Page 1

Pub. 42004-436C

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 12576-504 Rack-Mount

System Status Panel with LCD Display

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

Product Overview

The Model 12576-504 System Status Panel is a

component of GAI-Tronics’ ADVANCE System.

The operation of each system status panel is

programmed at the ADVANCE System control

cabinet. Operating capabilities include: reset of

fault alarms, and a text display of the system

operating status.

The system status panel includes a sounder

(sonalert) to annunciate system alarm /trouble

conditions.

Figure 1. Model 12576-504

Fea tures

• 12 V dc input power • LCD text display

• Standard 2U, 19-inch EIA rack-mount design • Sonalert with volume control

• Three push-button switches • One LED switch indicator

N

OTE: If this unit is to be used as a replacement for a previous system status panel it will be necessary to

make changes to the ADVANCE configuration file before use. Please contact GAI-Tronics Service for

details.

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 2 of 9

Options/Accessories

Model Description

3308-50008-00 Power Supply Unit 120 V ac – 12 V dc @ 1 A

Installation

Important Safety Instructions

1. Read, follow, and retain instructions – All safety and operating instructions should be read and

followed before operating the unit. Retain instructions for future reference.

2. Heed warnings – Adhere to all warnings on the unit and in the operating instructions.

3. Attachments – Attachments not recommended by the product manufacturer should not be used, as

they may cause hazards.

4. Servicing – Do not attempt to service this unit by yourself. Opening or removing covers may expose

you to dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

5. This permanently connected apparatus must operate from a UL Listed 12 V dc @ 1 A minimum

regulated power supply.

USA and Canada Consult the National Electrical Code (NFPA 70), Canadian Standards Association

(CSA 22.1), and local codes for specific requirements regarding your installation. Class 2 circuit wiring

must be performed in accordance with NEC 725.55.

