Page 1

User's Manual

FDC-2220

Self-T une Fuzzy / PID

Process Temperature Controller

Page 2

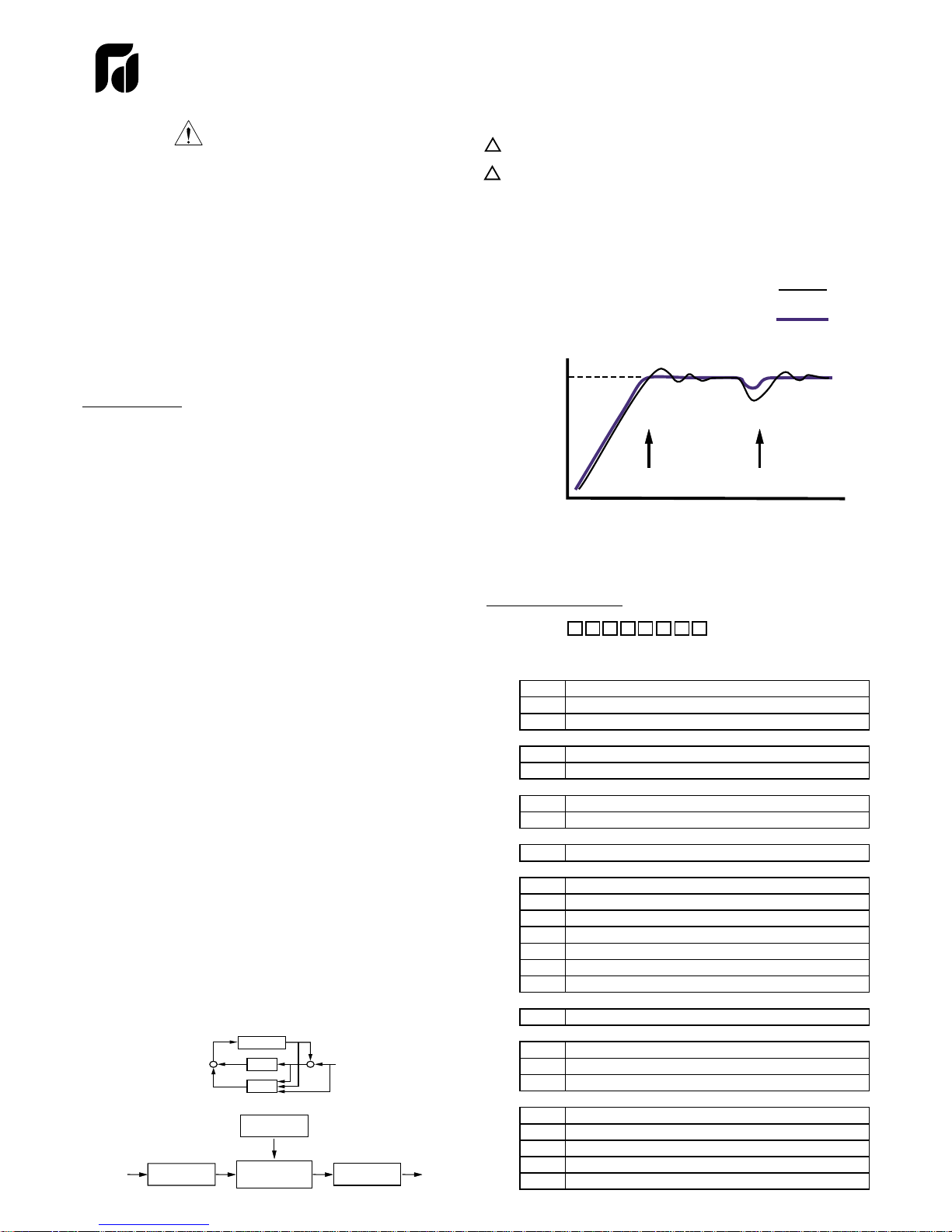

The function of Fuzzy Logic is to adjust the PID parameters internally in

order to make the manipulation output value MV more flexible and adaptive

to various processes.

The Fuzzy Rule may like these:

If temperature difference is large, and temperature rate is large, then

MV is large.

If temperature difference is large, and temperature rate is small, then

MV is small.

¦

¦

¦

PID + Fuzzy Control has been proven to be an efficient method to improve

the control stability as shown by the comparison curves below: CONTENTS

1. INTRODUCTION 5. OPERATION

2. NUMBERING SYSTEM 6. RE-CALIBRATION

3. SPECIFICATIONS 7. ERROR MESSAGE & DIAGNOSIS

4. INST ALLATION 8. COMMON FAILURE CAUSES

1. INTRODUCTION

The FDC-2220 Fuzzy Logic plus PID microprocessor controller,

incorporates a bright, easy to read 4-digit LED display, indicating process

value. The Fuzzy Logic technology enables a process to reach a

predetermined setpoint in the shortest time, with the minimum of overshoot

during power-up or external load disturbance. The units are housed in a

1/32 DIN case, measuring 24 mm x 48 mm with 98mm behind panel depth.

The units features three touch keys to select the various control and input

parameters. Using a unique command called " CONFIGURE LEVEL ", a

supervisor has the flexibility of determining which parameters are accessible

by the user. Also the scrolling sequence of parameters are fully configurable

according to your requirement. This is particularly useful to OEM's, as it is

easy to limit access to suit the specific application.

The FDC-2220 is powered by 20-32VAC/VDC or 90-264VAC supply,

incorporating a 3 amp. control relay output and a 3 amp. alarm relay output

as standard which can be programmed into Output 2 or dwell timer.

Alternative output options include SSR drive, 4-20mA and 0-10 volts. The

FDC-2220 is fully programmable for PT100, thermocouple types K, J, T, E,

B, R, S, N, 0-20mA, 4-20mA and voltage signal input, with no need to

modify the unit.

Digital communications RS-485 or 4-20mA retransmission are available as

an additional option. These options allow the FDC-2220 to be integrated

with supervisory control systems and software, or alternatively drive

remote display, chart recorders or data-loggers.

In last nearly a hundred years although PID control has been used and

proved to be an efficient controlling method by many industries, yet the PID

is difficult to deal with some sophisticated systems such as second order

systems, long time-lag systems, during setpoint change and / or load

disturbance circumstance etc. The PID principle is based on a mathematic

modeling which is obtained by tuning the process. Unfortunately, many

systems are too complex to describe in numerical terms precisely. In

addition, these systems may be variable from time to time. In order to

overcome the imperfection of PID control, the Fuzzy Technology is

introduced. What is the Fuzzy Control ? It looks like a good driver. Under

different speeds and circumstances, he can control a car well with

experiences he had before and does not require the knowledge of kinetic

theory of motion. The Fuzzy Logic is a linguistic control which is different

from the numerical PID control. It controls the system by experiences and

does not need to simulate the system precisely as been controlled by PID.

The basic theory used in this controller is described in the following block

diagrams:

Safety Symbol

The symbol calls attention to an operating procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in personal

injury or damage to or destruction of part or all of the product. do not

proceed beyond a safety symbol until the indicated conditions are fully

understood and met.

Model: FDC-2220

Instruction Manual

Fuzzy Rule

Fuzzy Inference

Engine

DefuzzifierFuzzifier

Numerical

information

Linguistic

information

Numerical

information

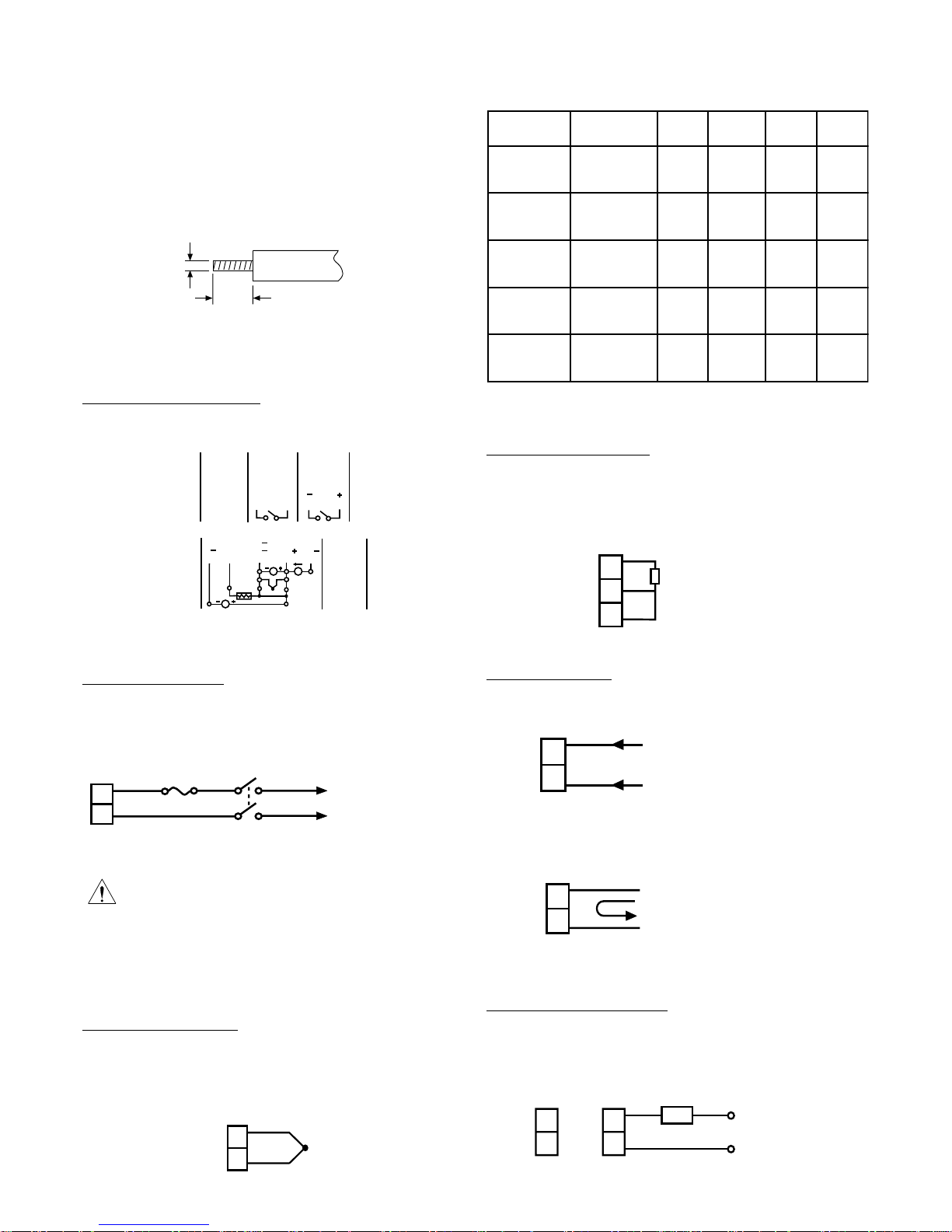

2. NUMBERING SYSTEM

Model No. -

(1) (2) (3) (4) (5) (6) (7) (8)

Warm Up

Load Disturbance

PID control when properly tuned

PID + Fuzzy control

Setpoint

Temperature

Time

(1) Power Input

4 90-264VAC

5 20-32VAC/VDC

9 Other

(2) Signal Input

5 Configurable (Universa l)

9 Other

(3) Range Code

1 Configurable

9 Other

(4) Control Mode

3 PID/ON-OFF Control

(5) Output 1 Option

0 None

1 Relay rated 3A/240VAC resistive

2 SSR Drive rated 20mA/24V

3 4-20mA linear, max. load 500 ohms ( Module OM 92-1)

4 0-20mA linear, max. load 500 ohms ( Module OM 92-2)

5 0-10V linear, min. impedance 500K ohms (M odule OM 92-3)

9 Other

(6) Output 2 Option

0 None

(7) Alarm Option

0 None

1 Relay rated 3A/240VAC resistive

9 Other

(8) Communication

0 None

1 RS-485

2 4-20mA retransmission

3 0-20mA retransmission

9 Other

SYSTEM

PID

FUZZY

MV

PV

_

+

SV

+

+

P I D + FUZZY CONTROL

Page 1

Page 3

Do not use this instrument in areas subject to hazardous conditions

such as excessive shock, vibration, dirt, moisture, corrosive gases or oil.

