HPC 210 M

# 86021

English

Dansk xx

Norsk xx

Sve

nska xx

Hrvatski

xx

Slovenščina xx

Româneşte xx

Български xx

Bosanski xx

Srpski xx

© Copyright Güde GmbH & Co. KG - Birkichstrasse 6 - 74549 Wolpertshausen - Germany

1

4

5

6

3

2

7

8

9

7

10

12

15

13

11

14

8

6

16

20

17

21

19

23

22

18

9

7

Apparatus

High-pressure cleaning equipment

HPC 210 M

Heavy duty mobile petrol driven high pressure

cleaner. To be used on any place because no

electric power is needed for its operation.

Outfit:

Professional brass pump, chemical injector, 5 m

long pressure hose, high quality spraying lance

and 4 jets (1 jet for chemicals, 1x 0°, 1x 15°, a 1x

40°) with quick-closing device. Sturdy steel frame

with foundation plate and wheels with tyres on

steel rims. With pressure hose and gun holder.

Scope of Application:

Your high pressure petrol driven cleaner is

designed for cleaning works in open countryside.

For cleaning of machines, trucks, tools,

structures, facades, terraces, garden tools etc..

Scope of Delivery and

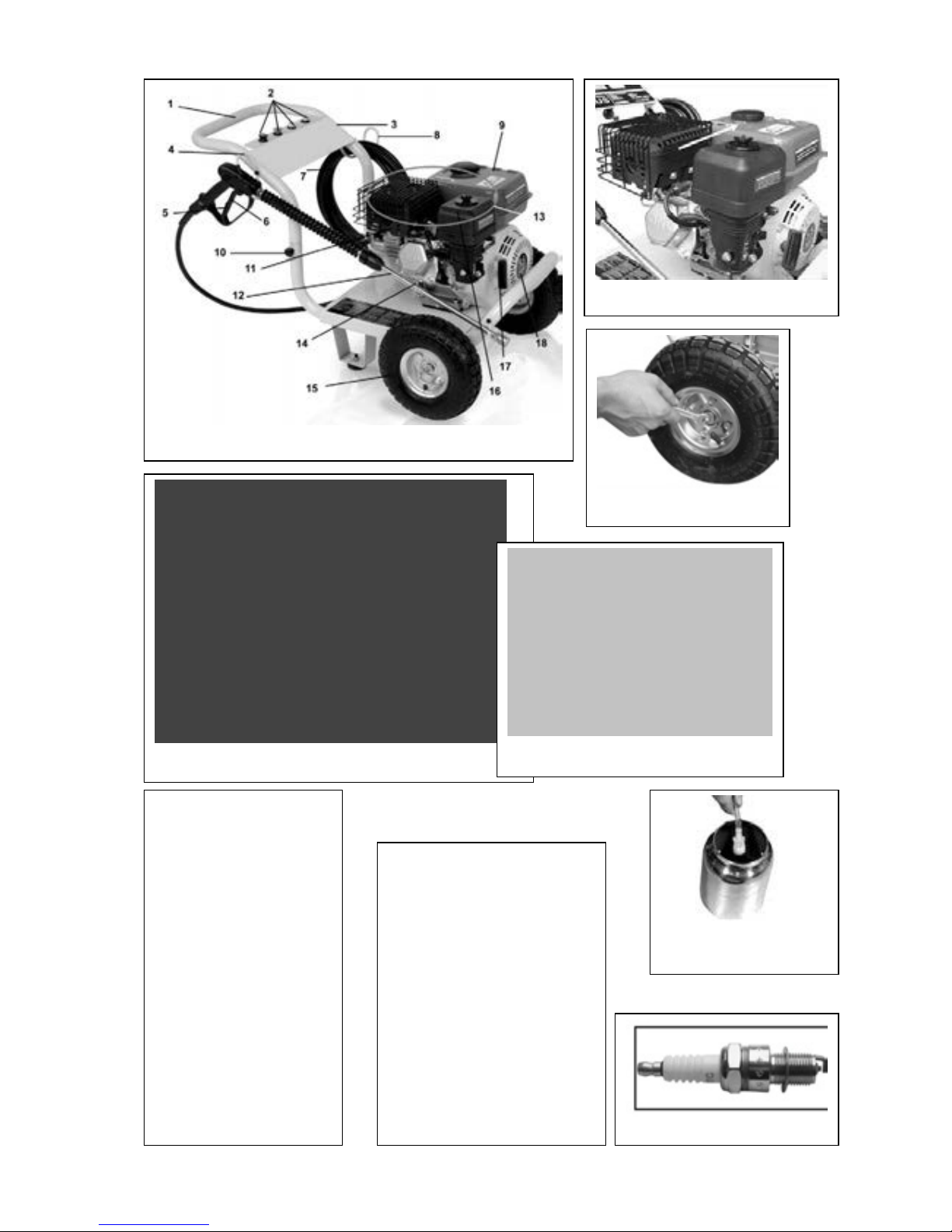

Description of Parts (fig. 1, 4, 5)

• Tyres (2)

• Spray gun handle (1)

