F.W. Bell 9900 Series Operation & Maintenance Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

9000

SERIES

GAUSSMETERS

SK NFg 9:!..'0

GAL'S:ME IEH

O

a

0

,12111b4U411,4 /CI !V q 1 I I I' 4,4

*AA

SERIES

9900 GAUSSMETER

900

SERIES

9900

9000

SERIES

GAUSSMETERS

SERIES 9900 GAUSSMETER

Operation and Maintenance Manual

E

6120 HANGING MOSS ROAD

ORLANDO, FLORIDA 32807

PHONE: 407-678-6900

TWX: 810-853-3115

FAX : 407-677-5765

91062.5S

LITHO IN U.S.A. UN-01-183

SERIES

9900

9000

SERIES

GAUSSMETERS

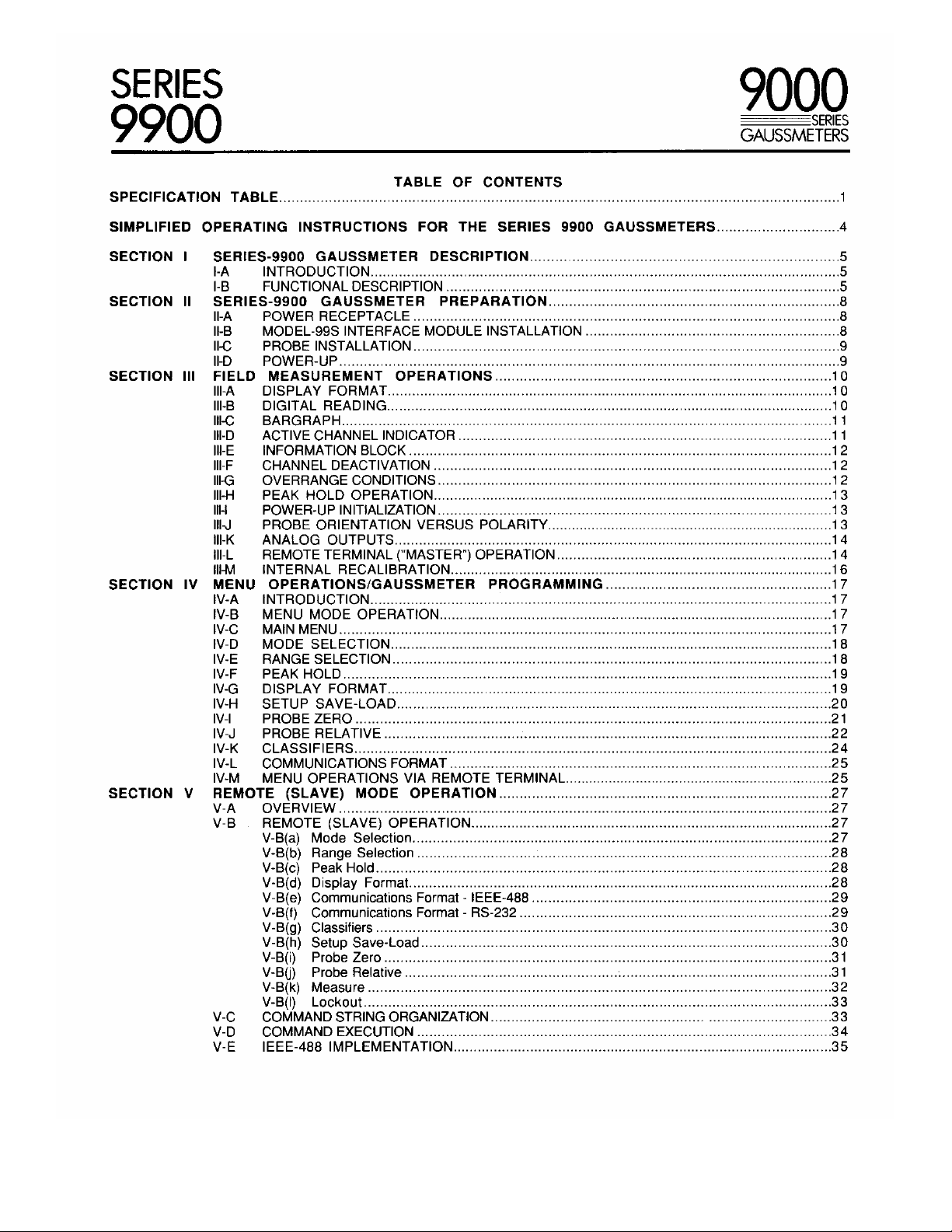

SPECIFICATION

SIMPLIFIED OPERATING

SECTION I

SECTION II

SECTION III FIELD

SECTION IV MENU

SECTION V REMOTE (SLAVE) MODE OPERATION 27

TABLE

INSTRUCTIONS FOR THE SERIES 9900 GAUSSMETERS

SERIES-9900 GAUSSMETER DESCRIPTION

-A INTRODUCTION

-B FUNCTIONAL DESCRIPTION

SERIES-9900 GAUSSMETER PREPARATION

V-A OVERVIEW 27

V-B

V-C

V-D

V-E

POWER RECEPTACLE

I-A

MODEL-99S INTERFACE MODULE INSTALLATION

I-B

I-C PROBE INSTALLATION 9

I-D POWER-UP

II-A DISPLAY FORMAT

II-B DIGITAL READING

II-C BARGRAPH

II-D ACTIVE CHANNEL INDICATOR 1 1

II-E INFORMATION BLOCK 12

II-F

I-G

II-H PEAK HOLD OPERATION

I-I POWER-UP INITIALIZATION

Il-J PROBE ORIENTATION VERSUS POLARITY

II-K ANALOG OUTPUTS

II-L REMOTE TERMINAL ("MASTER") OPERATION

I-M INTERNAL RECALIBRATION

V-A INTRODUCTION

V-B

V-C

V-D

V-E RANGE SELECTION

V-F PEAK HOLD

V-G DISPLAY FORMAT

V-H SETUP SAVE-LOAD 20

V-I PROBE ZERO 21

V-J

V-K CLASSIFIERS

V-L COMMUNICATIONS FORMAT

V-M MENU OPERATIONS VIA REMOTE TERMINAL

MEASUREMENT OPERATIONS 10

CHANNEL DEACTIVATION 12

OVERRANGE CONDITIONS 12

OPERATIONS/GAUSSMETER PROGRAMMING

MENU MODE OPERATION

MAIN MENU 17

MODE SELECTION 18

PROBE RELATIVE 22

REMOTE (SLAVE) OPERATION 27

V-B (a) Mode Selection

V-B(b) Range Selection

V-B (c) Peak Hold 28

V-B(d) Display Format 28

V-B(e) Communications Format - IEEE-488 29

V-B(f) Communications Format - RS-232

V-B(g) Classifiers

V-B(h) Setup Save-Load

V-B(i) Probe Zero

V-B(j) Probe Relative

V-B (k) Measure

V-B (I) Lockout

COMMAND STRING ORGANIZATION

COMMAND EXECUTION 34

IEEE-488 IMPLEMENTATION

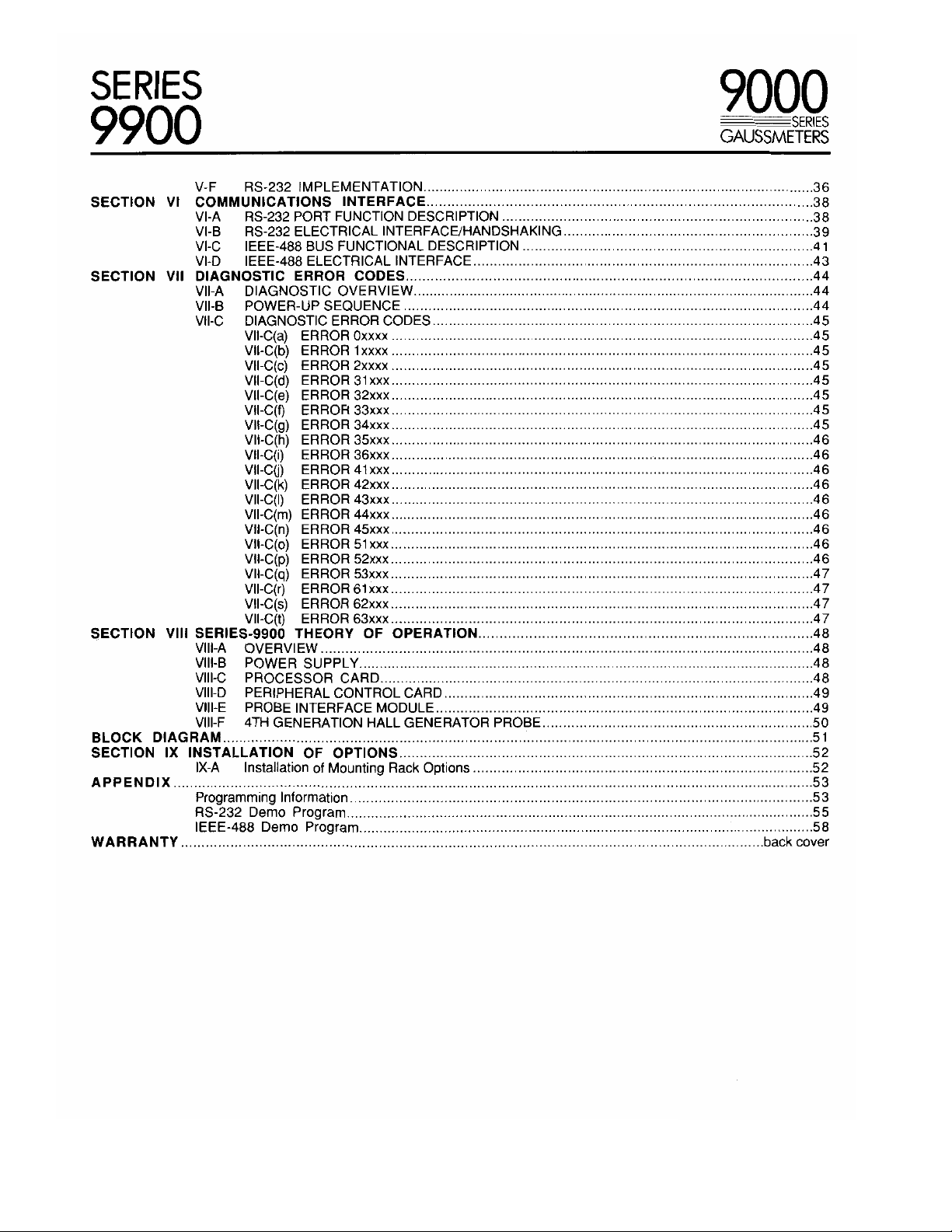

TABLE OF CONTENTS

10

10

11

13

13

13

14

14

16

17

17

17

18

19

19

24

25

25

27

28

29

30

30

31

31

32

33

33

35

1

4

5

5

5

8

8

8

9

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION VI COMMUNICATIONS INTERFACE38

