Page 1

Operators and Technicians Manual

PSA-66-ST2NU Printer

GEN2 Universal™

PSA-66-ST2NU (Netplex/USB)

While PSA-66-ST2 refers to all models of the printer, the content of this manual is primarily for the

Netplex/USB interface of the GEN2 Universal printer. For additional information on the Netplex and USB

interfaces, please contact IGT.

This document is uncontrolled when printed.

Page 2

Operators and Technicians Manual

PSA-66-ST2NU Printer (GEN2 Universal™)

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved.

TCL Printer Language © 1993 – 2006 FutureLogic, Incorporated. All Rights Reserved.

TCL Printer Language is a proprietary, copyrighted language developed by FutureLogic, Incorporated

for exclusive use with its printer products.

GEN2 Powered by FutureLogic, GEN2, GEN2 Universal, TCL, ITH, TRT, TCL Editor, FutureLogic

Exchange, and FutureLogic are either trademarks or registered trademarks of

FutureLogic, Incorporated in the United States and/or other countries.

Netplex is a proprietary hardware interface and protocol of International Game Technology

Corporation.

Microsoft, Windows, and Windows NT are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

Molex is a registered trademark of Molex Incorporated. All product names referenced herein are

trademarks of Molex, its affiliates, related companies, licensors, and/or joint venture partners.

All other trademarks and products or brand names mentioned herein are the property of their

respective owners.

This document contains Proprietary and Confidential information and its contents are covered by

Non-Disclosure Agreement.

Technical information in this manual is disclosed for informational purposes only.

No grant of license or use rights of any such information is made by publication or distribution of

this manual.

No part of this guide may be reproduced, stored in a retrieval system, or transmitted, in any form or

by any means, electronic, mechanical, recording, or otherwise, without the prior written permission

of FutureLogic, Incorporated.

These specifications are subject to change without notice and may not completely and correctly

document the operation of this product.

12/06/2007

MNL-000030

REV.X08

The GEN2 Universal printer (PSA-66-ST2NU) is in compliance with the Netplex and USB

protocols of International Game Technology Corporation (IGT).

The printer described in this manual is in compliance with all applied CE standards.

This document describes product functions and technology that may not be available in a particular

gaming jurisdiction, and would therefore not be available for sale and not approved for use at this

time. Please contact your local sales representative for information concerning what features are

available in your jurisdiction.

FutureLogic, Inc.

425 East Colorado Street • Suite 100

Glendale, CA 91205 USA

Phone 818.244.4700 • Fax 818.244.4764

www.futurelogic-inc.com

• info@futurelogic-inc.com

Page 3

Operators and Technicians Manual

Table of Contents

1 Product Overview ....................................................................................................1

Introduction .......................................................................................................................1

Warranty Information .........................................................................................................1

2 Operator Interface...................................................................................................2

Introduction .......................................................................................................................2

Operator Indicators and Controls........................................................................................2

Keypad Status Light...................................................................................................... 3

Bezel Operation.............................................................................................................3

Printer Sensor Functions .................................................................................................... 3

Printer Errors .....................................................................................................................4

Loading Paper..................................................................................................................... 4

Feeding Paper ..................................................................................................................... 5

Performing a Self Test .........................................................................................................5

Clearing a Paper Jam.......................................................................................................... 6

Cleaning the Print Head...................................................................................................... 7

3 Printer Service........................................................................................................... 8

Introduction .......................................................................................................................8

Removing the Printer ..........................................................................................................9

4 Ports .........................................................................................................................11

Introduction .....................................................................................................................11

Front Bezel Port ................................................................................................................11

PSA-66-ST2NU (GEN2 Universal Printer) ..........................................................................12

USB/Netplex Interface Cable....................................................................................... 12

Firmware Upload Port .................................................................................................13

Appendix A Technical Specifications ....................................................................14

Appendix B Paper Specifications............................................................................

Appendix C Part Numbers – Printer/Spares ...........................................................17

Appendix D Schematics ..........................................................................................21

Index ..........................................................................................................................

16

23

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page i of 29 12/06/2007

MNL-000030 REV.X08

Page 4

Operators and Technicians Manual

List of Figures

Figure 2-1 Operator Indicators and Controls.......................................................................2

Figure 2-2 Load a Paper Stack ............................................................................................ 5

Figure 2-3 Feed Paper into Paper Loading Slot....................................................................5

Figure 2-4 Sample Configuration Ticket .............................................................................. 6

Figure 2-5 Remove the Paper ..............................................................................................6

Figure 2-6 Open the Lid ...................................................................................................... 7

Figure 2-7 Clear the Paper Jam ..........................................................................................7

Figure 3-1 Ground Screw and Copper Grounding Clips Location ........................................8

Figure 3-2 Disconnect the Coiled Cable Connector .............................................................9

Figure 3-3 Slide the Printer until It Locks ...........................................................................9

Figure 3-4 Remove the Paper ............................................................................................10

Figure 3-5 Front Locking Bar............................................................................................ 10

