Basic 6T/W

English – GB

Translation of original operating instructions

WOOD SPLITTER

#02020

© Güde GmbH & Co. KG - Birkichstrasse 6 - D-74549 Wolpertshausen - Germany

1

2

11

12

3

2

5

2

1

10

4

7

9

6

13

8

A

4

3

5

7

3

8

9

10

1

2

10

GB

A.V. 2 Any reprints, even partial, are subject to approval. Technical changes reserved! Pictures just for illustration purposes !

Please read carefully the Operating Instructions before putting the appliance into operation

Translation of original operating instruction.

Marking on the appliance

Explanation of symbols

The following symbols are used in these Operating Instructions

and/or on the appliance:

Product safety:

Environment protection:

Dispose waste professionally

so as not to harm the

environment.

Packing cardboard material

may be delivered to collecting

centres for recycling.

Product corresponds to

appropriate standards of the

EU

Prohibitions:

General prohibition

(in connection with another

No touching inside!

icon)

No pulling the cable!

Not to be used in closed

rooms!

Machine may only be

operated by one person

Warning:

Warning/attention Warning against tripping!

Any damaged and/or

disposed electric or electronic

devices must be delivered to

Interseroh-Recycling system

with serial number

appropriate collection centres.

Package:

Protect against humidity!

Careful – fragile!

This side up.

Technical data:

Connector Engine power

Revolutions Splitting force

Keep a sufficient safe

Warning! Risk of getting

distance!

Warning! Flying parts!

Warning! Hand injury by

splitting cross!

Warning against dangerous

voltage!

Commands:

Read the Operating

Instructions before use

Use safety gloves Use safety shoes!

CAUTION! Please read the

Operating Instructions before

operating the machine!

Use protective glasses and

earphones!

jammed!

Max. diameter of the cut wood Max. length of the split wood

Table size app. Weight

Sonstiges:

Before operation, heat oil for 1

minute by pressing one

protective handle.

Keep one operating arm

pressed down when starting

the splitter!

During operation, the oil

gauge must be screwed out

by at least 2 full turns. During

Rotation direction

transportation, the oil gauge

must be screwed in.