SECTION VII DIAGNOSTIC ERROR CODES44

SECTION VIII SERIES-9900 THEORY OF OPERATION48

BLOCK DIAGRAM51

SECTION IX INSTALLATION OF OPTIONS52

APPENDIX53

WAR RANTYback cover

V-F RS-232 IMPLEMENTATION36

VI-A RS-232 PORT FUNCTION DESCRIPTION38

VI-B RS-232 ELECTRICAL INTERFACE/HANDSHAKING39

VI-C IEEE-488 BUS FUNCTIONAL DESCRIPTION41

VI-D IEEE-488 ELECTRICAL INTERFACE43

VII-A DIAGNOSTIC OVERVIEW44

VII-B POWER-UP SEQUENCE44

VII-C DIAGNOSTIC ERROR CODES45

VII-C(a) ERROR 0xxxx45

VII-C(b) ERROR 1 xxxx45

VII-C(c) ERROR 2xxxx45

VII-C(d) ERROR 31xxx45

VII-C(e) ERROR 32xxx45

VII-C(f) ERROR 33xxx45

VII-C(g) ERROR 34xxx45

VII-C(h) ERROR 35xxx46

VII-C(i) ERROR 36xxx46

VII-C(j) ERROR 41xxx46

VII-C(k) ERROR 42xxx46

VII-C(I) ERROR 43xxx46

VII-C(m) ERROR 44xxx46

VII-C(n) ERROR 45xxx46

VII-C(o) ERROR 51xxx46

VII-C(p) ERROR 52xxx46

VII-C(q) ERROR 53xxx47

VII-C(r) ERROR 61xxx47

VII-C(s) ERROR 62xxx47

VII-C(t) ERROR 63xxx47

VIII-A OVERVIEW48

VIII-B POWER SUPPLY48

VIII-C PROCESSOR CARD48

VIII-D PERIPHERAL CONTROL CARD49

VIII-E PROBE INTERFACE MODULE49

VIII-F 4TH GENERATION HALL GENERATOR PROBE50

IX-A Installation of Mounting Rack Options52

Programming Information53

RS-232 Demo Program55

IEEE-488 Demo Program58

SERIES

9900

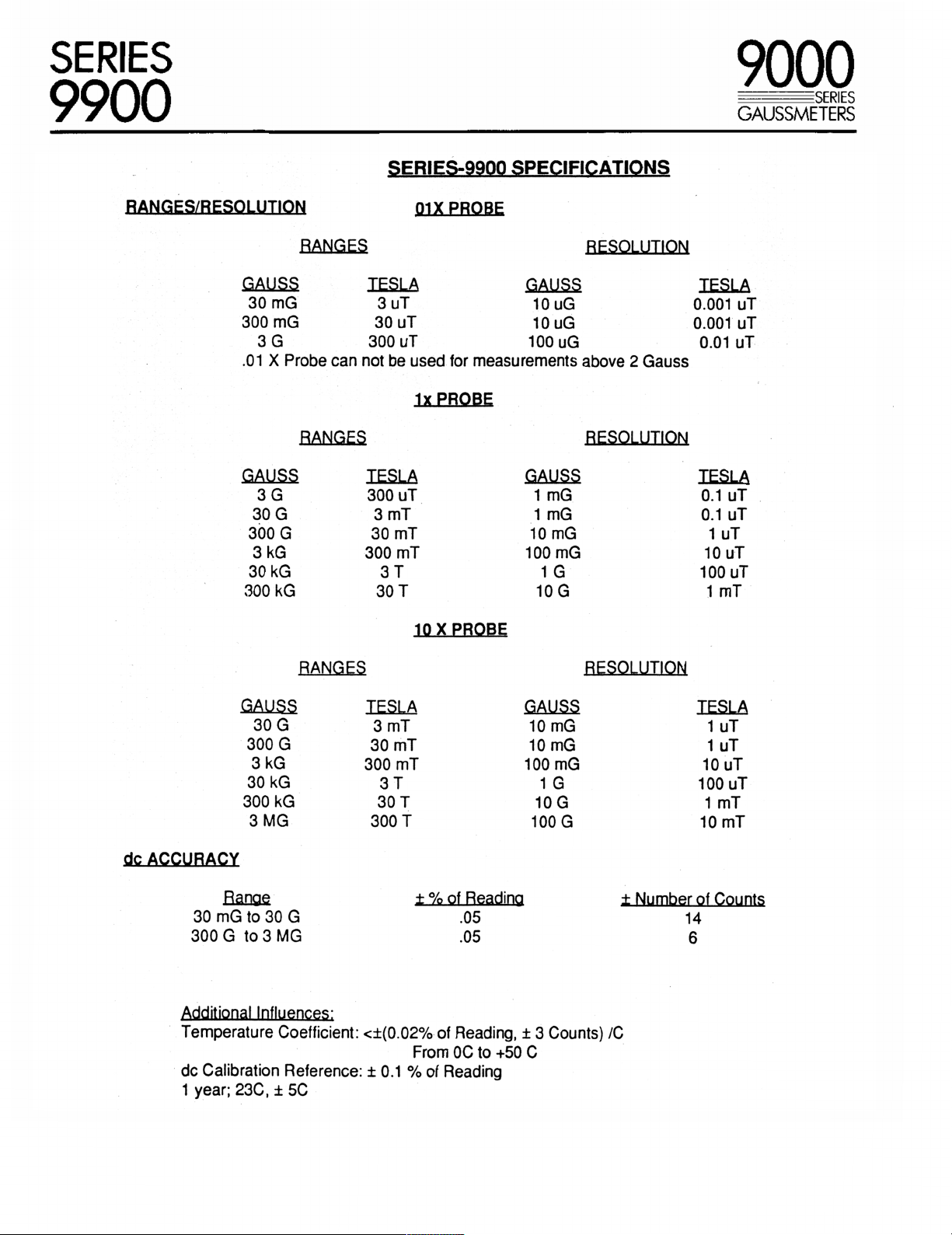

RANGES/RESOLUTION 01X PROBE

9000

SERIES

GAUSSMETERS

SERIES-9900 SPECIFICATIONS

RANGES RESOLUTION

GAUSS TESLA GAUSS TESLA

30 mG 3 uT 10 uG 0.001 uT

300 mG 30 uT 10 uG 0.001 uT

3 G 300 uT 100 uG 0.01 uT

.01 X Probe can not be used for measurements above 2 Gauss

lx PROBE

RANGES RESOLUTION

GAUSS TESLA GAUSS TESLA

3 G 300 uT 1 mG 0.1 uT

30 G 3 mT 1 mG 0.1 uT

300 G 30 mT 10 mG 1 uT

3 kG 300 mT 100 mG 10 uT

30 kG 3 T 1 G 100 uT

300 kG 30 T 10 G 1 mT

dc ACCURACY

Ran t % of Reading t Number of Counts

30 mG to 30 G .05 14

300 G to 3 MG .05 6

Additional Influences;

Te m p e r at u r e Coefficient: <±(0.02% of Reading, ± 3 Counts) /C

dc Calibration Reference: ± 0.1 % of Reading

1 year; 23C, ± 5C

10 X PROBE

RANGES RESOLUTION

GAUSS TESLA GAUSS TESLA

30 G 3 mT 10 mG 1 uT

300 G 30 mT 10 mG 1 uT

3 kG 300 mT 100 mG 10 uT

30 kG 3 T 1 G 100 uT

300 kG 30 T 10 G 1 mT

3 MG 300 T 100 G 10 mT

From OC to +50 C

SERIES

9900

9000

SERIES

GAUSSMETERS

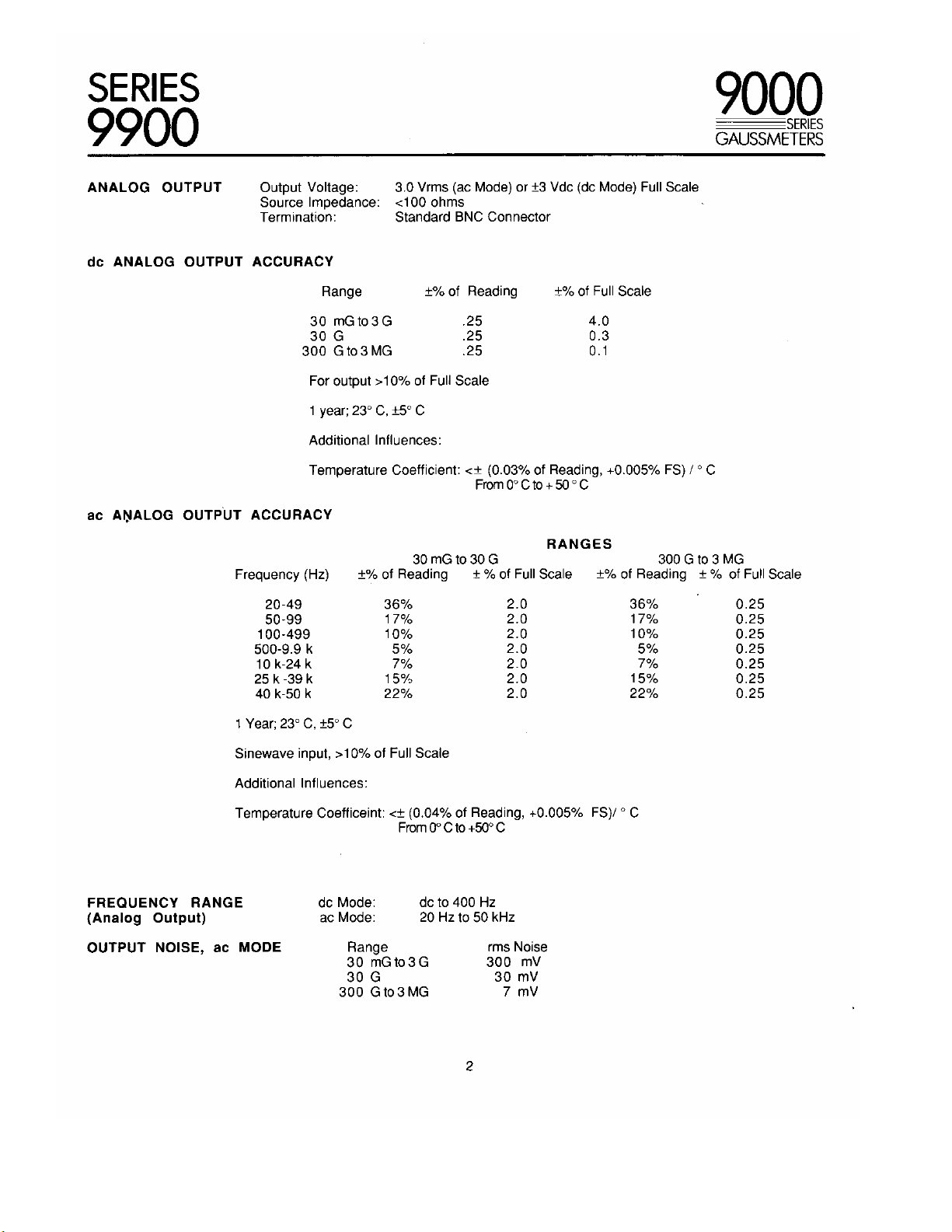

ANALOG OUTPUT

dc ANALOG OUTPUT ACCURACY

ac ANALOG OUTPUT ACCURACY

Output Voltage: 3.0 Vrms (ac Mode) or ±3 Vdc (dc Mode) Full Scale

Source Impedance: <100 ohms

Te r mi n a ti o n : Standard BNC Connector

30 mGto3G

30 G

300 G to 3 MG

For output >10% of Full Scale

1 year; 23° C, ±5° C

Additional Influences:

