F.W. Bell 7030 Instruction Manual

7030 GAUSS/TESLA METER

Instruction

Manual

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

THIS SIDE BLANK !

(Inside of Front Cover)

Instruction Manual

Manual UN-01-251

Item 359936

Rev. E, ECO 14211

All Rights Reserved.

MODEL 7030

GAUSS / TESLA METER

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

This symbol appears on the instrument and probe. It refers the operator

to additional information contained in this instruction manual, also

identified by the same symbol.

NOTICE:

See Pages 4-1, 4-2, and 4-3

for SAFETY

instructions prior to first use !

See Page 2-4

for EMC Notes concerning I/O Cables and I/O

Filter Adapters

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Table of Contents

Section – 1 Introduction

Overview…………………………………………………………………………………….………..

General Description………………………………………………………………………………….

Applications…………………………………………………………………………………..…….…

Section – 2 Specifications

Instrument……………………………………………………………………………………………..

Calibration Service……………………………………………………………………………………

Zero Flux Chamber…………………………………………………………………………………..

Section – 3 Probes

Overview………………………………………………………………………………………...…….

Probe Variations………………………………………………………………………………….….

Probe Memory……………………………………………………………………………………...…

Probe Stem…………………………………………………………………………………..………..

Temperature Effects…………………………………………………………………………..……..

Fixturing……………………………………………………………………………………………….

1-1

1-3

1-8

2-1

2-6

2-7

3-1

3-2

3-3

3-3

3-3

3-3

Section – 4 Setup

Safety…………………………………………………………………………………………………

Line Voltage Settings / Fuse Panel…………………………………………………………………

Adjusting the Handle…………………………………………………………………………………

Probe Installation……………………………………………………………………………………..

Power Up………………………………………………………………………………………………

Section – 5 User Interface

Overview………………………………………………………………………………………………

Front Panel Key Pad…………………………………………………………………………………

Menu System………………………………………………………………………………………….

Using the Mouse……………………………………………………………………………………..

Help System…………………………………………………………………………………………..

System Menu………………………………………………………………… ………… … ………..

Setup Save-Load……………………………………………………………………………………..

Display Format………………………………………………………………………………………..

Setting the Date and Time………………………………………………………………….

4-1

4-3

4-4

4-5

4-6

5-1

5-2

5-3

5-5

5-6

5-6

5-7

5-9

5-11

i

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Section – 6 Flux Density Measurement

Overview……………………………………………………………………………………………

Measurement Units and Selection………………………………………………………………

Present Flux Density Reading……………………………………………………..…….………

Measurement Mode Indicator……………………………………………………………………

Range Selection………………………………….………………………………………………

ac or dc Measurement Selection……………………………………………………………….

ac Mode Operation………………………………………………………………………………

ac Mode Analog Filtering…………………………………………………………………………

dc Mode Operation………………………………………………………………………………

Zeroing………..……………………………………………………………………………………..

Update Interval……………………………………………………………………………………

Hold Function……………………………………………………………………………………….

Relative Mode…………………………………………………………………………………..…

Vector Summation…………………………………………………………………………………

Analog Outputs…………………………………………………………………………………….

Classifiers………………………………………………………………………………………..

Sources of Measurement Errors…………………………………………………………………

Section – 7 Remote Operation

Introduction……………………………………………………………………………………………

IEEE 488 Functional Description……………………………………………………………………

RS-232 Functional Description……………………………………………………………………...

Communications Setup…………………………………………………………………………….

IEEE 488 General Bus Commands………………………………………………………………...

Error Queue and Output Queue…………………………………………………………………….

Status…………..………………………………………………………………………………………

Status Byte and Service Request…………………………………………………………………..

Standard Event Register…………………………………………………………………………….

Measurement Event Register………………………………………………………………….….

Operation Event Register…………………………………………………………………….……

Questionable Event Register……………..…………………………………………………….…

IEEE 488.2 “Common” Command Syntax……………………………………………….………

IEEE 488.2 “Common” Commands………………………………………………………………

SCPI Command Syntax……………………………………………………………………………

SCPI Commands – General………………………………………………………………………

SCPI Commands – Error Queue Messages and Commands…………………………………

SCPI Commands – System Information and Configuration Commands……………………

SCPI Commands – Status Commands…………………………………………………………

6-1

6-2

6-3

6-3

6-4

6-5

6-5

6-7

6-7

6-8

6-10

6-11

6-13

6-16

6-19

6-21

6-23

7-1

7-2

7-3

7-5

7-6

7-7

7-7

7-9

7-11

7-12

7-13

7-13

7-14

7-15

7-18

7-19

7-23

7-23

7-26

ii

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

SCPI Commands – Unit Commands…………………………………………………………

SCPI Commands – Range Commands…………………………………………………….……

SCPI Commands – Filter Commands……………………………………………………………

SCPI Commands – Averaging Commands……………………………………………………

SCPI Commands – Classifier (Limit) Commands………………………………………………

SCPI Commands – Zeroing Commands………………………………………………………

SCPI Commands – Relative Offset Commands………………………………………………

SCPI Commands – Analog Output Commands……………………………………………….

SCPI Commands – Vector Summation Commands……………………………………………

SCPI Commands – Hold Commands…………….………………………………………………

SCPI Commands – Measurement Commands……………………………………………….

Intermixing “Common” and SCPI Commands………………………………………………

Message Terminators……………………………………………………………………………

Example Using the Event, Enable, and Condition Registers…………………………………

Appendix A

Appendix B

Warranty

Understanding Flux Density…………………………………………………

Vector Summation Tutorial………………………………………………….

7-27

7-28

7-29

7-30

7-30

7-32

7-32

7-34

7-37

7-37

7-39

7-41

7-41

7-42

A-1

B-1

List of Tables

Table 1-1 Model 7030 gauss/tesla meter List of Features……………………….…….. 1-2

Table 1-2 Front Panel Description…………………………………………………..…….. 1-6

Table 1-3 Rear Panel Description…………………………………………………..……... 1-7

Table 2-1 Probe Ranges…………………………………………………………….…..….. 2-1

Table 2-2 Accuracies (Instrument Only)……………………………………………..……. 2-2

Table 3-1 Probe Maximum Field Levels and Resolutions…………………………..…... 3-2

Table 5-1 Default Configuration Settings…………………………………….…….……... 5-8

Table 5-2 Display Options…………………………………………………………..…….… 5-9

Table 6-1 Available Units………………………………………………….……………..…. 6-2

Table 6-2 Minimum Magnitudes for Rated ac Accuracy……………………..…….…… 6-6

Table 6-3 Autofilter Switch Points………………………………………………..…...……. 6-7

Table 6-4 Number of Samples for Update Interval Settings…………………………….. 6-10

Table 7-1 RS-232 Available Settings………………………………………………………. 7-5

Table 7-2 General Command Summary for IEEE 488…………………………………… 7-6

Table 7-3 Common Command Summary……………………………………………...….. 7-15

Table 7-4 SCPI Commands……………………………………………………...…………. 7-19

Table 7-5 12 Hour to 24 Hour Conversion Table…………………………………………. 7-24

Table 7-6 Operating Ranges with Various Probes…………………………………...…... 7-28

iii

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

List of Illustrations

Figure 1-1

Figure 1-2

Figure 1-3

Figure 2-1

Figure 2-2

Figure 2-3

Figure 3-1

Figure 3-2

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 4-6

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 6-5

Figure 6-6

Figure 6-7

Figure 6-8

Figure 6-9

Figure 6-10

Figure 7-1

Figure 7-2

Figure 7-3

Figure 7-4

Figure 7-5

Figure 7-6

Figure 7-7

Figure 7-8

Figure A-1

Figure A-2

Figure B-1

Figure B-2

Figure B-3

Figure B-4

Front Panel………………………………………………………………………..

Rear Panel…………………………………………………………………….…..

Various Positions of Instrument…………………………………………………

Frequency Response of Uncorrected Analog Outputs (%Deviation)……….

Digital I/O Connector……….…………………………………………………….

Zero Flux Chamber……………………………………………………………….

7000 Series Probe Ordering Guide……………………………………………..

Hall Probe Configurations………………………………………………….…….

Probe Electrical Warning………………………………………………….……..

Fuse Panel……………………………………………………………………..….

Adjusting the Handle………………………………………………………….….

Installing and Removing Probes…………………………………………….…..

Power Switch Positions…………………………………………………………..

Boot Up Screen…………………………………………………………………...

Front Panel Keys………………………………………………………………….

Menu Items………………………………………………………………………..

Using Selections………………………………………………………………….

Main Menu………………………………………………………………………..

Present Flux Density Reading…………………………………………………..

Measurement Mode Indicator…………………………………………………...

Frequency / Filter Indicator………………………………………………………

Indeterminate Frequency Indicator…………………………………………….

Relative Value Indicator…………………………………………………………

7000 Series 3-Axis Probe Orientation…………………………………………

Example Circuit for Classifier Outputs…………………………………………

Probe Output Versus Flux Angle……………………………………………….

Probe Output Versus Distance………………………………………………….

Flux Density Variations in a Magnet……………………………………………

IEEE-488 Connector…………………………………………………………….

RS-232 Connector……………………………………………………………….

Condition, Event, and Enable Registers……………………………………….

Status Byte and SRQ Enable Registers………………………………………

Standard Event Register………………………………………………………..

