Page 1

Operation, Maintenance and Installation Manual

VG 421 AU

Built-in gas hob

Page 2

1

VG 421 AU

FOR YOUR SAFETY Page 2

Warnings Page 3

1. Important Notes Page 5-6

For Your Safety Page 5

Operating for the First Time Page 5

About Use Page 6

2. Features Page 7

Features of the Appliance Page 7

Control Knobs Page 7

Burner Parts Page 7

3. Operating Principle Page 8

4. Operation Page 9

5. Settings Table Page 10

6. Cookware Recommendations Page 11

7. Cleaning and Care Page 12-13

8. Maintenance Page 14

9. Trouble Shooting Page 15

10. Technical Data / Nozzle Table Page 16-17

11. Installation Instructions Page 18-26

Important Notes on Installation Page 18

Connecting the Appliance Page 19

Preparing the Cabinet Page 20

Installing the Hob Page 21

Installing the Spindles Page 22-23

Nozzle Replacement Page 24-25

Fitting the Appliance Cover Page 26

Page 3

2

FOR YOUR SAFETY

WARNING: If the information in this manual is not followed exactly,

a fire or explosion may result causing property damage, personal

injury or death.

Do not store articles on or against this appliance.

Do not use or store flammable materials near this appliance.

Do not spray aerosols in the vicinity of this appliance while it is in

operation.

WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch;

do not use any phone in your building.

– Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

– If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by an authorised

person.

Where this appliance is installed in a marine craft or in caravans,

for safety reasons it shall not

be used as a space heater.

This appliance is not intended for the use of young children or

infirm persons without supervision. Young children should be

supervised to ensure they do not play with this appliance.

Page 4

1. Do not allow the flame to extend beyond the

edge of the cooking utensil. This instruction is

based on safety considerations.

2. Do not forget that the unit becomes hot when in

use. Common sense is important. Just because

the flame is out, it does not mean parts still

cannot be hot.

3. This appliance shall not be used for space

heating. This instruction is based on safety

considerations.

4. Be sure to disconnect the electrical supply

before disassembly of the appliance.

5. Keep the appliance area clear and free from

combustible materials, gasoline and other

flammable vapors and liquids.

6. Do not obstruct the flow of combustion and

ventilation air.

7. Do not install the appliance under a suspended

cabinet. For installation under a vapour extractor

hood, a minimum clearance of 650 mm from the

top edge of the pot stand to the bottom edge of

the extractor hood must be observed.

8. The gas pressure regulator supplied with the

appliance must be installed in line with the gas

pipe.

9. The appliance and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing of the

system at test pressures in excess of 3.5 kPa

(1/2 psig). The appliance must be isolated from

the gas supply piping system by closing its

individual manual shutoff valve during any

pressure testing of the gas supply piping system

at test pressures equal to or less than 3.5 kPa

(1/2 psig).

10.Important:

When using a very large pot, leave a gap of at

least 50 mm (2") to avoid damaging any parts in

counter top wood, plastic or other non-heatresistant materials. Never leave oil or hot fat

unattended.

Note:

To avoid jeopardising the electrical safety of the

appliance, it is forbidden to use high-pressure or

steam jet cleaning devices.

Note:

The name plate is attached to the bottom of the unit

and to the inside of the housing.

This appliance shall be installed in accordance with

the manufacturer’s installation instructions, local

gas fitting regulations, municipal building codes,

electrical wiring regulations, the Installation Code

for gas burning appliances, AS 5601 and any other

statutory regulation. Refer to the AGA Installation

Code for pipe sizing details.

3

Warnings

Page 5

4

Congratulations on buying your new

“Vario” appliance.

Before switching your appliance on for the first

time, we would like you to familiarize yourself with

your new appliance. In this manual you will find

important notes on safety and operation. These

will serve to ensure your personal safety and the

lasting value of your appliance. Keep the

instruction manual near your appliance for further

reference.

You will find notes on Page 5 that you ought to

observe before operating the appliance for the

first time.

The chapters entitled “Features" and “Operation"

tell you all about what your appliance can do and

how you operate it.

The chapter entitled “Cleaning and Care" gives

tips on how to keep your appliance looking good.

And now we wish you lots of fun cooking.

Page 6

5

For Your Safety

You must not operate the appliance if it is damaged.

When connecting electrical appliances in the proxi-

mity of the appliance, make sure that connecting

leads do not come into contact with hot cooking

surfaces!

As the user, you yourself are responsible for

maintenance and proper use in the household.

Only ever operate the appliance under supervision.

Do not operate the appliance without pots and pans

placed on it. Make sure that all the burner parts are

correctly fitted.

Caution: the appliance heats up during operation.

Keep children away.

Do not clean the appliance with a steam cleaning

apparatus or with water pressure - risk of short-

circuits!

Isolate the appliance from the mains during every

maintenance operation. To do this, remove the

mains plug or switch off the corresponding

household fuse. Close the gas supply.

Repairs must be carried out by an authorised

person.

No warranty claims can be lodged for any damage

resulting from failure to observe these instructions.

Observe caution with oils and fats. They may

overheat and burn easily.

Foodstuffs that are prepared in fat and oil must only

be prepared under constant supervision!

Technical modifications reserved.

Operating for the First Time

Remove the packaging from the appliance and

dispose of it according to local regulations. Be

careful to remove all accessories from the

packaging. Keep packaging elements and plastic

bags away from children.

