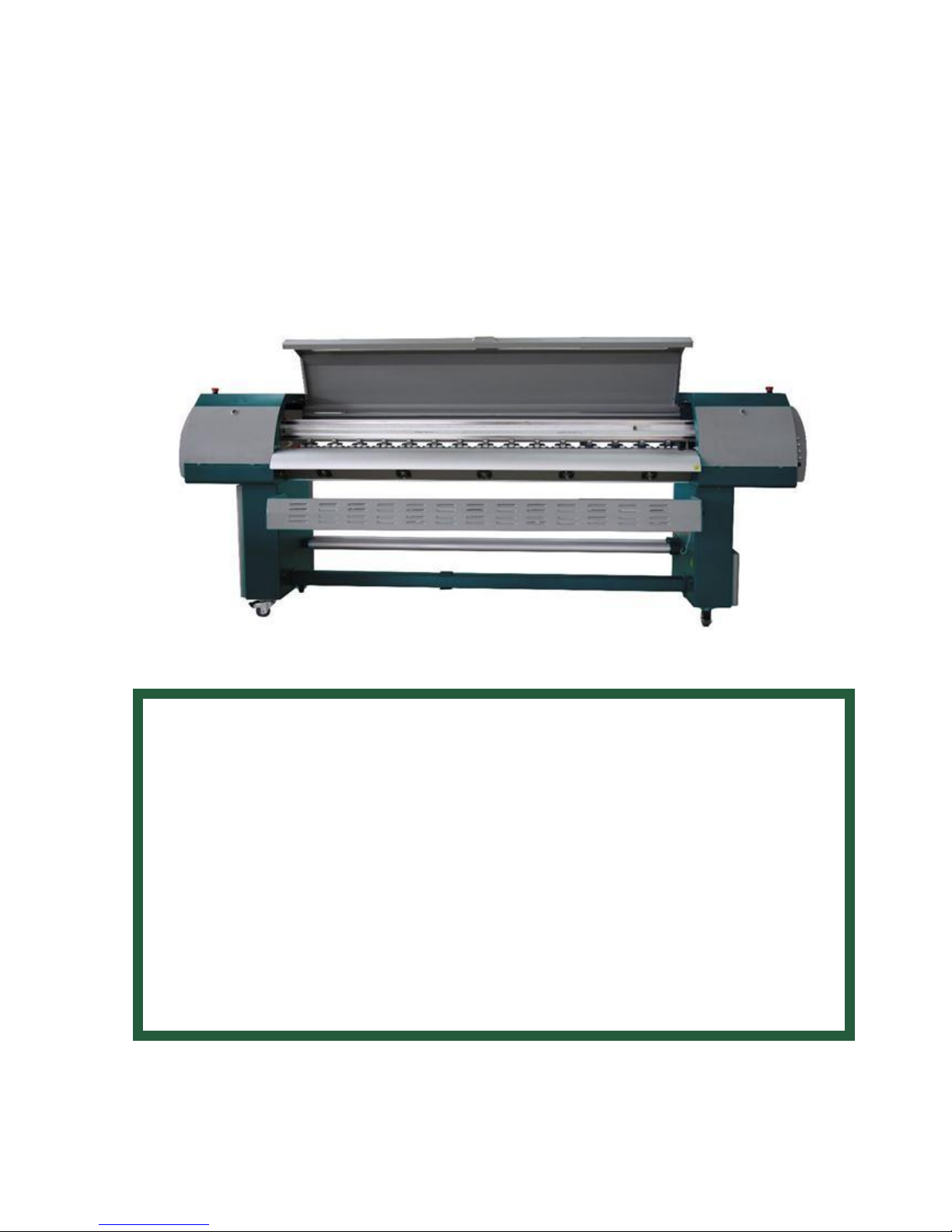

FY Union FY-212H, FY-3208G Operation Manual

1

Operation Manual

Thank you very much for purchasing FY series printer

15 June 2009

Version : 2.0

● In order to use FY series printer correctly and safely and understand this product’s capability,

please read through this manual.