Figure 3-6 Push Release Bar............................................................................................. 10

Figure 4-1 Front Bezel LED Control Port ...........................................................................11

Figure 4-2 USB/Netplex Interface Cable ...........................................................................12

Figure 4-3 Firmware Upload Port ...................................................................................... 13

Figure B-1 Ticket Dimensional Specification .....................................................................16

List of Tables

Table 2-1 Keypad LEDs Status Reporting Printer Condition ..............................................3

Table 2-2 Bezel Display Status .......................................................................................... 3

Table 2-3 Sensors..............................................................................................................3

Table 2-4 Errors and Error Descriptions............................................................................ 4

Table 4-1 Front Bezel LED Control Port Pins ................................................................... 11

Table 4-2 Base Port Cable Pin-outs .................................................................................13

Table 4-3 Netplex Port Pin-out.........................................................................................13

Table 4-4 USB Port Cable Pin-outs .................................................................................. 13

Table 4-5 Bezel LED Control Port Pin-out........................................................................ 13

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page ii of 29 12/06/2007

MNL-000030 REV.X08

Page 5

Operators and Technicians Manual

1 Product Overview

Introduction

Each GEN2 Universal™ printer is an advanced thermal printer capable of creating high quality

complex output with a minimum of development and effort on the part of the user. The printer

module supports both serial and a Netplex current loop interface to allow operation in any

standard slot machine on the market.

Note: While PSA-66-ST2 refers to all models of the printer, the content of this manual is

primarily for the Netplex/USB interface of the GEN2 Universal printer (PSA-66-ST2NU). For

additional information on the Netplex and USB interfaces, please contact IGT.

Features of the GEN2 Universal printer include:

• The ITH™ (Intelligent Ticket Handling) technology which prevents player interference with

any part of ticket production or presentation

• May be mounted on an angle or horizontally

• Simple paper loading—no loose parts

• Variable paper capacity with different paper trays—300, 600, and 900 ticket trays

• Windows® ticket/receipt development package via the TCL™ Editor utility

• Page mode printing with TCL printer language

• Line printer capability

• High quality laser-like san serif fonts in multiple sizes

• Advanced graphics printing

• Windows connectivity

• 3 inch per second print speed

• Wide temperature range operation

• Standard and customized serial interfaces available—Netplex and USB

Additionally, a key feature of the GEN2 Universal printer is Universal Communications:

• USB 2.0 Full Speed (Future GSA Compliant, IGT Compliant)

• Netplex Port (Backward Compatible)

Warranty Information

Each printer has a two-year warranty as per the manufacturer’s written warranty.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 1 of 29 12/06/2007

MNL-000030 REV.X07

Page 6

r

r

Operators and Technicians Manual

2 Operator Interface

Introduction

This chapter covers various operations of the printer including loading paper and clearing a

paper jam.

Operator Indicators and Controls

The printer is equipped with status indicators and a FEED button, which allow you to manage and

interpret the operations of the printer.

The status indicators are:

• The front bezel light

• Keypad lights:

• Ready – Green

• Paper – Yellow

• Open – Orange

• Fault – Red

The following figure illustrates the location of these indicators and controls.

Lid

Release

Leve

Status Lights

Pape

Loading Slot

and Keypad

with FEED

button

Figure 2-1 Operator Indicators and Controls

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 2 of 29 12/06/2007

MNL-000030 REV.X07

Page 7

Operators and Technicians Manual

Keypad Status Light

The keypad LEDs report the status of the printer whenever power is present. Table 2-1 lists each

condition of the keypad LEDs.

Table 2-1 Keypad LEDs Status Reporting Printer Condition

Condition Ready Paper Open Fault

Unit is Powered Off

Unit Ready blink

Unit Flushed

Paper Out

Head Up or Ticket Module Open

Temperature Error

Voltage Error

Print Head Error

Missing Black Index Mark

Paper is Jammed blink

Indicates the LED is ON.

Bezel Operation

Use the front bezel display to determine the state of the printer while on the casino floor, at a

distance, without disturbing the game. Table 2-2 lists the conditions indicated on the bezel display.

Table 2-2 Bezel Display Status

Bezel Display Status

Solid On Printer Idle and Ready

Slow Blink Paper Low or Printer Error

Fast Blink Ticket Printing and/or Ticket in Chute

Off Printer power off

See Chapter 4 for information on the current ratings of the bezel ports.

Printer Sensor Functions

There are six primary sensor functions on the printer. These sensors work with the game firmware to

provide reliable trouble-free operation. Any error conditions resulting from these sensors are

indicated by the front bezel light and keypad LEDs.

Table 2-3 Sensors

Sensor Description

Paper Out The Paper Out sensor is located in the print head. It terminates the print operation when

the paper has run out and checks for proper form registration. The printer ceases printing

and feeding operations when it detects a Paper Out condition. Correct a Paper Out

condition by loading more paper into the unit.

