Series S1501 Selectronic®

Micro-Controller/Annunciator

Model Year 2011 and Earlier

Installation and Operations Manual

00-02-0271

2018-10-23

Section 50

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS FW MURPHY

PRODUCT:

Read and follow all installation instructions.

A visual inspection of this product before installation for any

damage during shipping is recommended.

Disconnect all electrical power to the machine.

Make sure the machine cannot operate during installation.

Follow all safety warnings of the machine manufacturer.

Please contact FW MURPHY immediately if you have any

questions.

In order to consistently bring you the highest quality, full-featured products, we reserve the right to change our

specifications and designs at any time. The latest version of this manual can be found at www.fwmurphy.com.

Table of Contents

Product Description ................................................................................................................... 1

Installation ................................................................................................................................... 4

Mounting Dimensions ...................................................................................................4

Typical Hazardous Areas Installation ...........................................................................6

S1501 System - Typical Hook Up ................................................................................7

Power Supply – Typical Wiring Diagram .................................................................... 11

Operation ...................................................................................................................................12

Operating the S1501 Interface ................................................................................... 12

Sequence of Operations - Engine Mode .................................................................... 13

Sequence of Operations – Motor Mode ..................................................................... 15

System Set Up Menus ............................................................................................... 17

Editing System Set Up ............................................................................................... 18

Troubleshooting .......................................................................................................................25

Specifications ...........................................................................................................................27

Replacement Parts and Accessories ....................................................................................28

(THIS PAGE INTENTIONALLY LEFT BLANK)

Product Description

The Series S1501 system is a microprocessor based alarm, shutdown, and control system

with tachometer/hourmeter function. It tells in alphanumeric characters which protective device

has signaled an alarm or caused equipment shutdown. Application programming is completed

at Murphy and can be changed in the field.

The system consists of:

S1501 Head

Power Supply - explosion proof

Terminal Block Assembly, rail mount type, accommodates 32 sensors (2 needed for 64

sensor models)

Flat Ribbon Cable - 36 inch (914 mm) to connect the terminal block to the head.

The S1501 is powered from 120 VAC or 12/24 VDC. It is approved for Class I, Div. 1, Groups

C & D areas.

S1501 Head

The Head is the brain of the micro-controller system. It contains a microcomputer, an

alphanumeric display and keypad for operator access to field adjustable functions, and a

communication port: RS232 or RS485 (Modbus RTU slave). This port allows for remote

control functions such as Start/Stop, Load/Unload, etc., and for access to S1501 data

registers.

Alphanumeric Display

The S1501 Head displays each mode of operation. The display is a dot matrix alphanumeric

32-character display arranged in two lines (each with 16 characters). By observing the monitor,

the operator can determine the operating status of the control system.

Power Supply

An explosion-proof enclosure designed for Class I, Division 1, Groups C & D hazardous

locations contains the supply voltage conditioning circuits, head power supply, and the

intrinsically safe barriers for isolation between the power supply and the low energy head

circuits. The power supply accepts 120 VAC, 50-60 Hz and/or 12-24 VDC input power.

12-24 VDC power can be used as primary power or as a backup source of power when

120 VAC is used.

Section 50 00-02-0271

2018-10-23 - 1 -

Control Relays

The power supply has seven control relays to provide form “C” SPDT outputs for control

functions of either the engine or electric motor application.

Terminal Block Assembly

Each sensor input terminal block consists of a 64-position, 32 pair input rail-mount terminal

block for interface of panel or field-mounted end devices. For Class I Division 1 areas, end

devices must be non-energy storing devices, such as mechanical switches with dry contacts.

The terminal block is used for Normally Open sensors (one wire close to ground), and/or

Normally Closed sensors (two wires).

Ribbon Cable

A 36 in. (914 mm) flat ribbon cable is required for connection of the S1501 head and the

sensor input terminal block. The cable is supplied with two D-sub 37 PIN connectors at each

end of the cable.

Power and Control Cable

The S1501 is connected to the power supply via the Power and Control Cable

(15-conductor shielded cable, 72 in. [1.81 m] long). The cable is factory-sealed on the power

supply end, and has a 15-pin, D-sub connector on the S1501 Head end.

Sensor Inputs

User-selectable Sensor Input types (Shutdown or Alarm Only) are available for each sensor.

The sensor inputs are identified as follows:

Class A: Inputs are operative (armed) all the time.

Class B1: Inputs are enabled after the first preset Start-Run time period.

Class B2: Inputs are enabled after the second preset Start-Run time period.

Class C: Inputs are armed after the fault has been cleared for 2 seconds.

Class P: Armed after the Load Relay has exergized and the process time has expired.

Class ESD: Emergency Stop overrides the test lockout timer.

Permissive Function

This function was designed to monitor pre-lube pressure input. Terminal 32 of the sensor

terminal block is reserved for a permissive pre-lube input. The pressure signal can be obtained

from a pressure switch with normally open or normally closed contacts that indicates whether

or not sufficient oil pressure has been reached during pre-lubing. If permissive pressure has

not been reached, the system will not allow start-up. If the Permissive Function is not required,

install a wire jumper in Terminal 32 and set the Permissive Timer setting at zero.