● This manual includes equipment structure, description, technical parameters, operation manual,

safety information, application of software, etc.

● This manual is subject to change without notice.

● Contents herein contained are believed to be correct, however, please contact us if you find any

error or something not clear enough.

●Copyright 2009 FY Union. All rights reserved.

FY-212H

2

Table of Contents

Chapter 1: Safety Precaution…………………………………….… 3

Chapter 2: Preparation and Procedures for Assembling………5

Chapter 3: Machine Structure and Accessories…………………8

Chapter 4: Basic Operation………………………………….……....11

Chapter 5: Maintenance Guide………………………………………22

Chapter 6: Troubleshoot …………..…………………………………..27

Chapter 7: Technical Specification……..………………………..…..29

3

1.1 Important Safety Measures

Please read the following instructions before using the printer. Follow cautions and

instructions which are labeled on the printer.

Do NOT block the cover on the top of the printer.

Do NOT insert any object into the printing platform of the printer. Prevent spilling liquid onto

the printer.

ONLY 220V can be applied.

Connect all the power cord to a single socket extension. Avoid sharing the socket with other

devices which will be on and off frequently.

Avoid using the socket with self-timer control and with the switch on the wall.

Keep a distance from any device which may release electro-magnetic field, such as wireless

phone.

Do NOT use damaged power cord.

If using an extra power cord, keep in mind that the total ampere of this device does not exceed

the assigned ampere of the power. Also, the total ampere of all device which connect to single

socket cannot exceed the assigned ampere.

Do NOT try to repair the printer.

When encounter the following circumstance, disconnect the power and contact your local

distributor for support:

Liquid is spilled onto the printer;

The printer fells down or the surface is broken;

Printer does not run normally.

Chapter 1 Safety Precaution

4

1.2 Handling Printer Caution

Do NOT move the carriage when the power is on.

Always use the power switch to turn on or off the printer. Do NOT try to remove the data cable or

the power cord when the machine is on.

Make sure the carriage is stabilized in the origin position during transport.

Do NOT touch printing platform during printing.

1.3 Handling Ink Tank Caution

Please store ink tanks at the place where children cannot reach. Do NOT let children touch the

ink tank.

If ink is spilled into eyes, immediately wash with water and see your doctor.

Do NOT shake the ink tank, this may cause leakage.

Please often check the ink content in main ink tank, avoid unnecessary loss due to lack of ink.

Please often check the waste ink tank and replace it in time when it becomes full.

1.4 Printer Installation Site

Place the printer on a level floor. If the floor is not level, adjust the support of the printer.

Avoid placing the printer in the area with huge change of temperature and humidity. Do NOT

expose the printer to direct sunlight or heat.

Avoid placing the printer in any possible shaking or vibrating area.

Leave enough space around the printer to ensure normal ventilation.

Place the printer close to the power socket so that power cord can be removed and plugged

easily.

Chapter 1 Safety Precaution

5

2.1 Environment requirement

Keep the room temperature between 20—30℃, and the humidity between 40—60%. Air

conditioner and humidifier may require. Keep a distance from strong radiation field. The floor must be

level.

2.2 Electrical requirement

The printer only supports AC 220V. A transformer is needed if the area is using AC110V.

The printer must be well grounded ( the grounded voltage shouldn’t be more than 0.3V,

and the grounded resistance should be less than 3Ω ).

UPS and voltage stabilizer is highly recommended.

2.3 Computer requirement

1) Basic requirement:

CPU: 2.0 GHz or higher

Memory: 1Gb or higher

Hard disk: 80 Gb (recommend 20Gb free space)

Mother board: PCI card slot

Network card

Operating system: Microsoft Windows (2000, XP)

2) Recommended requirement:

CPU: 3.0 GHz or higher

Memory: 2 Gb or higher

Hard disk: 200 Gb or higher (NTFS format)

Mother board: PCI card slot

Network card

Operating system: Microsoft Windows (2000, XP)

NOTE: Suggest user format your hard disk into 2 partitions (NTFS). The first partition is used for

installing OS and other software, the second partition is used to save pictures and work files.