Measurement Event Register…………………………………………………..

Operation Event Register………………………………………………………..

Questionable Event Register……………………………………………………

Flux Lines of a Permanent Magnet……………………………………………..

Hall Effect Sensor……………………………………………………………...…

Two Dimensional Co-ordinate System…………………………………………

Vector Angle in a Two Dimensional System…………………………………..

Three-dimensional Co-ordinate System………………………………………..

Vector Angles in a Three-dimensional System………………………………..

1-6

1-7

1-8

2-3

2-4

2-6

3-2

3-4

4-2

4-3

4-4

4-5

4-6

4-7

5-2

5-3

5-4

5-4

6-3

6-3

6-5

6-6

6-14

6-16

6-22

6-23

6-24

6-24

7-2

7-4

7-8

7-9

7-11

7-12

7-13

7-13

A-1

A-2

B-1

B-2

B-3

B-3

iv

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

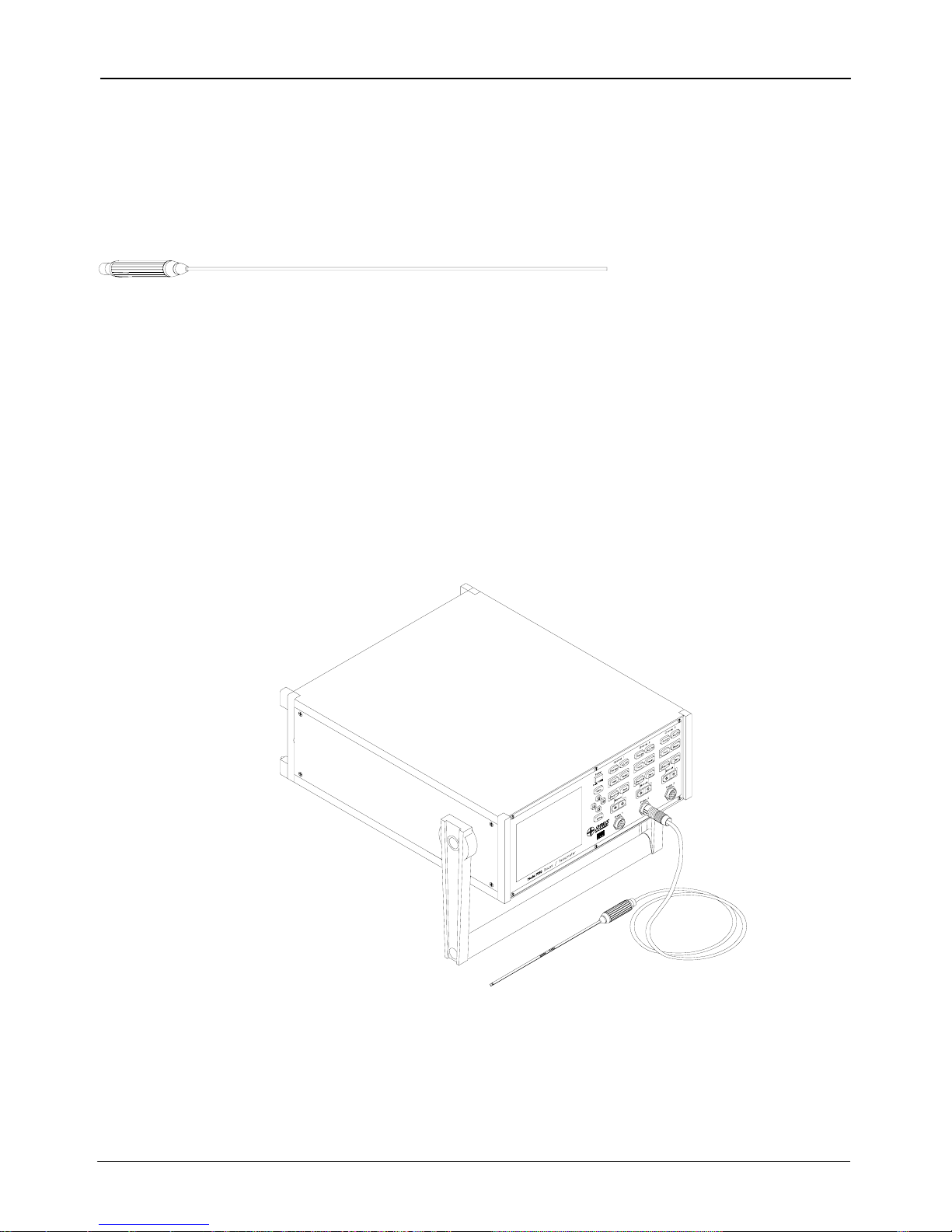

Section 1 Introduction

OVERVIEW

The F.W. BELL model 7030 gauss/tesla meter incorporates the latest

developments in magnetic flux density measurement technology with a

modern user interface. It features a large display for easy viewing, a

comprehensive keypad for control of common functions, and an easy-to-use

menu system. The model 7030 features three independent channels, with

high accuracy suitable for use in the laboratory, and enough features to be

versatile in a manufacturing environment. Table 1-1 on the following page

provides a list of features.

A detailed description of the 7030’s functions and features is provided in the

remaining sections.

F.W. BELL 7030 GAUSS/TESLA METER

Section 1 - Introduction 1-1

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Table 1-1 Model 7030 gauss/tesla meter List of Features

Flux Density

Measurement

User Interface

Support

Functions

Auto Range and Zeroing Capability

dc and ac Field Measurement up to 50 kHz

Automatic Calibration

Units in gauss (G), tesla (T), amp/meter (A/m), or oersted (Oe)

Temperature Compensated Hall Probes Available

Large ¼ VGA Multi-shade Amber Display

Display Arrangement is Configurable by the User

Each Channel’s Common Functions are Activated Quickly Through the Front Panel

Keypad

Other Functions are Accessible Through Graphical Menu System

Comprehensive Help System

Up to Four Configuration Setups May be Stored

Mouse Supported ( Optional )

Analog and Digital Filtering

Relative Feature Allows Small Fluctuations to be Observed Within a Larger Field

Hold Feature Includes Arithmetic Min/Max Readings Calculated by the Instrument and

Signal Peaks/Valleys of Rapid Changing Pulses

Remote Operation

Signal Outputs

Probe Styles

Software

Field Classifiers With Pass/Fail Outputs

IEEE 488.2 (GPIB) Interface

RS-232C Serial Port Interface

Each Channel Has a Corrected and Uncorrected Analog Output

Corrected Outputs Provide up to 50k samples/sec

3V, 10V, and 0-10V Adjustable Full Scale Range Settings

Either Raw or RMS Signals

Vector Summation Output

Transverse, Axial, and 3-Axis

Temperature Compensated

Low, Medium, and High Field

Standard and Heavy Duty

LabView Drivers Available

On-Site Firmware Updates

1-2 Section 1 - Introduction

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

The Model 7030 gauss/tesla meter is a three channel bench-top

instrument that utilizes Hall effect probes to measure magnetic flux

density in units of gauss (G), tesla (T), amp/meter (A/m), or oersted

(Oe). Either steady-state (dc) or alternating (ac) fields may be

measured. Fields as low as 10 µGauss (0.001 µT) or as high as 300k

gauss (30 tesla), at frequencies up to 50 kHz, can be measured with

extreme accuracy and 5-3/4 digit resolution. Each channel is

calibrated and linearized independently from data stored within its

probe. With a temperature compensated Hall probe, the instrument

can compensate for errors due to temperature variations.

User Interface

The instrument features a ¼ VGA multi-shade amber graphics

display. The display format and orientation may be customized by the

operator. The instrument automatically adjusts text sizes for the most

convenient view for a given amount of information being displayed.

Common functions are activated quickly through the front panel

keypad, with each channel having its own identical set of keys. Each

key has a back-light that is illuminated to indicate that it is active.

Less commonly used functions are easily accessible through the

menu system. The instrument also features a comprehensive help

system. As an option, the 7000 series supports the use of a standard

Microsoft® compatible serial mouse.

Up to four configuration setups may be saved and recalled.

Note: Each channel operates independently and each has the

following features.

Auto Range

Four measurement ranges may be selected manually or the

instrument can automatically select the best range based on the

present flux density level being measured.

Section 1 - Introduction 1-3

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

(Continued)

Zero

The “zero” function allows the user to remove undesirable readings

from nearby magnetic fields (including earth’s) as well as to remove

initial electrical offsets in the probe and instrument. A “zero flux

chamber” is included as an accessory which shields the probe from

external magnetic fields during this operation. Channels may be

zeroed independently or all at once.

Hold

When the hold function is enabled the instrument will “hold” and

display the highest and/or lowest flux density readings that have been

measured. Hold features include capturing peaks and valleys of rapid

changing pulses as well as arithmetically calculated max and min of

slow changing signals.

Relative

Another feature, called “relative mode”, allows large flux readings to be

suppressed so that small variations within the larger field can be

observed directly.

Update Interval

The update interval of the reading may be adjusted. Shorter update

intervals allow rapid fluctuations in flux density levels to be observed.

Longer update intervals provide higher resolution and stability in the

flux density reading.

Analog Output

Each channel provides a corrected and uncorrected analog output

voltage signal available from standard BNC connectors. The

uncorrected output signal is representative of the magnetic flux density

measured by the Hall probe. The corrected output signal is

compensated for influences of temperature and frequency variations,

as well as non-linearities inherent in the Hall probes and instrument.