Section 50 00-02-0271

2018-10-23 - 2 -

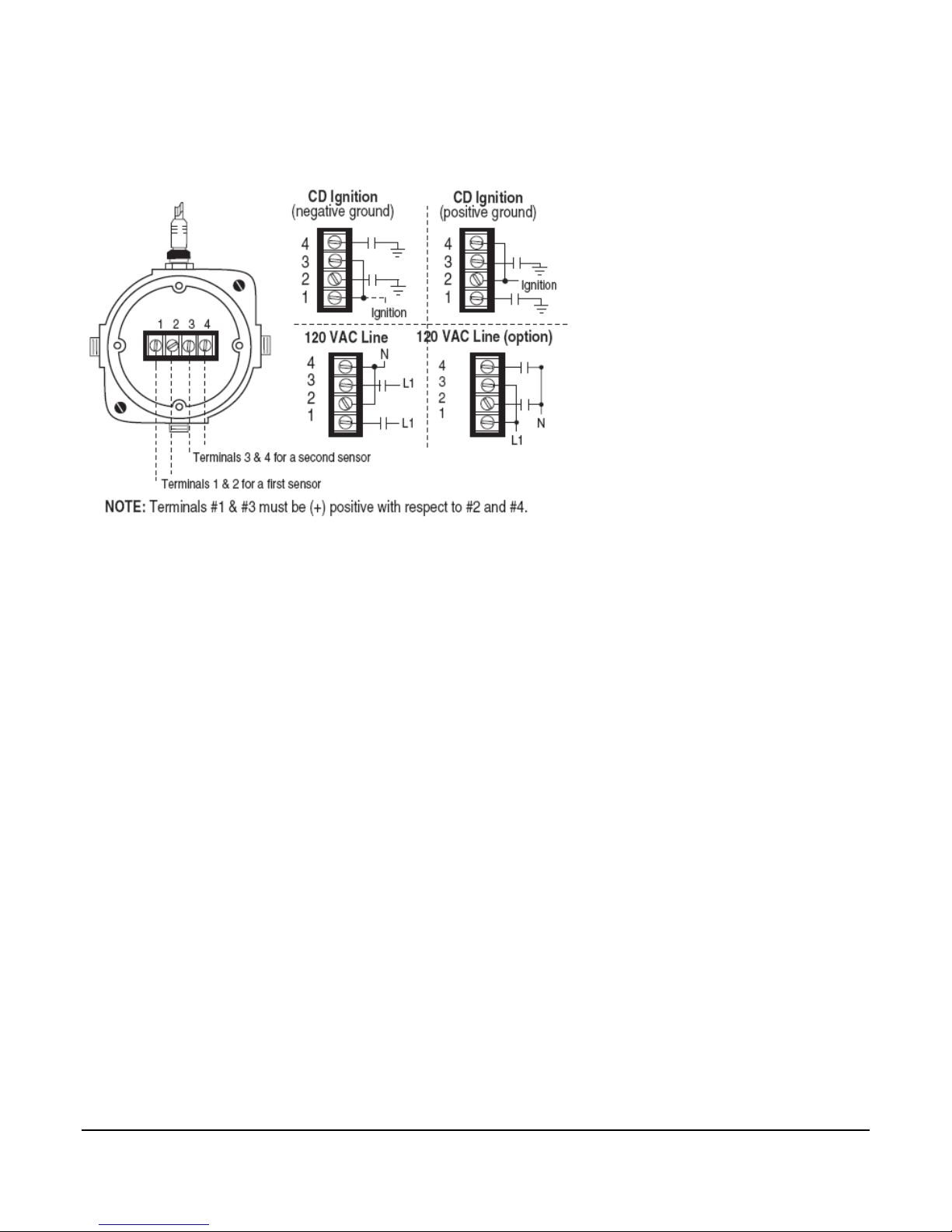

Opto-Isolated Tach/Run Input

The S1501 features an opto-isolated tach/run input located within the explosion-proof power

supply. This special input is used for Run Input Sensing from a CD ignition, Magnetic Pickup,

Motor Auxiliary Signal, or AC or DC run signals meeting the opto-isolated Tach/Run input

specifications (refer to the Specifications section of this manual).

NOTE: For tachometer sensing a magnetic pickup is recommended.

Built-In Barrier (within the Power Supply)

The S1501 power supply circuit is isolated from the Head by the intrinsically safe barrier

located on the printed circuit board (power supply enclosure), between the power supply

output and the power and control cable terminal block.

A fuse barrier mounted inside the Power Supply isolates the power output to the Head. Zener

diode shunt barriers isolate the seven control outputs from the Head.

Hourmeter

A hourmeter feature is available for the S1501 to record the engine or motor elapsed running

time.

Section 50 00-02-0271

2018-10-23 - 3 -

Installation

WARNING: Perform the mounting operation with power source off.

The S1501 Head was designed to be mounted within a

weatherproof enclosure. It is intended for mounting in a flat panel.

First, cut a square mounting hole of 3-5/8 in. (92 mm) x 3-5/8 in. (92 mm).

Insert the Head from the front side of the panel and install the two mounting clamps, one on

each side of the case, (see mounting clamp detail).

Secure the unit to the panel by tightening the clamps with a blade type screwdriver.

Mounting Dimensions

Section 50 00-02-0271

2018-10-23 - 4 -

Section 50 00-02-0271

2018-10-23 - 5 -

Typical Hazardous Areas Installation

WARNING: FOR HAZARDOUS APPLICATION REQUIREMENTS, THE

S1501 COMPLETE SYSTEM MUST BE INSTALLED IN ACCORDANCE

WITH THE NATIONAL ELECTRICAL CODE (NEC) CLASS I, DIVISION

1, GROUP D (ARTICLE 504) SPECIFICATIONS. SENSOR INPUT

WIRES MUST BE SEPARATED A MINIMUM OF 2 IN. (51 MM) FROM

OTHER WIRES. USE OF SENSOR INPUT WIRE TYPE CONDUIT IS

RECOMMENDED.

Section 50 00-02-0271

2018-10-23 - 6 -

S1501 System - Typical Hook Up

WARNING: PERFORM THE WIRING OPERATION WITH THE POWER

SOURCE “OFF” AND THE AREA MADE NON-HAZARDOUS. MAKE

SURE THE VOLTAGE AND CURRENT REQUIREMENTS ARE WITHIN

THE S1501 SYSTEM RATINGS. CONDUIT IS REQUIRED TO

PROTECT WIRES FROM DAMAGE. REFER TO THE SPECIFIC

SYSTEM APPLICATION WIRING DIAGRAM SUPPLIED WITH YOUR

UNIT.

Head Connections

a. Interconnect the S1501 head and the power supply with the power and control cable,

secure the connector in place by tightening the screws on each side of the connector.

b. Repeat step (a.) for the RS232/RS485 serial port (if applicable).

c. The sensor input connector(s) from the terminal block(s) plugs into the back of the

Head. Secure by tightening the screws on each side of the connector.

Section 50 00-02-0271

2018-10-23 - 7 -

Typical Power Supply Connections

WARNING: Do NOT route the power supply wiring and the sensor

input lead wiring in the same conduit.

a. Conduit installation:

1) Remove power before opening power supply cover.

2) Install one 1/2 in. NPT or two 3/4 in. NPT conduits, from customer end of the Power

Supply.

Note: Follow NEC guidelines for maximum number of wires in conduit.

3) Install an approved explosion-proof seal in the conduit within 18 in. (457 mm) of

Power Supply enclosure (seal unused conduit holes).

Important: Green screw above conduit hole (power supply) is to attach

equipment ground per NEC.

b. Customer Installed Field Wiring: Install wiring to power supply through conduit

installed in “step 2-a”.

1) Run wiring from the power source to the S1501 power supply.

2) Connect the 120 VAC to the two AC Power Input terminals. Connect equipment

ground to green screw (see schematic below).

3) Connect the 12 or 24 VDC Positive (+) lead to Power Input terminal 12-24 DC.

4) Connect 12 or 24 VDC “DC(–)” lead to the GND terminal. (See “Power Supply

Typical Wiring Diagram”.)