Te m pe r a t ur e Coefficient: <± (0.03% of Reading, +0.005% FS) I ° C

Frequency (Hz)

20-49 36%

50-99

100-499

500-9.9 k 5%

10 k-24 k

25 k -39 k

40 k-50 k

Range ±% of Reading ±% of Full Scale

.25 4.0

.25 0.3

.25 0.1

From 0° C to + 50 ° C

±% of Reading ± °/0 of Full Scale ±% of Reading ± % of Full Scale

30 mG to 30 G 300 G to 3 MG

17% 2.0 17%

10% 2.0

7% 2.0 7% 0.25

15% 2.0

22% 2.0 22% 0.25

RANGES

2.0 36% 0.25

10%

2.0 5% 0.25

15%

0.25

0.25

0.25

FREQUENCY RANGE

(Analog Output)

OUTPUT NOISE, ac MODE

1 Year; 23° C, ±5° C

Sinewave input, >10% of Full Scale

Additional Influences:

Te m pe r a t ur e Coefficeint: <± (0.04% of Reading, +0.005% FS)/ ° C

dc Mode:

ac Mode:

Range rms Noise

30 mGto3G 300 mV

30 G 30 mV

300 G to 3 MG 7 mV

From 0° C to +50° C

dc to 400 Hz

20 Hz to 50 kHz

2

SERIES

9900

9000

SERIES

GAUSSMETERS

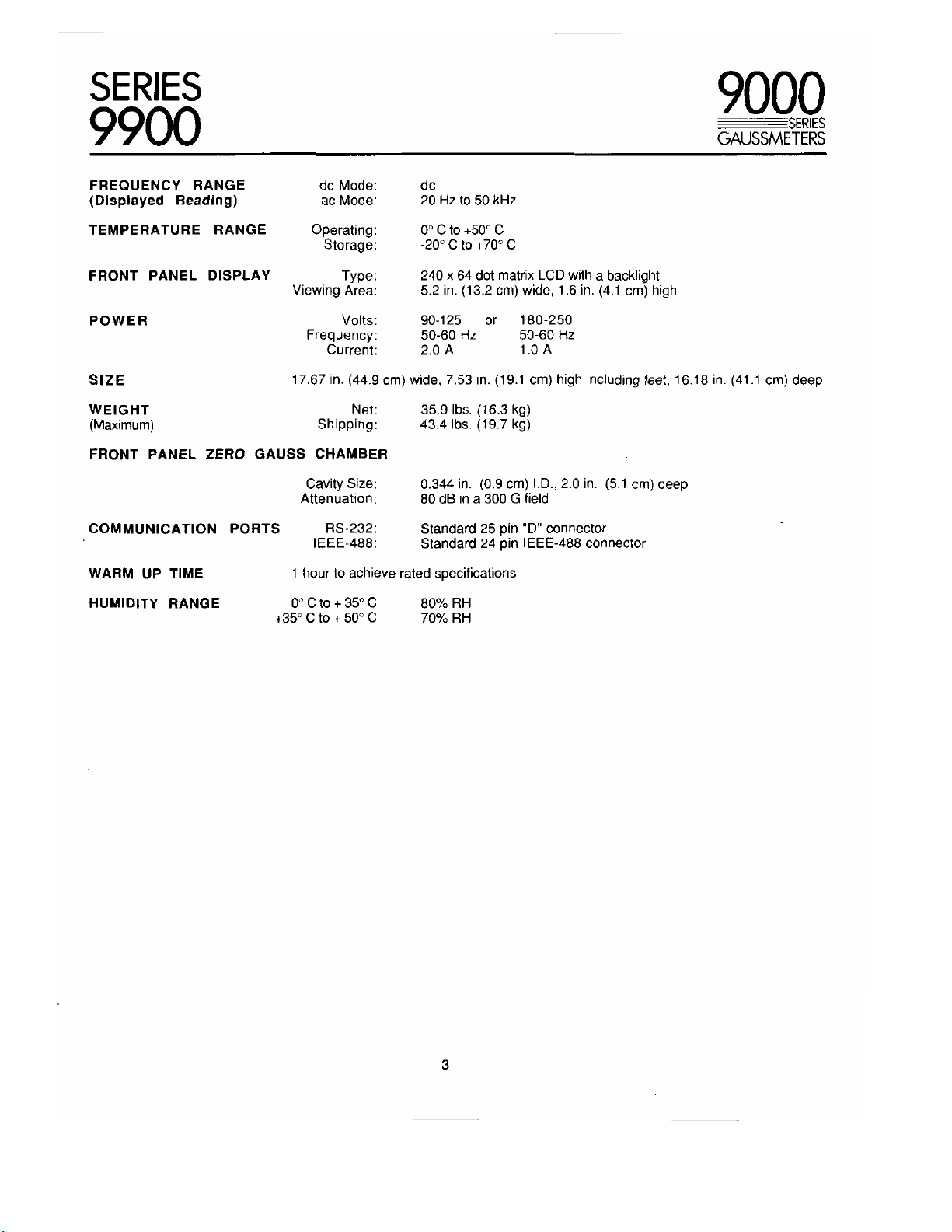

FREQUENCY RANGE

(Displayed Reading)

TEMPERATURE RANGE Operating: 0° C to +50° C

FRONT PANEL DISPLAY Type: 240 x 64 dot matrix LCD with a backlight

POWER Vo lts: 90-125 or 180-250

SIZE 17.67 in. (44.9 cm) wide, 7.53 in. (19.1 cm) high including feet, 16.18 in. (41.1 cm) deep

WEIGHT Net: 35.9 lbs. (16.3 kg)

(Maximum) Shipping: 43.4 lbs. (19.7 kg)

FRONT PANEL ZERO GAUSS CHAMBER

COMMUNICATION PORTS RS-232: Standard 25 pin "D" connector

WARM UP TIME 1 hour to achieve rated specifications

HUMIDITY RANGE

dc Mode: dc

ac Mode: 20 Hz to 50 kHz

Storage: -20° C to +70° C

Viewing Are a: 5.2 in. (13.2 cm) wide, 1.6 in. (4.1 cm) high

Frequency: 50-60 Hz 50-60 Hz

Current: 2.0 A 1.0 A

Cavity Size:

Attenuation:

IEEE-488: Standard 24 pin IEEE-488 connector

0°Cto+35°C 80% R H

+35° C to + 50° C 70°/0 R H

0.344 in. (0.9 cm) I.D., 2.0 in. (5.1 cm) deep

80 dB in a 300 G field

3

SERIES

9900

9000

SERIES

GAUSSMETERS

1) Check the rear panel power receptacle to insure that the voltage showing

is the voltage you will be using, 115 volts ac or 230 volts ac. If it is necessary

to change this setting, refer to Section II-A.

SIMPLIFIED

OPERATING

INSTRUCTIONS

FOR THE 9900

SERIES

GAUSSMETERS

2) With the power turned off, connect the required probes and probe

modules to the channels desired via the connectors on the front panel of the

gaussmeter. See Section II-B and II-C.

3) Connect power to the 9900 and turn on the instrument by locating the

Power Switch on the front panel and depressing the side marked 1.

NOTE: At turn-on, the screen should display a large F.W. Bell logo. Beneath

the logo, various messages will indicate the progress of the initialization. If any

error messages occur at this time, refer to Section VII, Diagnostic Error

Codes.

4) Assuming no error codes are present, the gaussmeter is now in the

MEASURE mode and will begin field measurements.

NOTE: All operating parameters such as range setting, peak/hold, classifier,

display format, communication format, etc... will be initialized to the same settings

that were present when the gaussmeter was last turned off.

5) Prior to making accurate readings, it is necessary to zero each probe by

following the procedures below:

a) Press the ENTER/PROGRAM pushbutton. The MAIN MENU will

appear.

b) Using the the up (T) and down (L) pushbuttons, advance the cursor to

PROBE ZERO function.

c) Press ENTER. The PROBE ZERO menu will appear.

d) Using the the up (T) and down (I) pushbuttons, advance the cursor to

the desired channel. Press ENTER.

e) Install the probe tip in the ZERO GAUSS CHAMBER located directly

below the display. Press ENTER.

f) The gaussmeter will proceed to zero the probe on each range setting for

either AC or DC operation, depending on the present mode setting.

g) Upon completion, the PROBE ZERO menu will reappear. Repeat steps

d-f for all remaining channels.

h) Advance the cursor to RUN. Press ENTER to resume field

measurements.

6) Consult Section IV for more information on MENU operations, or the

TABLE OF CONTENTS for references to other gaussmeter features.

NOTE: Greatest accuracy will be obtained after a 1-hour warm up period.

4

SERIES

9900

SECTION I I-A INTRODUCTION

The SERIES-9900 gaussmeter represents the latest developments in the

science of measuring magnetic flux density using the Hall effect. The unit is

GENERAL

DESCRIPTION

available in three configurations capable of processing a single channel

(Model 9901), two channels (Model 9902) or three channels (Model 9903) of

magnetic field information. Either steady-state (dc) or alternating (ac) fields

can be measured. When matched with the appropriate F.W. Bell fourth-

generation Hall generator probe, fields as low as 10 pG (0.0011.1T) or as high

as 2.9999 MG (299.99 T), at frequencies up to 50 kHz, can be measured with

extreme accuracy and 4-3/4 digit resolution.

