It is the responsibility of

the installer to warn all

potential end users of

the dangers of interfering

with mechanisms during

operation

WARNING

IMPORTANT

Mechanisms which lift

or move weights need

to be checked on a

yearly basis for any

damage which may

result in an accident

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 1 of 7

SCREEN MOUNT PLATE

BASE TOP

BOTTOM COVER FLANGE

TRANSPORT BRACKET

UPPER PLATE

BASE PLATE

SCREEN MOUNT COVER

CENTRE TUBE

IR RECEIVER

BASE SUB-ASSEMBLY

MOUNT SUB-ASSEMBLY

Package Contents

Each FME will be shipped in two subassemblies; mount and base, along with

all necessary fixings and cables.

Before installing the mechanism ensure

that the instructions are read carefully and

that all parts and wiring are undamaged

and secure.

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 2 of 7

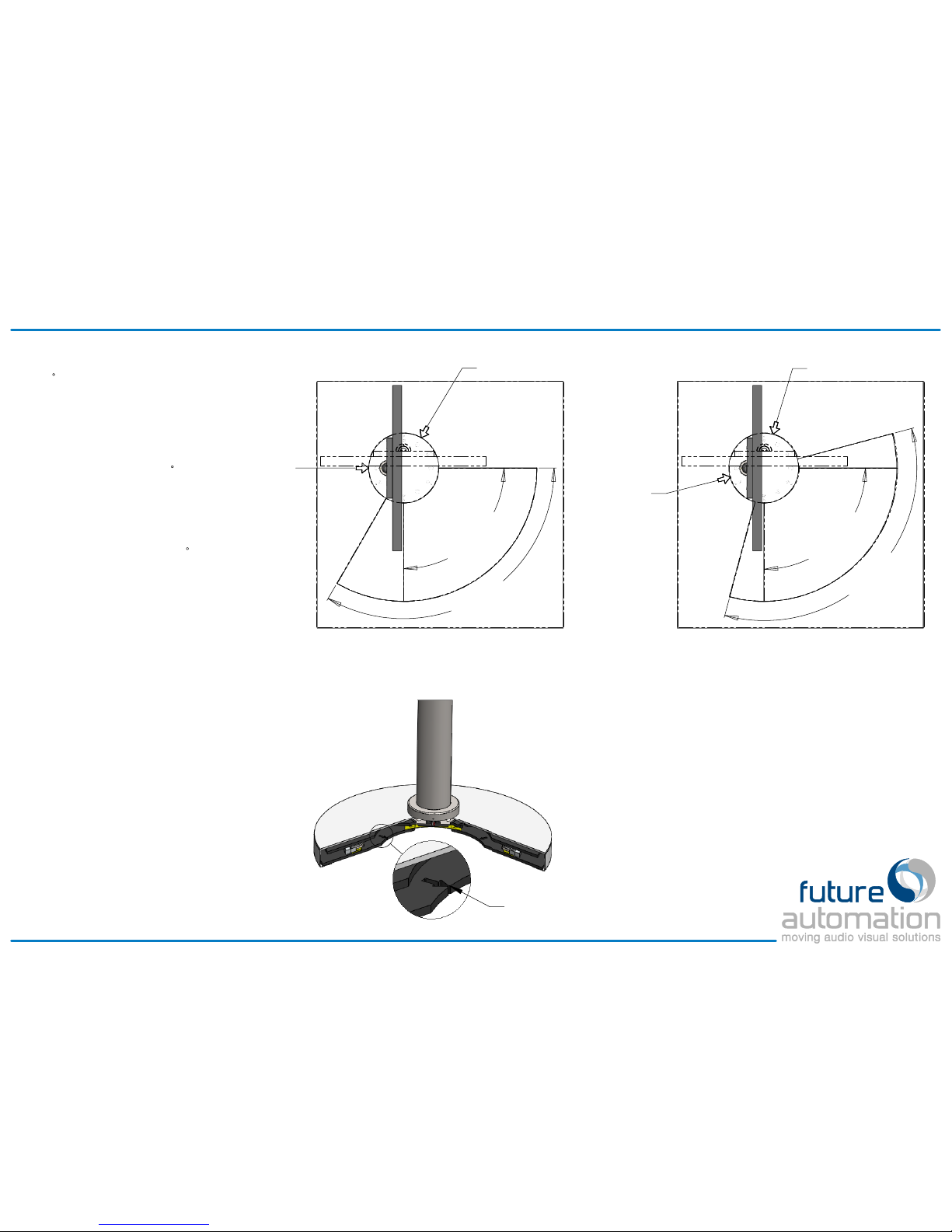

90°

Install Sweep

120°

Max Sweep

RIGHT

Limit Switch

LEFT

Limit Switch

CORRECT INSTALLATION

The installation sweep angle shares an end point

with the maximum sweep angle, allowing the

RIGHT limit switch to be seen.

