gabriel G421 Studio2 White Special, G420 Studio2 White, G422 Studio2 Black, G423 Studio2 Special Assembly Instruction Manual

TMS 2015-10-15

Contents

Tests and approvals ............................ 2

Explanation of symbols / foreword ......3

Body

Preparations ...................................... 4

Important measurements...................... 5

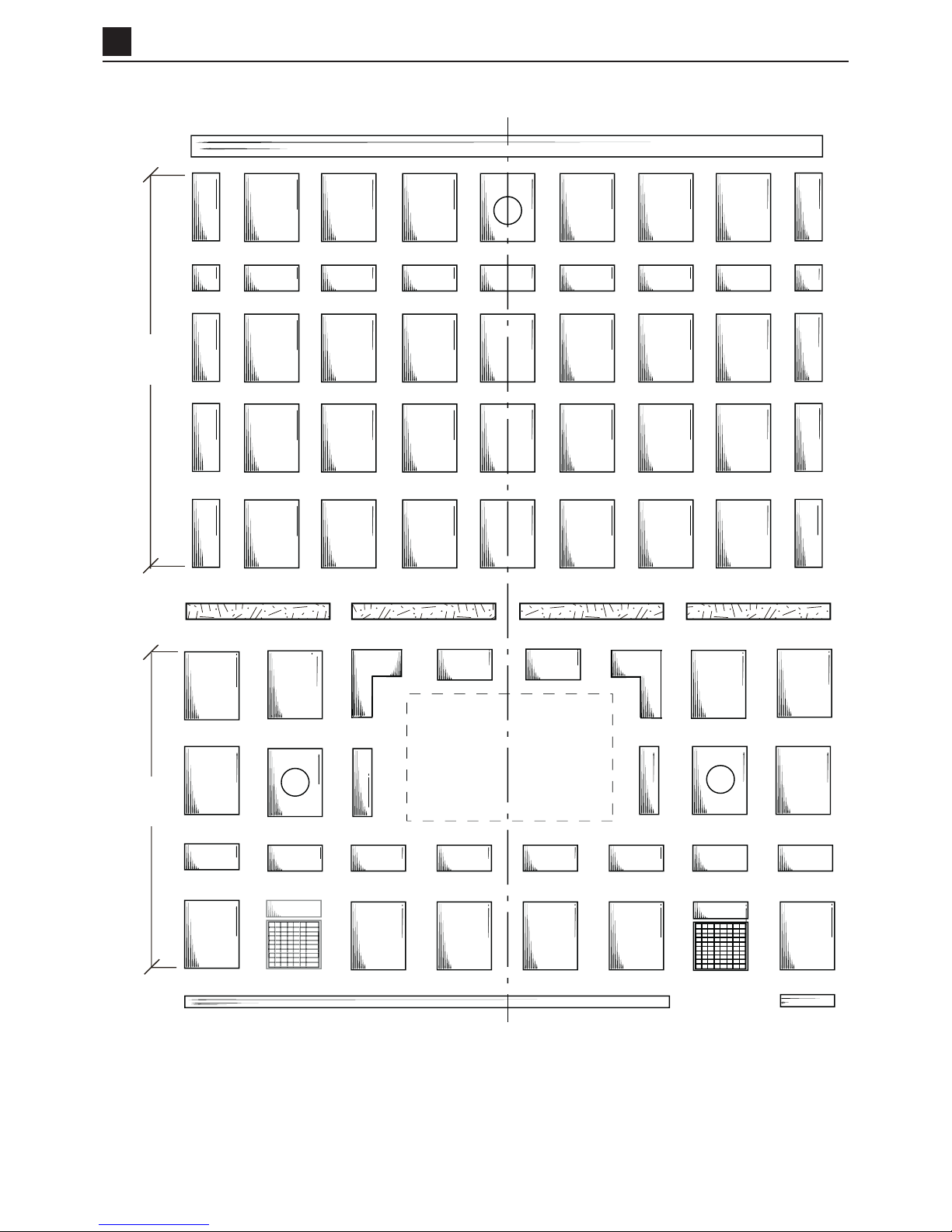

Overall installation sequence ............... 6

Assembly ..................................... 7-17

Tiles and cassette

Tiling preparation and assembly ... 17-18

Tiling plan ....................................... 19

Cassette installation ..................... 20-23

Fan installation ................................23

Assembly instruction

STUDIO2 tile stoves

Model:

G420 Studio2 White

G421 Studio2 White Special

G422 Studio2 Black

G423 Studio2 Special

GABRIEL KERAMIK AB

2 • STUDIO2

Tests and approvals

New installation / building registration

A building permit from the local housing authorities is required when build-ing a tiled stove. You shall also consult

your chimney sweep before building the stove. Weight from 1300 to 1800 kg. Bearing support is required.

Name: Gabriel kakelugnar (400-serie)

Model: Studio G400, G410, G411, G412,

Studio2 G420, G421, G422, G423

Brenstoff: Wood logs

Fire saftey Pass

Distance to

combustable materials:

Behind: 50 mm

Ceiling: 50 mm

Side: 50 mm

Emission of combustion products Pass

CO

NOx

OGC

PM

0,1%

78mg/m

3

46mg/m

3

37mg/m

3

Release of dangerous substances Pass

Surface temperature Pass

Cleanability Pass

Mechanical resistance Pass

Connection to shared chimney Pass

Temperature in ue spigot

During nominal heat output

During saftey test

120°C

170°C

Thermal storage capacity 100% Peak

50% from peak

25% from peak

after 2,9 h

after 8,0 h

after 17,2 h

Thermal output and Energy efciency

Efciency

Nominal heat output

Space heating output

Flue draught

92%

4,5 KW

156 MJ

12 Pa

Follow the manufactures instruction and

maintenance manual.

Use only recommended fuel.

Gabriel Keramik AB

Strandavägen 62

380 52 Timmernabben, SWEDEN

08

No. G400-423-CPR-150615

EN 15250:2007

Slow Heat Release Appliance (SHRA)

Space heating for recidental homes

0402/1015

This CE-sticker

is located on the

inside of the tile

stove‘s ventilation

grid.

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G800-G861-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 800-serie (G820 - G861)

Model: G820 Strömsrum, G830 Borgholm, G840 Ekeby, G855 Kungälv,

G860 Avanti, G861 Avanti.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavä gen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical Research Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential character istics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 300mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance Pass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h from max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

At nominal heat output

At saftey test

The undersigned is responsible for the production and compliance with the declared performance.

120 C

170 C

°

°

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G310-G360-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 300-serie (G310 - G360)

Model: G310 Kungsholm, G315 Karl-Johan, G320Drottningholm

G340 Gabriel, G350 Duvemåla, G360 Tillinge.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical Research Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pas s EN 15250:2007

Mecanical resistance Pass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h from max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

. Complies also with the following standards DINplus, BImSchVo II, 15a B-VG.

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance P ass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h fro m max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

At nominal heat output

At saftey test

120 C

170 C

°

°

SP. Technical Research Instute of Sweden NB0402 has controlled the declared

performance and released test report P800646-A.

Engineering Test Instute, Czech Republic NB1015 has controlled the declared

performance and released test report Nr.39-8796

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance P ass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h fro m max

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G310-G360-CPR-150615

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G800-G861-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 800-serie (G820 - G861)

Model: G820 Strömsrum, G830 Borgholm, G840 Ekeby, G855 Kungälv,

G860 Avanti, G861 Avanti.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G310-G360-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 300-serie (G310 - G360)

Model: G310 Kungsholm, G315 Karl-Johan, G320Drottningholm

G340 Gabriel, G350 Duvemåla, G360 Tillinge.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G800-G861-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 800-serie (G820 - G861)

Model: G820 Strömsrum, G830 Borgholm, G840 Ekeby, G855 Kungälv,

G860 Avanti, G861 Avanti.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavä gen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical Research Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential character istics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 300mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance Pass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h from max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

At nominal heat output

At saftey test

The undersigned is responsible for the production and compliance with the declared performance.

120 C

170 C

°

°

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G310-G360-CPR-150615

PRODUCT

Product type: Slow heat release appliance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 300-serie (G310 - G360)

Model: G310 Kungsholm, G315 Karl-Johan, G320Drottningholm

G340 Gabriel, G350 Duvemåla, G360 Tillinge.