The SERIES-9900 features PEAK HOLD, AU TORANGING, CLASSIFIER and

RELATIVE operation, auto ZEROing, GAUSS or TESLA readout, digital and

bargraph representation, diagnostics and remote operation with an IEEE-488

(GPIB) instrumentation bus and an RS-232 communications port. All

information is displayed on an illuminated graphics liquid crystal display (LCD).

The gaussmeter employs a menu-driven format to allow the user to program

all aspects of gaussmeter operation with ease and speed. Each gaussmeter

channel is completely and independently programmable.

I-B FUNCTIONAL DESCRIPTION

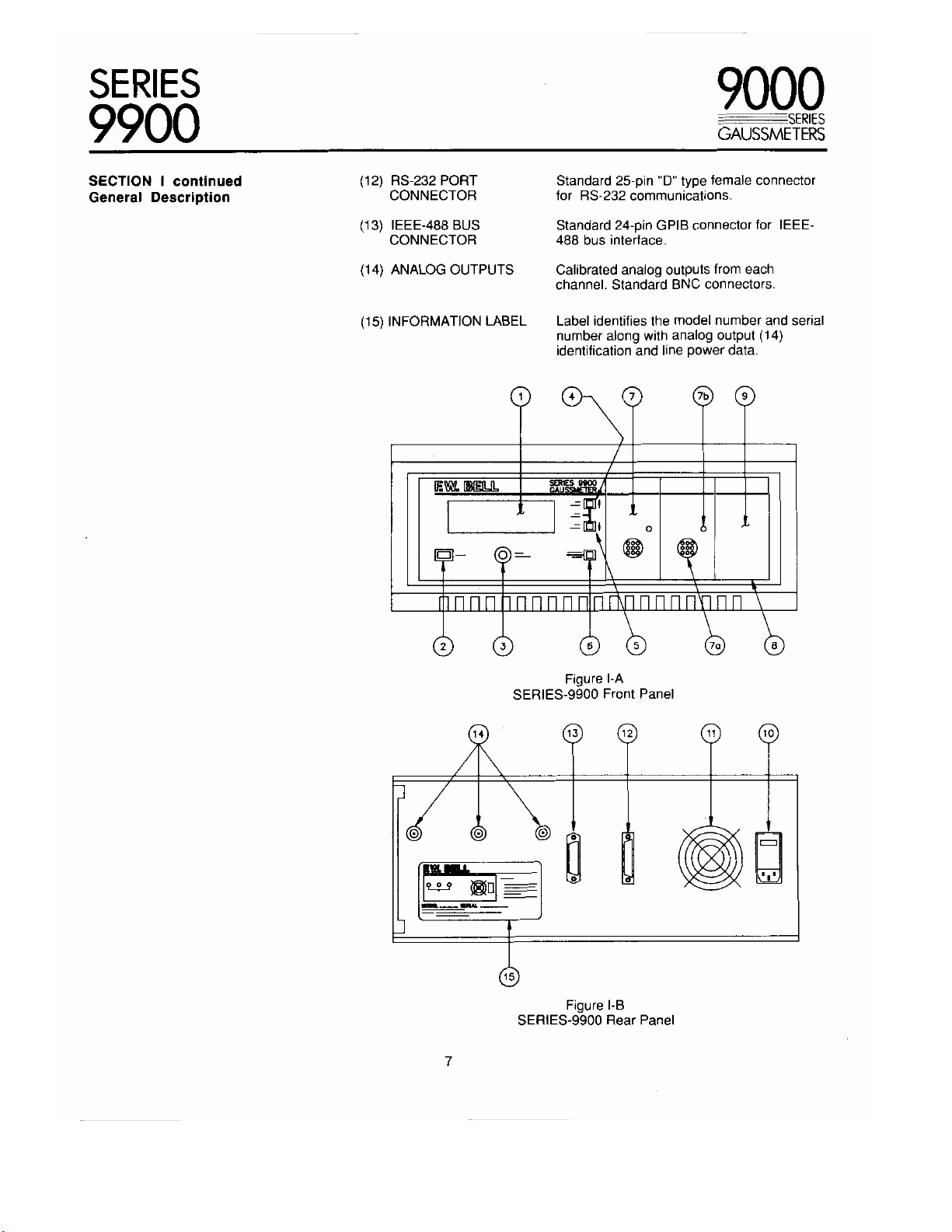

Figures I-A and I-B depict the SERIES-9900 front and rear panels,

respectively. The gaussmeter is housed in a standard 6.87" high x 17.67"

wide x 16.18" deep cabinet featuring pop-up feet for tabletop use and

(optional) brackets for rack mounting.

9000

SERIES

GAUSSMETERS

FRONT PANEL

(1) DISPLAY

(2) POWER SWITCH

(3) ZERO GAUSS CHAMBER

(4) "T" /CHANNEL 1 "RESET"

PUSHBUTTON

5

1920-pixel (240 x 64) dot matrix (graphics)

LCD with backlight. Contrast is preset at the

factory.

Rocker type power switch with international

legends ("0"=OFF, ''1"=ON).

Recessed double-wall Mu-metal chamber

used to shield the probe from stray magnetic

fields during the PROBE ZERO operation.

Attenuation is 80 dB in a 300 G field.

Dual-function momentary-contact

pushbutton switch used to reset PEAK

readings for CHANNEL 1 in the MEASURE

mode or advance the cursor up in the MENU

mode.

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION I continued

General Description

(5) "1" /CHANNEL 2 "RESET"

PUSHBUTTON

(6) "PROGRAM/ENTER"

PUSHBUTTON

(7) MODEL-99S PROBE

INTERFACE MODULE

(7-a) PROBE CONNECTOR

(7-b) ACTIV ITY INDICATOR

(8) INTERFACE MODULE

CAVITY

Dual-function momentary-contact

pushbutton switch used to reset PEAK

readings for CHANNEL 2 in the MEASURE

mode or advance the cursor down in the

MENU mode.

NOTE: Pressing both pushbuttons (4) and

(5) in the MEASURE mode will reset the

PEAK reading for CHANNEL 3.

Dual-function momentary-contact

pushbutton switch used to enter the MENU

mode and validate selections during MENU

operations.

Modular electronics package that accepts

fourth-generation Hall generator probe. Unit

interfaces to gaussmeter via a 64-pin dual-

row DIN connector.

9-pin twist-lock non-magnetic connector that

mates to F.W. Bell fourth-generation Hall

generator probes.

Red LED indicating module/probe activity.

Accepts MODEL-99S interface module (7)

or CAVITY blank panel (9). Cavity contains

an upper and lower card guide to ensure that

the interface module is properly aligned with

the rear mating connector.

WARNIN G! If a cavity is not used it must be

covered with a SERIES-9900 blank panel (9)

to ensure proper ventilation and protection

from contaminates. DO NOT USE

CAVITY AS A STORAGE AREA.

(9) CAVITY BLANK PANEL

REAR PANEL

(10) POWER RECEPTACLE/

FUSE HOLDER/

LINE VOLTAGE SWITCH

(11) VENTILATION FAN Regulates internal temperature of the

6

Used to cover an unused cavity (8). Order

F.W. Bell Item #338032.

This is a multi-purpose receptacle that

accepts an international instrumentation

power line cord. The middle (ground)

contact is connected to the chassis. This

receptacle also contains the line fuse,

storage space for a spare fuse and a line

voltage selector.

WARNIN G! See SECTION II before

applying power to the gaussmeter or

damage may result!▶

gaussmeter. DO NOT COVER !

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION I continued

General Description

(12) RS-232 PORT

CONNECTOR

(13) IEEE-488 BUS

CONNECTOR

(14) ANALOG OUTPUTS

(15) INFORMATION LABEL

Standard 25-pin "D" type female connector

for RS-232 communications.

Standard 24-pin GPIB connector for IEEE-

488 bus interface.

Calibrated analog outputs from each

channel. Standard BNC connectors.

Label identifies the model number and serial

number along with analog output (14)

identification and line power data.

0 0 0 0 0

E W. BELL

IM01111111111111111111111i11 I I I I I

SERIES Q900

= 1.1 1

= if

1

0 6 •-'

