TruSlate™ Ridge Vent

Attic Exhaust Ventilation

Application Instructions

Updated: 9/10

Quality You Can Trust Since 1886...

From North America’s Largest Roofing Manufacturer

™

APPLICATION

MC

INSTRUCTIONS

“Quality You Can Trust

Since 1886...From

North America’s Largest

Ridge Vent

Roofing Manufacturer”

Roof Deck: Use only over a well-seasoned, supported wood deck, tightly

constructed with maximum 6” (152mm) wide lumber, having adequate

nail-holding capacity. OSB or Plywood decking as recommended by The

Engineered Wood Association is acceptable.

For ridge vent to function properly, it must be the only exhaust vent for the

vented attic space. Do not use with gable-end louvers, turbines, roof vents,

or power vents.

Slope Restrictions:

Use only on slopes between 4/12 and 16/12

Do NOT install on hips.

NOTE: Install TruSlate™ Ridge Vent BEFORE installing the field slates. This

will ensure that a full course of TruSlate™ slates can be installed adjacent to

the ridge vent.

STEP 1

Calculations for a Balanced Ventilation System

To achieve a “balanced system” with ridge vents, there must be an air intake

system (i.e., soffits or undereave vents). For proper ventilation, the amount of

undereave ventilation must equal the amount of ventilation at the ridge.

NOTE: In no case should the amount of exhaust ventilation exceed the

amount of intake ventilation.

To determine the minimum square feet of net free ventilating

area (NFVA) needed for a balanced ventilation system, use the

following formula:

Sq. ft. of attic floor space

300

TruSlate™ Ridge Vent has 18 square inches of NFVA per

lineal foot. To determine how many feet of TruSlate

Min.Sq. ft. of

=

NFVA needed

™

Ridge Vent is needed, use the following formula:

1/2 x (Min. sq. ft. of NFVA needed) x 144/18 = Min. lineal feet of ridge

vent needed

To determine the amount of undereave vent required, use the

following formula:

X = NFVA (sq. in. per lin. ft.) of the undereave vent or intake vent

system selected 1/2 x (min. sq. ft. of NFVA needed) x 144/X = Min. lineal

feet of undereave vent needed

NOTE:

Consult local building codes for other ventilation requirements.

STEP 2

Instruction For Slots

1. After calculating the total length of TruSlate

determine the necessary slot opening required.

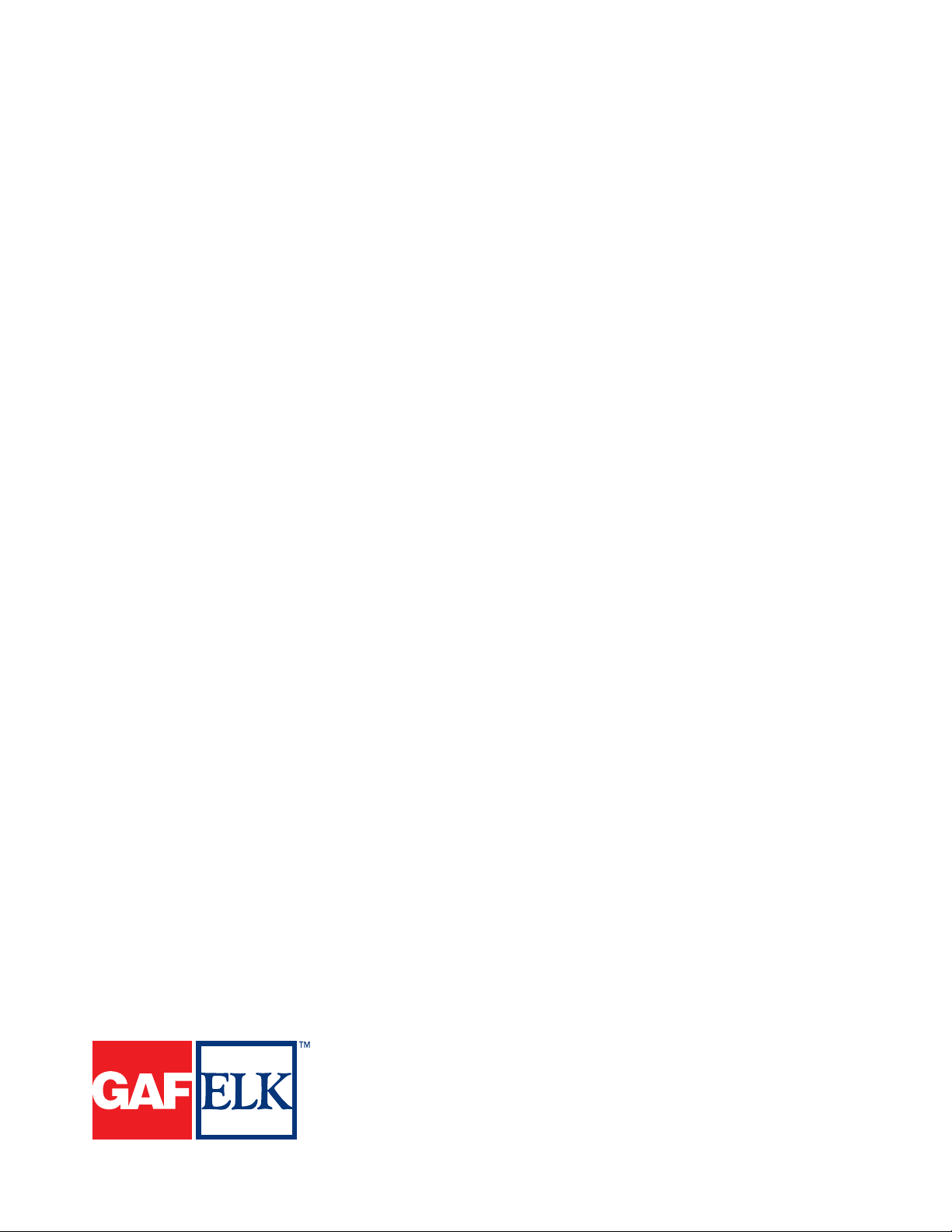

Roofs without a ridge board: Cut a 7/8” (22mm) opening along the ridge

on each side (Figure A). Roofs with a ridge board: cut a 1 5/8” (41mm)

opening along the ridge on each side (Figure B).