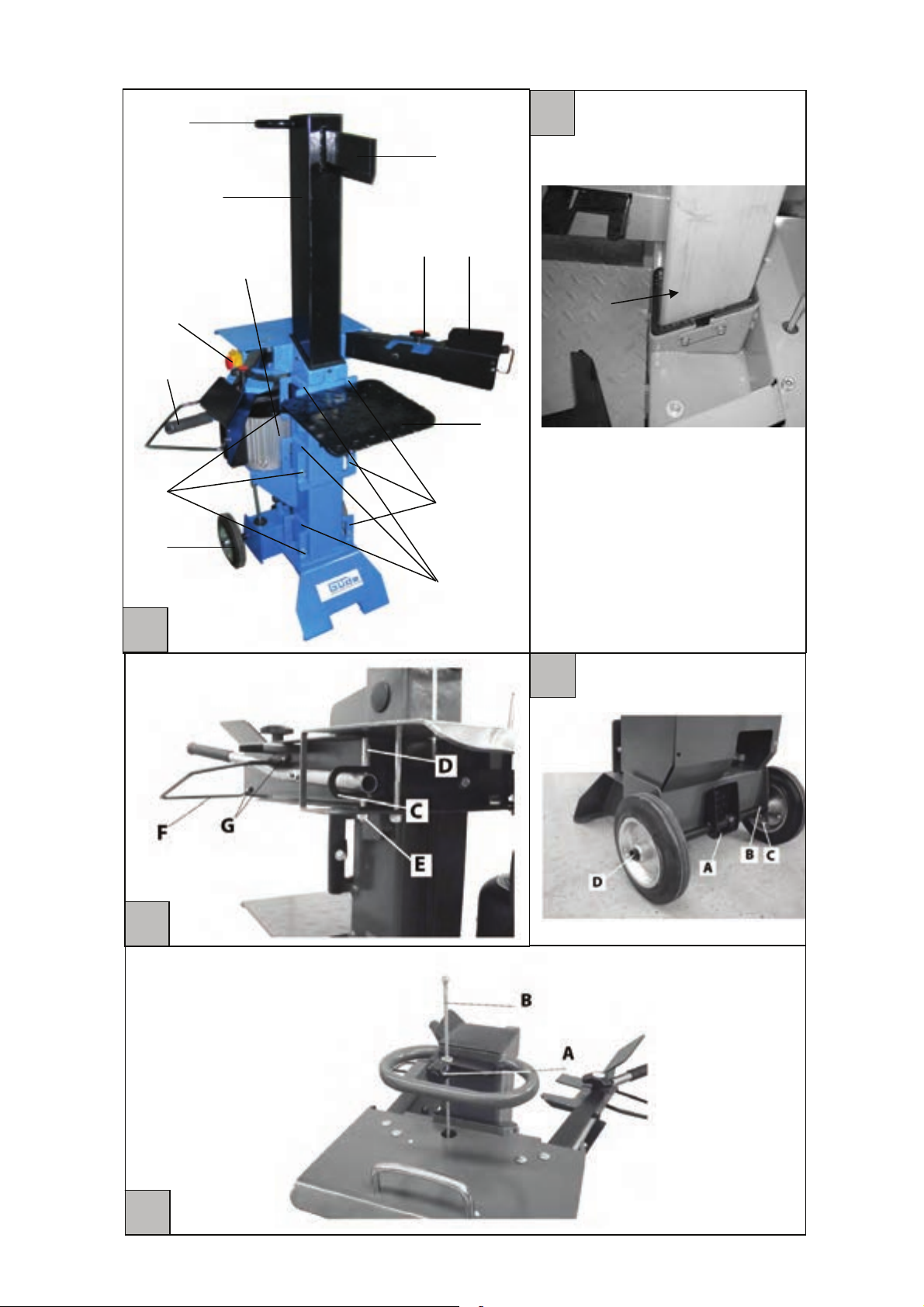

Appliance description (pic. 1)

11

1. Handle

2. Splitting knife

3. Clamping plate

4. Service arm

5. Handle covering

6. Table holder (in front)

7. Table blocking

8. Splitter table

9. Wheels

10. Switch / plug

11. Lift adjusting rod

12. Motor

13. Table holder (side)

Appliance

BASIC 6T/W WOOD SPLITTER

Robust design, splitting knife out of special steel, all steel parts

with high-quality powder coating, high-quality hydraulic pump.

Engine with overheating fuse.

Use as designated

The log splitter has exclusively been designed to split wood

along fibres.

Installation, maintenance, repair, etc. instructions must strictly

be followed to prevent risks and damage.

When splitting, it is necessary to make sure the split wood is

only fitted on the grooved sheet of the supporting plate or on

the grooved sheet of the splitter table.

The machine cannot be used for works other than for which

the machine has been designed and that are specified in the

Operating Instructions.

Any other use is a use in conflict with the designation. The

manufacturer will not be liable for any consequential damage

and injuries. Please be sure to know that the machine has not

been designed for industrial purposes.

Guarantee

The guarantee relates exclusively to faults caused by material

defect or manufacturing defect. Original proof of purchase with

the purchase date needs to be attached for claims in the

guarantee period.

The guarantee does not cover any unauthorised use such as

appliance overloading, violent use, damage by third party or

foreign items. The failure to follow the Operating Instructions

and assembly instructions and ordinary wear and tear is not

included in the guarantee.

Technical data

Technical data: 230 V~50 Hz

Connector: 3000 W P1 / S6 40%

Engine power: 2800 revolutions a minute

Engine revolutions: 6 Tonnen

Max. splitting force: 485 mm

Max. splitting lift: 4-5 cm/s

Forward feed rate: 10-12 cm/s

Backward feed rate: 4 l (Ölsorte: HLP 46)

Max. log length: 570 / 770 / 1060 mm

Splitter’s post: 100 mm x 100 mm

Max. diameter of split wood: ca. 400 mm

max. hydraulic pressure: 210 bar

Table dimensions: ca. 360 mm x 280 mm

Weight: 98,5 kg

Order No. 02020

Safety instructions

General

For safety reasons it is necessary to respect and follow safety

instructions specified in these Operating Instructions and

instructions on the appliance relating to appliance operation,

maintenance and repairs.