Section 50 00-02-0271

2018-10-23 - 8 -

Normally Open Sensor Input Wiring

Wire each normally open sensor on top of the factory-supplied jumper. Loosen the screw and

slide the wire lead into the terminal without removing the jumper (either side of jumper).

Normally Closed Sensor Input Wiring

Remove the factory-supplied jumper completely. Connect the two sides of the normally closed

sensor to the two terminals of the terminal block.

NOTE: Switches connected to the S1501 Sensor Input Terminal Block

must be dry contact mechanical switches.

Intrinsically Safe Barrier Wiring

Important (normally open sensor only): Secure area of hazardous

conditions before opening barrier cover or operating sensor contacts.

a. Run Sensor switches wiring through conduit and isolate from the S1501 terminal

block(s) with an explosion-proof barrier.

b. For wiring refer to the following typical wiring diagrams.

Section 50 00-02-0271

2018-10-23 - 9 -

Normally Open System Barrier

LCDT-ISB barrier (optional)

Normally Closed System Barrier

For normally closed non-intrinsically safe sensors, use an approved intrinsically safe barrier,

and wire according to manufacturer’s instructions.

Section 50 00-02-0271

2018-10-23 - 10 -

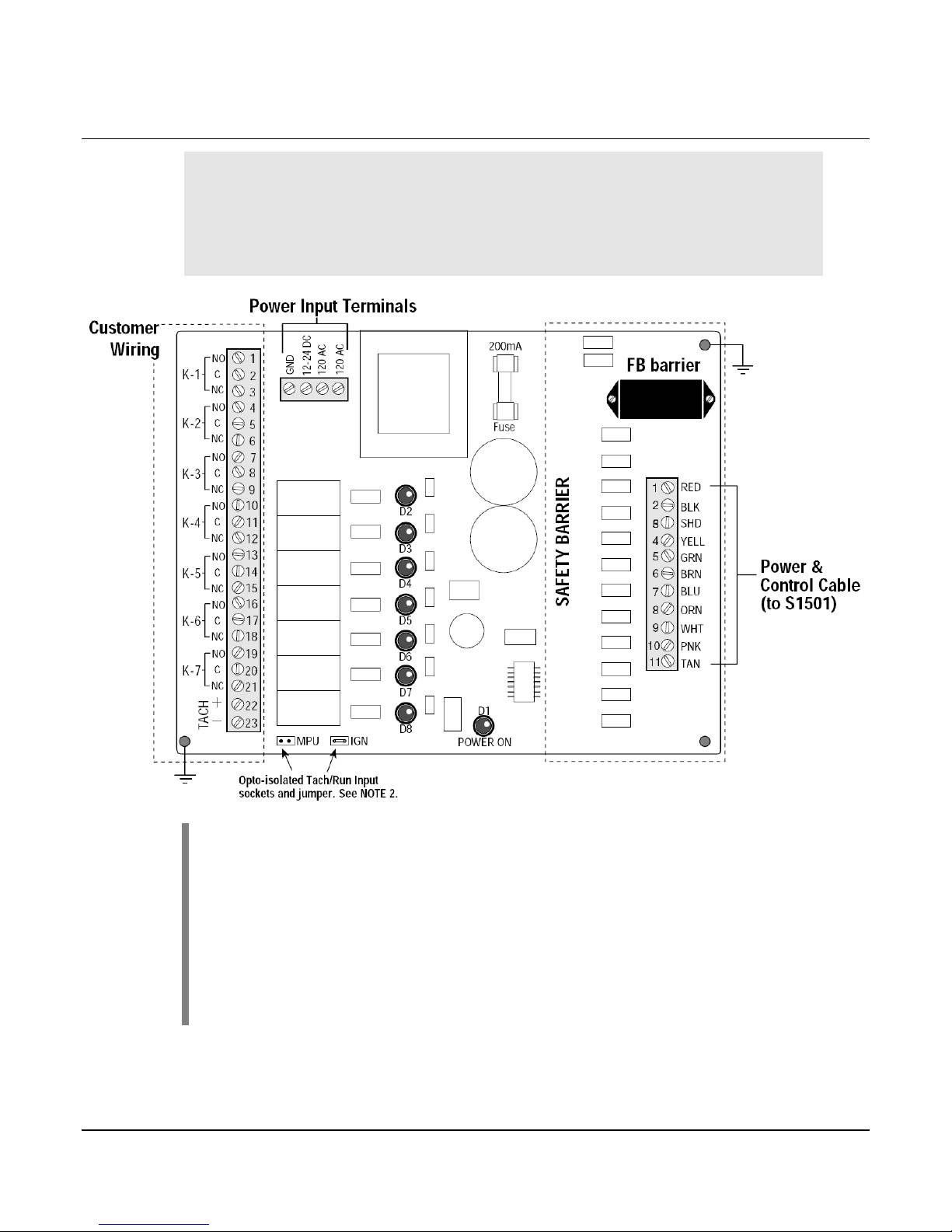

Power Supply – Typical Wiring Diagram

WARNING: Perform the wiring operation with the power source

“OFF” and the area made non-hazardous. Make sure the voltage

and current requirements are within the S1501 system ratings.

Conduit is required to protect wires from damage. Refer to the

specific system application wiring diagram supplied with your unit.

NOTE 1: K-1 thru K-7 are relay outputs form “C” dry contacts.

D1 thru D8 are LED indicators.

D1= POWER ON;

D2=K1; D3=K2; D4=K3; D5=K4; D6=K5; D7=K6; D8=K7.

NOTE 2: Opto-isolated tach/run input jumper is shipped in the IGN

position. IGN socket is used for negative or positive ground type CD

ignitions. MPU socket is used for magnetic pickup or motor starter

auxiliary contact not to exceed 120 Vrms.

Section 50 00-02-0271

2018-10-23 - 11 -

Operation

Operating the S1501 Interface

Use the six membrane keys to scroll throughout the menus and to make changes to the

System timers, Tachometer calibration, Overspeed, Underspeed, Run Hourmeter (ETM), and

Sensor Setup..

YES - key used for scrolling up (increment).

NO - key used for scrolling down (decrement).

RESET - key used to reset alarms or shutdowns.

MODE - key used for mode and test time modes.

START/STOP – key used for Local mode start and stop signals.

ENTER - key used for entering/confirming set points and exiting menus

Section 50 00-02-0271

2018-10-23 - 12 -

ENGINE APPLICATION

EVENT

DISPLAY

RELAY

K1

K2

K3

K4

K5

K6

K7

Lube

Crank

Ign.

Fuel

Load

Alar

m

SD

WAITING ON START

Unit monitors for a valid start signal. Shutdown and

Alarm relays are energized. * User can at this time,

press the Mode key to modify desired setup tables.