Chapter 2 Preparation and Procedures for Assembling

6

2.4 Procedures of Assembling

1) Move the packing box to the working site and avoid strong shaking.

2) Disassemble the wooden packing box from top to bottom. Check whether the parts are

complete or not according to the packing list.

3) Lift the printer out by a forklift, and move it to the installation site.

4) Check if the printer is level.

5) Get rid of all the parts that stabilize the carriage, and install all the spare parts.

6) Move the carriage manually to the right of the printer, then move back to the left. During this

process, check if there is abnormal resistance, and carefully inspect the belt & the encoder

sensor are situated in proper position.

7) Ground the printer. The grounded voltage shouldn’t be more than 0.3V, and the grounded

resistance should be less than 3Ω .

8) Install the PCI card into the computer. Check if the wires and data cables are plugged in

properly.

9) Install the output and the rip software.

10) Turn on the printer, and keep your hand on the emergency button for turning off the printer

if problem happens suddenly.

11) Send a file to print to test the condition of the printer.

12) Clean the whole ink supply system with solvent. Then empty the ink sub-tanks, and repeat

the step twice. At last, empty the remained solvent in the ink supply tubes through ink

sub-tanks.

13) Fill the main tank with ink. Then empty the ink sub-tanks, and repeat the step twice, in order

to ensure there is no mixture of ink and solvent in the ink supply system.

14) Dip the aluminous caps in the solvent and clean them, in order to ensure no any sundries

exist.

15) Turn off the printer. Take the black washer out from the white cap on the top of the damper,

and then place the washer in the aluminous cap. (Figure 2-1) Stabilize the printhead with

screws. Connect the tube, and tighten the aluminous cap at the ink incoming part on the

top of the damper. Finally, connect the data cable.

Chapter 2 Preparation and Procedures for Assembling

7

Figure 2-1

Attention A: When connecting the aluminum cap to the printhead damper, you

should screw it perpendicularly to avoid damaging the screw thread of the

damper.

Attention B: When assemble new printhead, it’s not necessary to flush the printhead

with solvent. It’s because no protective fluid remains in printhead.

16) Fill the printhead with ink by using positive pressure, And then, wipe the ink droplet on the

surface of the nozzle plate with sponge stick.

17) Print nozzle checking, and observe the condition of printheads. It is recommended to

keep a copy of the test for reference in the future.

18) Printhead alignment.

19) Start to Print.

