Page 1

1 | P a g e

User Guide

For the FutureCow ChemMix XV

Includes Product Manual and Troubleshooting Guide

Date: 9/19/16

The Gold Standard in Teat Prep

Page 2

2 | P a g e

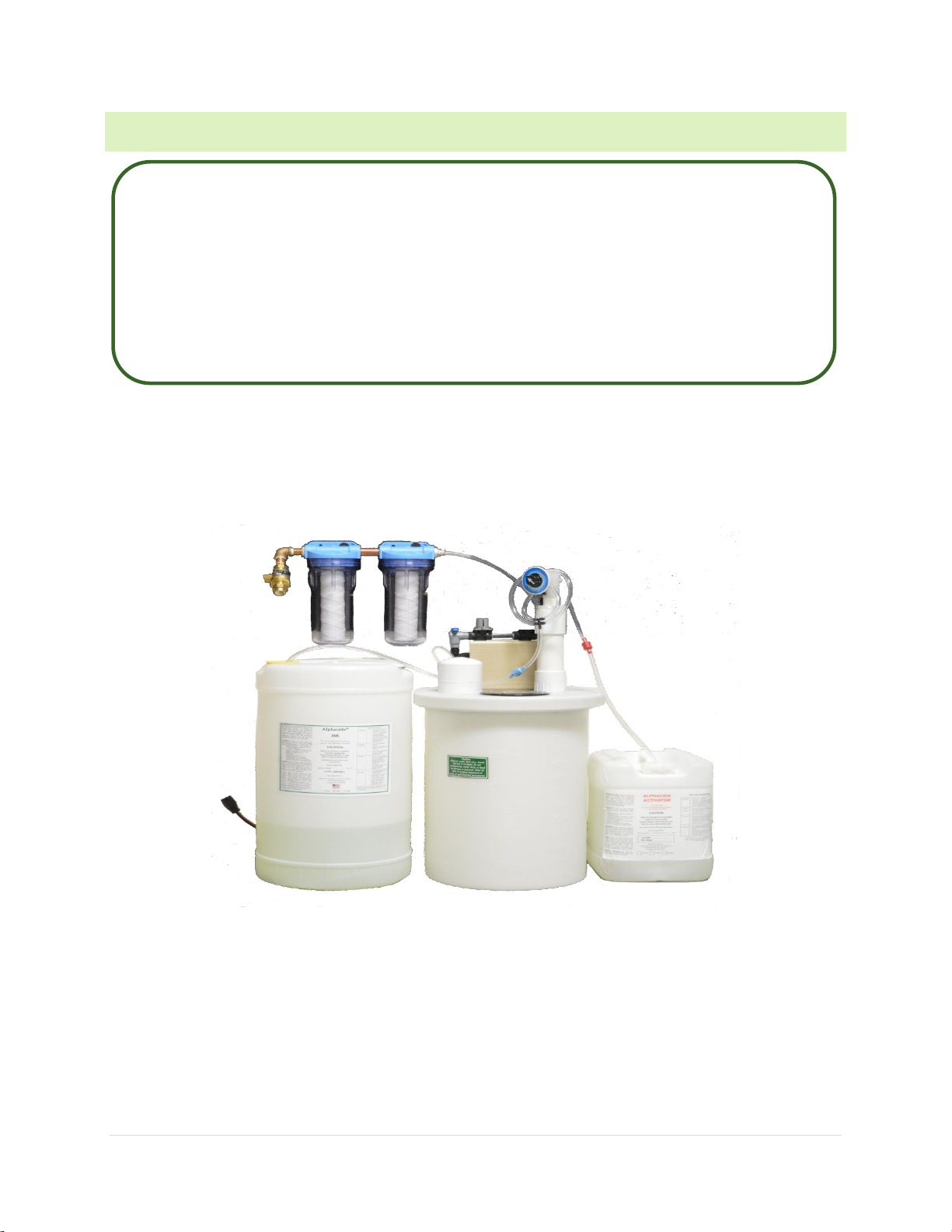

1 INTRODUCTION

The ChemMix XV system is a simple and convenient way to achieve the required activation for chlorine

dioxide based products. The ChemMix XV is designed to automatically prepare an activated solution at a

desired concentration.

