Page 1

Pub. 42006-011E

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Field Maintenance Bulletin

Handset/Cord Replacement Procedure

Part No. 10108-107, 10108-10715 & 10108-10725

FOR MODEL 780 AND 7805 SERIES DIV. 1 HAZARDOUS AREA STATIONS

Confidentiality Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information which is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

T ools Required

7/16-inch hex socket or combination wrench

Phillips screwdriver

Pipe wrench or channel-lock pliers

Hammer

Nail set or hardened 1/8-inch diameter rod, approximately 4 inches long

Torque wrench

Liability Disclaimer

NOTICE: Follow all the steps in the procedure outlined below to ensure personnel safety, to avoid

equipment damage, and to maintain agency approvals.

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Pub. 42006-011E

M

ODEL 780 AND 7805 SERIES DIV. 1 HAZARDOUS AREA HANDSET/CORD REPLACEMENT Page 2 of 3

Procedure

WARNING

OTE: The internal outer edge of the front cover is machined. Take precautions to ensure that the finish

N

Disconnect power before making any repairs to a hazardous area station.

is preserved. If damaged, the explosion-proof integrity can be lost.

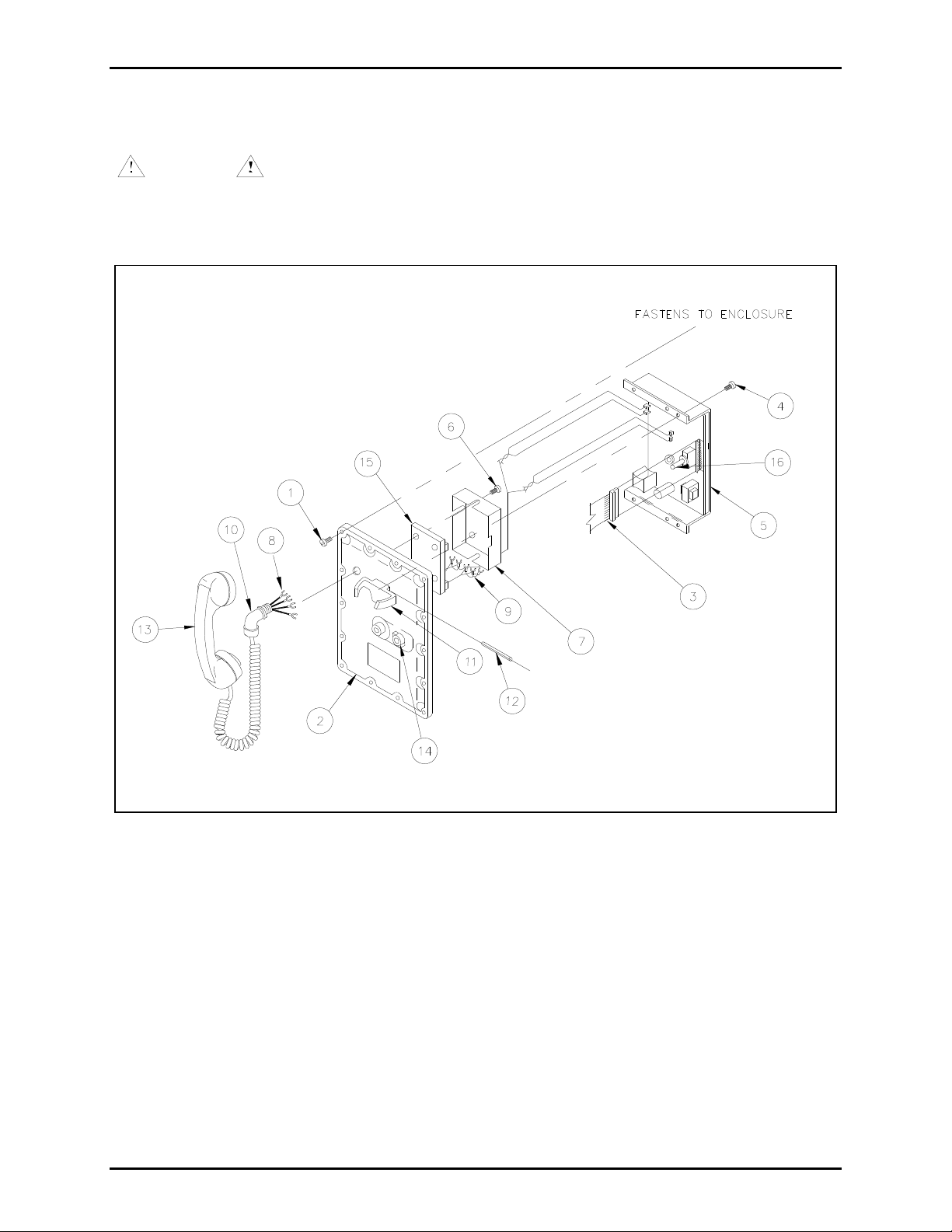

Figure 1. Replacement Handset with Cord and Amplifier Assembly

1. Turn off power.

2. Remove the 14 bolts (Ref. 1 typ.) from the front cover (Ref. 2) using a socket or a combination

wrench.

3. Lift off the front cover, and disconnect the flat ribbon cable (Ref. 3).

4. Remove the four screws (Ref. 4) that hold the amplifier assembly (Ref. 5) to the front cover (Ref. 2).

e:\standard ioms - current release\42006 field maint bulletins \42006-011e.doc

02/15

Page 3

Pub. 42006-011E

M

ODEL 780 AND 7805 SERIES DIV. 1 HAZARDOUS AREA HANDSET/CORD REPLACEMENT Page 3 of 3

5. Remove the four screws (Ref. 6 typ.) that hold the cover (Ref. 7) on the safety barrier (Ref. 15).

Remove the cover. Disconnect the four wires from the safety barrier to the amplifier assembly (Ref.

9) and the four handset cord wires (Ref. 8) from the safety barrier.

6. In order to rotate and remove the elbow (Ref. 10), the station handset hook (Ref. 11) must be

