- 1 -

Assembly and

Operating Instructions

Round Pool

FUN

Important notes:

Please first read all parts of these instructions very carefully

and follow the advice given.

Before beginning with installation, check the swimming pool

components and make sure that nothing is missing. Also

ensure that all components are in perfect condition. We cannot accept any liability for transport damage on parts which

have already been assembled or installed.

We reserve the right to make alterations which reflect technical progress.

If you fit your swimming pool with electrical equipment (e.g.

filter system, underwater spotlights, counter-current unit

etc.), all electrical work involved must be carried out by a

recognised specialist company in accordance with relevant

DIN and VDE regulations (e.g. DIN VDE 0100 Section

702).

Before beginning installation, you must observe

the following points:

Preparing the foundations:

The ground location for the swimming pool must be firm and

completely level; any sloping areas must therefore be dug

out.

The ground under the swimming pool must consist of naturally compacted soil and not simply filled in.

Filled-in soil must be compacted so that the pool does not

sink into it.

The soil must be freed from any pieces of wood or other

debris which could damage the PVC liner. Unevenness can

be covered using a layer of fine-sand.

In the case of an asphalt or concrete base the PVC liner must

be protected from direct contact with the ground. We recommend the use of our PE protective ground tarpaulins for

this, or insulating and protective matting.

Please be sure that the PVC liner only comes into contact

with materials which are compatible with PVC. We

therefore always recommend Future Pool PE protective

ground tarpaulins or insulating and protective matting as

underlay.

Temperature

The PVC liner of your swimming pool is made of thermoplastic material. You should therefore make sure that you

assemble your pool under external temperature conditions of

approx. + 15° C to +25° C. And you should also not hang the

liner in the pool in strong sunlight; on warm and sunny days

you should wait until evening before hanging the liner.

Above-ground or in-ground?

Erecting the pool in sloping locations

The location surface for the swimming pool must not be

made up of filled-in soil. The area which is prepared for the

pool must be a location with natural, well-compacted soil.

The uphill side of the pool must either be flanked by a shallow slope or a wall. On no account must the pool wall shore

up the slope!

Please make sure that in forming a shallow slope the pool

cannot be undermined by rainwater. Drainage must be installed if you meet any groundwater.

Pool installation

Swimming pools from Future Pool can at any time be

installed in the ground as in-ground pools if you comply with

the following rules. If in doubt you should consult a building

expert, as we accept no liability for in-ground installations.

Partial or complete in-ground installation:

When planning an in-ground swimming pool, make sure that

you do not encroach into the groundwater zone when excavating. Assembly of the pool is carried out in the same way

as for an above-ground model. The dimensions of the pit to

be excavated must be at least 20 cm larger than the pool

itself. Pools which are either partially or completely installed

in the ground must be backfilled with lean concrete.

Caution:

Pools with a depth of 1.50 m cannot be erected as completely

free-standing, but absolutely must be installed to a depth of

at least 50 cm in the ground. The section located in the

ground must be surrounded by a backfill of lean concrete.

- 2 -

Greater depth of water

With all swimming pools you can achieve a greater depth of

water by excavating the soil in the shape of a cone towards

the middle of the pool. The liner foil expands to the extent

that it has no problem in adapting to the greater depth. An

approximate guide to the permissible additional depth is set

out in the table below.

Pool diameter in cm

320

350

400

420

500

550

600

700

800

900

1000

Additional depth in the centre of the pool in cm: approx.

7 7 10

10

12

12

12

15

15

15

20

Pool assembly

Pool assembly should be carried out by 2 persons. We recommend that you wear gloves when erecting the steel wall.

