Page 1

9090 User's Manual9090 User's Manual

FDC-9090

FDC-9090

Self-Tune Fuzzy / PID

Self-Tune

Process

Process / Temperature Controller

Fuzzy / PID

/ Temperature Controller

Page 2

Warning SymbolWarning Symbol

This Symbol calls attention to an operating procedure, practice, or

the like, which, if not correctly performed or adhered to, could result

in personal injury or damage to or destruction of part or all of the

product and system. Do NOT proceed beyond a warning symbol

until the indicated conditions are fully understood and met.

Use the ManualUse the Manual

Specifications

Wiring

Programming

Warranty

NOTE:

It is strongly recommended that a process should

It is strongly recommended that a process should

incorporate a LIMIT like L91 which will shut down the

incorporate

equipment

equipment at a preset process condition in order

preclude possible damage to products or

to

to preclude possible damage to products or

system.

system.

Copyright a August 2001, Future Design Controls, all rights

reserved. No part of this publication may be reproduced,

transmitted, transcribed or stored in a retrieval system, or

translated into any language in any form by any means without

the written permission of Future Design Controls.

at a preset process condition in order

Page 3

Page 4

Page 6

Page 11

a LIMIT like L91 which will shut down the

2

UM9090Rev3.0

Page 3

Model:FDC 9090

Model:FDC 9090

Instruction Manual

Instruction

1. INTRODUCTION

1. INTRODUCTION

2. NUMBERING SYSTEM

2.