removed by driving out the metal retaining pin (Ref. 12).

OTE: The pin is tapered and can only be removed in one direction by driving it from the elbow side

N

of the hookswitch (when viewed from the front) using a nail set or 1/8-inch diameter rod.

7. Using a pipe wrench or channel-lock pliers, unscrew the elbow (Ref. 10) of the broken handset

assembly (Ref. 13).

8. Install the new handset assembly by feeding the wires on the elbow end of the handset assembly

through the threaded hole.

9. Secure the elbow (Ref. 10) to the front cover (Ref. 2) with a wrench. The handset elbow bushing

must be secured with 5 to 7 full threads. This is critical to the explosion-proof integrity. When

complete, the elbow should point downward.

10. Reconnect the four handset wires (Ref. 8) on the safety barrier inside the front cover to the terminals

labeled H

labeled A

ANDSET TERMINALS. Reconnect the amplifier assembly wires (Ref. 9) to the terminals

MPLIFIER TERMINALS. Ensure that the wire colors match the terminal markings.

11. Replace the safety barrier cover (Ref. 7) and secure with the four screws (Ref. 6 typ.).

12. Replace the amplifier assembly (Ref. 5) on the front cover, aligning the flat of the party line knob

shaft (Ref. 14) with the switch shaft (Ref. 16). Replace the four screws (Ref. 4 typ.).

13. Replace the handset hook and pin (Ref 11 and 12).

14. Carefully inspect the front cover’s machined edge for chips or gouges that could compromise

explosion-proof integrity.

15. Connect the flat ribbon cable (Ref. 3) and mount the station’s front cover (Ref. 2) onto the enclosure

and replace the 14 bolts (Ref. 1 typ.). Tighten each to a torque of 8 ft-lb.

16. Restore power and test for proper operation.

e:\standard ioms - current release\42006 field maint bulletins \42006-011e.doc

02/15

Page 4

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed-upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will

re-perform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor’s personnel from the work

site. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...