The ChemMix XV is manufactured to work with your FutureCow Teatscrubber System. The purpose is to

eliminate the need to hand measure, manual mix, or dilute your product. This system ensures precise and

consistent activation to your desired ppm.

This manual will walk you through replacement parts, troubleshooting, as well as, the testing of the product

for accurate product mixing.

Should any technical questions arise please call for a FutureCow Technician at 855.388.7269.

Please read the entire instruction manual and all associated technical

literature before beginning the setup and operation process.

Your safety, and the safety of others, is very important. To help, we have

provided setup, operating instructions and other information in this manual.

Please follow these instructions for any maintenance or troubleshooting

necessary. When handling chemical please take the recommended

precautions specified, ie: gloves and safety goggles.

Page 3

3 | P a g e

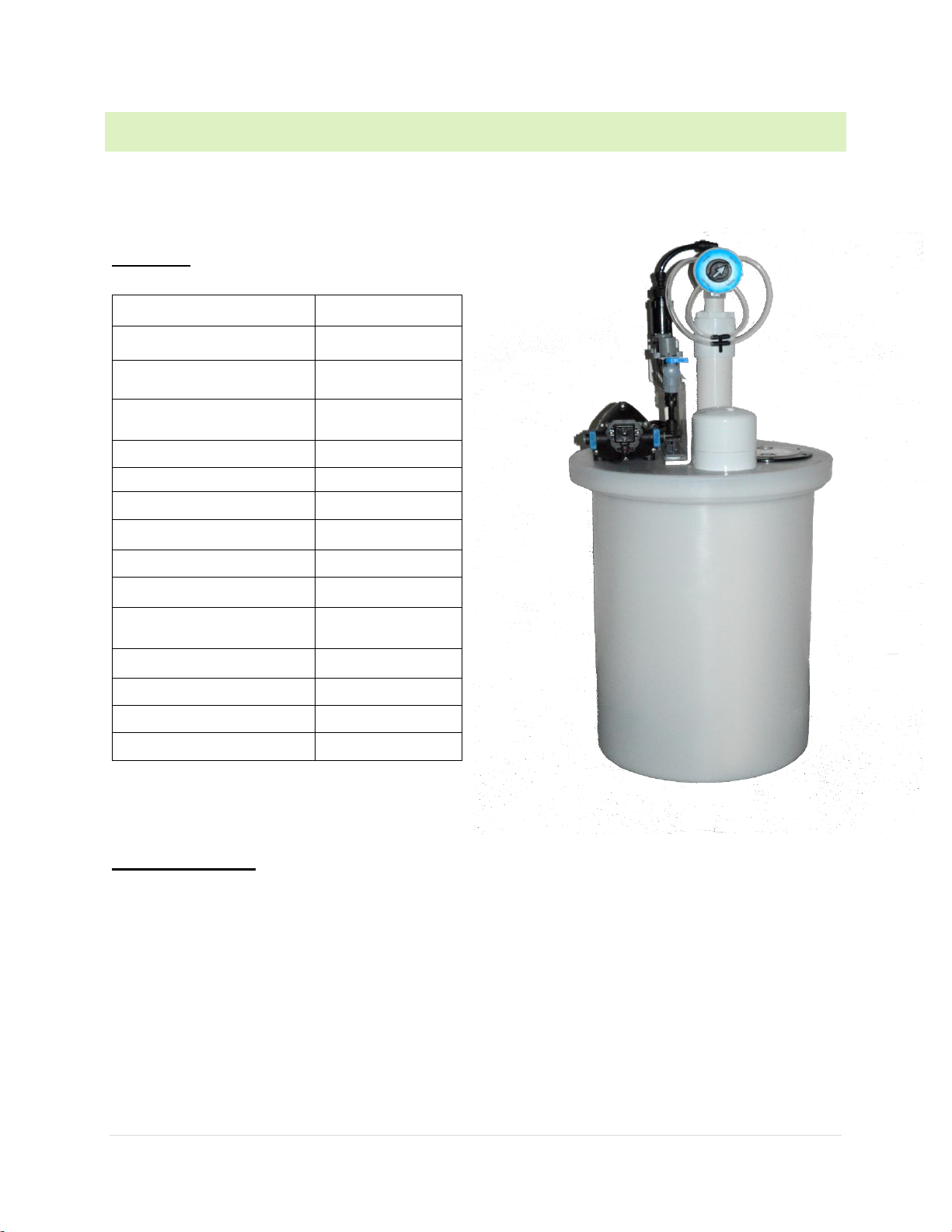

2 PARTS LIST / PART LOCATOR

Parts List

Dealer Only Parts

Chlorine Dioxide Test Kit

Multi PPM Dial

Demand Pump 115v

AANE-PMP115V

Metering Tip

E-NIPPLE

Adapter, ¼” MNPT x

3

/

8

”