• Pipe for water (to the jet) (1)

• High pressure hose (7,5 m)

• Water supply connection (1)

• Key for spark plugs (1)

• Jet cleaner (1)

• 5 mm imbuss key (1)

• Key for screws 10-13 (1)

• Gun handle (to be assembled) (1 set)

• Hose (to be assembled) (1 set)

• Instruction manual (1)

1. Holder

2. Jet

3. For placing accessories

4. Guide/holder of water pipe

5. Safety locking of spray gun

6. Spray gun

7. Flexible high pressure hose (5 m)

8. Crook for hanging the pressure hose

9. Petrol tank

10. Lock screws

11. Exhaust with damper

12. Protection against spraying away

13. Engine

14. Oil tank cover

15. Wheel

16. Air filter

17. Starting cord

18. Starting element

19. Gas handle

20. Choke

21. Petrol cock

22. Switch with on/off positions

23. Filter for cleaning means

24. High pressure connection/discharge

25. Pipe for suction of cleaning means

26. Connection to water main

Guaranty

For the claims on guaranty performance se

enclosed letter of guaranty.

General Safety Regulations

Read carefully the whole operation manual

before first use of the apparatus. In case of any

doubt related to connection and attendance of

the apparatus contact the manufacturer (service

department).

READ CAREFULLY FOLLOWING

INSTRUCTIONS FOR SECURING HIGH

GRADE SECURITY:

Danger of injury! The corresponding safety

provisions shall be always observed when

working at the petrol stations or in other

dangerous areas.

The water polluted with oil shall not be

discharged into soil, ground water or waste

water systems. Therefore the engine and

chassis of the apparatus shall be cleaned

only on places specially determined for these

activities and equipped for disposal of old oil.

Read carefully all instructions and all orders

related to safety. Nonobservance of safety

instructions and orders may cause electrical

accident, fires and/or serious injuries. Keep safe

for future use all safety orders and cautions.

Safety on the Workplace

• The apparatus with empty tank shall be

placed in a well ventilated place. No fuel

or oil is permitted to be placed near the

apparatus.

• The apparatus shall be placed on a hard

and load-bearing surface.

• The apparatus may only be used in open

countryside and shall not be operated in

closed spaces; the exhaust gases may

endanger the life!

• The working apparatus shall be in safe

distance from the object being cleaned.

• The persons and children standing

nearby shall keep sufficient distance from

the apparatus.

• During the operation the apparatus shall

be all the time under supervision

Safety of Persons

• Be constantly concentrated, pay

attention on what you are doing and

(pictures are a pattern only)

56

8

use common sense when working

with the apparatus. Even a moment

of inattention may cause serious

injuries. Wear always protecting

gloves, because during the spraying

very small particles may be

generated.

• Wear always noise protectors at

work.

• When working wear always long

trousers and solid footwear or high

boots. When using chemicals,

cleaning agents or other etching or

abrasive means the additional

protection outfit/wear is

recommended.

• Make sure that you always have

reliable posture and good balance.

Never work far away from the

apparatus. If you are nearer you may

better control the apparatus and you

will be better prepared for

unexpected situations.

• The apparatus shall never be

operated by persons under the

influence of alcohol, drugs or

medicines.

• If the apparatus is not being used or

if you want to remove high pressure

hose, pull out the spark plug or

ignition cable to prevent the

unwanted starting the engine.

• Do not wear loose clothing, jewellery

or other objects that may be caught

by the engine.

• The persons, children and pets

standing by shall keep the safe

distance from the working place. This

safe distance shall be at least 15

meters.

• Never aim the spray gun at yourself

or at other persons.

• Never place your hand, fingers or

another part of your body directly in

front of the spray pistol jet.

• Never smoke when operating the

apparatus.

Correct Application of the Apparatus and

Precautionary Safety Measures

• Never apply strength when handling the

apparatus. The apparatus shall be only

used for the purpose it was determined

for. The apparatus correctly used will

perform the work more efficiently and

better.

• Never use the electric power or engine

fuels driven apparatus if he has not

switch with on/off positions. The

apparatus working without this switch is

dangerous and shall be repaired.

• Keep off the children even if the

apparatus is switched off. The persons

not acquainted with the apparatus or

those ho have not read this instructions

are not allowed to operate the apparatus,

because the apparatuses driven by

electric power or engine fuel are

dangerous when manipulated by

uninstructed users.

•

The apparatus shall never be

operated under following

circumstances:

• Perceptible fluctuation of engine

revolutions

• Perceptible fall of pressure

• Faulty ignition

• Occurrence of smoke or fire, work in

closed rooms

• Excessive vibrations

• Rain or bad weather conditions

• Dirty apparatus. Keep apparatus clean

and clear from oil, impurities and other

foreign matters.

• Do not aim the water flow at electric

components or on the apparatus itself.

• Hold/aim the protection against spraying

away always with both hands

• The hose shall never touch hot exhaust

• Never touch the jet or water jet during the

operation.

• Never refuel if the engine is working or is

still hot or if there is open fire nearby. Do

not smoke near the apparatus.