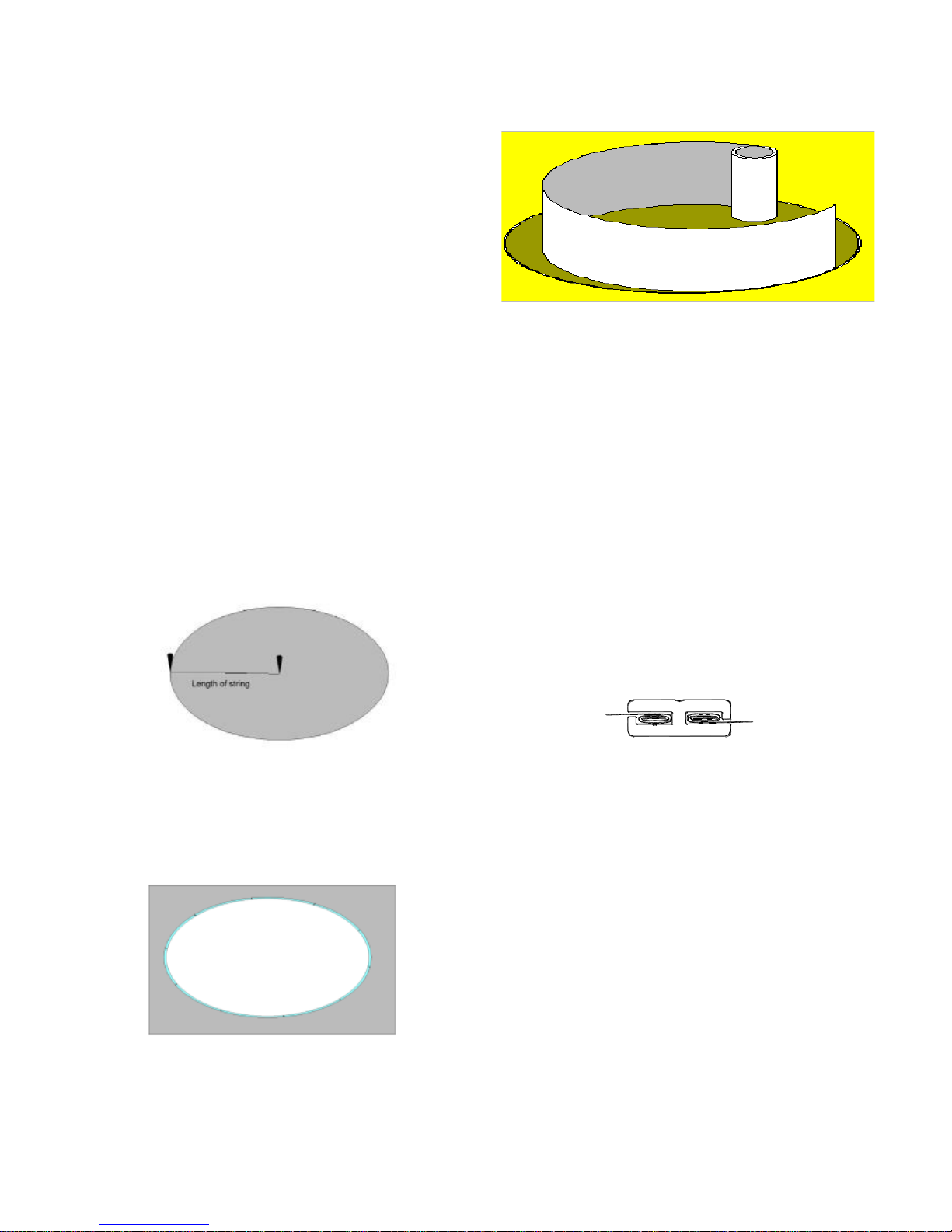

Marking out the pool ground plan

After you have prepared the foundations for your swimming

pool, mark the outline of the pool on the ground. You can

best mark out the circle using a piece of string fixed to a post

at the centre of the pool area. The string should be approx.

10 cm longer than the pool radius. Clearly mark out the circle outline or trace it out with sand.

Floor drain: If you plan to install a floor drain in your pool,

you should now also dig a trench to the pool’s deepest point.

Allow for a slight slope in the piping and prefit pipes to the

floor drain. Fill in the trench again with soil or concrete.

Laying out the wall tracks:

Plug together the individual hard-PVC wall tracks (width

approx. 22 mm) in each case with two connecting pins and

lay these out in the shape of a circle.

Caution: The wall tracks must not sink into the ground! It

may be necessary to lay down concrete slabs as supports.

Uncoiling the steel wall

Together with your helpers, place the steel wall on strong

planks in the middle of the circle of wall tracks. Uncoil the

steel wall and locate it in the wall tracks.

Make sure that the white-coated side is on the outside and

that the pre-punched holes for the skimmer and the inlet

nozzle are at the top.

Caution: The pre-punched skimmer hole is located approx.