Operating staff

Using the wood splitter can be associated with some

risks. Therefore only trained and experienced persons can

handle the appliance and work with it. The operating staff

must wear tight, close-fitting clothing and protective

shoes.

Caution: When splitting, dry and mature wood may

get intensely shot out and injure the face of the operator.

Please wear appropriate protective clothing!

Workplace

To ensure safe wood splitting, it is necessary that the

workplace is flat and enables stability keeping and sufficient

free moving. All obstacles need to be removed from access

paths when bringing the splitter and taking it away. Sufficient

workplace lighting must be ensured.

Make sure no persons are present in the workplace

during appliance operation or make sure they keep a

sufficient safe distance.

The log splitter has been designed to be operated by

1 person. Two or more persons must never work with the

appliance.

Work preparation

Current supply needs to be interrupted by pressing the red

button on the switch and disconnecting the plug at any repairs

or maintenance work and when leaving the wood splitter.

Interrupting the current supply by putting the switch to

OFF position is not sufficient. GÜDE wood splitters are

fundamentally supplied with hardened splitting knives.

However, if you detect any slight deformation of the knife edge

after splitting wood containing any invisible foreign particles,

e.g. out of concrete, steel, etc. then remove it by a file or

grinding off. Keeping the splitting knife permanently sharp

increases the working output.

TIP: Occasionally grease the splitting knife with fat (for

problem wood).

The function of safety equipment (especially the twolever operation) needs to be checked before the splitter is

put into operation for the first time.

ATTENTION! Make sure the splitting table is safely

secured to the splitter before the splitter is put into

operation.

Entsorgung

Die Entsorgungshinweise ergeben sich aus den Piktogrammen

die auf dem Gerät bzw. der Verpackung aufgebracht sind.

Eine Beschreibung der einzelnen Bedeutungen finden Sie im

Kapitel „Kennzeichnung“.

Entsorgung der Transportverpackung

Die Verpackung schützt das Gerät vor Transportschäden. Die

Verpackungsmaterialien sind in der Regel nach umweltverträglichen und entsorgungstechnischen Gesichtspunkten

ausgewählt und deshalb recycelbar. Das Rückführen der

Verpackung in den Materialkreislauf spart Rohstoffe und

verringert das Abfallaufkommen. Verpackungsteile (z.B.

Folien, Styropor®) können für Kinder gefährlich sein. Es

besteht Erstickungsgefahr! Bewahren Sie Verpackungsteile

außerhalb der Reichweite von Kindern auf und entsorgen Sie

sie so schnell wie möglich.

Operating staff requirements

12

The operating staff must carefully read the Operating

Instructions before using the appliance.

Qualification

Apart from the detailed instruction by a professional no special

qualification is necessary for using the appliance.

Minimum age

Only persons over 18 years of age can work with the

appliance. An exception includes youngsters if they work

within their professional education the purpose of which is to

obtain knowledge supervised by a trainer.

Inspections and servicing (pic. 2+7+10)

Safety instructions for inspections and servicing:

Only a regularly serviced and treated appliance may be a

satisfactory aid. Inadequate servicing and maintenance may

lead to unforeseen accidents and injuries.

• Never use aggressive cleaning agents to clean the

appliance. That could damage or destroy the

appliance.

• Unplug the appliance.

• Have any repairs and servicing of the electrical

equipment provided by electricians only.

• All protective and safety equipment must be immediately

refitted after repairs and servicing works are finished.

The following is recommended (pic. 2):

• Splitting knife

The splitting knife is a component that is subject to quick

wear and must be ground down additionally if necessary.

That will increase the splitting output and protect the

splitter. Tip: lubricate the splitting knife with fat!

• Two-hand protective equipment

The combined holding and clamping equipment must run

easily. From time to time, lubricate it with a few drops of

oil.

• Splitting post

Every time the appliance is to be used, lubricate the

splitting post with fat. That will increase the service life of

the sliding jaws (pic. 2/A). Pull the splitting post out to the

full extent and equally apply multi-purpose fat to all 4

sides of the splitting post.