The corrected output is specified with a higher accuracy than the

uncorrected output, with a bandwidth up to 200 Hz. The uncorrected

output is less accurate, but has a bandwidth up to 50kHz.

1-4 Section 1 - Introduction

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

(Continued)

A separate BNC connector, labeled “Vector Summation”, provides a

corrected output signal that is proportional to the resultant magnitude

of the three channels vector sum.

Standard full scale output ranges are 3V, 10V, 3V

adjustable full scale up to 9.9V or 9.9V

in increments of 0.1V, is

RMS,

, and 10V

RMS

RMS.

An

also available. These outputs may be connected to a voltmeter,

oscilloscope, recorder, or external analog-to-digital converter.

Analog Filters

A low pass filter is available for each channel that may be set to pass

frequencies only below 50kHz, 5kHz, or 500Hz. The instrument can

automatically select the best filter setting based on the present flux

density being measured. The filters affect both the displayed reading

and the analog outputs.

Field Classifiers

The “Classifier” function allows the user to define a lower and upper

limit of flux density that can be used to quickly determine the status of

a magnetic field. The instrument will indicate visually whether the

field is below, within, or above the pre-defined limits. The same

information is provided in the form of general purpose switch closures

available at a standard 15 pin “D” type female connector.

Remote Operation

Remote operation is supported through a standard 9-pin “D” RS232

serial port connector or through an IEEE-488.2 (GPIB)

instrumentation bus. The 7030 can be fully configured and flux

density readings and other information can be acquired by a remote

computer or PLC. The commands follow widely accepted protocols

established by the IEEE-488.2 and SCPI-1999 standards.

Accessories

The instrument is shipped with a “zero flux chamber” used for

shielding the probes from unwanted fields during zeroing. A sturdy

carrying case is provided for the zero flux chamber, probes, and this

manual.

Section 1 - Introduction 1-5

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

(Continued)

Front Panel

The front panel consists of the ¼ VGA display, keypad, probe

connectors, and power switch.

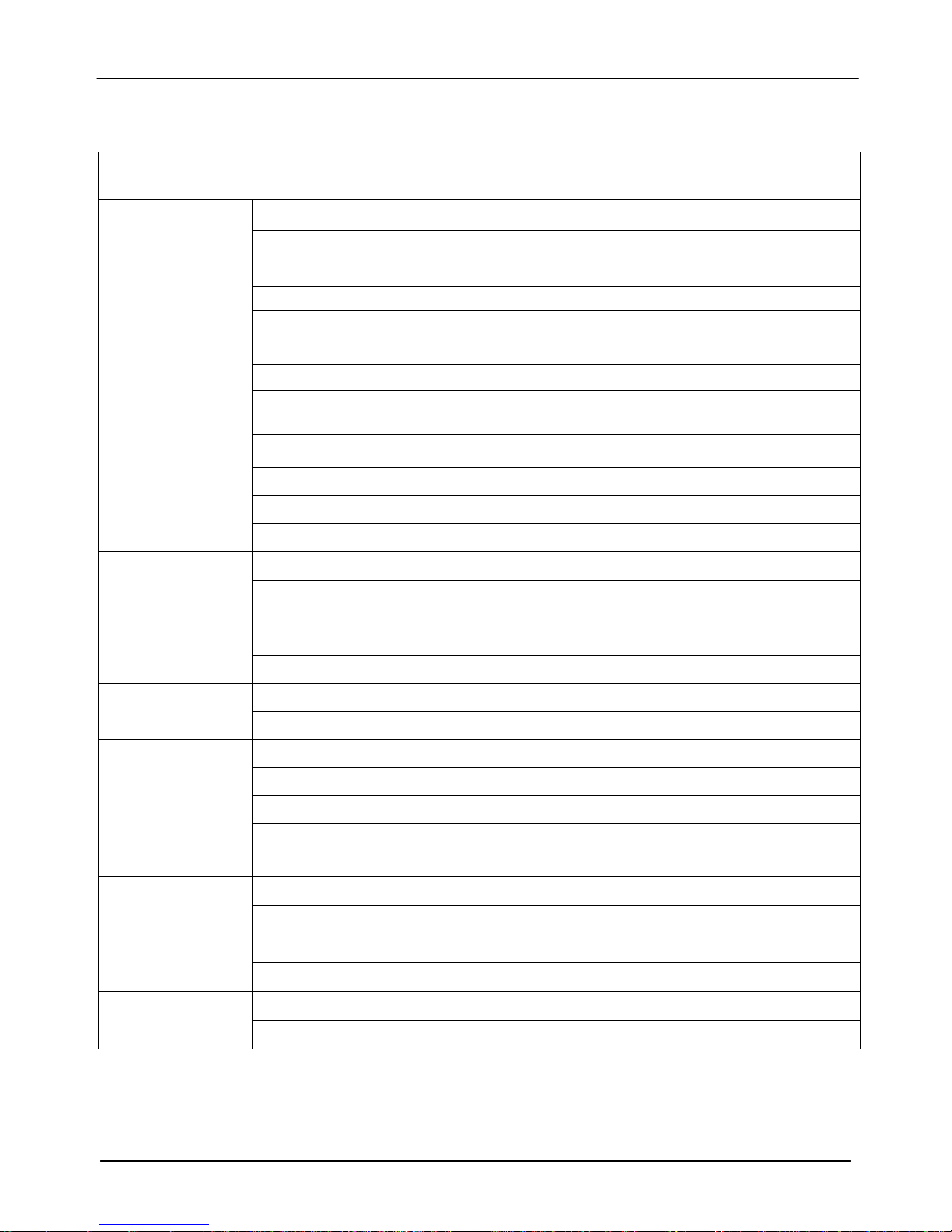

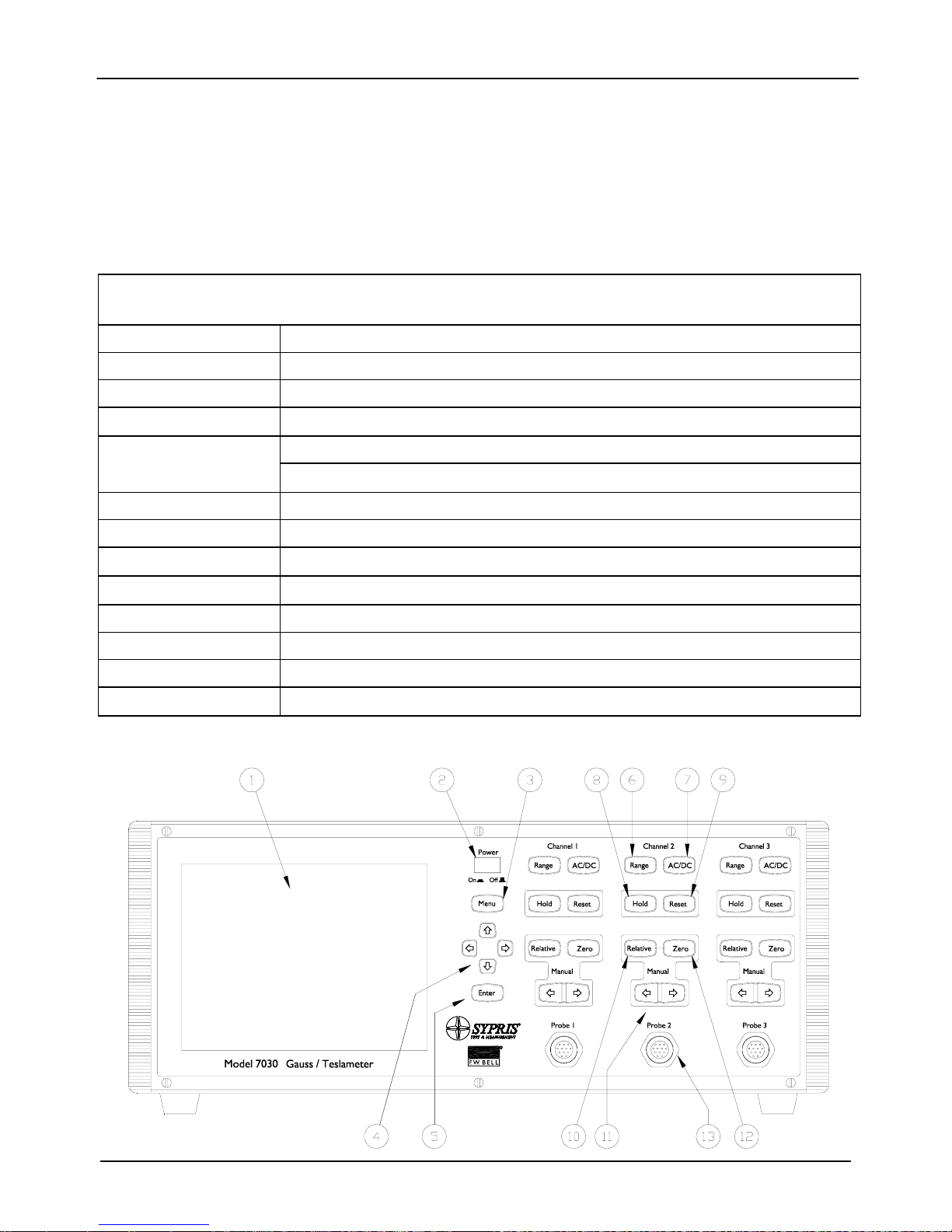

TABLE 1-2 FRONT PANEL DESCRIPTION

(1) Display

(2) Power Switch

(3) Menu Key

(4) Direction Keys

(5) Enter Key

(6) Range Key

(7) AC/DC Key

(8) Hold Key

(9) Reset Key

(10) Relative Key

(11) Manual Adjust

(12) Zero Key

(13) Probe Connector

Figure 1-1 Front Panel

320 x 240 Pixel Electro-luminescent ¼ VGA display, Multi-Shade Amber Color

Push Button Type Power Switch

Used to Enter and Leave the Menu System

Used to Navigate the Menu System

Activates / De-activates Selections in the Menu System

Acts as a Shift Key from the Measurement Screen

Selects Fixed Ranges or Autorange

Selects ac or dc Field Measurement

Activates / Deactivates the Hold Feature

Resets the Min/Max and Peak/Valley Detectors Used with the Hold Feature

Activates / De-activates the Relative Function

Adjusts the Relative or Zero Setting Up and Down

Starts the Channel’s Zeroing Process

12 Pin Non-Magnetic Female Connector for Hall Effect Probes

1-6 Section 1 - Introduction

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

(Continued)

