www.futureautomation.co.uk

www.futureautomation.net

PS Bracket Range Product Guide

Enables fast and easy

one person tting, even

with larger screens.

Hook On Hook Off

Screen Mount

Designed for safe and

smooth movement, with

minimal eff ort required.

Unique Scissor

Arm Design

2 FUTURE AUTOMATION MANUAL BRACKETS

Product Code PS40

Function On Wall Articulating Bracket / Service Mount

Movement Type Manual Advance / Swivel

Suggested Screen Sizes 40” - 75”

Max. Screen Weight 60kg (132lbs)

Min. Bracket Depth 52mm (2.0”)

Max. Rotation 50° Each Way (Screen Width Dependent)

VESA Compatibility Min. 200 x 200 - Max. 400 x 400

Standard Finish Satin Black (RAL 9005) Powder Coat

Wall Box Compatibility WB21 WB26 WB31

Accessory Compatibility AM1 / AM2 / USM / VOA / HOA

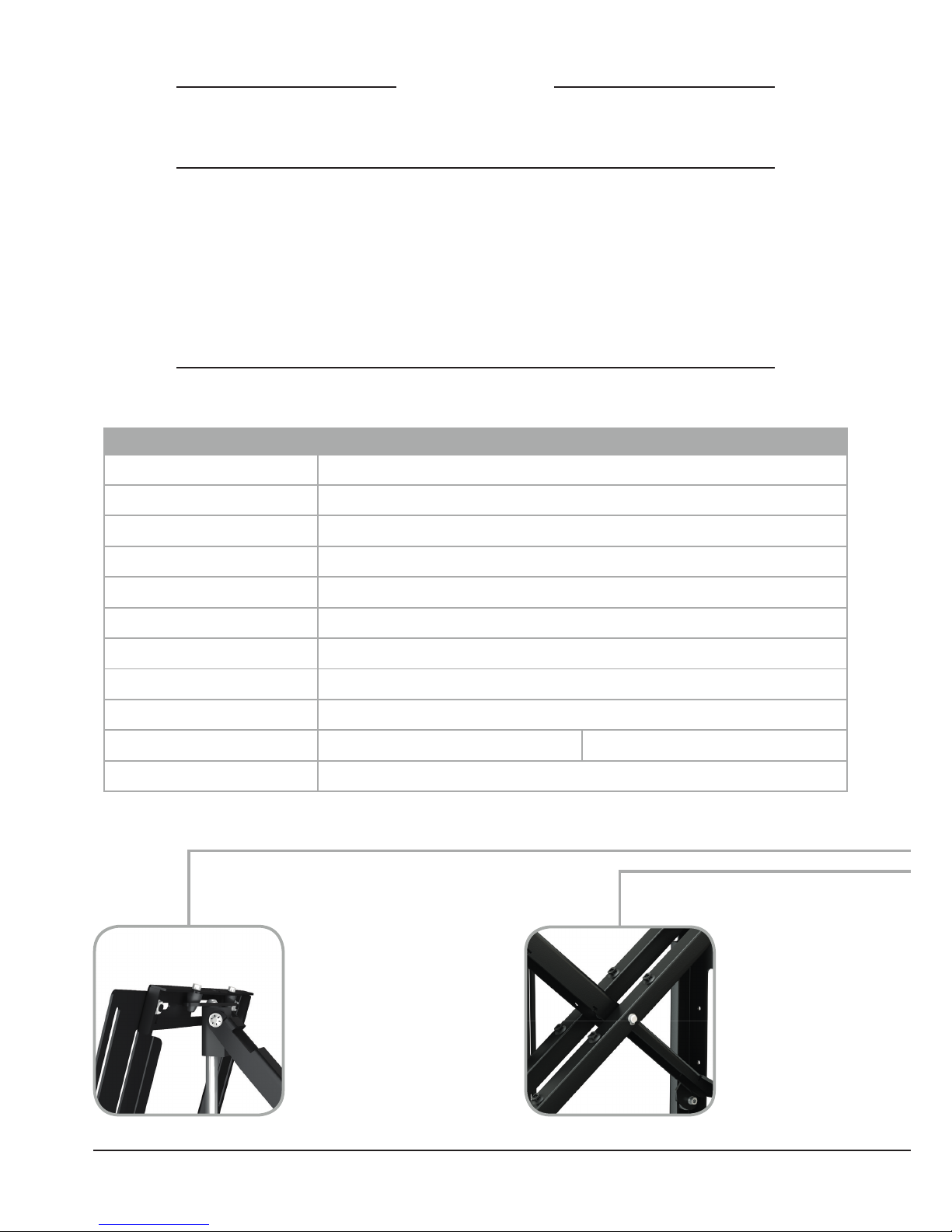

PS40 Product Specifi cation

The smoothest and most reliable product on the market, the PS Bracket

allows perfect parallel movement and the freedom and fl exibility to view

your screen in a variety of positions. Perfect for recessing screens in walls

for a completely fl ush nish either by itself or when combined with our

WB21, WB26 or WB31 In Wall Mounting Boxes. Compatibility with diff erent

height wall boxes allows for greater vertical and horizontal mounting

position adjustment.

On Wall Articulating / Service Mount (40”-75”)

PS40

In built cable tie anchors

for neat and simple

cable management.

Discreet Cable

Management

Optional 16” stud bay

mounting kit included

with all brackets from

the range.