• Check the jets and hoses before putting

the apparatus into operation.

• The gun handle shall not be gripped

during the operation

• High-pressure hose shall not have any

breaks, kinking or reductions when being

laid

• All hose supply pipe shall be properly

connected

• When putting the apparatus in operation

in cold weather the measures should be

taken preventing ice creation in the

equipment

• If the apparatus is not used the safety pin

shall be activated to prevent the

unwanted release of water jet under high

pressure (see operation manual)

• Trigger of the gun working under high

pressure shall not remain without

handling for more than 5 minutes,

otherwise the pump may be damaged.

• Check in regular intervals possible

untightness in fuel system or signs of

wearing as e.g. rubbing or wet line or

missing clamps, damaged tank or

(missing) cover. The failures like this

57

9

shall be unconditionally removed before

putting the apparatus into motion

• Do not touch hot exhaust

•

The apparatus shall be operated,

maintained and the refuelled only

under following conditions:

• Sufficient ventilation

• Refuel only at sufficient lighting

• Make sure the fuel does not spray away

and never refuel when the engine is on

• During refuelling no ignition source may

be nearby

• Use lead-free petrol

• Never work with damaged high-pressure

hose

General Safety Instructions for

High-Pressure Cleaning Fuel

Driven Apparatuses

Caution: This apparatus is determined for work

with cleaning means offered and recommended

by the Manufacturer. The use of other cleaning

means or chemicals may reduce the safety of the

apparatus.

Caution: Never operate the apparatus near other

persons, unless they wear protective clothing.

Caution: High-pressure jet may be very

dangerous if used incorrectly. Therefore the jet

shall never aim at persons, electric components

or at the apparatus itself. Never aim the jet at

yourself or at other persons to clean the shoes or

clothing.

The safety of the apparatus is guaranteed only

under condition that original Manufacturer’s spare

parts or spare parts recommended by the

Manufacturer are used.

Caution: Hoses, connections, supply

connections under high-pressure are most

important for the apparatus. Therefore only

supply connections and connections

recommended by the Manufacturer shall be

used.

The apparatus shall not be used further in case

the supply connection or other important parts

are damaged, as e.g. safety jigs, high-pressure

hoses or spray gun.

Caution: Use always proper type of petrol, other

fuels may be dangerous.

Caution: The apparatuses with combustion

engines shall not be used in closed spaces,

unless the authorized testing authority permits

the equipment with sufficient ventilation.

Caution: Exhaust gases shall not be released in

the surrounding of ventilating equipments.

Safety Instructions

Fuel

Caution: When handling fuels be always

extraordinary careful, because they can easily

ignite and the vapours are explosive! The

below mentioned safety instructions shall

always be observed:

• Use only properly checked tank/canister.

• If the engine runs, do not remove the

tank cover and to not pump refuel the

apparatus. The exhaust of the apparatus

must be sufficiently cold before refuelling.

• Do not smoke during refuelling

• Never refuel the tank of the apparatus in

the closed spaces.

• The apparatus or petrol canister shall

never be stored in closed spaces or in

the regions with open fire, as e.g. not far

of the water heater.

• If some petrol sprays out, the apparatus

shall not be started, it shall be placed in

another place in sufficiently safe

distance.

• The tank cover shall be always put on its

place and properly closed after refuelling.

• The tank content may be discharged only

in free space.

Other Safety Instructions

Safety Valve with Heat Effect

The apparatus is equipped with a safety valve

with heat effect protecting the pump against

overloading if the spray gun does not work for a

longer period of time or when a jet is clogged.

This safety system prevents overheating of the

pump.

Set the apparatus always on „AUS/OFF“, if you

do not use it for more than 5 minutes. Hereby you

will prevent wearing of the apparatus, reduce fuel

consumption and extend the service life of the

pump that will not be overheated so much.

Safety Locking of Spray Gun.

The safety locking (Fig.1, Part 5) of the spray gun

shall be activated to prevent unwanted release of

high-pressure water jet if the apparatus does not

work. (See Operation Manual)

Disconnecting Device at Low Oil Level

This apparatus is furnished with a device that will

switch off the apparatus when the oil level is low.

If the oil level drops under corresponding mark,

the apparatus will be automatically switched off.

Herewith the engine of the apparatus is protected

against operation with low oil level which may

result in unsufficient lubrication. If the device

switches off when the oil level is sufficient, check

if the apparatus has not been switched off due to

its sloping, not horizontal position. Place the

apparatus in a definitely horizontal position and

start it. If the apparatus does not start or quickly

58

10

switches off again, check the oil level. The oil

level may be too low to deactive the

disconnecting device. The pump shall always

have as high oil level as possible (full).

Caution: Should the pump run for more than 5

minutes in idle run, it may be damaged or

caused damage to the apparatus.

How to Proceed in Emergency

Performe measures of first aid according to the

kind of injury and call for qualified medical help

as soon as possible.

Protect the injured person against further

damage of health and sooth him/her.