200 cm away from the outer wall end. Make sure when locating the steel wall in the wall tracks that the skimmer hole

is also located in the correct required place. In the case of

swimming pools with 2 steel walls the skimmer hole is located in Wall 1.

The location of the skimmer should be at the downwind end

of the pool relative to the direction of the prevailing wind, so

that air movement reinforces the effectiveness of the filter

system by driving surface dirt towards the skimmer.

Important tip: So that the steel wall can provisionally be

kept in a circular shape during assembly it is necessary to

locate several upper handrail sections on top of the steel

wall. Also always make sure that the steel wall is standing in

the wall tracks.

Connecting the ends of the steel wall using the

plug-in section

The clearance between the steel-wall ends should be approx.

5 mm. Depending on the overlap of the wall tracks, they

must be correspondingly shortened. Make sure that you lay

out a perfect circle with the wall tracks. Check the symmetry

of the circle.

The plug-in section is sitting correctly when the bevelled

side is on the inside and at the top. By gently rocking the

plug-in rail back and forth you can ease insertion into the

plug-in section. To further facilitate insertion of the plug-in

rail you can lubricate both ends of the steel wall with engineering Vaseline.

Preparing openings for connections

If built-in components are to be installed (skimmer, inlet

nozzle), you must break out the corresponding pre-punched

holes. Carefully remove burrs and treat with an anticorrosion agent.

Caution: Follow the instructions for built-in components!!!

- 3 -

Earthing the swimming pool

According to statutory regulations, swimming pools and all

large-area metallic parts must be connected to a potential

equaliser.

Caution: All electrical work must be carried out by a recognised specialist company in accordance with the relevant

DIN and VDE regulations (e.g. DIN VDE 0100 Part 702).

Laying out the protective matting or protective

ground tarpaulin (not supplied)

We recommend the use of a protective ground tarpaulin or

matting to protect the liner from direct contact with the

ground or with any materials which may be harmful to PVC.

Thoroughly clean the ground again and lay out the protective

matting, overlapping the individual sheets by approx. 5 – 10

cm. Cut the protective ground tarpaulin or matting 5 – 10 cm

larger than the pool outline and tape the resulting overlap

firmly to the steel wall. Pull the edges over the wall tracks.

To do this, use PVC-compatible adhesive tape (e.g. parcel

tape). Pull the protective ground tarpaulin or matting tight to

straighten out any creases.

Hanging the liner

Caution: Hang the liner at temperatures between +15 and

+25° C, but not in strong sunshine! If the temperature is too

high the foil becomes soft and elastic and too large. If the

temperature is too low the liner becomes hard, inelastic and

too small.

Clean the inside of the pool again. Now place the liner in the

middle of the pool and spread it out, so that the outer bonded

seams lie up against the steel wall. The liner has a shaped

hanging fringe bonded onto the main liner. Push the outer

edges of the liner with the shaped fringe over the upper edge

of the steel wall. Provisionally fix in place with several individual handrail sections.

Caution: Only walk on the PVC liner barefoot or wearing

suitable shoes (no rough-studded rubber boots!).

Smoothing out the creases

Smooth the creases on the floor outwards towards the pool

wall. Now let water into the pool until the middle is covered

to a depth of approx. 2 – 3 cm. Smooth any creases outwards

from the centre by hand.

If the creases cannot be smoothed out:

Have the wall tracks sunk into the ground below the pool?

Lift them up! Is your foundation pit too shallow? Dig it

deeper! Have you overstretched the liner when hanging it in

the pool? Rehang the liner, perhaps after waiting for cooler

weather. Do not pull on the liner when hanging it! Is there

too much tension in the liner? If so, you have probably excavated the foundations too deeply. Then it is essential to fill in

as necessary, not forgetting to firmly compact any fill.

Caution: from a water depth of approx. 5 – 6 cm the liner

can no longer be smoothed out on account of the high water

pressure.

Caution: It is essential to check that the pool is standing

absolutely vertically.

Cover the pool floor with approx. 10 cm of water. Measure

the distance between the waterline and the upper edge of the

pool at several points. If the measured values differ by

more than 2 cm the pool has been incorrectly erected. In

this case the manufacturer’s guarantee is no longer valid!