NUMBERING SYSTEM

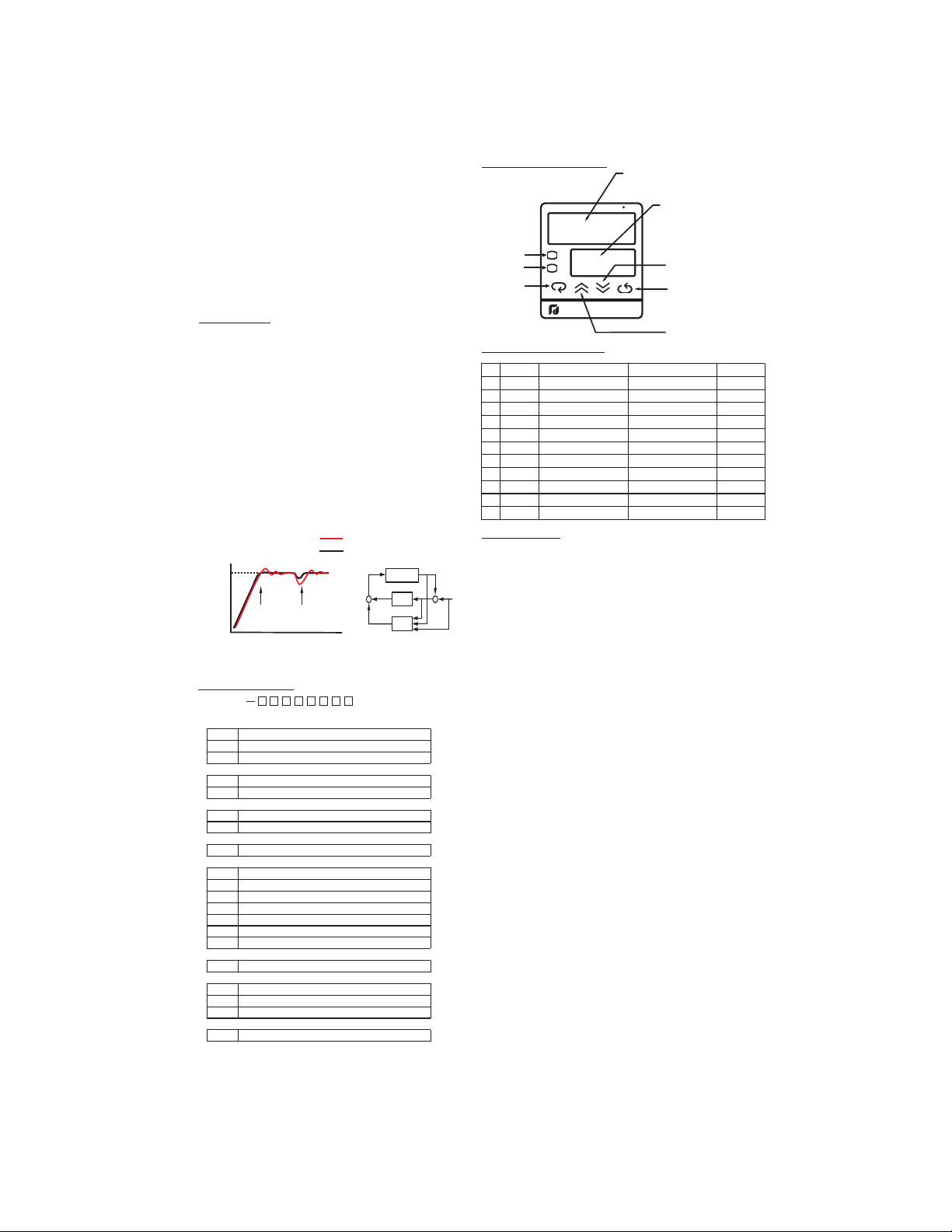

3. FRONT PANEL DESCRIPTION

3.

FRONT PANEL DESCRIPTION

4. INPUT RANGE & ACCURACY

4.

INPUT RANGE & ACCURACY

5. SPECIFICATIONS

5.

SPECIFICATIONS

6. INSTALLATION

6.

INSTALLATION

6.1 DIMENSIONS & PANEL CUTOUT

6.2 WIRING DIAGRAM

1. INTRODUCTION1. INTRODUCTION

This manual contains information for the installation and operation

of the Future Design Control’s model FDC-9090 Fuzzy Logic

micro-processor based controller.

The Fuzzy Logic is an essential feature of this versatile

controller. Although PID control has been widely accepted by

industries, it is difficult for PID control to work with some sophistic

systems efficiently, for example, systems of second order, long

time-lag, various set points, various loads, etc. Because of

disadvantage of controlling principles and fixed values of PID

control, it is inefficient to control the systems with many

variables and the result is unacceptable control for some

systems. The Fuzzy Logic control can overcome the

disadvantage of PID control only. It controls the system in a

efficient way by experiences it had before. The function of Fuzzy

Logic is to adjust the PID values indirectly in order to making the

manipulation output value MV adjusts automatically and quickly

to adapt to various processes. It enables a process to reach its

set point in the shortest time with minimum overshooting during

tuning or external disturbance.

PID control with properly tuned

PID + Fuzzy control

Set point

In addition, this instrument has functions of single stage ramp

and dwell, auto-tunung and manual mode execution. Ease of use

also an essential feature with it.

2. Model Order Matrix2. Model Order Matrix

FDC

(1) Power Input

4 90-264VAC

5 20-32VAC/VDC

9 Other

(2) Signal Input

5 Configurable (Universal)

9 Other

(3) Range Code

1 Configurable

9 Other

(4) Control Mode

3 PID / ON-OFF Control

(5) Output 1 Option

0 None

1 Relay rated 3A/240VAC resistive

2 SSR Drive rated 20mA/24V

3 4-20mA linear, max. load 500 ohms (Module OM93-1)

4 0-20mA linear, max. load 500 ohms (Module OM93-2)

5 0-10V linear, min. impedance 500K ohms (Module OM93-3)

9 Other

(6) Output 2 Option

0 None

(7) Alarm Option

0 None

1 Relay rated 2A/240VAC resistive

9 Other

(8) Communication

0 None

CONTENTS

Temperature

Load Disturbance

Warm Up

(1) (2) (3) (4) (5) (6) (7) (8)

Manual

7

. OPERATION

7

. OPERATION

7.1 KEYPAD OPERATION

AUTOMATIC TUNING

7.2

MANUAL P.I.D. ADJUSTMENT

7.3

RAMP & DWELL

7.4

MANUAL TUNING PROCEDURE

7.5

FLOW CHART

7.6

PARAMETER DESCRIPTION

7.7

8. CALIBRATION8. CALIBRATION

9. ERROR MESSAGES9. ERROR MESSAGES

PID+FUZZY CONTROL

MV

SYSTEM

PID

+

+

FUZZY

Time

PV

_

+

3. FRONT PANEL DESCRIPTION3. FRONT PANEL DESCRIPTION

Sensor

J

K

T

E

B

R

S

N

RTD

RTD

Linear

CON

ALM

Iron-Constantan

Chromel-Alumel

Copper-Constantan

Chromel-Constantan

Pt30%RH/Pt6%RH

Pt13%RH/Pt

Pt10%RH/Pt

Nicrosil-Nisil

PT100 ohms(DIN)

PT100 ohms(JIS)