Symbol Explanations

Following symbols are used in this Operation

Manual and/or on the apparatus:

Product Safety:

The product is in compliance

with corresponding standards of

European Community

Prohibitions:

General prohibition (in

connection with another

pictogram

Inflammable, no smoking near the

apparatus

Caution:

Caution/Attention

Warning against dangerous

electric voltage

Orders:

Use eye protection Use noise protectors

Read the Operation Manual before

use

Wear protective gloves

Environment Protection

Do not throw away wastes freely,

classify them and professionally

dispose of.

Cardboard packing material

may be delivered for recyclation

on particular places determined

for this purpose.

Electric or electronic devices that

are damaged or determined to be

disposed of shall be delivered for

recyclation on particular places

determined for it.

Packings:

Protect against the wet

Orientation on the packing

Up

Technical Data:

Weight

When the oil level is low the

engine cannot start or it will

switch off again immediately

The jet shall not aim at the persons

or animals, on parts

under power or at the

apparatus itself.

Residual Dangers and Protective Measures

Mechanical Residual Dangers

Trapping, Winding up

Hands, hair etc. can be trapped by running

engine.

Use protective gloves and/or keep distance from

the running engine

Heat Residual Dangers

Burns

Contact with the engine that is running or is

still hot may cause burns.

Keep safe distance from the running or still heat

engine. Wear protective gloves.

Noise Endangering

Damage of Hearing

Longer work with the apparatus may cause

damage of hearing.

Use noise protectors all the time.

Negligence of Ergonomic Principles

Inconsistent Use of Personal

Protective Aids

The operation of the machine without wearing

protecting aids may cause heavy external and

internal injuries.

Wear all the time prescribed protective clothing

and work with proper care.

Other Dangers

Insufficient Local Lighting

Unproper lighting represents high safety risk.

Care for sufficient lighting at work with the

apparatus.

Slip, Stumble or Fall of Persons

The cables and hoses may cause stumple and

59

11

fall.

Keep order on the working place.

Disposal

The instructions about the disposal of wastes are

shown in the pictograms placed on the apparatus

and/or on the packing. For the explanation of

individual marks see Chapter „Marking on the

Apparatus“.

Requirements on the Operator

The Operator shall carefully read Operation

Manual before using the apparatus.

Qualification

No special qualification is needed for the work,

just detailed training provided by the specialist.

Minimum Age

The apparatus may operate only persons at the

age of 16 years and more. An exception makes

the case is a special training for acquiring the skill

under supervision of a lecturer.

Training

Only corresponding instruction is needed for the

use of the apparatus. No special training is

necessary.

Technical data

Engine: 4-Stroke-OHV

Engine Power: 4 kW (5,5 PS)

Stroke Volume: 163 cm³

Engine Revolutions: 3600 min-1

Maximum Pressure: 210 bar

Working Pressure: 160 bar

Water Output: 10l/min

Tank Volume: 3,6 l

Oil Volume: 0,6 l

Weight: 41 kg

Storing

Should the engine be not used for longer period

of time or should it be stored for at least one

month, following working steps shall be

observed.

Discharge all petrol from the tank and from the

choke.

• Remove spark plug.

• Put about 1 tablespoonfull of clean

engine oil into the cylinder for spark plug

insert.

• At switched off engine pull several times

carefully the starting cord. Then insert

the ignition plug again and pull out the

starting cord until the piston is completely

up (compression point OT). Stop pulling

as soon as you feel perceptible

resistance.

Store the apparatus in a well ventilated, dry place

under protective cover so that no dust and dirty

may be deposited on it.

Measures for Storing for Winter or for a

longer Period of Time

If the apparatus is not used for at least 3 months

or if frosts are expected in winter months, the

pump shall be properly protected against damage

caused by frost or against freezing. Prepare

proper solution for protection in winter months

according to the instruction on the protective

means. Pour the solution carefully into the inlet of

the apparatus. After the solution dripped away at

the outlet, close it with cork or another suitable

plug or closing device. Place into the inlet so

much non-freezing liquid till the pump is full. Then

close the inlet with cork or another suitable plug.

Before using the apparatus after treatment with

protective non-freezing liquid all liquid shall be

discharged from the pump, hose and water piping

leading to the jet. After first restarting the

apparatus again a bit of liquid may pour out from

the pump. This pouring will stop shortly.

Installation

Remove all packing material from the apparatus.

Check the apparatus, all parts and accessories

and make sure that no part is missing and that no

damage occurred during the transportation.