Paper Low The Paper Low sensor is located in the paper well. It determines when the paper stack has

approximately 14 tickets remaining. A Paper Low condition automatically resets once a

stack with a greater height is loaded. Paper low sensing occurs when the system is idle

and takes a few seconds to detect the new paper level.

Paper Taken The Paper Taken sensor is located in the presentation chute of the printer. It determines

when the customer has actually taken their cashout ticket.

Drawer Open The Drawer Open sensor is located in the paper well. It detects when the printer is open.

Platen

Engaged

Printer Open The Printer Open sensor is located in the front of the unit. It detects when the printer

The Platen Engaged sensor is located in the print head. It detects when the printer

platen is in use.

clamshell is open.

Table 2-3 describes each of these sensors.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 3 of 29 12/06/2007

MNL-000030 REV.X07

Page 8

Operators and Technicians Manual

Printer Errors

Although there are a variety of error conditions that can occur, most printer errors are a result of the

printer running out of paper or the operator opening the lid.

remedy for each condition.

Table 2-4 Errors and Error Descriptions

Error Error Description Remedy

Paper Out Results when the printer does not detect paper present. Load a new paper stack.

Head Up or

Open

Temperature Results when the printer is operating outside of its allowable

Voltage Results if the printer detects a power supply voltage

Print Head Results when the printer senses an internal error due to

Missing Black

Index Mark

Paper Jam Results when the printer detects an error in the paper path

Results from raising the head release lever or opening

the lid.

temperature range.

If the printer is operating in an environment where the

ambient temperature is roughly room temperature, this error

would most likely be the result of a hardware problem.

(+24VDC to +25VDC) outside range.

This error could be the result of a poor cable connection.

connectivity or interfacing problem with the thermal print

head. This can be a result of a cable problem between the

main controller board and the printer engine.

Results if the paper type selected is indexed paper and while

feeding paper or printing a black mark is not seen within

approximately 10” of the paper.

This error alerts the user to the presence of the wrong kind

of paper in the printer or that the paper was inserted in

the wrong direction (so the black mark index is rotated

180 degrees).

for presenting the ticket to the customer.

Table 2-4 lists possible errors and the

Lower the blue lever on the side

of the unit.

The printer will automatically

resume operation after the

detected head temperature falls

within range.

The printer will automatically

resume operation after the

power supply is detected

within range.

The printer will remain in this

error state until the power is

cycled or the unit is reset.

If the problem persists, the

printer will require service.

Raise the head release lever

(presumably to change the

paper).

Open the printer head and

inspect for a jammed ticket.

Loading Paper

Generally, the only printer service required is to load new paper stacks. Use the automatic

paper-loading feature to simplify this process to two steps: putting the paper stack into the Paper

Tray and feeding the paper to the Paper Loading Slot of the printer.

To load paper:

1. Pull open the Printer Drawer until the Paper Tray is completely accessible.

2. Place the paper stack in the printer as indicated by the band around the stack and the label on

the bottom of the Paper Tray.

Tip: To prevent a new paper stack from sticking together, fan out the paper after you take

off the band.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 4 of 29 12/06/2007