-10mV to 60mV

Control Output

Alarm Output

Scroll Key

4. INPUT RANGE & ACCURACY4. INPUT RANGE & ACCURACY

IN

0

1

2

3

4

5

6

7

8

9

10

5. SPECIFICATIONS5. SPECIFICATIONS

INPUT

Thermocouple (T/C):

RTD:

Linear:

SV

Range:

Accuracy:

Cold Junction Compensation:

Sensor Break Protection:

External Resistance:

Normal Mode Rejection:

Common Mode Rejection:

Sample Rate:

CONTROL

Proportion Band:

Reset ( Integral ):

Rate ( Derivative ):

Ramp Rate:

Dwell:

ON-OFF:

Cycle Time:

Control Action:

POWER

Rating:

Consumption:

ENVIRONMENTAL & PHYSICAL

Approvals:

EMC Emission:

EMC Immunity:

Operating Temperature:

Humidity:

Insulation:

Breakdown:

Vibration:

Shock:

Net Weight:

Housing Materials:

Process Value Display

(0.4" red LED)

Set point Value Display

PV

SV

C

(0.3" green LED)

Down Key

Return Key

9090

Up Key

Input Type

J, K, T, E, B, R, S, N.

PT100 ohm RTD (PTDN or JIS)

-10 to 60 mV, configurable input attenuation

User configurable, refer to Table above

Refer to Table above

0.1 C/ C ambient typical

Protection mode configurable

100 ohms max.

60 dB

120dB

3 times / second

0 - 200 C ( 0-360F)

0 - 3600 seconds

0 - 1000 seconds

0 - 200.0 C / minute (

0 - 3600 minutes

With adjustable hysteresis (0-20% of SPAN)

0-120 seconds

Direct (for cooling ) and reverse (for heating)

90-264VAC, 50/ 60Hz

Less than 5VA

UR File E196206, CSA 209463

CE., RoHS Compliant

EN50081-1

EN50082-2

-10 to 50 C

0 to 90 % RH (non-codensing)

20M ohms min. ( 500 VDC )

AC 2000V, 50/60 Hz, 1 minute

10 - 55 Hz, amplitude 1 mm

200 m/ s ( 20g )

170 grams

Poly-Carbonate Plastic

Range( C/F )

-50/999C -58/1830F

-50/1370C -58/2498F

-270 to 400 C -454/752F

-50/750C -58/1382F

300/1800C 572/3272F

0/1750C 32/3182F

0/1750C 32/3182F

-50/1300C -58/2372F

-200/400C -328/752F

-200/400C -328/752F

-1999 to 9999

0 - 360.0 F / minute)

2

Accuracy

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-2 C(4F)

+/-0.4 C(.8F)

+/-0.4 C(.8F)

+/-0.05%

UM9090Rev3.0

3

Page 4

6. INSTALLATION6. INSTALLATION

6.1 DIMENSIONS & PANEL CUTOUT6.1 DIMENSIONS & PANEL CUTOUT

(45 mm)

1.77 “

1.77 “

(45 mm)

Panel

3.38 “

86 mm

3.70 “

Figure 6.1 Mounting Dimensions

6.2 WIRING DIAGRAM6.2 WIRING DIAGRAM

FDC-9090

Alarm

Com.

1

Alarm

2

N/O

RTD

7. OPERATION7. OPERATION

7.1 KEYPAD OPERATION7.1 KEYPAD OPERATION

TOUCHKEYS FUNCTION DESCRIPTION

3

_

_

4

V

+

+

5

* F1: Fuse, S1: Power Switch

* With power on, it has to wait for 12 seconds to memorize the new values of parameters once it been changed.

6

7

8

9

10

Scroll Key

94 mm

S1

F1

90 - 264 VAC,50/60HZ

+

_

Control Output 1

Advance the index display to the desired position.

Index advanced continuously and cyclically by pressing this keypad.

7.2 AUTOMATIC TUNING

1. Ensure that controller is correctly configured and installed.

2. Ensure Proportional Band 'Pb' is not set at '0'.

3. Press Return Key for at least 6 seconds ( maximum 16 seconds). This

initializes the Auto-tune function. (To abort auto-tuning procedure

press Return Key and release).

4. The Decimal point in lower right hand corner of PV display flashes to

indicate Auto-tune is in progress. Auto-tune is complete when the

flashing stops.

5. Depending on the particular process, automatic tuning may take up

to two hours. Processes with long time lags will take the longest to

tune. Remember, while the display point flashes the controller is

auto-tuning.