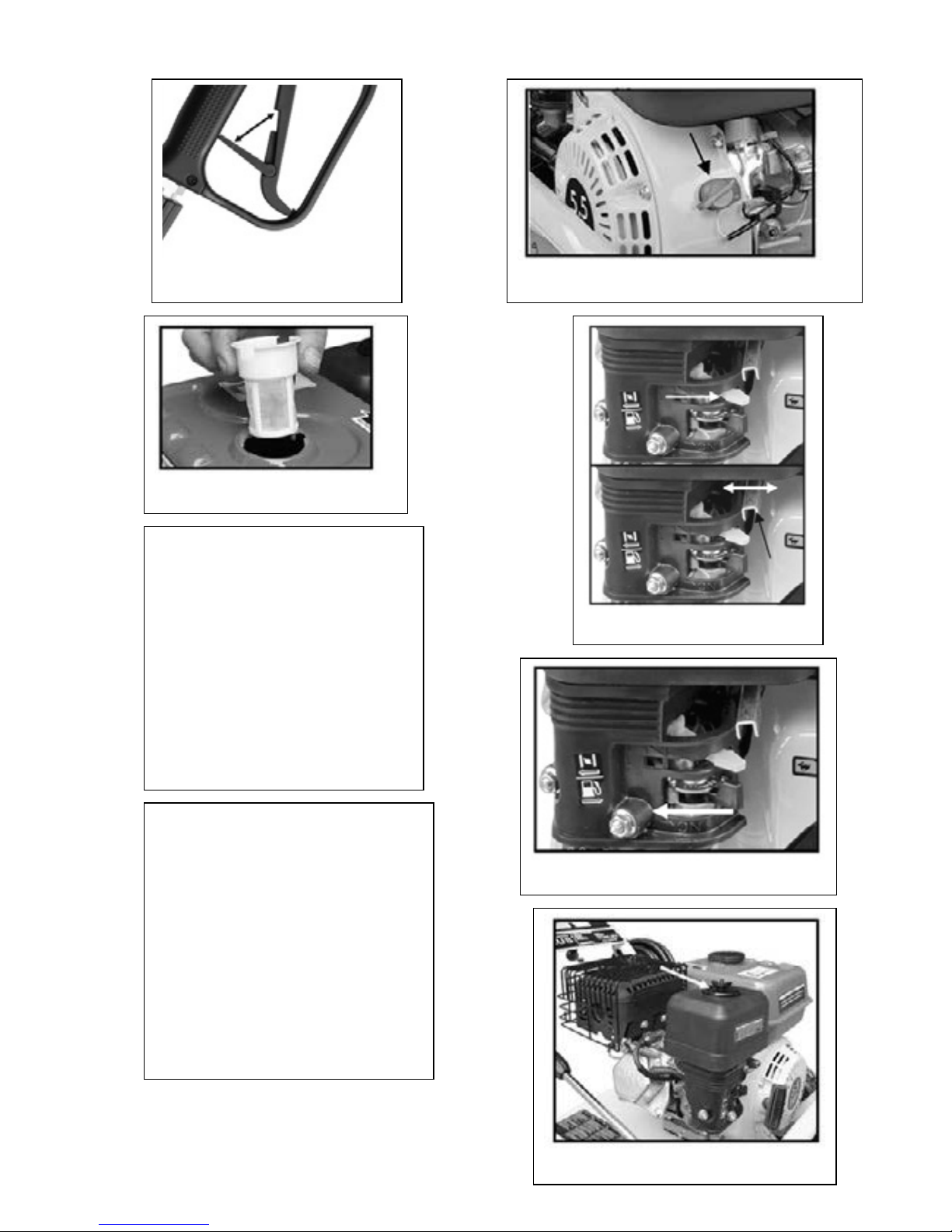

Setting on the Handle and Guides (Fig. 6)

Fix the handle and the device for placing

accessories to the frame of the apparatus. Stick

the lock screws through the holes outside the

apparatus and fix them with securing collar.

Tighten manually. Fix the hook for high-pressure

hose and guides to the upper handle.

Wheel Installation (Fig. 3)

Before fixing the wheel loose the screw and

release the axis. Set the wheel on the axis and

secure it with delivered locking nut.