The ambient temperature of the areas should not exceed the maximum

rating specified in Section 3.

4.1 UNPACKING:

Upon receipt of the shipment remove the instrument from the carton and

inspect the unit for shipping damage. If any damage due to transit is

notices, report and file a claim with the carrier. Write down the model

number, serial number, and date code for future reference when

corresponding with our service center. The serial number (S/N) and date

code (D/C) are located inside the control.

4.2 MOUNTING

Make panel cutout to dimension shown in Figure 4.1.

(a) The clamp for quick mounting:

Take the clamp away and insert the controller into panel cutout install

the clamp back and push it forward till the controller firmly onto the

panel.

(b) The clamps for protection NEMA 4X / IP65:

Take both mounting clamps away and insert the controller into panel

cutout. Install the mounting clamps back. Gently tighten the screws in

the clamp till the controller front panel is fitted snugly in the cutout.

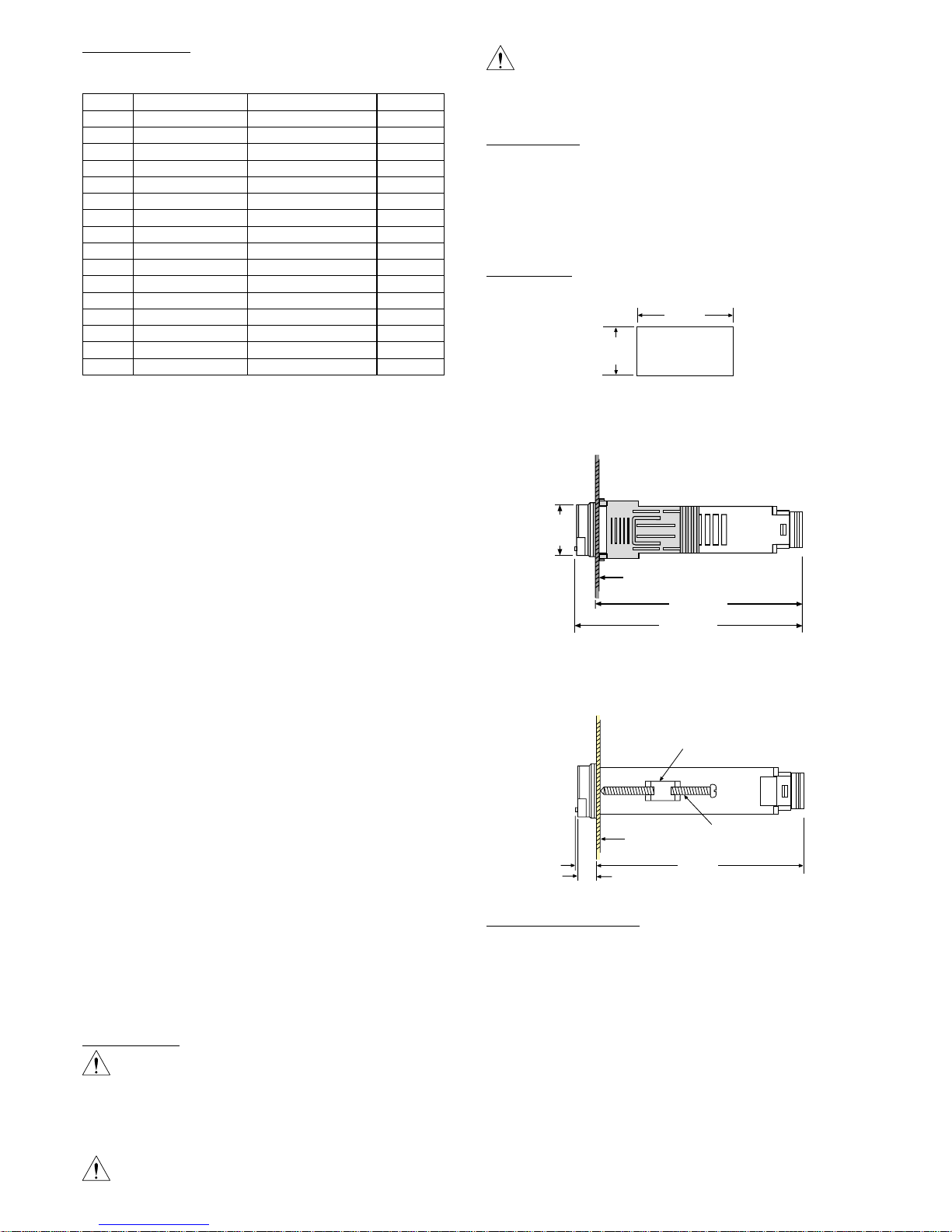

3. SPECIFICATIONS

Sensor Input Type Range (°C) * Accuracy

J Iron-Constantan -50 to 999 °C ±2 °C

K Chromel-Alumel -50 to 1370 °C ±2 °C

T Copper-Constantan -270 to 400 °C ±2 °C

E Chromel-Constantan -50 to 750 °C ±2 °C

B Pt30%RH/Pt6%RH 300 to 1800 °C ±3 °C

R Pt13%RH/Pt 0 to 1750 °C ±2 °C

S Pt10%RH/Pt 0 to 1750 °C ±2 °C

N Nicrosil-Nisil -50 to 1300 °C ±2 °C

RTD PT100 ohms (DIN) -200 to 400 °C ±0.4 °C

RTD PT100 ohms (JIS) -200 to 400 °C ±0.4 °C

Linear 4 - 20 mA -1999 to 9999 ±0.05%

Linear 0 - 20 mA -1999 to 9999 ±0.05%

Linear 0 - 1 V -1999 to 9999 ±0.05%

Linear 0 - 5 V -1999 to 9999 ±0.05%

Linear 1 - 5 V -1999 to 9999 ±0.05%

Linear 0 - 10 V -1999 to 9999 ±0.05%

INPUT

* Accuracy = Linearity Error + Cold Junction Compensating Error

+ Lead Compensating Error + Offset Drift Error

Linear Voltage Input Impedance:

Cold Junction Compensation:

Sensor Break Protection:

External Resistance:

Normal Mode Rejection:

Common Mode Rejection:

Sample Rate:

CONTROL

Proportion Band:

Reset ( Integral ):

Rate ( Derivative ):

Ramp Rate:

Dwell:

ON-OFF:

Cycle Time:

Control Action:

POWER

Rating:

Consumption:

ENVIRONMENTAL & PHYSICAL

Safety:

Protection:

EMC Emmission:

EMC Immunity:

Operating Temperature:

Humidity:

Insulation:

Breakdown:

Vibration:

Shock:

Moldings:

Weight:

100 K ohms

0.1 °C / °C ambient typical

Protection mode configurable

100 ohms max.

60dB

120dB

5 times / second

0-200 °C ( 0-360 °F )

0-3600 seconds

0-1000 seconds

0-55.55 °C ( 99.99 °F) / minute

0-9999 minutes

With adjustable hysteresis 0-11.0 °C ( 0.1-19.9 °F)

0-99 seconds

Direct ( for cooling ) and reverse ( for heating )

90-264VAC, 50 / 60 Hz

Less than 5VA

UL , CSA, CE

NEMA 4X, IP65

EN50081-1, EN55011

IEC801-2, IEC801-3, IEC801-4

-10 to 50 °C

0 to 90% RH ( non-codensing )

20M ohms min. ( 500 VDC )

AC2000V, 50 / 60Hz, 1 minute

10-55Hz, amplitude 1mm

200 m / s

2

(20g )

Flame retardant polycarbonate

110 grams

4. INSTALLATION

Dangerous voltages capable of causing death are sometimes

present in this instrument. Before installation or beginning any trouble

shooting procedures the power to all equipment must be switched off and

isolated. Units suspected of being faulty must be disconnected and

removed to a properly equipped workshop for testing and repair.

Component replacement and internal adjustments must be made by qualified

maintenance personnel only.

To help minimize the possibility of fire or shock hazards, do not

expose this instrument to rain or excessive moisture.

22.2

+0.3

45

+0.5

_

0

_

0

Fig. 4.1 Mounting dimensions

3.85”

Panel

.39”

.49”

SCREW

MOUNTING

CLAMP

3.89”

Panel

14.33”

.94”

4.3 WIRING PRECAUTIONS

* Before wiring, verify the label for correct model number and options.

Switch off the power when checking.

* Care must be taken to ensure that maximum voltage ratings specified in

Section 3 are not exceeded.

* It is recommended that power to these instruments be protected by

fuses or circuit breakers rated at the minimum value possible.

* All units should be installed inside a suitably grounded metal enclosure to

prevent live parts being accessible to human hands and metal tools.

* All wiring must conform to appropriate standards of good practice and

local codes and regulations. Wiring must be suitable for voltage, current,

and temperature ratings of the system.

* The " stripped " leads as specified in Figure 4.2 below are used for

power and sensor connections.

* Take care not to over-tighten the terminal screws.

Page 2

Page 4

4.4.5 Relay Output Direct Drive

Figure 4.9 shows connections using the internal relay to drive a small load.

The current does not exceed 3 amperes.