MNL-000030 REV.X07

Page 9

r

g

Paper Tray

Operators and Technicians Manual

Black Index

Mark

Figure 2-2 Load a Paper Stack

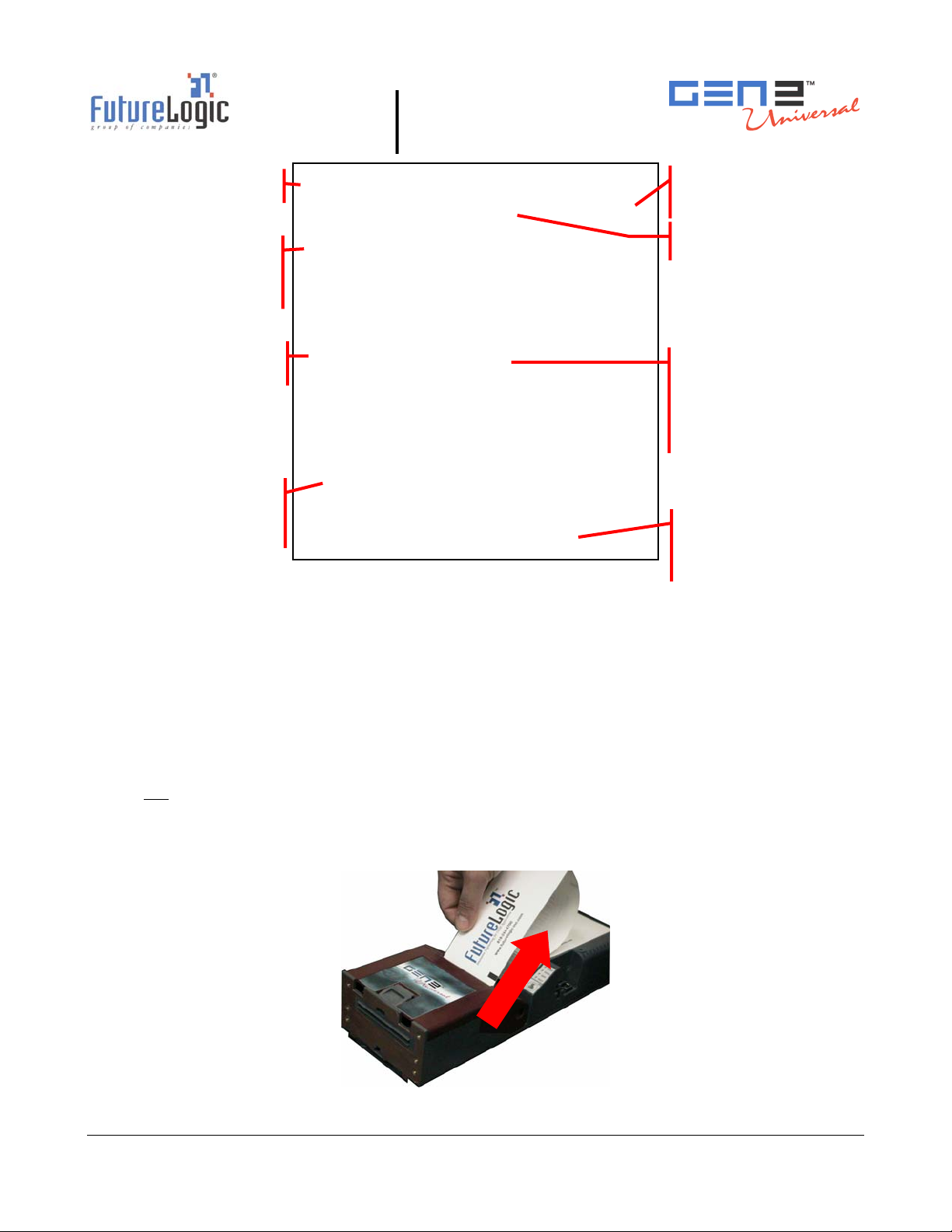

3. Feed the paper into the Paper Loading Slot and release it once the motor engages and the printer

takes hold of the paper.

The printer automatically pulls through a form or two, leaving it registered at the top of a form.

Pape

Loadin

Slot

Figure 2-3 Feed Paper into Paper Loading Slot

4. Remove any excess ticket(s) from the printer.

Feeding Paper

The printer is designed to run with black mark indexed paper.

Use the FEED button to feed paper into printer. Press the FEED button to advance the paper to the

top of the next form.