Check the appliance for transport damage before

installing it.

The appliance must be installed and connected by

an authorised specialist before operation. The

installation must conform with all current regulations

of the gas supply companies and the regional

construction regulations.

Turn all control knobs to the OFF position before

connecting the appliance to the power supply.

The serial number of the appliance can be found on

the quality control slip which is included with these

instructions. This quality control slip should be kept,

for guarantee reasons, together with your operating

and assembly instructions.

Read through these instructions carefully before

operating your appliance for the first time.

Thoroughly clean the appliance and accessories

before using them for the first time. This will

eliminate any 'newness’ smells and soiling (see

chapter “Cleaning and Care”).

1. Important Notes

Page 7

6

About Use

The appliance is intended solely for use in the

household and must not be put to any other uses.

Use the appliance to prepare meals only. It must not

be used to heat up the room in which it is installed.!

Use of a gas hob generates heat and humidity in

the room where it is installed. This is why attention

must be paid to good kitchen ventilation.

The natural ventilation openings must be kept

unobstructed. Prolonged use of the appliance

with several or all rings may call for additional

ventilation such as opening a window or a door,

or stronger air extraction by an extractor hood.

To guarantee good combustion, the room in

which the appliance is installed must have

a minimum volume of 20 m

3

and must possess

a door that opens outdoors or a window that

can be opened.

Keep the ventilation openings at the back of the

appliance free at all times.

Only use the burners after placing pots and

pans on them. Do not heat up any empty pots

or pans; this may result in a build-up of heat. Use

pots and pans with thicker bottoms because heat

distribution is particularly improved in the low

setting. Using pots and pans which are adapted to

the burner size increases the efficiency of the heat

from the gas flame, thereby reducing power costs.

It is not permitted to use roasting pans, frying pans

or grill stones heated simultaneously by several

burners because the resulting heat build-up may

damage the appliance.

Pots with a diameter of less than 90 mm or more

than 280 mm should not be used. When using large

pots, pay attention to keeping to a minimum

distance of 50 mm between the cooking vessel and

combustible surroundings.

In the event of a spill or boil over the burner ring

and head may need to be removed and cleaned.

Perform when burner is cold. For identification of

burner ring and head see page 7.

Switch the burners to the low setting whenever you

remove pots or pans briefly. In this way, you reduce

the risk of burns when working next to naked

flames; you also save gas and reduce pollution.

Whenever the gas hob is fitted under an extractor

hood, always cover the rings with pots or pans.

Otherwise, parts of the extractor hood may become

damaged by the extreme heat development or

grease residues in the filter may ignite.

Ensure an adequate supply of air when using

an extractor hood operating in the extraction

mode !

The appliance cannot be used during a power

failure.

In the event of malfunctions, please inform your

specialist dealer or your nearest Gaggenau aftersales service.

