Page 1

MCT-MC 4.3 User Manual

MCT-MC 4.3 User Manual Rev. A

February 2018

Page 2

Safety Information in this Manual

Notes, cautions and warnings appear throughout this book to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” appears with information that is important for protecting your equipment and insuring

performance.

A “WARNING” appears with information that is important for protecting you, others and equipment from

damage. Pay very close attention to all warnings that apply to your application.

This symbol (an exclamation point in a triangle) precedes a general CAUTION or WARNING

statement.

This symbol (a lightning bolt in a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your MC controller, review all of your configuration information to verify that

your selections are consistent with your application: inputs; outputs; alarms; limits; etc. If the problem persists

after checking the above, you can get technical assistance by dialing +1 (866) 342-5332 or by faxing your

request to +1 (866) 332-8014, Monday thru Friday, 8:00 a.m. to 5:00 p.m. Eastern Standard Time. You can

also email your request to support@futuredesigncontrols.com.

An applications engineer will discuss your application with you.

Please have the following information available:

• Complete Model #’s and/or Serial #’s for Component(s) in Question

• Complete Software Version #’s

• All Configuration Information

• All User Manuals

Warranty and return information is on the back cover of this manual.

Comments

Your comments or suggestions on this manual are welcome. Please send them to:

Future Design Controls, P.O. Box 1196, Bridgeview, Illinois, 60455

Telephone: +1 (888) 751-5444; fax: +1 (888) 307-8014

csr@futuredesigncontrols.com

The MCT-MC User Manual is copyrighted by Future Design Controls, Inc., © 2018, all rights reserved.

Page 3

MCT-MC 4.3

1 What is the MCT-MC? .................................................................................................. 7

1.1 Features ............................................................................................................................... 7

2 Installation .................................................................................................................... 9

2.1 Enclosure Guidelines ............................................................................................................ 9

2.1.1 Locating the MC Touch Screen Interface ......................................................................................... 9

2.2 Environmental Considerations ............................................................................................ 10

2.3 Mounting Dimensions ......................................................................................................... 10

2.3.1 MC Touch Screen Interface ............................................................................................................ 10

2.3.2 MC Process Loop Controls ............................................................................................................. 12

3 Wiring .......................................................................................................................... 13

3.1 Power Requirements .......................................................................................................... 13

3.1.1 Installing the Power-On Delay Relay .............................................................................................. 13

3.2 Connecting to the MCT-MC Interface ................................................................................. 15

3.2.1 Process Loop Controller Communications ..................................................................................... 16

3.2.2 Connecting to the Process Loop Controls ...................................................................................... 17

3.2.3 User Serial Communications .......................................................................................................... 17

4 Configuring the MCT-MC ........................................................................................... 19

4.1 Control Setup ..................................................................................................................... 21

4.2 Loop Address Utility ............................................................................................................ 21

4.3 Loop Configuration ............................................................................................................. 22

4.3.1 Tagname ......................................................................................................................................... 23

4.3.2 Input Type ....................................................................................................................................... 23

4.3.3 Input Units ....................................................................................................................................... 23

4.3.4 Decimal Point.................................................................................................................................. 24

4.3.5 Input Low/High Scale ...................................................................................................................... 24

4.3.6 Input Filter ....................................................................................................................................... 24

4.3.7 Event Input Function ....................................................................................................................... 24

4.3.8 Event Input Alarm Message ........................................................................................................... 26

4.3.9 Low/High Limit Setpoint .................................................................................................................. 26

4.3.10 Output 1 Function ........................................................................................................................... 26

4.3.11 Output 1 Failure Transfer ............................................................................................................... 27

4.3.12 Output 1 ON-OFF Control Hysteresis ............................................................................................ 27

4.3.13 Output 1 Cycle Time ....................................................................................................................... 27

4.3.14 Output 1 Low/High Limit Values ..................................................................................................... 27

4.3.15 Output 2 Function ........................................................................................................................... 28

4.3.16 Output 2 Failure Transfer ............................................................................................................... 29

4.3.17 Output 2 Low/High Limit Values ..................................................................................................... 29

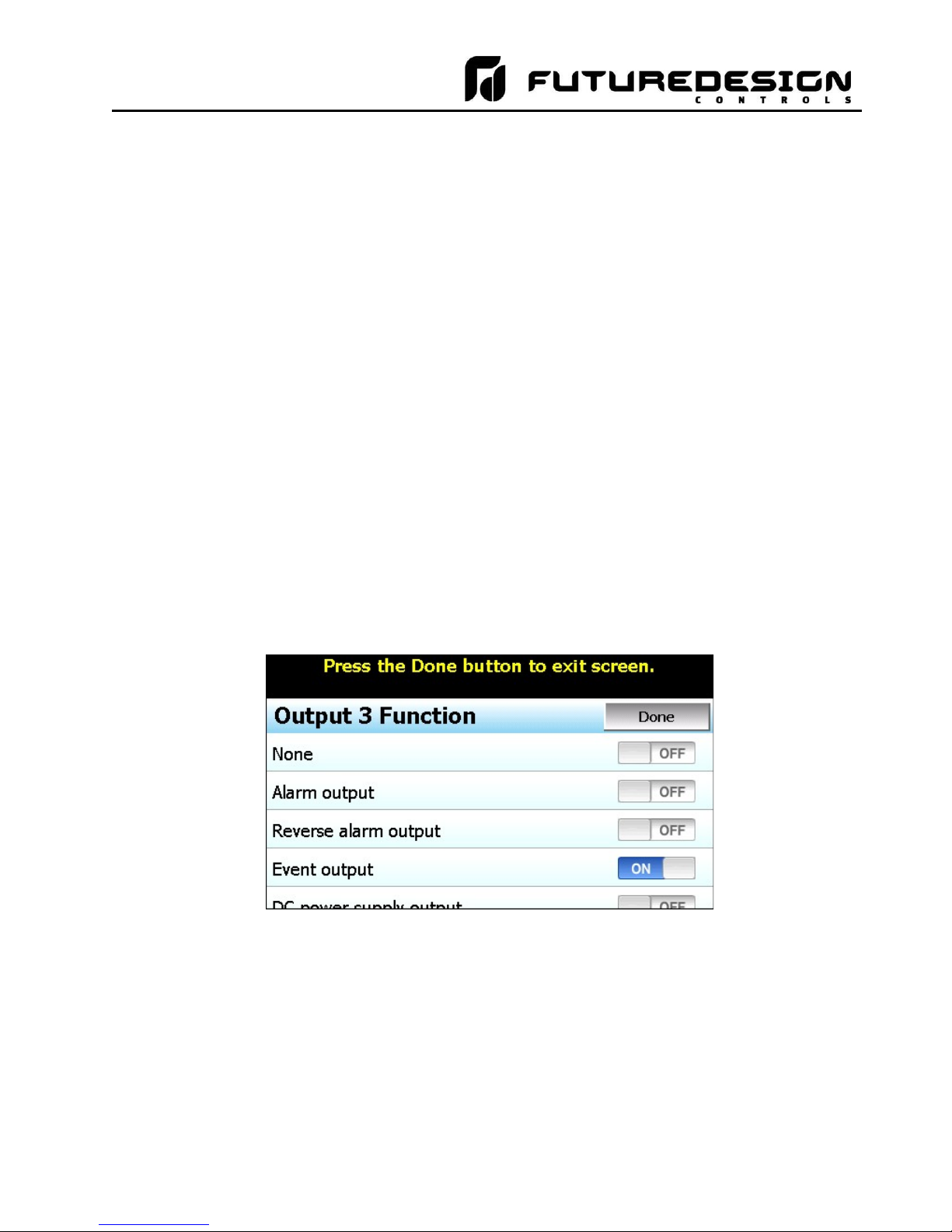

4.3.18 Output 3 Function ........................................................................................................................... 29

4.3.19 Output 3 Failure Transfer ............................................................................................................... 30

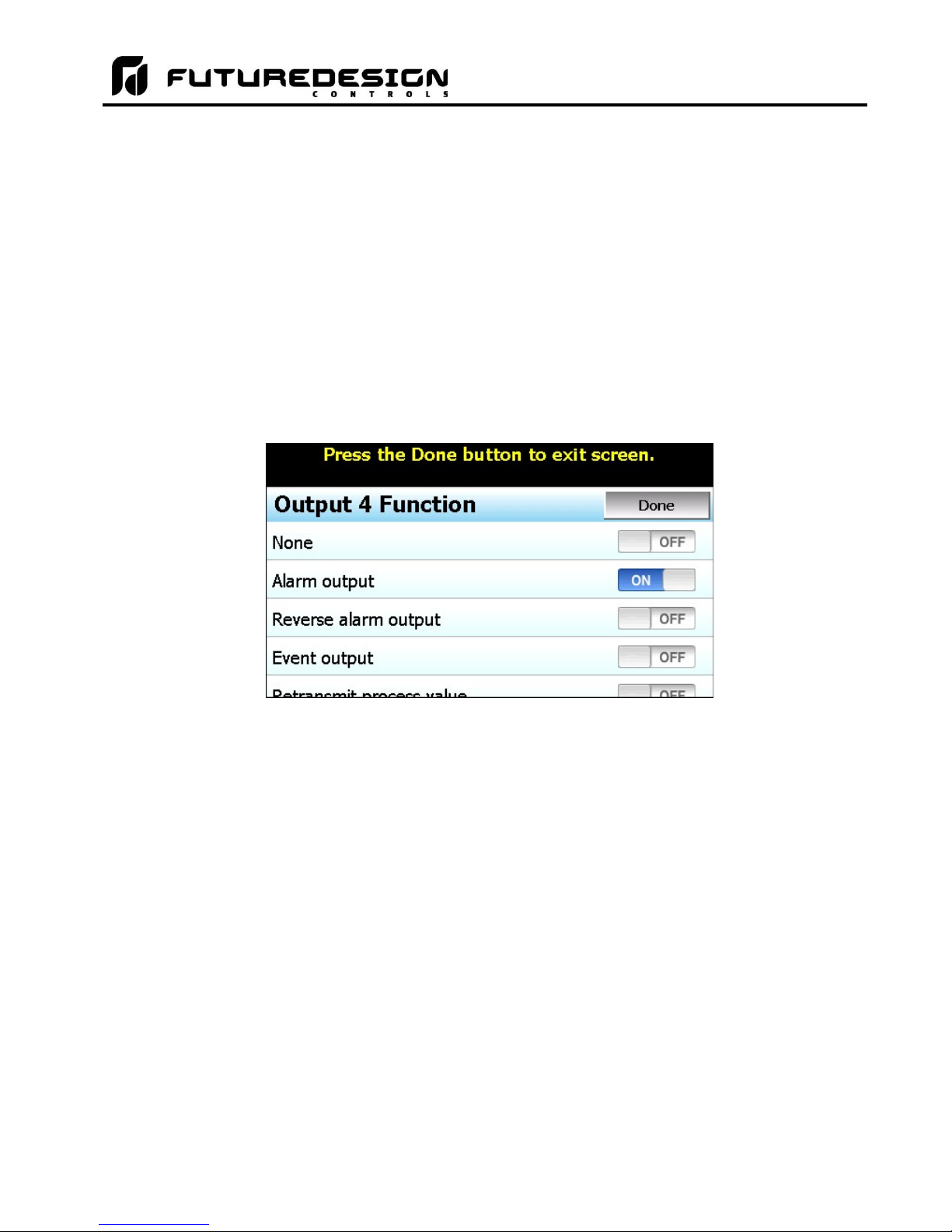

4.3.20 Output 4 Function ........................................................................................................................... 30

4.3.21 Output 4 Failure Transfer ............................................................................................................... 30

4.3.22 Output 4 Low/High Limit Values ..................................................................................................... 31

4.3.23 Output 4 Retransmit Low/High Scale ............................................................................................. 31

4.3.24 Alarm (1-3) Function ....................................................................................................................... 31

4.3.25 Alarm (1-3) Mode ............................................................................................................................ 32

4.3.26 Alarm (1-3) Indication ..................................................................................................................... 33

4.3.27 Alarm (1-3) Setpoint ....................................................................................................................... 33

4.3.28 Alarm (1-3) Hysteresis .................................................................................................................... 34

4.3.29 Setpoint at Start of Automatic Program .......................................................................................... 34

4.3.30 Setpoint at End of Automatic Program ........................................................................................... 35

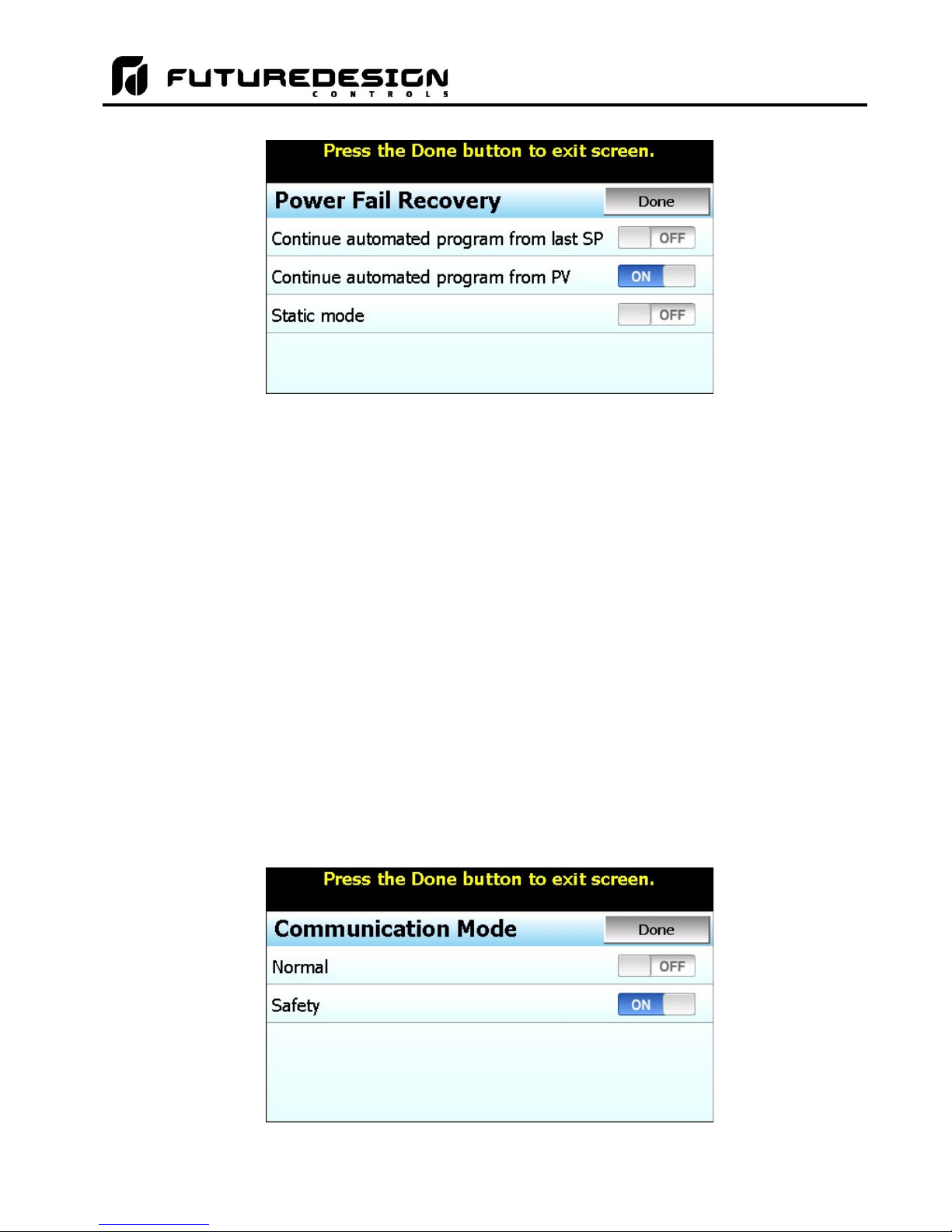

4.3.31 Power Fail Recovery ...................................................................................................................... 35

Table of Contents - 3 - FDC MC

Page 4

MCT-MC 4.3

4.3.32 Communication Mode ..................................................................................................................... 36

4.3.33 Monitor Only Mode ......................................................................................................................... 37

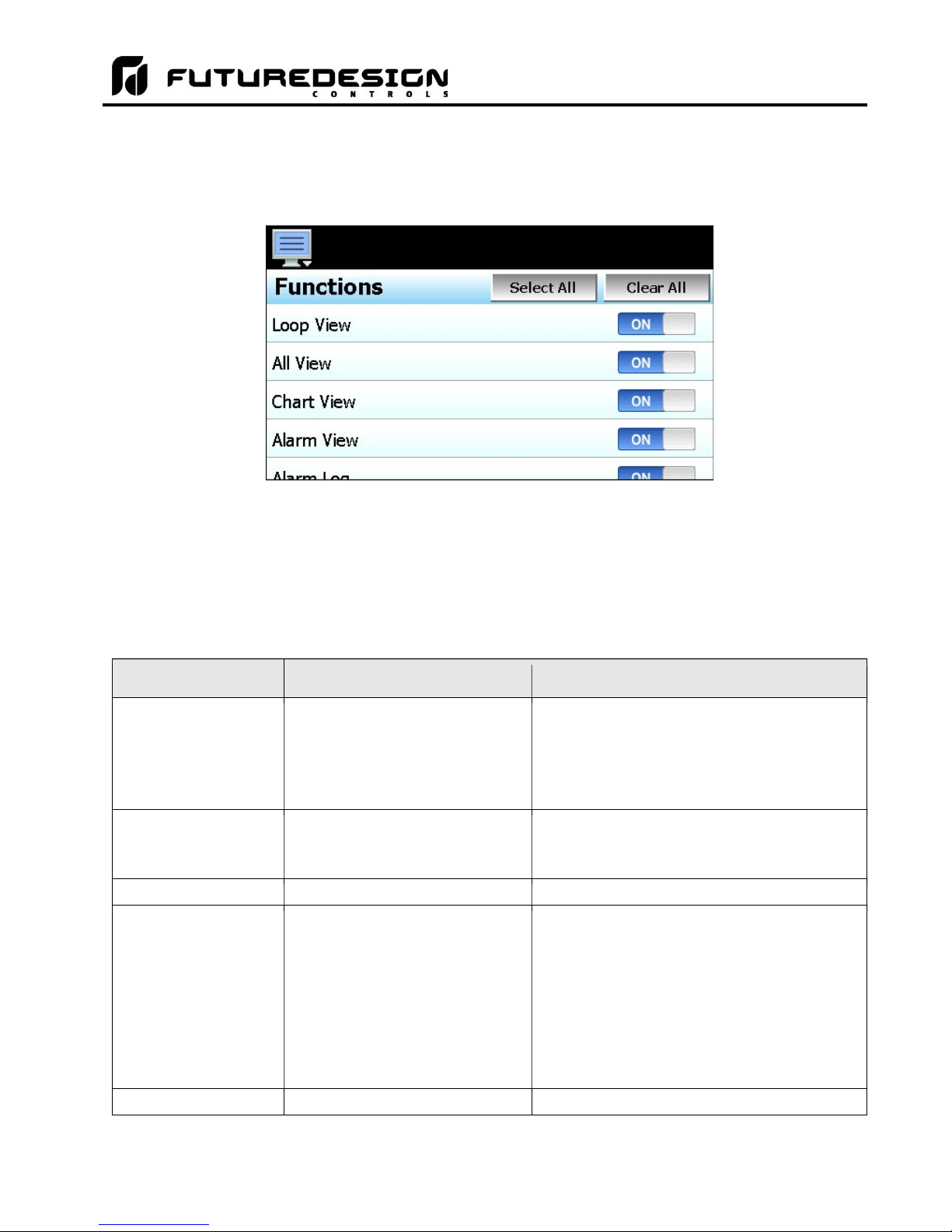

4.4 Functions ............................................................................................................................ 38

4.5 Startup View ....................................................................................................................... 41