PTC

CMM3/8PTCX1/4NPT

Demand Pump Fittings 3/

8

PTC

AANE-HB3/8

3

/8” THV Tubing

E-3/8THVTUBE

Intake Hose Assem

E-AANEINTAKE

Acid Check Valve

E-VALVESRED

Product Check Valve

E-VALVESBLUE

Acid Foot Valve

E-ACFTVALVE

Product Foot Valve

E-PRFTVALVE

Ceramic Weight, For Foot

Valve

E-C346

Orifice Pack

E-ORIMTRSET

Power Cord

E-POWCHD

Venturi Tower

E-VENTOW-LOW

Fill Foat Valve

E-VALVESFLT

Page 4

4 | P a g e

3 REQUIREMENTS

Water Supply

A back flow preventer is required in the water supply line. A water filter assembly with back flow preventer

is provided. Consult local inspector to insure minimum back flow protection is maintained.

Range 25 to 80 psi, 1.6 to 5.5 bar, a pressure booster pump is required if water pressure drops below 25 psi

at any time during operation.

1.3gpm, 4.5 liters per minute is the minimum water flow for proper activation.

33° to 100°F, 1° to 38°C is the operating range required.

Location and Chemicals

Place the unit and supply drums out of direct sunlight and accessible for chemical replenishment. We

recommend a dry room located close to the FutureCow ChemMix XV. DO NOT place the ChemMix XV

in the elements. Keep equipment and solution under cover at all times. DO NOT cross contaminate, this

will lead to inaccurate readings. When changing out the solution barrels always use proper eye and skin

protection. Gloves and goggles should be worn when handling the solution. See SDS for proper protection

guidelines.

Warning:

This unit has been approved for use with FutureCow solution and FutureCow parts ONLY. Use of

any other chemical products or replacement parts voids the warranties, and negates any

responsibility FutureCow may assume with regard to product support.

Consult FutureCow product SDS for safety instructions and safety equipment requirements.

The activator is an acid product. Consult the product SDS for safety instructions and safety

equipment requirements.

