Page 1

Pub. 42004-711L2B

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 12578-002

Monitored Input Module (MIM)

Confidentiality Notice

This manua l is provide d sole ly as an operatio nal, installation, and ma inte nance guide and conta ins

sensitive business and t e chnical informatio n tha t is confidentia l and pr opri et ary to GAI- Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manu al may not be dis clos e d in any form, in whole or in pa rt, direct ly or i ndir ectly, to a ny

third pa r ty.

How to Use the A ssembly/Model

Application

The 12578-002 Monitored Input Module (MIM) is used in SmartSeries ADVANCE systems.

GAI-Tronics uses the MIM to receive inputs from field devices, monitor the integrity of eight input lines

for trouble conditions or contact activation, and report these conditions to the 69254 Series or

69440 Series Master Control Unit (MCU). The MIM is comprised of two components: the 69248-xxx

Central Processing Unit (CPU) printed circuit board assembly (PCBA) and the 69251-xxx MonitoredIn-8 PCBA.

The MIM is designed to be mounted in a Snaptrack that is then installed in an equipment rack. Snaptrack

is a grooved plastic channel that is designed to allow PCBAs to securely ‘snap’ into the groove. The

Snaptrack provides flexible installation because the track may be installed inside a rack wherever it is

convenient.

The module communicates with the MCU via the 69248-xxx CPU PCBA over an RS-485 link. The CPU

PCBA interprets and reports the status of the inputs. The MIM is capable of monitoring up to eight

inputs.

GAI-Tronics Corporation 400 E. Wyomissing Av e. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 2 of 12