il! ,

0 0 0

Figure I-A

SERIES-9900 Front Panel

Figure I-B

SERIES-9900 Rear Panel

7

0 0

SERIES

9900

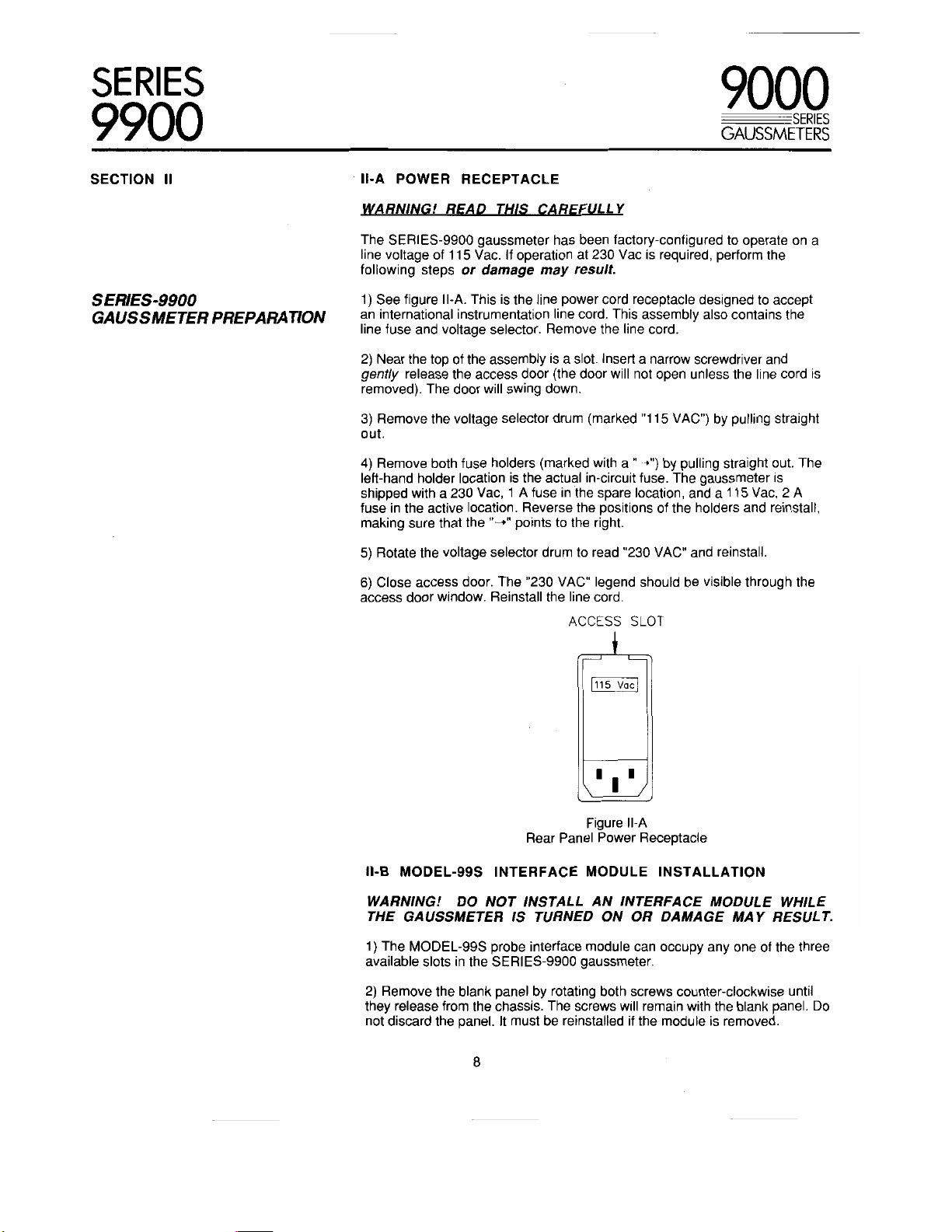

SECTION II II-A POWER RECEPTACLE

WARNING! READ THIS CAREFULLY

The SERIES-9900 gaussmeter has been factory-configured to operate on a

line voltage of 115 Vac. If operation at 230 Vac is required, perform the

following steps or damage may result.

9000

SERIES

GAUSSMETERS

SERIES-9900

GAUSSMETER PREPARATION

1) See figure II-A. This is the line power cord receptacle designed to accept

an international instrumentation line cord. This assembly also contains the

line fuse and voltage selector. Remove the line cord.

2) Near the top of the assembly is a slot. Insert a narrow screwdriver and

gently release the access door (the door will not open unless the line cord is

removed). The door will swing down.

3) Remove the voltage selector drum (marked "115 VAC") by pulling straight

out.

4) Remove both fuse holders (marked with a " 4") by pulling straight out. The

left-hand holder location is the actual in-circuit fuse. The gaussmeter is

shipped with a 230 Vac, 1 A fuse in the spare location, and a 115 Vac, 2 A

fuse in the active location. Reverse the positions of the holders and reinstall,

making sure that the "--," points to the right.

5) Rotate the voltage selector drum to read "230 VAC" and reinstall.

6) Close access door. The "230 VAC" legend should be visible through the

access door window. Reinstall the line cord.

ACCESS SLOT

115 Vac

Rear Panel Power Receptacle

II-B MODEL-99S INTERFACE MODULE INSTALLATION

WARNING! DO NOT INSTALL AN INTERFACE MODULE WHILE

THE GAUSSMETER IS TURNED ON OR DAMAGE MAY RESULT.

1) The MODEL-99S probe interface module can occupy any one of the three

available slots in the SERIES-9900 gaussmeter.

2) Remove the blank panel by rotating both screws counter-clockwise until

they release from the chassis. The screws will remain with the blank panel. Do

not discard the panel. It must be reinstalled if the module is removed.

8

Figure II-A

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION II continued

Gaussmeter Preparation

3) Locate the upper and lower card guides in the card rack. Install the module

so that the upper and lower card edges of the module mate with the card

guides. Slowly slide the module in until the rear connectors mate. Firmly push

the module into the chassis. Secure with the upper and lower screws.

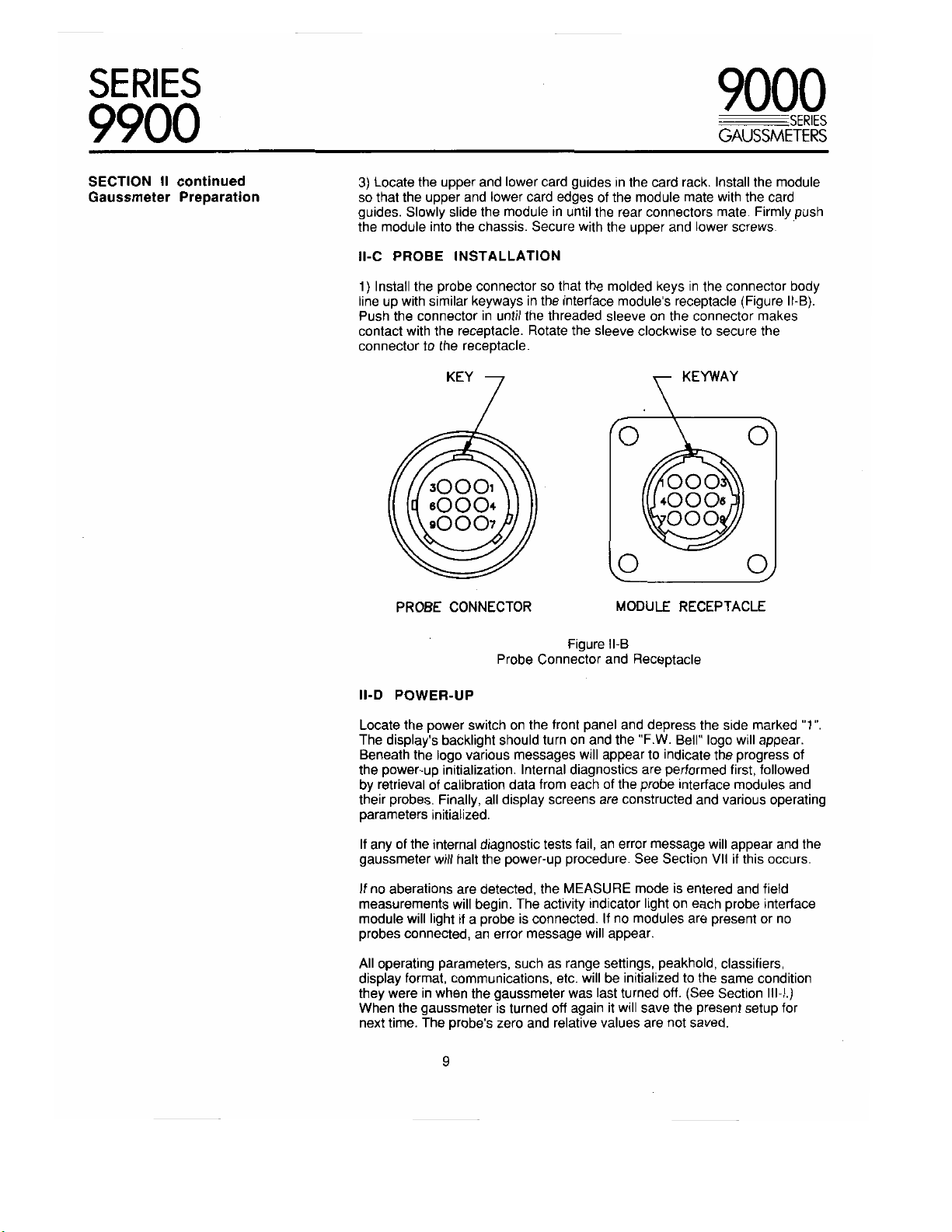

II-C PROBE INSTALLATION

1) Install the probe connector so that the molded keys in the connector body

line up with similar keyways in the interface module's receptacle (Figure II-B).

Push the connector in until the threaded sleeve on the connector makes

contact with the receptacle. Rotate the sleeve clockwise to secure the

connector to the receptacle.

0 0}

PROBE CONNECTOR

MODULE RECEPTACLE

Probe Connector and Receptacle

II-D POWER-UP

Locate the power switch on the front panel and depress the side marked "1".

The display's backlight should turn on and the "F.W. Bell" logo will appear.

Beneath the logo various messages will appear to indicate the progress of

the power-up initialization. Internal diagnostics are performed first, followed

by retrieval of calibration data from each of the probe interface modules and

their probes. Finally, all display screens are constructed and various operating

parameters initialized.

If any of the internal diagnostic tests fail, an error message will appear and the

gaussmeter will halt the power-up procedure. See Section VII if this occurs.

If no aberations are detected, the MEASURE mode is entered and field

measurements will begin. The activity indicator light on each probe interface

module will light if a probe is connected. If no modules are present or no

probes connected, an error message will appear.

All operating parameters, such as range settings, peakhold, classifiers,

display format, communications, etc. will be initialized to the same condition

they were in when the gaussmeter was last turned off. (See Section III-I.)

When the gaussmeter is turned off again it will save the present setup for

next time. The probe's zero and relative values are not saved.