Rear Panel

The rear panel consists of the power receptacle, fuse holder, line

voltage switch, analog signal outputs, communication ports, and

the cooling fan vent.

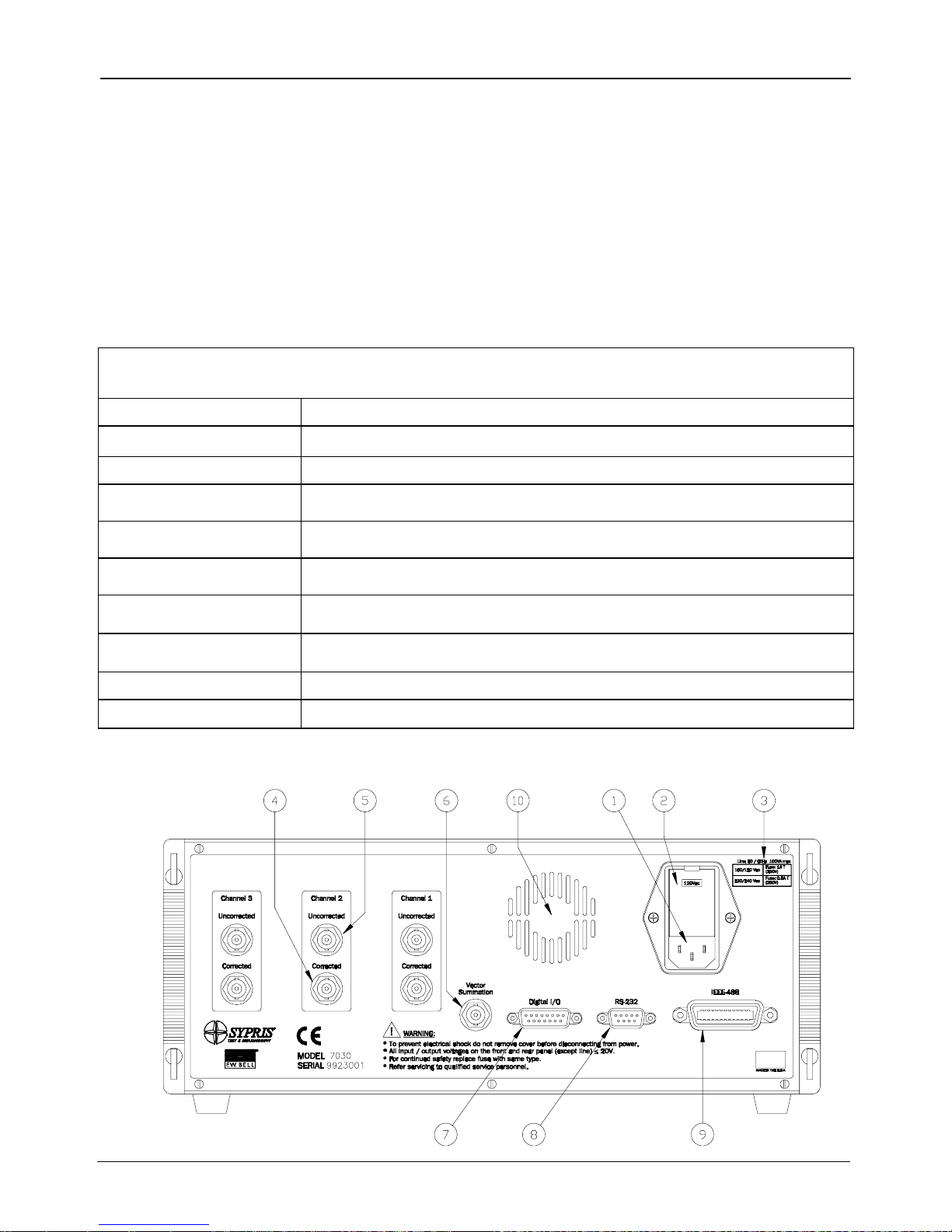

TABLE 1-3 REAR PANEL DESCRIPTION

(1) Power Receptacle

(2) Fuse Panel

(3) Fuse Chart

(4) Corrected Analog

Output

(5) Uncorrected Analog

Output

(6) Vector Summation

Analog Output

(7) Digital I/O

(8) RS-232

(9) IEEE-488 (GPIB)

(10) Cooling Vent

Figure 1-2 Rear Panel

Accepts an International Instrumentation Power Line Cord

Panel Opens to Access Fuses and Line Voltage Switch

Specifies the Proper Fuse Rating

Compensated Analog Output Voltage Signal, Standard BNC Connector.

Uncompensated Analog Output Voltage Signal, Standard BNC Connector.

Analog Voltage Signal Proportional to the Three Channels’ Vector Sum,

Standard BNC Connector.

Standard 15 Pin “D” Type Female Connector, Provides Switch Closure Points

for Classifier Operation

RS-232 Serial Communication Port. Standard 9 Pin “D” Type Female

Connector.

Standard 24-Pin GPIB Connector for IEEE-488 Bus

Vents for Cooling Fan (Should Remain Clear)

Section 1 - Introduction 1-7

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

GENERAL

DESCRIPTION

(Continued)

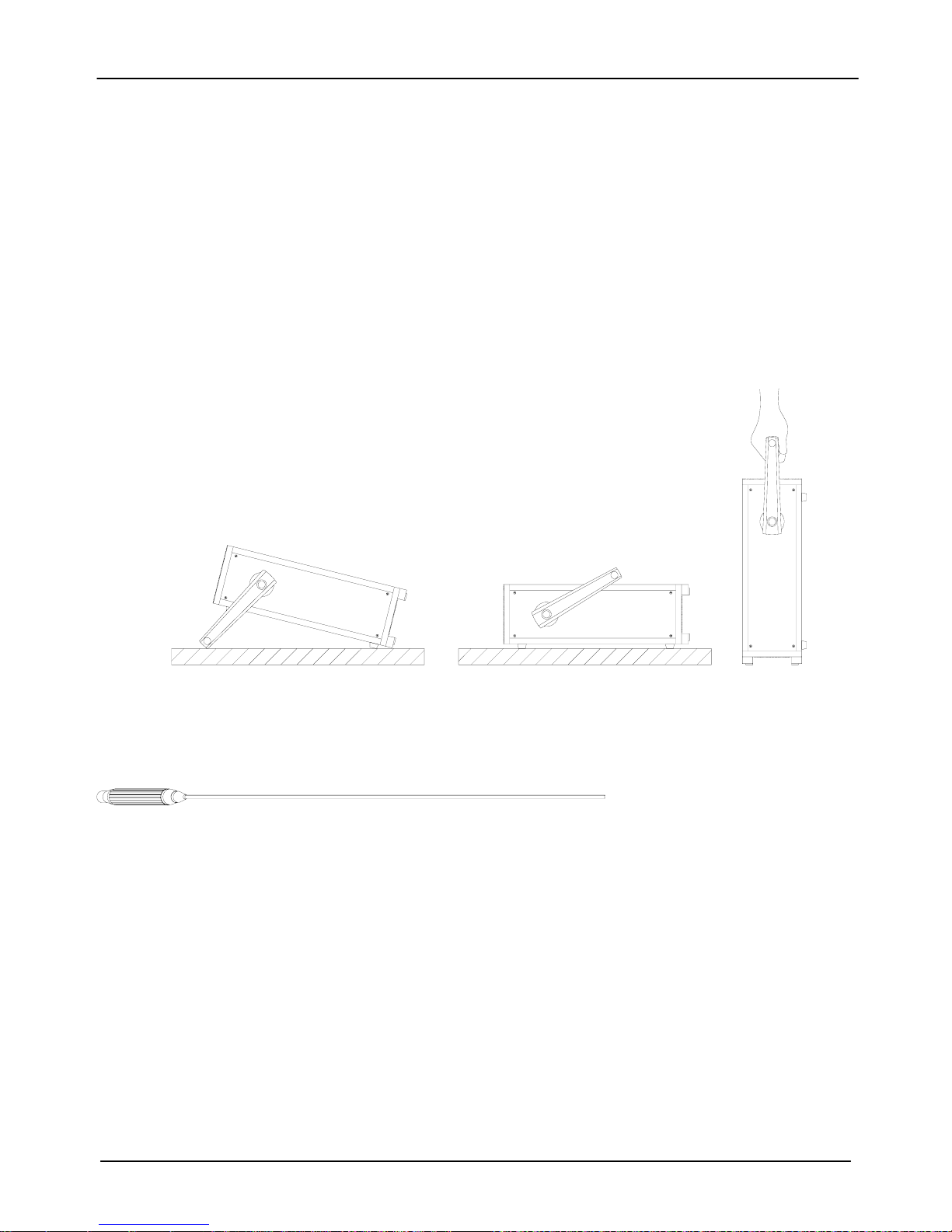

Cabinet

The cabinet is equipped with a rotating handle that also serves to

adjust the tilt angle of the instrument. If necessary, the handle is easily

removed with a standard Phillips screwdriver. The rear of the housing

features protruding feet that allow the instrument to be placed down in

a vertical position, without damage to the rear panel. Figure 1-3

shows the instrument in various positions.