Page 5

5 | P a g e

4 SETUP

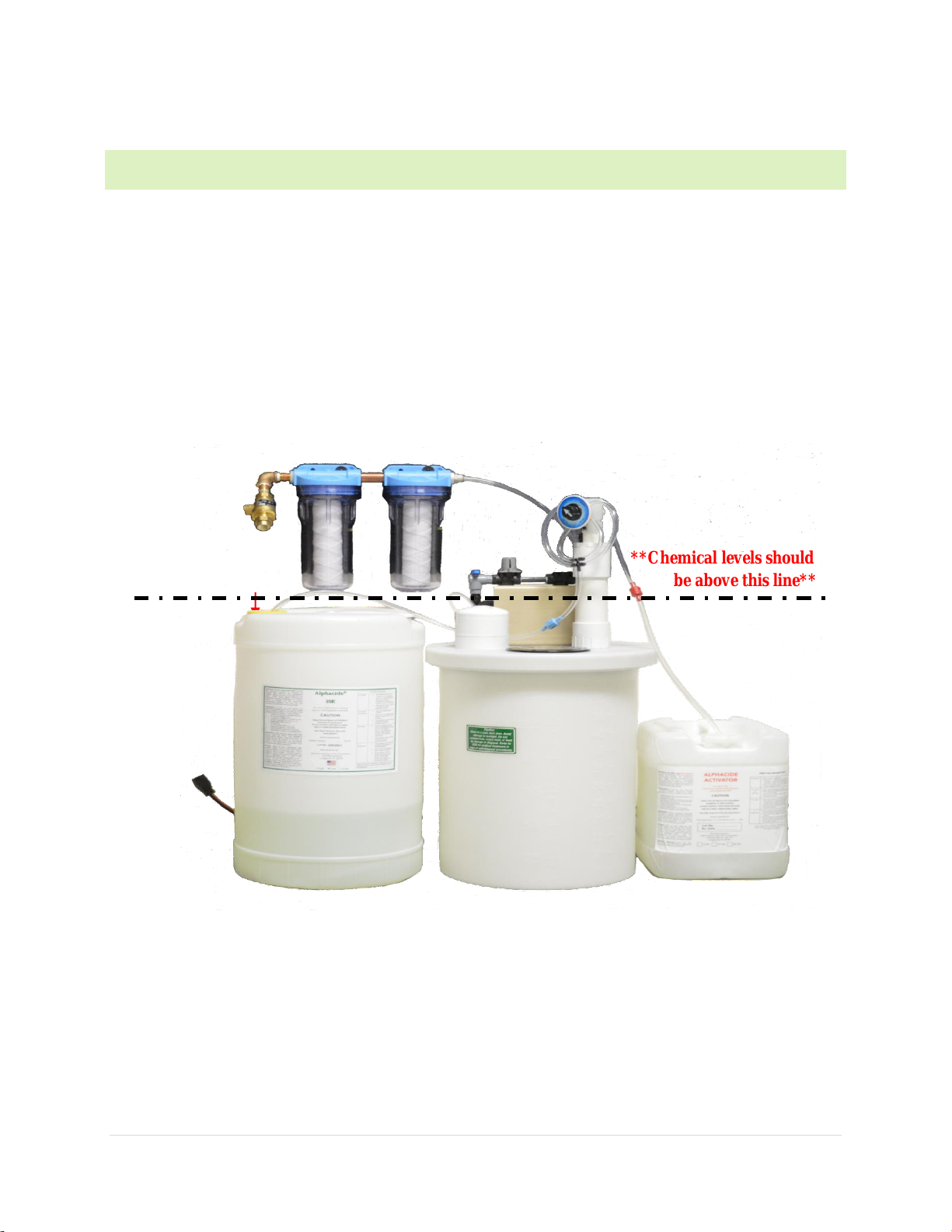

The ChemMix XV is shipped dialed to the correct chemical settings, you must turn on the valve with the

desired ppm after full set up is complete to get chemical flow. The preset ppm is 400, 600, 800 or 1000.

Based on the facility needs the dairy can open the valves necessary to achieve their desired ppm

requirements.

The location for the ChemMix XV should be one that is out of the elements and accessible to replace the

chemical when necessary. The chemical levels in the supply drums must never be higher than the venturi

intake points. If the supply drums are elevated by a secondary containment system, the unit must be raised

to an equal height or placed on a secondary containment system as well. This will prevent siphoning of

chemicals into the solution tank.

Connecting the unit to a water supply

is accomplished by attaching the supplied

water filter assembly to the

water inlet

and attaching to a potable water source. The unit must be installed in compliance with all local

plumbing codes.

Care must be taken during the installation process to

keep pipe and thread sealing

preparations

to a minimum. Introduction of foreign

materials into

the unit can cause a malfunction of the

valves and venturi.

**Chemical levels should never

be above this line**

Page 6

6 | P a g e

Next attach the floats. Before this step can be accomplished an estimate of the activated solution the unit

will need to produce per hour must be determined. This unique system will produce up to 24 times the

solution tank’s maximum volume per day. The 15-gallon unit holds 11 gallons of activated solution. Attach

and hang the fill-float directly on the fill-float actuator cable.

Each float can be attached by sliding the hook end of its cable into the well of the float, rotating the float

until the cross bar of the float is perpendicular to the hook of the cable and then lifting the hook on to the

cross bar. If it has been determined the extension wire is unnecessary, hang the fill-float directly on the fillfloat actuator cable.

If the float extension wire is necessary, bend the extension wire at the desired length, attach the fill-float to

the hook end, and attach the bent end to the fill-float actuator cable (see picture below). In either case hang

the safety-float directly on the safety-float actuator cable. Observe the floats to make sure they are properly

connected. Gently lift the fill-float actuator cable to assure the fill-float moves freely. When the cable is

lifted the fill-valve should click off. Once the cable is released it should click back on. Follow the same

procedure for proper connection of the safety-float.