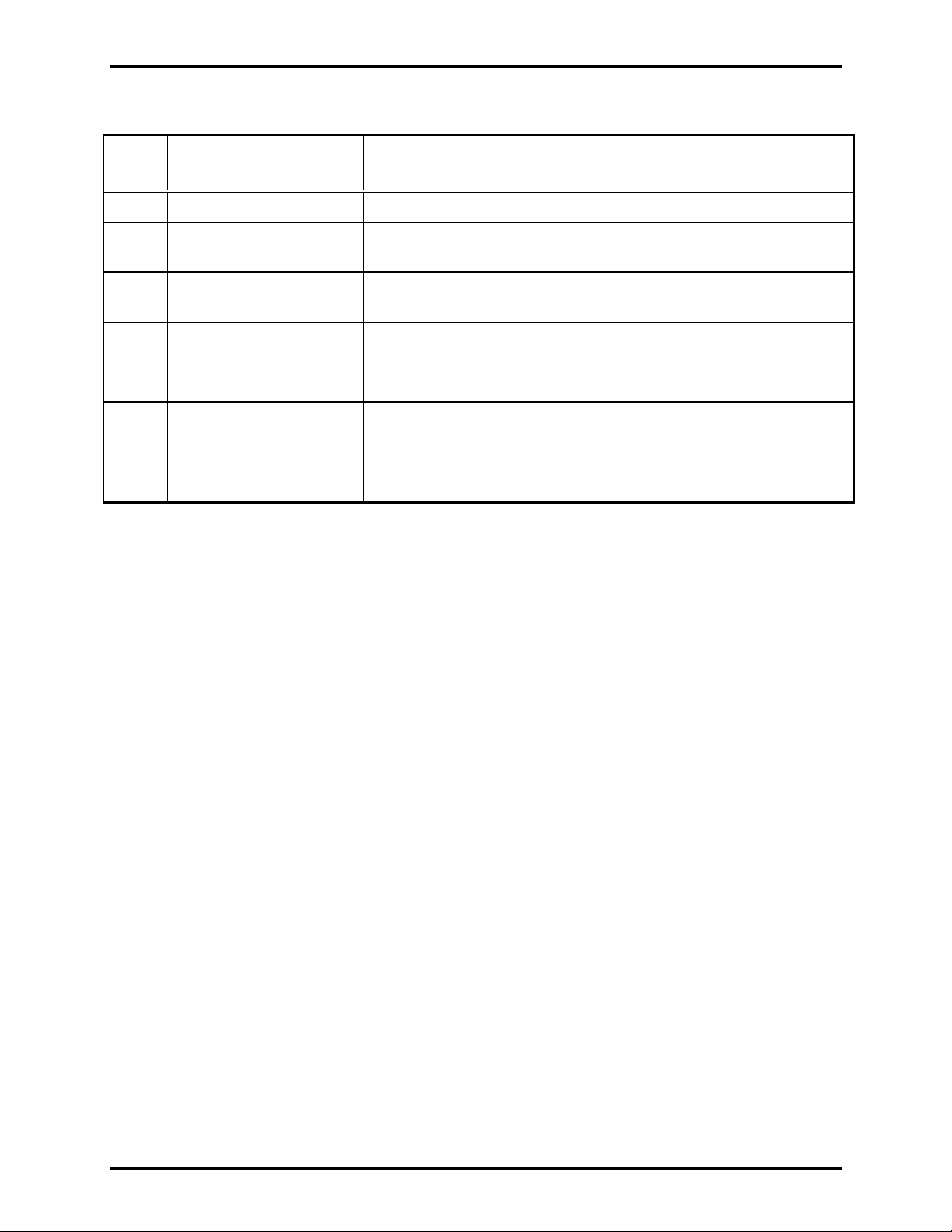

Each input may be independently configured to operate in one of the following five modes:

Input

Mode Description

Comments

0 Deactivate circuit Input is not monitored.

1

IDC line supervision

mult ip le swit ch

2 IDC single N.O. switch

Dete c ts open cir c uit, grou nd faults, and s witc h actu a tion from one or

more normal l y- op e n dr y co nt a ct closu res.

Dete c ts open circu it, wire-to-w i re short c i rcuit, ground f aults, and

swit ch actuat ion from a sin gle n ormally-open dry co ntact clos ure.

3 IDC single N.C. switch

Dete c ts open circu it, wire-to-w i re short c i rcuit, ground f aults, and

switch actuation from a single normally-closed dry contact closure.

4 IAC line supervision Reserved for 12579-002 Monitored Relay Module

5

IDC non-supervised N.O.

dry switch

5

IDC non-supervised, wet

switch

Dete c ts a swit ch ac tuation from one or more normally-open dry

contact closu res.

Detects the presence or absence of 24 V dc voltage depending on

applicable onboard jumper settings.

In order to utilize a particular input mode with a particular input, the appropriate external connections

must be made between the MIM and the field devices. Also, the input modes must be added to the MCU

Configuration using the ADVANCE Console System Configuration Software. Refer to the Installation

Guidelines section on page 4 for further details.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 3

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 3 of 12

Hardware Configuration

Figure 1. Model 12578-002 Monitored Input Module

Interfaces

The Model 12578-002 Monitored Input Module interfaces to an Amplifier Zone Interface via the RS-485

link.

Installa tion Safety Gui delines

Please adhere to all warnings, safety, and operating instructions on the unit and in the installation manual.

DANGER

• Disconnect power before servicing

• Do not disconnect equipment while circuit is energized.

• Avoid servicing the unit during electrical storms.

• Do not touch uninsulated wires.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 4

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 4 of 12

Installa tion Guidelines

1. Notify plant personnel of a system shutdown prior to servicing the unit.

2. Disconnect power before installing or removing the MIM.

Mounting

To install the module into the Snaptrack slide either the right or the left edge of the module into the top

groove on the track. On the opposite side, press firmly on the top and bottom corners of the module until

they snap into the groove. Carefully press from each corner toward the center and simultaneously snap

the edge firmly into place.

Power

After the PCBA is installed onto the Snaptrack, 12 V dc power is brought in from the equipment rack

power supply and terminated on TB9 (PWR IN). The positive leg is connected to TB9-1 (+) and the

return leg is landed on TB9-2 (-). An earth ground is connected to TB9-3 (EGND). TB9 is paralleled

with TB10. TB10 (PWR OUT) may be used to distribute power to additional Snaptrack modules.

The equipment rack power supply is not part of the 10457 Series Card Rack Assembly. The card rack

power supply is not used to provide power to the Snaptrack modules. An additional power supply must

be included in the cabinet to support these modules.

Connect the return leg of the power supply to earth ground at the supply terminals. N

OTE: The ground

reference for this assembly and the card rack must be identical.