35

46

or

Load

120V /240V

Mains Supply

Alarm

Output

Control

Output

Max. 3A

Resistive

Fig. 4.9 Relay Direct Drive Connections

TABLE 4.1 THERMOCOUPLE CABLE COLOUR CODES

Thermocouple

Type

Cable

Material

BritishBSAmerican

ASTM

German

DIN

French

NFE

T

Copper

Constantan

+ white

- blue

* blue

+ blue

- red

* blue

+ red

- brown

* brown

+ yellow

- blue

* blue

J

Iron / Constantan

+ yellow

- blue

* black

+ white

- red

* black

+ red

- blue

* blue

+ yellow

- black

* black

K

Nickel Chromium

Nickel

Aluminium

+ brown

- blue

* red

+ yellow

- red

* yellow

+ red

- green

* green

+ yellow

- purple

* yellow

R

S

13% Copper

10% Copper

Nickel

+ white

- blue

* green

+ black

- red

* green

+ red

- white

* white

+ yellow

- green

* green

B

Platinum /

Rhodium

+ grey

- red

* grey

* Colour of overall sheath

11

8

+

_

01V,05V

15V,010V

~

~~

~

Input Impedance = 100k ohm

11

12

+

_

0 20mA or

4 20mA

~

~

Fig. 4.7 Linear Voltage Input Connections

Fig. 4.8 Linear Current Input Connections

4.4.3 PT100 Ohm RTD Input

RTD connection are shown in Figure 4.6, with the compensating lead

connected to terminal 11. For two-wire RTD inputs, terminals 10 and 11

should be linked. The three-wire RTD offers the capability of lead resistance

compensation provided that the three leads should be of same gauge and

equal length.

4.4.4 DC Linear Input

DC linear voltage and linear current connections are shown in Figure 4.7

and Figure 4.8.

10

11

9

A

PT100

B

B

Fig. 4.6 RTD Input Connections

The colour codes used on the thermocouple extension leads are shown in

Table 4.1.

This equipment is designed for installation in an enclosure which

provides adequate protection against electric shock. The enclosure must

be connected to earth ground.

Local requirements regarding electrical installation should be regidly

observed. Consideration should be given to the prevention of unauthorised

personnel from gaining access to the power terminations.

4.4.2 Thermocouple Input

Thermocouple input connections are shown in Figure 4.5. The correct

type of thermocouple extension lead-wire or compensating cable must be

used for the entire distance between the controller and the thermocouple,

ensuring that the correct polarity is observed throughout. Joints in the

cable should be avoided, if possible.

Fig. 4.5 Thermocouple Input Connections

+

10

11

_

Fig. 4.4 Mains (Line) Supply Connections

* Unused control terminals should not be used as jumper points as they

may be internally connected, causing damage to the unit.

* Verify that the ratings of the output devices and the inputs as specified in

Table 4.1 on are not exceeded.

* Electric power in industrial environments contains a certain amount of

noise in the form of transient voltages and spikes. This electrical noise

can enter and adversely affect the operation of microprocessor-based

controls. For this reason we strongly recommend the use of shielded

thermocouple extension wire which connects from the sensor to the

controller. This wire is a twisted-pair construction with foil wrap and

drain wire. The drain wire is to be attached to ground at one end only.

4.4 CONNECTION AND WIRING

The following connections for outputs and inputs are provided at the rear

of the controller housing:

4.4.1 Mains (Line) Input

The controller is supplied to operate on 24V (20-32VAC/VDC) or 90-264V AC.

Check that the installation mains voltage corresponds to that indicated on

the product label before connecting power to the controllers.

+

_

RTD

0-10V

A

+

+

+

COM

_

TC

_

_

_

mV

mV

0-20 mA

4-20 mA

_

mA

B

PTA

B

_

V

POWER IN

90-264 VAC

50/60HZ

ALM OUT

3A/250 VAC

CNTL OUT

3A/250 VAC

LINEAR or

SSR DRIVE

1

2

3

4

5

6

L

N

N/O

N/O

N/O

C

C

C

8

9

10 11 12 13 14

TX1

TX2

INTERFACE

RS-485

I/O

FDC-2220

Fig. 4.3 Rear Terminal Connections

4.5 7.0 mm

0.18" 0.27"

~

~

2.0mm

0.08" max.

Fig. 4.2 Lead Termination

1

2

90 264VAC or

20 32VAC / VDC

~

~

Fuse

Page 3

Page 5

4.4.6 Relay Output Contactor Drive

4.4.7 SSR Drive Output

Controllers fitted with the SSR drive output produce a time-proportional

non-isolated pulse voltage (0-20V nominal, output impedance 660 ohms).

The connections are shown in Figure 4.11

4.5 SENSOR PLACEMENT

Proper sensor placement can eliminate many problems in a control system.

The probe should be placed so that it can detect any temperature change

with minimal thermal lag. In a process that requires fairly constant heat

output, the probe should be placed close to the heater. In processes

where the heat demand is variable, the probe should be closer to the work

area. Some experimenting with probe location is often required to find this

optimum position.

In a liquid process, addition of a stirrer will help to eliminate thermal lag.

Since the thermocouple is basically a point measuring device, placing more

than one thermocouple in parallel will provide an average temperature

reading and produce better results in most air heated processes.

Proper sensor type is also a very important factor in obtaining precise

measurements. The sensor must have the correct temperature range to

meet the process requirements. In special processes the sensor might

have to have different requirements such as leak-proof, anti-vibration,

antiseptic, etc.

Standard sensor limits of error are ±4 degrees F (±2 degrees C) or 0.75%

of sensed temperature (half that for special) plus drift caused by improper

protection or an over-temperature occurance. This error is far greater

than controller error and cannot be corrected at the sensor except by

proper selection and replacement.

5. OPERA TION

5.1 FRONT PANEL DESCRIPTION

OUT

FDC-2220

ALM

C

Control

Output

Indicator

Alarm

Output

Indicator

3 Silicon Rubber buttons

For ease of control set-up

and setpoint adjustment.

4-digit 0.4" red LED display indicating

process value or setpoint value.

35

46

or

120V /240V

Mains Supply

Alarm

Output

Control

Output

No Fuse

Breaker

Three

Phase

Heater

Power

Three Phase

Delta

Heater

Load

Fig. 4.10 Contactor drive Connections

Fig. 4.12 Linear Voltage / Current Connections

6

5

+

_

0 20mA,

4 20mA or

0 10V

~

~

~

4.4.8 Linear Output

There are three types of linear output modules (See Section 2) can be

selected for control output (OUT 1). The connections are shown in Figure

4.12.

6

5

Load

120V /240V

Mains Supply

+

+

_

_

SSR

Fig. 4.11 SSR Drive Connections

TOUCHKEYS FUNCTION DESCRIPTION

Up Key

Press and release quickly to select the desired digit of a numerical parameter

to change. Press and hold to increase the value of the selected digit for a

numerical parameter or to change the selection for an index parameter.

Down Key

Press and release quickly to select the desired digit of a numerical parameter

to change. Press and hold to decrease the value of the selected digit for a

numerical parameter or to change the selection for an index parameter.

(Direct) Scroll Key

Select the parameter in a direct sequence. Also used to select the tool

program parameters.

Long Scroll / Enter Key

Select the protected parameters in higher security level, also used to actuate

the execution for the selected tool program whenever the display is showing a

tool program.

Reverse Scroll / Calibration

Verification Key

Select the parameter in a reverse sequence during parameter scrolling, or

verify the display accuracy for various input types during the calibration mode.

Lock Key Disable keypad operation to protect all the parameters from tampering.

Tool Program Key Select the tool program in sequence.

Reset / Exit Key

Unlock keypad operation and reset the front panel display to a normal display

mode, also used to leave the tool program execution or ending the autotune

and manual control execution.

Autotune Key

Press and hold both keys for at least 3.2 seconds then release to start

execution of autotune program.

Engineering Key

By entering correct security code to allow execution of engineering programs.

This function is used only in the factory to speed up the production. The user

should never attempts to operate this function.

Press

for at least 3.2 seconds

Press

and

Press

and

Press

and

and

Press and

Press

for at least 3.2 seconds

and

Press

for at least 3.2 seconds

5.2 KEYPAD OPERA TION

* With power on, it has to wait for 12 seconds to memorize the new values of parameters once it been changed.

Page 4

Page 6

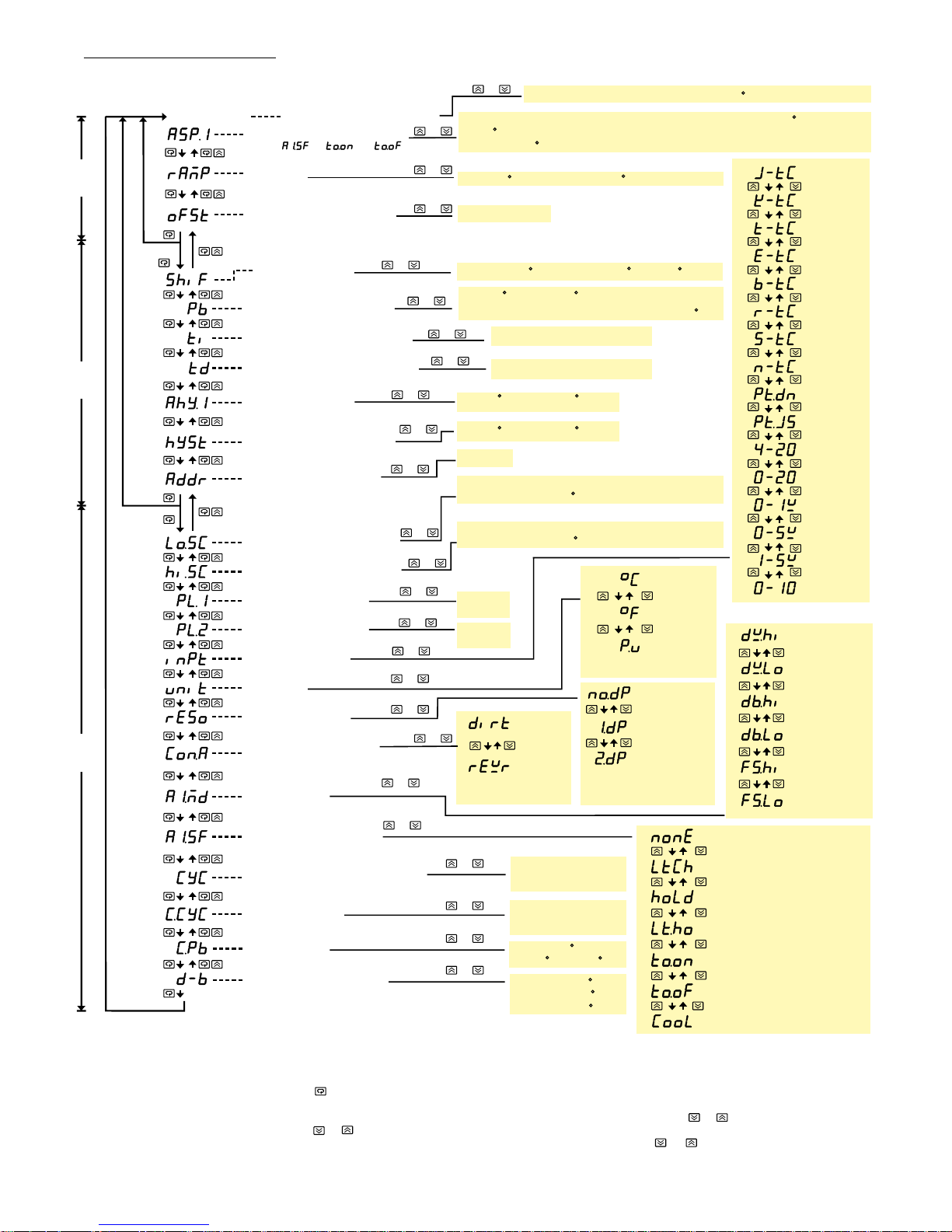

The following chart shows a typical (default) access sequence of parameters. Note 1 shows how to modify the display sequence and how to delete

unused parameters.