Class A inputs are scanned.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

Start signal received. Unit advances to Prelube cycle.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

On

Off

On

On

If an RPM signal is seen before the Start signal is

pressed, a fault occurs.

Unexpected

Engine Start!

Off

Off

Off

On

Off

Off

Off

PRELUBE CYCLE

Prelube cycle begins. Permissive timer starts. Lube

relay energized.

LUBE CYCLE...

Permissive x:xx

On

Off

Off

Off

Off

On

On

Permissive time expires before Permissive signal* seen

closed. Fault occurs. Lube relay is de-energized.

Permissive

Failure

Off

Off

Off

Off

Off

Off

Off

Permissive signal closed. Prelube Cycle timer started.

LUBE CYCLE...

Prelube x:xx

On

Off

Off

Off

Off

On

On

Prelube Cycle timer times down to zero. Unit advances

to Crank cycle.

LUBE CYCLE...

Prelube :00

On

Off

Off

Off

Off

On

On

CRANK CYCLE

Crank Relay energizes. If the Run Delay Preset is > 0,

the controller will wait for a Crank RPM permissive to

proceed. If set to 0, this cycle is skipped

CRANK PERMISS...

Run Delay x:xx

On

On

Off

Off

Off

On

On

Run Delay time expires before RPM > 10 is seen. Fault

occurs.

Engine Failure To

Crank!

Off

Off

Off

Off

Off

Off

Off

RPM > 10 is seen, or Crank Permissive cycle skipped.

Cranking continues with purge timer started at preset

time.

CRANK CYCLE...

Purge :xx

On

On

Off

Off

Off

On

On

Purge delay expires. Ignition relay is energized. Fuel

On delay is started.

CRANK CYCLE...

Fuel Delay :xx

On

On

On

Off

Off

On

On

Fuel On delay expires. Fuel relay energized. Crank

timer started. The Controller will monitor for a Crank

Disconnect RPM to advance to the Run Cycle.

CRANK CYCLE...

Crank :xx

On

On

On

On

Off

On

On

Crank timer expires before disconnect speed is

reached. Unit goes into Rest cycle. Crank, Ignition, and

Fuel relays are de-energized. When the Rest expires,

the Crank Cycle will repeat.

CRANK CYCLE...

Rest :xx

On

Off

Off

Off

Off

On

On

All crank attempts exhausted. Crank timer expires.

Disconnect speed not reached. Overcrank condition

occurs. All relays de-energized.

Overcrank

Shutdown!

Off

Off

Off

Off

Off

Off

Off

Sequence of Operations - Engine Mode

Section 50 00-02-0271

2018-10-23 - 13 -

K1

K2

K3

K4

K5

K6

K7

Lube

Crank

Ign.

Fuel

Load

ALM

SD

RUN CYCLE

Crank Disconnect RPM reached. Crank relay deenergized. Class B1 Lockout, B2 Lockout and Load

timers started. Class C shutdowns are allowed to arm.

Speed: xxxxrpm

Class-B1 x:xx

Off

Off

On

On

Off

On

On

Class B1 and B2 Lockout timers expire. Elapsed time

displayed. Unit monitors for stop condition.

Speed: xxxxrpm

ETM: xxxxx.x hrs

Off

Off

On

On

Off

On

On

Load timer expires. Load relay energized. Process

Lockout timer starts. When this timer expires, Class P

shutdowns will be armed. User can press the Mode key

to initiate the Test timer and test sensor inputs.

Speed: xxxxrpm

Test Timer 5:00

Off

Off

On

On

On

On

On

IDLE CYCLE

Stop signal is seen. Load relay is de-energized. Class

P shutdowns are disarmed. Idle timer is started.

Speed: xxxxrpm

Idle x:xx

Off

Off

On

On

Off

On

On

ALARM FAULT

Alarm only input faulted. Alarm relay de-energized.

Fault alternately displayed with previous message

displaying the speed and run hours.

Low Coolant

Level

Off

Off

On

On

On

Off

On

S1501 Reset key pressed. Alarm relay is picked up.

Unit continues to scans for fault or stop condition.

Speed: xxxxrpm

ETM: xxxxx.x hrs

Off

Off

On

On

On

On

On

FAULT SHUTDOWN

Unit receives a fault at sensor #4 for instance. The Fuel

Valve, Alarm, and Shutdown relays are de-energized.

Speed: xxxxrpm

Ign. Gnd. :xx

Off

Off

On

Off

Off

Off

Off

Ignition ground delay expires. Ignition relay deenergized. Postlube cycle begins. Lube relay

energized.

LUBE CYCLE...

Postlube x:xx

On

Off

Off

Off

Off

Off

Off

Postlube expires. Lube relay de-energized. Fault is

displayed.

Low Compressor

Oil Pressure

Off

Off

Off

Off

Off

Off

Off

S1501 Mode key pressed. Shutdown type displayed.

Sensor Input #04

Class B1,Shutdown

Off

Off

Off

Off

Off

Off

Off

S1501 Reset key pressed. Unit waiting on start input.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

NORMAL STOP (AFTER IDLE CYCLE)

Stop signal received and idle timer expired. Ignition

ground delay begins. Fuel Valve relay de-energized.

Speed: xxxxrpm

Ign. Gnd. :xx

Off

Off

On

Off

Off

On

On

Ignition ground delay expires. Ignition relay deenergized. Postlube cycle begins. Lube relay

energized.

LUBE CYCLE...

Postlube x:xx

On

Off

Off

Off

Off

On

On

Postlube cycle timer expires. The Lube relay is deenergized. Unit returns to Waiting on Start.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

Section 50 00-02-0271

2018-10-23 - 14 -

ELECTRIC MOTOR APPLICATION

EVENT

DISPLAY

RELAY

K1

K2

K3

K4

K5

K6

K7

Lube

Not

Used

Motor

Cooler

Load

Alarm

SD

WAITING ON START

Unit monitors for a valid start signal. Shutdown and

Alarm relays are energized. * User can at this time,

press the Mode key to modify desired setup tables.

Class A inputs are scanned.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

Start signal received. Unit advances to Prelube cycle.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

On

Off

On

On

PRELUBE CYCLE

Prelube cycle begins. Permissive timer starts. Lube

relay energized.

LUBE CYCLE...

Permissive x:xx

On

Off

Off

Off

Off

On

On

Permissive time expires before Permissive signal* seen

closed. Fault occurs. Lube relay is de-energized.

Permissive

Failure

Off

Off

Off

Off

Off

Off

Off

Permissive signal closed. Prelube Cycle timer started.

LUBE CYCLE...