Performing a Self Test

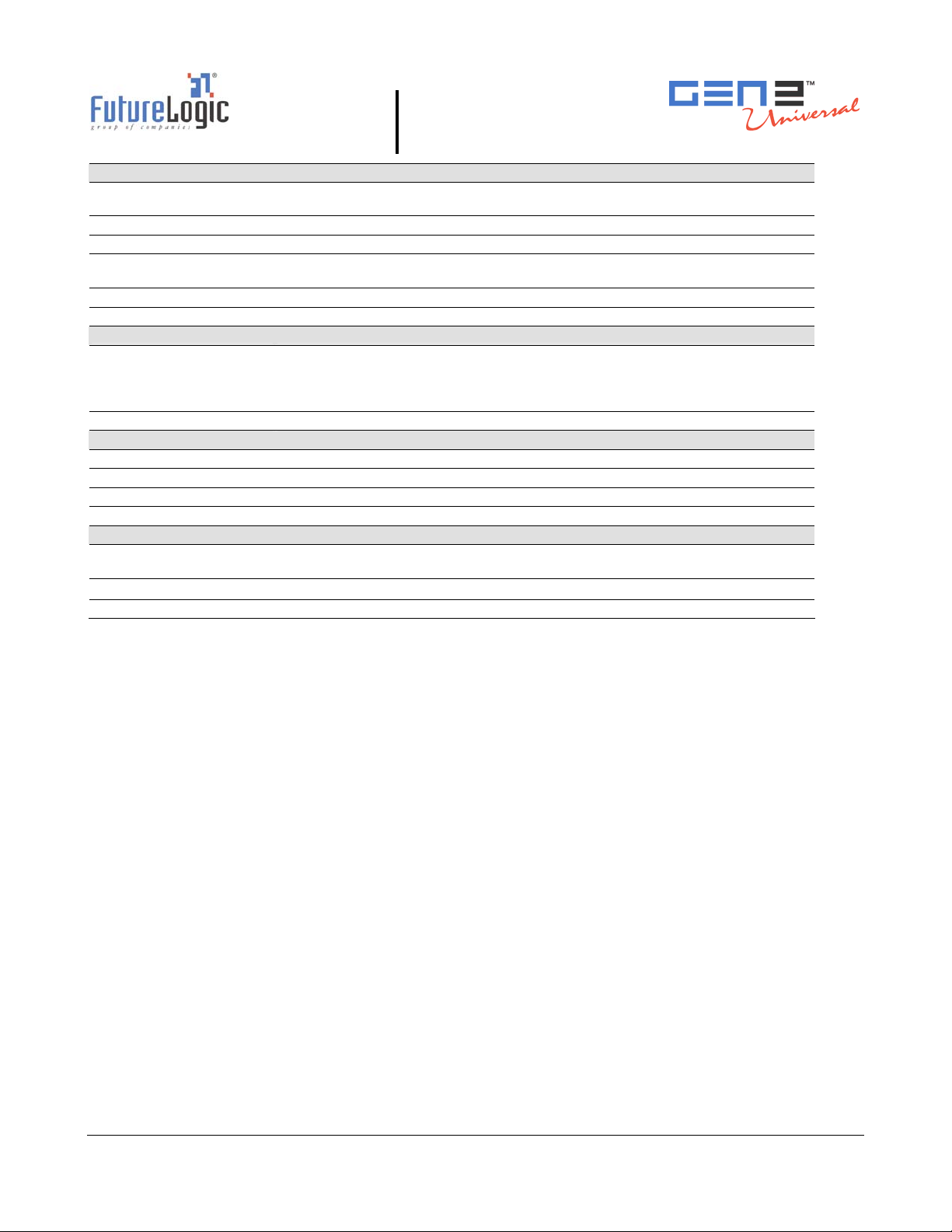

Press the FEED button during power up or reset to run a self test. This self test prints a

configuration ticket if the test passes successfully. The test ticket (illustrated in

important information on how the unit is configured.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 5 of 29 12/06/2007

MNL-000030 REV.X07

Figure 2-4) contains

Page 10

r

Model numbe

communications

Print Control Parameters

Listing of stored

Templates, Print

Regions and Graphics

Operators and Technicians Manual

System

setup

Model: PSA-66 USB REV A

Firmware: GUU0010432 2006-05-17

COMMUNICATION

Interface: USB 2.0 Full Speed

PRINT CONTROL

Darkness Control: +0.0

Black Bar Index: Enabled

Print On Demand: Disabled

Auto Sleep Timer: Off

SYSTEM RESOURCES

FLASH -Used: 000000

-Free: 065536

LIBRARY INVENTORY

Templates: 0,1,2,3,4,5,6,7,8,9,A,B,z,x

Print Regions: 1,2,3,4,5,6,7,8,h,9,A,B,

C,D,E,F,G,I,J,K,L,N,O,P,

Q,R,S,T,U,Z,X,a,b,c,d,e,

f,g,i,j,k,l,m,n,o,p,q,z,x

Graphics:

Fonts: 1,2,3,4,5,7,8,9

Resident ticket template

package version

Firmware version

Amount of memory

available for user-defined

font and graphics storage is

indicated by the “Free”

space.

List of fonts available

in the printer by TCL

page mode

Figure 2-4 Sample Configuration Ticket

Clearing a Paper Jam

The printer is designed to operate reliably with minimal paper jamming. If you need to clear a paper

jam, follow the instructions below. After you clear a paper jam, perform these steps in reverse to

load paper.

When clearing a paper jam:

• Ensure that all paper paths from the entry point at the back of the paper well, through the

printer, cutter, and the ticket module chute are clear of paper or obstructions.

• Use the Lid Release Lever located on the top of the unit.

• Do not

cause permanent damage to the printer.

To clear a paper jam:

1. Remove the paper from the printer.

allow a screwdriver or other probing object to come in contact with the printer. This can

Figure 2-5 Remove the Paper

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 6 of 29 12/06/2007

MNL-000030 REV.X07

Page 11

r

r

Operators and Technicians Manual

2. Open the lid by pressing the Lid Release Lever.

The spring-loaded lid opens, exposing the paper path.

Lid Release

Leve

Figure 2-6 Open the Lid

3. Remove the jammed ticket.

If necessary, access the paper path through the print mechanism by opening the

Mechanism Release Lever.

Mechanism

Release Leve

Voucher Path

Figure 2-7 Clear the Paper Jam

4. Once you clear the jam, reverse these steps to return the printer to a ready state.

5. Load the paper.

Cleaning the Print Head

To clean the print head, use canned air to blow out the paper particles. Then use a lint-free cloth or

cotton swab with isopropyl alcohol to clean the print head.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 7 of 29 12/06/2007

MNL-000030 REV.X07

Page 12

Operators and Technicians Manual

3 Printer Service

Introduction

This chapter provides instructions on how to remove the printer to service it outside of the game.

Note: While the printer is hot connectable, it is still a good maintenance procedure to turn

off the power.

Important Information!

Do not remove the ground screw in the rail as it will release the internal nut!

After removing the printer, do not

cause damage to the copper grounding clips on the bottom of the unit.

slide the unit on a tabletop or other surface. Doing so will

Ticket

Output

Ground Screw

Figure 3-1 Ground Screw and Copper Grounding Clips Location

Copper Grounding Clips

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 8 of 29 12/06/2007

MNL-000030 REV.X07

Page 13

r

Removing the Printer

CAUTION!