Alarm1 Set Point Value or Dwell

Time ( = or )

Shift Process Value

Proportional Band of Output 1

Integral (Reset) Time of Output 1

Derivative (Reset) Time of Output 1

Hysteresis of Alarm 1

Hysteresis of ON-OFF control

Address of the unit for the

communication

Low Scale of Range Adjust for

your process

High Scale of Range Adjust for

your process

Power Limit of Output 1

Power Limit of Output 2

Input Type Selection

Select Unit

Resolution Selection

Control Action of Output 1

Alarm 1 Mode

Alarm 1 Special Function

Proportional Cycle Time of Output 1

Cooling Cycle time

Cooling P Band

Dead Band for PB and CPB

~

0 3600 seconds **120

~

0 1000 seconds **40

~

~

~

~

0 11.0 C or 0.1 19.9 F **0.0

0 11.0 C or 0.1 19.9 F **0.0

~0 40 **0

Minimum value for the selected Input (INPUT) to High

Scale (HISC) **-17.7 C

Low Scale (LOSC) to maximum value for the selected

Input (INPUT) **537.7 C

~

0 100%

**100

~

0 100%

**100

~

0 99 Seconds, 0 for

Linear current / Voltage output. **20

~

0 99 Seconds, 0 for

Linear current / Voltage output. **20

~

~

-111.0 111.0 C or

-199.9 199.9 F,

**0.0 C

:0 10V

~

:1 5V

~

:0 5V~

:0 1V

~

:0 20mA

~

:4 20mA

~

:PT100 JIS

:PT100 DIN

:J TYPE T/C

:K TYPE T/C

:T TYPE T/C

:E TYPE T/C

:B TYPE T/C

:R TYPE T/C

:S TYPE T/C

:N TYPE T/C

**

Long

Long

Level 0

Level 1

Level 2

: degree C

:degree F

:process unit

**

Voltage or

Current Input)

:1 Digit Decimal

: No Decima

Point Used.

:2 Digit Decimal

(only for Linear

Voltage or

Current Input)

**

:Direct

(Cooling)

Action.

:Reverse

(Heating)

Action.

**

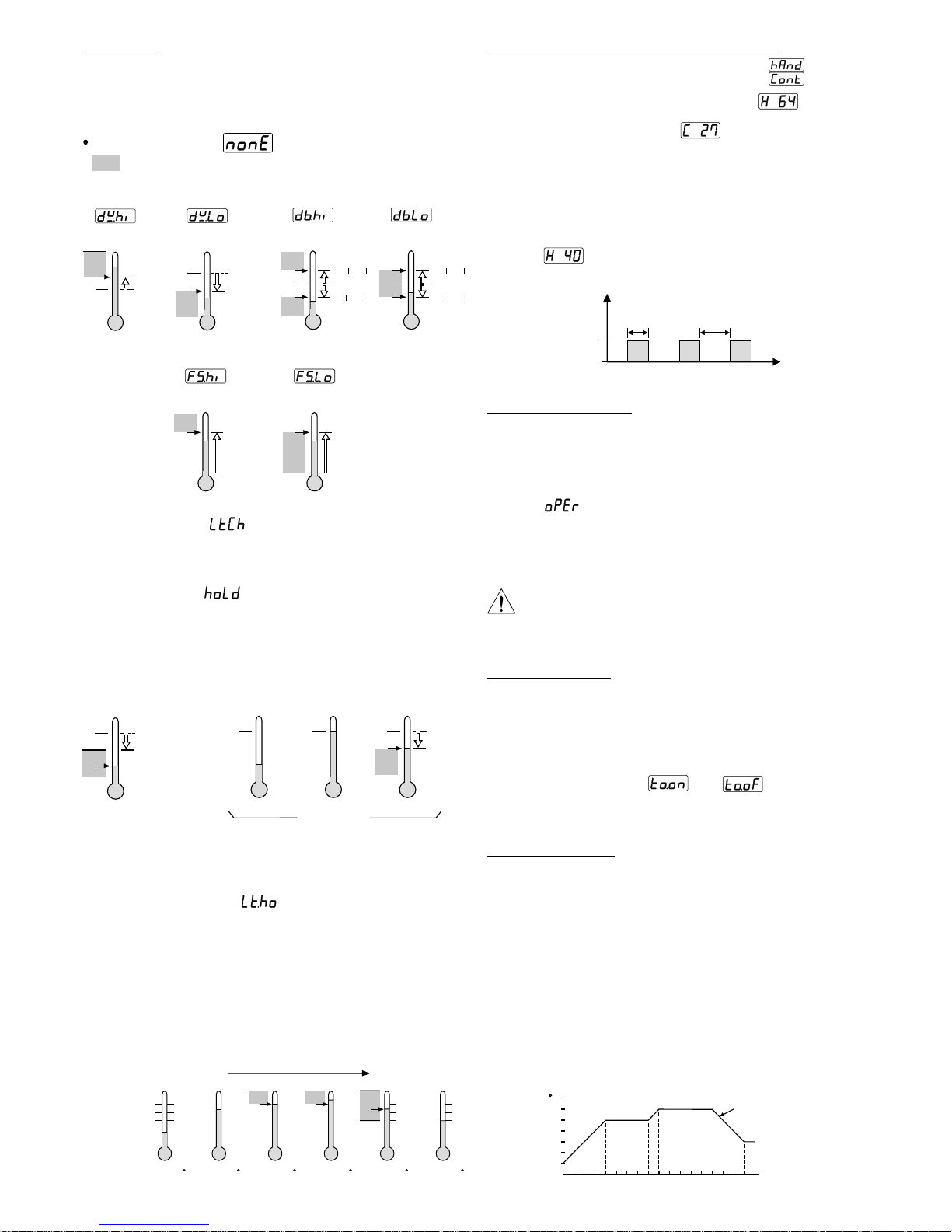

:Alarm with Hold Function.

:Dwell Timer ON as Time Out.

:No Special Function

:Alarm with Latch Function.

:Alarm with Latch & Hold Function.

:Dwell Timer OFF as Time Out.

**

:Deviation High

Alarm.

:Full Scale High

Alarm.

:Full Scale Low

Alarm.

:Deviation Band

High Alarm.

:Deviation Band

Low Alarm.

:Deviation Low

Alarm.

**

5.3 FLOW CHART OF PARAMETERS

Normal Display Process value / setpoint value

Low scale to high scale value

** 100.0 C

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

Ramp Rate

or

0 55.55 C/minute or 0 ~ 99.99 F/minute~

**0.00

Offset Value for Manual Reset

( Integral Time TI=0 )

or

~

0 100.0%

Time)

10.0

C

**0.0

~~

0 200.0 C or 0 360.0 F

0 : For ON-OFF control

**10.0 C

~

~

~

~

Low scale high scale value (for Full scale Alarm), -111.0 111.0 C or -199.9

199.9 F (for Deviation and Deviation Band Alarm), 0 9999 minutes (for Dwell

**

~

~

0.0 200.0 C or 0.1

360.0 F **10.0 C

-111.0 111.0 C or -199.9 199.9 F ** 0.0 C

~

~

Note 1:Using the Tool Program ( Refer to sec .5.4 and sec. 5.6.5 for the configuration of security level ) the display sequence and the security level for

111 any parameter are configurable. Also any unused parameter can be removed from the display sequence to simplify the operation.

Note 2:Using long scroll key ( press and hold for at least 3.2 seconds ) to select parameters in higher security level.

Note 3: To chang the value of a numerical parameter ( the value of which is denoted by a number ) press and release the or key to select the

111111desired digit ,then press and holld the or key to chang the value of the value selected digit.

To chang the value of an index parameter ( the value of which is abbreviated by letters ) press and hold the or key to select the desired

1 1111 value.

**

:Denotes the default setting.

:Proportional cooling.

Page 5

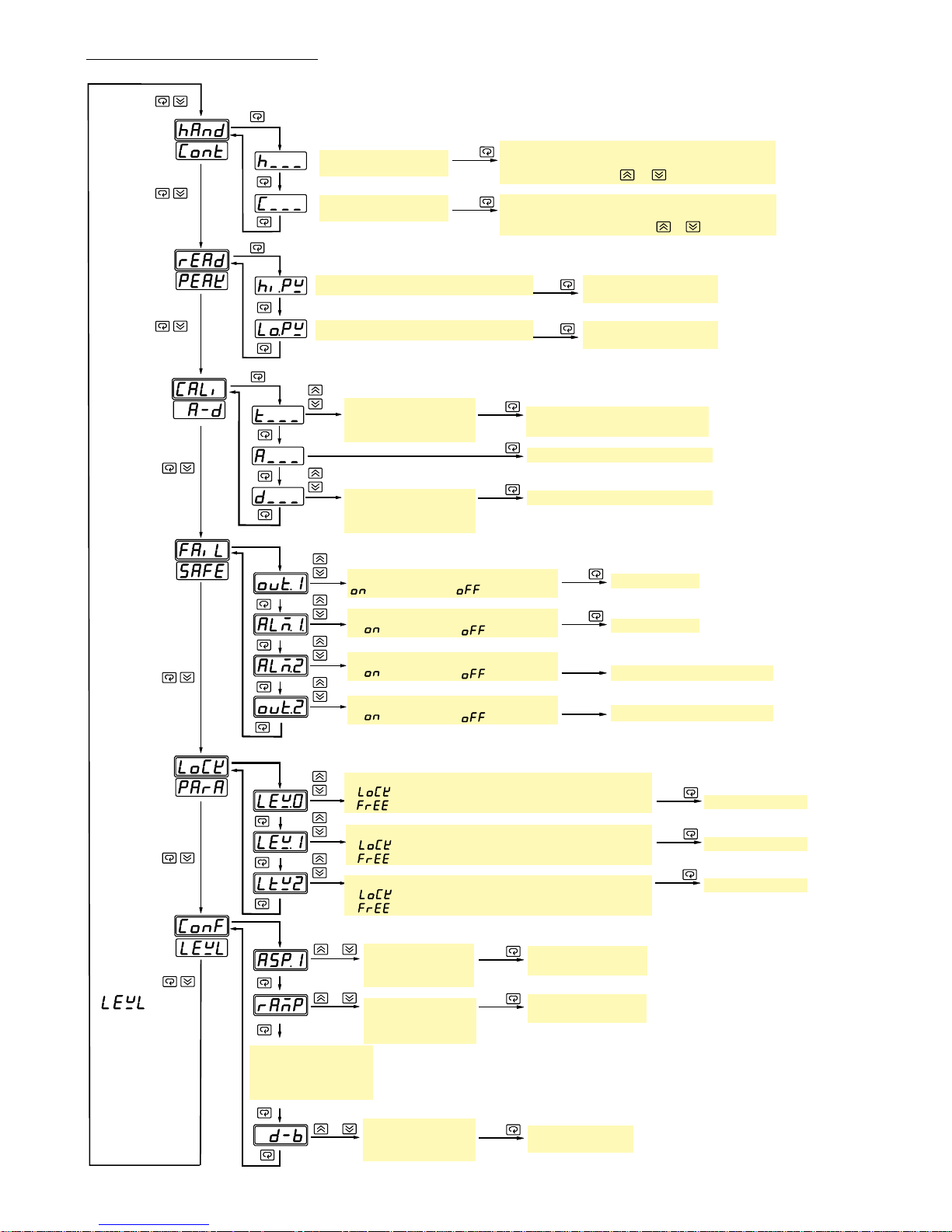

Page 7

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

View the percentage power

of Heating output.