4.6 Alarm Names ...................................................................................................................... 41

4.7 Event Names ...................................................................................................................... 42

4.8 Custom Name\Address ...................................................................................................... 42

5 Basic Operation .......................................................................................................... 43

5.1 OEM Configuration Options ................................................................................................ 43

5.1.1 Loop Control Monitor Only Mode.................................................................................................... 43

5.2 Touch Screen Interface ...................................................................................................... 44

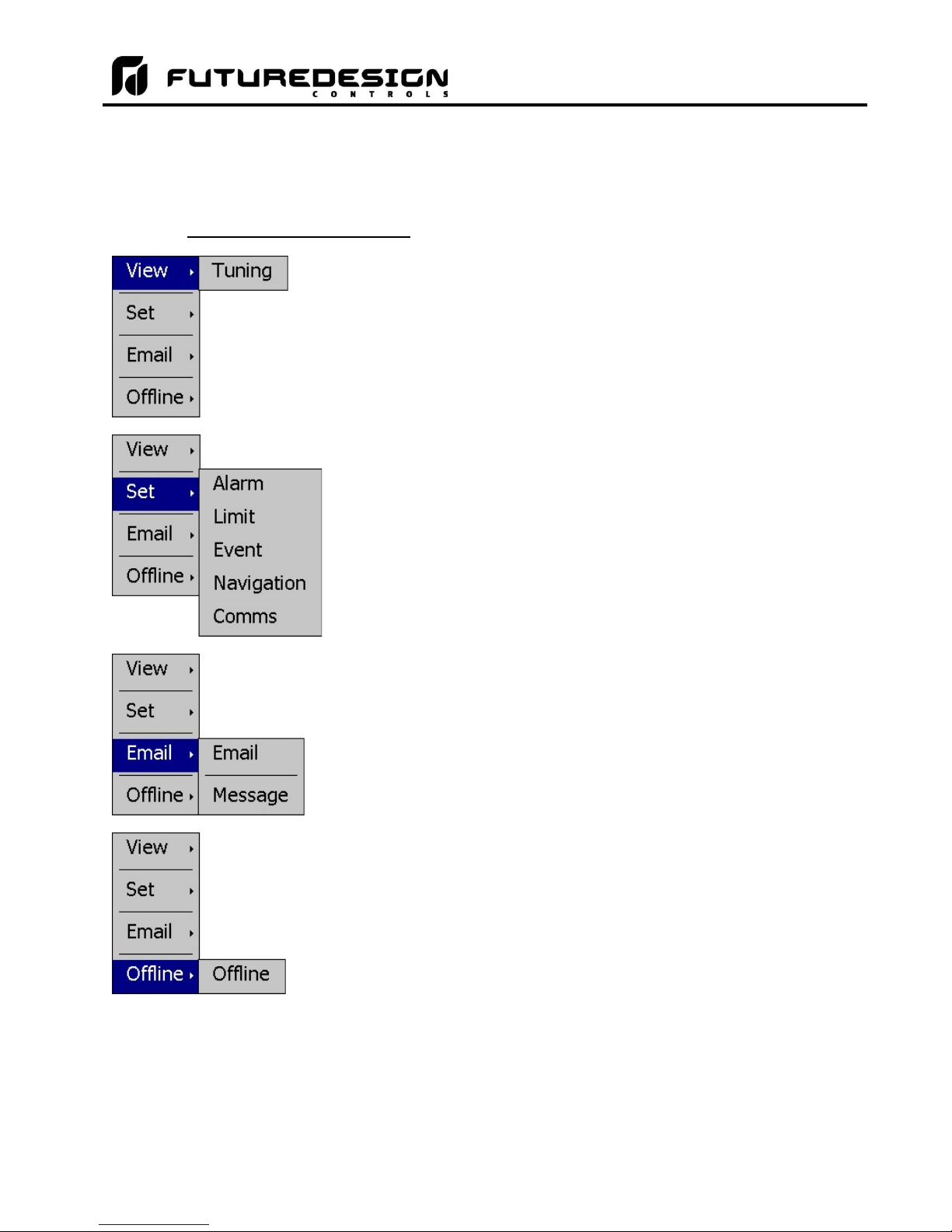

5.3 Menu Navigation ................................................................................................................ 45

5.3.1 Home Menu .................................................................................................................................... 46

5.3.1.1 Text Based Home Menu ......................................................................................................................... 46

5.3.1.2 Icon/Slide Page Based Home Menu ....................................................................................................... 47

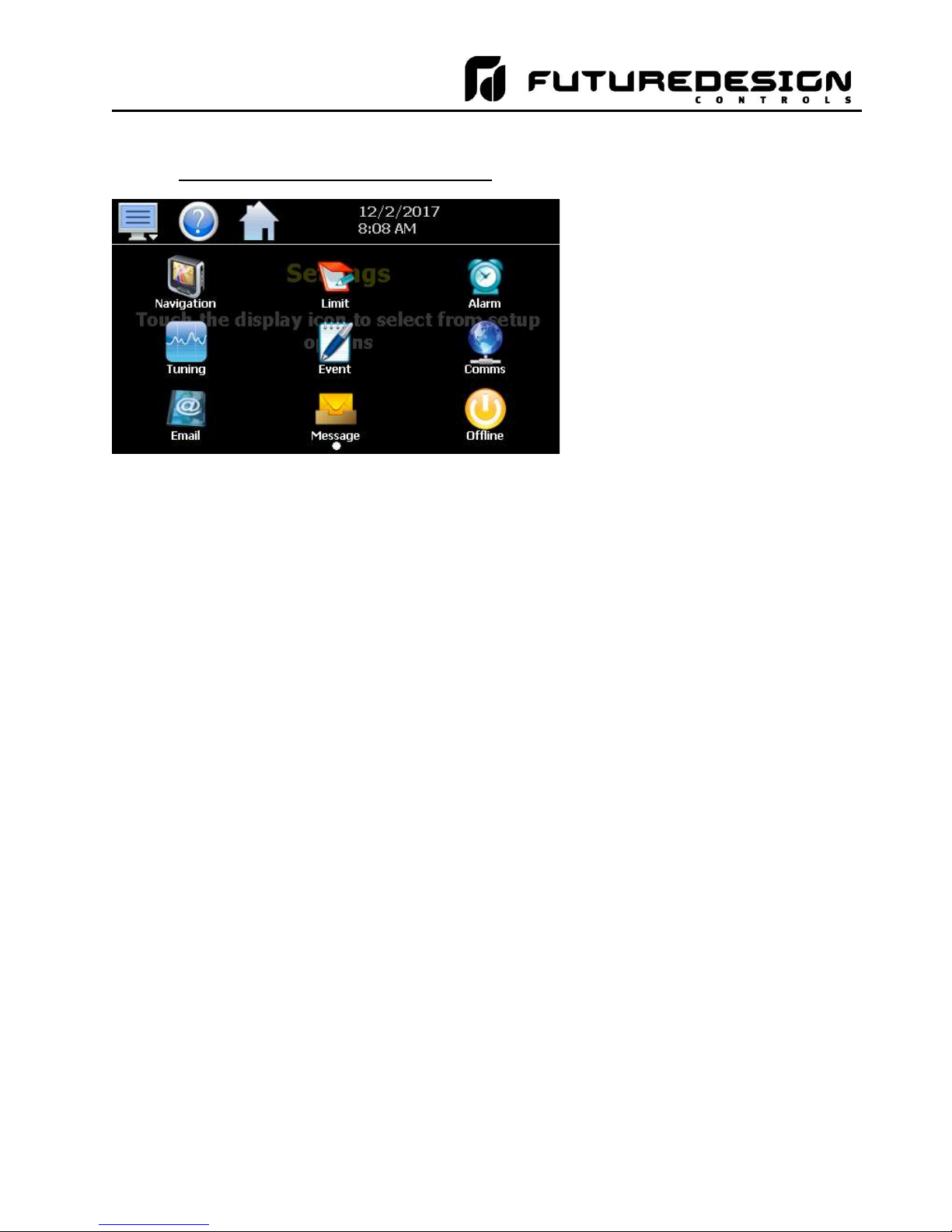

5.3.2 Device Settings Menu ..................................................................................................................... 48

5.3.2.1 Text Based System Setup Menu ............................................................................................................ 48

5.3.2.2 Icon/Slide Page Based Device Settings Menu........................................................................................ 49

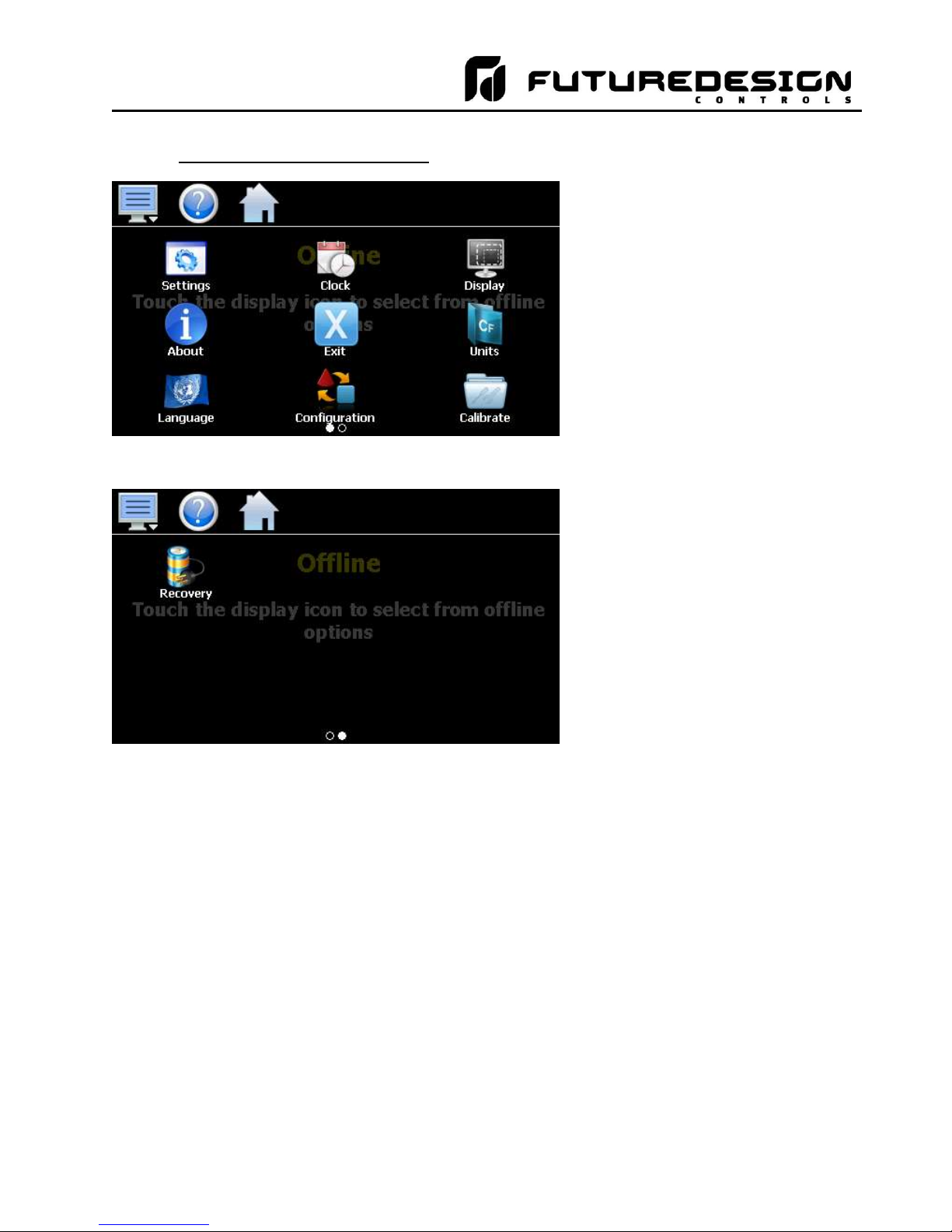

5.3.3 Offline Menu ................................................................................................................................... 50

5.3.3.1 Text Based Offline Setup Menu .............................................................................................................. 50

5.3.3.2 Icon/Slide Page Based Offline Menu ...................................................................................................... 51

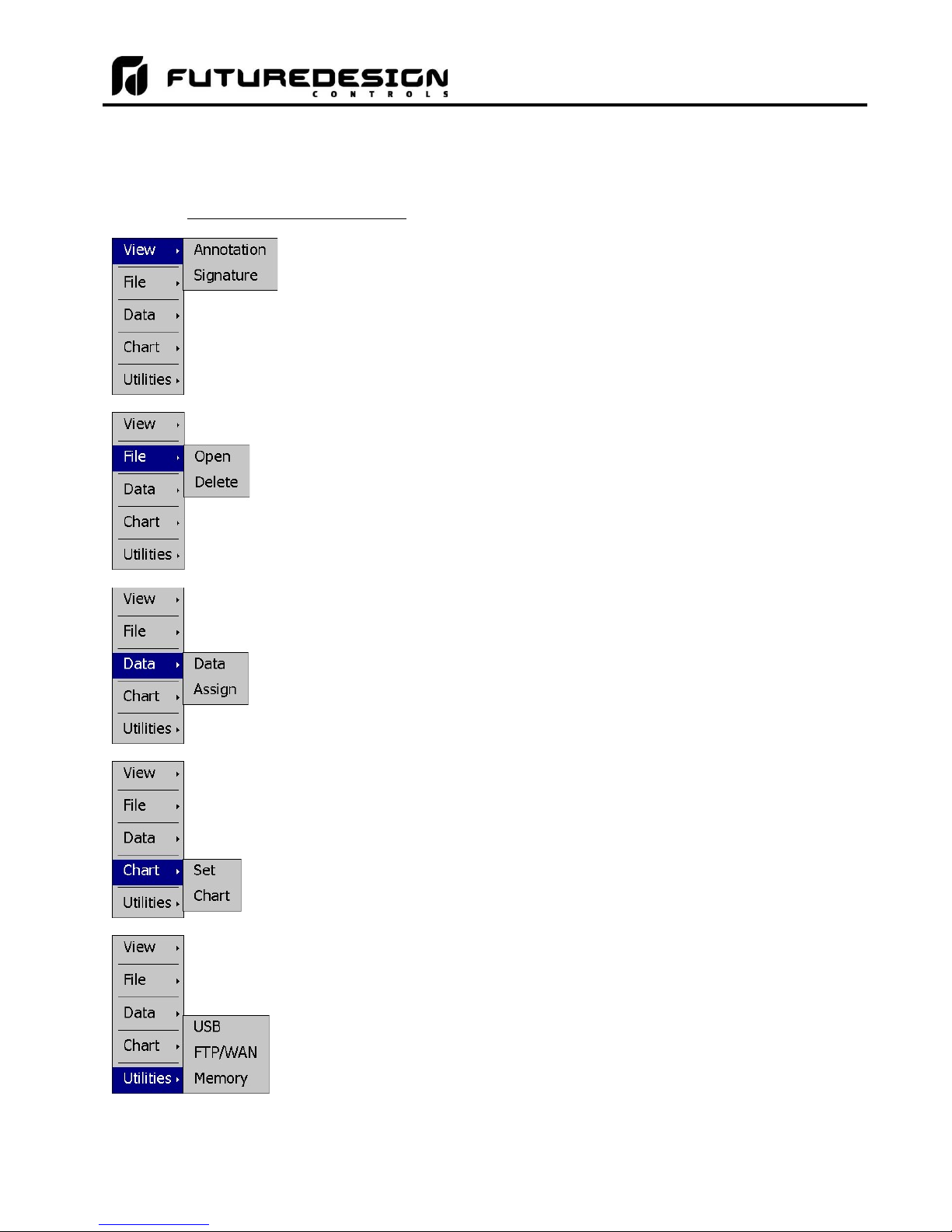

5.3.4 Data Menu ...................................................................................................................................... 52

5.3.4.1 Text Based Data Logging Menu ............................................................................................................. 52

5.3.4.2 Icon/Slide Page Based Log Menu .......................................................................................................... 53

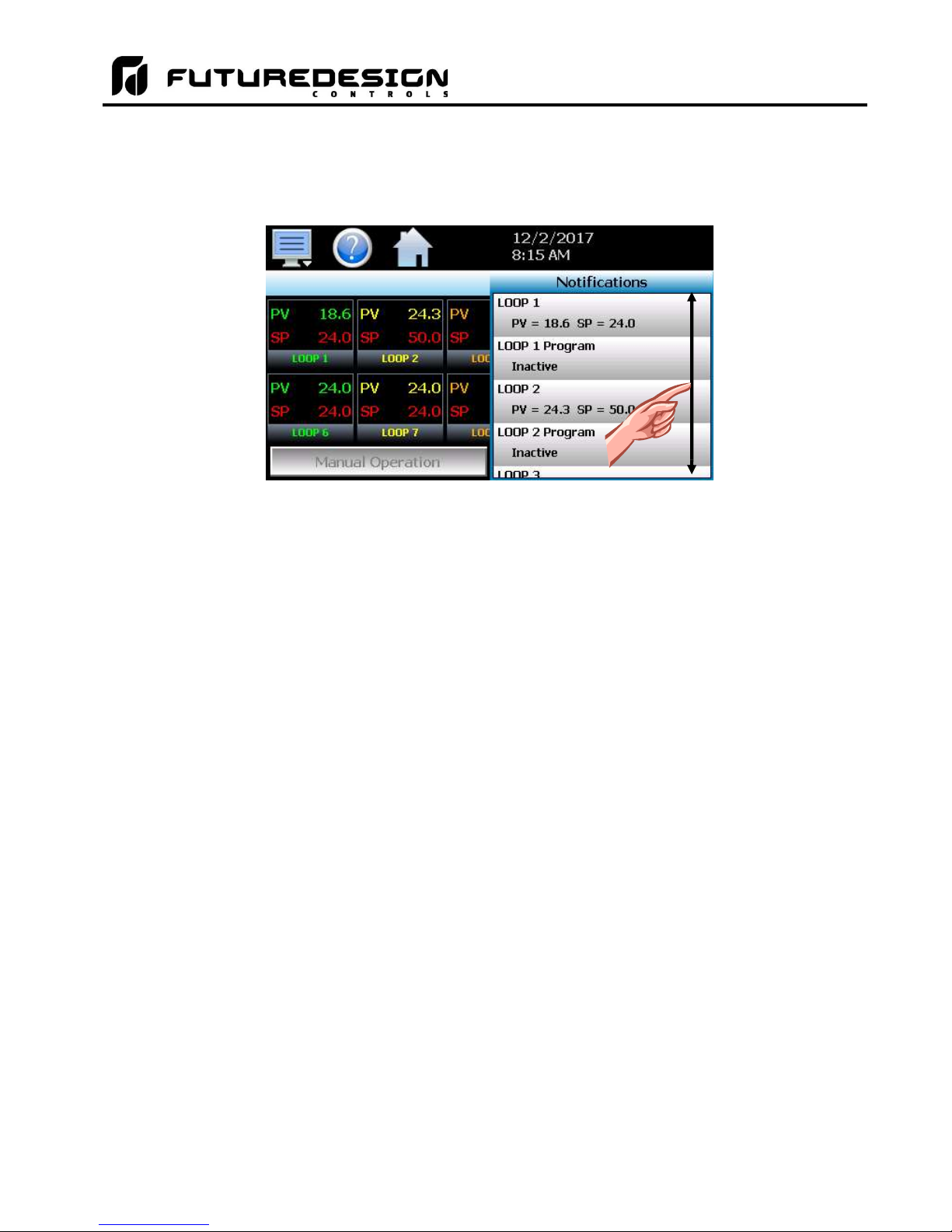

5.4 Notifications ........................................................................................................................ 54

5.5 Control Loops (Single Set point Operation) ........................................................................ 55

5.5.1 Loop View ....................................................................................................................................... 55

5.5.1.1 Historical Minimum and Maximum .......................................................................................................... 56