9

Figure II-B

SERIES

9900

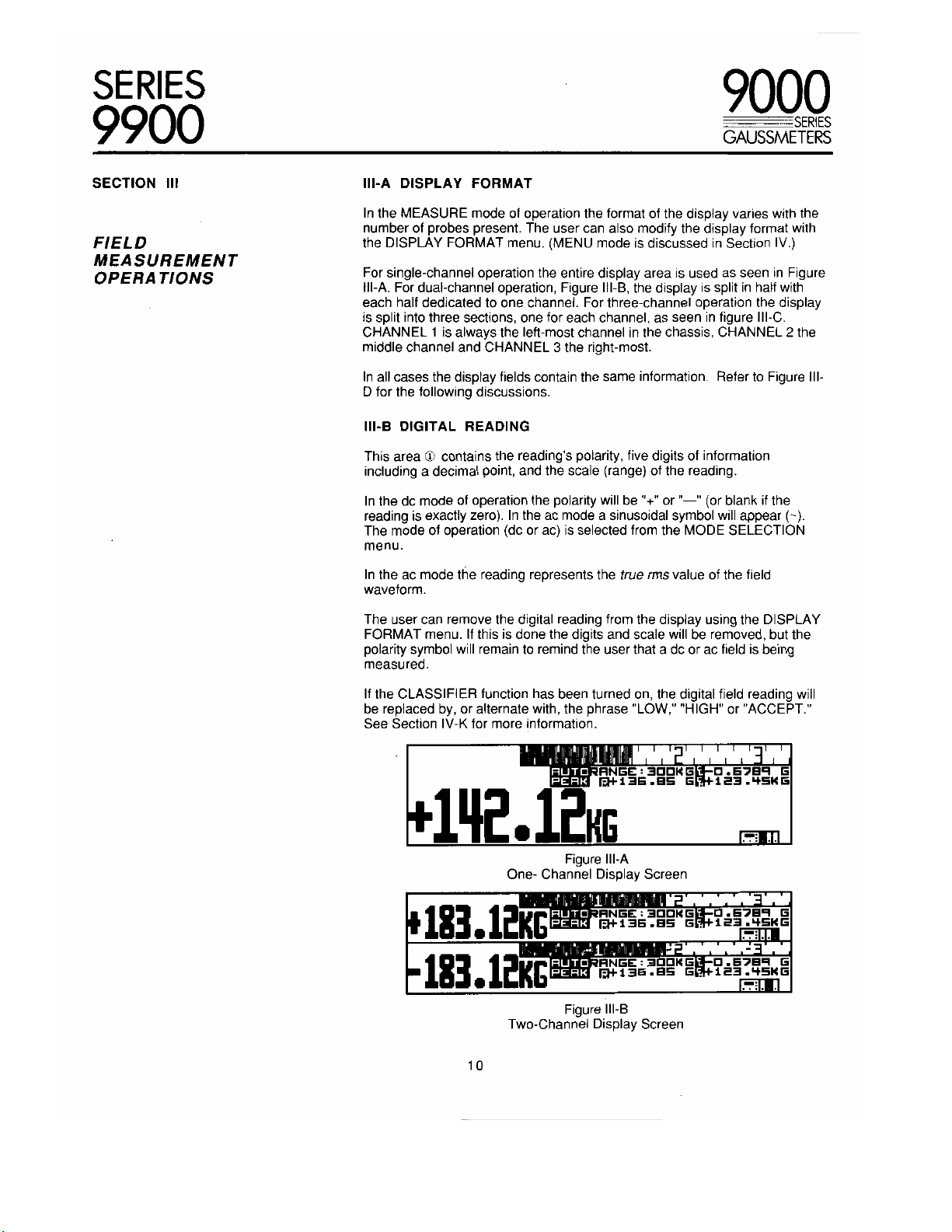

SECTION III III-A DISPLAY FORMAT

In the MEASURE mode of operation the format of the display varies with the

number of probes present. The user can also modify the display format with

FIELD

MEASUREMENT

OPERATIONS

the DISPLAY FORMAT menu. (MENU mode is discussed in Section IV.)

For single-channel operation the entire display area is used as seen in Figure

III-A. For dual-channel operation, Figure 111-B, the display is split in half with

each half dedicated to one channel. For three-channel operation the display

is split into three sections, one for each channel, as seen in figure III-C.

CHANNEL 1 is always the left-most channel in the chassis, CHANNEL 2 the

middle channel and CHANNEL 3 the right-most.

In all cases the display fields contain the same information. Refer to Figure III-

D for the following discussions.

III-B DIGITAL READING

This area 0 contains the reading's polarity, five digits of information

including a decimal point, and the scale (range) of the reading.

In the dc mode of operation the polarity will be "+" or "—" (or blank if the

reading is exactly zero). In the ac mode a sinusoidal symbol will appear (-).

The mode of operation (dc or ac) is selected from the MODE SELECTION

menu.

9000

SERIES

GAUSSMETERS

In the ac mode the reading represents the true rms value of the field

waveform.

The user can remove the digital reading from the display using the DISPLAY

FORMAT menu. If this is done the digits and scale will be removed, but the

polarity symbol will remain to remind the user that a dc or ac field is being

measured.

If the CLASSIFIER function has been turned on, the digital field reading will

be replaced by, or alternate with, the phrase "LOW," "HIGH" or "ACCEPT."

See Section IV-K for more information.

11111111 I in, I I F JnuTin-RNGE:EDDNG D.67B9 G

PERK iii3E.GE G. 123.4SWG

1.1.112 12H

One- Channel Display Screen

18361 G

11 3 . 12KG

Two -Channel Display Screen

Figure 111-A

AUTO

PERK

AUTO

PERK

Figure III-B

I I L

FAGE:3=4G 13.67139 c

M+136.85 G. 123.4514c

RNGE:31:1014G 0.67Eg G

M*136.8S G. 123.4514G

LIFZIMONIIIMMON

WIN

10

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION III continued

Field Measurement Operations

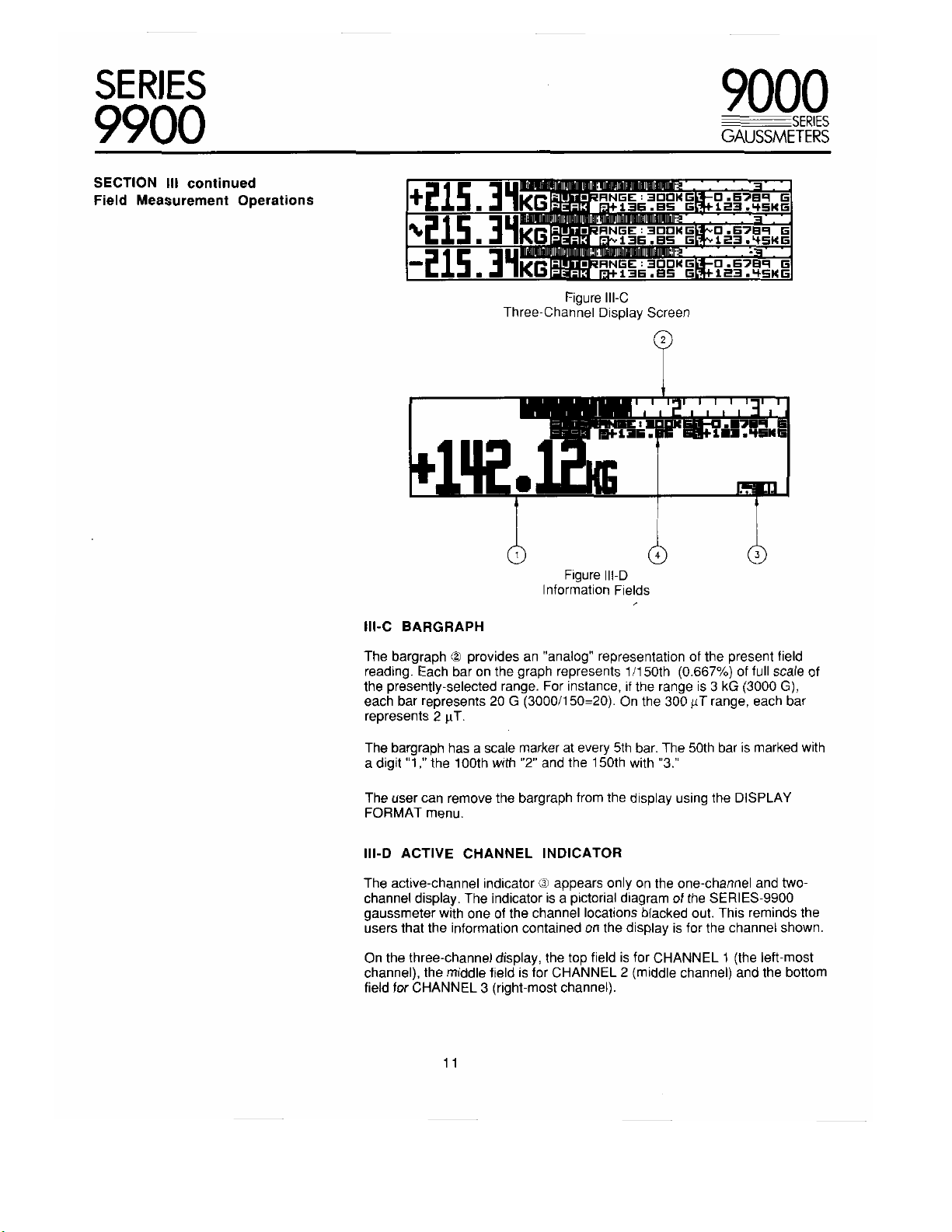

Ill-C BARGRAPH

1 1r %.11LJa11 L, a if W40'1U If! trilMOMMOMFMMIO

AUTO—I:INGE:30014Si 0.6789 G

PERK p 136.85 G. 123.45KG

IL now lui ffivalumt ul IN g meliffINMOREIIINJ

AUTO RNSE:300KG4_

PERK p 136.85 651

motimuktnuliffivuNISMINMERWMMO

AUTO I:INGE:3001MT. 0.6789 G

PERK p 136.85 Gia 123.46KG

Three-Channel Display Screen

S

Figure III-C

WIZEN LEE • IFEN

0.6789 G

123.45KG

..M71119

0 0

Figure III-D

Information Fields

The bargraph provides an "analog" representation of the present field

reading. Each bar on the graph represents 1/150th (0.667%) of full scale of

the presently-selected range. For instance, if the range is 3 kG (3000 G),

each bar represents 20 G (3000/150=20). On the 300 µ-1- range, each bar

represents 2 µT.

The bargraph has a scale marker at every 5th bar. The 50th bar is marked with

a digit "1," the 100th with "2" and the 150th with "3."

The user can remove the bargraph from the display using the DISPLAY

FORMAT menu.

III-D ACTIVE CHANNEL INDICATOR

The active-channel indicator ® appears only on the one-channel and two-

channel display. The indicator is a pictorial diagram of the SERIES-9900

gaussmeter with one of the channel locations blacked out. This reminds the

users that the information contained on the display is for the channel shown.

On the three-channel display, the top field is for CHANNEL 1 (the left-most

channel), the middle field is for CHANNEL 2 (middle channel) and the bottom

field for CHANNEL 3 (right-most channel).