The unit should appear as one of the two

pictured to the right. Which one depends

on whether or not the extension-wire was

used. Notice the difference in solution

levels that must be reached before the fillfloat will shut off the fill-valve and stop

filling each unit.

In either case, the unit will automatically

refill the solution tank to the preset level

with fresh active solution as needed.

Page 7

7 | P a g e

The final step in setting up the un

it is to attach each chemical intake tube to its respective

intake point. Each

intake

point is marked at the top of the venturi intake assembly. Connect

each intake tube by gently

sliding

its open end into the designated area. The blue product tube will go into the PTC marked Alphacide 30K and

the red acid tube will go on the venturi marked Activator.

Make sure the ceramic weight

is at the bottom end

of each intake tube next to its foot valve

and place the intake tube

s into the bottom of their respective supply

drums. The hose should always be cut to length to eliminate any loops and insure proper flow of chemical.

Picture above is the Alphacide 30K (product) check valve, intake hose, and weighted foot valve and the

Activator (acid) check valve, intake hose, and weighted foot valve. The weight goes into the product and

the check valve should be closest to the ChemMixXV hook up. The product (Alphacide 30K) will always

be the blue hose and the acid (Activator) will always be the red hose.

These should never be switched for any reason.

Page 8

8 | P a g e

5 TESTING THE UNIT

At this point, the unit should be properly

assembled, positioned, connected to a water

supply, and its intake

tube

s placed in their respective supply drums. Turn the blue water inlet valve to “on”. Water should begin

to flow through the system and

into the solution tank. Check the

function of the fill-valve and the safety-

valve by gently

lifting each actuator cable one at

a time. When each actuator cable is lifted, its valve

should

stop the water flow. After

releasing the

cable, water should again flow. Within

seconds, the product intake

tube

will fill with product. The activator intake tube will take

longer to fill, approximately 15-30

seconds.

As the water flows, check the chemical intake

tubes for suction. After verification

of suction, the unit is

now functioning properly and

ready for sampling. Set the ppm dial to desired concertation.

Wait one to two minutes after flow

has been established through the unit and into

the solution tank. Sample

the solution

with a plastic cup as it enters the solution tank.

To do this, simply remove

the 4" access port

plug on the top of the lid. Slide the cup

through the access port and

under the solution outlet inside the

solution tank. Collect

approximately 6 ounces of sample

and turn the control valve to the "off" position.

Set

the sample aside for approximately

5 minutes. Observe the sample. It should have a

slight yellow color

present. If the

color is present, activation is occurring and the factory

product parameters are adequate.

Check

the pH of the sample. The sample should

have a pH range of 2.0 to 3.0 or

as specified by application.

After verification, slowly

turn the control valve back to the

"on" position and continue filling the solution

tank.

The system will continue

to fill until water flow is stopped by the fill-valve at the pre-set

level

determined by the fil

l-float. During initial setup, after the unit has filled for the first

time, wait one hour

before using the activated

solution.

The unit is equipped with a solution

well designed for drawing active solution from the

bottom of the

solution tank. Simply

drop metering equipment tube(s) through the predrilled

holes in the solution well

access

cap. Additional holes or larger holes can be bored in the

cap if needed. Consult metering equipment

instruction

manuals for installation requirements.

Page 9

9 | P a g e

6 CHOOSING METERING TIPS

Over time, the Chem Mix XV will need to be recalibrated to mix the correct ppm. When it is time to do

this, you simply will need to test the solution and change the orifice on the valves accordingly. When

starting maintenance on the valves, always start will the lowest concentration first and work your way up

to the highest. This will eliminate any false readings.

You will need:

1- Orifice Pack

1- Needle Nose Pliers

1- Chlorine Dioxide Test Kit

All of these can be ordered through FutureCow or your FutureCow Dealer. All parts are shown on your

Parts List in the User Manual. If any questions arise please seek a FutureCow Technician.

To start you will need to test the chemical ppm levels, first start with the lowest ppm valve. Run the chemical

with only that valve on, take a sample of the mixed product. Use your Chlorine Dioxide Test Kit to test the

ppm. If it reads correctly move on to the next higher valve. If it does not read correctly, you will have to

change that orifice.