NOTE: If an AT error( ) occurs, the automatic tuning process

is aborted due to the system operating in ON-OFF control(PB=0).

The process will also be aborted if the set point is set to close to

the process temperature or if there is insufficient capacity in the

system to reach set point (e.g. inadequate heating power

available). Upon completion of Auto-tune the new P.I.D. settings

are automatically entered into the controller's non-volatile memory.

7.3 MANUAL P.I.D.ADJUSTMENT7.3 MANUAL P.I.D.ADJUSTMENT

Whilst the auto-tuning function selects control settings which should prove

satisfactory for the majority of processes, you may find it necessary to

make adjustments to these arbitrary settings from time to time. This may

be the case if some changes are made to the process or if you wish to

'fine-tune' the control settings.

It is important that prior to making changes to the control settings that

you record the current settings for future reference. Make slight changes

to only one setting at a time and observe the results on the process.

Because each of the settings interact with each other, it is easy to become

confused with the results if you are not familiar with process control

procedures.

TUNING GUIDETUNING GUIDE

Proportional Band

Symptom

Slow Response

High Overshoot or Oscillations

Integral Time (Reset)

Symptom

Slow Response

Instability or Oscillations

Derivative Time (Rate)

Symptom

Slow Response or Oscillations

High Overshoot

Solution

Decrease PB Value

Increase PB Value

Solution

Decrease Integral Time

Increase Integral Time

Solution

Decrease Deriv. Time

Increase TimeDeriv.

Press

for 6 seconds

Press

for 6 seconds

Press and

Press and

for 6 seconds

Up Key

Down Key

Return Key

Long Scroll

Long Return

Output Percentage

Monitor

Manual Mode

Execution

Increases the parameter

Decreases the parameter

Resets the controller to its normal status. Also stops auto-tuning,

output percentage monitoring and manual mode operation.

Allows more parameters to be inspected or changed.

1. Executes auto-tuning function

2. Calibrates control when in calibration level

Allows the set point display to indicate the control output value.

Allows the controller to enter the manual mode.

4

UM9090Rev3.0

Page 5

7.4 RAMP & DWELL7.4 RAMP & DWELL

The FDC-9090 controller can be configured to act as either a fixed

set point controller or as a single ramp controller on power up. This

function enables the user to set a pre-determined ramp rate to

allow the process to gradually reach set point temperature, thus

producing a 'Soft Start' function.

A dwell timer is incorporated within the FDC-9090 and the alarm

relay can be configured to provide either a dwell function to be

used in conjunction with the ramp function.

The ramp rate is determined by the ' ' parameter which can be

adjusted in the range 0 to 200.0 C/minute. The ramp rate function

is disabled when the ' ' parameter is set to ' 0 '.

The soak function is enabled by configuring the alarm output to act

as a dwell timer. The parameter needs to be set to the

value 12. The alarm contact will now operate as a timer contact,

with the contact being closed at power up and opening after the

elapsed time set at parameter .

If the controller power supply or output is wired through the alarm

contact, the controller will operate as a guaranteed soak controller.

In the example below the Ramp Rate is set to 5 C/minute,

=12 and =15 (minutes). Power is applied at zero

time and the process climbs at 5 C/minute to the set point of 125

C. Upon reaching set point, the dwell timer is activated and after

the soak time of 15 minutes, the alarm contact will open, switching

off the output. The process temperature will eventually fall at an

undetermined rate.

BC

150

125

15 minutes

10 20 30

Process Value

Alarm Output

ON

40 50

60

OFF

t(minutes)

70

90

80

100

75

50

25

0

The dwell function may be used to operate an external device such

as a siren to alert when a soak time has been reached.

need to be set to the value 13. The alarm contact will now

operate as a timer contact, with the contact being open on the

initial start up. The timer begins to count down once the set point

temperature is reached. After the setting at has elapsed, the

alarm contact closes.

7.5 MANUAL TUNING PROCEDURE7.5 MANUAL TUNING PROCEDURE

Step 1: Adjust the integral and derivative values to 0. This inhibits the

rate and reset action

Step 2: Set an arbitrary value of proportional band and monitor the

control results

Step 3: If the original setting introduces a large process oscillation, then

gradually increase the proportional band until steady cycling

occurs. Record this proportional band value(Pc).