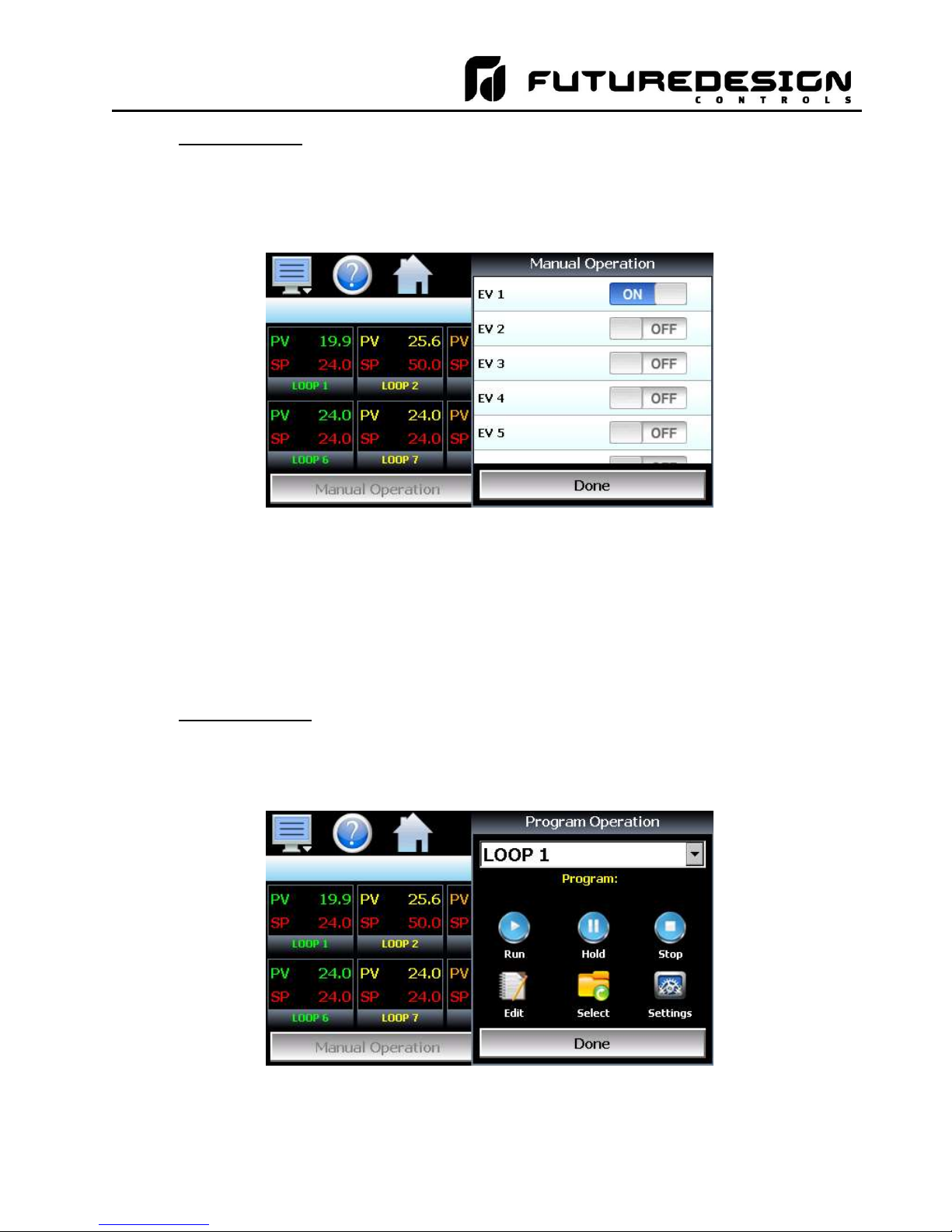

5.5.1.2 Manual Operation ................................................................................................................................... 57

5.5.1.3 Program Operation ................................................................................................................................. 57

5.5.2 Overview Screen ............................................................................................................................ 58

5.6 Process Monitoring ............................................................................................................. 59

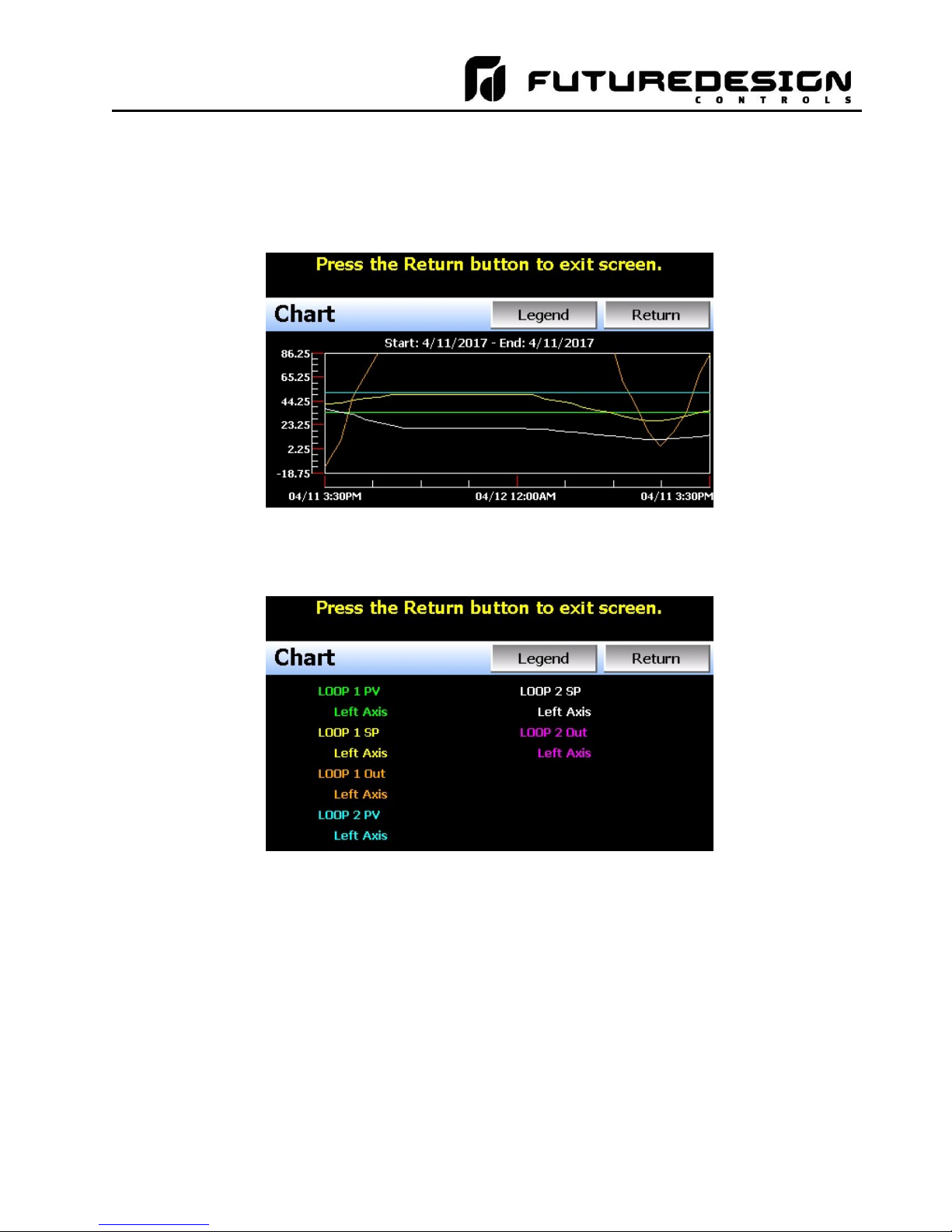

5.6.1 Charts ............................................................................................................................................. 59

5.6.1.1 Chart Setup ............................................................................................................................................ 60

5.7 System Alarms ................................................................................................................... 61

5.7.1 Alarm Monitor ................................................................................................................................. 61

5.7.2 Alarm File ........................................................................................................................................ 62

6 Automatic Ramp/Soak Program Operation ............................................................. 63

6.1 Entering a Ramp/Soak Program ......................................................................................... 64

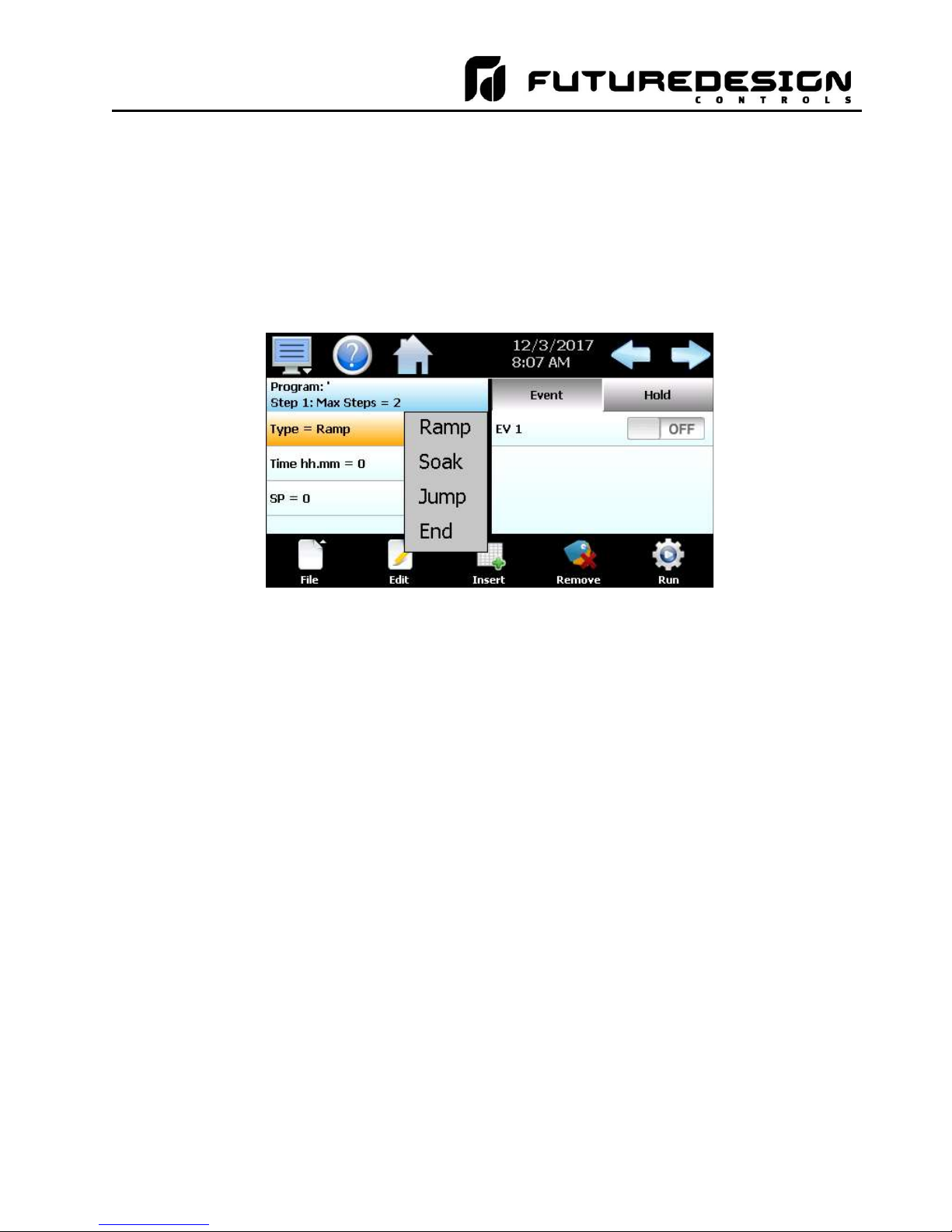

6.1.1 Setting Step Type ........................................................................................................................... 65

6.1.2 Setting Step Set Point and Time .................................................................................................... 65

6.1.2.1 Ramp/Soak Time Units Selection ........................................................................................................... 66

6.1.3 Setting Step Events ........................................................................................................................ 67

6.1.4 Setting Hold Events ........................................................................................................................ 68

6.1.4.1 HoldBack Limits ...................................................................................................................................... 68

6.1.5 Setting Jump Steps ........................................................................................................................ 69

6.1.6 Setting the End Step ....................................................................................................................... 70

6.2 Starting an Automatic Ramp/Soak Program ....................................................................... 71

6.2.1 Hold/Resume Ramp/Soak Program Operation .............................................................................. 72

6.2.2 Program Mode Settings .................................................................................................................. 72

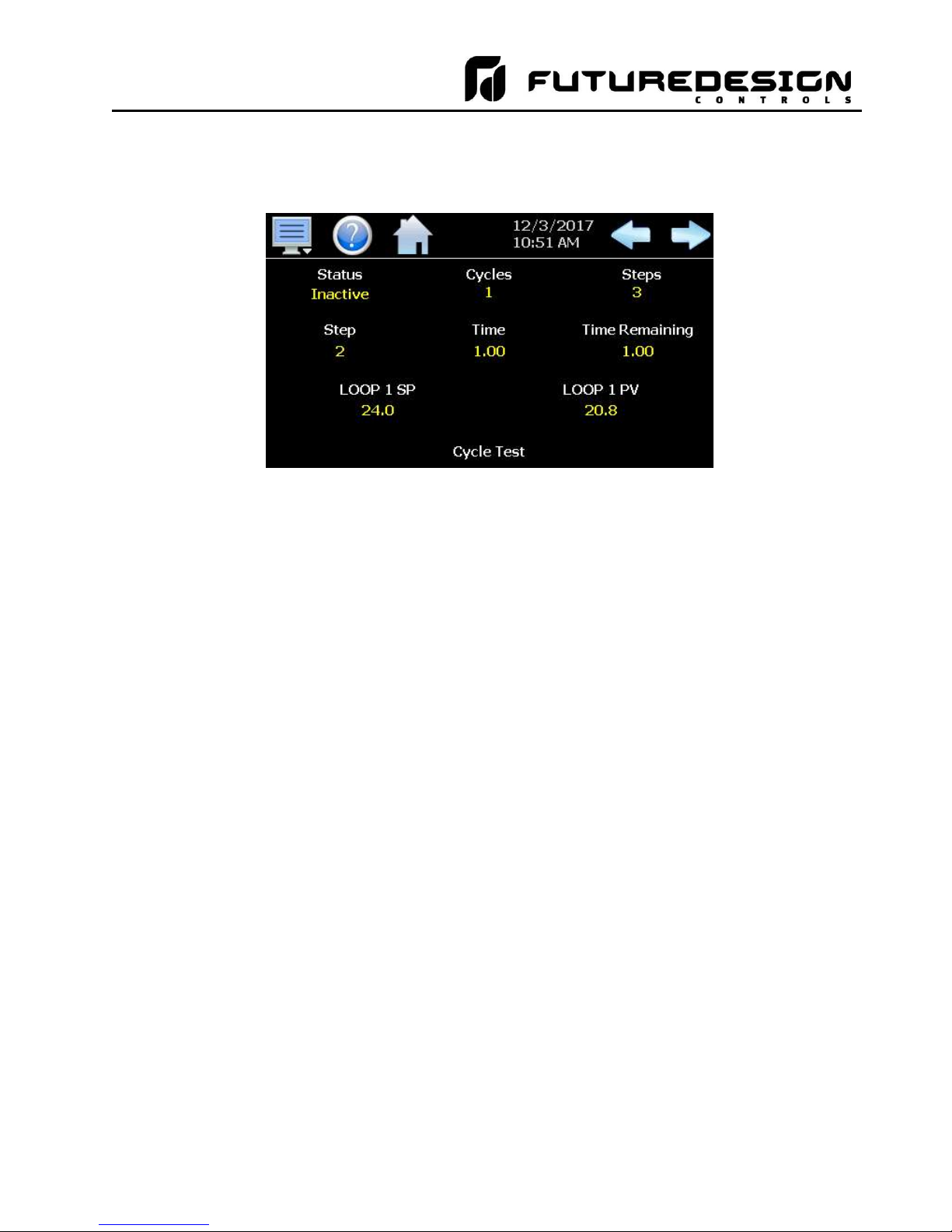

6.3 Monitoring Automated Ramp/Soak Program Operation ...................................................... 73

6.4 Common Questions About Ramp/Soak Program Operation ............................................... 74

7 Security ....................................................................................................................... 75

FDC MCT-MC - 4 - Table of Contents

Page 5

MCT-MC 4.3

7.1 Adding Users ...................................................................................................................... 76

7.2 Viewing Users .................................................................................................................... 76

7.2.1 New Password Entry ...................................................................................................................... 76

7.3 Setting User Access ........................................................................................................... 77

7.3.1 Security System User Access ........................................................................................................ 77

7.4 Setting Security Options ..................................................................................................... 79

7.5 Audit Trail ........................................................................................................................... 80

8 Data Logging .............................................................................................................. 81

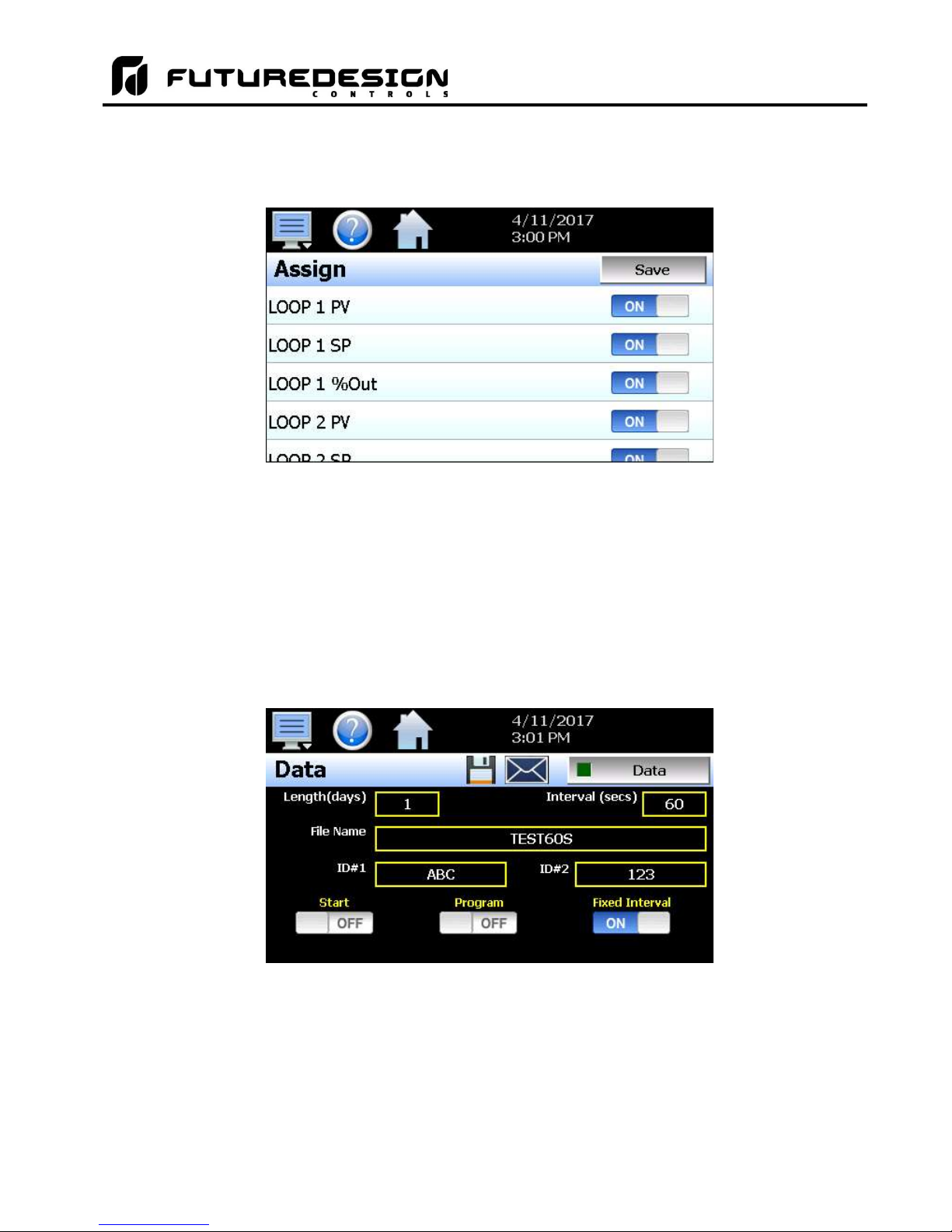

8.1 Selecting Points for Logging ............................................................................................... 82