Page 8

7

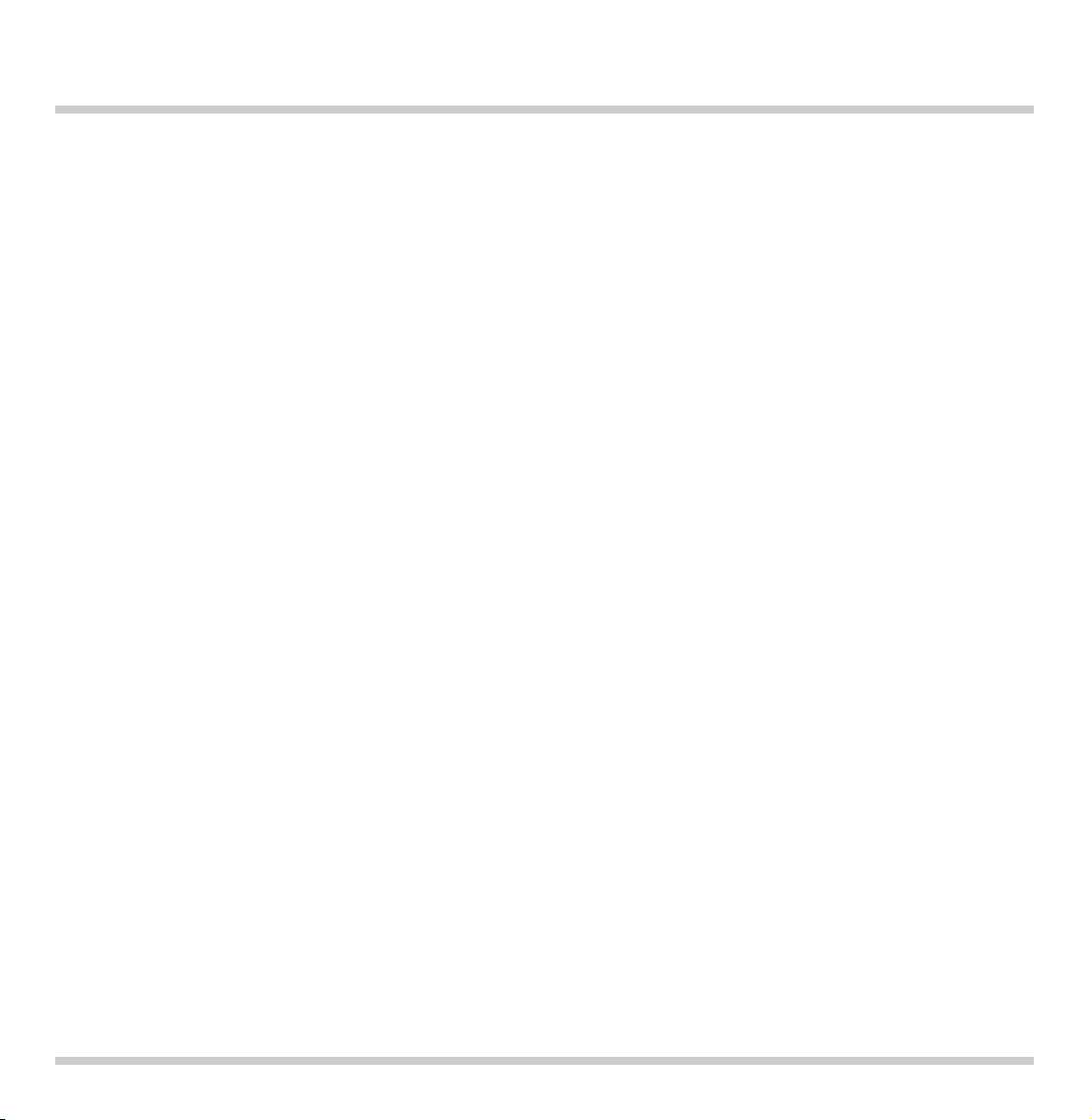

Features of the Appliance

Control Knobs

Burner Parts

1 Appliance cover

2 Ventilation openings

3 Normal burner

4 Large burner

5 Pot grid

6 Control knob for front cooking zone

7 Control knob for rear cooking zone

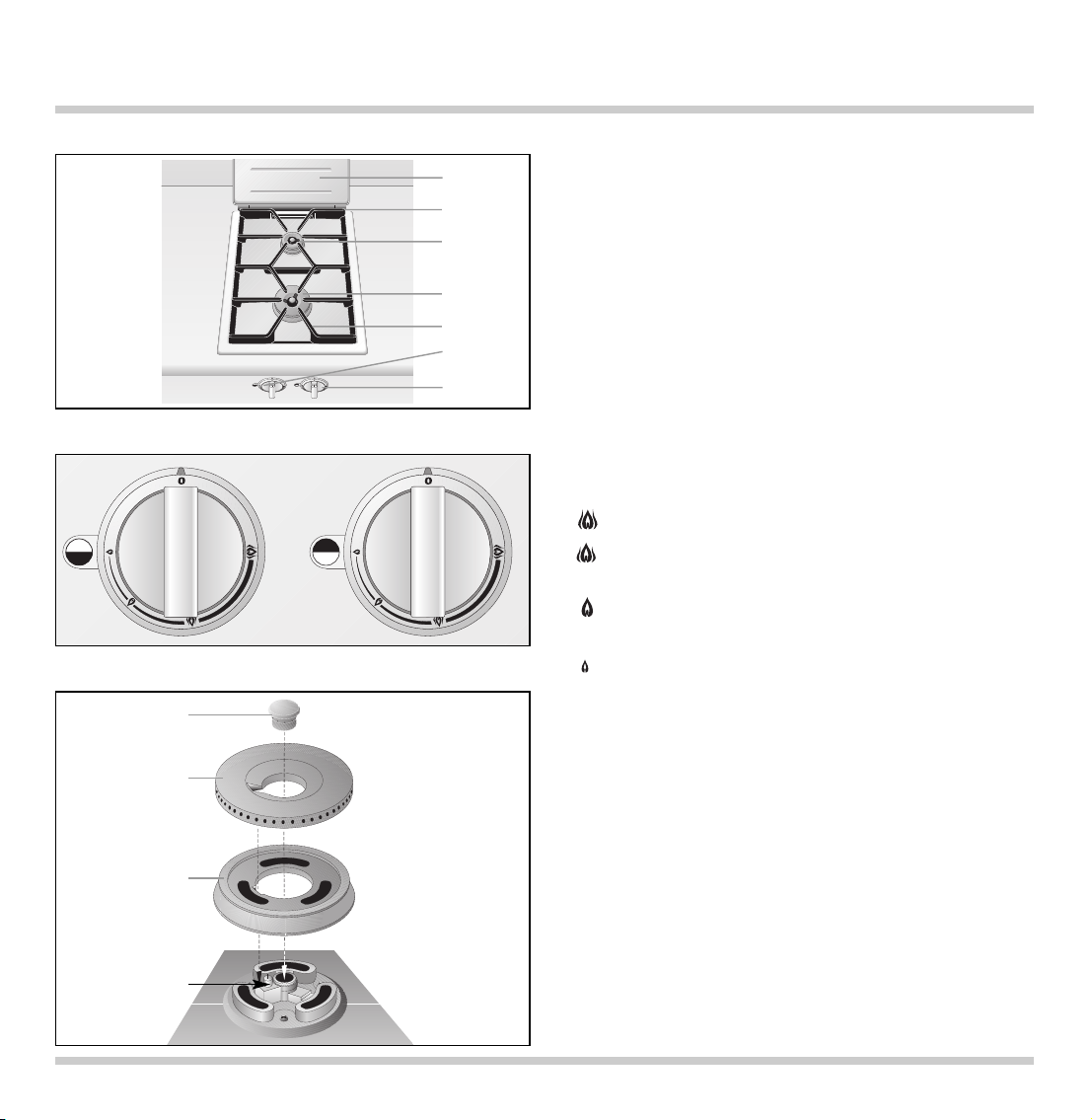

Flame setting:

0 OFF

High setting of outer and inner flame ring

Low setting of outer flame ring

High setting of inner flame ring

Outer flame ring off

High setting of inner flame ring

Outer flame ring off

Low setting of inner flame ring

1 Burner head cover

2 Burner ring

3 Burner head

4 Electrode for automatic ignition,

flame detection and flame control

You can order the following special accessory:

VV 400-000 Connecting trim

SV 402-090 Spindle extension up to 140 mm

SV 402-205 Spindle extension up to 300 mm

LS 330-000 Air baffle for installation next to

VL 430/431

2. Features

2

1

3

4

1

2

3

4

5

6

7

Page 9

8

3. Operating Principle

The appliance features one-hand operation, flame

detection and automatic re-ignition. The ignition is

activated when the control knob is turned.

Should the flame go out during operation, the

appliance will automatically re-ignite the burner.

During a disturbance, the appliance will cut off

the gas supply as a safety measure, to prevent

unburned gas escaping.

The flame setting is infinitely variable between high

and low.

The total rated thermal load amounts to:

20.5 MJ (5.69 kW) for natural gas

22.5 MJ (6.16 kW) for propane gas

The specified rated load is defined by installation

of the fixed nozzles.

The gas hob is converted to a different gas

type by nozzle replacement (full and low-burning

nozzles) (see nozzle table on page 16-17).

Off

High

Low

Page 10

9

Switching on

• Place a suitable pot or a pan on the corresponding

cooking position.

• Press down the control knob for the cooking

position and turn it to the required position

between the and symbols. The burner ignites

automatically.

• When using large pots or pans you should ignite

the burner in the low position.

• Every time the gas hob is switched on, the

electronics run an auto test. The electrode fires

and the burner ignites after a few seconds.

• When being switched on, a short sound may be

heard when the electronic of the gas hob opens

the gas supply valve. This is a normal condition.

The flame size can be set continuously between full

and low by slowly turning the control knob.

Should the flame go out during operation (e.g.

because of a draught), the appliance will

automatically re-ignite the burner.

Should the re-ignition be unsuccessful (e.g. burner

is soiled by spilled over food or liquid), the gas

supply is switched off automatically and a signal is

sounded. Turn the control knob to the OFF position.

After the appliance has cooled down sufficiently,

check if all the burner parts have been assembled

correctly. Check if the burner or the electrode have

been soiled.

Switching off

Fully turn the control knob to the OFF position.

The electronics of the appliance switch the gas

supply off.

4. Operation

Only light a burner if all burner parts are dry, and

assembled correctly. Otherwise, malfunctions may

occur or the appliance may switch off.

Page 11

10

5. Settings Table

Cooking Cooking method Examples

level

High Boiling Water

Searing Meat

Heating Fat, liquids

Boiling Soup, sauce

Blanching Vegetables

Roasting Meat, fish, potatoes

From Browning Flour, onions

Roasting Almonds, breadcrumbs

Baking Pancakes, egg dishes

to Boiling in open pot Liquids

Simmering in open pot Dumplings, sausages, soup garnish,

meat stock, poached eggs

Simmering Sweet sauces

From Boiling with closed lid Pasta, soup, sauces

Steaming Vegetables, potatoes, fish

to Stewing Vegetables, fruit, fish

Braising Goulash, rolled beef steaks, roasts,

vegetables

Low Thawing Frozen foods

Slow cooking Rice, pulses

Reheating Soup, casserole, vegetables in a sauce

Switch to the high setting in order to reach the required temperature quickly. Then switch back to a lower

setting.

The values given above must be looked upon as recommended values. The heat required depends not

only on the type and condition of the food, but also the size and contents of the pot.

Due to the high performance of the cooktop, fat and oil will heat up quickly. Never leave the cooktop

unattended, fat can ignite, food can burn.

Page 12

Pots with a diameter of less than 90 mm or more

than 280 mm should not be used. When using large

pots, pay attention to keeping to a minimum

distance of 50 mm between the cooking vessel and

combustible surroundings.

When buying pots, pay attention to the fact

that the manufacturer frequently specifies the top

pot diameter, which is generally larger than the

diameter of the base.

Observe the manufacturer’s specifications! Use

cooking utensils that the manufacturer states as

being “suitable for gas". Use pots with heat resistant

handles.

Use pots and pans with a thick base, because heat

distribution is particularly improved in the low

setting. Using the correct size of pots and pans for

the burner ensures improved cooking performance

and energy efficiency.

To ensure an even distribution of heat, center the

pot above the burner. The flames should be

covered by the pot base.

Place the pot or pan securely and level on the pot

grid. Turn the pan handle to the side, it should not

point to the front. In order to guarantee a secure

position on the pot grid, the pot base should be flat

and not warped or dented.

Placing a fitting lid on the pot will shorten cooking

times. Through a glass lid you can watch the

cooking progress without having to take the lid off.

11

6. Cookware Recommendations

VG 421 Recommended Minimum

pot diameter pot diameter

Normal Burner 200 - 240 mm 90 mm

Large Burner 240 - 280 mm 90 mm

Page 13

12

Keep the ventilation openings on the rear of the

appliance clean. Do not block the ventilation

openings.

The burners (burner head cover, burner ring and

burner head) will change their color during

operation and become darker. This change in color

will not influence the use-value.

Please thoroughly clean the appliance before

operating it for the first time and after every use.