Step 4: Measure the period of steady cycling

PV

PV(Process value)

Record this value (Tc) in seconds

Step 5: The Control Settings are determined as follows:

Proportion Band(PB)=1.7 Pc

Integral Time (TI)=0.5 Tc

Derivative Time(TD)=0.125 Tc

Tc

TIME

9. ERRORMESSAGES9. ERRORMESSAGES

Symptom

Cause (s) Solution (s)

Sensor break error

Process display beyond

the low range set point

Process display beyond

the high range set point

Analog hybrid module

damage

Incorrect operation of

auto tune procedure

Prop. Band set to 0

Manual mode is not

allowable for an ON-OFF

control system

Check sum error, values

in memory may have

changed accidentally

Replace RTD or sensor

Use manual mode operation

Re-adjust value

Re-adjust value

Replace module. Check for

outside source of damage

such as transient voltage spikes

Repeat procedure. Increase

Prop. Band to a number larger

than 0

Increase proportional band

Check and reconfigure the

control parameters

UM9090Rev3.0

5

Page 6

7.6 Flow Chart7.6 Flow Chart

The "return" key can be pressed at any time.

This will prompt the display to return to the

Process value/Set point value.

Power Applied:

1.

(Software Version 3.6 or higher)

2.

All LED segments must be lit for 4 seconds.

3. Process value and set point indicated.

6

PROCESS VALUE DISPLAY

SET POINT VALUE DISPLAY

Long

(6 seconds)

Long

(6 seconds)

Parameters

are factory set.

If change is

required

see page 6 for

proper setting

Long

(6 seconds)

Long

(6 seconds)

of PVL & PVH

All Units are

factory calibrated.

If performing a

calibration follow

proper procedure.

See page 4 and 5.

Please turn to Page 6 for

proper setting of these

parameters. Failure to

proper set can cause

loss of

calibration of unit.

Displayed for 4 seconds.

LED test.

7.7 PARAMETER DESCRIPTION7.7 PARAMETER DESCRIPTION

Level 0

Level 1

INDEX

CODE

SV

DESCRIPTION

ADJUSTMENT RANGE

Set point Value Control

*Low Limit to High Limit Value

Alarm Set point Value

* Low Limit to High Limit Value.(if =0, 1, 4 or 5)

* 0 to 3600 minutes ( if =12 or 13)

* Low Limit minus set point to high Limit minus set

point value ( if =2, 3, 6 to 11 )

Ramp Rate for the process value to limit an abrupt

change of process (Soft Start)

* 0 to 200.0 C (360.0 F) / minute ( if = 0 to 9 )

* 0 to 3600 unit / minute ( if =10 )

Offset Value for Manual Reset ( if = 0 )

* 0 to 100%

Offset shift for process value

*-111Cto111C

Proportional Band

* 0 to 200 C ( set to 0 for on-off control)

Integral (Reset) Time

* 0 to 3600 seconds

Derivative (Rate) Time

* 0 to 1000 seconds

Local Mode

0: No control parameters can be changed

1: Control parameters can be changed

Parameter Selection ( allows selection of additional

parameters to be accessible at level 0 security)

0: None 4:

1: 5:

Level 2

Level 3

Level 4

2: 6:

3: 7:

Proportional Cycle Time

* 0 to 120 seconds

Input Mode Selection

0: J type T/C

1: K type T/C

2: T type T/C

3: E type T/C

4: B type T/C

5: R type T/C

Note: T/C-Close solder gap G5, RTD-Open G5

Alarm Mode Selection

0: Process High Alarm

1: Process Low Alarm

2: Deviation High Alarm

3: Deviation Low Alarm

4: Inhibit Process High Alarm

5: Inhibit Process Low Alarm

6: Inhibit Deviation High Alarm

7: Inhibit Deviation Low Alarm

Hysteresis of Alarm 1

* 0 to 20% of SPAN

C / F Selection

0: F, 1: C

Resolution Selection

0: No Decimal Point

1: 1 Digit Decimal

(2 & 3 may only be used for linear voltage or current

=10 )

Control Action

0: Direct (Cooling) Action 1: Reverse (Heat) Action

Error Protection

0: Control OFF, Alarm OFF

1: Control OFF, Alarm ON

Hysteresis for ON/OFF Control

*0 to 20 % of SPAN

6: S type T/C

7: N type T/C

8: PT100 DIN

9: PT100 JIS

10: Linear Voltage or Current

,

8: Outband Alarm

9: inband Alarm

10: Inhibit Outband Alarm

11: Inhibit Inband Alarm

12: Alarm Relay OFF as

Dwell Time Out

13: Alarm Relay ON as

Dwell Time Out

2: 2 Digit Decimal

3: 3 Digit Decimal

2: Control ON , Alarm OFF

3: Control ON, Alarm ON

Low Limit of Range

High Limit of Range

Low Calibration Figure

High Calibration Figure

**** * *

Low Calibration Figure Set to One Tenth the LCAL Value

*

**** * *

High Calibration Figure Set to One Tenth the HCAL Value

* Adjusting Range of the Parameter

** Factory settings. Process alarms are at fixed temperature points. Deviation alarms move with setpoints

*

NOTE *** Parameters are for Version 3.7

*

*

ONLY

UM9090Rev3.0

,

,,

**DEFAULT

SETTING

Undefined

200 C

(392F)

0C/min

(32F / min).