In order to change an orifice, first turn the valve to off, then remove the manifold to expose the metering

tip where the orifice is located. The orifice will be the small colored piece sticking out of the metering tip.

Take needle nose pliers and unscrew the orifice.

The orifice tip needed to achieve the designated ppm might not always be the same color as the one

previously in place, however, a good place to start would be by replacing the orifice with the same color as

previously used.

Place the manifold back over the new orifice and metering tip, turn the valve to on and take another sample

of the finished solution. If the reading is the desired ppm move on to the next valve until you have finished

all of the recalibrations.

If the reading is not accurate, follow the sizing chart located in the orifice pack bag for the next larger or

smaller orifice depending on how the solution read until you achieve the correct ppm.

Page 10

10 | P a g e

7 PROBLEMS AND SOLUT IONS

This unit has been tested and approved for use with the FutureCow Teatscrubber System and FutureCow

approved products only. Use of any other chemical or products voids all warranties, and negates any

responsibility FutureCow may assume with regard to product support.

Consult the appropriate product SDS for safety instructions and safety equipment requirements.

The activator is an acidic product. Consult the product SDS for safety instructions and safety equipment

requirements.

Water will not flow through the system

With the control valve in the "on"

position, lift up and then pull down on the two

actuator cables attached

to

the fill and safety valves at the same time. Water should

pass through the unit and into t

he solution tank. If

this does not happen, follow the

steps below until

problem is

resolved.

1. Check the water source for

proper pressure and volume.

2. Make sure the control valve is

in the "on" position. When the blue handle is pointed

toward the safety

valve and parallel

to the support structure it is on.

3. Check to see if the solution tank

is full. Normal operating tank volume is 1/2 to 2/3 full,

less, if the float

extension wire

is installed.

4. Make sure the fill-float actuator cable

and the safety-float actuator cable are connected

to their respective valves. Each cable should

be hooked around the bail wire of its valve.

5. Observe the floats to make sure

they are properly connected. Check the function of th

e

fill-valve and

the safety-valve

by gently lifting each actuator cable one at a time. When

each actuator cable is lifted; the valve

should stop the water flow. After releasing the

cable, water should again flow.

6. Remove the filter cartridge and check

for clogging. Clean if necessary.

If the above steps do not facilitate

water flow through the unit, one or both of the valves

may need to be

cleaned or replaced

.

Page 11

11 | P a g e

No suction in chemical

intake tubes

As water flows through the unit, the

chemical intake tubes should begin to fill. The

product intake tube

should fill within

seconds. The activator intake tube will take longer

to fill, approximately 15-30 seconds

.

Verify suction by lifting each intake tube one at a

time from its supply drum, it should

begin to suction in

air, creating small air bubbles in

the intake tube. If this does not happen, follow

the steps below until the

problem is resolved.

1. Check the product levels in the

chemical supply drums.

2. Make sure the orifice tip at each intake

point is not clogged or crystallized.

3. Make sure each foot valve, inline check valve

, and intake tube is not clogged or damaged.

4. Check to see that water supply line meets p

si and flow requirements.

If the above steps do not facilitate

suction through the intake tubes, one or both sides of

the venturi intake

assembly

may need to be repaired or replaced.

No yellow color present

If the directions for setting up the

unit have been followed, but the product shows no sign

of activation within

5 minutes

, follow the steps below until the problem is resolved.

1. Verify suction in the product in

take tube and the activator intake tube.

Read "No suction in chemical

intake

tubes" for help verifying suction and the

steps to be taken for correcting.

2. Check the pH of the sample

. Make sure the pH of the solution is within the range of

2.0 to 3.0 or as

specified by application

. To do this, simply remove the 4" access port

plug on the top of the lid. Slid

e a

plastic cup through the access port and under the

solution outlet inside the solution tan

k. Collect

approximately 6 ounces of sample and

turn the control valve to the "off" position, then

check the pH. Set

the sample aside for

about 5 minutes. Observe the sample. The

solution should have a slight yellow color

present.

If the color is present, activation

is occurring and the factory product parameters are adequate

.

If the pH of

the solution is

out of range, read "Changing pH of activated solution" to correct.

Changing the pH of the

activated solution

Before making any changes to the

pH or concentration, check the QC sheets that accompany

this manual

for the factory preset

pH and concentration levels of this unit. Note the color o

f the

orifice to be changed.