ESD Sensitive Equipment!

Electronic boards and their components are sensitive to static electricity. Care must be

taken during all handling operations and inspections of this product in order to ensure

product integrity at all times.

Do not handle this product out of its protective enclosure while it is not used for operations

purposes unless it is otherwise protected.

Discharge your clothing before touching the assembly. Discharge tools before use.

Whenever possible, unpack or pack this product only at EOS/ESD safe workstations. Where

a safe workstation is not guaranteed, it is important for the user to be electrically

discharged before touching the product with his/her hands or tools.

To remove the printer from the game:

1. Disconnect the power.

2. Disconnect the Coiled Cable Connector.

CAUTION! The cable is under tension.

Operators and Technicians Manual

Coiled Cable

Connecto

Figure 3-2 Disconnect the Coiled Cable Connector

3. Pull the printer out of the game until it locks.

Figure 3-3 Slide the Printer until It Locks

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 9 of 29 12/06/2007

MNL-000030 REV.X07

Page 14

Operators and Technicians Manual

4. Remove the paper from the printer.

Figure 3-4 Remove the Paper

5. Push the Front Locking Bar unit to unlock the sliding module from stationary module.

Slide the drawer module completely out of the stationary module.

Figure 3-5 Front Locking Bar

6. Push the Release Bar (located on the bottom of the unit).

While holding in the Release Bar, gently pull the printer towards you.

Figure 3-6 Push Release Bar

Front

Locking

Bar

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 10 of 29 12/06/2007

MNL-000030 REV.X07

Page 15

2 3

Operators and Technicians Manual

4 Ports

Introduction

This chapter describes the interface connectors and port pin-outs for the printer. For complete

electrical specifications on these ports, refer to Appendix A in the Developers Manual

(MNL-000029) for the power connector.

Note: While PSA-66-ST2 refers to all models of the printer, the content of this manual is

primarily for the Netplex/USB interface of the GEN2 Universal printer (PSA-66-ST2NU). For

additional information on the Netplex and USB interfaces, please contact IGT.

Front Bezel Port

Bezel LED Control Port

1

Connector: Molex Micro-Fit 43640-0301

Mate: Molex Micro-Fit 43645-0300

Figure 4-1 Front Bezel LED Control Port

Table 4-1 lists information on the LED bezel port on the printer. This is an open drain

modulated high side drive 25VDC port capable of driving up to a maximum 1.5A.

Table 4-1 Front Bezel LED Control Port Pins

Pin Function

1 Switched 25VDC, 100mA Min

2 BGND

3 Frame (Chassis) Ground

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 11 of 29 12/06/2007

MNL-000030 REV.X07

Page 16

PSA-66-ST2NU (GEN2 Universal Printer)

USB/Netplex Interface Cable

Base Port

Connector: Molex 43025-1800

Mate: Molex 43045-1812

Operators and Technicians Manual

Bezel LED Control Port

Connector: Molex Mini-Fit Jr. 39-01-4037

Mate: Molex Mini-Fit Jr. 39-01-4031

Figure 4-2 USB/Netplex Interface Cable

Netplex Port

Connector: Molex Mini-Fit Jr. 39-01-3089

Mate: Molex Mini-Fit Jr. 39-01-2085

USB Port (Series A)

USB/Netplex Cable P/N 150-00109-100

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 12 of 29 12/06/2007

MNL-000030 REV.X07

Page 17

Table 4-2 Base Port Cable Pin-outs

Pin Function

1 RAW BGND

2 D3 +13V

4 SWITCHED 24V

5 DTR 232

6 MRESET

7 D+

8 RAW 24V

9 RTS 232

10 RX2/SCL

11 TX2/SDA

12 RX1/232

13 TX1 232

14 TX1 NET

15 RX1 NET

16 OPTO GND

17 DGND

18 +9 – 14V

Operators and Technicians Manual

Table 4-3 Netplex Port Pin-out

Pin Function

1 MRESET

2 RX1 NET

3 +13V

4 TX1 NET

5 OPTO GND

6 +24V

7 GND

8 NO CONNECT

Table 4-4 USB Port Cable Pin-outs

Pin Function

1 USB BUS SUPPLY

2 D3 D+

4 GND

Table 4-5 Bezel LED Control Port Pin-out

Pin Function

1 SWITCHED 24V

2 NO CONNECT

3 GND

Firmware Upload Port

The Firmware Upload Port upgrades the printer firmware while the printer is still installed and

powered in the game. The printer uploads through its Firmware Upload Port just as it would

through its communications connector at the rear of the printer.

To use this port, slide the printer out until the upload port (shown in the following figure) is

visible. Then plug an appropriate upgrade cable into the printer. This connection may be made

while the power is on.

Firmware Upload Port

Connector: Molex 6717101-000

Figure 4-3 Firmware Upload Port

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 13 of 29 12/06/2007

MNL-000030 REV.X07

Mate: USB B Plug

Page 18

Operators and Technicians Manual

Appendix A Technical Specifications

This appendix identifies the general specifications of the printer.