0.0 %

0C

(32F)

10 C

(50F)

120 sec.

30 sec.

1

0

Relay

Pulsed Voltage

Linear Volt/mA

T/C

RTD

Linear

0

0.5%

1

0

1

1

0.5%

-50 C( -58F)

1000C (1832F)

0 C (32F)

800 C (1472F)

0 C (32F)

80 C (176F)

20

1

0

0

8

10

Page 7

PROCESS VALUE DISPLAY

SET POINT VALUE DISPLAY

Long

(6 seconds)

Long

(6 seconds)

Level 0

Level 1

Level 2

Supplemental Instruction for the New Version V7.3 ONLY

NOTE: This procedure does NOT have to be performed unless the

LLit and/or Hlit have been changed from the factory setting.

This routine properly adjusts the calibration values IF the Llit

and/or Hlit parameters have been changed from factory default.

Setting the PVL and PVH correctly allows proper operation of unit.

No additional calibration is required.

The unit with firmware version V3.7 has two additional parameters - "PVL"

and "PVH" located in the level 4 as parameters flow chart on the left hand

side indicates.

When you need to change the LLit value to a higher value or change the

HLit value to a lower value, the following procedures MUST be

performed to make the PVL value equivalent to one tenth of LCAL value

and the PVH value equivalent to one tenth of HCAL value. Otherwise

the measured process values will be out of specification.

1.Follow the Setup Parameter procedure and scroll down to the "LLit"

parameter. Change parameter using the up and down arrow to new

desired value you require.

2.Press and release the Scroll Key, "HLit" appears on the PV Display.

Use Up and Down Keys to set the HLit value to the new desired value

you require.

3.Turn the power OFF wait 5 seconds and re-power the unit.

4.Following the Setup parameter entry routine advance until the "LCAL"

appears on the PV Display. Record the LCAL value.

5.Press and release the Scroll Key, then "HCAL" appears on the PV

Display. Record the HCAL value.

6.Press the Scroll Key for at least 6 seconds and then release, "PVL"

appears on the PV Display. Use UP and Down Keys to set the PVL value

to of LCAL value.

one tenth

7.Press and release the Scroll Key, "PVH" appears on the PV Display.

Use UP and Down Keys to set the PVH value to of HCAL value.

one tenth

8. Adjustment is complete. Exit by depressing the Return Key.

9. Unit should display the proper process value.

Long

(6 seconds)

Long

(6 seconds)

Level 3

Level 4

Proper setting of the PVL and PVH parameters can be confirmed by entering

the Setup parameter routine and scrolling through the complete parameter

listing and verifying the PVL and PVH parameters are set to the required

one tenth

the value of LCAL and HCAL respectively.

7

UM9090Rev3.0

Page 8

7.0 Manual Calibration Procedures

All units are factory calibrated. If field calibration is required you must use NIST traceable

calibration equipment to meet specifications. If proper equipment is not available please

return to factory for proper service.

Equipment required is:

1.) A Millivolt source 0/100Mv +/- 0.005% accuracy

2.) K thermocouple simulator 0.01% accuracy

3.) RTD simulator 0/300 ohms 0.01%accuracy

Main A to D Calibration:

This calibration procedure requires a Millivolt source.

This calibration be done for input types.

Connect the Millivolt source as shown below:

1.)

Positive lead to terminal 5 and negative lead to terminal 4.

Set the Millivolt source for 0.00 MV.

must ALL

Millivolt

- Lead

Simulator

+ Lead

Millivolt wiring DiagramMillivolt wiring Diagram

FDC-9090

1

2

3

4

5

S1

F1

6

90 - 264 VAC,50/60HZ

7

8

9

10

AC power to unit

AC power to unit

calibration

under calibration

under

2.)