Prelube x:xx

On

Off

Off

Off

Off

On

On

Prelube Cycle timer times down to zero. Unit advances

to Wait On Run cycle.

LUBE CYCLE...

Prelube :00

On

Off

Off

Off

Off

On

On

WAIT ON RUN CYCLE

Motor Relay energizes. Run delay and Cooler On

Delays begin timing. The controller monitors for an

electric motor auxiliary contact run confirmation.

Waiting On Run

Run Delay x:xx

On

Off

On

Off

Off

On

On

Run Signal not received before the delay expires, Fault

occurs. All relays de-energize.

Motor Starter

Failure!

Off

Off

Off

Off

Off

Off

Off

S1501 Reset key pressed. Unit waiting on start input.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

RUN CYCLE

Motor auxiliary contact seen closed. Lube relay deenergizes. Class B1 Lockout, B2 Lockout and Load

timers started. Class C shutdowns are allowed to arm.

Motor Running...

Class-B1 x:xx

Off

Off

On

On

Off

On

On

Cooler On delay expires. The Cooler relay energizes.

Motor Running...

Class-B1 x:xx

Off

Off

On

On

Off

On

On

Class B1 and B2 Lockout timers expire. Elapsed time

displayed. Unit monitors for stop condition.

Motor Running...

ETM: xxxxx.x hrs

Off

Off

On

On

Off

On

On

Load timer expires. Load relay energized. Process

Lockout timer starts. When this timer expires, Class P

shutdowns will be armed. User can press the Mode key

to initiate the Test timer and test sensor inputs.

Motor Running...

Test Timer 5:00

Off

Off

On

On

On

On

On

IDLE CYCLE (COOLDOWN)

Stop signal is seen. Load relay is de-energized. Class

P shutdowns are disarmed. Idle timer is started.

Motor Running...

Idle x:xx

Off

Off

On

On

Off

On

On

ALARM FAULT

Alarm only input faulted. Alarm relay de-energized.

Fault alternately displayed with previous message

displaying the speed and run hours.

Low Coolant

Level

Off

Off

On

On

On

Off

On

S1501 Reset key pressed. Alarm relay is picked up.

Unit continues to scans for fault or stop condition.

Motor Running...

ETM: xxxxx.x hrs

Off

Off

On

On

On

On

On

Sequence of Operations – Motor Mode

Section 50 00-02-0271

2018-10-23 - 15 -

K1

K2

K3

K4

K5

K6

K7

Lube

Not

Used

Motor

Cooler

Load

Alarm

SD

FAULT SHUTDOWN

Unit receives a fault at sensor #4 for instance. Motor,

Cooler, Load, Alarm and Shutdown relays are deenergized. Postlube cycle begins. Lube Relay

energized.

LUBE CYCLE...

Postlube x:xx

On

Off

Off

Off

Off

Off

Off

Postlube expires. Lube relay de-energized. Fault is

displayed.

Low Compressor

Oil Pressure

Off

Off

Off

Off

Off

Off

Off

S1501 Mode key pressed. Shutdown type displayed.

Sensor Input #04

Class B1,Shutdown

Off

Off

Off

Off

Off

Off

Off

S1501 Reset key pressed. Unit waiting on start input.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

NORMAL STOP (AFTER IDLE-COOLDOWN CYCLE)

Stop signal received and idle timer expired. Motor, and

Cooler relays de-energized. Postlube cycle begins.

Lube relay energized

LUBE CYCLE...

Postlube x:xx

On

Off

Off

Off

Off

On

On

Postlube cycle timer expires. The Lube relay is deenergized. Unit returns to Waiting on Start.

Waiting On Start

ETM: xxxxx.x hrs

Off

Off

Off

Off

Off

On

On

Section 50 00-02-0271

2018-10-23 - 16 -

System Set Up Menus

While the S1501 displays “Waiting On Start”, pressing the MODE key will access the SYSTEM

SET UP menu. The following options are available:

Timer Set Up

Tach/Crank Set Up

ETM Set Up

Sensor Set Up

Timer Set Up - This set up screen allows you to preset the system timers. Zeroing out a

function’s timer will bypass that particular function.

Advanced Set Ups (password protected screens)

The following Set Ups are available only under ADVANCED SETUP mode.

Tach/Crank Set Up - This set up screen allows you to calibrate the internal tachometer with

pulses per revolution and set the Overspeed, Underspeed, Crank Attempt set points, and

Crank Disconnect.

ETM Set Up - This set up screen allows you to preset the Elapsed Time Meter (ETM).

Sensor Set Up - This set up screen allows you to edit shutdown or alarm messages and also

to edit the input sensor class (A, B1, B2, C, P, or ESD) and the action (Alarm only or

Shutdown).

NOTE: Communications will be disabled while using the keypad to

access the System Setup menu.

Section 50 00-02-0271

2018-10-23 - 17 -

Editing System Set Up

Timer Set Up Menu

There are a number of Timers that the S1501 system uses to carry out the start/stop

sequencing. With all shutdowns cleared, and the S1501 at the “Waiting On Start” prompt,

press the ■ MODE key to gain access to the Timer Setup Menu.

TIMER SETUP

Permissive x:xx

This displays the timer preset in MM:SS format. Press ▲ UP/YES or ▼ DOWN/NO keys to

increase or decrease the time. Press ■ RESET to zero the timer. Press ■ ENTER to accept

and save the setting and advance to the next timer.

Repeat the procedure to preset all available timers.

NOTE: To bypass a particular function, zero out the corresponding timer.

For example, to bypass Prelube, zero out the Prelube timer.

Permissive x:xx

During the Prelube cycle, this is the preset time by which the Permissive input must be seen

closed (NC system) or ungrounded (NO system). If the Permissive input is not satisfied, when

the timer expires, a Permissive Failure fault shutdown will occur.

NOTE: Terminal 32 is dedicated for the Permissive Pressure Input. To

bypass this function, install a jumper at terminal 32.

Prelube x:xx

During the Prelube cycle, this is the preset time for which the Lube relay remains energized

after the Permissive input is satisfied, prior to starting.

Purge Delay x:xx

Timer to purge excess fuel out of the engine on a crank attempt. The Crank relay is energized

with the fuel valve relay de-energized and the ignition relay de-energized.

Fuel Delay x:xx

Timer to delay energizing the fuel valve relay on a crank attempt to burn unspent fuel. The

ignition relay is energized during this time.

Crank x:xx

Time duration for the crank attempt after energizing the crank, ignition, and fuel valve relays.

Rest x:xx

Time duration for the Crank Rest period after the Crank period expires. However, if the

specified number of Crank attempts is exhausted, an Overcrank Shutdown occurs.