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical Research Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pas s EN 15250:2007

Mecanical resistance Pass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h from max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

At nominal heat output

At saftey test

Undertecknad ansvarar för tillverkning och överensstämmelse med deklarerad prestanda.

Lars Burmeister, CEO Gabriel Keramik

Timmernabben 1 juli 2015

120 C

170 C

°

°

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

. Complies also with the following standards DINplus, BImSchVo II, 15a B-VG.

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance P ass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h fro m max

Thermal output 156MJ

Nominal space heating output 4,5KW

Energy efficiency 92%

Fluegas temperature in flue spigot

At nominal heat output

At saftey test

120 C

170 C

°

°

SP. Technical Research Instute of Sweden NB0402 has controlled the declared

performance and released test report P800646-A.

Engineering Test Instute, Czech Republic NB1015 has controlled the declared

performance and released test report Nr.39-8796

DECLARATION of PERFORMANCE (DoP) according to Regulation (EU) 305/2011

No. G400-G423-CPR-150615

PRODUCT

Product type: Slow heat release appl iance (SHRA) fired by solid fuel

Type & serial no. Gabriel Kakelugnar 400-serie (G400 - G423)

Model: Studio G400-G412

Studio2 G420-G423

Intended use: Space heating in residential buildings

Fuel type: Wood logs

MANUFACTURER

Name AB Gabriel Keramik

Address Strandavägen 62, 38052 Timmernabben, SWEDEN.

CONTROL

According to AVCP System 3

European Standard EN15250:2007

Test institute SP. Technical R esearch Institute of Sweden NB0402

Has controled the declarerd performance and released test report P800646-A

Engineering Test Institute, Czech Republic NB1015

Has controled the declarerd performance and released test report nr. 39-8796

DECLARED PERFORMANCE

Essential characteristics Performance Harmonized technical

specification

Reaction to fire A1 WT

Distance to combustable Behind 50mm

material Side 50mm

Ceiling 50mm

Risk for burning fuel falling out Pass

Emission of combustion products CO 0,1%

NOx 78mg/m3

OGC 46mg/m3

PM 37mg/m3

Surface temperature Pass

Cleanability Pass EN 15250:2007

Mecanical resistance P ass

Release of dangerous substances Pass

Thermal storage capacity Max: 2,9h after start

50% av max: 8,0h from max

25% av max: 17,2h fro m max

Technical description

CE-marking

The Gabriel tiled stoves are built with an ingenious

module system of refractory heat accumulating

material, consisting of an inner core and an outer

mantle, which are separated from each other. The

inner core absorbs a large part of the heat expansion

and reduces the furnace heat movement. The efficient

5-channel flue gas principle gives a high energy

efficiency and radiates a uniform and pleasant heat

into the room over a longer period.

The Gabriel tiled stoves can either be rear connected to

an existing approved chimney, or top mounted with a

prefabricated module steel or precasted block chimney.

A building permit is needed when building a new tiled

stove. Before starting to fire, the tiled stove installation

has to be inspected and approved by the Building

Control Officer. (See local and national regulations

regarding installation of fire places.)

The Gabriel tiled stoves are CE-approved by the

accredited test laboratory SP Technical Research

Institute of Sweden, and fulfil the environmental and

safety requirements stipulated in the new European

standard for “Slow heat release appliance fired

by solid fuel”. The stoves carry the CE mark by

The Gabriel tiled stoves are Swedish products and

fulfill the requirements for CE-marking, meaning

that they comply with EU health, environmental and

safety requirements. CE stands for Communaútes

Européennes. CE-marked products can be produced

and sold in every member country of EU and EES

community without any national product restrictions.

A CE-marked product is normally provided with

the document “Declaration of Performance”

in which the manufacturer assures that the product

fulfills the requirements designated by EU.

SP, Sweden’s Technical Research Institute, and the

Engineering test Institute of the Czech Republic meet

the environmental and safety requirements in the

new EU standard for the slow heat release appliance

(SHRA). The stoves also complies with the German

standards DINplus, BImSchVor 2, and the Austrian

15a B-VG.