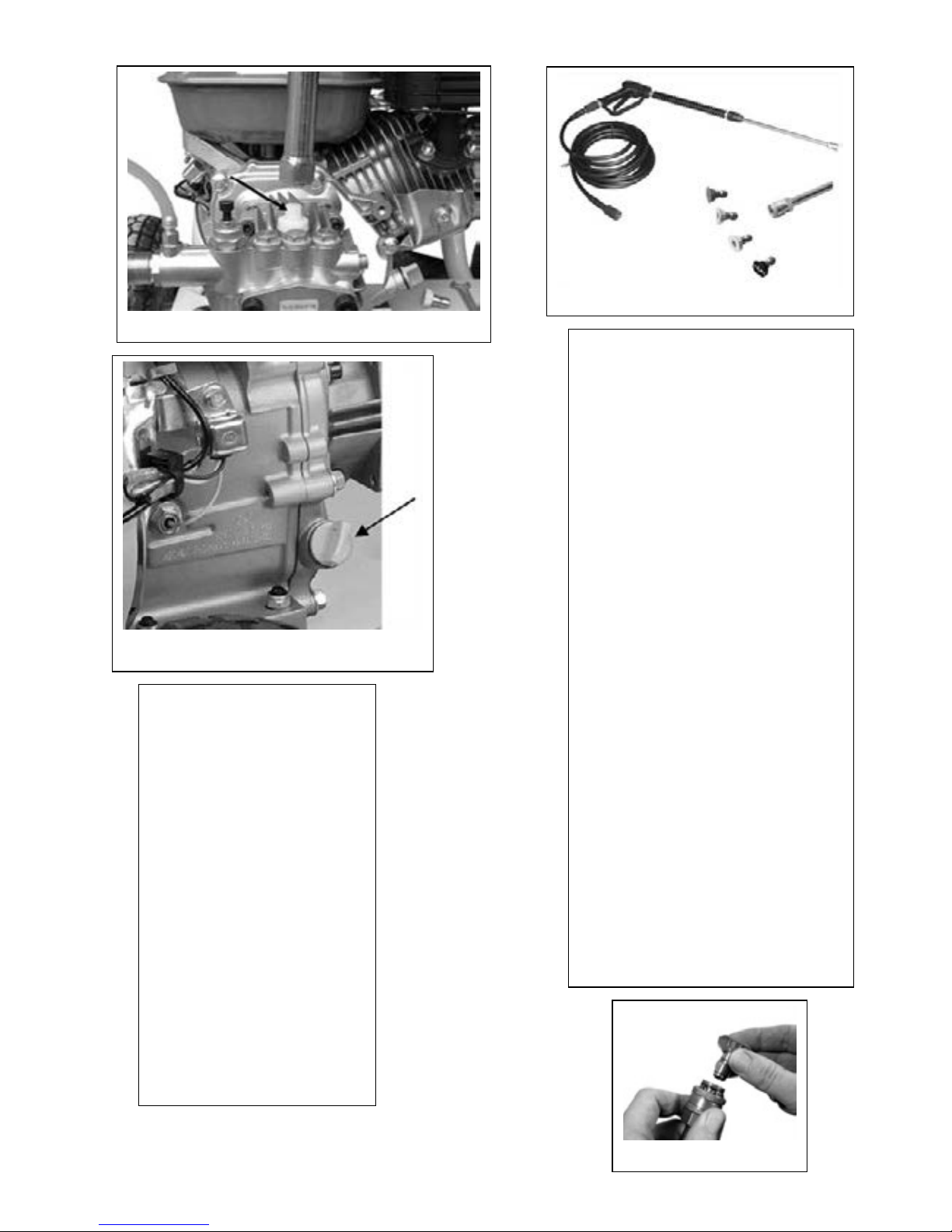

Pump Plug (Fig. 10)

Observe the rules of your water company.

According to the EN 61 770 standard, the

appliance must not be immediately connected to

public drinking water supply. However, short-term

connection is according to DVGW (German

Association of Gas and Water Branch) accepted

if there is a backflow barrier with air intake inbuilt

in the supply line. Also mediated connection to

public drinking water supply through free output

according to EN 61 770 is allowed; e.g. by

inserting a container with a float valve. Immediate

connection to the line network not designed for

distribution of drinking water is admissible.

The apparatus is furnished with the plug

preventing leakage of the oil during

transportation. Remove the transport plug and

60

12

replace it with the plug with bleeding function that

is included in the delivery. The pump of the

apparatus has closed oil circulation that needs no

maintenance. (Refuelling or exchange of oil is not

necessary).

Before Putting into Operation

Following operations shall be performed before

putting the apparatus into operation:

• pour the engine oil into gearbox

• pour the petrol into the tank

• connect the high-pressure hose to the

spray gun and to the pump

• connect the pump to the water main

• connect the jet to the spray gun

Important Warning: The engine and the pump

of your apparatus needs some period of time

to run in. Therefore the apparatus will operate

with full output after a few hours of operation.

Pouring the Engine Oil into Gearbox (Fig. 12)

Never try to start the apparatus if there is not

enough corresponding oil in the engine. There is

no oil in the apparatus at delivery thereof. If the

apparatus operates without (sufficient quantity of)

engine oil, the engine will get damaged. Place

the apparatus on flat surface and remove the

cover from the oil tank. Fill the engine oil at least

up to the half of the measuring bar length.

Pouring the Petrol into the Tank (Fig. 2)

High-pressure cleaner is driven by a 4-stroke

engine requiring leadless petrol. Use suitable

funnel for filling up the petrol. Make sure there is

not too much petrol in the tank and prevent

spraying the petrol out. The oil should reach up to

the fuel filter, not higher.

Connection of High-Pressure Hose to the

Handle of the Gun and the Pump (Fig. 7)

Put the water pipe on the spray gun. Hold the

end of the gun and screw the pipe on it so that

the connection is firm and sure. Caution! Do not

tighten the screw too much, both supply

connections may be damaged.

The supply connection of the high-pressure hose

with the supply connection on the bottom side of

the spray gun handle connect firmly and safely.

Caution! Do not tighten the screw too much, both

supply connections may be damaged.

Safety Stop for High-Pressure Water Pipe

(Fig. 16)

The gun handle has a safety device preventing

unwanted activation of high-pressure pipe. This

device can be put into operation by leasing the

handle and activating safety stop between the

trigger and the handle.