Stud Mounting Kit

3WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

4 FUTURE AUTOMATION MANUAL BRACKETS

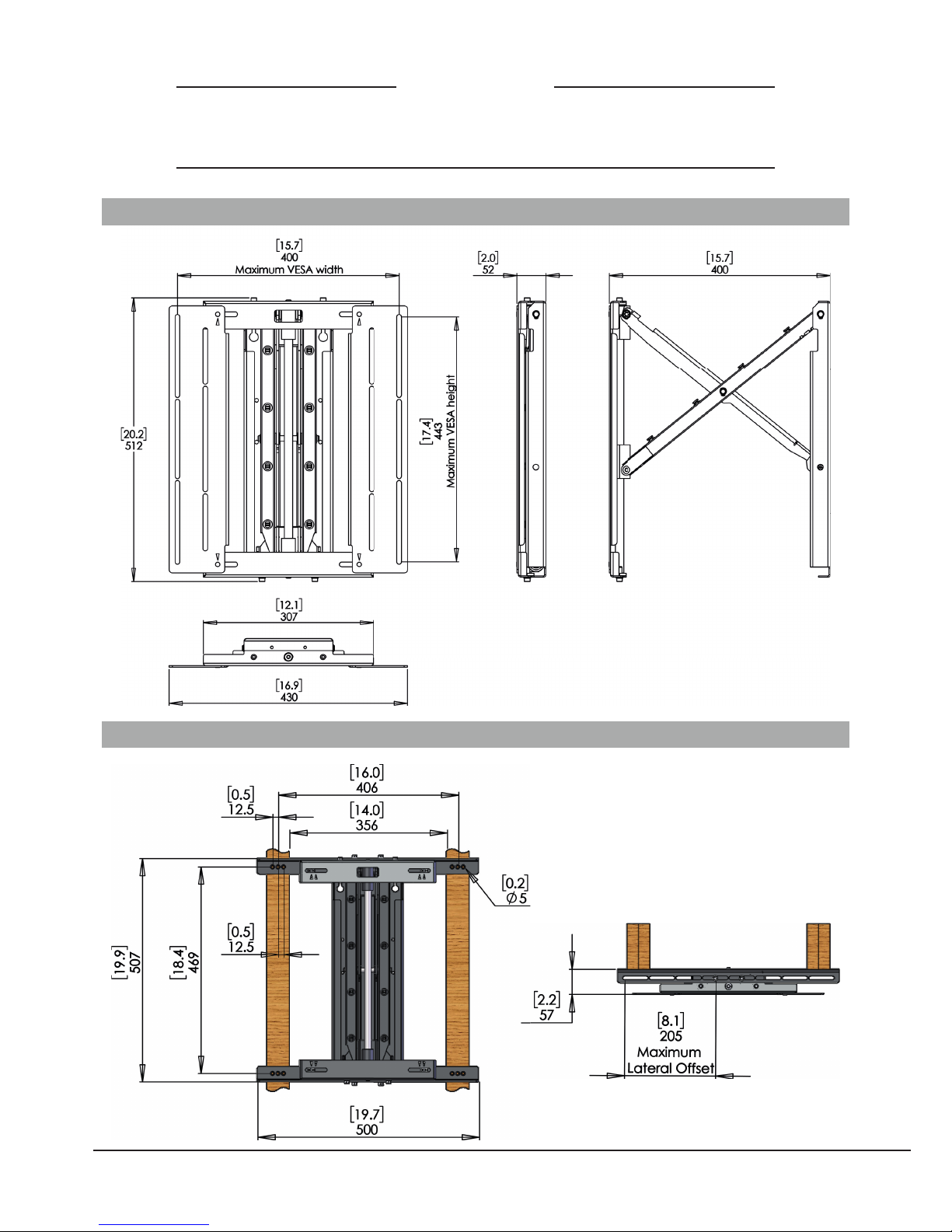

PS40 Size Overview

PS40 Stud Mounting Overview

Note: Screen uprights hidden for clarity

On Wall Articulating / Service Mount (40”-75”)

PS40

5

PS40 Maximum Rotation Overview

PS40 Shown With Included

Vertical Off set Adaptor Kit (VOA)

Note: The maximum swivel angle achievable is 50° regardless of screen size

PS40 Shown With Included Stud

Rail Kit (SRK)

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

Enables fast and easy

one person tting, even

with larger screens.

Hook On Hook Off

Screen Mount

Designed for safe and

smooth movement, with

minimal eff ort required.

Unique Scissor

Arm Design

6 FUTURE AUTOMATION MANUAL BRACKETS

Product Code PS55

Function On Wall Articulating Bracket / Service Mount

Movement Type Manual Advance / Swivel

Suggested Screen Sizes 55” - 75”

Max. Screen Weight 60kg (132lbs)

Min. Bracket Depth 52mm (2.0”)

Max. Rotation 50° Each Way (Screen Width Dependent)

VESA Compatibility Min. 200 x 200 - Max. 400 x 400

Standard Finish Satin Black (RAL 9005) Powder Coat

Wall Box Compatibility WB26 WB31

Accessory Compatibility AM1 / AM2 / USM / VOA / HOA

PS55 Product Specifi cation

The smoothest and most reliable product on the market, the PS Bracket

allows perfect parallel movement and the freedom and fl exibility to view

your screen in a variety of positions. Perfect for recessing screens in walls

for a completely fl ush nish either by itself or when combined with our

WB26 or WB31 In Wall Mounting Boxes. Compatibility with diff erent height

wall boxes allows for greater vertical and horizontal mounting position

adjustment.

On Wall Articulating / Service Mount (55”-75”)

PS55

In built cable tie anchors