Figure 1-3 Various Positions of Instrument

Raised Lowered

APPLICATIONS

• Sorting or performing incoming inspection on permanent magnets,

particularly multi-pole magnets.

Testing audio speaker magnet assemblies, electric motor armatures

•

and stators, transformer lamination stacks, cut toroidal cores, coils

and solenoids.

Determining the location of stray fields around medical diagnostic

•

equipment.

Determining sources of electromagnetic interference.

•

Locating flaws in welded joints.

•

Inspection of ferrous materials.

•

• 3-dimensional field mapping.

• Inspection of magnetic recording heads.

• Designing new magnetic assemblies.

Carrying

1-8 Section 1 - Introduction

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

µ

Section 2 Specifications

INSTRUMENT

Full-scale ranges are shown in the Tables 2-1a – 2-1c below; listed by probe type. In all cases, the

resolution is 1 part in 300,000.

Table 2-1a: Ranges for Low Field Probe:

gauss (G) tesla (T) oersted (Oe) ampere-turn/meter (A/m)

300.000 mG

3.00000 G 300.000 µT 3.00000 Oe 238.732 A/m

Note: Low Field probe cannot be used for measurements above 2 Gauss.

30.0000

T

300.000 mOe 23.8732 A/m

Table 2-1b: Ranges for Mid Field Probe:

gauss (G) tesla (T) oersted (Oe) ampere-turn/meter (A/m)

30.0000 G 3.00000 mT 30.0000 Oe 2.38732 kA/m

300.000 G 30.0000 mT 300.000 Oe 23.8732 kA/m

3.00000 kG 300.000 mT 3.00000 kOe 238.732 kA/m

30.0000 kG 3.00000 T 30.0000 kOe 2.38732 MA/m

Table 2-1c: Ranges for High Field Probe:

gauss (G) tesla (T) oersted (Oe) ampere-turn/meter (A/m)

300.000 G 30.0000 mT 300.000 Oe 23.8732 kA/m

3.00000 kG 300.000 mT 3.00000 kOe 238.732 kA/m

30.0000 kG 3.00000 T 30.0000 kOe 2.38732 MA/m

300.000 kG 30.0000 T 300.000 kOe 23.8732 MA/m

Section 2 - Specifications 2-1

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Table 2-2 Accuracies @23°C ( Instrument Only *)

Display and Digital

Outputs (min speed)

±0.05% of reading and

dc accuracy

±0.01% of range

ac accuracy

In dc mode

ac accuracy

in ac mode

ac peak accuracy

N/A

2.0% of reading ± 0.15% of

range (20 Hz to 50 kHz)

5.00% of Reading N/A N/A

*Probes Errors Not Included

Corrected Analog Output and

Digital Outputs (max speed)

±0.15% of 3V or 10V ranges

2% of range

dc to 100 hz

2.0% of 3V or 10V ranges

(ac 20 to 500 Hz)

(ac rms (dc) 20Hz-50kHz)

Uncorrected Analog

Output

3V range: 0.25% of

reading ±40mV

10V range: 0.25% of

reading±120mV

2% of range

dc to 100Hz

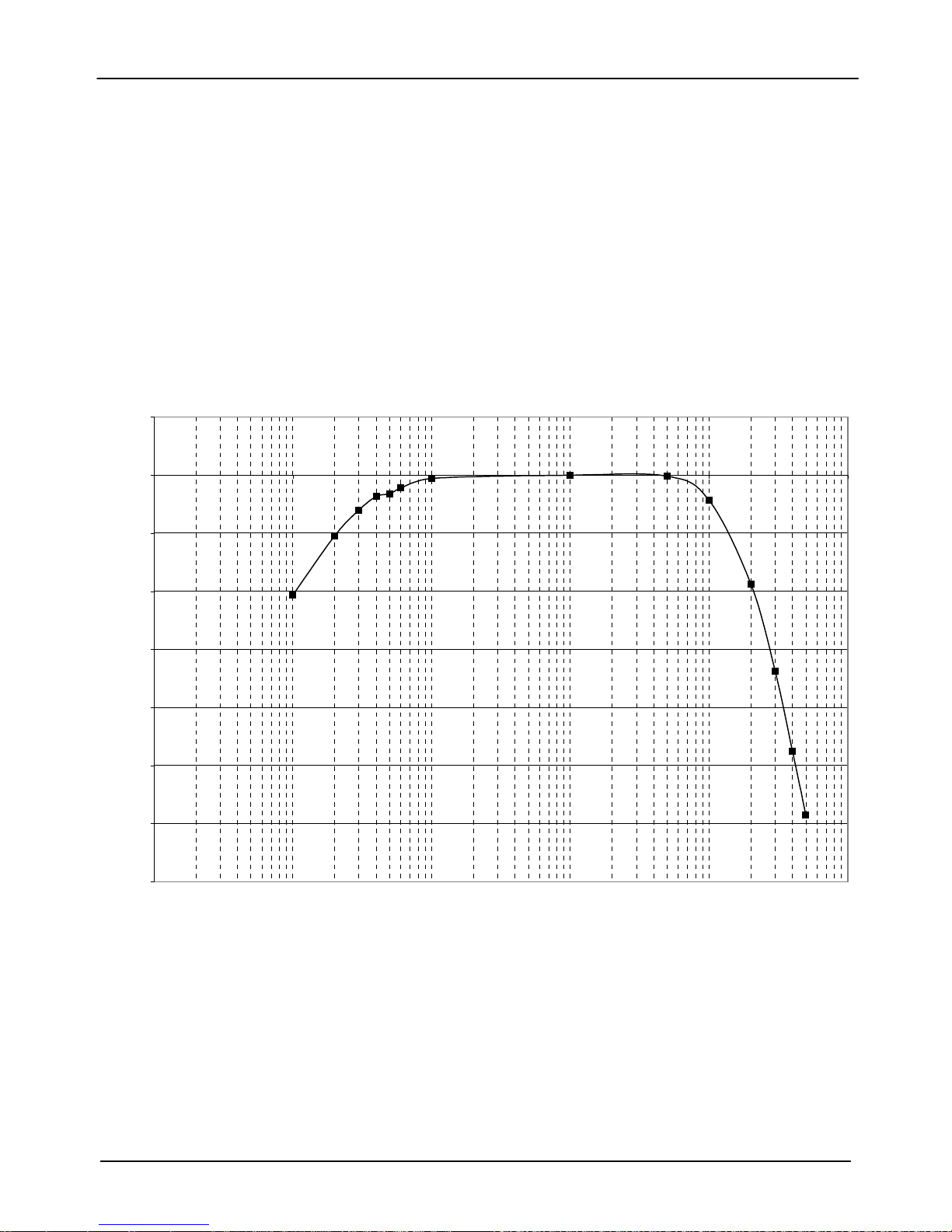

See Figure 2-1 for Graph

(Typical)

ac and ac rms (dc) output

2-2 Section 2 - Specifications

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Min / Max Hold Acquisition Time:

dc Mode: 200mS

ac Mode: 200mS

Peak / Valley Hold Acquisition Time:

dc Mode: 2ms

ac Mode: 200µs

Temperature Coefficient:

0.02% of reading

±1 count/degree celsius

Update Rate:

Display: 5/s (max)

IEEE Output: 100/s (max)

RS-232 Output: 100/s (max)

Temperature Range:

Operating: 0 to 50 degrees celsius

Storage: -20 to 60 degrees celsius

Humidity Range:

0 to 35 degrees celsius 80% RH

Corrected Analog Output Noise

(3V output range with 500 Hz filter):

All ranges:

2mV rms (35mV p-p)

Un-Corrected Analog Output Noise

(3V output range with 500 Hz filter):

300G, 3kG, 30kG ranges:

50µV rms (10mV p-p)

30G range:

2mV rms (20mV p-p)

Analog Output Impedance:

<100 Ohms

Analog Output Connector:

Standard BNC

Analog Output Scaling:

dc Mode: 3V or 10V standard

± 0.1V to ± 9.9V adjustable,

with increments of 0.1 V

ac Mode: 3Vrms or 10Vrms standard

± 0.1Vrms to ± 9.9Vrms adjustable,

with increments of 0.1 Vrms

Front Panel Display:

Type: ¼ VGA 320 x 240 pixels graphic Electro-

luminescent display with 4 shades of

amber.