Enter into the setup parameter menu and set the following parameters to the settings shown below;

IN = 1, LLiT= -50.0, HLit = 1370

With HLit on the display press and hold scroll key for 6 seconds then release. The display should read

3.)

LCAL set this value to 0.0 using up/down arrow keys to obtain 0.0

Press and release scroll key the display reads HCAL set this value to 800.0 using arrow keys.

4.)

Press and hold the scroll key for 6 seconds then release the display will read PVL, set this value to 0.0

5.)

using the arrow keys.

Press and release scroll key display reads PVH set this value to 80.0 using the arrow keys.

6.)

Press and hold the scroll key for 6 seconds then release. The display will read AdLo Input a 0.0 MV

7.)

signal then press and hold the scroll key for 6 seconds, then release. The display will blink momentarily

and a new value will be obtained.

If the display does not blink or the value is equal to -199.9 or 199.9 then calibration failed.

Press and release scroll key. The display will read AdHi. Input a 60.0 MV signal then press and hold the

8.)

scroll key for 6 seconds then release.

The display will blink momentarily a new value will be obtained.

If the display does not blink or the value is equal to -199.9 or 199.9 then calibration fails.

If calibrations fails check equipment connections and setting and repeat. If unsuccessful return to

manufacturer.

If calibration is successful then proceed to next page for Cold Junction Calibration for

thermocouples and RTD calibration if using RTD input.

8

Page 9

7.0 Manual Calibration Procedures (continued)

RTD Input calibration

Solder Gap G5 be prior to performing RTD calibration.*

Connect a 3 wire RTD simulator to the RTD input as shown below: The “hot” lead connects to terminal

1.)

- Perform this calibration if RTD input is to be used on the unit.

MUST OPENED

3. The 2 common leads go to terminals4&5.

6.2 WIRING DIAGRAM6.2 WIRING DIAGRAM

RTD

Simulator

2.)

Set the RTD simulator to simulate 100 ohms.

If you exited the calibration mode, Re-enter as described in the parameter setup routine and scroll

3.)

Hot lead

Common lead

Common lead

RTD Input

Alarm

Com.

Alarm

N/O

1

2

3

4

5

FDC-9090

F1

6

7

8

+

_

9

10

AC power to unit

AC power to unit

S1

90 - 264 VAC,50/60HZ

Control Output 1

calibration

under calibration

under

down until display reads rtdL. With rtdL on the display and 100 ohm input from simulator, press and hold

the scroll key for 6 seconds then release.

The display will blink momentarily and a new value will be obtained.

If the display does not blink then calibration fails.

4.)

Press and release the scroll key the display reads rtdH. Now set the RTD simulator to 300 ohms,with rtdH

on the display press and hold the scroll key for 6 seconds then release the scroll key.

The display will blink momentarily and a new value will be obtained.

If the display does not blink or the value equals -199.9 or 199.9 then calibration fails.

If successful RTD calibration is complete. Disconnect the RTD and program as needed.

Cold Junction Calibration

unit. NOTE: Solder MUST be to perform this calibration. *

Connect a K thermocouple simulator wired as shown below:

1.)

Gap G5 ClOSED

- Perform this calibration if Thermocouple input is to be used on the

Terminal 5 is the Positive lead (Yellow) and terminal 4 is negative lead (Red).

Set the K simulator to simulate 0.0 C degrees.

2.)

FDC-9090

Alarm

Com.

Temperature

Calibrator

K-TC

K

K+

2.)

If you exited the calibration mode enter as performed in the main calibration routine and scroll down

Alarm

N/O

1

2

3

4

5

6

7

8

9

10

AC power to unit

AC power to unit

S1

F1

90 - 264 VAC,50/60HZ

calibration

under calibration

under

to the parameter CJLo. With 0.0C simulated on input use the Up and Down arrow key to obtain a reading

of 40.0. Once value at unit is set to 40.0 press and hold the scroll key for 6 seconds then release key.

The display should blink momentarily and a new value is obtained.

If display does not blink and a value equals -5.00 or 40.00 the calibration fails.

If unit can not be field calibrated return to factory for evaluation/repair.

NOTE: All units are shipped typically in thermocouple mode. If RTD input is required you must

OPEN the solder gap G5 on processor board. You do NOT need to recalibrate as ALL

calibration procedures were performed at factory.

* Solder Gap G5 is found on the small “ tail like” PC board inside of unit. To remove unit from

housing push up on the release tab on the bottom from of display bezel and pull bezel

forward. Observer PC board where solder gap G5 is located.