Make no more

than one orifice size changes up or down between

adjustments (see

color orifice

chart

in

orifice pack).

The Alpha is a venturi based system

that draws chemicals through orifices to control pH

and

concentration

(ppm). Therefore,

when a change of orifice is made on one side of the vent

uri

assembly,

the

other side is

slightly

affected as well. For example, if a change is made to a

larger

size orifice in the activator side of

the

Page 12

12 | P a g e

venturi assembly, the pH will drop and the concentration will lower

. This occurs because

the venturi

assembly is now pulling more on

the

activator intake and compensating

by pulling less on the product intake.

In contrast, a change

to a smaller orifice will cause the

pH to go higher, and the concentration to increase.

If the solution pH is higher than 3.0

, follow the steps below to lower the pH.

**Never operate without both product

and activator orifices in place. **

1. Turn control valve to the

off position.

2. Carefully remove the activator intake hose from

its intake point.

3. Unscrew the exposed orifice tip.

4. Replace the orifice with the next

larger size according to the chart insert in the

orifice pack, (more

activator lowers

the pH). Be careful not to over

tighten.

5. Reinstall the activator intake hose.

6. Restart water flow, verify suction, and check

the pH of the solution.

If the solution is higher than 3.0,

repeat steps 1 through 5 until the desired pH is

reached.

If the solution pH is lower than 2.

0, follow the steps below to raise the pH.

**Never operate without both product

and activator orifices in place. **

1. Turn the water valve to

the off position.

2. Carefully remove the activator intake hose from

its intake point.

3. Unscrew the exposed orifice tip.

4. Replace the orifice with the next

smaller size according to the chart insert in the

orifice pack, (less

activator raises

the pH). Be careful not to over tighten.

5. Reinstall the activator intake hose.

6. Restart water flow, verify suction, and check

the pH of the solution.

If the solution is lower than 2.0, repeat

steps 1 through 5 until the desired pH is reached.

Page 13

13 | P a g e

8 MAINTENANCE

Please read the entire instruction manual before performing any of the maintenance tasks listed below.

Information on how to accomplish these tasks as well as important safety information can be found in

previous sections within this manual.

Follow this chart to maintain performance and extend the life of the unit:

FutureCow additional technical information and can answer questions about the proper maintenance

and/or replacement parts for this unit.

Contact FutureCow for any additional information or assistance not contained in this manual.

Page 14

14 | P a g e

CHEM MIX XV QUALITY AND PERFORMANCE CHECK LIST

PHYSICAL CHECK LIST-WATER OFF

Each test must pass before proceeding.

Check to see that the unit is configured to the specifications order sheet.

Check to see that all plumbing is correct according to assembly drawing.

Check for physical flaws. (Dents, scratches, cracks, improper holes)

WET CHECK LIST-HIGH PRESSURE

Attach the unit to a pressure system capable of 75psi.

Incresase the pressure to 75psi. Allow unit to pressurize for at least 15 minutes. Engage both float

valves by lowering the bail of each. This action will allow water to flow through the unit. Allow

water to flow through the unit for 1 minute and release the bail of each float valve. Check for

leaks.

WET CHECK LIST-WORKING PRESSURE

Place the Fill Float and Safety Float in a bucket of water to check buoyancy. The tops of both

floats should float approximately 1” above surface of the water. Set Pressure system to 50psi,

unless an otherwise specific pressure is listed on the order sheet. Connect floats to the unit and

check for binding by raising and lowering each float in turn. Check for flow of water through the

venture when the floats are down and the float valves snap open. Check for no flow of water

when the floats are up and the float valves snap shut. Both floats and valves should perform the

same.

CHEMICAL INJECTION CHECK LIST

Chemicals listed here must match specifications listed on order sheet.

Precursor ____________________ Precursor Orifice Color _____________________

Activator _____________________ Activator Orifice Color _____________________

LABORATORY CHECK LIST

Water Pressure during check _______ psi

The pH of the solution from the venturi ______ pH

The available ClO2 concentration of the solution ______________________________ ppm w/w

Lab Tech Signature ____________________________________ Date _________________

Q.C. Signature ________________________________________ Date _________________

Unit Serial Number ________________

Loading...

Loading...