Dimensions: 4.7 W x 3.5 H inches

119 W x 89 H millimeters

Power:

Volts: 100/120 220/240

Frequency: 50-60 Hz or 50-60 Hz

Current: 1.0 A (max) 0.5 A (max)

Size:

16.3 W x 5.2 H x 13.5 D inches

414 W x 132 H x 343 D millimeters

Weight:

Net: 19.4 lbs. / 8.8 kg

Shipping: 25.8 lbs. / 11.6 kg

Warm-up Time to Rated Accuracy:

60 Minutes

Section 2 - Specifications 2-3

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Figure 2-1 Frequency Response of Uncorrected Analog Outputs (Typical)

No Probe (Instrument Only)

5.00

0.00

1 10 100 1000 10000 100000

-10.00

-15.00

-20.00

PERCENT OF READING ERROR

-25.00

-30.00

-35.00

-5.00

FREQUENCY (Hz)

2-4 Section 2 - Specifications

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Ω

±

±

Communications

EMC application note

Use only high quality, double shielded cables for the RS-232, IEEE-488 and Digital I/O connections. Keep

the length of the cables less than 3 meters. Cables greater than 3 meters with insufficient EMI shielding can

cause excessive emissions or may be susceptible to external interference. Adapters specified below for the

RS-232 and digital I/O connectors must be used prior to connecting the RS 232 and digital I/O cables.

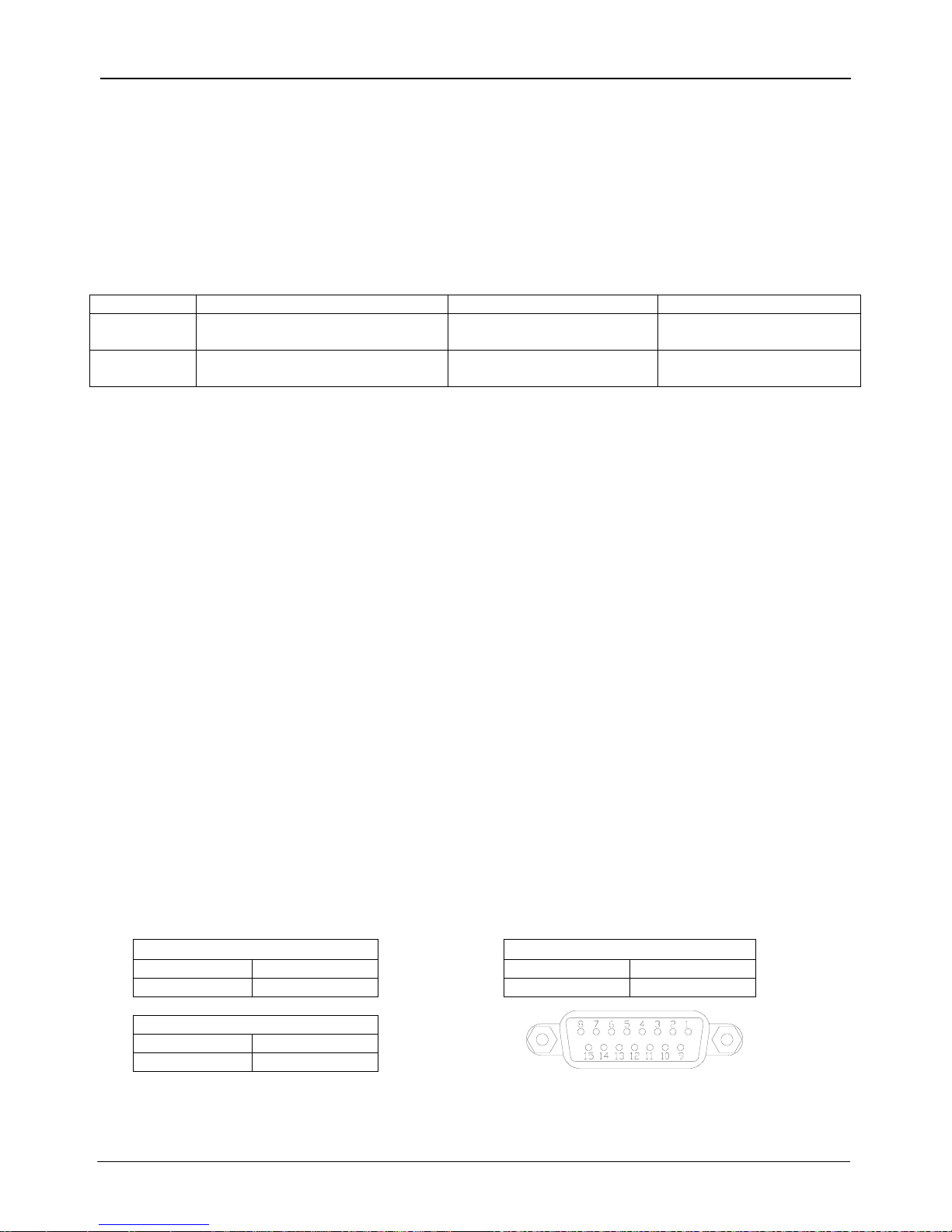

Connection Description Insertion Loss Spectrum Control Part #

RS-232 830pF Capacitive Type Filter,

“D” Type 9 Pin Male to Female

Digital I/O 1000pF Capa citive Type Filter,

“D” Type 15 Pin Male to Female

22dB @ 100MHz,

39dB @ 1GHz

20dB @ 100MHz,

40dB @ 1GHz

56-705-008 , 830 pF

56-715-002, 1000 pF

Serial

Format: RS-232C

Connector type: 9-pin “D” female

Cable length: 3 m (9.8 ft.) maximum

Receive input resistance:

Receive voltage limit:

Transmit output voltage:

Baud rate:

Stop bits: 1, 2

Character length: 7,8

Parity: None, Odd, Even

Handshaking None, Hardware, Software

Standards supported: IEEE-1987.2, SCPI-1999

3 k

minimum

30 V maximum

5 V min, ± 8 V typical

300, 600, 1200, 2400, 4800, 9600, 19200, 38400

IEEE 488.2 (GPIB)

Format: IEEE 488.2

Standards supported: IEEE-1987.2, SCPI-1999

Digital I/O

Signal Type:

Relay Closure

Connector: 15-Pin “D” Female

Switching Voltage:

100 V dc or ac Peak MAX

Switching Current: 0.25 A dc or ac Peak MAX

Operating Time, Including Bounce:

2 mS MAX

Classifier Connections

Channel 1

Low

High

1,9

2,10

Channel 2

Low

High

3,11

4,12

Note: Do not connect to pins 7, 8, 15 Pin “D”

and 15; factory use only! Figure 2-2 Digital I/O Connector

Channel 3

Low

High

5,13

6,14

Section 2 - Specifications 2-5

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Regulatory Information:

Compliance was demonstrated to the following specifications as listed in the official Journal of the European

Communities:

EN 50082-1:1997 Generic Immunity

EN 61000-4-2 Electrostatic Discharge (ESD) Immunity

EN 61000-4-3 and Radiated Electromagnetic Field (RF) Immunity

EVN 50204

EN-61000-4-4 Electrical Fast Transient/Burst (EFT) Immunity

EN-61000-4-5 Electrical Surge Immunity

EN-61000-4-6 Conducted RF Disturbance Immunity

EN-61000-4-8 Power Frequency Magnetic Field Immunity

EN 50081-1:1992 Generic Emissions

EN 55022 Class B and Radiated and Conducted Emissions

EN 55014

EN61010-1: 1993 and Safety

EN61010-1 A2:1995

Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory use.

CALIBRATION

SERVICE

The instrument is calibrated at the factory prior to shipment. To maintain

rated accuracy, it is recommended that the instrument be re-calibrated

every 12 months.

Answers to any questions concerning the calibration of this instrument

may be obtained by contacting OECO at the address below:

OECO, LLC

4607 SE International Way

Milwaukie, OR 97222

Phone: 503-659-5999

2-6 Section 2 - Specifications

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

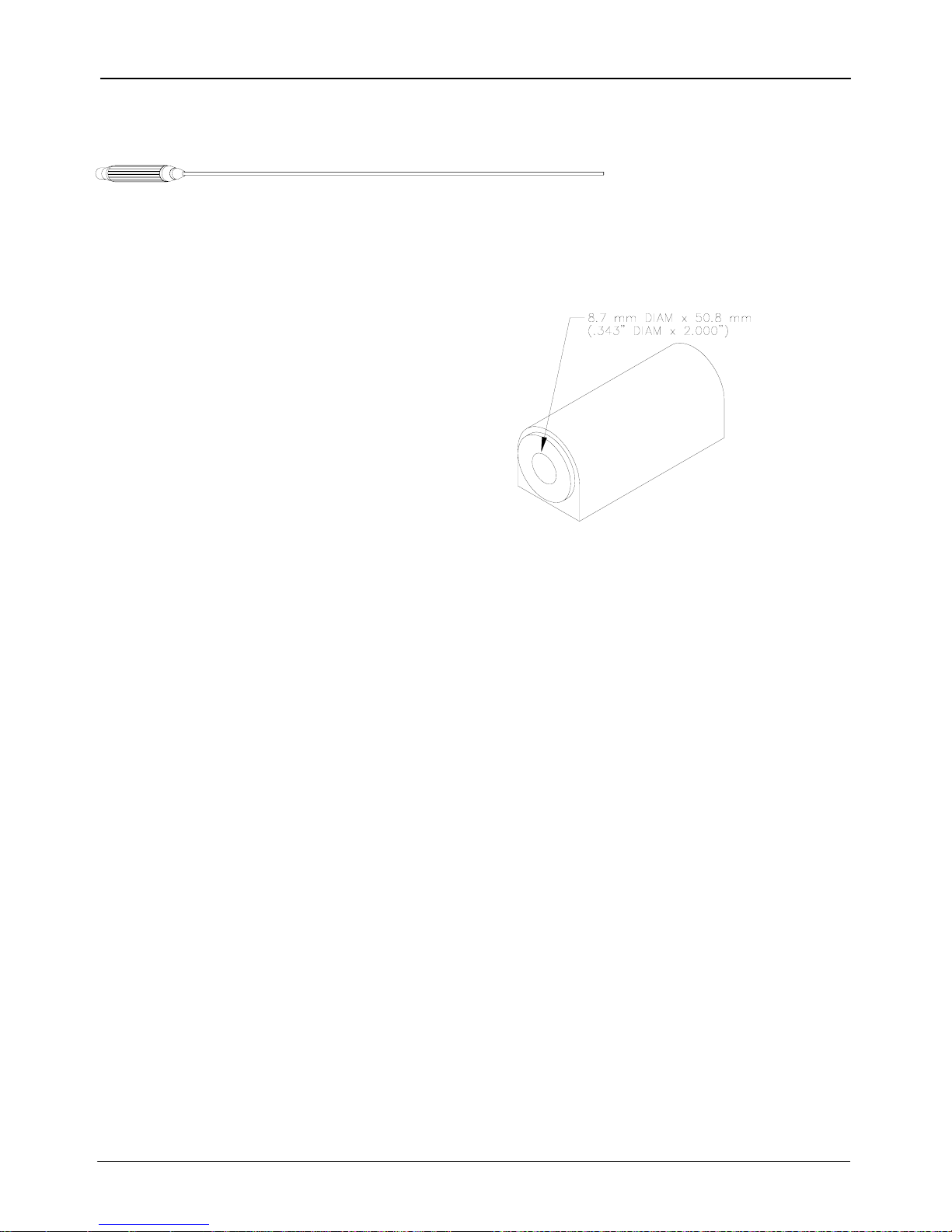

ZERO FLUX CHAMBER

Model Number:

YA-111

Cavity Dimensions:

Length: 50.8 mm (2”)

Diameter: 8.7 mm (0.343”)

Attenuation:

80 dB to 30 mT (300 G)

Purpose: Figure 2- 3

To shield the probe from external magnetic fields

during the ZERO or RELATIVE operations.

Zero Flux Chamber

Section 2 - Specifications 2-7

THIS SIDE BLANK !

(Rear of page 2-7)

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Section 3

OVERVIEW

Probes

F.W. Bell’s 7000 series gauss/tesla meter probes are designed to meet

the electrical and mechanical requirements of virtually any application.

Models are available for transverse, axial, 3-axis and very low field

measurements. The probe style is dependent upon the measurement

environment. The standard fiberglass stem is recommended for

laboratory or light handling environments, while the heavy duty aluminum

stem is recommended for harsher environments. The probe’s length,

outside diameter (axial probes) or thickness and width (transverse

probes) are important if there are physical constraints where the probe

will be used.

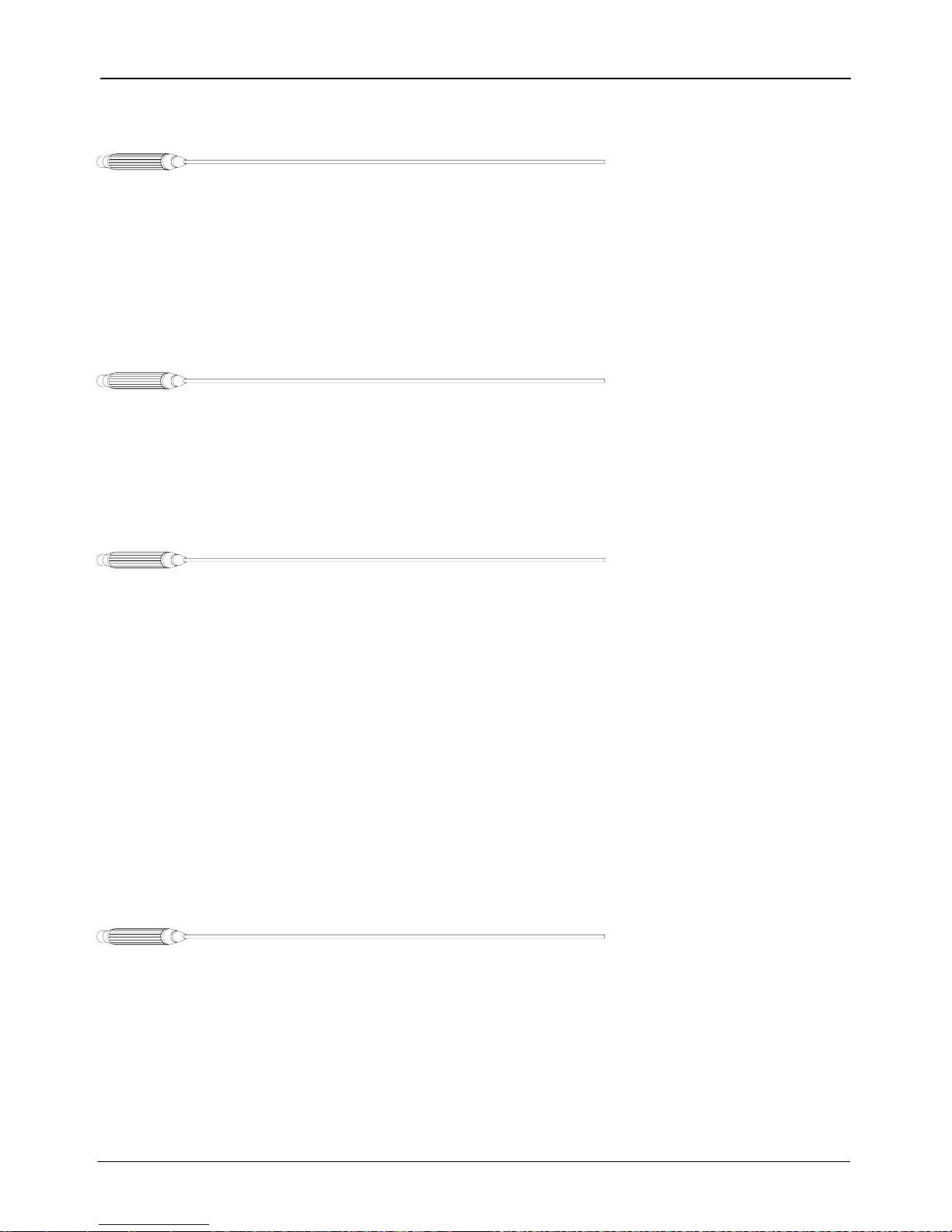

In “transverse” probes the Hall generator is mounted in a thin, flat stem

whereas in “axial” probes the Hall generator is mounted in a cylindrical

stem. The primary difference is the axis of measurement, as shown by

“+B” in Figure 3-2. Generally transverse probes are used to make

measurements between two magnetic poles such as those in audio

speakers, electric motors and imaging machines. Axial probes are often

used to measure the magnetic field along the axis of a coil or solenoid.

Either probe can be used where there are few physical space limitations,

such as in geomagnetic or electromagnetic interference surveys.

A 3-axis probe is a special configuration of three sensing elements

positioned orthogonally within a cylindrical stem. The instrument can

provide a separate reading for each axis as well as a vector sum of all

three axes.

The low field probe is designed for high sensitivity, volumetric

measurement such as mapping variations in the earth’s magnetic field or

detecting the presence of ferrous objects.

Handle Hall probes with care. Do not bend the stem or apply

pressure to the probe tip as damage may result.

Section 3 - Probes 3-1

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

PROBE

VARIATIONS

A wide variety of probes are available for use with the 7030 gauss/tesla meters.

The types include 3-axis, heavy-duty transverse and axial, standard transverse

and axial, standard transverse with exposed element, flexible transverse and axial

with exposed element and low field probes. All of these probes are available with

or without temperature compensation. All probes are available with 5, 15 or 30

foot (1.5, 4.5 and 9 meter) cable lengths and most are available with various stem

lengths. Table 3-1 lists the maximum field measurement capabilities and

resolutions.