Run Delay x:xx

Section 50 00-02-0271

2018-10-23 - 18 -

In Electric Motor applications (Pulses/rev = 0), this is the timer to gain the Motor Starter

Auxiliary Run signal, after energizing the motor relay. If this signal is not seen before this timer

expires, a “Motor Starter Failure” shutdown will occur.

In Engine applications (Pulses/rev > 0), this is the timer to gain RPM reading > 10 before the

Ignition and Fuel relays are energized. If this signal is not seen before this timer expires, an

“Engine Failure To Crank” shutdown will occur. If set to 0, this RPM permissive is ignored.

Class-B1 x:xx

This timer locks out sensor inputs configured as Class B1 on startup.

Class-B2 x:xx

This timer locks out sensor inputs configured as Class B2 on startup.

Load x:xx

This timer delays energizing of the Load relay after starting, and is typically used as a warmup

time.

Process x:xx

This timer locks out sensor inputs configured as class P after energizing the Load relay. This

is typically used for Process alarms and shutdowns which do not clear until the unit has

loaded.

Idle x:xx

This timer determines the length of time the system will run after de-energizing the Load relay

after a stop signal is received. This is typically used for a Cooldown time period for the

equipment.

Ign. Gnd. x:xx

In Engine applications (Pulses/rev > 0), this is the delay between de-energizing the fuel valve

relay and de-energizing the ignition relay. This allows remaining fuel in the line to be burned

off, prior to disabling the ignition system.

Postlube x:xx

After a stop or shutdown fault (non-ESD) this is the time for which the Lube relay will be

energized for a postlube cycle.

Cooler Dly x:xx

In Electric Motor applications ((Pulses/rev = 0), this timer delays energizing the cooler relay

after energizing the motor relay to reduce inrush current imposed on the power source for the

AC motors.

Section 50 00-02-0271

2018-10-23 - 19 -

Advanced Set Up Menu

To calibrate the Tachometer and Elapsed Time Meter, select Crank attempts, Modbus RTU

address, and modify sensor input information, a password protected setup mode is available.

After the Timer Setup is complete, the LCD will read...

ADVANCED SETUP

Password XXXX

To Exit Setup quickly without entering the Advanced Setup at this point, press ■ RESET and ■

ENTER at the same time.

The first “X” will be blinking, to enter the password use the ▲ UP/YES or ▼ DOWN/NO keys to

scroll through the characters. Press ■ RESET and ■ MODE to scroll between characters.

When the correct password is entered, press ■ ENTER to acknowledge. The following screen

will be briefly displayed:

ADVANCED SETUP

PASSWORD OK!

If password is incorrect the screen will be the following:

ADVANCED SETUP

PASSWORD ERROR!

User will again be prompted to enter correct password. After 3 unsuccessful entries, the

Advanced Set up is aborted and screen will return to “Waiting On Start”.

ADVANCED SETUP

Pulses/rev xx

Press ▲ UP/YES or ▼ DOWN/NO keys to increase or decrease the value. Press ■ ENTER to

accept and save the setting and advance to the next setting.

Pulses/rev xx

To calibrate the internal tachometer, enter the pulses per revolution of the engine. To set the

controller for an electric motor logic sequence, this setting must be set to “0”.

Enter either the number of teeth in the fly wheel if using a Magnetic Pickup, or use the

following equation if using the Ignition input:

Pulses = 2*Cylinders\Cycles

For instance, for an 8 cylinder, 4 cycle engine,

Pulses = 2*8\4 = 4

Attempts x

Engine sequence only-This is the number of allowable engine crank cycles before an

Overcrank Shutdown occurs.

Disconnect xxxx

Engine sequence only-This is the RPM at which the crank relay de-energized and the engine

is considered running.

Section 50 00-02-0271

2018-10-23 - 20 -

Overspeed xxxx

Engine sequence only-This is the excessive speed RPM at which the S1501 signals an

internal Overspeed Shutdown.

Underspeed xxxx

Engine sequence only-This is the low speed RPM at which the S1501 signals an internal

Underspeed Shutdown. This is not armed until the Class B1 timer expires.

ETM 1k Hr xx

Preset the Elapsed Time Hours thousands hours or use the RESET button to zero it.

ETM 100 Hr xx

Preset the Elapsed Time Hours hundred hours or use the RESET button to zero it.

ETM Secs Hr xx

Preset the Elapsed Time Hours seconds or use the RESET button to zero it.

Section 50 00-02-0271

2018-10-23 - 21 -

Sensor Set Up

The S1501 system allows you to edit the Shutdown Message, Class Type and Shutdown

Action (Shutdown Alarm or Alarm only) for each Sensor Input. Class Type are defined as

follows:

Class A, Shutdown

Class B1, Shutdown

Class B2, Shutdown

Class C, Shutdown

Class P, Shutdown

ESD Shutdown

Class A, Alarm

Class B1, Alarm

Class B2, Alarm

Class C, Alarm

Class P, Alarm

Ignore Point

Press ▲ UP/YES or ▼ DOWN/NO keys to select the input to modify. Select INPUT #0 to exit.

Press ■■ ENTER once the desired input is chosen, and the corresponding shutdown message

will be displayed.

LOW OIL

PRESSURE

With the first character blinking you may change the character by pressing the ▲▲ UP/YES or

▼ DOWN/NO keys to scroll through available characters. Press ■■ MODE to move forward on

character, or ■■ RESET to move backward. When the shutdown modification is completed,

press ■■■ ENTER to save the new message. The Sensor Class Type and function will now be

displayed, for example:

SHUTDOWN TYPE

CLASS A SHUTDOWN

To change the Class Type and function, use the ▲▲ UP/YES or ▼ DOWN/NO keys until the

desired combination of Class and Function is reached. Press the ■■■ ENTER key to save and

return to the Setup screen. Repeat as above for all Sensors Inputs and Messages to be

edited.