GABRIEL KERAMIK AB

STUDIO2 • 3

Foreword

General

Gabriel tiled stoves consist of prefabricated modules,

cast from fireproof material. The stoves should be

built by an approved tradesman.

A building permit is needed when building a new

tiled stove. Before starting to fire, the tiled stove has

to be inspected by the Building Control Officer (see

local and national regulations regarding installation

of fire places).

Distance and measurements

As to the following pictures in this manual you place

the first module 75 mm from a combustible wall. A

non-combustible hearth shall be placed on the floor

in front of the stove (for size, see local regulations).

A 300 mm free space is needed in front of the soot

holes on each side of the stove. The hole in the

base for inlet air to the convection heat must not be

blocked. The manual’s control measurements (page 5)

are very important, while the other measurements

should be seen as a guide during the assembly.

Support

The foundation and floor support of the stove has to

be approved before assembly.

The weight of the stove is between 1300-1800 kg

depending on the model and flue connection.

Therefore the foundation requires sufficient bearing

capacity and shall be checked and approved in

accordance with the building permit (consult your

local building authorities).

Thickness of joints

The mortar joints between the modules are

approximately 5-10mm. Use a slightly dryer mortar

mix for the first half of the assembly. Use a suitable

wet brush for neat and tight joints.

Explanation of symbols/foreword

Marking with a pen

Important positions, areas for sawing and

placing of mortar are marked with a pen.

Control measurement

Shows important measurements during

assembly.

Trowel

Shows where the clay mortar is placed.

Rendered areas

Shows the areas that shall be rendered

with clay mortar.

Saw

Shows where the prefabricated modules

should be sawn.

Insulation

Shows where you place the insulation.

Flue connection

Gabriel stoves can be either rear or top connected.

A prefabricated flue can be directly connected on the

top of the stove. Check with your local dealer for the

best solution.

Step-by-step installation

Please follow the step-by-step assembly and pay

attention to the control measurements that are shown.

A certain tolerance is allowed but make sure the

control measurements are kept as it has a profound

impact on the tiling, which is to follow.

For good adherence, wipe the contact surfaces with

a squeezed sponge before jointing.

During the assembly the outer rings are always to be

one step ahead of the inner blocks.

Equipment

Trowels, brick layer, a long water level, radiator

brush, folding rule, chisel, buckets, sponge, rubber

mallet, covering plastic, angular grinder, hack saw,

2 ladders, joint sponge, wooden wedges.

Material included in the delivery

• Clay and sand - Clay mortar mix: 1:3½ (1 part

of clay to 3½ part of sand).

• Tile adhesive

• Grout

• Silicon - if during transport a module is broken it

can easily be fixed with the supplied heat-resistant

silicon or clay mortar by gluing the pieces together.

Safety instructions

Read these instructions carefully before

starting the assembly. Incorrect assembly

can cause serious damage and fire risk.

Make sure prior to the assembly that the

building permit is approved and that the

local chimney sweep has approved the

installation.

GABRIEL KERAMIK AB

4 • STUDIO2

min. 75 mm

415 mm

415 mm

min. 75 mm

415 mm

min. 75 mm

278 mm

Ø 150

min. 75 mm

min. 75 mm

278 mm

318 mm

318 mm

Ø 150

Ø 150

min. 75 mm

415 mm

Base block

Ø 680 mm

Top connection 2302 mm

Rear connection c/c 2148 mm

Preparations

In a corner Against a straight wall

In a corner

Against a straight wall

Combustible wall

Combustible wall

Combustible wall

Combustible wall

Measurement for ø 125 mm combustion air inlet connection

Top plate

Top plate

Measurement for ø 150 mm flue pipe connection

GABRIEL KERAMIK AB

STUDIO2 • 5

1003

0

406

508

2312

1862

1654

1446

1238

406

508

1965

2018

2244

1573

1953

1030

0

914

2071

10

10

1041

1282

406

17

16

15

14

7

7

7

7

7

7

7

7

7

6

5

5

4

3

2

1 *

2

1

8

8

8

A

8A

9

10

10

10

10

10

10

11

13

13

13

12

12

* 1–17 shows the numbers of all parts, see page 6.