for neat and simple

cable management.

Discreet Cable

Management

Optional 16” stud bay

mounting kit included

with all brackets from

the range.

Stud Mounting Kit

7

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

8 FUTURE AUTOMATION MANUAL BRACKETS

PS55 Size Overview

PS55 Stud Mounting Overview

Note: Screen uprights hidden for clarity

On Wall Articulating / Service Mount (55”-75”)

PS55

9

PS55 Maximum Rotation Overview

PS55 Shown With Included

Vertical Off set Adaptor Kit (VOA)

Note: The maximum swivel angle achievable is 50° regardless of screen size

PS55 Shown With Included Stud

Rail Kit (SRK)

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

Enables fast and easy

one person tting, even

with larger screens.

Hook On Hook Off

Screen Mount

Optional mount plates

enable VESA600 screen

mounting.

Up To VESA600

Mounting

10 FUTURE AUTOMATION MANUAL BRACKETS

Product Code PS65

Function On Wall Articulating Bracket / Service Mount

Movement Type Manual Advance / Swivel

Suggested Screen Sizes 65” - 75”

Max. Screen Weight 60kg (132lbs)

Min. Bracket Depth 52mm (2.0”)

Max. Rotation 50° Each Way (Screen Width Dependent)

VESA Compatibility Min. 200 x 200 - Max. 600 x 600 (With H600 Kit)

Standard Finish Satin Black (RAL 9005) Powder Coat

Wall Box Compatibility WB31

Accessory Compatibility AM1 / AM2 / USM / VOA / HOA / H600

PS65 Product Specifi cation

The smoothest and most reliable product on the market, the PS Bracket

allows perfect parallel movement and the freedom and fl exibility to view

your screen in a variety of positions. Perfect for recessing screens in walls

for a completely fl ush nish either by itself or when combined with our

WB31 In Wall Mounting Box.

On Wall Articulating / Service Mount (65”-75”)

PS65

In built cable tie anchors

for neat and simple

cable management.