™

Ridge Vent needed,

Fig. A

(22 mm)

(22 mm)

(44 mm)

Fig. B

(41 mm)

”

”

5

5

(41 mm)

1

1

/8

/8

”

1

(82 mm)

3

/4

NOTE: The total maximum slot opening is 3 1/4” (83mm) wide.

2. Mark off and cut the slot opening, making sure that the ends of the

opening stop at least 6” from any end walls and at least 12” (30mm)

from hip and ridge intersections or chimneys. (Figure C)

(152 mm)

Fig. C

(152 mm)

(152 mm)

(305 mm) (305 mm) (152 mm)

Where short ridges (dormers, ridge intersections) are used, mark and cut the

slot and make sure that the end of the opening stops at least 12” (305mm)

from the ridge intersection (Figure D).

Fig. D

(152 mm)

(152 mm) (152 mm)

(305 mm)

3. Install an 18” (459mm) wide piece of peel and stick leak barrier, such as

GAF-Elk Weather Watch® or StormGuard® Leak Barrier, from the edge of the

ridge slot extending down towards the roof deck.

STEP 3

Ridge Vent Installation

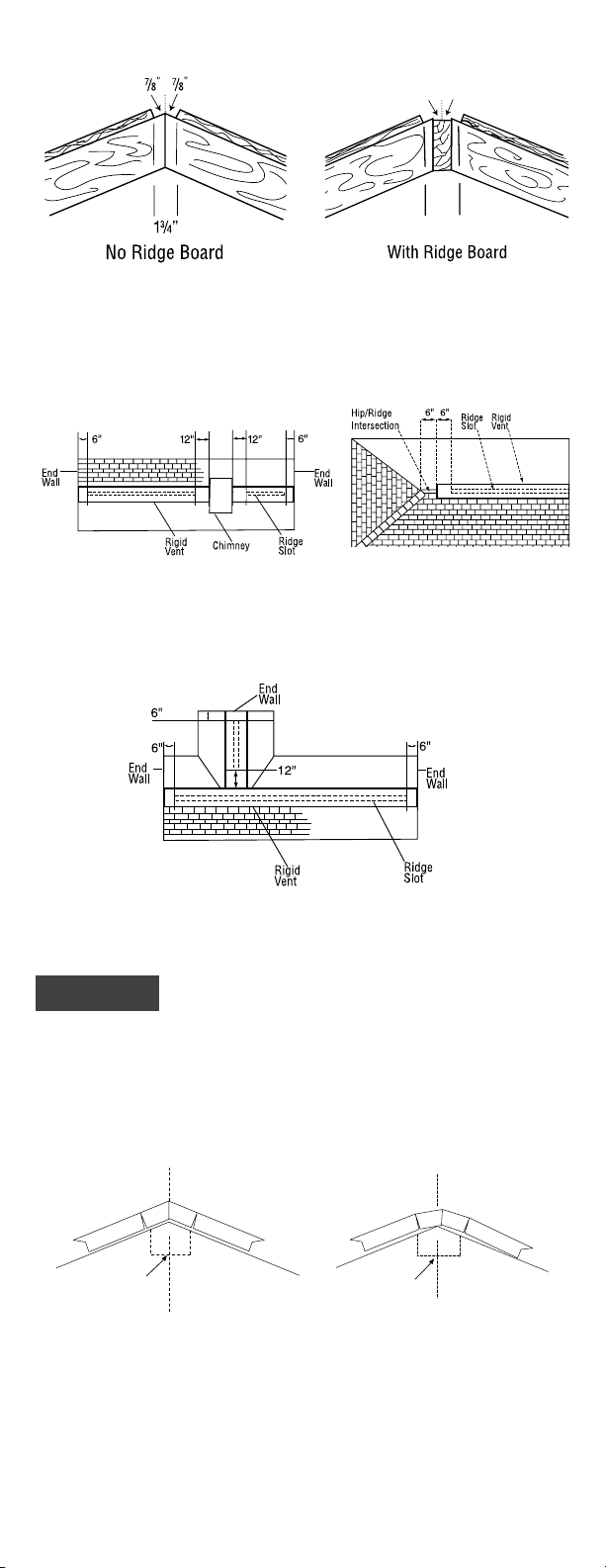

1. Place the TruSlate™ Ridge Vent over the ridge slot. The ridge vent must

always be “peaked” and centered over the ridge slot. The top panel on each

side of the ridge vent must be parallel to the roof deck below to avoid sizing

problems when installing trim slates (Figure E).

Fig. E

Correct

Ridge Slot

Centerline

Vent “peaked” and centered

over ridge slot

Ridge Slot

Centerline

Vent o-center

over ridge slot

Incorrect

2. Attach the vent section using minimum 1 3/4” (44mm) roofing nails

through pre-molded nail holes on the vent (Figure F).

• Fasteners must always penetrate through plywood decks or at least

3/4” (19mm) into wood planks. 3” (76mm) ring shank nails are

recommended for increased uplift resistance.

3. Apply the subsequent ridge vent sections over the length of the ridge

utilizing male/female connectors on each vent. Cover all of the

exposed nail heads on the vent with silicone caulk.

Loading...

Loading...