8.2 Starting/Stopping Data Logging .......................................................................................... 82

8.2.1 Calculating Log File Size ................................................................................................................ 83

8.3 Reviewing Historical Data ................................................................................................... 84

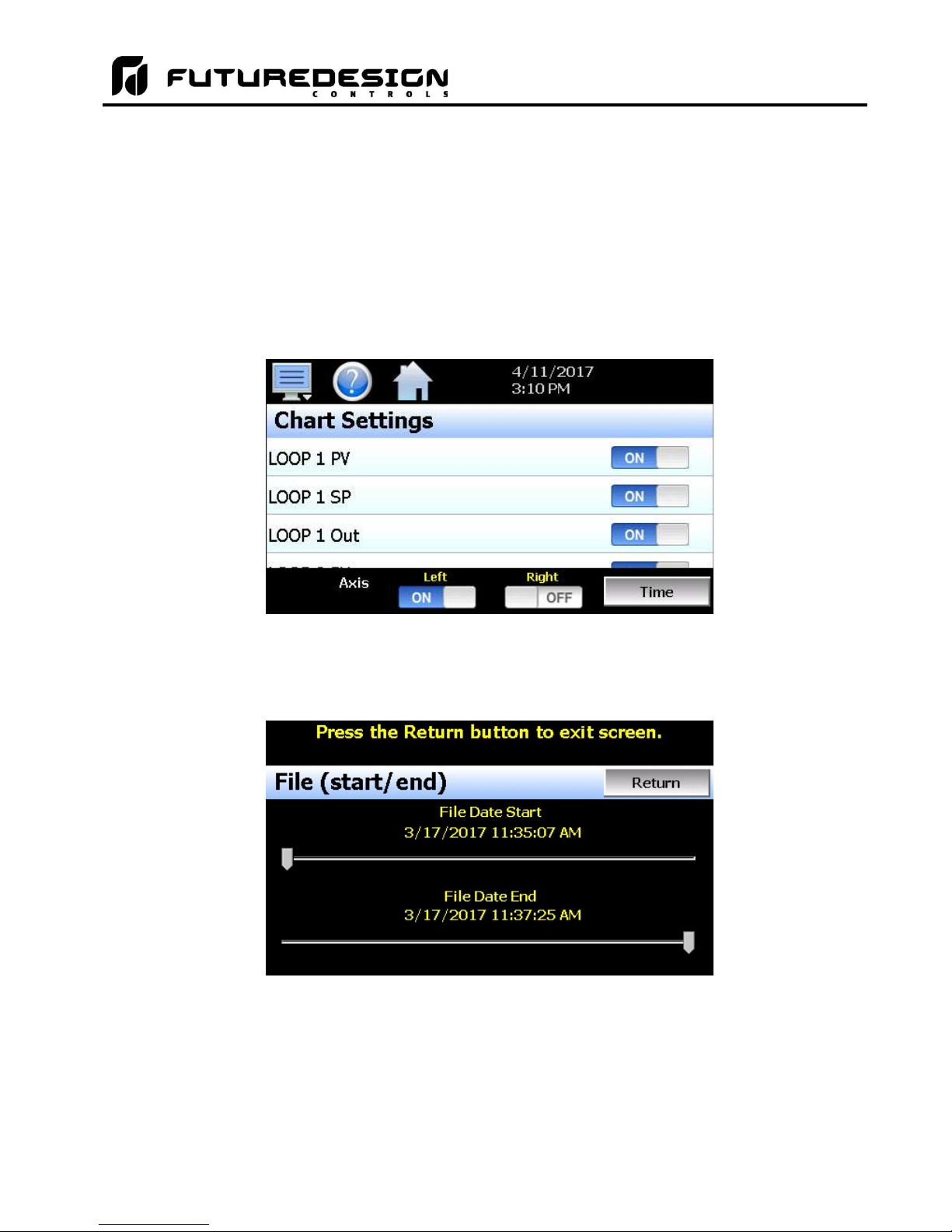

8.3.1 History Plot Setup ........................................................................................................................... 84

8.3.2 Plotting Historical Data ................................................................................................................... 84

8.4 USB File Transfer ............................................................................................................... 86

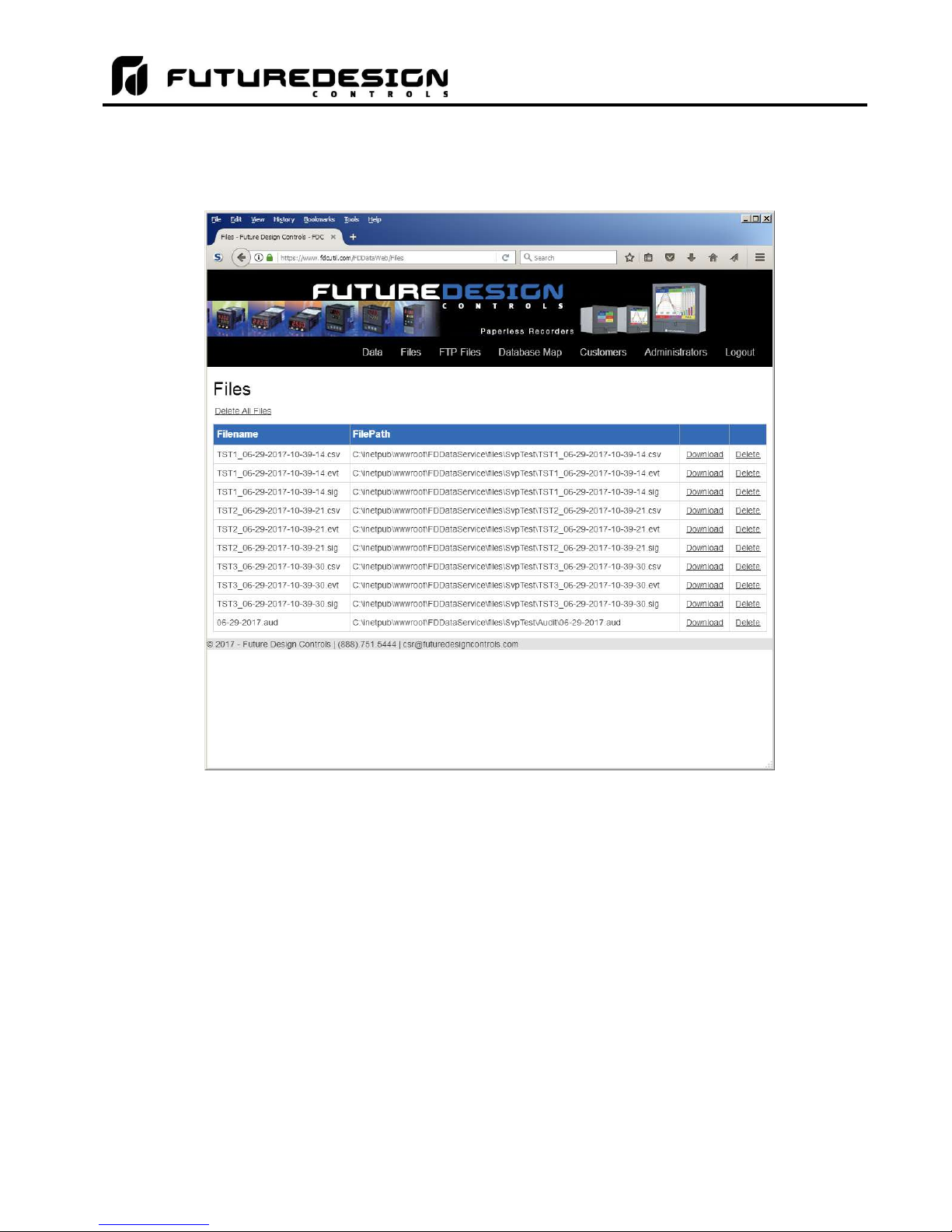

8.5 FTP/FileWeb/DataWeb Interface ........................................................................................ 88

8.5.1 More About FTP, FileWeb and DataWeb Interfaces ...................................................................... 89

8.5.2 FileWeb/DataWeb Server Components and Requirements. .......................................................... 91

8.6 FDCUtil.com Web site for FTP, FileWeb and DataWeb Testing.......................................... 92

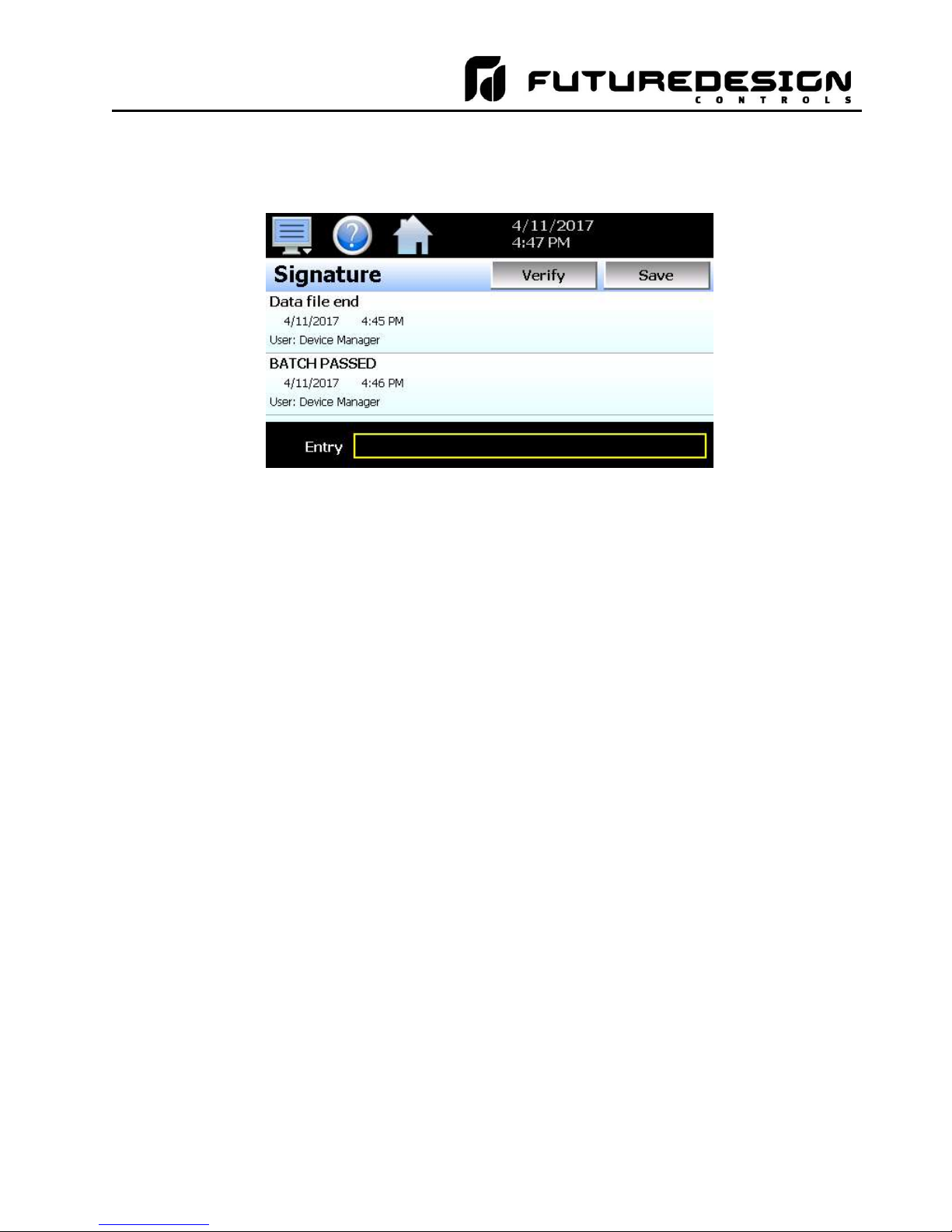

8.7 Annotation .......................................................................................................................... 98

8.8 Add\View Digital Signatures ............................................................................................... 99

9 Device Settings ........................................................................................................ 100

9.1 Tuning .............................................................................................................................. 101

9.1.1 Heat or Cool only P (or PD) Control ............................................................................................. 101

9.1.2 Heat/Cool (Bimodal) Control ......................................................................................................... 102

9.2 Alarms .............................................................................................................................. 102

9.3 Setpoint Limits .................................................................................................................. 103

9.4 Event Names .................................................................................................................... 104

9.5 Navigation ........................................................................................................................ 104

9.6 Communication Settings ................................................................................................... 105

9.7 Email ................................................................................................................................ 106

9.7.1 Email Address Entry ..................................................................................................................... 106

9.7.2 Email Addresses ........................................................................................................................... 106

9.7.3 Email Settings ............................................................................................................................... 107

9.7.4 Email Message ............................................................................................................................. 108

10 Offline ........................................................................................................................ 109

10.1 Power Recovery ............................................................................................................... 110

10.1.1 Recovery Interval .......................................................................................................................... 110

10.2 Degrees C/F Units Selection ............................................................................................ 111

10.3 Clock Settings .................................................................................................................. 111

10.3.1 Time Options ................................................................................................................................ 112

10.3.1.1 Local Time Server Settings................................................................................................................... 112

10.3.2 Daylight Savings ........................................................................................................................... 112

10.4 Language ......................................................................................................................... 113

10.5 Calibration ........................................................................................................................ 114

10.5.1 Loop Calibration Offset ................................................................................................................. 115

10.5.2 Manual (Factory) Calibration ........................................................................................................ 116

10.5.2.1 Thermocouple Input Calibration............................................................................................................ 116

10.5.2.2 RTD and Linear Input Calibration ......................................................................................................... 118

10.6 Display Settings ................................................................................................................ 120

10.6.1 Calibrate Touch ............................................................................................................................ 120

Table of Contents - 5 - FDC MC

Page 6

MCT-MC 4.3

10.6.2 Backlight Settings ......................................................................................................................... 121

10.7 Configuration .................................................................................................................... 122

10.7.1 Importing an OEM Default Configuration ..................................................................................... 123

10.8 About MCT-MC ................................................................................................................ 124

10.9 Exit Application ................................................................................................................. 125

11 Communications ...................................................................................................... 126

11.1 Ethernet Communications ................................................................................................ 126

11.1.1 Guide to Smart Networking Practices .......................................................................................... 126

11.1.2 Configuring the MC Network ........................................................................................................ 127

11.1.2.1 Obtaining the MC MAC Address ........................................................................................................... 127

11.1.2.2 Setting a Static IP Address ................................................................................................................... 129

11.1.3 Using the Web Server .................................................................................................................. 131

11.1.4 Using the VNC Server .................................................................................................................. 133

11.1.4.1 Recommended VNC Viewer Settings (PC/MAC) .................................................................................. 133

11.1.4.2 Recommended VNC Viewer Settings for Tablets ................................................................................. 135

11.1.4.3 Accessing the MC through a VNC Viewer ............................................................................................ 136

11.2 Serial Communications Option ......................................................................................... 138

12 Alarm Codes and Troubleshooting ........................................................................ 139

Appendix .......................................................................................................................... 141

A.1 Communications ............................................................................................................... 141

A.1.1 Explanation of Terms .................................................................................................................... 141

A.1.2 Serial Communications ................................................................................................................. 143

A.1.3 Interface Standards ...................................................................................................................... 144

A.1.4 Interface Converters ..................................................................................................................... 144

A.1.5 Protocol ......................................................................................................................................... 146

A.1.6 Creating Your Own Modbus Application ...................................................................................... 148

A.1.7 Packet Syntax ............................................................................................................................... 149

A.1.8 Error Checking .............................................................................................................................. 152

A.1.9 Transmitting and Receiving Messages ........................................................................................ 153

A.1.10 MCT-MC Loop Control Data Registers ........................................................................................ 155

A.1.10.1 Control Registers.................................................................................................................. 156

A.1.10.2 Automatic Program Registers .............................................................................................. 159

A.1.10.3 Starting an Automatic Program ............................................................................................ 162

A.2 FTP, FileWeb, DataWeb Requirements/Installation .......................................................... 164

A.2.1 Introduction ................................................................................................................................... 164

A.2.2 System Overview .......................................................................................................................... 164

A.2.3 System Requirements .................................................................................................................. 164

A.2.4 MySQL Installation ....................................................................................................................... 164

A.2.5 Website Installation ...................................................................................................................... 164

A.2.6 Data Transfer Service Installation ................................................................................................ 165

A.2.7 HTTP vs HTTPS ........................................................................................................................... 165

A.2.8 FTP Server ................................................................................................................................... 165

A.2.9 File Transfer Service Configuration (FileWeb) ............................................................................. 166

A.2.10 Database Transfer Service Configuration (DataWeb) .................................................................. 167

A.2.11 Database Field Map ..................................................................................................................... 167

A.3 Profile Recovery Detail ..................................................................................................... 170

A.4 Touch Screen Interface Specifications.............................................................................. 172

A.5 Power Supply Specifications ............................................................................................ 175

A.6 Power-On Delay Relay Specifications .............................................................................. 179

A.7 Ordering Specifications .................................................................................................... 181

A.8 Support and Warranty Information .................................................................................... 184

FDC MCT-MC - 6 - Table of Contents

Page 7

MCT-MC 4.3

1 What is the MCT-MC?

The MCT-MC system combines all of the features of a loop controller, video/chart recorder and data logging

system into a single/intuitive display device. Email (supporting SSL/TLS), SMS (text messaging), FTP,

FileWeb, DataWeb (file transfer protocols for automated data backup and web database interface) and remote

viewing/control (via Web server/VNC server) are standard with the MC and can be accessed via LAN/WAN

using a PC, tablet or smart phone device.

Future Design Controls’ “MC” provides a 4.3” color touch screen interface with standard “Smart Device” user

interface features for multi-loop OEM control applications. All loop configuration and runtime user access is

configurable at the device with no PC software required. OEM’s have the ability to configure runtime features

(screen availability, menus, language, etc...) to easily customize the system for their requirements. These

configurations can be imported/exported to any other MC device for setup (from scratch) within minutes.

Individual high performance board level PID loop controls (one for each loop up to a maximum of 10) offer up

to four control outputs each, powerful profiling capabilities with up to three events and full auto tune functionality

with high resolution universal process inputs.

1.1 Features

Each of the MC loop control boards provide a single digital input that can be programmed as an automatic

program control input, input alarm or input status (visual loop status indication).

Each of the loop control boards also provide up to four control outputs which can be used as PID control outputs

for heat/cool, direct outputs for controlling external equipment related to the application through software

switches called events, or be programmed to act as system alarm outputs.

The MC can be operated in single set point or automatic program control mode. Program entry is made easy

through the use slide list selections and menu items on a single entry screen. Programs can be copied to the

external USB memory stick and then imported to another MC controller which eliminates the need to enter

duplicate programs on multiple systems.

Data file analysis tools make looking at historical data a simple task. Any control variable saved to the data file

can be plotted on the historical data chart for any time frame within the data file’s total time range.

The built in Ethernet functionality includes a Web Server to provides access to all MC data (view only), a VNC

interface for remote control and monitoring and an NTS clock, all available via a local Intranet connection (wired

or wireless), or the World Wide Web using standard software like Microsoft’s Internet Explorer.

The MC provides a rich set of tools for control interaction and process monitoring. The interface provides

various loop, chart, alarm, automated program status as well as historical data, alarm log and audit trail views.

The menu driven interface eliminates screen “clutter” by providing an easy to use “Smart Device” interface for

interaction between the user and MC.