Discreet Cable

Management

Optional 16” stud bay

mounting kit included

with all brackets from

the range.

Stud Mounting Kit

11

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

12 FUTURE AUTOMATION MANUAL BRACKETS

PS65 Size Overview

PS65 Stud Mounting Overview

Note: Screen uprights hidden for clarity

Note: VESA600 requires H600 adaptor

On Wall Articulating / Service Mount (65”-75”)

PS65

13

PS65 Maximum Rotation Overview

PS65 Shown With Included

Vertical Off set Adaptor Kit (VOA)

Note: The maximum swivel angle achievable is 50° regardless of screen size

PS65 Shown With Included Stud

Rail Kit (SRK)

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

Provides a stable base

for mounting screens up

to 75”.

Solid Steel

Construction

Bracket xing depth can

be adjusted to allow

mounting of deeper

accessories inside the

wall box

Variable Bracket

Mounting Depth

14 FUTURE AUTOMATION MANUAL BRACKETS

Product Code WB21 WB26 WB31

Function In Wall Mounting Box

PS Bracket Compatibility PS40 / PS55 / PS65 PS55 / PS65 PS65

Min. Cut Out Height 533mm (21.0”) 660mm (26.0”) 878mm (31.0”)

Min. Cut Out Width 355mm (14.0”) / Single Stud Bay

Min. Cut Out Depth 102mm (4.0”)

Standard Finish Satin Black (RAL 9005) Powder Coat

Max. Junction Boxes 4

Max. Accessory Size (WxDxH) 200mm (7.8”) x 40mm (1.6”) x Variable

In Wall Box Product Specifi cation

Designed for fl ush single stud bay mounting, the WB21, WB26 and WB31

pair perfectly with the PS Bracket Range of On Wall Articulating / Service

Mounts. Adjustable mounting depth, multiple accessory brackets and size

compatibility across the PS Bracket Range make Future Automation In

Wall Mounting Boxes ideal for the custom install market. The option of

mounting diff erent size PS Brackets into each wall box allows for greater

adjustment and mounting fl exibility.

In Wall Mounting Boxes for PS40, PS55 and PS65

WB21 / WB26 / WB31

Adjustable accessory

clamp brackets enable

mounting of mini-amps,

Roku/Apple TV, power

conditioners and more.

Adjustable

Accessory Clamps

Metal edge trims off er

a cleaner nish around

the installed wall box.

On Wall Trim

Panels

15

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

16 FUTURE AUTOMATION MANUAL BRACKETS

WB21 Size Overview

WB21 Features Overview

In Wall Mounting Box for PS40

WB21

Note: Wall Box has two bracket mount depths to allow

increased or decreased space to accommodate accessories.

Note: Bracket mount position can be adjusted laterally to

change mount location relative to studs.

17

WB21 / PS40 Fitting Overview

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

18 FUTURE AUTOMATION MANUAL BRACKETS

WB26 Size Overview

WB26 Features Overview

In Wall Mounting Box for PS40 and PS55

WB26

Note: Wall Box has two bracket mount depths to allow

increased or decreased space to accommodate accessories.

Note: Bracket mount position can be adjusted laterally to

change mount location relative to studs.

WB26 / PS55 Fitting Overview

WB26 / PS40 Fitting Overview

19WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

20 FUTURE AUTOMATION MANUAL BRACKETS

WB31 Size Overview

WB31 Features Overview

In Wall Mounting Box for PS40, PS55 and PS65

WB31

Note: Wall Box has two bracket mount depths to allow

increased or decreased space to accommodate accessories.

Note: Bracket mount position can be adjusted laterally to

change mount location relative to studs.

WB31 / PS40 Fitting Overview

WB31 / PS55 Fitting Overview

WB31 / PS65 Fitting Overview

21WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

22 FUTURE AUTOMATION MANUAL BRACKETS

Who Are We?

The Premier Manufacturer of Moving Audio Visual Solutions

“Future Automation oers a comprehensive range of standard and custom built products for discerning customers.”

Future Automation have designed and manufactured exceptional television and projector lifts and mounts for the

Residential, Marine, Commercial, Hospitality and Outdoor applications since 1998, a customer rst business that

prides itself on its creativity, passion and excellence. Future Automation are a design led mechanical engineering

company that is known for providing the highest quality products across a wide range of applications and industries,

our primary focus is supplying technology integrators with solutions to move and conceal televisions, projectors,

appliances and other similar equipment for functional and aesthetic purposes.