View the percentage power

of Cooling output (Alarm).

Hand ( Manual )

Control

Read Peak

Process Value

Calibrate

A-D converter

Enter the manual control mode.

Allow to adjust the percentage value of

Heating output by using

or

.

Enter the manual control mode.

Allow to adjust the percentage value of

Cooling output (Alarm) by using

or

.

or

or

or

or

or

or

or

Change the value of

security level for the

selected parameter .

Change the value of

security level for the

selected parameter .

Change the value of

security level for the

selected parameter .

Display the rest of

parameters according

to the standard access

sequence.

or

or

or

or

or

Calibrate the A-D and Enter the

Cold-Junction compensation

Enter the drift compensation code.

Calibrate the 0 20mA and Enter it.

~

Enter the status.

Enter the status.

Enter the Selection.

Enter the Selection.

Enter the Selection.

Enter the updated

security level of ASP1.

Enter the updated

security level of RAMP.

Enter the updated

Adjust the Cold-junction

compensation code.

(-19.9 42.7 count)

~

Adjust the

drift

~

Adjust the drift

compensation code.

(-6.6 6.6 count)

~

Select a proper status for Output 1.

:Output 1 ON

:Output 1 OFF

:Protect (Lock) all the Level 0 parameters

:Allow all the Level 0 parameters to be adjustable.

Select Lock or F ree for the Security Level 1.

:Protect (Lock) all the Level 1 parameters

:Allow all the Level 1 parameters to be adjustable.

Select Lock or F ree for the Security Level 2.

:Protect (Lock) all the Level 2 parameters

:Allow all the Level 2 parameters to be adjustable.

View the maximum (peak) process value.

View the minimum (peak) process value.

5.4 FLOW CHART OF TOOL PROGRAMS

Define

protection

mode for the

status of

control and

alarm outputs

to ensure a

safe condition

while the

control fails.

Lock

parameters

Configure

Security

levels for all

parameters.

:Security LEVEL

= 0 :Put the parameter

in LEVEL 0.

= 1 :Put the parameter

in LEVEL 1.

= 2 :Put the parameter

in LEVEL 2.

Reset the maximum and

minimum process values.

Reset the maximum and

minimum process values.

000 100%

~

000 100%

~

**

:Alarm 1 ON :Alarm 1 OFF

**

**

**

**

(No function with FDC -2220.)

(No function with FDC -2220.)

Select a proper status for Alarm 2.

:Alarm 2 ON :Alarm 2 OFF

**

Select a proper status for Output 2..

:Output 2 ON :Output 2 OFF

**

Select Lock or F ree for the Security Level 0.

Select a proper status for Alarm 1.

Page 6

Page 8

LOSC, HISC - Low / High Scale Range

If thermocouple or PT100 is selected as input type (INPT) these parameters

are used to define the range of the setpoint adjustment. Otherwise, If

linear process input is selected, these parameters are used to define the

range of the process value and setpoint adjustment, refer section 5.14 for

more details.

PL1, PL2 - Power limit for Heating and Cooling Outputs

These parameters limit maximum heating and cooling percentage power

during warm up and in proportional band. These are used only for those

processes that heat or cool with full speed are dangerous or not

satisfactory with the results. For normal applications these parameters

are set to 100%.

INPT - Input Type selection

Select a correct type in accordance with the input connection.

UNIT - Process Unit

Select a correct unit for the process. for linear process input select Pu

(Process Unit) if the unit is other than °C or °F.

RESO - Select Decimal Point Position (Resolution)

This parameter defines the position of the decimal point on the process

value and setpoint.

Value Decimal Point Position

xxxx

xxx.x

xx.xx

Note that is used only for linear process input.

CONA - Control Action of Output 1

Select (Reverse) action for heating process, that is to increase

output power as the process value decreases ( or setpoint increases).

Select (Direct) action for cooling process, that is to increase output

power as the process value increases (or setpoint decreases).

A1MD - Alarm Mode Selection for Alarm 1

Refer section 5.10 for an in-depth description.

A1SF - Alarm 1 Special Function

Select a hold function or latch function for Alarm 1. See section 5.10 for

more details. Select or to reconfigure Alarm 1 output

as a dwell timer. See section 5.13 for more details.

CYC, CCYC - Proportional Cycle Time of Output 1 and Cooling Outtput

Select a proper value for the process in accordance with the output

devices fitted. See section 5.5.2 for further discussion.

CPB, DB - Cooling P Band, Cooling Dead Band

Refer section 5.9 for description. If no cooling is fitted for the controller,

these parameters may be neglected.

5.5.1 Learning the Parameters

SV - Setpoint Value

This parameter is the desired target of the process. It can be adjusted

within the range defined by the Low Scale Value (LOSC) and High Scale

Value (HISC). The default value is 100°C (212°F).

ASP1 - Alarm 1 Setpoint Value or Dwell Time

This sets the levels at which the alarm 1 will operate if AISF is selected for

alarm function. If AISF is selected for dwell timer ( or ),

ASP1 is used as setting value of dwell timer. The timer start to count as the

process value reaches the setpoint value, see section 5.10 and 5.13 for

more details.

RAMP - Ramp Rate

This forces the process to warm up (or cool) with a predetermined rate as

power applied. Setting this parameter to zero if no ramp is needed. The

process will warm up (or cool) with maximum speed.

OFST - Offset Value for Manual Reset

For those systems it is desired to perform manual reset control by setting

integral time ( TI ) to zero, OFST is adjusted to compensate the deviation

between PV and SV. If PV is too low for reverse control action (or too high

for direct control action) then increase value of OFST. If TI is not zero,

OFST is unchangeable.

SHIF - Shift Process Value

This value will be added to the process value so that the process value will

be read with minimum error. For those process with bad circulation may

use this parameter to compensate the temperature difference between

sensor and the process.

PB, TI, TD - Constants for PID Control

Refer section 5.7 for an in-depth description.

AHY1 - Hysteresis Values of Alarm 1

These values define the dead bands for alarm action. As the process

value exceeds the boundary of the dead band and stays within the band

the alarm will remain same status.

HYST - Hysteresis Value of ON-OFF Control

This parameter defines a dead band for the ON-OFF control.

ADDR - Address of the unit for the communication

This parameter provides an identity code for the RS-485 interface. Note

that it is not allowable to set the same ADDR code for those controllers

communicating with same computer to prevent line contention problems. If

the controller does not use the RS-485 interface, the ADDR can be

neglected.

5.5 SETTING-UP PROCEDURES

As power applied, the model number of the controller and its software

version number will be displayed for 3.2 seconds, then all the display

segments and LED indicators will be lit for 3.2 seconds. After the 6.4

seconds of initial cycle the controller enters the normal display mode, the

display shows the current process value and the alternative display shows

the setpoint value. The display will continuously flash in cases of:

(1) during executing autotune program

(2) during executing manual mode program

(3) warning that the next parameter is a higher level parameter as scroll

key is depressed. The warning message will maintain a duration of

3.2 seconds. If the scroll key is released after the duration elapses

the display will indicate the code of next parameter ( in the display)

and its value ( in the alternative display ), otherwise, the display will

return to normal mode to indicate process value and setpoint value.

The display will blink a moment as a new value of parameter is written into

the non-volatile memory. The display is also used to indicate the error

messages in case of abnormal condition occurs. Subsequently, each

depression of the scroll key will step down the controller through the

default sequence of displays shown in Table of section 5.3. If unfortunately

the desired parameter passed on the display, it can still be retained by

pressing and to prevent frustration. The sequence of displays

can be reconfigured by changing the security level of parameters as

described in subsequent section.

5.5.2 Initial Setup

Access the keypads to view the value of each parameter. For an

undesirable value of parameter perform up and down key to obtain a

correct value, then proceed to the next parameter until all parameters are

verified. Note that the new value of parameters are entered into nonvolatile

memory automatically.

The adjustment of proportional cycle time (CYC and CCYC) is related to the

speed of process response and the output device fitted. for a faster

process it is recommended to use SSR ( to select SSR Drive Output) or

SCR ( to select linear current or voltage output) to drive the load. The

relay output is used to drive magnetic contactor in a slow process. If a

long cycle time is selected for a fast process an unstable result may occur.

Theoretically the smaller the cycle time is selected, the better control can

be achieved. But for relay output, the cycle time should be as large as

possible (consistent with satisfactory control) in order to maximize relay

life.