Chapter 2 Preparation and Procedures for Assembling

Washer

8

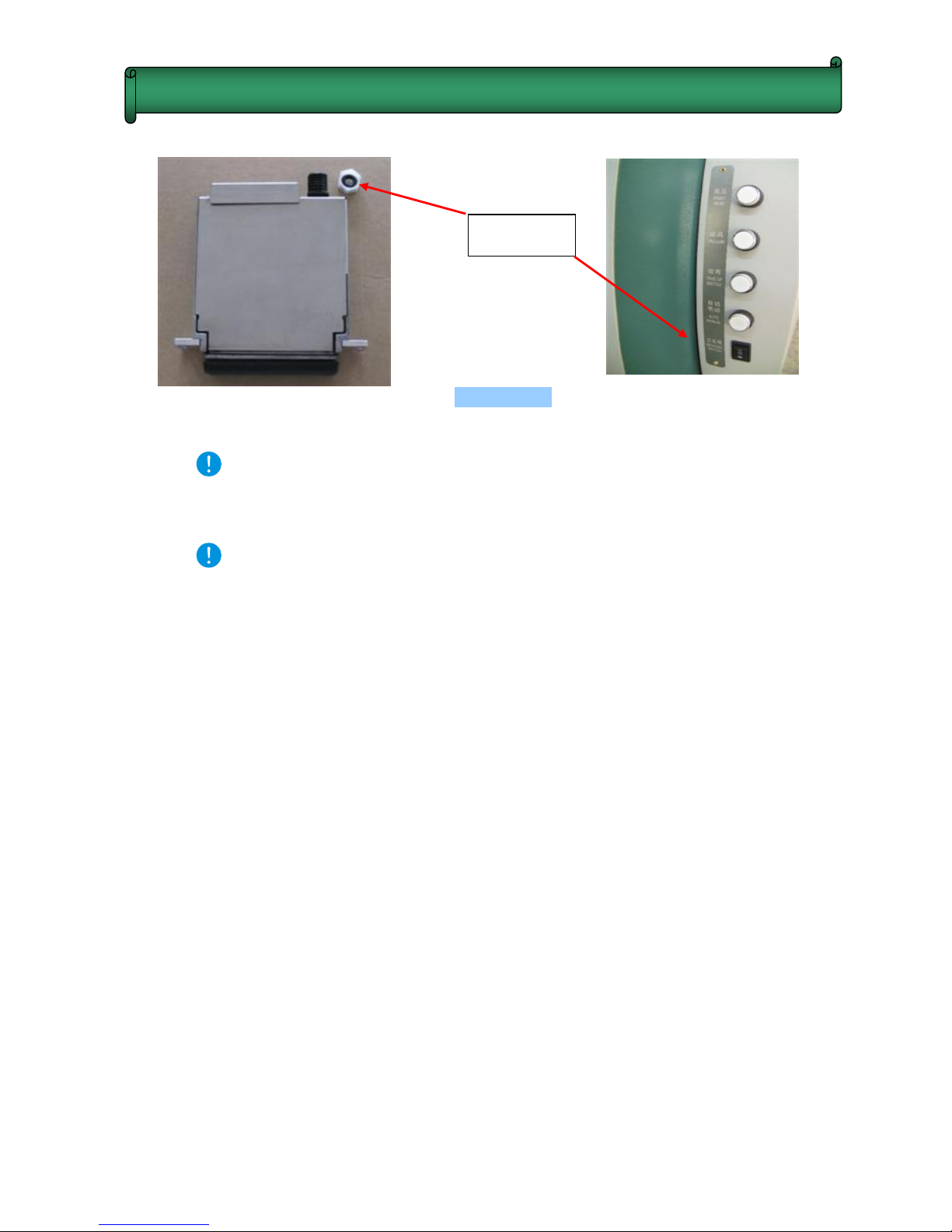

Machine Appearance

(1) (2) (3) (4) (5) (6) (7) (8)

(9) (10) (11) (12)