Data C ommunicat ion Line

Terminal block TB12 has been provided to distribute the RS-485 data communication line to additional

Snaptrack modules. If there are no additional Snaptrack modules, connect a 47207-151 150-ohm, ½ watt

terminating resistor (sold separately) across TB12 of the 69251-xxx, or install a jumper across the pins of

P2 on the 69248-xxx CPU PCBA.

CAUTION

The RS-485 line is polarity-sensitive. Be sure to maintain circuit polarity throughout installation.

N

OTES:

1. The conductor terminated on TB12

should be a twisted pair.

2. Only one termination is to be applied to an RS-485 circuit - either a 150-ohm resistor across TB12, or

a jumper across the pins of P2 on the 69248-xxx CPU PCBA.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 5

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 5 of 12

Inputs

The MIM contains eight individually configurable inputs, allowing it to interface with field devices.

Connections with these field devices are made at connectors TB1 through TB8. Ea ch connector

corresponds to a single input (TB1 is used for input #1, TB2 is used for input #2, etc.) Each one of these

inputs may be configured to operate in one of five input modes.

Each input mode requires a unique connection scheme between the external field devices and the

appropriate input connector on the MIM. The connection scheme for each input mode is indicated below.

Since the connection scheme is independent of which input is used, only input #1 will be discussed.

To ensure proper termination, ferrules must be crimped on the end of all conductors that are

terminated on the terminal blocks. The size of the ferrule is dependent upon the size of the

conductor used and may be sourced from any supplier such as Phoenix, Altec or Weidmuller.

The terminal blocks may accept conductors between sizes No. 28 AWG to 12 AWG.

Mode 0: D eactiv ate Circuit

In this mode, input #1 is not used and is not monitored by the MIM. If this mode is used, no external

connections should be made to connector TB1.

Mode 1: IDC Line Supervision Multiple Switch

In this mode any number of normally- open dry contact clos ures may b e i nsta lled o n the l ine. T he loop is

monitored for ground faults and open circuits in Mode 1. The end-of-line device is a 20 kΩ, 5% tolerance

resistor.

Figure 2. ID C Line Superv ision M ultip le Switch

N

OTE: The 20 kΩ, 5% tolerance resistor is not included with the MIM. This resistor is included in a kit

(12509-003), which must be ordered separately.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 6

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 6 of 12

Model 2: IDC Single Normally-Open (N.O.) Switch

In this con f igur atio n, only one normally- open dry co ntact closure may be i nstal led p er sup ervised li ne. In

this mode, the loop is mo nitored f or op e n c ircuits, w ire-to-wire short c ircuits (across + and -) , and ground

faults. When the contact closure is not active (open), the loop appears as 20.1 kΩ load (15 kΩ in series

with 5.1 kΩ). This appears on the input to the MIM and indicates a healthy loop. When the contact

closure is active (closed), the 15 kΩ resistor is bypassed.

Figure 3. IDC Single Normally-Open Switch

The circuit then sees only the 5.1 kΩ load. This changes the value of the input and indicates to the MIM

that the conta c t closu re is active. If there is a s hort ac ross + and -, if e ither leg is grou n ded, or if a break

occu rs on either leg, the M I M indicates that a f a ult has occurred.

N

OTE: The terminating resistors are not included with the MIM. These resistors are included in a kit

(12509-003) that must be ordered separately.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 7

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 7 of 12

Mode 3: IDC Single Normally-Closed (N.C.) Switch

In this con f igur atio n, only one norma lly- c lose d dry cont act c l osure may be i nstal led p er sup ervised li ne.

In this mode, the loop is mon itored for open c i rcuits, wire-to-wire short c i rcuits (across + a nd - ), a nd

ground faults. When the contact closure is not active (closed), the 15 kΩ is bypassed and the circuit sees

only the 5.1 kΩ load.

Figure 4. IDC Single Normally-Closed Switch

When the c ontact clos ure is active ( open), the loop appears as a 20.1 kΩ load (15 kΩ in series with 5.1

kΩ). This changes the value of the input and indicates to the MIM that the contact closure is active. If

there is a short a c ross + and -, if e i ther leg is grounded, or if a break occurs on e ither leg, the MIM

indicates that a fault has occurred.