Page 7

Page 9

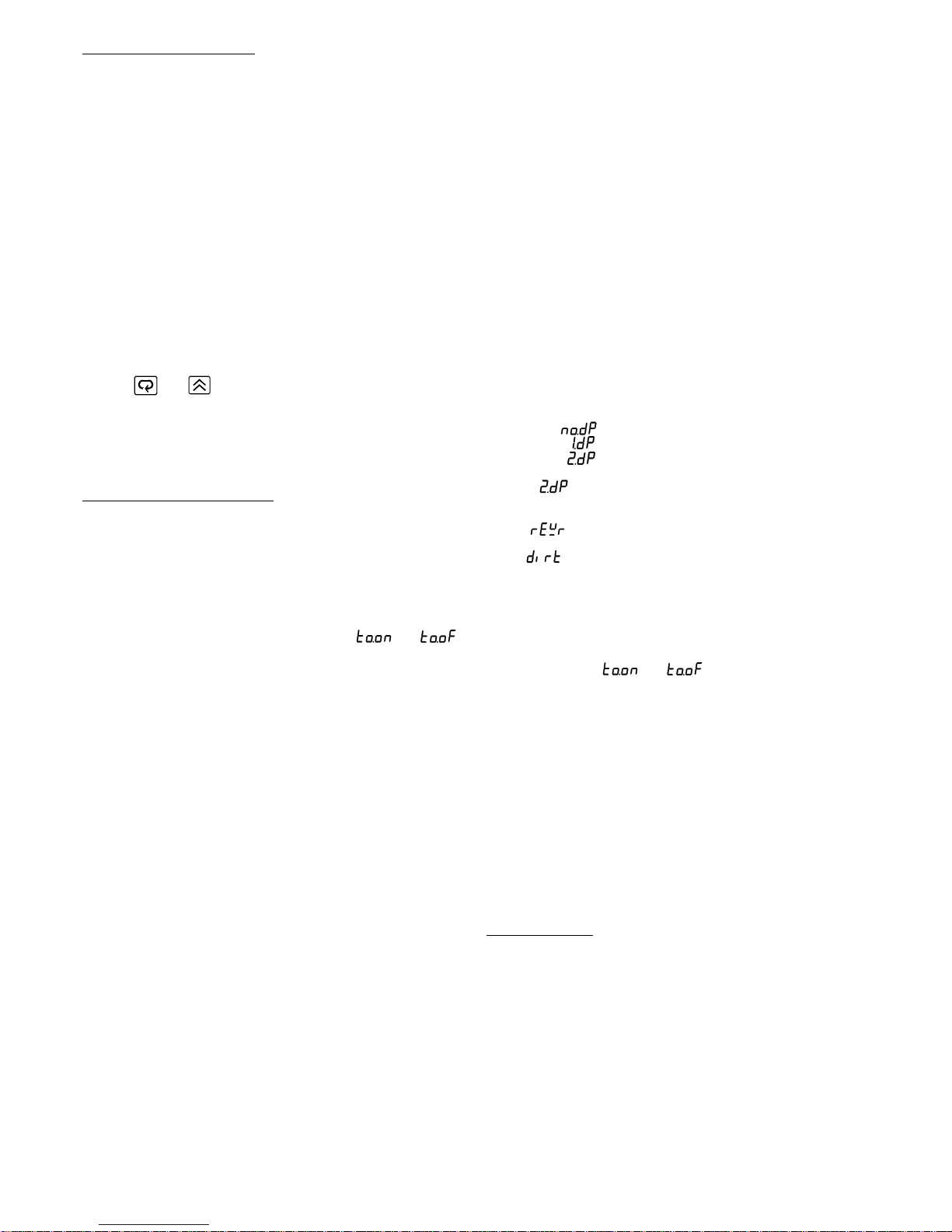

5.6 AUTO-TUNE

The process is tuned at setpoint. The process will oscillate about

the setpoint during auto-tune. Set a setpoint to a lower value if overshoot

beyond the normal process value is likely to cause damage.

The auto-tune program is applied during:

* Initial set-up

* The setpoint is changed substantially from the previous auto-tune

* The control result is unsatsifactory

The auto-tune procedures:

* To ensure that all parameters are configured correctly.

* T o ensure that PB is not zero because that ON-OFF control is not allowable

to perform auto-tune.

* Set the setpoint to the normal operating process value ( or to a lower

value if overshoot beyond the normal process value is likely to cause

damage) and use normal load conditions.

* Press and hold both up and down keys for 3.2 seconds then release

together. The display is flashing during execution of auto-tune

program.

Auto-tune " teaches " the controller the main characteristics of the process.

It " learns" by cycling the output on and off. The results are measured and

used to calculate optimum PID values which are automatically entered in

nonvolatile memory.

During the second period of auto-tune the controller performs PID control

to verify the results and finally an OFST value is obtained and entered in

the memory.

To stop the auto-tune, press both up and down key then release together,

the display will stop to flash. But if the controller has entered in the

verifying period, the display will continue to flash until auto-tune is finished.

5.5.5 Configure Security Levels of Parameters

The user of the controller may often complain that the operation is so

complicated, most of parameters are unused for them and it takes long time

to get a parameter to access. You will no longer worry about this. One of

the versatile functions of this controller is that the security level for each

parameter can be redefined arbitrarily. One of four levels (Level 0, Level

1, Level 2 and Level 3) can be assigned to any parameter. The parameters

with lower level will be displayed before those parameters with higher

level as one performs scroll key. Furthermore, the level 3 parameters will

never be displayed on the front panel. Hence the user can assign level 3

to those unused parameters and assign level 0 to those most frequently

used parameters according to his requirements. Then the unused

parameter will never appear on the display to avoid confusion and the

display sequence of parameters is reconfigured.

To configure level for each parameter one can follow the flow chart in

section 6.4 by pressing and keys to reach ,

then perform key to get the desired parameter. The display indicates

the level of the parameter. Now one can change the level value for that

parameter by using up key or down key. Finally press and hold

3.2 seconds or longer, now the new level value is entered. If the

level value is unchanged the above operation for entering can be omitted.

For example: If ASP1, RAMP are configured as level 0, PB, TI, TD are

configured as leve 1, and the other parameters are configured as level 3,

the scrolling sequence of parameters will be as follows:

5.7 TUNING THE CONTROLLER MANUALL Y

* To ensure that all parameters are configured correctly

* Set PB to zero. Set HYST to the smallest ( 0 °C or 0.1 °F )

* Set the setpoint to the normal operating process value ( or to a lower

value if overshoot beyond the normal process value is likely to cause

damage) and use normal load conditions.

* Switch on the power supply to the heater. Under these conditions, the

process value will oscillate about the setpoint and the following

parameters should be noted:

(1) The peak to peak variation (P) of the first cycle in °C or °F ( i.e. the

difference between the highest value of the first overshoot and the

lowest value of the first undershoot ).

Normal Cycle time

Cycle time too long

(oscillates)

The follow table provides cycle time recommendations to avoid premature

relay failure:

Note: For an ON-OFF control ( by setting PB = 0) the cycle time selection

may be ignored.

Output Device

(OUT1 or Cooling Output)

Cycle Time

( CYC or CCYC )

Load ( resistive)

Relay

20 sec or more

recommended

10 sec. minimum

2A / 250VAC

or contactor

5 sec. minimum 1A / 250VAC

Solid State Relay Drive 1- 3 sec. SSR

Linear Current / Voltage 0.1 sec. Phase control module

5.5.3 FAIL-SAFE Configuration

FAIL-SAFE is a Tool Program used to define an ON or OFF status of failure

for Output 1 (OUT1), Alarm 1 Output (ALM1). Press and ,

then release both keys until FAIL-SAFE is viewed in the display windows.

Then press scroll key to obtain the desired output which is shown in the

display. Now press and hold up or down key to change the status which

is shown in the display. Note that if the desired value is different from the

original one, a long scroll (pressing scroll key 3.2 sec.) has to be operated

to enter the new value before proceeding to the next Tool Parameter . If

the FAIL-SAFE status is not critical for a process as the controller fails, the

configuration of this section can be omitted.

5.5.4 LOCK Parameter

According to the flow chart shown in section 6.4, one can reach LOCK

PARA and obtain LEVEL ( ~ ) which is shown in the display

and the Lock status ( LOCK or FREE ) is shown in the display . For example,

if we select LOCK for , and press scroll key 3.2 seconds to enter the

selection, then all the parameters configured in level 2 can not be changed.

A LOCK message will be indicated in display if one attemps to change a

locked (protected) parameter.

PID+FUZZY

Verifying period

PID Control

Teaching Period

ON-OFF Control

Setpoint

Value

PB,TI,TD

Obtained

Auto-tune

finished

OFST Value

Obtained

Process

Value

SV ASP1 RAMP PB TI TD

Page 8

Page 10

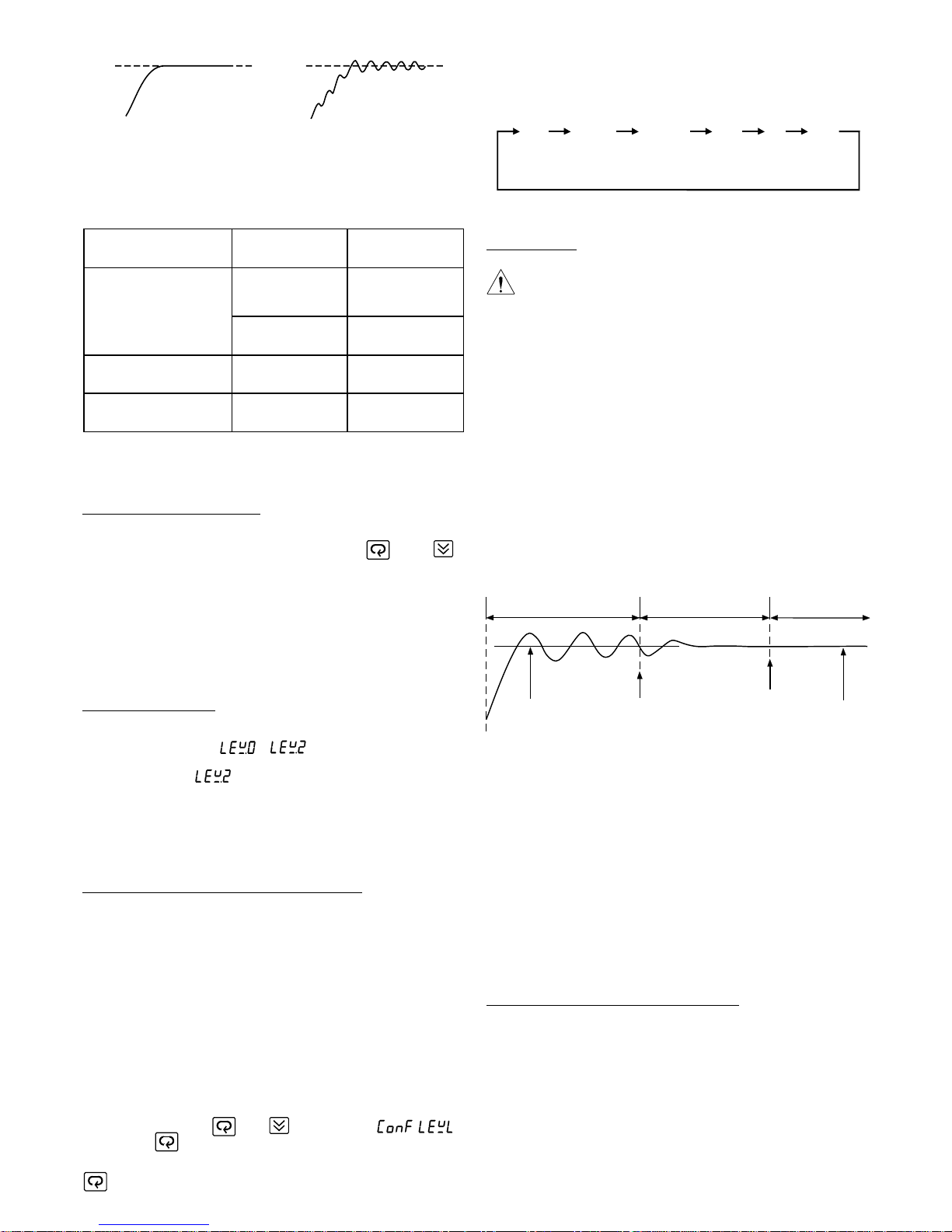

5.9 COOLING CONTROL

Cooling Control Options:

Functions of CPB and DB:

The cooling P band CPB and dead band DB are measured in degree.