11

SERIES

9900

SECTION III continued III-E INFORMATION BLOCK

Field Measurement Operations

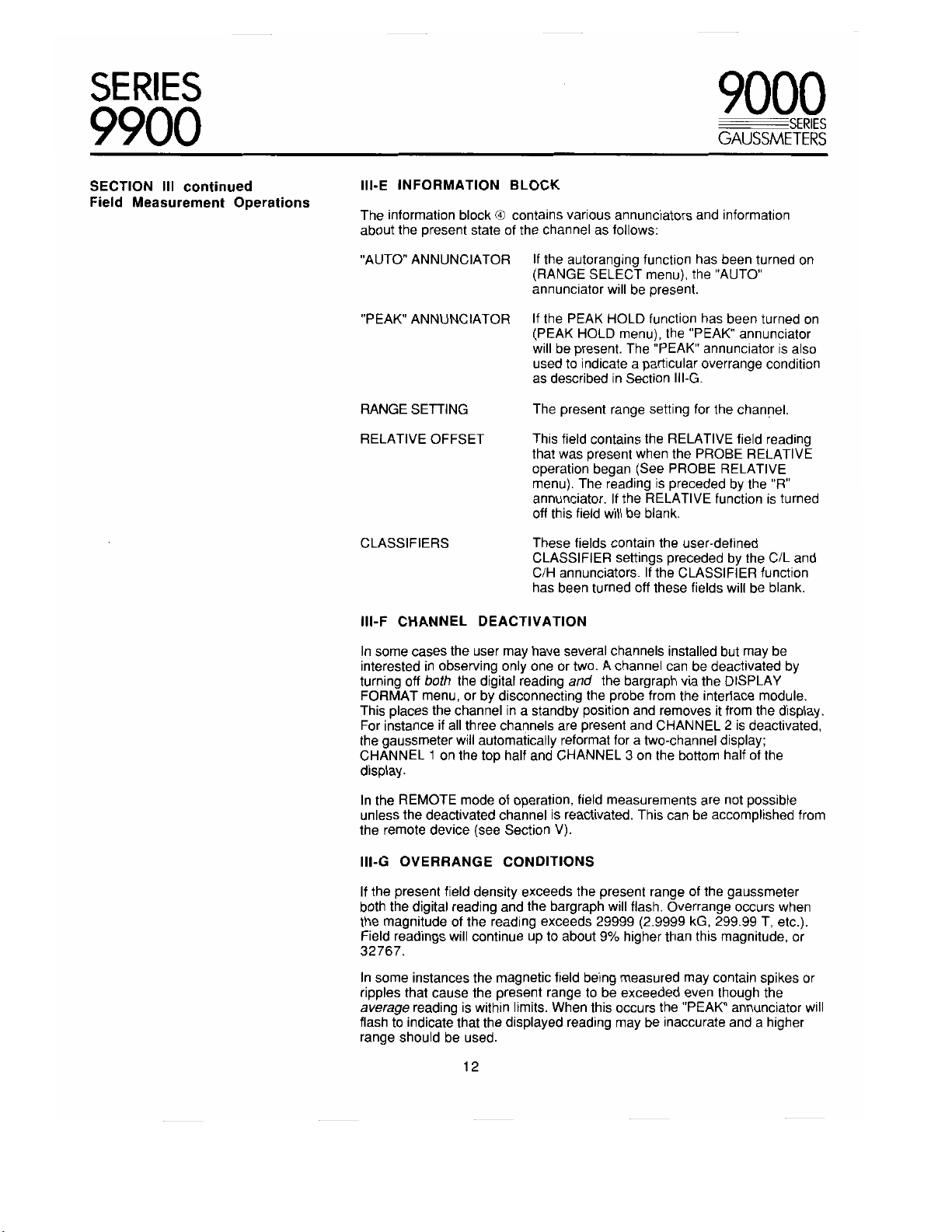

The information block ® contains various annunciators and information

about the present state of the channel as follows:

9000

SERIES

GAUSSMETERS

"AUTO" ANNUNCIATOR

"PEAK" ANNUNCIATOR

RANGE SETTING The present range setting for the channel.

RELATIVE OFFSET

CLASSIFIERS

III-F CHANNEL DEACTIVATION

In some cases the user may have several channels installed but may be

interested in observing only one or two. A channel can be deactivated by

turning off both the digital reading and the bargraph via the DISPLAY

FORMAT menu, or by disconnecting the probe from the interface module.

This places the channel in a standby position and removes it from the display.

For instance if all three channels are present and CHANNEL 2 is deactivated,

the gaussmeter will automatically reformat for a two-channel display;

CHANNEL 1 on the top half and CHANNEL 3 on the bottom half of the

display.

If the autoranging function has been turned on

(RANGE SELECT menu), the "AUTO"

annunciator will be present.

If the PEAK HOLD function has been turned on

(PEAK HOLD menu), the "PEAK" annunciator

will be present. The "PEAK" annunciator is also

used to indicate a particular overrange condition

as described in Section li I-G.

This field contains the RELATIVE field reading

that was present when the PROBE RELATIVE

operation began (See PROBE RELATIVE

menu). The reading is preceded by the "R"

annunciator. If the RELATIVE function is turned

off this field will be blank.

These fields contain the user-defined

CLASSIFIER settings preceded by the C/L and

C/H annunciators. If the CLASSIFIER function

has been turned off these fields will be blank.

In the REMOTE mode of operation, field measurements are not possible

unless the deactivated channel is reactivated. This can be accomplished from

the remote device (see Section V).

III-G OVERRANGE CONDITIONS

If the present field density exceeds the present range of the gaussmeter

both the digital reading and the bargraph will flash. Overrange occurs when

the magnitude of the reading exceeds 29999 (2.9999 kG, 299.99 T, etc.).

Field readings will continue up to about 9% higher than this magnitude, or

32767.

In some instances the magnetic field being measured may contain spikes or

ripples that cause the present range to be exceeded even though the

average reading is within limits. When this occurs the "PEAK" annunciator will

flash to indicate that the displayed reading may be inaccurate and a higher

range should be used.

12

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION III continued

Field Measurement Operations

III-H PEAK HOLD OPERATION

When the PEAK HOLD function is engaged (via the PEAK HOLD menu) the

largest absolute field reading will be held on the display. For instance a

+200.00 G reading will replace a +100.00 G reading and be held, and a

-250.00 G reading will replace the previously-held +200.00 G reading.

The user can reset a held reading at any time by pressing and releasing that

channel's RESET pushbutton on the front panel. As the pushbutton is

pressed the ''PEAK" annunciator will flash to indicate that the reset command

has been recognized but the actual reset operation will not occur until the

pushbutton is released.

One pushbutton is dedicated to resetting CHANNEL 1, another for

CHANNEL 2 and both for CHANNEL 3. In the case of a CHANNEL 3 reset,

the user might press one pushbutton before the other, say CHANNEL 1

before CHANNEL 2. In this case the CHANNEL 1 "PEAK" annunciator will

flash. As soon as the CHANNEL 2 pushbutton is pressed the CHANNEL 1

annunciator will return to normal and the CHANNEL 3 annunciator will flash.

This will not cause a problem since the actual resetting operation will not

occur until both pushbuttons are released, properly resetting CHANNEL 3's

peak reading only.

III-I POWER UP INITIALIZATION

The gaussmeter permanently stores each channel's MEASURE mode setup.

When the gaussmeter is powered off and on again, the previous settings are

restored and the gaussmeter is reinitialized to those settings. The following

information is saved:

• MODE (ac/dc A ND GAUSS/TESLA)

• RANGE SETTING (INCLUDING AUTORANGE)

• PEAK HOLD ON/OFF (LAST PEAK READING WILL NOT BE SAVED)

• CLASSIFIER SETTINGS

• CLASSIFIER ON/OFF STATUS

• DIGITS ON/OFF

• BARGRAPH ON/OFF

• BACKLIGHT ON/OFF

• IEEE-488 PRIMARY ADDRESS

• RS-232 PARITY, STOP BITS, CHARACTER LENGTH AND BAUD RATE

The RELATIVE mode will be turned off and the relative offset will be reset to

zero.

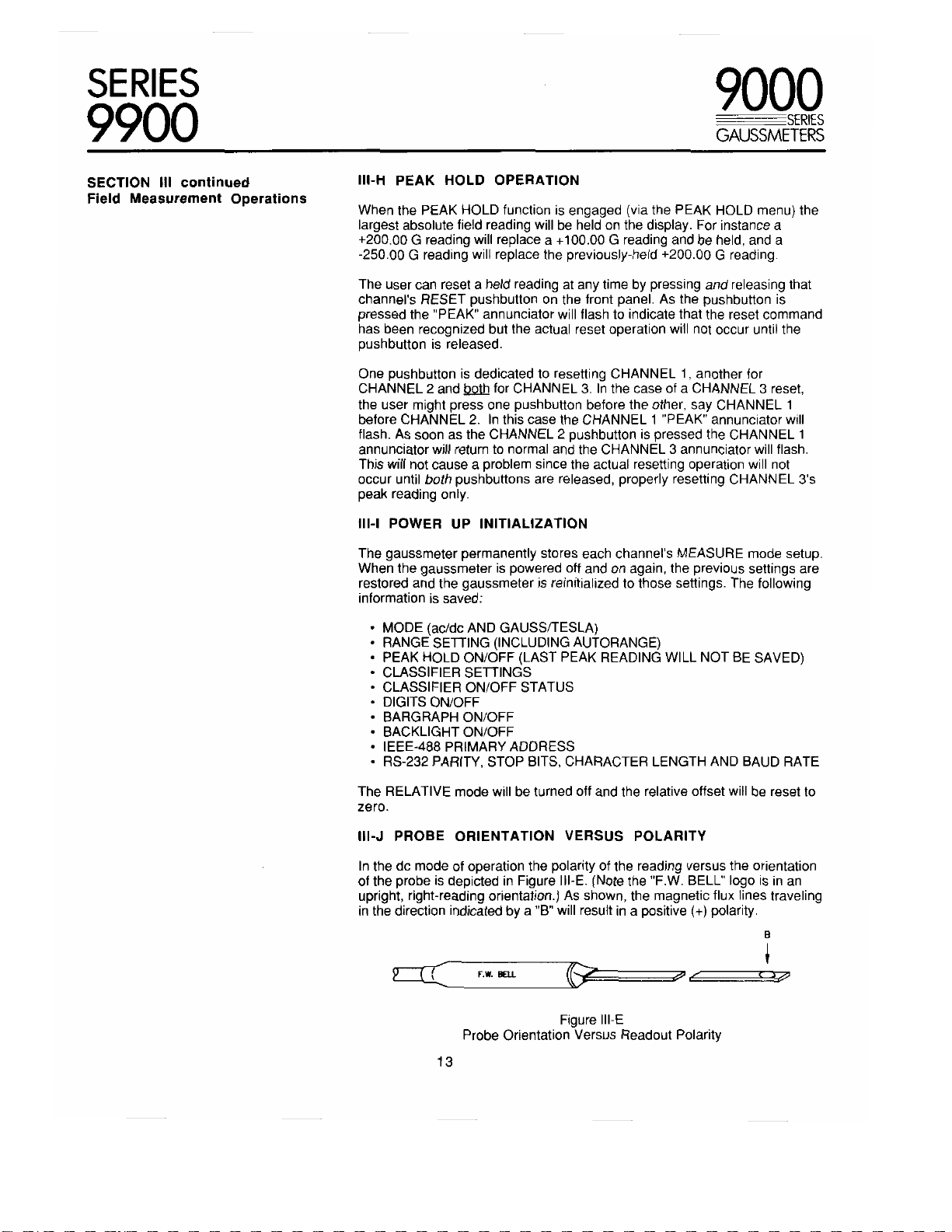

III-J PROBE ORIENTATION VERSUS POLARITY

In the dc mode of operation the polarity of the reading versus the orientation

of the probe is depicted in Figure III-E. (Note the "F.W. BELL" logo is in an

upright, right-reading orientation.) As shown, the magnetic flux lines traveling

in the direction indicated by a "B" will result in a positive (+) polarity.