• Movable parts

Keep the splitting knife guide clean (remove any dirt,

splinters, bark, etc.). Slide rails to be lubricated with fat.

• Hydraulic equipment

Hydraulic connections screwing should be checked for

leaking and wear. Tighten the screwing if necessary.

Checking the hydraulic oil level (pic. 7+10):

Check the hydraulic oil level only when in a cold

condition, feeder cable disconnected and splitting post

pulled in.

On the oil level dipstick there are two notches – the lower (pic.

10/1) is the minimum hydraulic oil limit level in the tank and the

upper notch (pic. 10/2) is the maximum limit.

• Unscrew the oil level dipstick (pic. 7/A) from the

opening.

• Wipe the oil from the dipstick with a non-felt cloth.

• Re-screw the dipstick in the opening.

• Unscrew the filling screw with the dipstick again and

check whether the hydraulic oil upper limit is between

both notches.

Change the oil once a year (pic. 7+10):

• Unscrew the oil drain plug (pic.7/A).

• Catch the waste oil (every model with different amount)

• Dispose the waste oil in an environment-friendly manner

• Re-screw the oil drain plug. No particles of dirt may get

in the oil tank.

• Add the hydraulic oil up to the upper notch on the dipstick

(pic. 10/2)

• Try the wood splitter with no load several times.

Recommended hydraulic oil: DIN ISO HLP 46

Güde Art. No. 42004

Viscosity: 46

Oil amount: (see Technical specifications)

Oil to be added only when the splitting post is in the

engaged position.

Hydraulic equipment:

Hydraulic hoses and couplings must be checked after app. 4

hours of operation whether tight and must be tightened if

necessary.

Checking the appliance whether it is working properly

The hydraulic wood splitter is supplied in a ready-to-operate

state. The following functional checks need to be carried out

every time the appliance is to be used.

• Let both switching handles go down and the splitting knife

as low as app. 5 cm above the table

• Lower one switching handle at a time – the splitting knife

will remain in the selected position

Assembly of service arms, wheels, splitting

cross and table (pic. 1+3+4+8+9)

Assembly of service arms - pic. 1+3

Feed the service arm (pic. 1/4) into the switching cradle (pic.

3/C) and screw with hexagonal bolt (pic. 3/D), bed (pic. 3/E)

and check nut. Tighten the check nuts to such an extent that

the service arm could be moved. Now connect the service arm

according to the described method on the right. Protective

arches (pic. 3/F) on both service arms are always assembled

using 2 bolts with cross groove (pic. 3/G).

TIP: Grease metal couplings with fat from above and

below before that!

Assembly of wheels – pic. 4

Put the wheel axis with the foot lever (pic. 4/A) through both

holes on the oil tank.

Put the M6 socket-head screw (pic. 4/B) through the wheel

axis and screw it with the check nut on the plate (pic. 4/C).

Then install the turning wheel on both sides and secure it with

a safety pin (pic. 4/D) on both sides. Slightly bend the safety

pin to prevent falling out.

Work table mounted pic 8/9

The wood splitter is equipped with three table settings

equipped. Thanks to the adjustable table position can be

different lengths easily split wood.

1. Make sure that the hooks on the table lock on the pillar

upwards.

2. Run the table in one of three designated devices (Fig.

9/A).

3. Fix the table by clicking on both sides provided the hook

(Fig. 8/B) to the leadership of the working table can be

locked.

Lift adjusting (pic. 5)

The working output can be increased for wood pieces smaller

than app. 50 cm and for more wood pieces by shortening the

backward movement of the splitting knife.

Proceed as follows:

Put a short piece of wood on the splitter table and move the

splitting knife as low as app. 2 cm above the wood. Switch the

splitter off (red button on the switch and disconnect the plug).

Now you can shorten the backward movement using the fixed

rod (pic. 5/B) by fixing the rod in the required height with the

adjusting screw (pic. 5/A).

Area of application

13

The appliance can only be used for wood processing. The split

material must have the following dimensions:

- Minimum diameter: 120 mm

Maximum diameter: 400 mm

- Wood splitting along fibre is only allowed.