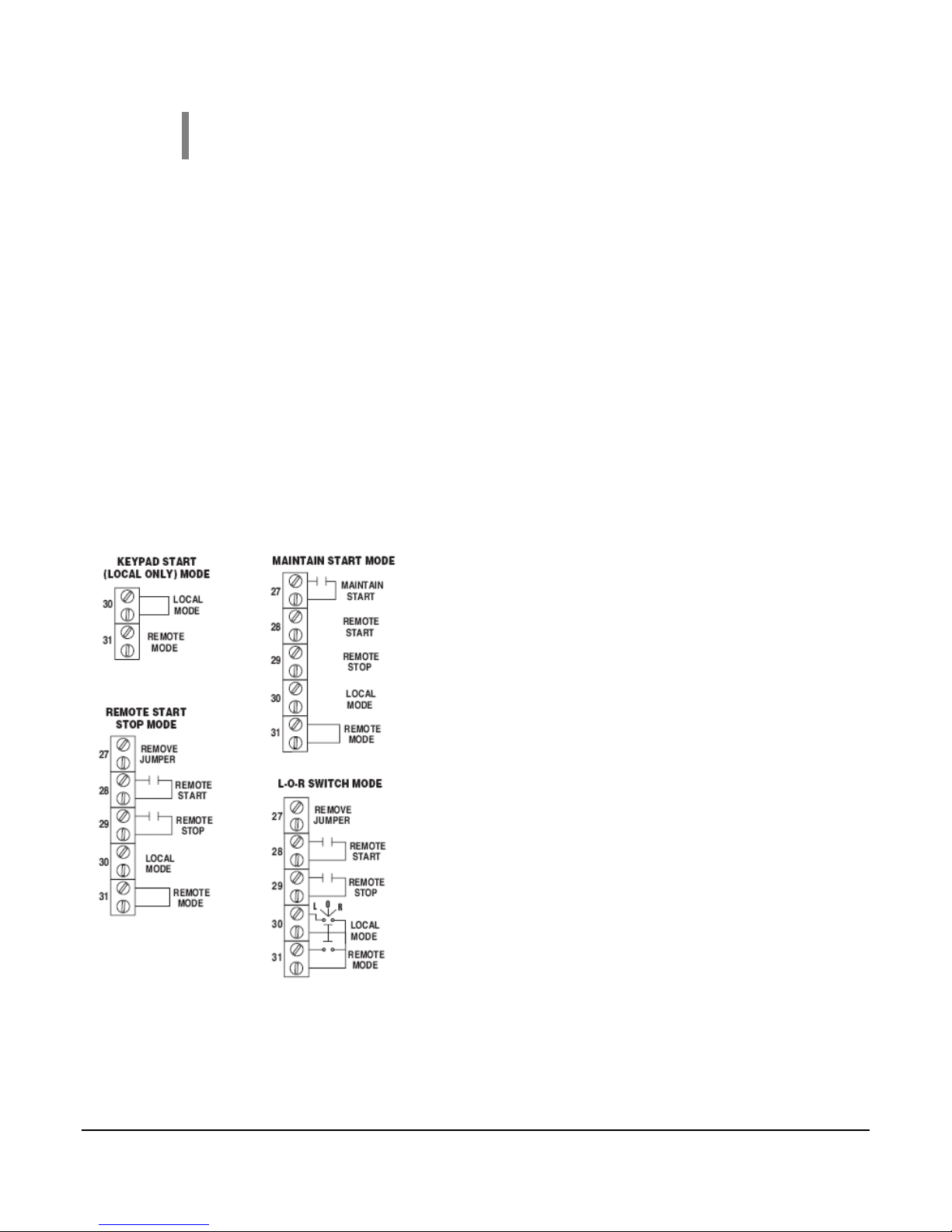

Start/Stop Configuration

The S1501 system can be configured for Local and/or Remote Start-Stop. Start-Stop is

configured via terminal block inputs TB30 (local), TB31 (Remote).

Keypad Start

Jumper installed in TB30. A valid sequence occurs when the ■ START/STOP key is pressed.

Likewise, while running, a valid stop sequence occurs when the ■ START/STOP key is

pressed.

Section 50 00-02-0271

2018-10-23 - 22 -

NOTE: A valid stop occurs when the ■ START/STOP key is pressed

Regardless of the Start-Stop mode.

Local-Off-Remote (L-O-R) Switch

L-O-R switch installed across TB30 (Local) and TB31 (Remote). A valid sequence occurs

when the L-O-R switch is placed in the Local position and the Start-Stop key is pressed OR the

L-O-R is placed in the Remote position, and the Remote Start signal is seen. A valid Stop

occurs when the L-O-R switch is placed in the OFF position, OR of in the Remote position and

a Remote Stop is seen.

Remote Start-Stop

Jumper installed in TB31. A valid sequence occurs when a Remote Start signal is seen.

Likewise, a valid stop occurs when the Remote Stop signal is seen.

Maintain Start

Jumper installed in TB31. A valid sequence occurs when the Maintain Start signal is seen.

Likewise, a valid stop occurs when the Maintain Start signal is lost.

Typical Start/Stop Wiring

Modbus Start/Stop and Reset

The S1501 system can be started and stopped remotely through the

Modbus communications port (RS232/RS485 serial port). Writing a “1”

to the start/stop register (40010) will initiate a start. Writing a “Ø” to the

start /stop register will initiate a stop. Writing “Ø” to the shutdown status

register (40004) will cause a reset.

Section 50 00-02-0271

2018-10-23 - 23 -

Address

Access

Description

40001

Read

RPM

40002

Read

ETM (Elapsed Run Time Meter) Hundred Hours ( 0 – 999)

40003

Read

Class B1 Timer Accumulator Seconds

40004

Read/

Write

Shutdown Status Enumeration/Remote Modbus Reset (0=OK, or terminal block number of

Shutdown event...writable to 0 for Modbus Reset)

System Internal shutdowns:

68 = Engine Overspeed (engine applications)

70 = Engine Underspeed (engine applications)

72 = Overcrank (engine applications)

74 = Permissive Failure

76 = Motor Starter Failure (motor applications)

78 = Local Stop (by keypad)

80 = Unexpected Engine Start (engine applications)

86 = Loss of Tach Signal (engine applications)

88 = Loss of Run Signal (motor applications)

96 = Engine Failure To Crank (engine applications)

40005

Read

Relay Output Status (bitmapped Bit 0=K1 ... Bit 1=K2, etc)

40006

Read

Inputs TB01-16 Status (bitmapped Bit 0=TB1 ... Bit 1=TB2, etc)

40007

Read

Inputs TB17-32 Status (bitmapped Bit 0=TB17 ... Bit 1=TB18, etc)

40008

Read

Inputs TB33-48 Status (bitmapped Bit 0=TB33 ... Bit 1=TB34, etc)

40009

Read

Inputs TB49-64 Status (bitmapped Bit 0=TB49 ... Bit 1=TB50, etc)

40010

Read/

Write

Start/Stop Register (writable for remote commands if Remote Mode on TB29 is closed and

remote maintained start digital input TB27 not used. It is active for a write of "0" at all

times to allow remote stopping, until a start signal is received again)

40011

Read/

Write

40011 = Load/Unload Register (writable for resetting the Load relay after the LOAD relay

has been energized by the program, and setting it again if it has been

reset through Modbus. This resets and restarts the Process delay, at the same time as the

Load relay is reset and set)

40012

Read

ETM (Elapsed Run Time Meter) Thousand Hours ( 0 – 99 )