General

Dimensions (WxDxH) 110 x 304.8 x 64.3 mm

Weight 2.7 lbs.

Power Requirements 24VDC @ 2.7A avg. (4.0A peak with 60% gaming ticket)

Sensors Paper Low, Paper Out, Printer Drawer Open, Ticket Taken, Ticket Jam, Ticket

in Chute, Black Mark

(Includes a Host Controllable Buzzer)

Printing Speed 90mm/Second (3.5”/Second)

Print and Present 2.2 Seconds

Printing Width 62mm (true near-edge printing)

Storage 300 Tickets

Ticket Tray Extenders Interchangeable, 600, 900 Ticket Tray

Resolution 8 dots/mm (203 dpi)

Firmware Application in Memory is Reprogrammable (via Flash BIOS)

Self Test Yes

Page Mode Full Page Mode Printing (Simultaneous 4 Orientation Printing:

0°, 90°, 180°, 270°)

Line and Box Draw Printer Resident

Bitmap Graphics

Printer Resident (Stored in Flash) Graphics

Paper Loading Automatic Hands Free

Paper Feed Manual

Method Direct Thermal, Top Coated, Fanfolded and Perforated

Width 64mm

Length 156mm

Thickness 4.5 mil, 1 Color/2 Colors

Bezel Control Two High Current Ticket Printing Bezel Control Ports

User Interface 4 LED Indicators, Paper Advance Button

Update Port Allows for Printer Upgrades via Handheld Download Tool

Hot Swappable 100%

Printing Resources

Template Capacity 8Mb; Stores hundreds of clip art objects & thousands of graphic templates

Graphic Storage 6Mb

Color Printing Red on Black and Blue on Black are available. Other colors can be supported

as the print media becomes available. Color selection is controlled through

the TCL language.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 14 of 29 12/06/2007

MNL-000030 REV.X07

Page 19

Characteristics

Printer Languages TCL Printer Language (Page Description Language)

Subset of ESCP2

Fonts 8 (2.5 cpi, 3.3 cpi, 4.0 cpi, 5.5 cpi, 5.6 cpi, 7.3 cpi, 10.1 cpi, 20.5 cpi)

Font Scalability May Be Independently Scaled from 1x – 7x in Both Height and Width

Bar codes Interleaved 2 of 5, Code 39, UPC-A, UPC-E, UPC-E+2, UPC-E+5, Codabar,

EAN-13, EAN-8, Code 128, MSI

Memory

Interface

Communications USB 2.0 game interface (full speed of 12Mbps) with separate

Environmental

Operating temperature 0°C to 65°C

Storage temperature -20°C to 75°C

Operating humidity 5 to 95% RH

Reliability

Maintenance No User Maintenance Required

Print Head Life 50km Min. (320,000 Tickets Based on US Currency Size)

Certifications CE Certified, ISO 9001, RoHS

2MB with 512K RAM

USB Download Port, Future GSA Compliant,

Compliant with IGT Gaming Machines

A Traditional Game Communication Port (Netplex)

Printer Completely Removable with Quick Release Bar

Operators and Technicians Manual

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 15 of 29 12/06/2007

MNL-000030 REV.X07

Page 20

Operators and Technicians Manual

Appendix B Paper Specifications

This appendix provides information on the paper used in the printer. For authorized ticket

converters and complete paper specifications, contact your sales representative or visit our Web

site:

www.futurelogic-inc.com.

Note: Use only approved paper in the printer. Use of improper paper may cause

damage to the device and will void the printer’s warranty.

Nominal paper thickness: 4.5mil

Paper dimensions: 65mm x 156mm (width dimension +

Ticket Stack

Ticket, 300STK, 65X156, 5M, Fanfold

Ticket, 600STK, 65X156, 5M, Fanfold

Ticket, 900STK, 65X156, 5M, Fanfold

Note: Paper width is +0mm, –1mm.

1mm

Figure B-1 Ticket Dimensional Specification

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 16 of 29 12/06/2007

MNL-000030 REV.X07

Page 21

Operators and Technicians Manual

Appendix C Part Numbers – Printer/Spares

This appendix provides the part number and description of the GEN2 Universal printers and

spares.

Printers – P/N Description

220-00046-101 GEN2 Universal Printer (RoHS)

PSA-66-ST2NU

USB, NETPLEX,

IGT Compliant, Future GSA

Compliant*

*Netplex equipped printers meet the Netplex specification of International Game Technology

Corporation. For additional information, please contact IGT.