The MC can store over a years worth of data on its SD memory card. Data logging can be enabled manually

or automatically during program operation. Data backup is provided via a USB memory stick for plug and play

transfer of files to any PC and through the included FTP back-up utility.

The MC protects system access with a four level security system (user rights based), including audit trail

capability that documents all user activity and ensures data integrity by digitally signing all data files and audit

trails to meet regulatory requirements.

What is the MCT-MC - 7 - FDC MCT-MC

Page 8

MCT-MC 4.3

The MCT-MC controller includes the following features:

ACCESSIBILITY

Touch screen, “Smart Device” user interface (UI) with

30,000 hour LED display

Built in configuration software; no external software or

PC required

Email, SMS, FTP, FileWeb, DataWeb, VNC and Web

functionality standard

Remote View/Control using PC, Tablet or Smartphone.

National time server connectivity with daylight savings.

COMMAND BAR ICONS

NAVIGATION, HELP & HOME

The Master Command Bar located on the top of the

display provides easy & intuitive 1-touch access from

anywhere in the system to Navigation, Help and

configured Home view.

Home brings the user back to the system “Home” view.

The Home icon can be configured for the following

standard views:

Loop view: includes PV & SP digital display, PV

min/max, PID % Output, Auto-Manual, event, profile

access and more.

Overview: all loops, profile and event status

Chart view: (trend up to the last 24 hours from system

RAM) supporting 4 trends with up to 8 values per trend

Alarm view or Alarm File

Help offers content sensitive text for every view / page

in one of 11 supported languages chosen by the user.

Navigation provides access to the configured menu

system, traditional drop down or icon.

SECURITY AND AUDIT TRAIL

• Supports up to 30 users over four user groups with

access to 40+ functions restricted by user group.

• Supports password aging and verification.

• Operator Audit Trail provides history for all user activity

that includes date, time, user name and action; i.e. Loop

SP change from 55.2 to 103.5.

PROFILE RAMP/SOAK

• Individual operation per loop or set point generator

(one loop runs profile and other loop set points

automatically set to follow master loop)

• Start: via touch screen or Event input

• Profile Name: 16 character naming convention

• Global Profile Configuration:

- Start from PV or static SP

- Guaranteed Soak & Ramp band

- Power Fail / Recovery: Continue from last SP value,

PV or static mode.

• Profile Segments: (maximum of 64)

• Guaranteed Soak & Ramp per step

• Events: up to 3 per step (based on loop configuration).

• Jump-To Step: configurable per step

• Profile End Alarm

• Configurable Profile End Logic:

- Current (Static) Control SP: Set Point & Event

status prior to Profile Start is loaded at end of the

Profile.

- Final SP of Profile with all Events off

ALARMS

• Up to 30 alarms configurable to B42 (up to 3 alarm

outputs per B42).

• Loop* Alarm Types: Process High & Low, Deviation High

& Low, Deviation Band, Event Input and End of Profile.

* B42 configured as Monitor Input (no PID control)

configurable only with Process alarms.

Alarm Mode:

Normal or Hold (on start-up Hold mode will not

activate if in alarm condition and arm once out of

alarm condition).

Silent Alarm, activation does not indicate alarm or

write to alarm log file.

Alarm outputs configurable as latching or nonlatching.

DATA ACQUISITION

• Data log PV, SP and PID percent output.

• File name: Free form 16 character appended by

time/date or the profile name if started with a profile.

• File Start/Stop: user on-demand, on system boot or

profile ramp-soak start/end.

• Data Log interval: configurable 1 second to 31 minutes.

• File Interval: configurable to set time in days (1 to 31) to

end and start a new file. This allows syncing files to

match product cycles as well as keeping file size

manageable.

• ID#1 and ID#2 fields allow user to enter specific

information such as a batch and/or lot information that is

associated with the data file.

• Operator Comments/Events: Unlimited operator

comments/events linked to each file

• File Type: Data Log fi les are saved in .csv format.

• Digital Signatures: Automatic system as well as user

entered signatures.

• Historical Data Viewer: View data log fi les on the display.

Chart is auto-scaled on an X & Y axis for time and units.

• Meets the requirements for:

- CFR21 Part 11

- AMS2750E

EVENT INPUTS

• B42 each have 1 event input configurable for one of the

following functions.

- Profile Run

- Hold

- Run/Hold

- Abor

- Step Advance

- Failure Transfer (Outputs)

- Alarm Input (indication only)

- Loop Status Input

FDC MCT-MC - 8 - What is the MCT-MC

Page 9

MCT-MC 4.3

2 Installation

All MC components are pre-loaded with all operating software and firmware before leaving the factory so it is

ready to install when you receive it. Before beginning installation, completely read through this section as well

as the following section (3. Power and W iring) to gain an understanding of the entire installation process.

Consider the installation carefully. Plan the power, signal and control wiring before installing the MC. Also

consider the cabinet space, hardware dimensions, environmental conditions and use good wiring practices to

minimize problems that may occur due to electrical interference.

To avoid potential electric shock and other hazards, all mounting and

WARNING:

Special expertise is required to install, wire, configure and operate the

Prevent metal fragments and pieces of wire from dropping inside the

CAUTION:

When handling the B42 series loop control boards, use proper ESD

Locate the MC and all related control components away from AC

2.1 Enclosure Guidelines

wiring for the MC must conform to the National Electric Code (NEC)

and other locally applicable codes.

MC controller. Personnel without such expertise should not install, wire

or operate the MC.

housing of any MC component. If necessary, place a cover over the

components during installation and wiring. Ingress of such fragments

and chips may cause a fire hazard, damage or malfunction of the

device.

(electro-static discharge) handling procedures to prevent damage to

board components.

power/motor wiring and sources of direct heat output such as

transformers, heaters or large capacity resistors.

The MC must be installed correctly for reliable operation. The MC controller is designed for installation within

a suitable enclosure. Do not install the MC outside of an enclosure. Care must be taken when locating

components to ensure that AC power wiring, contactors, starters, relays and other sources of electrical

interference are properly located to minimize their impact on the MC control system.

Particular note should be taken to the position of variable speed drives and switching power supplies. Their

input and load cables should be screened and properly grounded to a central equipment grounding point to

prevent radiated emissions from affecting MC operation.

2.1.1 Locating the MC Touch Screen Interface

It is recommended that the unit be mounted within the front panel of a steel enclosure, through an appropriately

sized opening. Proper enclosure depth is required to insure that there is adequate spacing between the rear

of the interface and the front of any high voltage devices mounted in the enclosure when the enclosure door is

closed. It is required that a minimum separation of 2” be maintained, so plan a depth to accommodate at least

4” (102mm) behind the front of the panel.

Installation - 9 - FDC MCT-MC

Page 10

MCT-MC 4.3

Proper clearance must also be maintained above, below and on both sides of the interface to allow for heat

dissipation and to facilitate mounting. A minimum of 2” is recommended. Note that additional space may be

required below and to the right of the interface (looking from rear of unit) to accommodate the communications

wiring depending upon the type of communication cables used.

2.2 Environmental Considerations

Do not subject the MC touch screen interface to operating temperatures below 0°C (32°F) or above 50°C

(122°F). The operating temperature for the P41/B42 loop controls is limited from -10°C (14°F) to 50°C (122°F).

Minimum and maximum relative humidity levels are limited between 10% and 90% (non-condensing) for the

touch screen and 0 to 90% for the loop controls. The MC touch screen interface is to be used indoors only.

The unit should not be installed where fast temperature variations may occur as this can cause condensation

of water vapor on the device.

The MC should not be exposed to excessive dust, dirt, salt, direct sunlight or shock and vibration. Do not

operate the MC controller in an area where chemicals or flammable gases are present. Permitted storage

temperature extremes for the MC control system are limited to -10°C (14°F) and 60°C (140°F) for the touch

screen and -40°C (-40°F) and 60°C (140°F) for the loop controls.

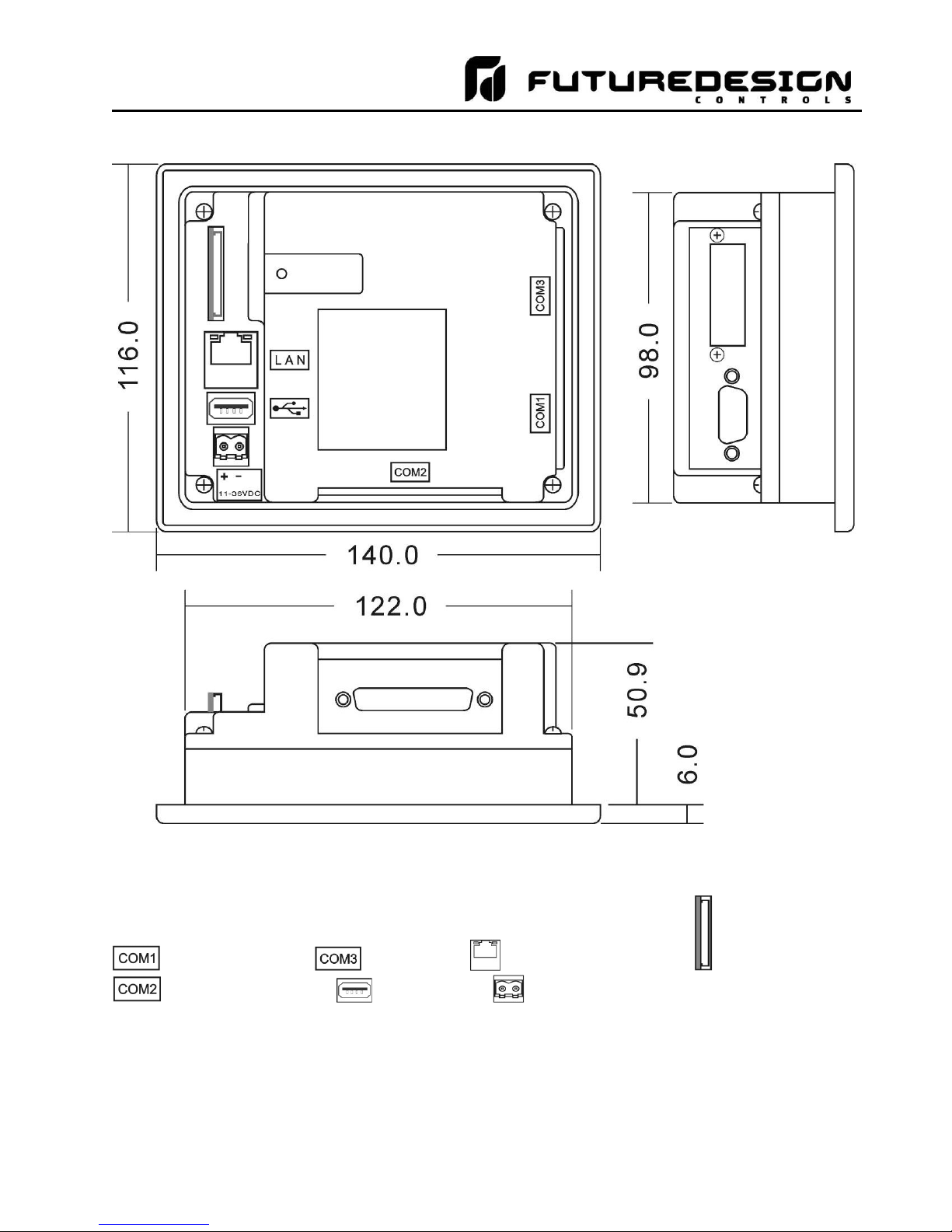

2.3 Mounting Dimensions

Note that your system may not include some of these components, and that quantities of certain components

vary depending upon the application and options ordered. Make sure that you have all components required

for your application prior to installation.

2.3.1 MC Touch Screen Interface

The MC 4.3 interface is supplied with four mounting clips. All four clips must be installed and properly tightened

to insure the IP65 protective rating. Failure to install all mounting clips may also affect touch screen operation.

Be sure to tighten each one evenly so as not to flex the case of the unit. DO NOT over tighten the mounting

clips. The clips should be tightened just enough to fully compress the gasket so that the bezel around the

interface is parallel with the mounting surface.

Mounting Clip Slot (4 total) Mounting Clip Installed in Slot

NOTE: The MC will not operate properly without the SD card installed into the SD card slot on the back of

the unit. The SD card has all software required, loaded onto the card for ‘Auto-Boot’ operation. The

slot on the back of the interface is ‘keyed’ so the card can only be installed in one direction. The card

is pre-installed for your convenience. If the card is removed, take care when inserting the SD card

and DO NOT force it into the slot. The card MUST be installed prior to application of power.

FDC MCT-MC - 10 - Installation

Page 11

MCT-MC 4.3

All dimensions are in mm. Tolerance +/- 1 mm.

Panel cutout: 123+1 x 99+1

DB9, Male Not Used LAN, Ethernet (RJ45) SD slot

DB25, Female USB port Power supply

Installation - 11 - FDC MCT-MC

Page 12

MCT-MC 4.3

2.3.2 MC Process Loop Controls

One PID loop control is required for each process control loop in the system. The MC is compatible with both

the Future Design Controls P41, ¼ DIN control and the B42 board level control. Refer to the FDC controller

manual for the model of loop control being used for dimensions, appropriate mounting and installation

instructions.

For applications requiring frequent access to the process controllers, the panel mounted P41 series provides

direct access to the controllers. For applications where operator access to the controls is not required, or is

desired to be kept at a minimum, the B42 loop controls can be mounted directly inside of an enclosure. This

also reduces wiring concerns by eliminating the need to run the sensor, communication and control wiring for

each control to and from an enclosure door.

NOTE: The MC requires firmware version V.22 or later in the P41/B42 loop control for proper manual event

operation. Early model controls can be used, but the manual event control will not function. Only

automatic ramp/soak program event control will be available.

FDC MCT-MC - 12 - Installation

Page 13

MCT-MC 4.3

3 Wiring

This section describes the methods and precautions for wiring the MC system components.

Turn off power to the MC before starting installation, removal, wiring,

WARNING:

Emergency stop and interlocking circuits MUST be configured outside

This section presents recommended installation practices and

CAUTION:

Electrical interference in an operator interface can lead to equipment

maintenance and inspection of the MC controller. Failure to turn off

power may cause electric shock, create a fire hazard or cause damage

to the MC.

of the MC control system. If such circuits are made through the MC,

failure of the MC control system may cause uncontrollable operation,

damage to equipment or accidents.

procedures. Since no two applications are identical, these

recommendations should be considered as guidelines. The system

designer should be aware that devices in control systems could fail and

thereby create an unsafe condition.

start-up, which could result in property damage and/or physical injury

to the equipment operator.

If the application requires an operator or attendant, you should be

aware that this potential safety hazard exists and take appropriate

precautions. Consult NEMA ICS 3-304 for more information regarding

safety for the installation of solid-state programmable control devices.

3.1 Power Requirements

The MC control system touch screen operates on a nominal 24Vdc supply voltage with an allowable range of

11 to 36Vdc. The P41/B42 loop controls can be ordered to operate from either a DC (11-26Vdc) or an AC (90250Vac) supply. Do not power the MC controller components and highly inductive DC loads or input circuitry

to other equipment with the same DC power supply used for the MC.

If the MC is installed in an area with poor power quality or frequent power interruptions, it is recommended that

a time delay-on relay be installed in the power supply wiring to all components of the MC. This will prevent

rapid on-off cycling of the MC during brown-out or momentary power interruptions. Rapid power cycling to MC

can cause damage to the electronics and/or loss of data.

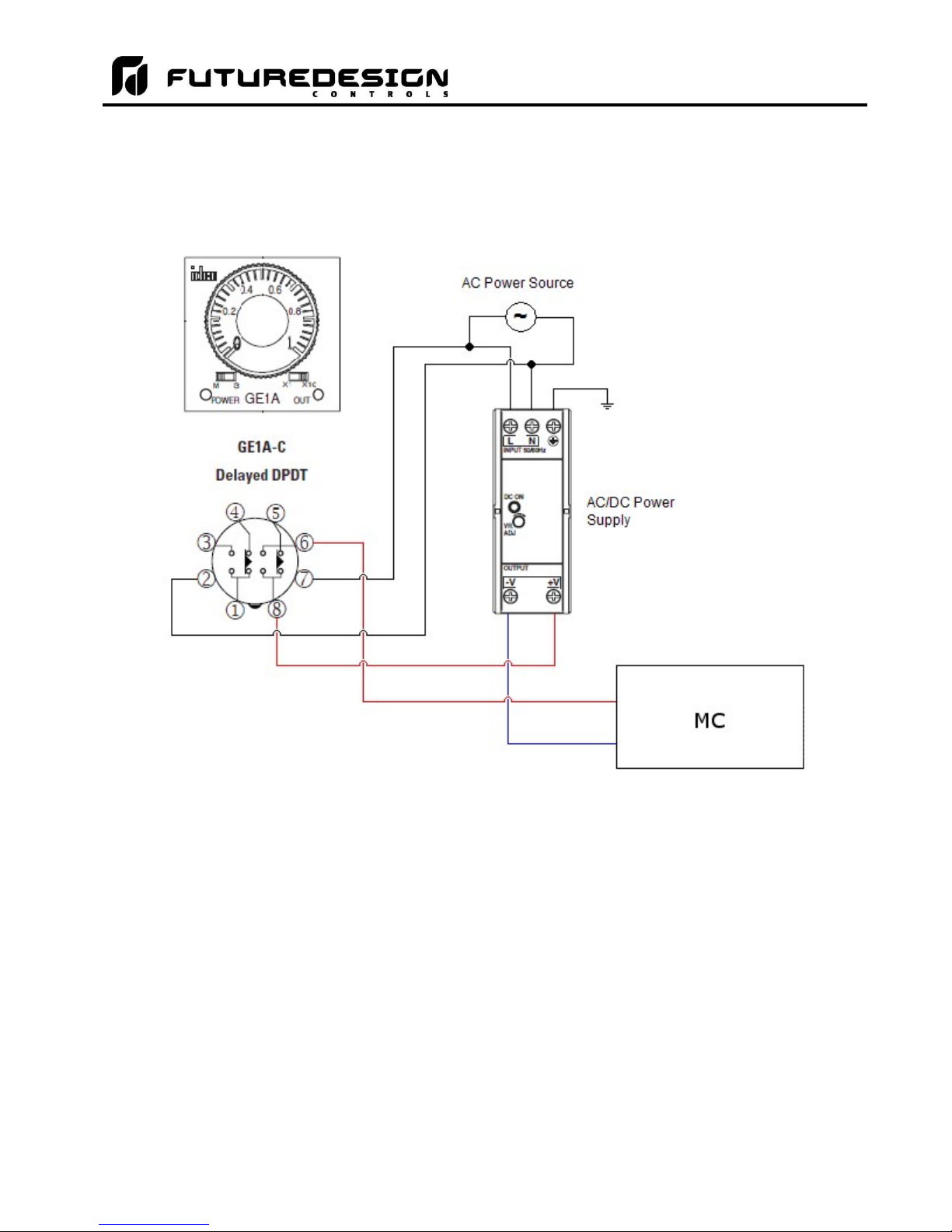

3.1.1 Installing the Power-On Delay Relay

Due to the rate at which AC/DC power supplies reach their nominal supply voltage after application of power,

the relay contact of the timer should be installed between the output of the power supply and the power input

of the MC control system components. This allows the power supply output voltage to reach its nominal value

prior to connecting the MC to its output terminals.

Wiring - 13 - FDC MCT-MC

Page 14

MCT-MC 4.3

In order to properly sense the loss of power, the time delay relay coil should be wired to the AC power source

for the DC power supply of the MC. This will insure that the MC is turned off/on at the proper times and prevent

malfunction that can be caused by rising or falling voltage at the power supply output during power interruption.

NOTE: It is recommended that the time delay-on relay be set for a minimum period of 3 seconds.