Our products are designed and engineered in the UK and the US to maximize system reliability and to meet the

needs of installers. We design and build products that combine functionality with quality engineering and aesthetic

appeal.

The distinctive range of products from Future Automation allows AV products to be integrated within the fabric of

a room like never before, making them as unobtrusive, eective, and as easy to operate as possible. Our product

range includes, television lifts, wall mounts, projector lifts, moving panel mechanisms, ceiling mounts, DIN rail

enclosures, motorised pocket doors, cabinet airow control products and motorised shades.

We are a vertically integrated manufacturing company that operates a lean manufacturing philosophy across our

factories in both the UK & the US. We have invested heavily in facilities and state of the art machinery to ensure that

we can keep improving our products in current markets, whilst innovating and expanding our range into new areas.

Our fabrication capabilities span laser cut sheet metal, electro-mechanical CNC punch, CNC mills & lathes, CNC

press brakes, welding, manual & drill presses and powder coating. Coupled with our dedicated in-house design

team, and experienced assembly engineers, we make our clients ideas reality.

Focused on putting the custom back into custom installations, Future Automation products are unrivalled in their

diversity, and our innovative product range is manufactured to order to the highest possible standards. Combined

with the company’s unparalleled service, Future Automation delivers a solution for every project; whatever the size

and however challenging.

“Specialised in Developing Moving Solutions that Combine

Functionality with Quality Engineering and Aesthetic Appeal”

1998 - Future Sound & Vision

Founded

A high end, bespoke installation

company focusing on Linn Speakers and

Lutron Installation.

2006 – Future Automation Begins

International Sales

Manual and automated products are showcased at ISE

in Brussels, followed shortly by the opening of the export

side of Future Automation.

2011 – US Oces and Factory Open

Opening of American admin oces and factory in

Dover, NH along with showcasing of Future Automation

products at CEDIA US Expo.

2002 – First Future Automation

Products Launched

Prototype manual and automated products are

showcased at CEDIA Expo in the UK followed by

rst UK sales.

2007 – New UK Premises and Self Sucient

Sheet Metal Fabrication

Acquired additional admin oces in Stevenage, UK, along

with workshop space and machinery including Trumpf CNC

Laser and sheet metal welding/nishing facilities.

2015 – UK Manufacturing Expansion

Movement of European based manufacture to new premises

in Bedford, UK, taking total manufacturing space up to

50,000 sq/ft.

23

Orders can be placed;

Online via the dealer portal - www.futureautomation.co.uk / www.futureautomation.net

By Email - info@futureautomation.co.uk / info@futureautomation.net

By Phone - +44 (0)1438 833577 / +1 (603) 742 9181

We appreciate that, by its very nature, custom installation is a highly specialised eld and one that demands

high quality and often custom solutions.

At Future Automation we have both the expertise and resources to deliver fully customised mechanisms,

manufactured to a very precise set of criteria. And, whilst it may have started with AV, it certainly doesn’t end

there. As an engineering company we have the ability to meet any motorised automation requirement; from

hidden bookcases, to revolving snooker tables and moving room dividers – anything is possible. So, whether

it’s a product from our standard range or something out of the box, Future Automation can come up with the

goods.

We have invested heavily in resources and our state of the art facilities are fully equipped with the latest

technology. A full CAD department allows us to customise drawings in 3D and 2D and as well as a laser proling

machine, CNC lathes and CNC mills, we have full metal fabrication facilities to enable us to take on even the

most demanding of projects.

Our dedicated assembly facility is where our products are brought to life, along with the ability to control

them. All Future Automation products are designed to interface with whatever third party control system

that the installer requires. By working in this way, we can ensure our products t seamlessly into any custom

installation.

From Superyachts in Miami to Penthouses in New York, we continue to work with leading architects, designers

and installers on the most prestigious projects around the world. But no job is too big or too small. Whoever

you are and whatever your requirements, Future Automation has the product that ts.

+44 (0)1438 833577

+1 (603) 742 9181

www.futureautomation.co.uk

www.futureautomation.net

info@futureautomation.co.uk

info@futureautomation.net

Custom Services

Contact Us

How To Order

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

WWW.FUTUREAUTOMATION.CO.UK | WWW.FUTUREAUTOMATION.NET

Loading...

Loading...