Spares – P/N Description

370-00015-100 Base RoHS

RoHS Versions—Look

for either of these

labels:

370-00018-100

150-00032-100

150-00045-100

150-00109-100 Cable, USB-Netplex, 18 pin RoHS

Bottom Chute RoHS

Cable, Coiled, Netplex RoHS

Cable, Display Adapter RoHS

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 17 of 29 12/06/2007

MNL-000030 REV.X07

Page 22

Spares – P/N Description

370-00021-100 Floating Part RoHS

370-00024-100 Hinge RoHS

370-00025-100 Hinge Pin RoHS

500-00005-100 Keypad Membrane RoHS

362-00047-105 Lid, Label, USB/Netplex RoHS

Operators and Technicians Manual

370-00020-101 Lid, Top, Red RoHS

370-00022-100 Locker RoHS

370-00023-100 Locker Base RoHS

370-00016-100 Main Bracket RoHS

140-00099-100

Paper Taken Sensor Board RoHS

140-00074-001

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 18 of 29 12/06/2007

MNL-000030 REV.X07

PCBA P9-GEN2 Mother Board RoHS

Page 23

Spares – P/N Description

460-00005-100 Platen Shaft Assembly RoHS

350-00031-102 Power Supply RoHS

400-00007-100 Print Mech, F03-66 RoHS

310-00112-100 Release Bar Bracket RoHS

310-00115-100 Release Bar Guide RoHS

Operators and Technicians Manual

460-00006-100 Roller Idler RoHS

473-00078-100 Screws (100 pack) RoHS

485-00008-100 Spring (50 pack) RoHS

370-00026-100 Spring Plate RoHS

482-00012-100 Star Washers (100 pack) RoHS

320-00224-103 Ticket Extension Tray, 600 Tickets RoHS

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 19 of 29 12/06/2007

MNL-000030 REV.X07

Page 24

Spares – P/N Description

320-00224-104 Ticket Extension Tray, 900 Tickets RoHS

370-00019-100 Top Presenter RoHS

370-00017-100 Tray, Paper RoHS

Operators and Technicians Manual

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 20 of 29 12/06/2007

MNL-000030 REV.X07

Page 25

Operators and Technicians Manual

Appendix D Schematics

The schematics included in this appendix are provided solely for use by technicians who service the

GEN2 Universal printer. This information is provided AS IS and without warranty, expressed or

implied.

Note: The information contained in the following schematics is copyrighted information and is

the exclusive intellectual property of FutureLogic, Incorporated. All rights are reserved. No

transfer or grant of rights is created by the publication of this information.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 21 of 29 12/06/2007

MNL-000030 REV.X07

Page 26

Operators and Technicians Manual

This information is copyrighted material and is the exclusive intellectual property of FutureLogic, Incorporated. All rights are reserved.

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 22 of 29 12/06/2007

MNL-000030 REV.X07

Page 27

Index

B

bezel, 3

LED control port, GEN2 Universal, 11

black mark indexed paper, 5

C

clearing a paper jam, 6

coiled cable connector, 9

configuration ticket, 5

controls, 2

D

Drawer Open sensor, 3

E

errors

Head Up, 4

Missing Black Index Mark, 4

Paper Jam, 4

Paper Out, 4

Print Head, 4

Temperature, 4

Voltage, 4

F

FEED button, 2, 5

Firmware Upload Port, 13

Front Locking Bar, 10

G

GEN2 Universal

bezel LED control port, 11

firmware upload port, 13

specifications, 14

H

Head Up error, 3, 4

I

indicators, 2

L

LEDs, 3

Operators and Technicians Manual

lid release lever, 2

M

mechanism release lever, 7

Missing Black Index Mark error, 3, 4

N

Netplex/USB interface cable, GEN2 Universal, 12

P

paper

capacity, 1

feeding, 5

specifications, 16

Paper Jam

clearing, 6

error, 3, 4

Paper Low sensor, 3

Paper Out

error, 3, 4

sensor, 3

Paper Taken sensor, 3

Platen Engaged sensor, 3

ports

bezel LED control, GEN2 Universal, 11

firmware upload, 13

Print Head

cleaning, 7

Print Head error, 3, 4

printer

part numbers, 17

removing, 9

specifications, 14

Printer Open sensor, 3

R

release bar, 10

removing the printer, 9

S

schematics, 21

self test, 5

sensors, 3

Drawer Open, 3

Paper Low, 3

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 23 of 29 12/06/2007

MNL-000030 REV.X07

Page 28

sensors (continued)

Paper Out, 3

Paper Taken, 3

Platen Engaged, 3

Printer Open, 3

spares, part numbers, 17

status

conditions, 3

indicators, 2

T

TCL Editor, 1

Temperature error, 3, 4

Operators and Technicians Manual

test ticket, 5

ticket dimensional specifications, 16

U

USB/Netplex interface cable, GEN2 Universal, 12

V

Voltage error, 3, 4

W

warranty information, 1

© 2006 – 2007 FutureLogic, Incorporated. All Rights Reserved. MNL Page 24 of 29 12/06/2007

MNL-000030 REV.X07

Page 29

FutureLogic, Inc.

425 East Colorado Street • Suite 100

Glendale, CA 91205 USA

Phone 818.244.4700 • Fax 818.244.4764

www.futurelogic-inc.com • info@futurelogic-inc.com

Loading...

Loading...