= Control measurement

min. 75 mm

min. 75 mm

min. 75 mm

min. 50 mm

Body

In a corner Against a straight wall

Base blok

Ø 730 mm

Distance to wall (75 mm)

Combustible wall

Distance to ceiling (50 mm)

Body

Combustible wall

Combustible ceiling

Important measurements • STUDIO2

Outer section

Inner section

Floor level

Control and guide measurements (all measurements in mm)

GABRIEL KERAMIK AB

6 • STUDIO2

Start A

7

7

6

5

5

4

3

2

1

17

6

15

14

7

7

7

7

7

7

7

10

10

9

8A

8A

8

8

10

10

10

10

13

13

13

12

12

11

Overall installation sequence STUDIO2

GABRIEL KERAMIK AB

STUDIO2 • 7

1000

1000

710

45

min 75

min 75

400 mm

1

600 mm

1

1

2a

2b

Assembly

Mark on the floor exactly where the

stove is going to be placed. Also

mark the direction of the opening.

The example on the picture shows

45° from existing 90° corner.

In a corner

Set the base block (1) with a 10

mm thick layer of mortar on the

prepared floor. Make sure the

regulation distance to the wall is

kept. Level vertically and horizontally. The opening can be directed

at right.

Check the distance to the

wall (min. 75 mm)

Before starting the assembly,

make sure that the support is

approved according to your

building permit and that it is

in level with the floor.

Against a straight

wall

Set the base block (1) with a 10

mm thick layer of mortar on the

prepared floor. Make sure the regulation distance to the wall is kept.

Level vertically and horizontally,

see figure 1. The opening can be

directed at right.

Check the distance to the

wall (min. 75 mm)

GABRIEL KERAMIK AB

8 • STUDIO2

3

250 mm

4

406 mm

3

4

5

2

Assembly

Set the firebox block (2) with

mortar.

Mark the centre line on the first

block, it will help you to position

the opening and the soot hole

correctly.

Set the outer block (3) with mortar.

The opening shall face the 45°marking on the floor (step 1).

Seal with insulation where

indicated.

Set the outer block (4) with mortar,

level the soot hole with the previous

block. Level vertically and horizontally.

For a better joint, wipe the

contact surfaces with a

squeezed sponge, then

brush with a wet radiator brush. This is a general

instruction for the whole

assembly.

GABRIEL KERAMIK AB

STUDIO2 • 9

5

S

8

8

6

7

8

Set the outer block (5) with mortar.

Level vertically and horizontally.

Set the firebox (8) with mortar.

The firebox block may not touch

the outer rings (the firebox block

must be allowed to expand freely

without affecting the outer ring).

Level vertically and horizontally.

Push the firebox block backwards

as much as possible. Place the insulation and pull the firebox block

back to ”lock” the indsulation.

Set the second firebox block (8) on

top of the first one. Make sure that

no mortar falls between the blocks.

Level vertically and horizontally.

Make sure that no mortar

falls between the firebox

block and the outer ring.

Make sure that no mortar

falls between the firebox

block and the outer ring.

Brush the joints with a wet

radiator brush.

Assembly

GABRIEL KERAMIK AB

10 • STUDIO2

508 mm

5

6

8A

9

10

11

Set the outer ring (5) with mortar.

Level vertically and horizontally.

For a better joint, wipe the

contact surfaces with a

squeezed sponge, then

brush with a wet radiator

brush.

Set the third firebox block (8A)

on top of the second one. Make

sure that no mortar falls between

the blocks. Level vertically and

horizontally.

Note! Clean off mortar leftovers.

Plain with a radiator brush.

Assembly

Set the outer ring (6) with mortar.

Check that the height is

within the tolerane (508 mm).

GABRIEL KERAMIK AB

STUDIO2 • 11

min.

500

953 mm

8A

12

13

1030 mm

9

min.

500

14

7

Ø 630 mm

Ø 680 mm

14

Assembly

Set the top of the firebox

block (9) with mortar.

Set the fourh firebox block (8A)

on top of the third one. Make sure

that no mortar falls between the

blocks.

Level vertically and horizontally.

Cut off the insulation.