- Risk of getting jammed at branchy wood when splitting.

- Jammed piece of wood is released by tipping on the

wood.

- Cutting the split wood out prohibited!

Electric/hydraulic connection (pic. 7)

Plugging

All splitters are fitted with undervoltage release in the switch in

accordance with provisions of branch professional

organisations “CE“, etc. The release prevents automatic

starting of the appliance in case supply is interrupted as a

result of power failure, unintentional unplugging, defective

fuse, etc. The appliance must unconditionally be switched on

again by pressing the green switching button.

Wilful holding or blocking of the switching button with no

directly earthed conductor automatically leads to switch failure.

In this case that can subsequently be identified the guarantee

expires.

• The appliance meets EN 61000-3-11 requirements and is

subject to special connection conditions. That means that

use on optionally selected connection points is

inadmissible.

• The appliance can lead to occasional voltage fluctuations

under unfavourable power conditions.

• The appliance is only designated to be used for connection

points not exceeding the maximum allowed impedance of

Z

= 0,233 Ω.

max

• As a user, you must make sure your connection point on

which you want to use the appliance meets the abovementioned requirements – after agreement with your

electricity supplier if necessary.

Hydraulic equipment

Tightness needs to be checked at hydraulic hoses and

couplings after app. 4 running hours and tighting must be

provided if necessary.

Hydraulic oil/tank

Common hydraulic oil (e.g. HLP 46 or oil of different producer

of identical viscosity) can be filled in all splitters. Oil change is

not necessary.

Vent the tank before each operation by screwing the filling

screw out and in (pic. 7/A).

Operation

Attention: Make sure wood is cut at right angle, if

possible, and seated closely on the splitting table. Crosscut or extremely branchy wood can slide or bend the

service arms.

Always put wood on surfaces (tables) designated for

this purpose (never on the frame). That could damage the

splitter.

1. Start the engine by pressing the green switching button.

2. Keep the feeder cable as short as possible at 230 V

models and select as big cross section as possible.

3. When the temperature is low, let the splitter run idle

for app. 15 minutes so that oil warms up to

corresponding temperature.

4. Put the split material on the table and hold it using

clamping plates on the lever.

5. Splitting starts by pressing both levers down (as soon as

the splitting knife enters wood tip the lever slightly out

while pressing it down. This will prevent holding sheets

(arms) from bending).

6. Lift at least one lever after you have finished splitting – the

splitter pillar will automatically go up.

It is strictly prohibited to operate the wood splitter in

two persons with one holding wood and the other one

pressing on the clamping plates. Blocking one lever

(clamping plate) is prohibited, too.

Transport instructions

Transport

All wood splitters are fitted with big wheels. Grasp the handle

on the splitting pillar with one hand and handle above the

engine with the other hand and slightly tilt the splitter to you for

transport purposes. The splitter can effortlessly be moved in

this position.

To prevent hydraulic oil leakage, never transport the splitter

laid down.

Always let the splitting knife go absolutely down for transport.

Residual risks and protective measures

Warning!!!

Taking out of operation, any change, blocking,

disassembly, changeover or assembly of all parts on

safety and protective equipment of the appliance is strictly

prohibited and can have serious consequences, i.e. life

threatening injuries if not observed.

The producer cannot be held liable for material damages

or injuries caused as a result of such negligence.

All guarantee claims towards the producer immediately

expire at each of the above-mentioned negligence.

The splitter can only be operated by one person. Remove

wood remnants that could block or negatively influence

the safety and service elements near the splitter and

workplace during operation.

Maintenance

Do you have any technical questions? A claim? Do you

need spare parts or the Operating Instructions?

You will be helped quickly and without needless bureaucracy

at our webpage www.guede.com in the Services section.

Please help us be able to assist you. To identify your machine

when claimed, we need to know its serial No., order No, and

year of production. All these details can be found on the type

label. Enter the details below for future reference.

Serial No.

Order No.

Year of production:

Tel. +49 (0) 79 04 / 700-360

Fax: +49 (0) 79 04 / 700-51999

Email: support@ts.guede.com

Loading...

Loading...