Do not use scouring agents, abrasives or chemically

aggressive cleaners (for example oven cleaner)!

Do not use any nitro polishing agents for cleaning!

Do not use any abrasive sponges either.

Before cleaning, please wait until the cooktop

has cooled to hand-warm !

• First lift the pot grid with both hands (be careful

not to scratch the base).

• Remove the burner head cover, the burner

rings and the burner head.

• Important! Only clean the burner parts when

cold!

• Soak burnt-in remainders in a little water and

detergent. This loosens even the most stubborn of

soiling. Do not use any abrasive agents and

abrasive sponges.

• Only use very little water to clean your cooktop.

Be careful that no water enters the burner base.

• As the result of heat development, slight discoloration can appear on the stainless steel

surface. Do not attempt to scrape away such

discoloration. This damages the surface.

Distribute stainless steel care agents uniformly

and thinly on the hob. This will ensure an even

surface and will keep your hob in a good

condition for a long period of time.

• Make sure the burner parts are dry before

assembly. Only operate the appliance with all

parts dry. Damp burner parts will cause

malfunctions when igniting or unstable flames.

• When assembling the burner parts, make sure

that the burner ring and burner head are placed

in such a way that the locking lugs fit in the

corresponding recesses.

7. Cleaning and Care

Note: to avoid jeopardising the electrical safety of

the appliance, do not use high-pressure or steam

jet cleaning devices – risk of short circuits!

Caution, risk of burns! Before cleaning,

please wait until the cooktop has cooled to

hand-warm. Never switch on the cooktop

while cleaning.

burner head

cover

burner ring

burner head

electrode

burner base

burner assembly

Page 14

13

Part / Material Suggested Cleaning Procedure Important Reminders

Pot Grid Take pot grids off for cleaning. Do not clean in a dishwasher.

(enamel on Soak in sink. Soak burnt-in remainders in sink.

cast iron) Clean with detergent and brush. Abrasive cleaners, used too vigorously or

too often can eventually mar the enamel.

Burner Head Cover, Remove coarse soiling with damp Do not clean in a dishwasher.

Burner Ring, cloth and detergent. Port openings must be kept free.

Burner Head Use brass polish to keep the Be careful not to loose the small parts.

(brass) original shiny surface.

Electrode Clean with brush, fine glass-paper Soiled electrodes may cause malfunctions

or scouring pad. when igniting or flame control disturbance.

Be careful when cleaning electrodes,

they are fragile, do not turn.

Caution: never switch on cooktop while

cleaning electrodes.

Base Cloth with detergent and hot water. To prevent marring the polished stainless

(stainless steel, Soak burnt-in remainders with a steel trough, always polish in the direction

shot blasted, little detergent solution. of the polish lines.

brushed) After cleaning, polish dry with a Light discolorations may form if the

soft cloth to prevent water stains natural oxidation is removed together

forming on the surface. with the soiling. Put some commercially

For heavy soiling, you can order available stainless steel polish on a cloth

our stainless steel cleaner (Order and polish the whole cooktop after cleaning

No. 310631) from your Gaggenau to get an even stainless steel surface.

dealer. Never allow food stains or salt to remain

Caution: no liquid should enter on stainless steel for any length of time.

the housing of the cooktop Important: certain stainless steel cleaners

through the burner base. will scratch the surface. Chlorine or

chlorine compounds in some cleaners are

corrosive to stainless steel. Check

ingredients on label.

Control knob Wipe with a damp cloth. Cloth should not be too wet, as moisture

could penetrate behind the control knob.

Page 15

The appliance must be disconnected from the

power and gas supply during all repair work.

In the event of malfunctions, check whether the gas

and electricity supplies are in proper working

order.

The hob cannot be used during a power failure.

If the hob is being used when the power failure

occurs, turn the burner control knob to the OFF

position. The hob will not turn back on after a

power failure until the control knob is first turned

OFF and then turned back on again.

Before calling the service engineer, check the

trouble-shooting guide on page 15 to see, if you can

rectify the problem yourself. If your appliance still

does not work, please contact your dealer or your

local Gaggenau customer service agency. Specify

the appliance type (see rating plate).

Repairs may only be carried out by authorised

technicians, in order to guarantee the safety of the

appliance.

Unauthorised tampering with the appliance will

invalidate any warranty claims.

Only use original spare parts.

Abnormal Operation

Flames are normally blue and sharply defined.

If flames are ever yellowish or noisy or if the gas

does not ignite within the period specified under

“Turning on”, abnormal operation is indicated.

In that case call:

Sampford & Staff Pty Ltd, 421 Smith Street,

Fitzroy, Vic. 3065, Tel. (03) 9418 5800.

Service Centres in other States:

Melbourne

Y (03) 9418 5800

Sydney

Y (02) 9331 8888

Adelaide

Y (08) 8212 7000

Brisbane

Y (07) 3358 3000

Perth

Y (08) 9242 5333

14

8. Maintenance

Page 16

15

9. Trouble Shooting

No electrical

power

Switch the appliance on again. Should the appliance still not work,

contact your Gaggenau after-sales service.

Burner does not ignite when switched on

Overheating

protection

Wa it, until

the appliance

has cooled

and the signal

goes off

Turn all control knobs to 0

Burner goes off during operation

A signal is

sounded

A signal is sounded

Check the

domestic fuse

Signal

goes off

Signal

goes off

Signal

continues to

sound

• Are all burner

parts correctly

assembled?