90°

Install Sweep

120°

Max Sweep

RIGHT

Limit Switch

LEFT

Limit Switch

INCORRECT INSTALLATION

The installation sweep angle works within the

maximum sweep angle so neither limit switch can

be seen during normal operation.

Cut-outs in base plate identify

limit switch positions

Mechanism Positioning

The FME enables a screen to be rotated

up to 60

in both directions from center.

Software allows intermediate positions to

be learnt and selected using the IR

remote.

! IMPORTANT !

In installations where the full 120

of

travel is not required or possible it is

important that the RIGHT end switche can

be seen to ensure accurate and

consistent positioning of the mechanism.

If there are obstructions that prevent the

mechanism being able to rotate 120

the

RIGHT limit switch must be positioned

within the installation sweep angle.

A new LEFT limit position can be set

using the IR remote (see Page 4).

Arrow cut-outs in the base plate show

each limit switch position, these should be

used when positioning the mechanism.

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 3 of 7

LEFT

A

B

C D

E

F

RIGHT

PRESET

Mechanism Control

PRESET POSITIONS

Preset positions become active once the

mechanism has travelled fully LEFT and fully

RIGHT or a maximum LEFT limit is set.

To adjust presets press STOP in the desired

position then STORE and you’ll have a 2 sec

window to press PRESET or buttons A-F to

save that position to that particular button.

If the power is cut while the mechanism is

moving its position will need to be rereferenced (see Mechanism Reset).

Until referenced, the mechanism will not be

able to access stored positions and will only

be able to move right in short pulses.

MECHANISM RESET

If the mechanism does not see one of the limit

switches for a long period of time its position

counting may lose accuracy.

To re-reference the position counting simply

send the mechanism to the RIGHT position.

If the full 120

sweep is not being used the

mechanism must be able to be sent to the

RIGHT limit (see Page 3 for details).

SETTING LEFT LIMIT

If the full 120

travel cannot be used because

of physical obstructions the LEFT limit can be

programmed by stopping the mechanism at

the desired position and pressing STORE then

LEFT.

This limit can be cleared by pressing STORE

then STOP then LEFT.

If the LEFT limit is set by the installer the

preset positions will be equally spaced

between this new travel sweep.

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 4 of 7

1.

Remove Base Top from Base sub-assembly.

3.

Mount the Center Tube to the Base Top Plate using

4 x M6x12 bolts supplied.

Note:

The tube must be orientated so that the IR

receiver is facing in the direction shown.

4.

Remove the red Transport Bracket from the base.

! IMPORTANT !

This must be removed before operating the

mechanism.

Installation

2.

Remove 4 x M4 bolts from Center Tube and lift off

screen mount.

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 5 of 7

SCREEN MOUNT COVER

SCREEN MOUNT PLATE

SCREEN

6.

Remove Cover from Screen Mount by releasing 4 x

M6 CSK bolts.

7.

Fix screen to Screen Mount using appropriate fixings.

Note:

Spacers may be required if the screen

mounting holes are recessed or if the back of the

screen is not flat.

5.

Run screen cables up Center Tube.

Screen and power cables can terminate in the center

of the mechanism or run out underneath to another

location.

SIDE ELEVATION

8.

Slide Base Top and Bottom Cover over Center Tube

before remounting Screen Mount (screen not shown)

Installation

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 6 of 7

12 0.5

TYP

10.

Return mechanism to its central position, rotate base

top as shown and fix to the floor through 4 x

12mm

fixing holes.

11.

Make any adjustments to the vertical position of the

TV and remount Back Cover.

Installation

9.

Power mechanism to the RIGHT position and

position the base so that all criteria mentioned on

Page 3

are satisfied.

www.futureautomation.co.uk tel: +44 (0) 1438 833 577 fax: +44 (0) 1438 833 565

FME - Floor Mount Electric

Installation Guide

ISSUE 001

SHEET 7 of 7

Loading...

Loading...