B

=Cr BELL

Figure III-E

Probe Orientation Versus Readout Polarity

13

C

SERIES

9900

SECTION III continued III-K ANALOG OUTPUTS

Field Measurement Operations

On the rear panel of the gaussmeter are connections that, when connected

to an oscilloscope, allow the user to observe the actual magnetic field

waveforms.

In the ac mode, the waveform is the actual field waveform calibrated to 3 volts

rms full scale. For instance, with the gaussmeter programmed for a 3 kG range

setting (3000 G) a 2.0000 Vrms signal correlates to a 2.0000 kG field density.

In the dc mode, the output is instantaneously proprotional to the field in

magnitude and polarity from dc to 400 Hz.

NOTE: The gaussmeter digitally corrects the magnetic field density signals for

errors due to probe offset, amplifier offset, frequency-related attenuation,

temperature-related effects, etc. before the final reading is displayed. The

signals available at the ANALOG OUTPUT connectors ARE NOT

CORRECTED for these errors.

III-L REMOTE TERMINAL ("MASTER") OPERATION

There are two modes of remote operation available in the SERIES-9900

gaussmeter. In the "SLAVE" mode, available from either the RS-232 serial

port or the IEEE-488 bus, a remote device (typically a computer system or

industrial controller) controls all gaussmeter operations. This is discussed in

Section V.

9000

SERIES

GAUSSMETERS

In the "MASTER" mode, available only from the RS-232 serial port, the

gaussmeter controls a remote terminal or printer device. This is particularly

useful if the the user and gaussmeter must be separated by some distance,

or if the user wishes to have a hardcopy of all gaussmeter activity.

The terminal/printer may be connected directly to the gaussmeter, or

indirectly through a modem following the electrical connections shown in

Section VI. The RS-232 characteristics of both devices must match. The

gaussmeters' parameters can be modified via the COMMUNICATIONS

FORMAT menu. All MEASURE mode and MENU mode operations are

accessible from the terminal. See Section IV-M for further information.

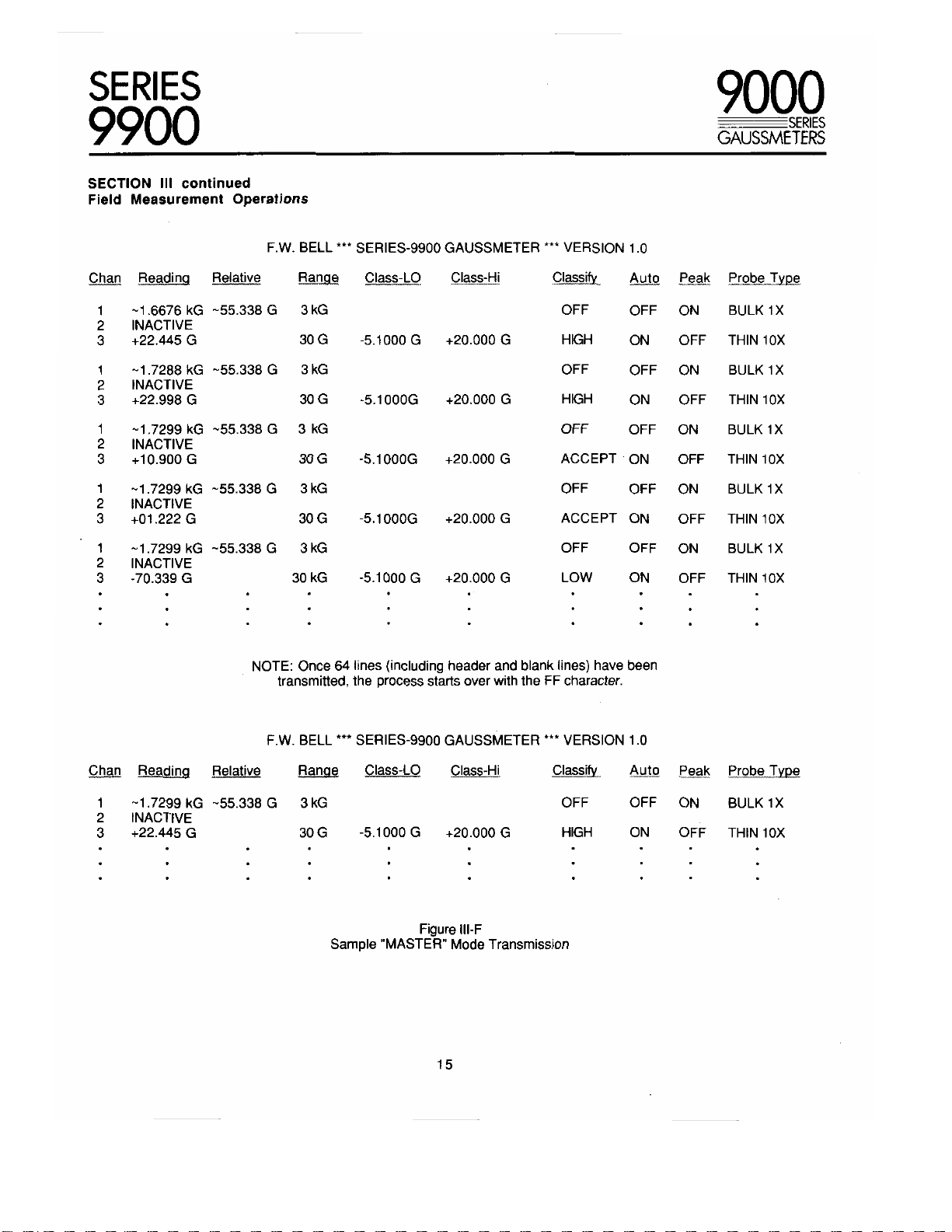

Whenever field measurements are taking place the gaussmeter will transmit a

continuous listing of field measurements and channel status in a formatted

ASCII character stream as shown in Figure Ill-F. Note that CHANNEL 1 is

programmed for the RELATIVE mode, CHANNEL 2 has been deactivated

and CHANNEL 3 has been programmed for CLASSIFIER operation.

CHANNEL 1 has a 1X bulk Hall generator probe attached, CHANNEL 3 a 10X

thin film device.

Initially, a FORMFEED (FF) control character is transmitted. If a printer is

connected this should cause the paper feeder to advance to the top of the

next sheet of paper. If a terminal is connected this usually clears the screen.

The FF is followed by CARRIAGE RETURN (CR) and LINEFEED (LF) control

character and then a three-line header containing 79 printable characters per

line. Each line is followed by a CR and LF.

Each line of measurement data contains 79 printable AS CII characters

followed by a CR and LF. The third (CHANNEL 3) information line is followed

by one more LF to create a blank line between each group of readings.

14

SERIES

9900

SECTION III continued

Field Measurement Operations

F. W. BELL *** SERIES-9900 GAUSSMETER *** VERSION 1.0

9000

SERIES

GAUSSMETERS

Chan

Reading Relative Range Class-LO Class-Hi Classify Auto

1 -1.6676 kG -55.338 G 3 kG OFF

INACTIVE

2

3 +22.445 G 30 G -5.1000 G +20.000 G

1 -1.7288 kG -55.338 G 3 kG

2 INACTIVE

3

+22.998 G 30 G -5.1000G

1 -1.7299 kG -55.338 G 3 kG

2 INACTIVE

+10.900 G

3

1

-1.7299 kG -55.338 G

INACTIVE

2

+01.222 G

3

1 -1.7299 kG -55.338 G 3 kG

2 INACTIVE

3

-70.339 G

• • •

30 G -5.1000G

3 kG OFF OFF

30 G

30 kG -5.1000 G +20.000 G LOW ON OFF THIN 10X

NOTE: Once 64 lines (including header and blank lines) have been

transmitted, the process starts over with the FF character.

-5.1000G

+20.000 G HIGH

+20.000 G ACCEPT ON OFF

+20.000 G ACCEPT

OFF

HIGH ON

OFF

OFF OFF

OFF OFF

OFF ON BULK 1X

ON OFF THIN 10X

ON OFF THIN 10X

Peak Probe Type

ON BULK 1X

OFF THIN 10X

ON BULK 1X

THIN 10X

ON BULK 1X

ON BULK 1X

F. W. BELL *** SERIES-9900 GAUSSMETER *** VERSION 1.0

Chan Reading Relative Range Class-LO Class-Hi Classify Au to Peak Probe Type

1 -1.7299 kG -55.338 G 3 kG OFF OFF ON BULK 1X

2 INACTIVE

3 +22.445 G 30 G -5.1000 G +20.000 G HIGH ON OFF THIN 10X

• •

•

Figure III-F

Sample "MASTER" Mode Transmission

15

•

SERIES

9900

9000

SERIES

GAUSSMETERS

SECTION III continued

Field Measurement Operations

DISPLAY UPDATE

(CHANNEL1)

+23.998 kG

+24.220 kG

+25.770 kG

+24.556 kG

+24.234 kG

+21.002 kG

NOTE: The user should be aware that the serial transmission rate is much

slower than the rate at which the display is updated with new readings. In

other words the gaussmeter does not wait for a transmission to complete

before taking another reading. Readings taken during transmissions will

never appear in a transmission, as the following scenario illustrates:

TRANSMISSION HISTORY

Transmission starts (CHANNEL 1 = +23.998 kG)

Transmission continues

Transmission continues

Transmission continues

Transmission ends

New Transmission starts (CHANNEL1 = +21.002 kG)

III-M INTERNAL RECALIBRATION

Occasionally, the gaussmeter will inititate an internal calibration cycle in order

to maintain optimum performance. During this time, the phrase

"GAUSSMETER BEING RECALIBRATED" will appear on the display and field

measurement activity will be suspended. A recalibration will occur:

a) Immediately after the power-up initialization sequence.

b) Any time a new probe is connected.

c) Whenever the internal temperature has changed more than ±5° C since

the last recalibration cycle.

16

Loading...

Loading...