FDC MCT-MC - 14 - Wiring

Page 15

MCT-MC 4.3

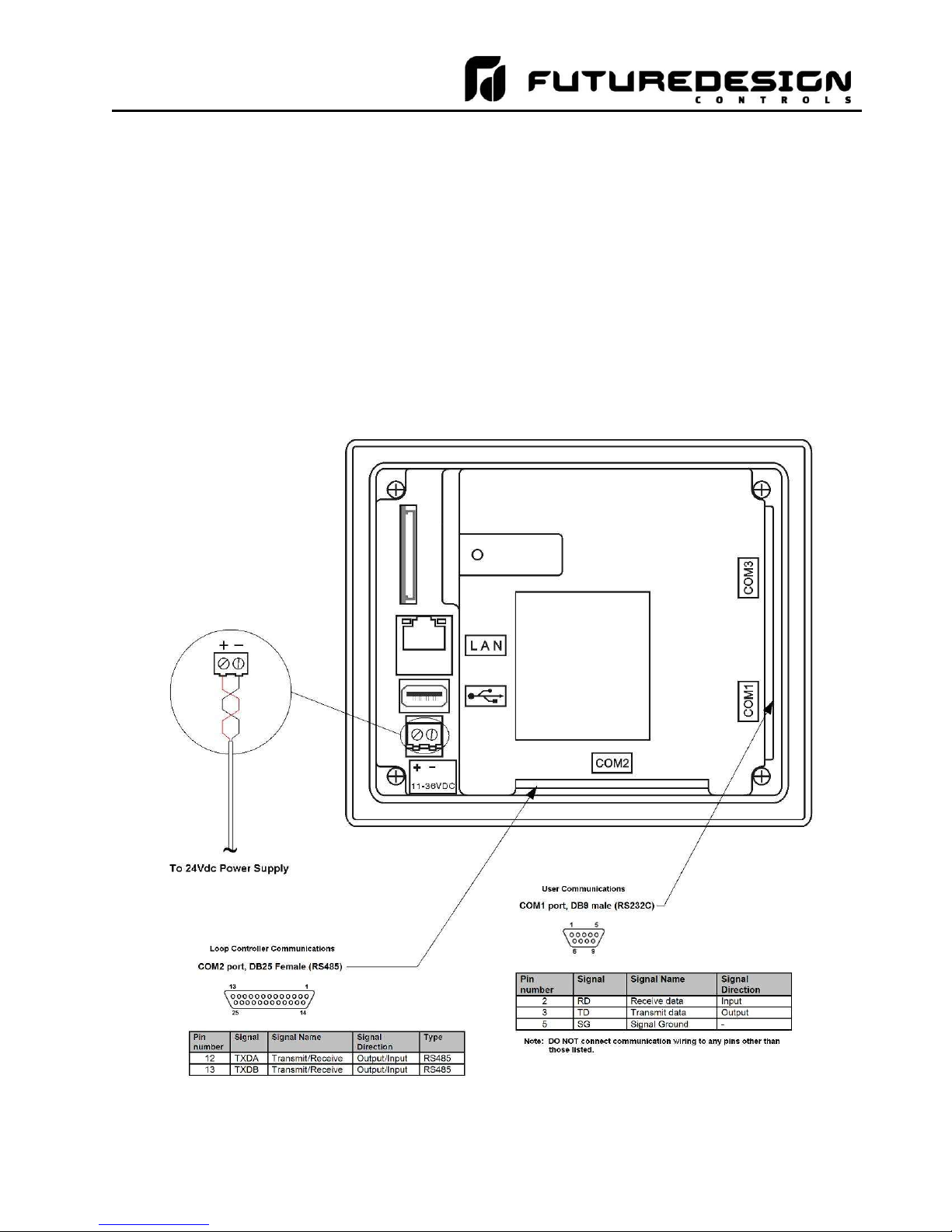

3.2 Connecting to the MCT-MC Interface

Power wiring lengths should be kept to a minimum, and it is preferable to have the power wiring run using a

minimum of 18/2 twisted shielded cable. This keeps the “hot” and “common” wires paired to minimize the

effects of external noise.

To make a connection, strip about ¼” of insulation off the end of the wire, turn the connector screw

counterclockwise until the gap is wide open, insert the wire all the way in, and turn the screw clockwise until it’s

tight. Connect positive DC line (hot) to the ‘+’ terminal and the negative DC line (common) to the ‘-’ terminal.

The other end of the cable should be properly terminated at the 24Vdc power source, and the shield connected

to the main earth ground.

NOTE: Upon application of power, if the display does not come on within 2 seconds, remove power. The

interface is reverse polarity protected. Check wiring to insure proper connections and try to power up

again. An Internal fuse will prevent damage for over voltage conditions; however, it isn’t guaranteed.

DC voltage sources should provide proper isolation from main AC power and similar hazards.

Wiring - 15 - FDC MCT-MC

Page 16

MCT-MC 4.3

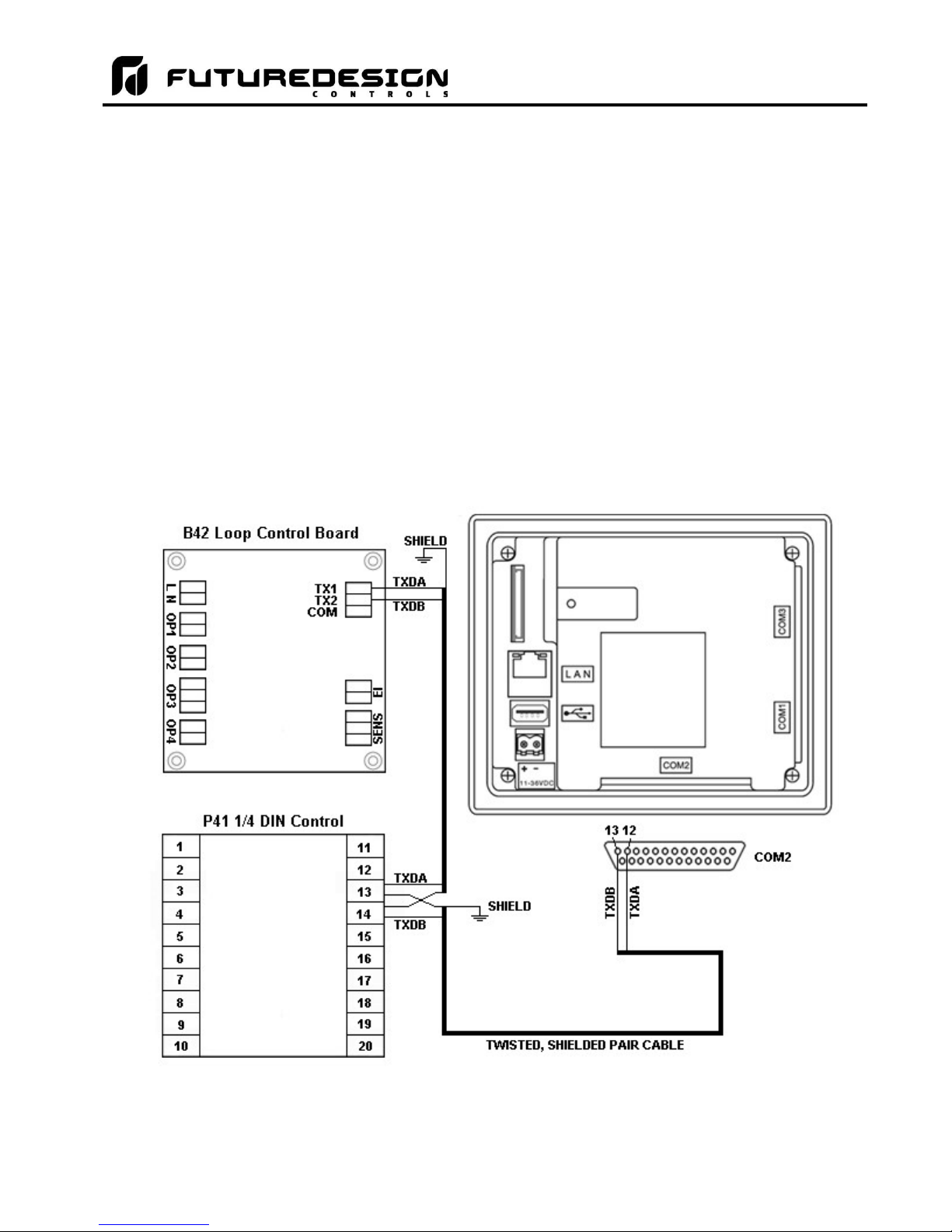

3.2.1 Process Loop Controller Communications

The loop controls communicate with the MC touch screen using the RS485 communications port. This allows

up to ten P41/B42 boards to be connected using one 2-wire link. The controllers are wired in parallel with each

one having their own communications address of 1 through 10 (corresponding to loops 1 through 10).

Communication wiring should be run using a minimum of 24 AWG twisted-pair, copper conductors. For short

runs (< 10 feet total), non-shielded wiring can be used as long as proper separation from power/control

conductors is maintained. For communications wiring where the total length will exceed 10 feet, shielded

twisted-pair should be used.

NOTE: It is important to keep the power/control and sensor/communications wiring separated from one

another. Relay and/or high voltage outputs can interfere with the sensor and communication wiring

as they cycle on and off, which can cause erroneous sensor readings or communications errors.

FDC recommends the use of shielded wire for all installations in order to maintain optimum

performance and minimize the possibility of communications errors.

When using shielded twisted-pair, be sure to ground only one end of the cable, preferably at the loop controller.

Allowing any other portion of the cable shield to come in contact with ground, or grounding both ends, will cause

ground loop currents to flow in that section of the cable shield which can disrupt communications.

FDC MCT-MC - 16 - Wiring

Page 17

MCT-MC 4.3

3.2.2 Connecting to the Process Loop Controls

The MC is compatible with both the Future Design Controls P41, ¼ DIN control and B42 board level process

loop controls. The input and output wiring to the individual loop(s) is dependant upon options ordered on each

device as well as the intended application. For detailed information on input and output wiring, refer to the user

manual for the type of control used.

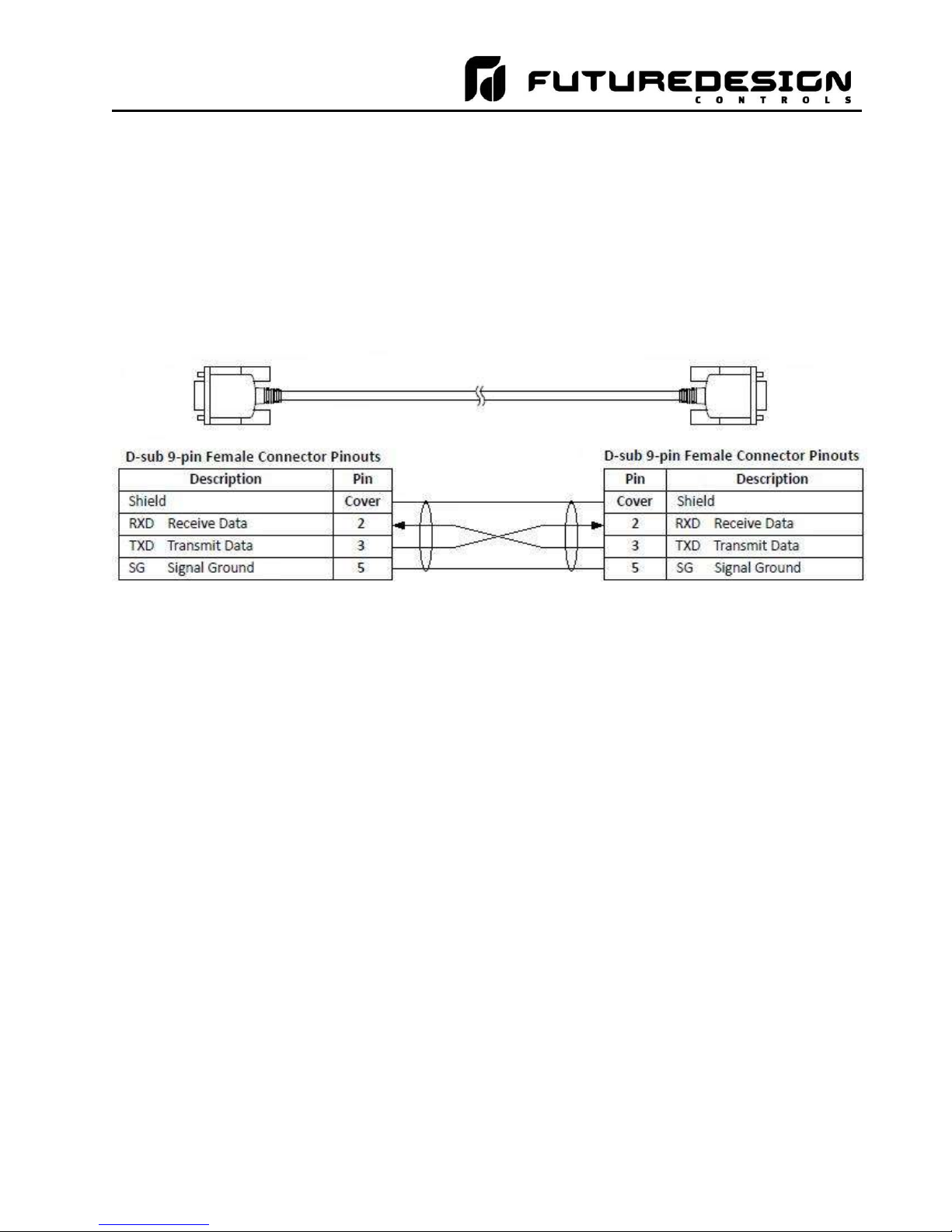

3.2.3 User Serial Communications

The MC touch screen provides an RS232C user communications port for connecting the MC to a PC running

software such as Future Design Control’s Envision software. In order to connect the MC to a PC, a cable must

be fashioned according to the diagram below.

NOTE: DO NOT use a standard null-modem cable to connect the MC to a PC. Most computers do not

provide a standard serial port and a USB to serial converter must be used. Incompatibilities may exist

between the MC and certain USB to serial adapters which may cause the MC to malfunction when

connected using a standard null-modem cable.

If more than one MC controller is to be placed on the communication link with a PC, an RS232/485 converter

is required for each MC in order to convert the RS232 communications port to a RS485 multi-drop

communications for connecting multiple MC controls on the same PC communications link.

Wiring - 17 - FDC MCT-MC

Page 18

MCT-MC 4.3

NOTE: The connection requires a single twisted-pair cable that is daisy-chained from one MC to the next.

When using shielded twisted-pair cable, be sure to ground only one end of the cable, preferably at the

RS232 to RS485 network adapter. Allowing any other portion of the cable shield to come in contact

with ground, or grounding both ends, will cause ground loop currents to flow in that section of the cable

which can cause communication errors.

FDC MCT-MC - 18 - Wiring

Page 19

MCT-MC 4.3

4 Configuring the MCT-MC

IMPORTANT: Once all configuration settings are made, you must select “Exit” from the File menu to exit the

Cconfigurator prior to cycling power to the MC. All configuration files are written upon exiting

the Configurator. Do not cycle power prior to exiting the Configurator or settings will be lost

and the MC will not operate properly once the runtime application starts.

The MC Configurator is a powerful tool that is built in to the system. It is a program that allows the OEM or user

to set up control system options for the MC runtime application. This allows for on-the-spot setup of the MC

without the need for external hardware and software. The user or OEM must first run the Configurator prior to

putting the MC into service in order to properly setup the system for its intended use.

The Configurator program does not run at the same time as the main runtime software. It can be run by exiting

the runtime software via the Offline Setup\Exit Application screen. When the “Exit application (configuration

mode startup)” option is selected, on the next power-up, the Configurator application will automatically start.

From the Configurator, the user or OEM can then setup all process loop controls as well as choose from a long

list of standard features to provide in the runtime application. During setup, the output control functions of each

device can be changed, so any equipment being controlled by the outputs should be placed in an “off” state, so

that any modifications to output functions will not cause an unsafe condition or damage to equipment.

NOTE: On exit of the MC Configurator application, the MC runtime application will automatically run on the

next power-up.

The MC Configurator provides the following functionality:

Set the number of control loops that the system will use (one to ten).

Provide control loop configuration settings for input type, output function, set point range, etc.

‘Splash Screen’ name editing for custom OEM or user requirements

Enable/disable options for runtime menu and screen availability

Text editing for all system event and alarm names

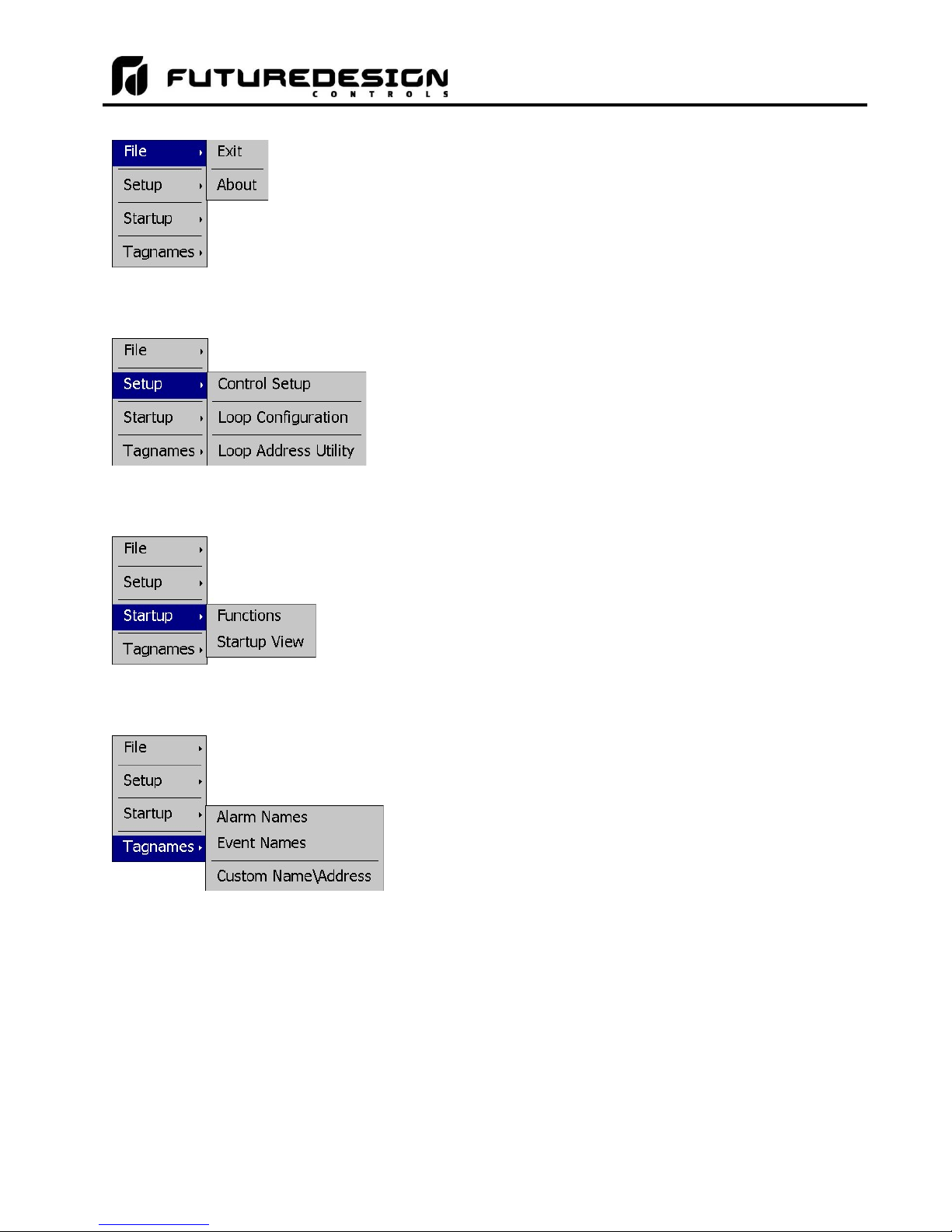

The Configurator menu is accessed by pressing the “Monitor” icon at the top left of the screen.