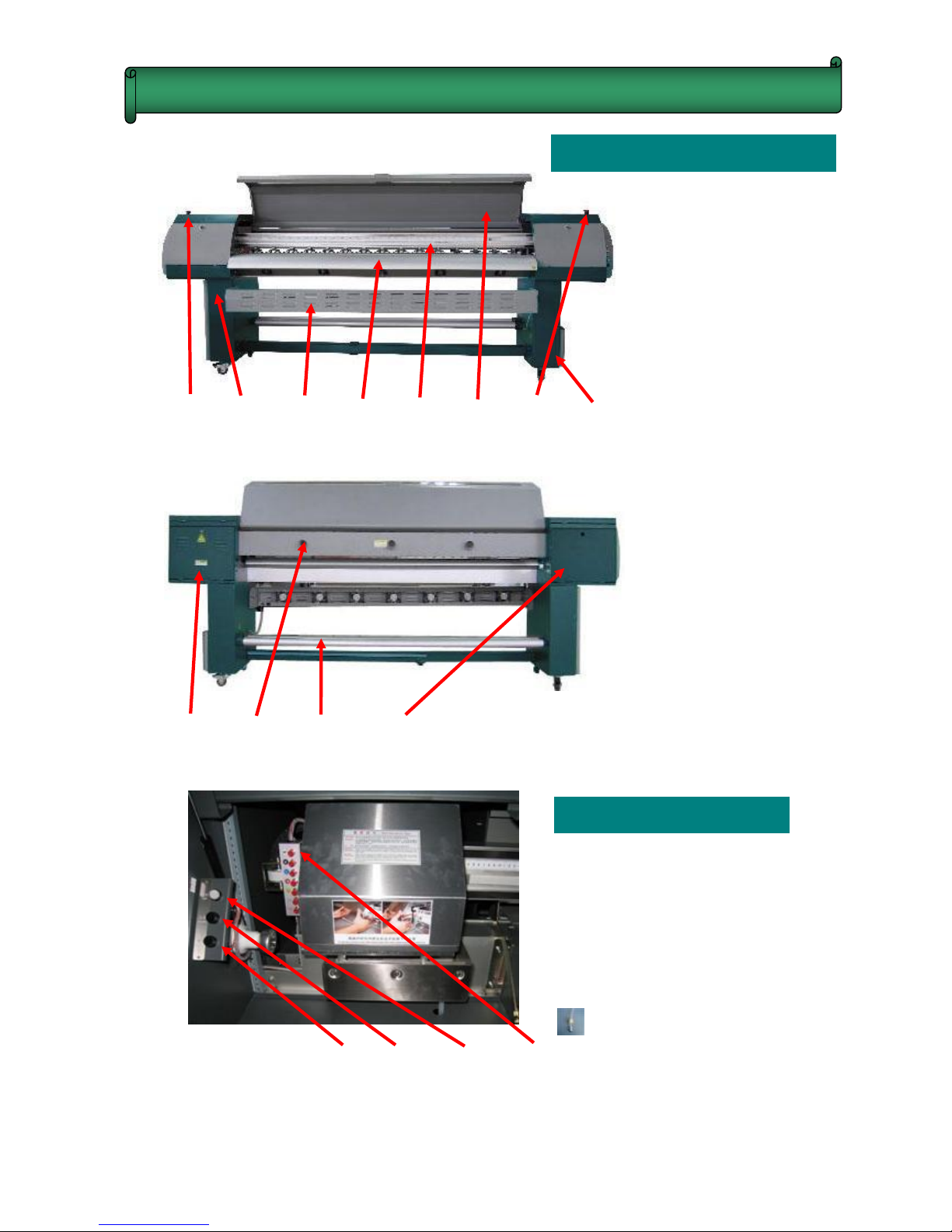

Cleaning Control

(13) Solvent Cleaning Switch

(14) Solvent Cleaning Switch

(15) Light Switch

(16) Individual Purging Switches

Individual Purging Switch:

“AF” is used to clean all

printheads. In addition, press

switches (13)+(14) together

to start solvent cleaning.

(13) (14) (15) (16)