• Is the g

as shut-

off valve open?

• Is the burner

dry and clean?

• Is there an air

pocket in the

gas supply line

after first installation or

changing the LP

(propane) gas

tank?

• LP (propane)

gas: is the gas

tank empty?

Wait, until the

appliance has

cooled, then

check:

• Are all burner

parts correctly

assembled?

• Is the e

lectrode

soiled (food

remains) or wet?

• Is the burner

soiled by boiled

over food?

• Check for strong

draughts (for

example open

window behind

the cooktop)?

• LP (propane)

gas: is the gas

tank empty?

After a power

cut, the

appliance does

not re-ignite

automatically

A signal is

sounded

Check the power

supply

Turn

all control

knobs to 0

Contact your

Gaggenau after-

sales service

Control knob

is turned to 0

but the appliance

tries to

re-ignite

Page 17

16

Technical data (gas)

Burners: Normal burner

Full burning 6.5 MJ (1.8 kW)

Low burning 0.55 MJ (0.15 kW)

Large burner

Full burning 14 MJ (3.9 kW)

Low burning 0.55 MJ (0.15 kW)

Gas connection: R 1/2 ´ ´ BSP male

Technical data (electrical)

Rated consumption 15 W

Voltage AC 220-240 V

Frequency 50 Hz

Technical modifications reserved.

10. Technical Data / Nozzle Table

Countries AU AU

Gas family / Gas type Natural gas / N Propane gas / X

Pressure 1.0 kPa (10 mbar) 2.75 kPa (27.5 mbar)

Nozzle, full burn, outer 1.68 1.05

Nozzle, low burn, outer 0.70 0.45

Nozzle, full burn, inner 0.42 0.29

Nozzle, low burn, inner 0.42 0.28

Air gap adjustm. outer [mm] 42

Air gap adjustm. inner [mm] open, fixed open, fixed

Total output 20.5 MJ (5.7 kW) 20.5 MJ (5.7 kW)

Nozzle table large burner

Page 18

17

Countries AU AU

Gas family / Gas type Natural gas / N Propane gas / X

Pressure 1.0 kPa (10 mbar) 2.75 kPa (27.5 mbar)

Nozzle, full burn, outer 1.13 0.68

Nozzle, low burn, outer 0.57 0.34

Nozzle, full burn, inner 0.42 0.29

Nozzle, low burn, inner 0.42 0.28

Air gap adjustm. outer [mm] open 6 (max)

Air gap adjustm. inner [mm] open, fixed open, fixed

Total output 20.5 MJ (5.7 kW) 20.5 MJ (5.7 kW)

Nozzle table small burner

Page 19

Important Notes

This appliance can be combined with all Gaggenau

Vario 400 Series appliances.

Please observe the general safety notes and the

important information in chapter 1.

The installer is responsible for perfect functioning

of the appliance at its installation location.

He must show the user how to switch off the

electricity and gas supply whenever required.

After unpacking, check the appliance for any

transportation damage and report this immediately

to the transportation company.

Note: operation next to a downdraught

ventilator VL 430/431 is only allowed with the

air baffle LS 330-000.

Caution:

before connecting the appliance, please check

whether the local connection conditions such as

gas type, gas pressure and mains voltage match the

appliance settings. This gas hob conforms to the

categories that are specified on the rating plate.

The rating plate can be found on the appliance and

additionally on the quality control slip which is

included with these instructions. By replacing

nozzles, it is possible to set the appliance to any

gas listed on the rating plate.

If the data should not match, the appliance must

be changed over to the required gas type and the

available pressure.

As this gas hob is not intended for connection to an

exhaust gas system, pay attention to the applicable

installation conditions.

The appliance may be installed in kitchen

combinations made of wood or similar combustible

materials without taking additional measures.

The rear wall must consist of non-combustible

material.

A minimum distance of 100 mm from heat-sensitive

items of furnishing or contact surfaces (cupboard

side panel) must be observed.

The hob conforms to appliance class 3 and must be

installed in the worktop as shown in the installation

sketch.

Do not install the appliance under a suspended

cabinet. For installation under a vapour extractor

hood, a minimum clearance of 650 mm from the top

edge of the pot stand to the bottom edge of the

extractor hood must be observed. If several gas

appliances are installed, a larger distance from the

extractor hood might be needed. Observe the

installation manual of the extractor hood. Wall trims

must be heat-resistant, and the minimum distance

between the hob and the wall trim is at least 35 mm.

The appliance must be installed and connected by

an authorised gas installer. The installation must

conform with all current regulations of the gas

supply companies and the regional construction

regulations.

Warning:

this appliance must be installed and connected by

an authorised gas installer.

This appliance shall be installed in accordance with

the manufacturer’s installation instructions, local

gas fitting regulations, municipal building codes,

electrical wiring regulations, the Installation Code

for gas burning appliances, AS 5601 and any other

statutory regulation. Refer to the AGA Installation

Code for pipe sizing details.

Technical modifications reserved.

18

11. Installation Instructions

Page 20

19

Connecting the Appliance

Gas connection

The gas connection must be in a location that

permits access to the shut-off valve and which,

if applicable, is visible after opening the door of

the cabinet.

By means of the included R 1/2 ´´ BSP Male

connection (on the appliance end) with the

affiliated washer, the appliance must be connected

to a fixed connecting line.