(2) The cycle time (T) of this oscillation in seconds (see following Figure).

* The control setting should then be adjusted as follows:

PB = P (°C or °F)

TI = T (seconds)

TD = T/4 (seconds)

The PID parameters determined by the above procedures are just rough

values. If the control results by using above values are unsatisfactory, the

following rules may be used to further adjust the PID parameters:

5.8 ON-OFF CONTROL

The alarm output if configured as alarm function performs an ON-OFF

control basically. Adjust the P band to PB = 0, an additional channel of

ON-OFF control with variable hysteresis is obtained. Hysteresis is

measured with degree. It is also named differentials or deadband

sometimes. Refer to following Figure for the description of ON-OFF control.

ON-OFF control may introduce excessive process variation even if the

hysteresis is minimized to the smallest. If the ON-OFF control is set,

parameters TI, TD and CCT will have no effect on the system, nor can the

manual mode and the auto-tune program be executed.

PV

Time

D action

Perfect

TD too high

TD too low

SP

PV

Time

Time

P action

SP

100%

0%

100%

0%

Reverse

Action

Action

(CONA=REVR)

(CONA=DIR)

Direct

OUTPUT

SP+HYST/2

SP-HYST/2

SV+DB

CPB

SV

DB

Negative

DB

Positive

100%

0%

Cooling

Output

PV( C or F)

P

T

SV

PV

Time

PV

Time

P action

Perfect

PB too high

PB too low

SP

PV

Time

I action

Perfect

TI too low

TI too high

SP

Effect of PID adjustment on process response:

ADJUSTMENT SEQUENCE SYMPTON SOLUTION

(1) Proportional Band (P) Slow Response Decrease PB

PB

High overshoot or

Oscillations

Increase PB

(2) Integral Time (I) Slow Response Decrease TI

TI

Instability or

Oscillations

Increase TI

(3) Derivative Time (D)

Slow Response or

Oscillations

Decrease TD

TD

High Overshoot Increase TD

Output

Configurations

Heating Output Cooling Output

Adjustment of

Parameters

ON-OFF Cooling

( No Heating)

None OUT1

CONA = DIRT

HYST

SV

Proportional Cooling

( No Heating)

None OUT1

CONA = DIRT

PB, TI, TD, CYC, SV

Heating +

ON-OFF Cooling

OUT1 ALM1

CONA = REVR

A1SF = NONE

A1MD = DVHI (or FSHI)

AHY1, SV (or ASP1)

Heating +

Proportional Cooling

OUT1 ALM1

CONA = REVR

A1SF = COOL

CPB, DB, CCYC, SV

Page 9

Page 11

5.10 ALARM

There is a independent alarm available by adjusting the alarm special

function A1SF and A2SF. The following descriptions of this section are

based on Alarm 1.

* Latch Alarm: A1SF =

When selected, the alarm output and indicator latch as the alarm occurs.

The alarm output and indicator will be energized even if the alarm condition

has been cleared unless the power is shut off.

* Hold Alarm: A1SF =

When selected, in any alarm mode, prevents an alarm on power up. The

alarm is enabled only when the process value reaches setpoint value

(SV).

Example: Hold function used with deviation low alarm

* Lach & Hold Alarm: A1SF =

When selected, in any alarm mode, prevents an alarm on power up. The

alarm is enabled only when the process value reaches setpoint value

(SV). Thereafter, the alarm acts as a latch alarm described above.

* Hysteresis (AHY1) adjustment

Example: No special function used with deviation high alarm,

SV = 100 °C, ASP1 = 10 °C, AHY1 = 4 °C

5.11 VIEWING THE OUTPUT PERCENT AGE POWER

Selecting the T ool Programs until the HAND CONTROL is obtained.

Press scroll key, the display will show the process value and the display

will show the percentage power of output 1 such as . To view the

cooling output, press scroll key again. The lower display will show the

percentage power of alarm 2 such as , if alarm 2 is reconfigured as

cooling output (A2SF = COOL). If alarm 2 is configured as alarm, the

percentage power is invalid and should be ignored.

The range of the output percentage power is within 0 and 100 (%). If an

on-off control is selected, only 0 and 100 are displayed. For a proportional

control, the output percentage power represents the duty cycle of the

output ON-state.

Example: is viewed with cycle time CYC = 10 sec.

The output 1 act as follows:

0 1020304050607080

25

50

75

100

125

150

C

t (minutes)

Process Value

4 sec.

6 sec.

OFF

ON

OUTPUT

Time

5.12 MANUAL CONTROL

Following the procedure as in section 5.11, then press and hold the scroll

key for 3.2 seconds and release, the controller will enter the manual

control mode. The display begins to flash. The output percentage power

can be adjusted by using up or down keys. Note that for an on-off control

with PB = 0, the manual control is not allowable to be used. An error

message will be shown in the display.

The manual control is used during:

* Teaching the process

* The controller fails

The manual control is an open loop control The process may rise

to a dangerous value (temperature). Special attention to the process has

to be given to prevent a system damage.

5.13 RAMP & DWELL

The controller can be configured to act as either a fixed setpoint controller

or as a single ramp controller on power up. This function enables the user

to set a predetermined ramp rate (RAMP) to allow the process to gradually

reach setpoint temperature thus producing a " soft start " function.

A dwell timer is incorporated within the controller and the alarm 1 can be

configured by setting A1SF = or to provide either a

dwell function or a soak function to be used in conjunction with the ramp

function.

5.13.1 Ramp Function

If the ramp function is selected, the process will increase or decrease at

a predetermined rate during initial power up, or with setpoint changes/

process variations.

The ramp rate is determined by the " RAMP " parameter which can be

adjusted in the range 0 to 55.55 °C / minute ( 99.99 °F / minute). The ramp

rate function is disabled when the " RAMP " parameter is set to " 0 ".

In the example below the " RAMP " is set to 5.00 °C / minute, power is

applied at zero time and the process value climbs to the 125 °C setpoint

over a period of 20 minutes. This process temperature is held until the

setpoint value is changed to 150 °C at 40 minutes. The process value then

climbs to the new setpoint over a period of 5 minutes and the new setpoint

is held. At 70 minutes the setpoint value is decreased to 75 °C and the

process value falls to the new setpoint over a period of 15 minutes.

: Alarm on

No special function: A1SF=

SV

SV+ASP1

*

Without

hold alarm

alarms on

power up

SV SV SV

SV+ASP1

*

With hold alarm

No alarm

on power up

Alarm

enabled

Alarm

operates

normally

there after

*

Full scale

high alarm

A1MD

ASP1

*

Full scale

low alarm

A1MD

ASP1

SV+ASP1+ 1/2AHY1

SV+ASP1

SV+ASP1- 1/2AHY1

Below 108 C

alarm off

Below 112 C

alarm off

* *

*

Above 112 C

alarm on

Above 112 C

alarm on

112

110

108

Above 108 C

alarm stays on

112

110

108

Below 108 C

alarm off

112

110

108

Process proceeds

SV

SV+ASP1

*

Deviation

high alarm

A1MD

SV

SV+ASP1

*

Deviation

low alarm

A1MD

(ASP1 negative)

SV

*

*

Deviation band

high alarm

A1MD

SV- ASP1

SV+ ASP1

SV

*

*

Deviation band

low alarm

A1MD

SV- ASP1

SV+ ASP1

Page 10

Page 12

5.15 READ PEAK PROCESS VALUES

The maximum and minimum values of the process value are continuously

updated and stored in the memory as power up. Press both and

to obtain " READ PEAK " Tool Program. Press scroll key to select

or which is shown in lower display. Now the upper display

will show the high peak value or low peak value of the process.

To reset the values, press and hold the scroll key for 3.2 second and

release, this moment both low peak value and high peak value will be

revised by the current process value.

This Tool Program provides an useful function for monitoring the stability of

the process.

5.14 RE-RANGING LINEAR PROCESS INPUTS

Select an appropriate Input Type ( INPT). Define the range by adjusting

LOSC and HISC. In the example below, INPT = 4-20 (mA), LOSC = 0, HISC

= 100.0, RESO =

For a 4 mA input the process value will read 0 (=LOSC), and for a 20 mA

input the process value will read 100.0 (HISC). For a 10 mA input the

process value will read 37.5. If the input signal is beyond the limits, an

error message LLEr or HLEr will be shown in the upper display.

5.13.2 Ramp & Soak Function

The soak function is enabled by configuring the alarm 1 to act as a dwell

timer. If A1SF is set to ( time out on), the alarm 1 relay will now

operate as a timer contact, with the contact being opened at power up and

closing after the elapsed time set at parameter ASP1. If A1SF is set to

( time out off), a reverse action of alarm 1 relay will perform.

If the controller power supply or output is wired through the alarm contact,

the controller will operate as a guaranteed soak controller.

In the example below the " RAMP " is set to 5.00 °C / minute, A1SF = time

out off, and ASP1 = 20 ( minutes). Power is applied at zero time and the

process climbs at 5 °C / minute to the setpoint of 125 °C. Upon reaching

setpoint, the dwell timer is activated and after the soak time of 20 minutes,

the alarm 1 relay will open, switching off the output. The process

temperature will eventually fall at an undetermined rate.

01020304050

25

50

75

100

125

150

C

t (minutes)

Process Value

ON

OFF

Alarm 1

output

20 minutes

0

(LOSC)

100.0

(HISC)

PV

420

Input Signal (mA)

LLEr HLEr

01020304050

25

50

75

100

125

C

t (minutes)

Process Value

ON

OFF

Alarm 1

output

30 minutes

5.13.3 Dwell Function

The dwell function is enabled by configuring the alarm 1 to act as a dwell

timer. If A1SF is set to (time out on), the alarm 1 relay will now

operate as a timer contact with the contact being opened on initial start up.

The timer begins to count down once the setpoint temperature is reached.

After the setting at ASP1 has elapsed, the alarm 1 relay closes.

The dwell function may be used to operate an external device, such as a

siren to alert (for example) when a soak time has been reached.

In the example below, the ramp rate has been set to " 0 ", A1SF=

and ASP1 = 30 (minutes). Initial start up is a zero time and the process

climbs to the 125 °C setpoint with a maximum rate. Once setpoint is

reached, the dwell timer begins to count. After 30 minutes the alarm 1

relay closes. The controller will continue to operate as a fixed setpoint

controller. Timer reset on power up only.