N

OTE: The terminating resistors are not included with the MIM. These resistors are included in a kit

(12509-003) that must be ordered separately.

Mode 4: IAC Line Supervision

(Reserved for 12579-002 Monitored Relay Module)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 8

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 8 of 12

Mode 5: I DC Non-Su pervisi on Multipl e Switch (Dry Conta ct)

In this mode, a ny numb er of n orma lly-open dry co ntact closures can b e insta lled on the line. The loop

will not

be monitored for any faults in Mode 5.

Figure 5. IDC Non- Supervis ion Mu ltiple Swit ch (Dry Contact)

Mode 5: I DC Non-Su pervisi on (Wet Cont act)

In this wet contact mode, shorting jumpers for each input must be moved from the factory default of

“dry” to “wet” contact mode. When in “wet” contact mode, the input can be activated during a 0 V

condition or a 24 V condition. The factory default setting is “24 V dc input when active” (position 2-3).

If “0 V dc input when active” is desired, move jumper from position 2-3 to position 1-2. The loop will

not

be monitored for any faults in Mode 5. Ensure the polarity of input connection is correct as it is

polarit y sensitive.

Figure 6. IDC N on- Supervision ( Wet C ontact)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 9

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 9 of 12

Table 1. Jumper Settings for Mode 5 Input Operation

Input No.

Dry Contact

Input Selection

1 P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 &3

2 P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

3 P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

4 P10 – Pins 2 & 3

P11 – Pins 2 & 3

24 V DC Wet Contact Input

Selection

P1 – Pins 1 & 2

P2 – Pins 1 & 2

0 V dc – Active: P3 – Pins 1 & 2

24 V dc – Active: P3 – Pins 2 & 3

P4 – Pins 1 & 2

P5 – Pins 1 & 2

0 V dc – Active: P6 – Pins 1 & 2

24 V dc – Active: P6 – Pins 2 & 3

P7 – Pins 1 & 2

P8 – Pins 1 & 2

0 V dc – Active: P9 – Pins 1 & 2

24 V dc – Active: P9 – Pins 2 & 3

P10 – Pins 1 & 2

P11 – Pins 1 & 2

Factory Default

Setting

P1 – Pins 2 & 3

P2 – Pins 2 & 3

P3 – Pins 2 & 3

P4 – Pins 2 & 3

P5 – Pins 2 & 3

P6 – Pins 2 & 3

P7 – Pins 2 & 3

P8 – Pins 2 & 3

P9 – Pins 2 & 3

P10 – Pins 2 & 3

P11 – Pins 2 & 3

P12 – Pins 2 & 3

5 P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

6 P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

7 P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

8 P22 – Pins 2 & 3

P23 – Pins 2 & 3

0 V dc – Active: P12 – Pins 1 & 2

24 V dc – Active: P12 – Pins 2 & 3

P13 – Pins 1 & 2

P14 – Pins 1 & 2

0 V dc – Active: P15 – Pins 1 & 2

24 V dc – Active: P15 – Pins 2 & 3

P16 – Pins 1 & 2

P17 – Pins 1 & 2

0 V dc – Active: P18 – Pins 1 & 2

24 V dc – Active: P18 – Pins 2 & 3

P19 – Pins 1 & 2

P20 – Pins 1 & 2

0 V dc – Active: P21 – Pins 1 & 2

24 V dc – Active: P21 – Pins 2 & 3

P22 – Pins 1 & 2

P23 – Pins 1 & 2

P12 – Pins 2 & 3

P13 – Pins 2 & 3

P14 – Pins 2 & 3

P15 – Pins 2 & 3

P16 – Pins 2 & 3

P17 – Pins 2 & 3

P18 – Pins 2 & 3

P19 – Pins 2 & 3

P20 – Pins 2 & 3

P21 – Pins 2 & 3

P22 – Pins 2 & 3

P23 – Pins 2 & 3

P24 – Pins 2 & 3

0 V dc – Active: P22 – Pins 1 & 2

24 V dc – Active: P22 – Pins 2 & 3

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

P24 – Pins 2 & 3

Page 10

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 10 of 12

Operation

The operation of the Model 12578-002 MIM is controlled by the MCU configuration. See the MCU

configuration details in the system manual for all operation information.