Attaching the handrail sections

Join the handrail sections (width approx. 40mm) together in

each case with two round connectors; press them onto the

edge of the pool by banging with the flat of the hand or using

a rubber hammer, at the same time firmly fixing the shaped

hanging fringe. If necessary, shorten one handrail section.

Correct any liner creases along the side wall by pushing the

liner sideways. When the liner is sitting correctly, completely press down the handrail by banging down with the

flat of the hand or using a rubber hammer. If you want to

use silicon when flanging built-in components, then it

must be suitable for use in swimming-pool areas. Other-

Wrong!

Important!

Gap for intermediate piece 2 mm

observed during assembly

handrail.

- 4 -

wise there is the danger that the PVC foil will stretch in

the long term and that foil creases will develop.

Lean-concrete backfill for in-ground pools

Fill the fully assembled and installed pool with water (to a

depth of approx. 60 cm). Attach Styropor panels (thickness

15 – 25 mm) around the outside of the pool to insulate and

protect the outside of the steel wall. Backfill the pool wall in

several layers (each maximum 50 cm.) with damp lean concrete BN 10. In the case of naturally compacted soil (e.g.

cohesive clay), the concrete backfill must be at least 10 cm

thick. For yielding soils we recommend a backfill layer of

approx. 30 cm. When backfilling, the water level in the pool

must always be approx. 30 cm above the external concrete

fill. Pouring of the second and third layers should only be

done after the respective previous layer has set. When backfilling the pool with concrete you must take care that the

pool wall does not lose shape because of the pressure from

the concrete.

We recommend letting the pool coping project by about 10

cm in order to provide protection against contamination by

small animals, dust, leaves etc.

Repairs/Spare parts

Damage to the swimming-pool liner can easily be repaired

using a Future Pool Repair Set. Please be sure to follow the

instructions in the repair pack.

Further notes or advice on filter systems, water treatment,

heating, solar absorbers, canopies and accessories can be

obtained from your specialist swimming-pool dealer or our

customer-service representatives.

Care and maintenance

The combination of mechanical water purification and

chemical water treatment ensures clean and clear water at all

times.

Mechanical water purification

Prevent contamination by dirt (e.g. leaves, grass, hair) by

installing a filter system from Future Pool. Remove coarse

dirt (leaves, insects) with a net and/or floor cleaner from the

Future Pool range.

Chemical water treatment

Future Pool supplies the complete Future Pro-Aqua watertreatment range with outstandingly suitable products which

are also compatible with healthy swimming.

Additional recommendations and advice on water treatment

are available from your specialist swimming-pool dealer or

from your Future Pool customer-service representative.

Please send for our detailed water-care instructions.

Overwintering

Above-ground swimming pools:

All above-ground pools should remain filled with water

throughout the winter. The metal components are sufficiently

elastic to withstand ice pressure.

Partially in-ground pools:

Leave filled with water throughout the winter.

In-ground pools:

All in-ground pools must remain filled with water throughout the winter in order to compensate for ground pressure.

Dismantling and storage

Dismantle pools in the reverse order to that for assembly.

Clean and dry the individual components and store them in a

frost-free location. Do not fold the liner too small (do not

cause any sharp creases). The liner should be stored at room

temperature. Roll up the steel wall in generous coils and take

care not to cause any buckling.

Safety advice

General precautions

Never allow children to play in or close to the swimming

pool without supervision; explain the possible dangers to

them. If necessary, teach children to swim. Cover the pool if

it is not being used. Go into the water very slowly after a

meal or after sunbathing. Otherwise there is a danger of

circulatory collapse or heart failure!

Immediate action after a swimming accident:

Rescue the casualty without delay. Check the casualty’s

pulse and breathing. If necessary, immediately apply mouthto-mouth resuscitation and heart massage. Alert the emergency services.

Ordering spare parts / Advice

Do you need spare parts, accessories or advice?

Please contact the dealer from whom you bought your

swimming pool. There you will be able to obtain all available spare parts as well as the whole range of Future Pool

products.

Copying and reproduction – including extracts – require the

written approval of:

Future Pool GmbH

Innovative Products for Swimming Pools

Daimlerstr. 6

D-63741 Aschaffenburg

Telephone +49 (0) 6021 / 79750-0

Fax +49 (0) 6021 / 79750-10

As at 23.07.2012

Loading...

Loading...