(1) Left Emergency Switch

(2) Bottom Left Machine box

(3) Cooling System

(4) Printing Platform

(5) Girder

(6) Printer Cover

(7) Right Emergency Switch

(8) Bottom Right Machine Box

(9) Circuit Controlling Box

(10) Exhaust Emission

(11) Media Feeding Bars

(12) Top Left Machine Box

Chapter 3 Machine Structure and Accessories

9

Basic Operation

(17) Printhead Voltage Switch

(18) Media Suction Switch

(19) Media Take-up Switch

(20) Automatic or Manual Mode

(21)Turning Direction Switch

Media Feeding Button

(22) Media Feeding Switch

(23) Automatic or Manual Mode

(24) Turning Direction Switch

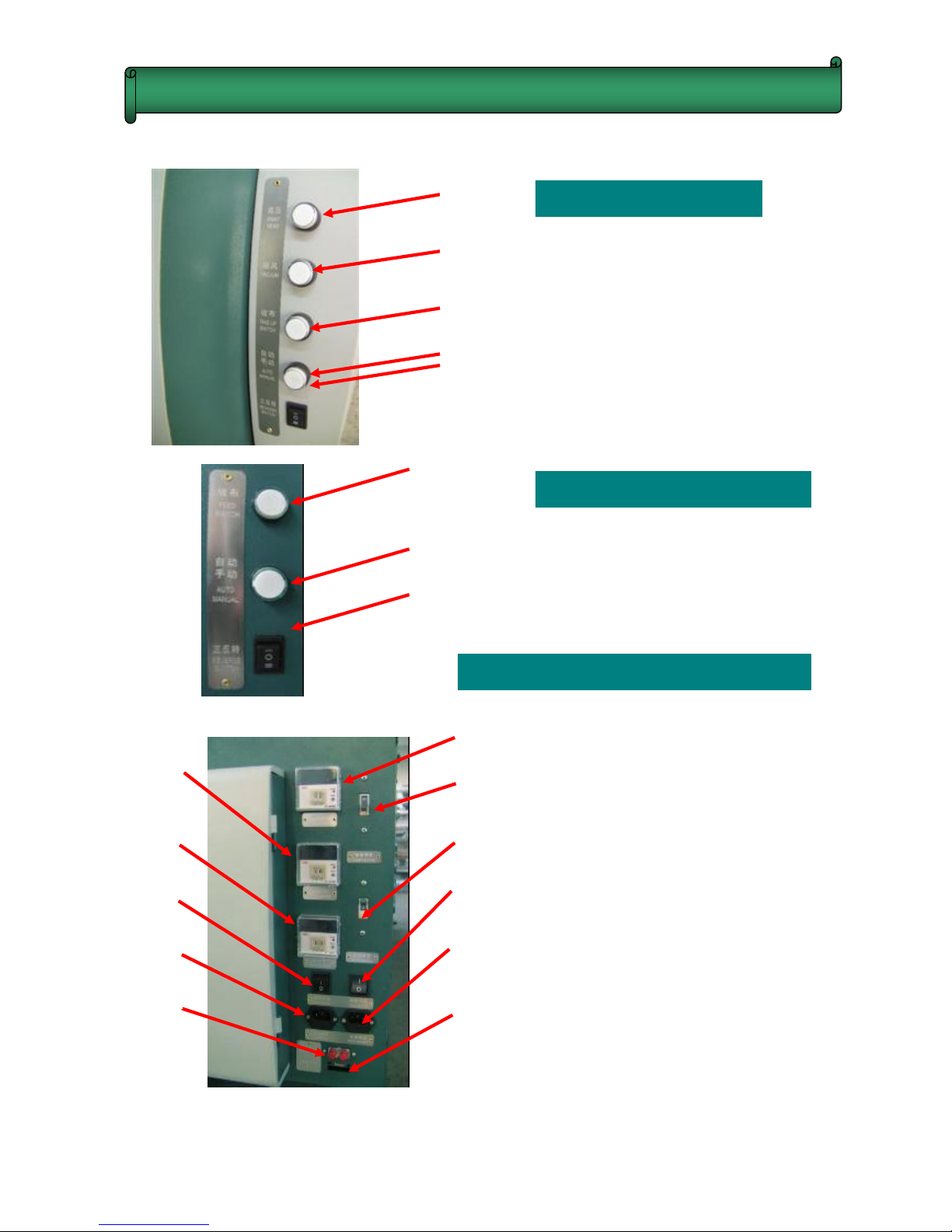

Main Power Controlling Area

(25) Optical Fiber Interface

(26) Heater Power Socket

(27) Heater Power Switch

(28) Rear Heater Controller

(29) Middle Heater Controller

(30) Front Heater Controller

(31) Heater Safety Switch

(32) Printer Safety Switch

(33) Printer Power Switch

(34) Printer Power Socket

(35) High Density Data Cable

Interface

( 17)

( 18)

( 19)

(20)

(21 )

( 22)

( 23)

( 24)

Chapter 3 Machine Structure and Accessories

( 31 )

( 32)

( 33)

( 34 )

( 35 )

( 25 )

( 26)

( 27 )

( 28 )

( 29 )

( 30 )

Loading...

Loading...