Software Configu ration

69248-xxx Jumper must be removed from P1 to operate in a MIM configuration.

How to Diagnose As sembly/Model Faul ts

Symptom Action

MIM does not

communicate

with MCU

MIM does not

rec ognize dr y

inputs

MIM does not

activate an

alarm with 24 V

dc ap plied to

input terminal.

(Wet contact

mode ONLY.)

• Verify power is applied to the MIM.

• Verify RS-485 is connected to the MIM.

• Verify RS-485 is properly terminated at the last device in the RS-485 link.

• Veri fy addres s of MIM agrees with t he setup co nfigu rat ion.

• Ensure CPU PCBA is correctly connected via J2.

• Call for service of the MIM.

• Verify total loop resistance is less than 100 Ω.

• Verify power is applied to the MIM.

• Verify RS-485 is connected to the MIM.

• Verify RS-485 is properly terminated at the last device in the RS-485 link.

• Veri fy end of line resistor(s) properly insta lled on each input circuit.

• Call for service of the MIM.

• Verify that the jumper that selects the proper “_ V dc when active” mode is in

the correct position for the desired mode. Refer to Mode 5- IDC NonSupervision (Wet Contact) information.

• Verify that the applicable input jumpers have been repositioned for WET

operation.

• Verify that the input is within the acceptable dc voltage range (20–30 V dc)

• Verify that the proper voltage polarity has been observed for external

connections to the input terminals.

• Call for service of the MIM.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Page 11

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 11 of 12

Specification s

Electrical

Power requirements..................................................................................... 9–15 V dc (12 V dc nominal)

Current draw ................................................................. 300 mA maximum @ 12 V dc (no ground faults)

Number of input loops................................................................................................................... 8 loops

Maximum devices on input loop................................................................................. Unlimited (Mode 1)

1 (Mode 2)

1 (Mode 3)

Unlimited (Mode 5 - Dry)

1 (Mode 5 – Wet)

Input/output................................................................................................................................. Power in

Power out

RS-485 in

RS-485 out

8 field inputs

Data communications....................................................................................................................RS-485

RS-485 termin ation........................................................................ On board when P2 jumper is installed

End-of-line device........................................................................................................... 20 kΩ (Mode 1)

5.1 kΩ in series with 15 kΩ across contact (Mode 2)

5.1 kΩ in series with 15 kΩ across contact (Mode 3)

None (Mode 5)

Field Inputs

Mode 1:

Contact closure resistance (activated)............................................................................... 1 kΩ maximu m

Open Fault Detection....................................................................................................... Minimum 65 kΩ

Ground Fault Detection....................................................................................Less than 200 Ω to ground

Modes 2 and 3:

Contact closure resistance (Mode 2: activated/ Mode 3: de-activated)............................... 3 kΩ max imum

Open fault detection ........................................................................................................ Minimum 65 kΩ

Ground fault detection...................................................................................... Less than 200 Ω to ground

Wire-to-wire short fault detection.....................................................................................Less than 200 Ω

Mode 5 (Dry)

Contact closure resistance............................................................................................... 900 Ω maximu m

Mode 5 (Wet)

DC input voltage range...............................................................................20–30 V dc (24 V dc nominal)

Limitations:

Cable limitations .................................................................................... 100 Ω maximum lo o p resistance

Terminals:

Minimum conductor size...................................................................................... No. 28 AWG (0.5 mm

Maximum conductor size...................................................................................... No. 12 AWG (3.0 mm

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

2

2

)

)

Page 12

Pub. 42004-711L2B

Model 12578-002 Monitored Input Module (MIM) Page 12 of 12

Mechanical

Unit dimensions ...................................... 4.00 H × 10.5 W × 1.250 D inches (101.6 × 266.7 × 31.75 mm)

Unit weight .................................................................................................................. 1.00 lb. maximum

Environmental

Temperature range (operating/storage).................................................. -30° C to 70° C (-22° F to 158° F)

Humidity ....................................................................................... 95% non-condensing relative humidity

Replaceme nt Parts

Model No. Description

69248-xxx CPU PCBA

69251-xxx Monitored In 8 PCBA

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-711l2b.doc

01/09

Loading...

Loading...