Connection of the Hose (Fig. 13)

The water supply connection is furnished with

particle filter. Never let the apparatus work

without filter. The intervals for checking and

cleaning of the filters depend on the water

quality. If the water in the water mains contains

impurity articles, the filter shall be cleaned after

every use because otherwise the apparatus

output will (considerably) fall and the pump may

be damaged.

The supply connection part for water supply has

a form of a (male) plug and shall be fastened with

screw on the inlet to water tank of the apparatus.

Put the clamping element (female) to the hose

and then connect this element with the part of

supply connection in form of a plug. Connect the

high-pressure hose to the connection/discharge

for high-pressure. Release water and press the

handle in form of a gun till the water starts flowing

from the pipe continuously. The water

temperature shall not exceed 40

0

C..

Setting the Spraying Angle (Fig. 11)

Warning: The protection against spraying away

shall always be properly set, otherwise it could be

pushed in under the influence of the highpressure jet, and it may also cause injury and

damage.

You may chose from 4 different jets market by

your colour that may show various spraying

angles.

0° jet (red):

This jet creates an extremely focused jet with

very high pressure force. It is suitable for

particularly careful cleaning of small areas. The

jet is therefore applicable only on the areas that

can resist such a pressure, e.g. metal or

concrete. Not suitable for wood.

15° jet (yellow):

This jet creates a jet 15° wide, therefore it is

especially suitable for intensive cleaning of

smaller areas. The jet can be used only for areas

that can resist such high pressure.

40° jet (white):

The jet creates a jet 40° wide, water pressure is

medium strong. This jet is suitable for cleaning

larger areas and may be used for most cleaning

works.

Low-Pressure Jet (black):

This jet can be used for chemicals and cleaning

agent’s application. It creates the lowest

pressure.

Important warning: The high -pressure jet can

damage the lining, coating and pavement due

to the type of m aterial or insufficient knowhow. Therefore check first the effect on a

smaller area. If nece ssary the water pressure

can be ch anged by replacement of the jet or

by reduction of the engine output.

61

13

Connection of the Jet (Fig. 15)

Connect the jet with quick-coupling device to the

water pipe leading to the jet. By means of the

quick-coupling the jets can be replaced quickly

and without any problems. After the jet is

connected, shift the safety collar back towards

the gun, then set the jet on the end of water pipe.

Release the safety collar. The jet is firmly set in

the required position. When replacing the jet shift

the safety collar back, remove the old jet and set

the new one.

Caution: Check always carefully if the jet has

been set correctly.

Caution: If the safety collar cannot be s hifted

back without problems, the je t has no t been

correctly set. Press the jet with strength into

the corresponding hole, bec ause the safety

collar will not return back by itself and the jet

will get out.

Cleaning Means (Fig. 8)

Use suitable tank with cleaning means

determined for pressure washing machines. Do

not use rinsing means for washing, they contain

salt. Quality cleaning means for pressure

washing machines are recommended for this

high-pressure cleaner. Observe the instructions

on the vessel/canister. Most washing means for

cars contain combination of washing means and

wax for chassis (wax-washing means mixture).

They are mostly dense, viscous means. The

viscosity (hence liquid density) of the cleaning

means usually increases in cold weather. We

recommend to solve this kind of washing means

in hot water before pouring it into the vessel. At

combination of washing and wax means it is

recommended to prepare a solution before use.

As basic principle the ratio of the mixture 50:50 is

recommended. Of course, you can create a

mixture with a different ration based on testing,

that may be more suitable for your purposes.

Instructions:

• Dense cleaning means cannot flow

properly from the cleaning vessel and

it can clog the system with deposits.

• The cleaning vessel shall be

thoroughly rinsed with water after

use.

When using the delivered cleaning means the

black jet (low pressure) shall be fixed on the end

of the water pipe. Insert the end of the suction

pipe into the cleaning means vessel of the highpressure cleaner. Suction and mixing of the

cleaning means will pass automatically if the

water flows through the pump.

Installation of High-Pressure Cleaner

• Place the high-pressure cleaner on solid

and even surface in a way enabling

properly lubrication of the engine and the

pump. When installing avoid the places

with depressions or holes (e.g. places

with puddles). When the surfaces are

smooth and slippery, there is danger of

injury!

• Place the apparatus on a well ventilated

place in sufficiently safe distance from

inflammable materials or vapours. Safety

regulations for proper ventilation shall be

principally observed. Minimum distance

from inflammable materials shall be 50

cm.

• The apparatus shall be placed so that the

operator will have easy access to all

parts thereof and to the control elements.

During installation the apparatus shall be

properly protected against the damages

from outside.

• The high-pressure hose shall not be laid

across the traffic area, otherwise it may

be worn very quickly and damages may

occur.

Putting the Apparatus into

Operation

• Remove dirt and foreign particles from

the spray gun and from the connection in

form of a plug.

• Put the jet on the spray gun.

• Start the engine

Warning: The pr otection against spraying

away shall all the time be properly set,

otherwise it could be depressed by highpressure jet, and damage and injury may

occur.