Before continuing above

the firebox opening,

construct a prop to support both

the outer

ring and

the firebox

top block as

shown in

the picture.

The support

will also

be of help

when tiling

above the

firebox. Keep the support

in position till the next day

or even longer.

Note! Clean off mortar leftoers.

Plain with a radiator brush.

Set the outer block (7) in mortar.

GABRIEL KERAMIK AB

12 • STUDIO2

10

7

7

10

10

7

10

7

10

7

10

7

16

10

15

Assembly

Place the inner block (10) on top

of the firebox block without

mortar joint. Make sure that

this and the following blocks are

in level and do not ignore any

irregularities.

Seal/isulate the hollow space

under the outer ring as indicated.

Carefully centre and set the outer

blocks (7). Make sure that the

outer block is one step ahead

of each inner block - set without

mortar - during the assembly. Outer

blocks and inner blocks must not

be in contact. Level vertically and

horizontally.

Check the control measurements,

see page 5.

For a better joint, wipe

the contact surfaces with

a squeezed sponge. Afterwards gently brush the

mortar joints with a wet

radiator brush.

GABRIEL KERAMIK AB

STUDIO2 • 13

17

18

11

7

7

17

18

19

Assembly

Set the “church roof” (11).

Level vertically and horizontally.

Seal with 2-3 mm insulation.

Set the outer block (7) in mortar.

Level vertically and horizontally.

Make sure that no mortar

falls between the firebox

block and the outer block.

Set the outer block (7) in mortar.

Level vertically and horizontally.

GABRIEL KERAMIK AB

14 • STUDIO2

22

1965 mm

13

7

7

20

21

22

Assembly

Set the outer block (7) with mortar.

Level vertically and horizontally.

Set the flame protection block (13)

with mortar.

Level vertically and horizontally.

Set the outer block (7) with

mortar.

Level vertically and horizontally.

GABRIEL KERAMIK AB

STUDIO2 • 15

23

24

13

12

25

13

12

23

24

25

Set the divider block (12) and the

flame protection block (13) with

mortar.

Level vertically and horizontally.

The divider block (12) and flame

protection block (13) must be

2-4 mm below the outer block to

allow the inner body to expand.

Smear a small string of mortar

on top of the divider block and

the flame protection block. Fix

the insulation in the mortar string.

The insulation creates an expansion gap aginst the divider block,

allowing the inner core to move

vertically.

Set the divider block (12) and the

flame protection block (13) with

mortar.

Level vertically and horizontally.

Assembly

GABRIEL KERAMIK AB

16 • STUDIO2

27

2071 mm

15

14

16

40 mm

26

27

28

Ø125 mm

Assembly

Set the damper lid (15) with mortar.

Level vertically and horizontally.

Set the damper frame with a thin

bed of mortar and make sure the

damper runs freely.

Set the top lid (14) with mortar.

Level vertically and horizontally.

Lay mortar over the damper and

the pipeattachment. Set the Leca

blocks (16) with mortar. The inside

of the blocks shall be rendered with

clay mortar (easiest done before

the assembly).

Top flue connection

Join the two blocks together with

the heat-resistant silicon or mortar.

Side flue connection to an existing chimney.

Cut the back of the block for a suitable connection.

GABRIEL KERAMIK AB

STUDIO2 • 17

29

17

29

Ø150 mm

Assembly

Render and brush the soot

channel surfaces, also the

downside of the top lid when

it is installed.

Top connected chimney

Set the top lid (17) with mortar

and make sure it is in level with the

underlying flue gas hole.

Side connected chimney

Turn the lid to fit the hole exactly

over the underlying block. Fill and

even with mortar.

Assembly

tiles and cassette

GABRIEL KERAMIK AB

18 • STUDIO2

Tiling preparation and assembly

IMPORTANT STEPS PRIOR TO TILING

• Mark the centre line.

• Check that the floor is level.

• Check the body surface. Is it vertical? Be aware that

you must compensate for any irregularities.

• All tiles shall be in level vertically and horizontally.

• Adhesive shall be applied on both tiles and body

with an 8 mm toothed trowel.

• A joint width of approx. 3mm is recommended.

The tiles are handmade with tolerance and joints

could vary accordingly. The overall appearance is

important. We recommend wooden wedges.