Table 3-1 Probe Maximum Field Levels and Resolutions

Probe Type Maximum Field Resolution

Low Field

2 G (200 µT) 1 µG (0.1 nT)

Medium Field 30 kG (3 T)

High Field 300 kG (30 T)

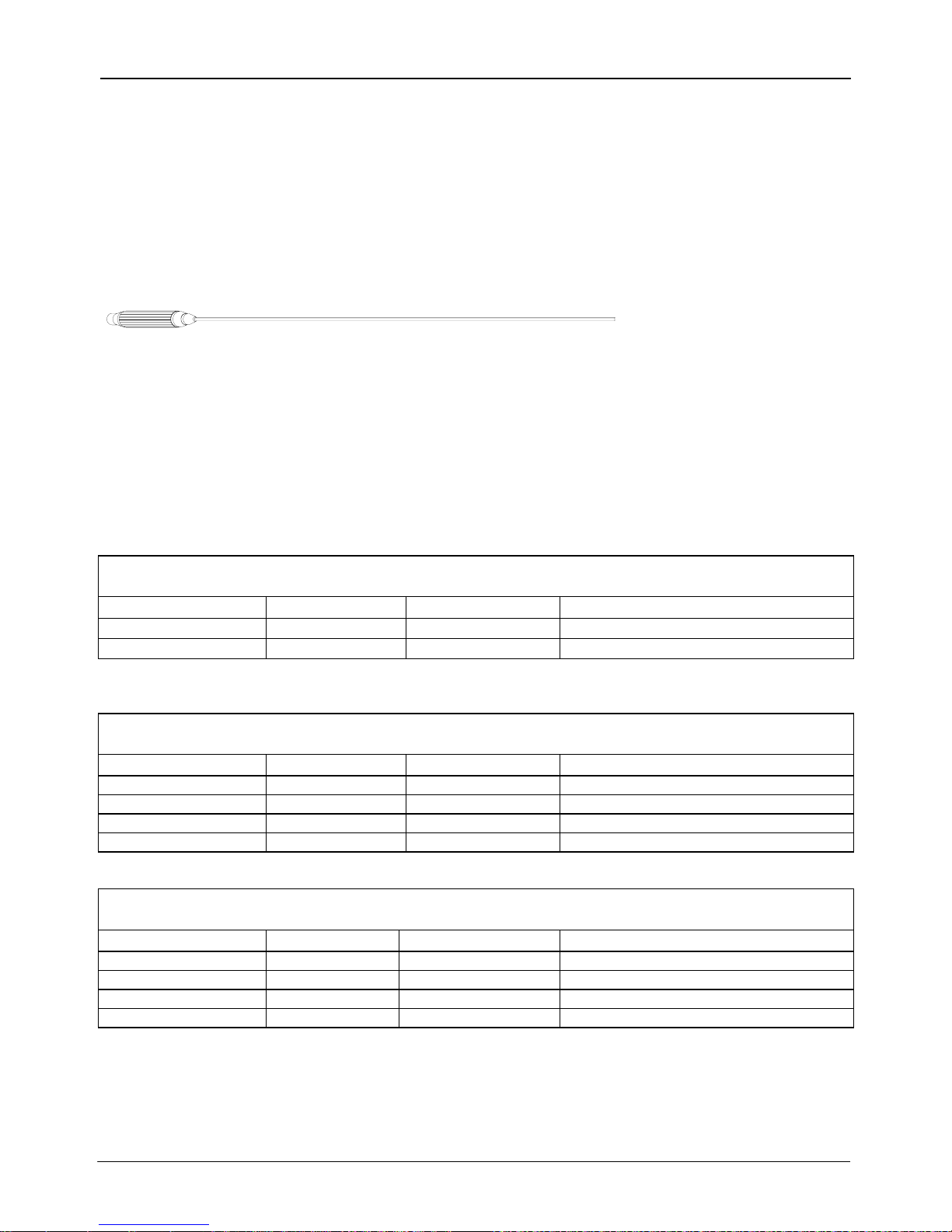

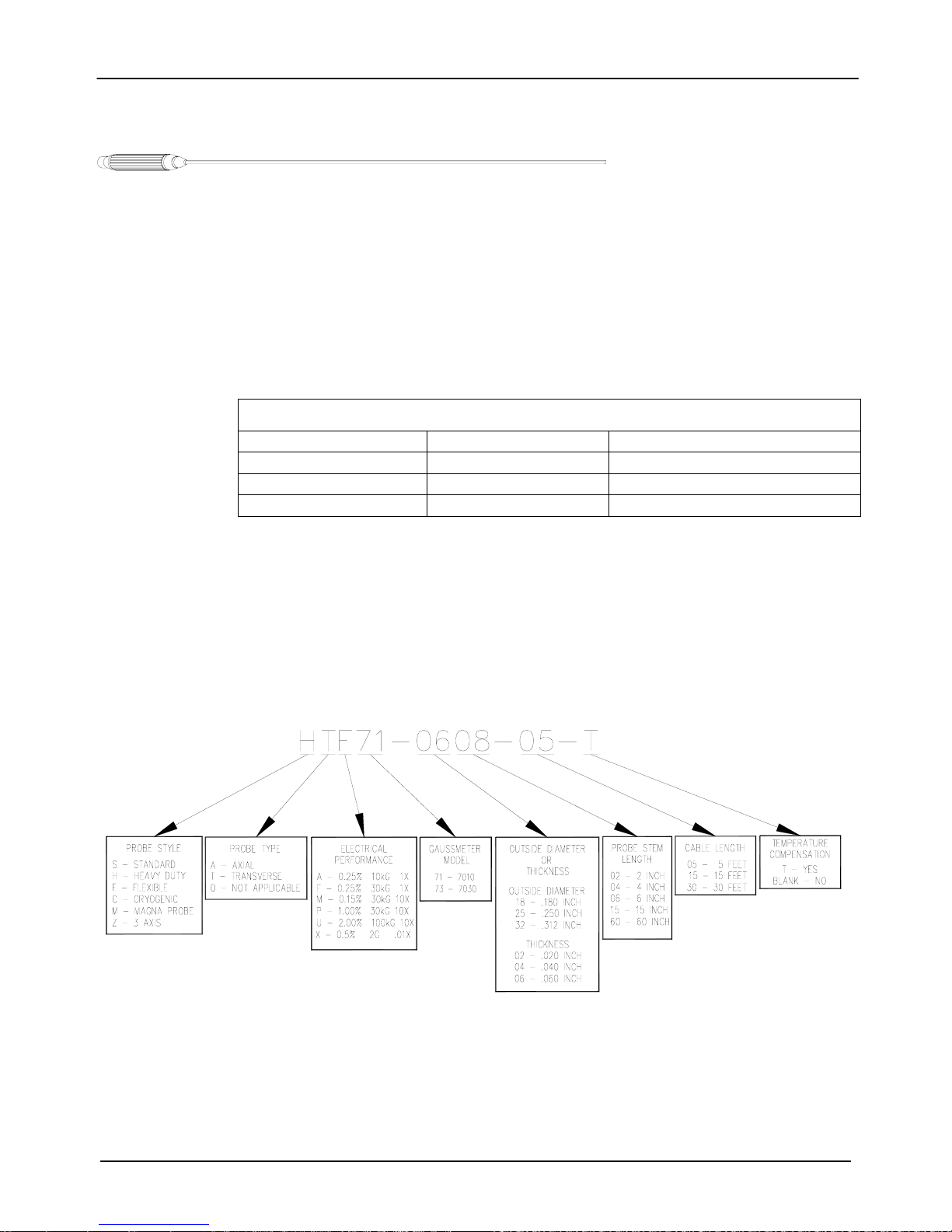

Figure 3-1 serves as an ordering guide for F.W. BELL 7000 series probes.

Full electrical and mechanical specifications of all probes are available on

request.

Figure 3-1 7000 Series Probe Ordering Guide

Note: Probes are not available in all part number combinations.

0.1 mG (0.01 µT)

1 mG (0.1 µT)

3-2 Section 3 - Probes

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

PROBE

MEMORY

The connector of each probe contains a memory device which stores

registration information (model number, serial number, date calibrated, etc.)

as well as performance information for Hall generator sensitivity, linearity,

frequency response and temperature response. Each probe is physically

identified with model number, serial number and a maximum voltage rating of

“30VRMS / 60Vdc MAX” on a durable polyester label wrapped around the

cable jacket.

PROBE STEM

All probes except the low field probe are supplied with a rigid stem cover to

protect the probe when not in use. It is strongly recommended to use the

stem protector when storing the probe or when the probe will not be used for

any length of time. If a probe stem becomes damaged it can not be repaired.

TEMPERATURE

EFFECTS

All Hall probes have an initial electrical offset that will affect the accuracy of

static (dc) field measurements. This offset should be canceled using the

instrument’s “zero” function. However, the probe’s offset and sensitivity will

change with temperature. Using temperature-compensated probes will

minimize these effects.

There can be substantial errors in uncompensated probes. A typical probe’s

dc offset can change by ± 0.1 G / °C (±10 µT / °C). It is best to allow the

probe’s temperature to stabilize before performing a “zeroing” operation.

Zeroing is discussed in Section 6 – Flux Density Measurement. The

probe’s sensitivity will decrease as temperature increases. Probes are

calibrated at ambient temperature (23 °C). A typical probe may change by

–0.05% / °C. For instance a reading of 200 mT at 23°C may drop to 197 mT

at 50°C.

FIXTURING

In some applications it may be necessary to install a probe into a holding

fixture to maintain a constant probe position. If this becomes necessary, do

not clamp onto the probe stem as this will most likely damage the probe.

Rather, clamp onto the aluminum probe body.

Section 3 - Probes 3-3

F.W. BELL Model 7030 Gauss/Tesla Meter Instruction Manual

Figure 3-2 Hall Probe Configurations

3-4 Section 3 - Probes

Loading...

Loading...