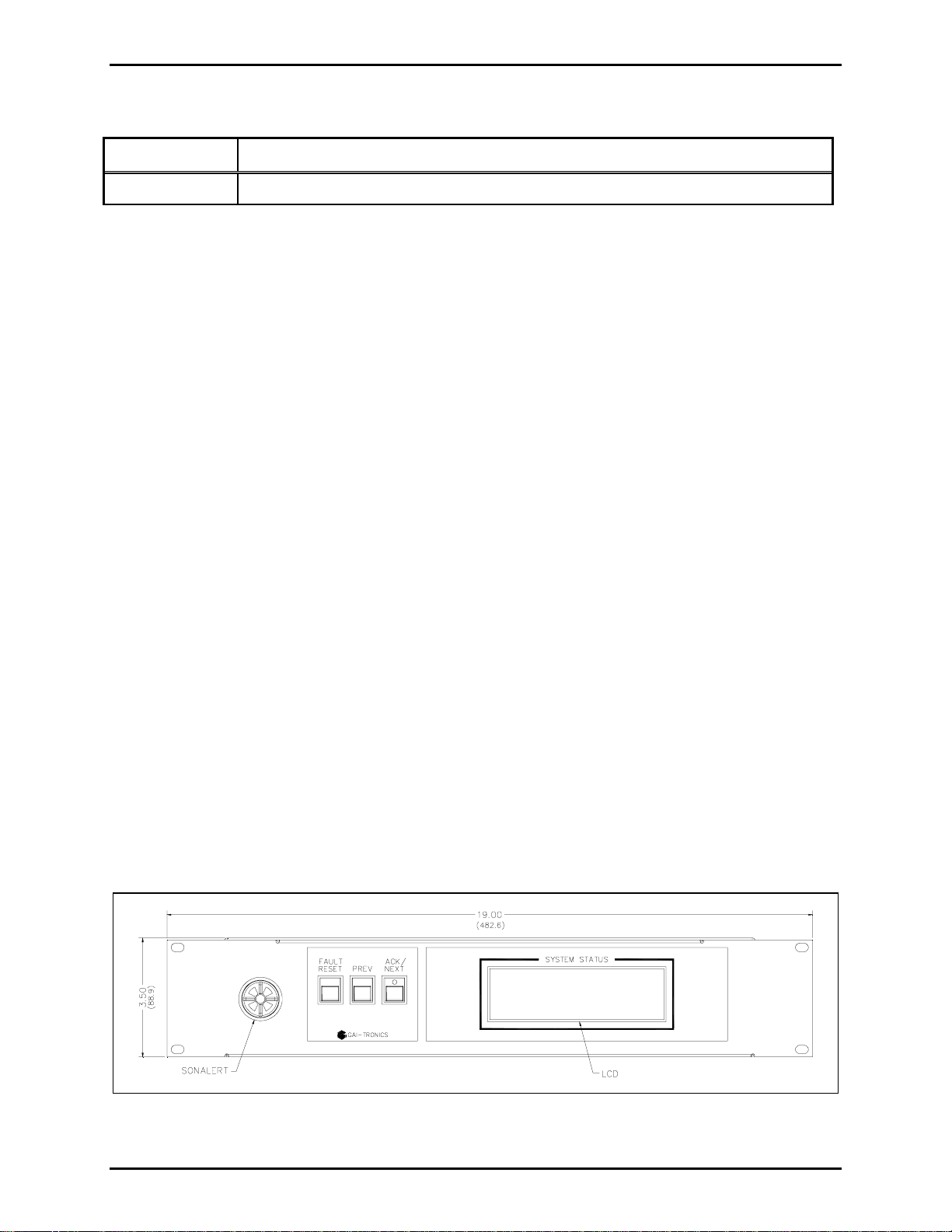

Mounting

NOTES:

1. Mounting hardware is not included with this assembly and must be purchased separately.

2. Due to the insertion depth and weight of this system status panel, chassis supports should be installed

under the unit on both sides to prevent twisting of the front panel.

Remove the system status panel from its protective packing. Position the system status panel in the 19inch EIA cabinet (or rack) and secure with the appropriate screws. A plastic shoulder washer should be

installed behind each screw to prevent scratching of the painted finish.

Figure 2. System Status Panel - Front View

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 3

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 3 of 9

Field Wiring

TX/RX Data

The modular terminal block labeled +/−

TX/RX at the rear of the system status panel provides connection

for the data line to the API connection module (or DIN terminal blocks) at the ADVANCE system control

cabinet.

A twisted pair cable (minimum Category 3) should be used for this connection. Observe cable conductor

polarity (+/−) when making connections at the control cabinet: (+ connects to + and − connects to −). No

damage will occur if the polarity is reversed, but the system status panel will not function.

If installing this panel external to the ADVANCE System control cabinet, the maximum cable distance to

the cabinet is 3 km when using No. 24 AWG (Category 3) cable. Refer to Figure 3 for terminal block

location and Table 1 for additional details.

Table 1. Data Terminal Assignment

Label

+

− TB1-2

Internal Terminal

Number

TB1-1

Function or ACT Descripti on

Positive terminal of data line connection

(to designated + terminal at API connection module)

Negative terminal of data line connection

(to designated − terminal at API connection module)

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 4

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 4 of 9

Power

The modular terminal block labeled CLASS

2 12V DC provides power connection for the system status

panel. Refer to Table 2 and Figure 3 for terminal details.

Table 2. DC Power Terminal Assignment

Label

+

−

GND

Internal Terminal

Number

TB2-1

TB2-2

TB2-3 Frame/chassis ground

Function or ACT Descripti on

Positive terminal of external power supply

(Red wire from 12 V dc power supply)

Negative terminal of external power supply

(Black wire from 12 V dc power supply)

N

OTE: The system status panel does not have an on/off power switch and will power up immediately

upon application of 12 V dc power. The ADVANCE System control cabinet must also be powered and

running before the system status panel is operational. The A

CK/NEXT switch LED on the system status

panel will flash, the sonalert will sound and the display will read “No communication with ADVANCE”

until data communication is established with the ADVANCE control cabinet.

Grounding

The system status panel is equipped with a ground stud on the rear panel. The ground stud is supplied

with two KEPS type hex nuts. Internally, the ground stud connects to chassis and the ground terminal at

TB3-3. Be sure to connect this ground stud to the appropriate ground bar or ground terminals within the

cabinet using a #6 ring lug crimped to a No. 14 AWG green/yellow (or green) wire.

Figure 3. System Status Panel Rear View

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 5

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 5 of 9

Settings and Adjustments

User Adjustments

Sonalert Volume Adjus tment

The volume adjustment on the rear panel adjusts the volume level of the sonalert alarm. Clockwise

rotation will increase the volume and counterclockwise rotation will decrease the volume.

Internal Adjustments

Removing the Cover

Remove the two screws from top cover, and the two screws from each side (a total of six). Open the

system status panel by lifting and rotating the cover back 180º and place on a flat surface. Be careful not

to disconnect any cables.

Figure 4. Interior View of System Status Panel

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 6

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 6 of 9

Jumper Settings

TX/RX Data

Jumper P9 provides a ground reference to the access panel data line. A similar jumper is located on the

Access Panel Interface (API) card in the system control cabinet. The data line must be ground referenced

on one side of the communication link but not both. Place P9 in the GND position to create a ground

reference. Place P9 in the FLOAT position (default) to remove the ground reference. Refer to Figure 5

for jumper location.