Start of the engine: (Fig. 14/20/17/21)

• Turn the petrol cock (ON)

• Open the choke (ON)

• Set the engine switch on EIN/ON

• Hold firmly the engine on the frame with

one hand. Hold the starter cord with the

other hand and pull it slowly until you feel

the resistance and the starting element

reaches the required position. When you

feel the resistance, pull the cord strongly

and quickly. Repeat this procedure till the

engine starts.

• If the engine has been put into running

and runs evenly, put the choke lever on

OFF (deactivation).

• The number of revolutions of running

engine may be modified with gas lever.

By shifting the lever to the right, the

number of revolutions will drop, by

shifting it to the left the number of

revolutions will increase.

• Switch off the engine by putting the

engine switch to position AUS/OFF.

62

14

Warning: After switching off th e engine stop

water supply and release the residual

pressure by pressing of gun handle till no

pressure remains in th e apparatus and the

water stops flowing out. Then secure the

spray gun with safety stop, protectin g it

against unwanted switching on. Remove the

water pipe leading to spray jet and discharge

the remaining w ater from all hose parts. Roll

up carefully the hoses, no bends or

depressions are permitted. Wh en doing so,

check if the hose elements are not damaged,

replace the dama ged parts if ne cessary.

Faulty hoses can be v ery dangerous when

under pressure!

• Before storing the switched off engine

close the petrol cock (OFF)

Trouble Shooting

(Problem): Alternating Pressure

(Cause):

1. The pump intakes the air,

dirty, worn or blocked valves

2. Clogged jet

(Measure):

1. Check the tightness of all

supplying connections

2. Remove the deposits with jet

cleaner

(Problem): Water is flowing out of the

pump

(Cause):

1. Worn sealing

(Measure):

1. Contact customer service

(Problem): Pump does not reach the

necessary pressure

(Cause):

1. The pump intakes the air at

the supply connections or at

the hose

2. Clogged suction or discharge

valves

3. Blocked discharge valve

4. Worn water pipe or jet

(Measure):

1. Check the tightness of all

supply connections

2. Clean or replace the valves,

have apparatus checked by

customer service

3. Loosen or tighten with the

set screw.

3. Check and/or replace

(Problem): The pump runs but does not

pump the water

(Cause):

1. Inlet or pressure hose are

clogged or blocked

2. Suction filter is clogged

3. The jet is clogged

(Measure):

1. Check, repair or replace, if

necessary

2. Remove and clean the filter

3. Clean the clogged jet with jet

cleaner

Cleaning and Maintenance

Remove Clogging (Fig. 22)

Warning: Switch off the engine and let it get cold

before checking, cleaning, maintenance or

replacement. The pressure shall be completely

reduced. If the effect of water jet is permanently

changing and water does not flow regularly,

release the trigger and switch off the apparatus.

When the apparatus is switched off, press the

trigger and discharge the residual pressure.

Check the jet at the end of the water pipe if t is

not clogged. If you suspect that there are some

deposits inside, remove them with special

cleaner. The water jet shall be checked regularly

and maintain in good condition by jet cleaner that

is involved in the delivery. Before performing

these works the engine shall be principally

switched off and the apparatus disconnected

from the water supply

Regular Maintenance

Spark Plug (Fig. 9)

Check the spark plug every 50 hours of

operation. Check the colour of deposits on the

end of the plug. The colour should be „slightly

brown-row brown“. Remove the deposits with

wire brush. Check the distance of electrodes on

the spark plug and set the correct 0.7-0.8 mm

distance, if necessary.

Refilling/exchange of Engine Oil (Fig. 19)

The first exchange of engine oil is recommended

after 40 operation hours, then after every 100

hours.

• Place the apparatus on even surface and

let the engine getting hot for a few

minutes.

63

15

• Then stop the engine.

• Place a suitable vessel under the pump

for catching the old oil.

• Remove the cover from the oil tank,

remove the discharge screw and sealing

so that the oil may be completely

discharged. Use the pipe or another aid

preventing creation of stains on the

frame of the apparatus by discharging oil.

• Check the discharge oil screw, sealing,

closing device on oil inlet and O-ring.

Replace if necessary.

• Set again the oil discharging screw and

sealing. Tighten the oil discharge well

and firmly.

• Refill the oil at least up to the half of the

gauge

• Fix again firmly and securely the oil inlet

closing device.

The waste oil shall be removed according to the

principles of environment protection. In many

cases the waste oil can be delivered to your

pump station. Never dispose of the oil together

with domestic refuse and do not discharge it into

the soil!

Air Filter (Fig. 23)

Remove the air filter and check if it does not

contain impurities or is not damaged and clean it

every 100 operation hours or once in a month.

Clean the filter thoroughly with cleaning means

on water basis that is not harmful for the

environment and has degreasing effect. Let the

air filter get dry well and put it back again.

Warning! Never let the engine on without air

filter!

Oil Vessel Filter (Fig. 18)

The oil vessel filter shall be removed and cleaned

always after 150 operation hours or every 3

months. In this case remove the closing device

from the oil vessel and thoroughly clean the filter

with cleaning means on water basis that is not

detrimental for the environment. Then put the

filter back and put the closing device back.

64

Loading...

Loading...