PTA

TC

_

COM+

_

mA

_

V

+

_

40mV

200 ohm 20mA

10V

+

_

FDC-2220

SW1

8910

11 12

6. RE-CALIBRA TION

Do not proceed through this section unless there is a definite need

to re-calibrate the controller. All previous calibration data will be lost. Do

not attempt recalibration unless you have available appropriate calibration

equipment. If calibration data is lost, you will need to return the controller

to your supplier who may charge you a service fee to re-calibrate the

controller.

* Equipment needed

(1) Standard millivolt source with range 0-100mV, accuracy ±0.01%

(2) Standard voltage source with range 0-10V, accuracy ±0.01%

(3) Standard current source with range 0-20mA, accuracy ±0.01%

(4) Standard ohm source with range 0-300 ohm, accuracy ±0.01%

(5) Standard thermometer with range 0-50.0 °C, accuracy ±0.2 °C

(6) A cooling fan or at the best a calibration fixture equiped with a fan

and a push-button switch

(7) Thermocouple simulator

* Calibration Setup

(1) Select T/C input, UNIT = °C, RESO =

(2) Switch the power off

(3) Disconnect the sensor wiring

(4) Connect the input terminals of the controller to the signal sources

according to the following diagram

(5) Install a fan to blow the cold-junction compensator which is located at

the rear edge of the lower PCB to prevent the cold-junction compensator

from warming up

5.16 LOCK / UNLOCK PARAMETERS

* Lock all the parameters

press and hold both for 3.2 seconds then release, the keypad

operation is disabled to protect parameters from tampering. Unlock keypad

operation, press both up and down keys then release.

* Lock parameters in the same security level

Refer to section 6.6.4 for the operation

Page 11

Page 13

* Calibration Procedures

(1) Press both scroll and down key, then release. Tool program will

appear on the upper and lower displays. Repeat above operation until

appear on the displays.

(2) Press and release the scroll key. The display will show a

number with a prefix " "

(3) Use the up and down keys to change the value on the display

until this value coincide with the ambient temperature in degree C

which is measured by the standard thermometer.

(4) Press the scroll key for at least 3.2 seconds, then release. The

display will blink a moment and then show the ambient temperature in

degree C.

(5) Press and release the scroll key. The display will show a number with

a prefix " " , and the display will show 0.00.

(6) Press and hold down the push-button switch SW1. Don't release

SW1. Press the scroll key for at least 3.2 seconds, then release. The

display now will show 20.00. Release SW1.

(7) Press and release the scroll key. The display will show a number

with a prefix " ". If the number is not equal to 0.0, use the up and

down keys to set the value to 0.0. Then press the scroll key for at

least 3.2 seconds, then release. The " " code is reset.

* Verify Calibration Accuracy

(1) Operate the key pads until the display reaches the calibration mode

( appear on the displays ).

(2) Press and release the scroll key until a code is shown in the display.

The display will indicate process value with respect to the 0-20mA

input. Feed a standard signal to the correct mA input terminals and

examine the accuracy of the display.

(3) Press and release the scroll key again until a code is shown in the

display. Now the display will indicate process value with respect to

the INPT type selected. Feed a standard signal to the appropriate input

terminals and examine the accuracy of the display.

(4) Press and , then release quickly, the display will indicate

process value with respect to the PT100/DIN input. Feed a standard

signal to the PT100 input terminals and examine the accuracy of the

display.

(5) Press and , then release quickly, the display will indicate

process value with respect to the 0-10V input. Feed a standard signal

to the voltage input terminals and examine the accuracy of the display.

* Warm-up drift correction for thermocouple input after completing the

above calibration procedure, connect a thermocouple to terminal 13 and

14 ( observing polarity ) and select a correct " INPT " for the thermocouple.

Switch the power on and let the controller to be powered for at least 30

minutes. If the controller does not measure a correct temperature for the

thermocouple, the following procedures may be employed to correct the

error.

(1) Perform procedure (1) and (2) stated in calibration procedures.

(2) Press and release the scroll key.

(3) Press and release the scroll key again. Now the " " code with zero

value is obtained on the display.

(4) Use the up and down keys to change the " " code value until the

display shows a correct temperature. The unit of " "code

value is always in degree C independent of the selection of " UNIT ".

(5) Press the scroll key for at least 3.2 seconds, then release. The

display will blink a moment and show an accurate temperature. If the

accuracy of the controller is still unacceptable, replace the controller.

7. ERROR MESSAGE & DIAGNOSIS

This procedure requires access to the circuitry of a live power unit.

Dangerous accidental contact with line voltage is possible. Only qualified

personnel are to perform these procedures. Potentially lethal voltages are

present.

Experience has proven that many control problems are not caused by a

defective instrument. See chart below and Table 7.1 for some of the other

common causes of failures:

* Line wires are improperly connected

* No voltage between line terminals

* Incorrect voltage between line terminals

* Connections to terminals are open, missing or loose

* Thermocouple is open at tip

* Thermocouple lead is broken

* Shorted thermocouple leads

* Short accross terminals

* Open or shorted heater circuit

* Open coil in external contactor

* Burned out line fuses

* Burned out relay inside control

* Defective solid-state rellays

* Defective line switches

* Burned out contactor

* Defective circuit breakers

If the points listed on the chart have been checked and the controller does

not function. it is suggested that the instrument be returned to the factory

for inspection.

Do not attempt to make repairs. It usually creates costly damage. Also, it

is advisable to use adequate packing materials to prevent damage in

shipment.

Press both sides of the latch located on

rear terminal block.Hold tightly and

remove the terminal block from the

housing.

(1)

Expand the rear edge of the housing by

using a tool. Pull out the PCB from the

(2)

FD

C

OUT

ALM

C

Dismantling the controller

-

2220

Page 12

Page 14

TABLE 7.1 TROUBLESHOOTING

Sympton Probable Causes (s) Solution (s)

1) Keypad no function - Bad connection between PCB & keypads

- Clean contact area on PCB

- Replace keypads

2) LED's will not light

- No power to instrument

- Power supply defective

- Check power line connections

- Replace power supply board

- LED display or LED Lamp defective

- Related LED driver defective

- Replace LED display or LED lamp

- Replace the related transistor or IC chip

4) Process Display shows: - Sensor break error

- Replace RTD or sensor

- Use manual mode operation

5) Process Display shows:

- Input signal beyond the low range, sensor fails

- Incorrect input type selected

6) Process Display show:

- Input signal beyond the high range,sensor fails

- Incorrect input type selected

7) Process Display shows: - A to D module damage

8) Process Display shows:

9) Process Display shows: - Check and reconfigure the control parameters

10) Process Display shows: - Fail to enter data into EEPROM - Replace EEPROM

11) Process Display shows:

12) Process Display shows: - Attempt to change a locked parameter - Unlock procedures stated in section 5.16

13) Display Unstable

- Analog portion or A-D converter defective

- Thermocouple, RTD or sensor defective

- Intermittent connection of sensor wiring

- Replace related components or board

- Check thermocouple, RTD or sensor

- Check sensor wiring connections

14) Considerable error in temperature indication

- Reversed input wiring of sensor - Check and correct

16) No heat or output

- Check output wiring and output device

- Replace output device

- Replace output fuse

- Check and replace

18) Control abnormal or operation incorrect

- Check and replace

- Read the operation procedure carefully

- Overflow error, data out of range during

execution of software program

- Wrong sensor or thermocouple type. Wrong

input mode selected.

- Analog portion A-D converter defective

- Replace sensor

- Check sensor or thermocouple type, correct

input selection

- Replace module. Check for outside source of

damage such as transient voltage spikes.

- Repeat procedure. Increase Prop. Band to a

number larger than 0.

- Increase proportional band

- Check if there is a noise comming in. Solve

the problem by means of item (19).

3) Some segments of the display or LED lamps

not lit or lit erroneously.

- Check sum error, values in memory may have

changed accidentally

- Incorrect operation of auto tune procedure.

Prop. Band set to 0

- Manual mode is not allowable for an ON-OFF

control system

- Replace sensor

- Check sensor or thermocouple type, correct

input selection

17) Heat or output stays on but indicator reads

normal

- CPU or EEPROM (non-volative memory)

defective. Key switch defective

- Operation of control incorrect

- Output device shorted, or power service

shorted

19) Display blinks, entered values change by

themselves

- Electromagnetic interference (EMI), or Radio

Frequency interface (RFI)

- EEPROM defective

- Suppress arcing contacts in system to eliminate

high voltage spike sources. Separate sensor

and controller wiring from " dirty" power lines,

ground heaters

- Replace EEPROM

- No heater power (output), incorrect output

device used

- Output device defective

- Open fuse outside of the instrument

15) Display goes in reverse direction ( counts

down scale as process warms)

- Check sensor or thermocouple type and if

proper input mode was selected

- Replace related components or board

Page 13

Page 15

ommon Failure Causes and Corrective Actions

Symptom

Probable Causes Corrective Actions

1) Keypad no function

-Bad connection between PCB & keypads

- Clean contact area on PCB

- Replace keypads

2) LED's will not light

- No power to instrument

- Power supply defective

- LED display or LED lamp defective

- Related LED driver defective

- Check power line connections

- Replace power supply board

- Replace LED display or LED lamp

- Replace the related transistor or IC chip

3) Some segments of the display or

LED lamps not lit or lit erroneously.

4) Display Unstable

5) Considerable error in temperature

indication

6) Display goes in reverse direction

( counts down scale as process warms )

- Analog portion or A-D converter defective

- Thermocouple, RTD or sensor defective

- Intermittent connection of sensor wiring

- Replace related components or board

- Check thermocouple, RTD or sensor

- Check sensor wiring connections

- Wrong sensor or thermocouple type, wrong

input mode selected.

- Analog portion of A-D converter defective

- Check sensor or thermocouple type and if

proper input mode was selected

- Replace related components or board

- Reversed input wiring of sensor

- Check and correct

7) No heat or output

- No heater power ( output ), incorrect output

device used

- Output device defective

- Open fuse outside of the instrument

- Check output wiring and output device

- Replace output device

- Replace output fuse

8) Heat or output stays on but indicator

reads normal

- Output device shorted, or power service

shorted

- Check and replace

9) Control abnormal or operation incorrect

- CPU or EEPROM ( non-volatile memory )

defective. Key switch defective

- Incorrect setup values

- Check and replace

- Read the setup procedure carefully

10) Display blinks; entered values change

by themselves

- Electromagnetic interference ( EMI ), or

Radio Frequency interference ( RFI )

- EEPROM defective

- Suppress arcing contacts in system to

eliminate high voltage spike sources.

Separate sensor and controller wiring from

" dirty " power lines, ground heaters

- Replace EEPROM

8.0 COMMON FAILURE CAUSES

Page 14

Page 16

User's Manual FDC-2220 Process / Temperature Controller

7524 West 98th Place

Bridgeview, IL 60455

Phone 888-751-5444

Fax 888-307-8014

Loading...

Loading...