Potentiometer Adjustments

LCD Display Brightness

R2 adjust the brightness of the backlight of the display. Clockwise rotation increases the brightness.

Refer to Figure 5 for potentiometer location.

LCD Display Contrast

R1 adjusts the contrast of the display. Clockwise rotation increases the contrast. Refer to Figure 5 for

potentiometer location.

Figure 5. System Status Panel Board

Attaching the Cover

After all adjustments have been completed, replace the cover over lower chassis, being careful not to

pinch any cables. Secure the cover using the six screws originally removed from the top and sides.

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 7

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 7 of 9

Operation

The system status panel operator is only capable of viewing the system operating status on the LCD

display. The following paragraphs provide a general overview of the system status panel features. Pushbutton switches provided on the system status panel are assigned specific system control functions.

Push-Button Swi tch Summary

Each push-button switch function is assigned a specific function. The following describes the function(s)

of each switch on the front panel of the system status panel:

A

CK/NEXT – the ack/next push button performs three unique functions, each of which is dependent upon

system status or conditions. The 1

event(s) or condition(s) in the system. The 2

depressed is used to acknowledge an event, causing the switch lamp to extinguish (if there are no other

unacknowledged events). The 1

events or conditions exist. The 3

acknowledged. The next function is used in conjunction with the previous push-button to navigate

forwards and backwards, respectively, through the history buffer of messages.

st

function is an illuminated state which indicates unacknowledged

st

and 2nd functions are sequenced repeatedly as long as outstanding

rd

function (next) is available only when all events or conditions are

nd

function is an acknowledge function, which when

REV – is an abbreviation for previous and is used in conjunction with the next function (of the ack/next

P

push-button switch) to navigate forwards and backwards, respectively, through the history buffer of

messages.

F

AULT/RESET – the Fault/Reset push-button switch used to reset active alarms displayed on the LCD and

fault relay outputs at the ADVANCE System control cabinet, which are retained until the faulted

condition is corrected.

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 8

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 8 of 9

Maintenance

Troubles hooting

Symptom Possible Cause

The system status panel has lost data communication with the Access

Panel Interface (API) card at the ADVANCE System control cabinet.

Possible Causes:

System Status Panel

Ack/Next LED flashes and

sonalert is sounding. The

panel is not operational.

• Disconnected data cable between the API card and system status

panel.

• Data cable is connected to an un-programmed API card output.

• Data cable polarity is reversed (observe +/− polarity).

• Defective API card at ADVANCE system control cabinet.

• Defective APU board inside system status panel.

Some or all push-button

switches do not function.

Display does not function

• Push-button switches are not programmed.

• Defective switches or an improper connection exists between

switch board and APU board inside unit.

• The display is not enabled in the system programming.

• Display cable is not properly connected at the APU board inside

the unit.

Servicing Guideli nes

1. Notify plant personnel of a system shutdown prior to servicing the unit.

2. Disconnect power before connecting external wiring or installing or removing this panel.

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 9

Pub. 42004-436C

Model 12576-504 ADVANCE Rack-Mount System Status Panel with LCD Display Page: 9 of 9

Specification s

Power Requirements

DC Power Supply

Input voltage ..................................................................................................................... 12 V dc (nominal)

Maximum current draw..................................................................................................................... 700 mA

Access Panel Cabling

Twisted pair cable........................................................................................................ Category 3 minimum

Nominal cable characteristic impedance......................................................................................... 100 ohms

Frequency response............................................................................................................... 32.0 to 256 kHz

Maximum attenuation........................................................................................................................... 24 dB

Signal level..................................................................................................................... 1.000 to 1.125 Vp-p

Signal-to-noise level ...................................................................................... >16.5 dB, 300 kHz bandwidth

Line length ............................................... 3.0 km with Category 3, No. 24 AWG; attenuation = 8.0 dB/km

Mechanical

Chassis dimensions.................................................. 19.00 × 3.47 × 8.00 inches (482.6 × 88.1 × 203.2 mm)

Overall dimensions .................................................. 19.00 × 3.47 × 9.13 inches (482.6 × 88.1 × 231.9 mm)

Net weight........................................................................................................................... 6.1 lbs. (2.77 kg)

Shipping weight ..................................................................................................................... 8 lbs. (3.63 kg)

Environmental

Operating temperature range.................................................................. +32° F to +120° F (0° C to +49° C)

Relative humidity.................................................................................................Non-condensing 85% max.

f:\standard ioms - current release\42004 instr. manuals\42004-436c.doc

01/12

Page 10

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...