200 to ground

Modes 2 and 3

Contact closure resistance (Mode 2: activated/ Mode 3: de-activated) ................................ 3 k maximum

Open fault detection ............................................................................................................ Minimum 65 k

Ground fault detection ......................................................................................... Less than 200 to ground

Wire-to-wire short fault detection ........................................................................................ Less than 200

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Page 16

Pub. 42004-716L2C

Model 12579-003 Monitored Relay Module Page

16 of 16

Mode 4

Maximum current draw (per output) ............................................................. 5 amps @ 24 V dc or 132 V ac

Maximum dc switching voltage ....................................................................................................... 150 V dc

Maximum ac switching voltage ....................................................................................................... 132 V ac

Open fault detection ............................................................................................................ Minimum 65 k

Ground fault detection ......................................................................................... Less than 200 to ground

Wire-to-wire short fault detection .......................................................................................... Less than 1 k

Mode 5 (Dry)

Contact closure resistance ................................................................................................... 900 maximum

Mode 5 (Wet)

DC input voltage range ................................................................................. 20–30 V dc (24 V dc nominal)

Loop Supervision Limitations:

Cable limitations ........................................................................................ 100 maximum loop resistance

Resistance across loop (excluding end-of-line device) ...................................................... 100 k minimum

Terminals:

Minimum conductor size ......................................................................................... No. 28 AWG (0.5 mm

Maximum conductor size ......................................................................................... No. 12 AWG (3.0 mm

Mechanical

2

2

Unit dimensions ..................................................... 4.00 H 10.5 W 2.25 D inches (102 267 58 mm)

Unit weight ..................................................................................................................... 1.75 lbs. maximum

Environmental

Temperature range (operating/storage) ................................................. −30 C to 70 C (−22 F to 158 F)

Humidity .......................................................................................... 95% non-condensing relative humidity

Replacement Parts

Part Number Description

69613-001 CPU PCBA

69251-201 Monitored In 8 PCBA

69252-001 Power Relay Module

)

)

References

Published By Title GAI-Tronics Ref. No.

GAI-Tronics

f:\standard ioms - current release\42004 instr. manuals\42004-716l2c.doc

05/12

Monitored Relay Module Assembly Drawing 73568

Page 17

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will reperform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor's personnel from the work

site. Re-performance of services shall be Buyer's sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...