Electrical connection

Electrical connection (AC 220-240 V) is established

by means of a connecting cable with an earthing

contact plug connected to an earthed socket, which

must also be accessible after installation of the gas

hob.

When establishing connections, make sure that the

connecting lead cannot come into contact with hot

parts of the gas hob or other hot parts.

Turn all control knobs to the OFF position before

connecting the appliance to the power supply.

Connection type Y: if damaged, the mains cable

must be replaced by a special mains connecting

cable. The mains connecting cable must only be

connected by the manufacturer or the manufacturer's after-sales service.

105

50

max.

28

1

"

/

2

Page 21

Preparing the Cabinet

• Cut out the recess for the hob in your worktop.

Proceed as indicated on the installation sketch.

The installation sketch contains the measurements

of the space required for the trim between the

appliances. Several appliances can also be

installed in individual recesses, as long as a

minimum clearance of 50 mm is kept to between

the appliances.

• As shown in the installation sketch, drill the

Ø35mm holes to secure the control knobs in the

cabinet front.

• If the cabinet front is thicker than 26 mm, the front

must be routed from the back to max. 26 mm on

an area of 80 x 310 mm.

20

515

min. 35

min. 50

8

0

3

1

1,4 m

23

1

490

380

360

510

80

1

60

90

765

117 0

35

1575

min. 5

min. 5

80 x

310

D = 26

16 – 26

D > 26

Page 22

Installing the Hob

Please note: if you want to convert the appliance

to a different type of gas, change the nozzles

before installing the appliance (see pages 24 - 25).

• Before installation, remove all styrofoam

packaging from the control knobs and peel off

the protective film.

• Hold the support plate from the rear against the

cabinet front, insert control knobs into the holes,

secure from the rear with the nuts.

Take care to install control knobs in the correct

order: left for front cooking zone, right for rear

cooking zone.

• Undo trough securing nuts and carefully detach

the trough.

• Turn the clamping screws to the side. Insert the

hob with the Gaggenau logo on the front into the

cut-out and align it.

Note: do not stick the hob onto the worktop with

silicone.

• Turn the clamping screws under the countertop

and tighten them evenly. Do not tighten the

clamping screws too tightly, as a uniform sealing

gap should be left all round.

• Connect the appliance to the gas supply.

• Check the installation for gas leaks.

21

Page 23

22

Installing the Spindles

The numbers correspond to the diagram on the

opposite page. Spindle extensions (SV 402-090 /

SV 402-205) are available should the appliance be

installed in a worktop which is non-standard depth.

Loosen the nuts of the spindle covers and remove

covers.

1 Insert the spindles from behind into the fittings of

the control knobs. Be careful that the broader pin

of the control knob fits the broader fitting of the

spindle.

2 The gas taps of the burners must be in the off

position (flat side to the top). Slide the spindles

on the gas taps.

3 Fix the spindles with the screws provided.

Turn the control knob to the off position. Connect

the appliance to the power supply, and check for

correct functioning. If the appliance switches off

there may be air in the gas supply line. Turn the

control knobs to the off position and relight. This

may need to be repeated until the appliance

ignites.

min. 5

ø 35

ø 60

38

105-162,5

< 60< 140< 300

StandardSV 402-205 SV 402-090

spindle covers

Page 24

23

Page 25

24

Nozzle Replacement

Changing over to a different gas type

Only authorised specialists are permitted to

change over to a different gas type.

The nozzles needed for the gas type to be set

are available as a conversion kit. Please specify the

appliance type and the required gas type.

The nozzles can be changed on the installed

appliance.

Loads for all gases

For all gas types and pressures, the rated load

is achieved by installing the high and low setting

nozzles for the required gas type (see nozzle

table).

Replacing the low setting nozzles

• Switch off the power at fuse point and close the

gas supply!

• Detach pod grid, burner rings, burner head

covers and burner heads.

• Undo trough securing nuts and carefully detach

the trough. Loosen the nuts of the spindle covers

and remove covers.

• Detach the spindles between the control knobs

and the gas taps.

• Turn the black plastic part so that the recess is

above the nozzle. Screw out nozzle and take

nozzle out with small pliers.

• Replace both low setting nozzles on the gas taps

according to the new gas type and as detailed in

the low setting nozzle table. Fully screw in the

new low setting nozzles.

Important: be careful not to damage the O-ring.

See table on page 16-17

for details of nozzle settings.

outer low

setting nozzle

inner low

setting

nozzle

Page 26

Replacing the main burner nozzles of the

normal burner and large burner

• Detach the safety spring on the supply lines.

Leave the electrode connected. Unscrew the

burners from the trough (Torx T20) and pull off the

burner from both supply lines.

• Carefully pull off both main nozzles together with

the O-ring by hand.

• Check whether the O-rings of the new nozzle

seats are fitted correctly. Fully push nozzles onto

the supply lines. Note: do not bend supply lines.

• Push the burners onto the supply lines.

Push the safety springs back on.

• Screw the burners back on the trough.

• Loosen the locking screw and adjust the air

regulation bush according to the nozzle table.

Tighten the locking screw.

• Fit the trough and tighten it firmly.

Checking functions

The flames are adjusted correctly if no yellow tips

are visible and if they do not go out when switching

over swiftly from the high to the low setting.

Please do not forget to stick the new adhesive label

included with the nozzle set over the old adhesive

label on the gas connection, thus documenting the

changeover to a different gas type.