Configuring the MCT-MC - 19 - FDC MCT-MC

Page 20

MCT-MC 4.3

The File menu provides selections of “Exit” and “About”. The exit

function for the Configurator saves all settings and closes the

Configurator application.

The about selection displays version information for the

Configurator application and configured control devices.

The Setup menu provides access to the primary controller setup

options. These options include the controller setup (number of

loops), the loop control board configuration settings and the loop

address utility that can be used to automatically assign the

proper communications address to an attached loop control

board.

The Startup menu provides access to enable and disable

runtime screens/menus and set the desired startup view

selection.

The Tagnames menu provides access to the text editing

functions of the Configurator which allow the event and alarm

names to be changed to match their use in the system. The

menu also provides access to edit the splash screen information

that is shown when the runtime application starts.

FDC MCT-MC - 20 - Configuring the MCT-MC

Page 21

MCT-MC 4.3

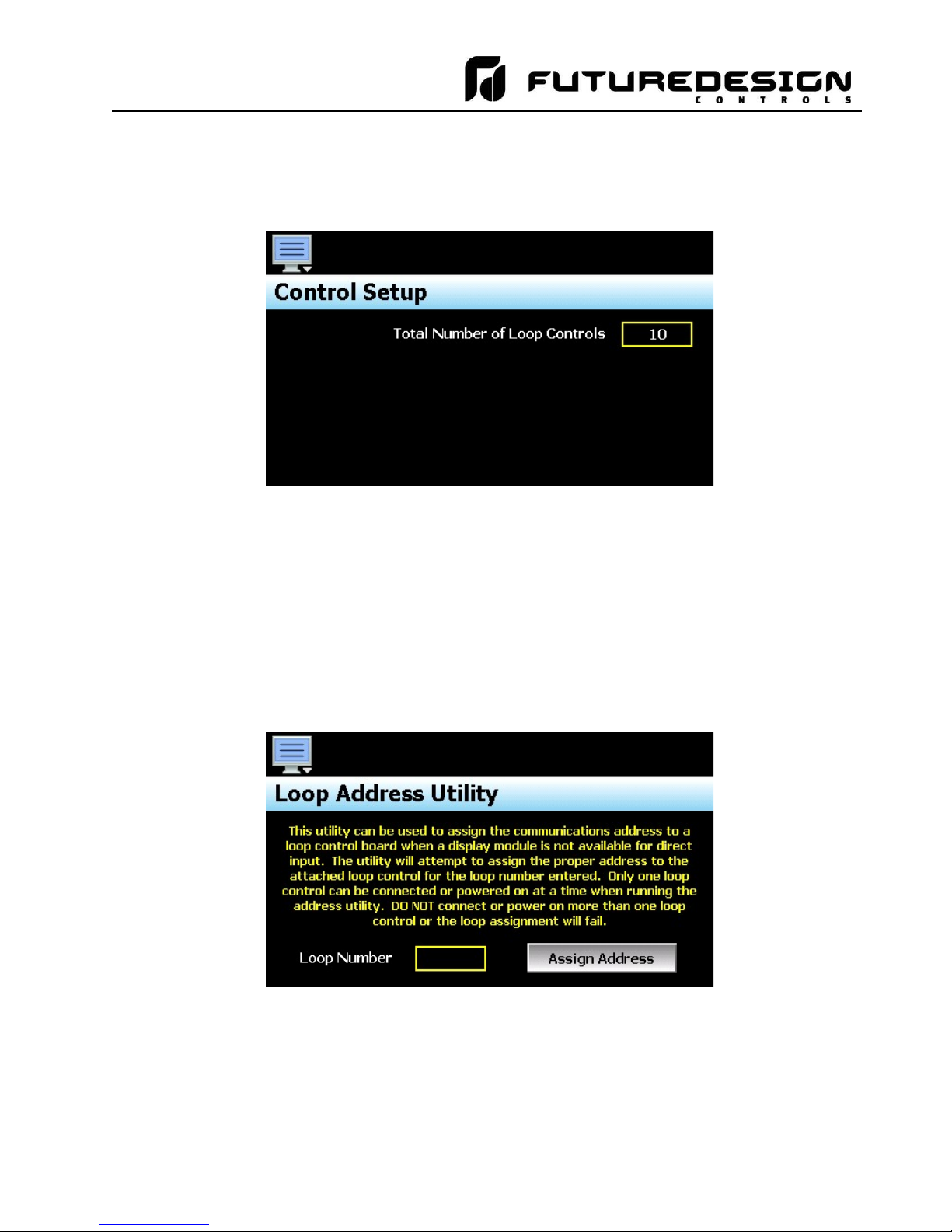

4.1 Control Setup

The “Control Setup” screen is accessed from the Setup menu. It allows the user or OEM to set the number of

control boards that are attached to the system. Once set, the loop configuration settings will be made available

for the total number of loops entered.

4.2 Loop Address Utility

In order for the MC to properly communicate with each of the loop control boards, they must be configured for

the proper communications address. The factory default communication settings of the loop control boards are

set for a communications address of one, which correspond to the proper settings for loop 1. For a single loop

MC control system, no further settings are required. Simply connect the communications wiring between the

control board and the MC interface, and the system is ready to go.

For a multi-loop control system, the other loop control board(s) must be set for an address that corresponds

with the loop number, i.e., 2, 3, 4…. If a display module is not available to connect to the loop control board in

order to set its address, the Loop Address Utility can be used. It is accessed from the Setup menu.

In order to use the utility, only one loop control board can be connected to the MC touch screen display at a

time. Since the default address of all control boards is 1, if more than one was connected, they would all

respond to the same command which would cause them all to be set to the entered address. If more than one

loop control board is connected, disconnect the communications wiring from the loop control board(s) that you

DO NOT want to set the address on. An alternative is to remove power from the loop control board rather than

disconnecting the communications wiring.

Configuring the MCT-MC - 21 - FDC MCT-MC

Page 22

MCT-MC 4.3

With only one loop control board powered on or connected to the MC via the communications link, press the

Loop Number field and enter the address to assign to the attached loop control. Once entered, press the

“Assign Address” button and the utility will begin scanning for the loop control board and set its address to the

one entered once found. If the utility fails to set the address, check the wiring to insure it is properly connected.

If the loop control board has been previously used for another application, it may be possible that the address

or other communications settings have been changed, which prevent the utility from working. In this case, a

display module must be connected to the loop control board to set the proper communications settings:

Address: 1 to 10 (for loop 1 to 10)

Baud rate: 9600

Parity: Even

IMPORTANT: The loop input number corresponds to the communications address that must be set in the

loop control board for the MC to access it properly. If the communications address is not set

properly in the loop control, the MC will not be able to communicate with it, or may communicate

with the wrong loop control and assign incorrect values for the loop.

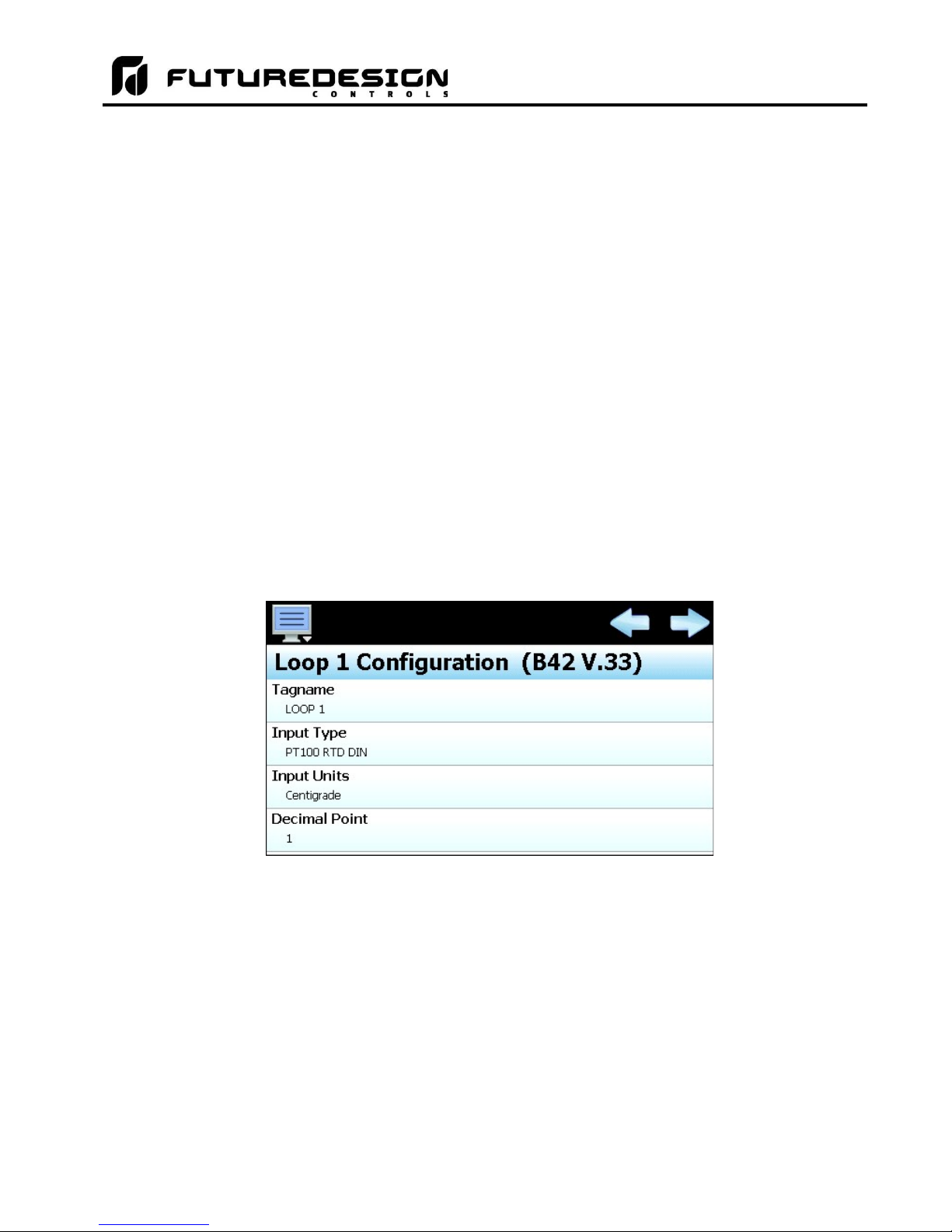

4.3 Loop Configuration

The Loop Configuration screen is accessed from the Setup menu. The screen provides access to all loop

control board settings. When more than one loop is configured, the left/right scroll buttons will be provided at

the top right of the screen. These buttons are used to scroll through all available loop controls in order to

view/edit settings for each.

The model and version of the loop control attached will be shown in the scroll list header. To view all of the

available settings, simply swipe up or down on the screen to scroll through the list items. To edit a value, tap

the row for the desired item. If the entry is a simple numeric value, the number entry pad will be shown. If the

item has multiple selections to choose from, a list of individual selections for the item will be shown.

IMPORTANT: Care should be taken when configuring loop controls as automatic ramp/soak programs may

be downloaded to any loop configured in the system. Each loop should be configured with the

appropriate settings to insure the ramp/soak programs operate properly. Typically all loops,

with the exception of communication address, are configured identically. This especially

applies to the automatic ramp/soak program global settings.

- Setpoint at start of automatic program (section 4.3.29)

- Setpoint at end of automatic program (section 4.3.30)

- Power Fail Recovery (section 4.3.31)

FDC MCT-MC - 22 - Configuring the MCT-MC

Page 23

MCT-MC 4.3

4.3.1 Tagname

The Tagname entry allows the user or OEM to assign a specific name for each control loop, up to 11 characters

in length. This name will be used throughout the MC runtime application and can be used to provide a more

detailed description as to the function the loop provides. Default tag names are LOOP 1 through LOOP 10.

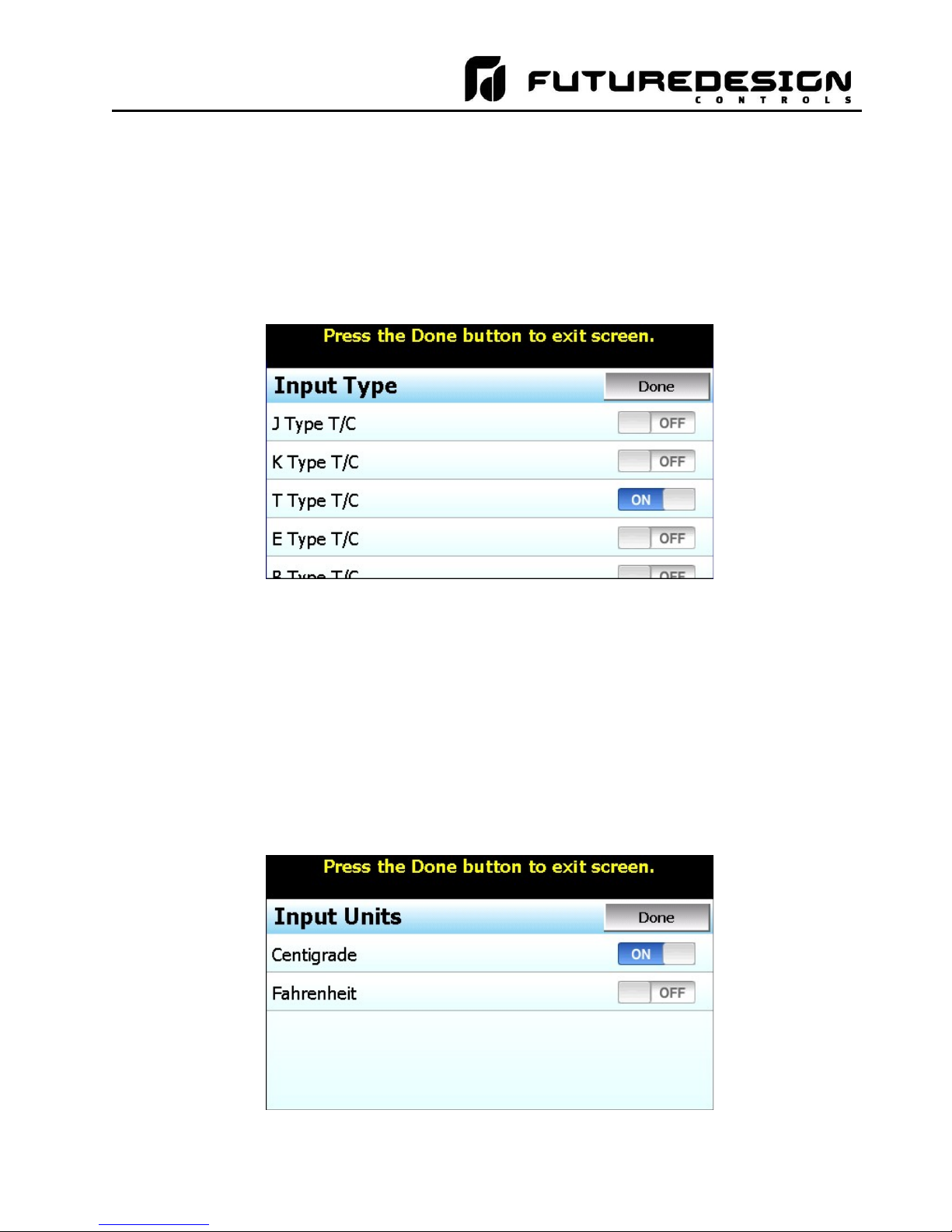

4.3.2 Input Type

The Input Type entry is used to select the type of sensor that will be connected to the loop control. The input

type can be a temperature input (thermocouple or RTD) or a linear input type (Vdc or mA).

The input type selections are mutually exclusive, i.e., selecting one input will turn all other selections off. Once

the desired input type has been selected, press the “Done” button to set the input type for the loop control board

and return to the main Loop Configuration screen.

NOTE: The loop control board is ordered with either a standard input for thermocouples and RTD’s, a voltage

input or a milliamp input. The selected input type must be set to match the type of input supplied on

the loop control board or the unit will not operate correctly.

4.3.3 Input Units

The Input Units entry is used to select the temperature units for temperature input types (thermocouple or RTD).

If the selected input type for the loop is a linear input (Vdc or mA), the Input Units entry will display the text entry

keypad allowing the user or OEM to enter specific engineering units up to 4 characters.

Configuring the MCT-MC - 23 - FDC MCT-MC

Page 24

MCT-MC 4.3

The input unit selections for temperature are mutually exclusive, i.e., selecting one will turn off the other. Once

the desired temperature units have been selected, press the “Done” button to set the input units for the loop

control board and return to the main Loop Configuration screen.

4.3.4 Decimal Point

The Decimal Point entry allows the input precision to be adjusted between 0 and 1 decimal digits for temperature

input types, between 0 and 2 for a 0-60mV input and from 0 to 3 for Vdc and mA input types.

IMPORTANT: Once the loop control board has been configured with a specific decimal point, changing the

decimal point will require the loop control board to be reconfigured in order to maintain previous

control settings. Automatic programs, alarm set points, set point limits, input low/high scale,

etc., DO NOT automatically scale. An entry of 100.0 becomes 1000 when changing the

decimal point to zero (not 100), and must be re-entered to set the proper value.

4.3.5 Input Low/High Scale

The Input Low Scale and Input High Scale entries are used to set the input range for linear input types (Vdc or

mA). The entries are not available for temperature input types since they utilize a fixed range based on the

sensor type. The input low scale value can be set from -32768 up to the high scale value minus 50. The high

scale value can be set from the low scale value plus 50 up to 32767.

NOTE: The minimum and maximum scale values are limited by the decimal point selection. For a decimal

of 0, the values are -32768 and 32767 respectively. For one decimal point, the values are -3276.8

and 3276.7. For two decimal digits, the values are -327.68 and 327.67 and for three decimal digits

the values are -32.768 and 37.767.

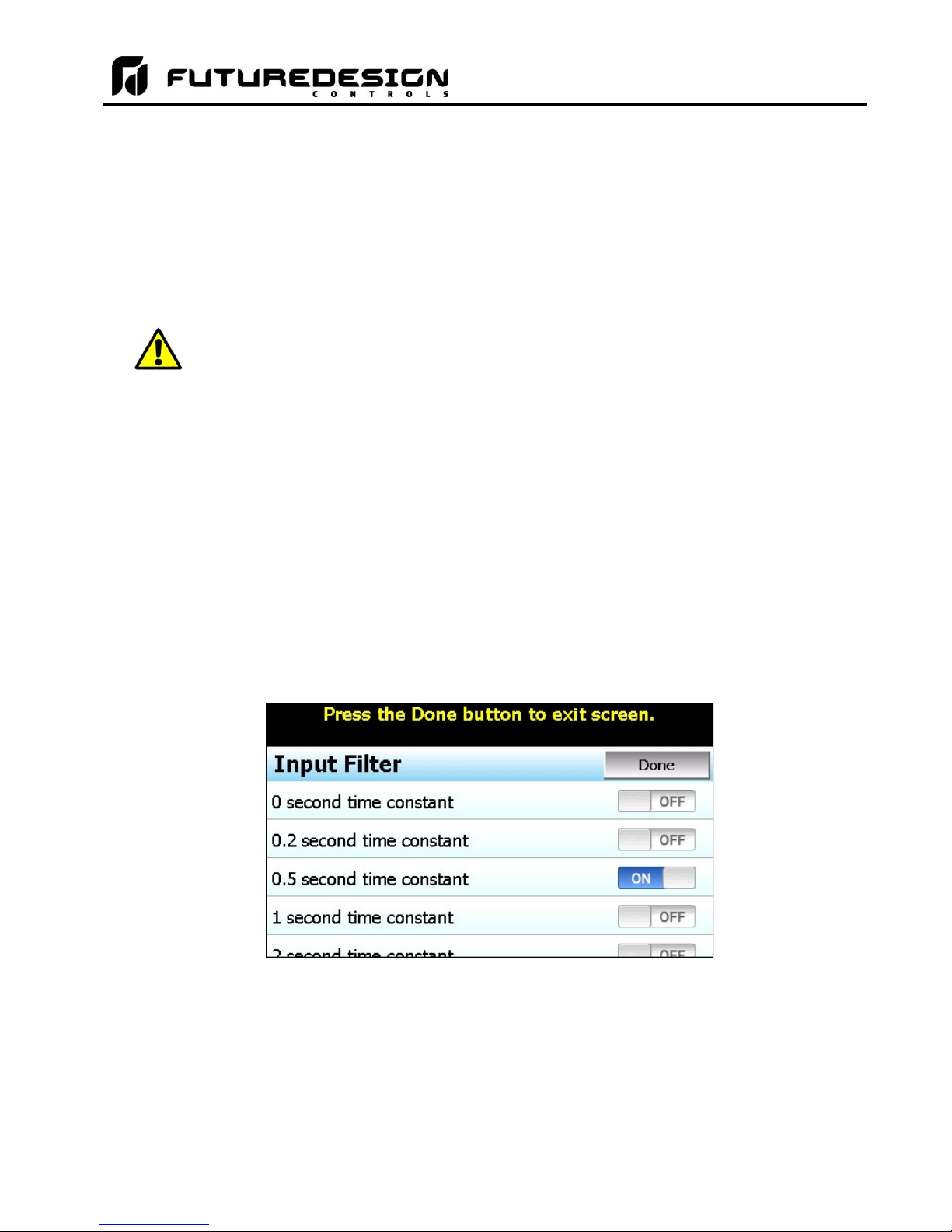

4.3.6 Input Filter

The Input Filter entry is used to select the time constant used for filtering the process input.