9

UM9090Rev3.0

Page 10

This Page Intentionally Left Blank

10

Page 11

Warranty and Return StatementWarranty and Return Statement

User's Manual

WARRANTY

Future Design Controls products described in this manual are warranted to be free

Future Design Controls products described in this manual are warranted to be free

from functional defects in materials and workmanship at the time theproducts leave

from functional defects in materials and workmanship at the time theproducts leave

Future Design Controls Facilities and to conform at that time to the specifications set

Future Design Controls Facilities and to conform at that time to the specifications set

forth in the relevant Future Design Controls manual, sheet or sheets for a period of 3

forth in the relevant Future Design Controls manual, sheet or sheets for a period of 3

years after delivery to the first purchaser for use.

years after delivery to the first purchaser for use.

There are no expressed or implied Warranties extending beyond the Warranties

There are no expressed or implied Warranties extending beyond the Warranties

herein and above set forth.

herein and above set forth.

Limitations:

Limitations:

Future Design Controls provides no warranty or representations of any sort regarding

Future Design Controls provides no warranty or representations of any sort regarding

the fitness of use or application of its products by the purchaser. Users are responsible

the fitness of use or application of its products by the purchaser. Users are responsible

for the selection, suitability of theproducts for theirapplication or use ofFuture Design

for the selection, suitability of theproducts for theirapplication or use ofFuture Design

Controls products.

Controls products.

Future Design Controls shall not be liable for any damages or losses, whether direct,

Future Design Controls shall not be liable for any damages or losses, whether direct,

indirect, incidental, special, consequential or any damages, costs or expenses

indirect, incidental, special, consequential or any damages, costs or expenses

excepting only the cost or expense of repair or replacement ofFuture Design Controls

excepting only the cost or expense of repair or replacement ofFuture Design Controls

products as described below.

products as described below.

Future Design Controls sole responsibility under the warranty, at Future Design

Future Design Controls sole responsibility under the warranty, at Future Design

Controls option, is limited to replacement or repair, free of charge or refund of

Controls option, is limited to replacement or repair, free of charge or refund of

purchase price within the warranty period specified. The warranty does not apply to

purchase price within the warranty period specified. The warranty does not apply to

damage resulting from transportation, alteration, misuse or abuse.

damage resulting from transportation, alteration, misuse or abuse.

Manual

FDC-9090

F

DC-9090 Process / Temperature ControllerUser's

Process

/

Temperature

Controller

Future Design Controls reserves the right to make changes without notification to

Future Design Controls reserves the right to make changes without notification to

purchaser to materials or processing that does not effect the compliance with any

purchaser to materials or processing that does not effect the compliance with any

applicable specifications.

applicable specifications.

Return Material Authorization:Return Material Authorization:

Contact Future Design Controls for Return Material Authorization Number prior to

Contact Future Design Controls for Return Material Authorization Number prior to

returning any product to our facility.

returning

Future

Future Design Controls

7524 West 98th Place, P.O. Box 1196

7524

Bridgeview,

Bridgeview, IL. 60455 USA

888.751.5444

888.751.5444 - Office

888.307.8014

888.307.8014 - Fax

866.342.5332

866.342.5332 - Technical Support

E-mail:

E-mail:

Website:

Website:

any product to our facility.

Design Controls

West 98th Place, P. O . Box 1196

IL. 60455 USA

- Office

- Fax

- Technical Support

csr@futuredesigncontrols.com

csr@futuredesigncontrols.com

http://futuredesigncontrols.com

http://futuredesigncontrols.com

FDC 9090 Users Manual version 3.0 6/4/2013FDC 9090 Users Manual version 3.0 6/4/2013

11

Page 12

User's Manual

Manual FDC-9090

F

DC-9090 Process / Temperature ControllerUser's

Process

/

Temperature

Future Design Controls

Future Design Controls

West 98th Place, P. O . Box 1196

7524 West 98th Place, P.O. Box 1196

7524

Bridgeview,

Bridgeview, IL. 60455 USA

888.751.5444

888.751.5444 - Office

888.307.8014

888.307.8014 - Fax

866.342.5332

866.342.5332 - Technical Support

E-mail:

E-mail:

Website:

Website:

IL. 60455 USA

- Office

- Fax

- Technical Support

csr@futuredesigncontrols.com

csr@futuredesigncontrols.com

http://futuredesigncontrols.com

http://futuredesigncontrols.com

Controller

Um9090 Rev 3.0Um9090

Rev

3.0

Version3.0 Dated 6/2013

Loading...

Loading...