25

See table on page 16-17

for details of nozzle settings.

outer main nozzle

inner main nozzle

Page 27

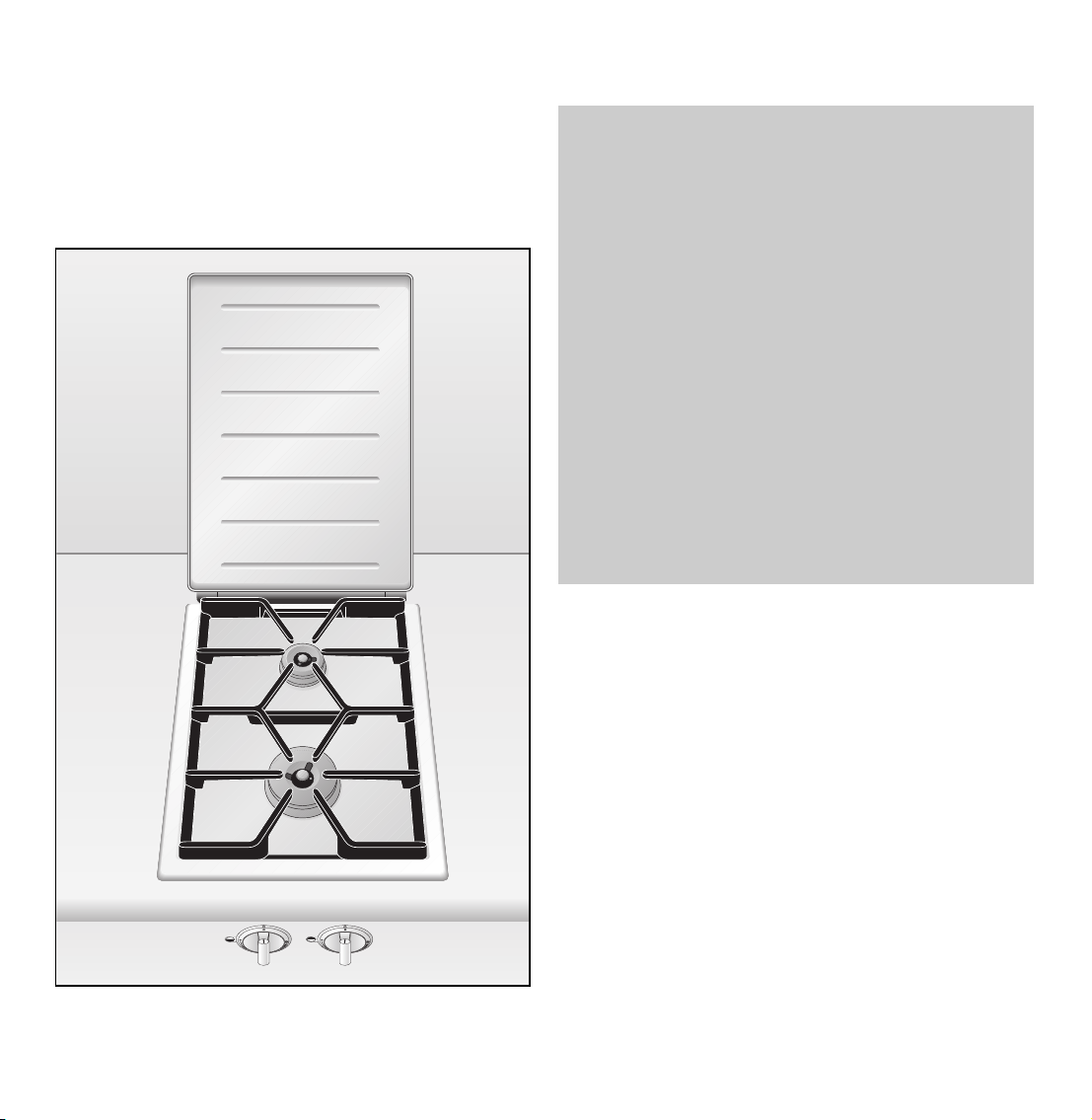

Fitting the Appliance Cover

• The securing brackets are already fitted on the

base.

• Place the appliance cover on the brackets in

upright position and screw it down using the

pre-mounted grub screws.

• Close the appliance cover. It must lie evenly on

the appliance.

• If the cover is not fitted straight, loosen the sheet

metal screws holding the securing brackets and

fit the included shims on the securing bracket

until the appliance cover lies evenly on the panel

edge.

• Again firmly screw down the appliance cover.

Note:

do not use the appliance cover as a surface for

placing objects or for keeping things warm. Wipe

away spills before opening the appliance cover.

Do not close the appliance cover until the

appliance has cooled down completely. Do not

operate the appliance with the cover closed! This

may damage the appliance and the cover due to

the development of heat.

26 9000044519 en 06.05 EB

Page 28

Distributed by:

SAMPFORD & STAFF PTY LTD

421 SMITH STREET, FITZROY, VIC. 3065

HEAD OFFICE: Y (03) 9418 5800

www.gaggenau.com

GAGGENAU HAUSGERÄTE GMBH

CARL-WERY-STR. 34 · 81739 MÜNCHEN

GERMANY

Y (089) 45 90-03

FAX (0 89) 45 90-23 47

Service Centres in other States:

Melbourne Y (03) 9418 5800

Sydney Y (02) 9331 8888

Adelaide Y (08) 8212 7000

Brisbane Y (07) 3358 3000

Perth Y (08) 9242 5333

Loading...

Loading...