• Start tiling from the bottom and the centre and work

towards the sides.

• Seal with adhesive between tiles and body at the

firebox and the soot holes.

• The granite shelf shall be set in mortar.

• Do not block the hole/grate for inlet air for convection

heat.

• Glue or attach the decor lists with silicone. Use

clamps for the top list and a strap for the bottom list.

• The tiles are hand-made - there might be some

variations in measurements and colours.

GABRIEL KERAMIK AB

STUDIO2 • 19

Kakelsats Studio2

27 "

tile

s

66 cm

tiles

Granite

shelf

Decor steel band

50 mm

30 mm

Decor steel band

(Alternative placement)

Tiling plan

GABRIEL KERAMIK AB

20 • STUDIO2

30

31

32

80/125 80/100

Cassette installation (Studio, Studio2 and round tiled stove)

Outdoor cumbustion air inlet

Mount the reduction flange to the flexible tube and

connect to the flange for inlet air through the floor.

Indoor cumbustion air inlet

Mount the reduction flange to the flexible tube and

connect to the flange for inlet air through the base.

Place the enclosed rockwool sheet.

Cut out a square hole the same

size as the hole in the firebox plate

as indicated.

Fit in the cassette so that the steel

flanges round the cassette are

inside the tiles and the brass frame

is in contact with the tiles.

Note:

If the cassette does not fit correctly

at the bottom edge this can be

compensated by removing some

rockwool in the forward edge or

with a thin layer of mortar in the

rear edge under the plate. There

after the cassette should rest stable

and even on the bottom. The brass

frame should at the same time fit

tight against the tiles.

GABRIEL KERAMIK AB

STUDIO2 • 21

33

34

35

Cassette installation

Pass the flexible tube through the

cassette bottom and fit it over

the connecting flange. Fasten the

flange plate.

Mount the damper in the bottom

of the cassette, do not forget the

cotter pins. Make sure the damper

has a free action.

Fasten the cover plate.

GABRIEL KERAMIK AB

22 • STUDIO2

36

20mm

37

38

Cassette installation

Place the vermiculite plate in the

bottom.

Protect the brass frame and tiles

around the cassette with masking

tape to ensure a neat silicon seal.

Pull out the cassette approx.

20 mm and apply silicon just

inside the edge around the brass

frame, then push the cassette back

in. Even the seal with a wet finger

(dipping the finger into water with

washing-up liquid will make it

easier to get a neat joint).Remove

the masking tape.

Insulate behind the cassette,

around the sides and in the front

edge between the cassette and the

body.

GABRIEL KERAMIK AB

STUDIO2 • 23

1

2 3 4

40

39

41

Cassette installation

Install the last vemiculite plate on

the two tubes in the cassette and

push it as far back as possible.

This improves the combustion and

forces the flame forward.

Cut the sealing block to shape,

use e.g a hack saw blade.

Ensure that it fits exactly and

seals around the base block

walls.

Make sure the sealing block is not

pushed to far in as it will restrict

the inlet convection air flow to the

cassette.

Press the fan carefully into the pre

cut hole in the sealing block.

Note! The fan must be mounted so that air is sucked into the

fan. The air flow passes through

channels in the cassette and exit

through the upper front edge.

Fan installation

Insert the steel plate vertically

over the edge of the cassette. Turn

the plate horizontally and pull it

backwards firm and tight against

the top of the fire box block so that

it at the same time is fitted tight

between the cassete and the body

as shown in picture 3 and 4.

Sealing block

Extra large glass door

enhances the fire side

comfort

Fan for efficient

direct heat circulation

Low temperature flue gas

outlet

Inner core

Outer mantle

Expansion area

Heat accumulating,

dense, fire-resistant

material for long-lasting

heat radiation

Fan controlled direct heat through

channels in the hot air cassette for

efficient heat circulation

Connection for combustion

air from the outside

The traditional

5-channel flue gas

principle is still

incomparable

Airflow on the inside keeps

the glass cleaner

GABRIEL KERAMIK AB

info@gabriel-keramik.se | www.gabrielkakelugnar.se

Tel. +46(0)499-233 00

Loading...

Loading...