The time constant selections are mutually exclusive, i.e., selecting one will turn off the others. Once the desired

filter constant has been selected, press the “Done” button to set the input filter for the loop control board and

return to the main Loop Configuration screen.

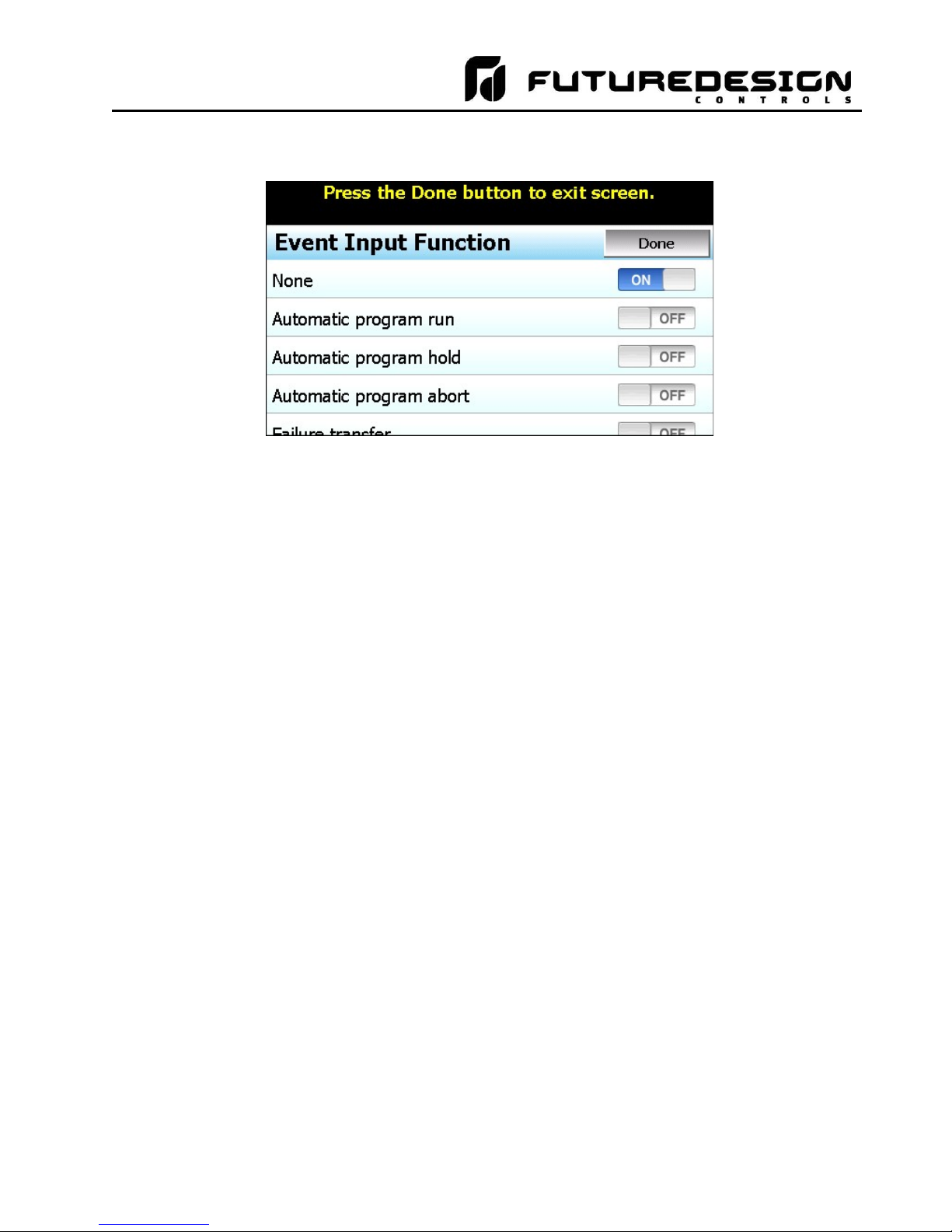

4.3.7 Event Input Function

The Event Input Function is used to select the desired mode of operation for the digital input of the loop control

board. The event input selections are mutually exclusive, i.e., selecting one will turn off the others. Once the

FDC MCT-MC - 24 - Configuring the MCT-MC

Page 25

MCT-MC 4.3

desired function has been selected, press the “Done” button to set the event input function for the loop control

board and return to the main Loop Configuration screen.

The Automatic program run function is a single-shot action that will start the currently loaded program when

the event input is activated.

The Automatic program hold function will put the currently running program into hold when the event input is

activated. The program will resume operation and return to the run mode when the input is deactivated.

The Automatic program abort function is a single-shot action that will abort the currently running program.

Note that the abort function does not work if the program is in hold. The program must be running in order for

the abort function to work.

The Failure transfer function puts the loop control outputs into failure transfer mode when the input is activated.

The output will then go to the percent output value set for failure transfer. The loop control outputs will return

to normal PID control when the input is deactivated.

NOTE: If an automatic ramp/soak program is in operation and one or both programmed control loops are

placed in failure transfer via the event input, the program will be stopped. When the event input is

then turned off and failure transfer is disabled, the loops will operate in static mode at the set point

and event output status prior to the time which the program was started.

The Automatic program advance next step function is a single-shot action that will advance the currently

running program by one step each time the event input is activated.

The Automatic program run/hold function is a combination of the automatic program run and program hold

functions. Upon first activation of the input, the currently loaded program will be started if not already running.

Deactivating the input will then cause the program to go into hold. The input must then be reactivated in order

for the program to resume operation.

The Loop status input function provides a visual indication on the Loop View screen in the runtime application.

When the input is activated, the border around the loop is highlighted blue. When the input is deactivated, the

border around the loop returns to the default dark gray color. This can be used as a means for alerting the user

of an operating condition, such as the equipment the loop is controlling is in operation.

The Alarm input function allows the event input to be used for alarm indication. When the input is activated,

the Event Input Alarm Message (see section 4.2.8) is displayed on the alarm screen in the runtime application

and the audible alarm sounds.

NOTE: The MC does not support the P41/B42 event input functions of “Manual Mode”, “Off Mode” and “PID2

Select”. These selections are not available through the MC configuration.

Configuring the MCT-MC - 25 - FDC MCT-MC

Page 26

MCT-MC 4.3

4.3.8 Event Input Alarm Message

When the event input function is set to alarm input, the Event Input Alarm Message entry allows the user or

OEM to assign the alarm message that will be shown on the alarm screen in the runtime application when the

input is activated. The alarm message can be up to 25 characters long.

4.3.9 Low/High Limit Setpoint

The low and high limit set points are used to set the minimum and maximum allowed set points that can be

entered for the loop control. These are typically set by the OEM to limit the control range to within the safe

operating range of the equipment.

NOTE: The runtime application provides additional user low and high set point limits. These can be adjusted

to further limit the allowable set point range within the band set by the OEM low and high set point

limits.

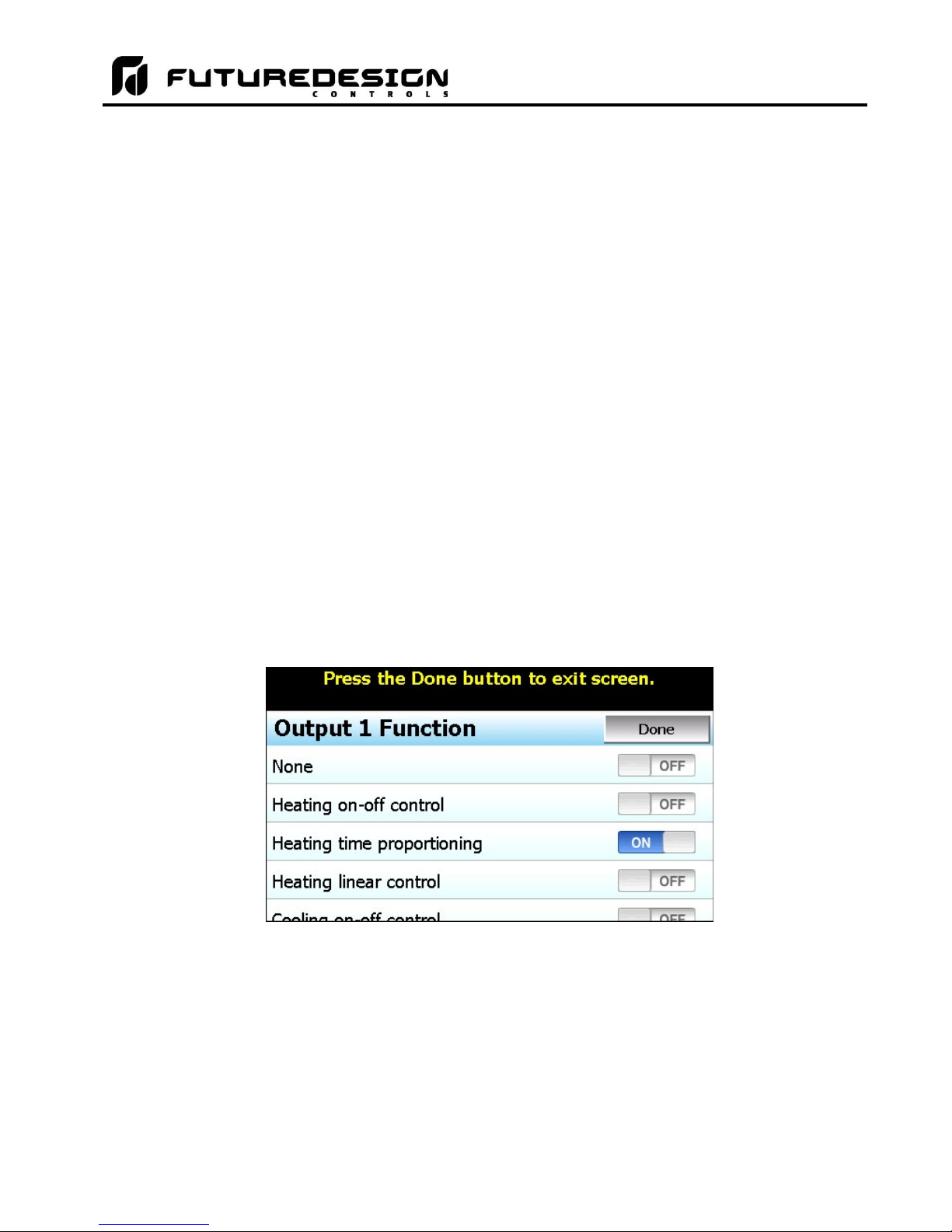

4.3.10 Output 1 Function

The Output 1 Function is used to set the mode of operation for the primary control output of the loop control

board. The output can be set for heating or cooling on/off control, time proportioning or linear control. The

output selections are mutually exclusive, i.e., selecting one will turn off the others. Once the desired function

has been selected, press the “Done” button to set the output function for the loop control board and return to

the main Loop Configuration screen.

NOTE: The output function must be set to match the type of output ordered on the loop control board. Relay,

triac and SSR output types are used for on/off and time proportioning control. The isolated Vdc and

mA output types are used for linear control.

The Heating on-off control function will turn on the output when the process value is below set point. When

the process value rises above the set point plus the on-off control hysteresis, the output will turn off.

The Heating time proportioning function uses the PID settings to cycle the output on and off according to the

percentage of heating required using the cycle time configured for output 1. For example, if the percentage of

output is 50% and the cycle time is 18 seconds, the output will repeat on/off cycles of 9 seconds each. If the

output was only 25%, the output would be on for 4.5 seconds and off for 13.5 seconds of the 18 second cycle

time.

The Heating linear control function uses the PID settings to vary the Vdc or mA output from the minimum to

the maximum range of the output as a direct percentage of the heating output.

FDC MCT-MC - 26 - Configuring the MCT-MC

Page 27

MCT-MC 4.3

The Cooling on-off control function will turn on the output when the process value is above set point. When

the process value falls below the set point minus the on-off control hysteresis, the output will turn off.

The Cooling time proportioning function uses the PID settings to cycle the output on and off according to the

percentage of cooling required using the cycle time configured for output 1. For example, if the percentage of

output is 50% and the cycle time is 6 seconds, the output will repeat on/off cycles of 3 seconds each. If the

output was only 25%, the output would be on for 0.75 seconds and off for 5.25 seconds of the 6 second cycle

time.

The Cooling linear control function uses the PID settings to vary the Vdc or mA output from the minimum to

the maximum range of the output as a direct percentage of the cooling output.

4.3.11 Output 1 Failure Transfer

The output 1 failure transfer setting is used to set the value the output should go to if there is an input failure,

i.e., sensor break. The output can be set for bumpless (-1) operation or a fixed percentage of output (from 0 to

100%) if proportioning or linear control is selected fro the output function. When failure transfer is set to

bumpless, the output will remain at its previous percentage of output until the input condition is corrected. Note

that this should not be used for extended periods of time as a runaway condition could occur if separate limit

devices are not installed to insure safe limits of operation by turning off the system should a limit be exceeded.

If the output function is set for on-off control, the failure transfer can be set to have the output turn on (1) or turn

off (0) when a sensor break occurs.

4.3.12 Output 1 ON-OFF Control Hysteresis

The output 1 on-off control hysteresis can be set when the output 1 function is set for heating or cooling on-off

control. It is used to eliminate rapid cycling of the control output by applying a safe-sided dead band to the

control output. When the control set point is exceeded, the output will turn on. The output will not turn off until

the process rises above (for heating) or falls below (for cooling) the set point by the hysteresis value.

The hysteresis can be set from a minimum of 0.1 to a maximum of 50.0 for units of degrees Centigrade and to

a maximum of 90.0 for units of degrees Fahrenheit and when a linear input type is used.

4.3.13 Output 1 Cycle Time

The output 1 cycle time can be set when the output 1 function is set for heating or cooling proportioning control.

The cycle time can be adjusted from 0.1 to 90.0 seconds. For cycle times less than 18 seconds, it is

recommended that the loop control board be ordered with the triac or SSR drive output for output 1 to extend

the life of the control output.

4.3.14 Output 1 Low/High Limit Values

The output low and high limit values can be set when the output 1 function is set for heating or cooling time

proportioning or linear control. They are used to set the minimum and maximum percentage of output that the

output will control to with a default of 0% for the low and 100% for the high. By raising the low limit or reducing

the high limit, the output will not exceed the output value regardless of the percent output required by the PID

values.

For example, raising the low limit to 5% with the output set for heating proportioning control, even if the process

value is over set point and the PID values are calling for a 0% output, the output will continue to cycle on and

off at 5% heating output.

Configuring the MCT-MC - 27 - FDC MCT-MC

Page 28

MCT-MC 4.3

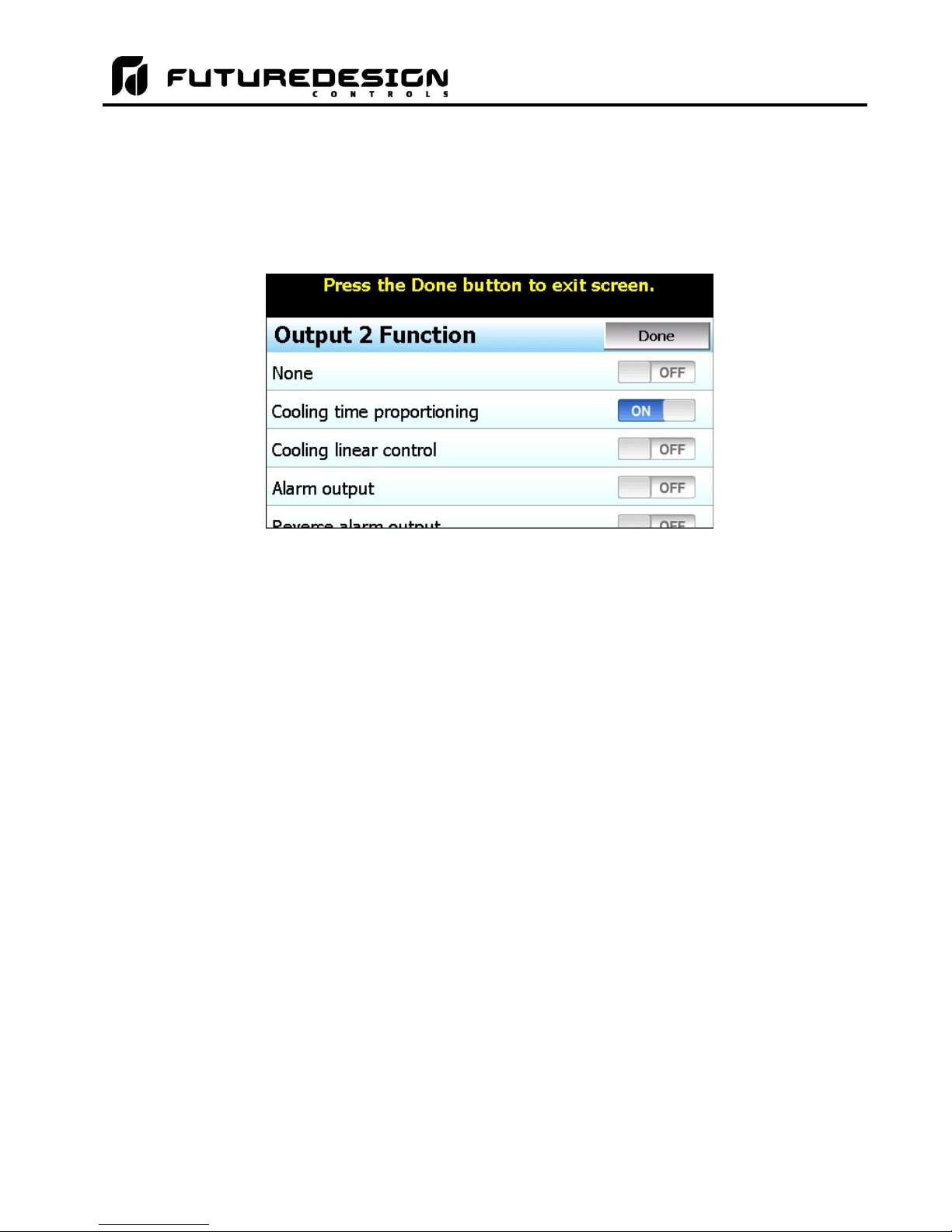

4.3.15 Output 2 Function

The Output 2 Function is used to set the mode of operation for the secondary control output of the loop control

board.