40013

Read

State Bitmap

Bit 0 = “WAITING ON START”

Bit 1 = “PERMISSIVE”

Bit 2 = “PRELUBE”

Bit 3 = “CRANK PERMISSIVE”

Bit 4 = “PURGE”

Bit 5 = “FUEL DELAY”

Bit 6 = “CRANK”

Bit 7 = “REST”

Bit 8 = “RUN DELAY”

Bit 9 = “LOAD DELAY (WARMUP)”

Bit 10 = “LOADED”

Bit 11 = “UNLOADED”

Bit 12 = “IDLE (COOLDOWN)”

Bit 13 = “IGN GND DELAY”

Bit 14 = “POSTLUBE“

Bit 15 = “SHUTDOWN”

40014

Read

Alarm Status Enumeration (0=OK, or terminal block number of last alarm event)

Modbus Integer Holding Registers

Section 50 00-02-0271

2018-10-23 - 24 -

Troubleshooting

WARNING: Do NOT open power supply until operations have been

shut down and area has been rendered non-hazardous. Do NOT run

sensor wires in conduit with any other wire. Do NOT apply voltage

to any annunciator input terminals. Do NOT bundle sensor wires

with any other wiring. Make sure the voltage and current

requirements are within the S1501 system ratings.

Before going through the checklist below, refer to the connections and operation procedures.

Also check your system wiring schematic.

If any problems persist after you have made these checks, consult your nearest Murphy

facility.

Symptom: No display

Check that the Power & Control cable is firmly connected to the back of the S1501.

Check for damaged or broken wire.

Check for power failure or power input shutdown.

Check the 200 mA fuse within the S1501 power supply and replace if necessary.

NOTE: If after all of the above has been done, and there is still no display,

return the S1501 to Murphy for repair or replacement.

Symptom: Engine fails to start (Sensor switch fault display cannot be

cleared.)

Check that the Power & Control cable is firmly connected to the back of the S1501.

Check for damaged or broken wire.

Check that the sensor input cable connector (ribbon cable) is properly connected to

the back of the S1501.

Verify that the LED lights (within the power supply box) are lit indicating relays are

functioning.

Check that the wire leads on the terminal block under the Safety Barrier cover are

connected and tight. (See drawing at right.)

Measure the voltage between terminals 1 and 2 on the terminal block under the

Safety Barrier cover (voltage should read between 5 - 6 VDC). Do this with the

S1501 connected to the power supply, and with it disconnected. There should not be

more than a 0.5 V difference between the readings with the S1501 connected and

not connected.

Section 50 00-02-0271

2018-10-23 - 25 -

Check sensor wires with an ohmmeter and meg or high potential test only with wires

disconnected from sensor terminal block.

NOTE: If shutdowns still result, contact your nearest Murphy

representative/dealer.

Section 50 00-02-0271

2018-10-23 - 26 -

Power Consumption

120 VAC (7.5 VA)

12 VDC (3.5 watts)

24 VDC (3.5 watts)

Sensor Inputs

32 or 64 N.O. and/or N.C. inputs such as Murphy Swichgage®

instruments.

Field selectable as a Class A, B1, B2, C, P or ESD for shutdown,

alarm, or control function.

NOTE: Sensor inputs 27 through 32 reserved for control

functions.

Outputs

7-SPDT relay outputs, 5 A, 1/16 HP,

125/250 VAC/ 1 A, 30 VDC

NOTE: For hazardous areas an approved isolation barrier must

be used between sensor switch and input terminals if the sensor

output comes from any energy storing device such as a relay or

transistor.

Adjustable Time Delays

Permissive

Prelube

Purge

Fuel

Crank

Run

Class B1 Lockout

Class B2 Lockout

Process Lockout

Idle/Cooldown

Ignition Ground

Postlube

Cooler

Sensor Inputs Terminal Block

Rail mount DIN type; 32 terminals, screw type

Opto-Isolated Tach/Run Input

Magnetic pickup, 4.5 to 120 Vrms, 0-10 kHz. CD ignition,

positive or negative ground, 100 to 300 VDC, 3-666 Hz.

12 to 125 VDC or 120 Vrms, 50/60 Hz may be used for

run signals.

Operating Temperatures: 32 to 122°F (0 to

50°C)

Storage Temperatures: -4 to 158°F (-20 to

70°C)

Case : ABS plastic, 1/4 DIN (90 x 90 mm)

Communications

Factory configured for RS232; field-selectable for

RS485.

Alphanumeric Display

2 lines, each line with 16 characters (32 characters total)

Power Supply Enclosure

Explosion-proof, Class I, Division 1. Intrinsically safe

barrier built into the power supply, 120 VAC with 7 form

“C” relay outputs for the following functions (with

standard S1501):

Lube

Crank

Ignition/Motor

Fuel/Cooler

Load

Alarm

Shutdown

Specifications

Section 50 00-02-0271

2018-10-23 - 27 -

S1501H-32-2

S1501H-64-2

S1501CH-32-2

S1501CH-64-2

S1500TB32

S1500CA36

S1501PS-120

Accessories:

S1501PCA72

S1501PS-120-E

S1501PS-120-LC

Head with RS232/RS485 port for 32 sensors

Head with RS232/RS485 port for 64 sensors

Head w/custom* program, RS232/RS485 port, 32 sensors

Head w/custom* program, RS232/RS485 port, 64 sensors

Terminal Block only**

Ribbon Cable Assembly**

120 VAC, 12 or 24 VDC Power Supply

Power and Control Cable Assembly, 72 in. (1.8 m) long

Power Supply with 90° Conduit Elbow fitting

Power Supply less case

Replacement Parts and Accessories

To order the S1501 system specify the model number for each individual component and accessory:

Approximate Shipping Weights / Dimensions

S1501 complete system:

28 lb. (12.7 kg) / 20x14x12.5 in. (508x356x218mm)

S1501H-32-2; S1501H-64-2; S1501CH-32-2; S1501CH-64-2:

2 lb. (0.907 kg) / 6x6x6 in. (152x152x152mm)

S1500TB32:

2 lb. (0.907 kg) / 12x7x4 in. (305x178x102mm)

S1500CA36; S1501PCA72:

2 lb. (0.907 kg) / 6x6x6 in. (152x152x152mm)

S1501PS-120-LC:

3 lb. (1.36 kg) / 12x7x4 in. (305x178x102mm)

S1501PS-120 and S1501PS-120-E:

22 lb. (9.98 kg) / 17x10x9.75 in. (431x254x248mm)

Section 50 00-02-0271

2018-10-23 - 28 -

.

Section 50 00-02-0271

2018-10-23 - 29 -

Loading...

Loading...