Installation Instructions

ET / ET60 - Electric Tilt Mechanism

Design Highlights

-Downward Tilt Up To 20 Degrees

-Smooth Quiet Motion

-Onboard Electronics

Wall Mounts

Thank you for choosing

futureautomation

email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565 ISSUE 001

ET / ET60 - Electric Tilt Mechanism

Safety Disclaimer

Important Safety Instructions

Explanation of graphical symbols

-(Electric Shock Symbol) = The lightning flash within an equilateral triangle is intended to alert you to the presence of un-insulated

“dangerous voltage” within the products enclosure that may be of sufficient magnitude to constitute an electric shock to persons

-(Caution Symbol) = The exclamation point within an equilateral triangle is intended to alert you to the presence of important

operating and maintenance (servicing) instructions in the literature accompanying the product

-(Tools Symbols) = The tools symbol within a coloured square are intended to highlight the required tools necessary for correct and

safe installation of the product. These are intended as a

guide only, and it is at the installer’s discretion as to which tools are used.

WARNING: RISK OF ELECTRIC SHOCK, ONLY AUTHORIZED INSTALLERS TO OPEN THE POWER CONTROL BOX.

WARNING: To reduce the risk of fire or electric shock, do not expose electrical parts to rain or moisture, unless the

product has been specifically designed to do so.

Introduction: Safety disclaimer

WARNING: Failure to provide adequate structural strengthening, prior to installation can result in serious personal injury or damage to the

equipment. It is the installer’s responsibility to ensure the structure to which the component is affixed can support the four times the

weight of the component.

WARNING: Do not exceed the weight capacity. This can result in serious personal injury or damage to the equipment. It is the installer’s

responsibility to ensure that the total combined weight of all attached components does not exceed that of the maximum figure stated.

WARNING: Failure to provide adequate structural strength for this component can result in serious personal injury or damage to equipment! It is the installer’s responsibility to make sure the structure to which this component is attached can support five times the combined

weight of all equipment. Reinforce the structure as required before installing the component.

Warnings:

1. Read all technical instructions fully before installation and use. It is the installer’s responsibility to ensure that all

documentation is passed on the end user and read fully before operation.

2. Keep all documentation.

3. Heed all warnings.

4. Follow all technical specifications and instructions during installation.

5. Do not use near water unless the product has been specifically designed to do so.

6. Clean only with a dry cloth.

7. Do not defeat the purpose of the polarized or grounding type plug. A polarized plug has two blades, one wider

than the other. A grounding type plug has two blades and a grounding prong. The wide blade or third prong are

provided for your safety. If the provided plug does not fit your outlet, consult an electrician or contact the

manufacturer.

8. Protect the power cord from being walked on or pinched, particularly at plugs, convenience receptacles, and the

point where the exit from the apparatus.

9. Unplug the apparatus during lightning storms or when unused for long periods of time.

10. Only use attachments/accessories specified by the manufacturer.

11. Refer all servicing to qualified personnel. Servicing is required regularly on an annual basis, when the apparatus is

damaged in any way, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

12. To completely disconnect the apparatus form the AC mains, disconnect the power cord plug from the AC

receptacle on the power control box.

13. To prevent overheating, do not cover the apparatus. Install in accordance with the instructions.

14. UK, Ireland and Hong Kong only – The power cord is supplied with a 13A plug having an earthing pin. The

apparatus is earthed and this pin is not required for safety, merely to operate the safety shutter of mains outlet.

15. No naked flames such as lit candles should be placed on the unit.

16. Observe and follow the local regulations when disposing of batteries.

17. Do not expose the unit to dripping or splashing fluids.

18. Do not place objects filled with liquid, such as vases, on the unit.

19. Do not expose the batteries to excessive heat such as sunshine, fire or the like.

20. For all mounted apparatus, the apparatus should be installed on solid wood, bricks, concrete or solid wood

columns and battens.

21. Always turn off power at source before putting on or taking off parts and cleaning.

22. Do not use outdoors unless marked for outdoor use.

23. Exceeding the weight capacity can result in serious personal injury or damage to equipment.

Caution

Warning

Beware of

Moving Parts

Danger

Electricity

Keep Hands

Clear

Future Sound & Vision trading as Future Automation intend to make this and all documentation as accurate as possible. However, Future

Automation makes no claim that the information contained herein covers all details, conditions or variations, nor does it provide for every

possible contingency in connection with the installation or use of this product. The information contained in this document is subject to

change without prior notice or obligation of any kind. Future Automation makes no representation of warranty, expressed or implied,

regarding the information contained herein. Future Automation assumes no responsibility for accuracy, completeness or sufficiency of the

information contained in this document.

Page 1 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Contents Page

Introduction

Safety Disclaimer 1

Warning Icons 1

Contents 2

Contents 2

Tool Indicator Icons 3

Installation

Package Contents

Before You Start Check 4

Stage 1

Decide On The Mechanism Position 5

Positioning The First Hole In The Wall 5

Stage 2

Fixing To The Wall 6

Stage 3

Removing The Uprights 7

Stage 4

Fitting The Uprights To The Screen 8

Stage 5

Fitting The Screen To The Mechanism 9

Stage 6

Adjusting The Out Position 10

Electrical Connections

Electrical Connections In The Control Box 11

Contact Closure 12

Warning Lights 12

RS232

Wiring & Control Box Detail 13

Introduction: Contents

Operation

Operation Details 14

Remote Control 15

Trouble Shooting 15/16

Technical Overview 16

Product Warranty and Notes 17

Page 2 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

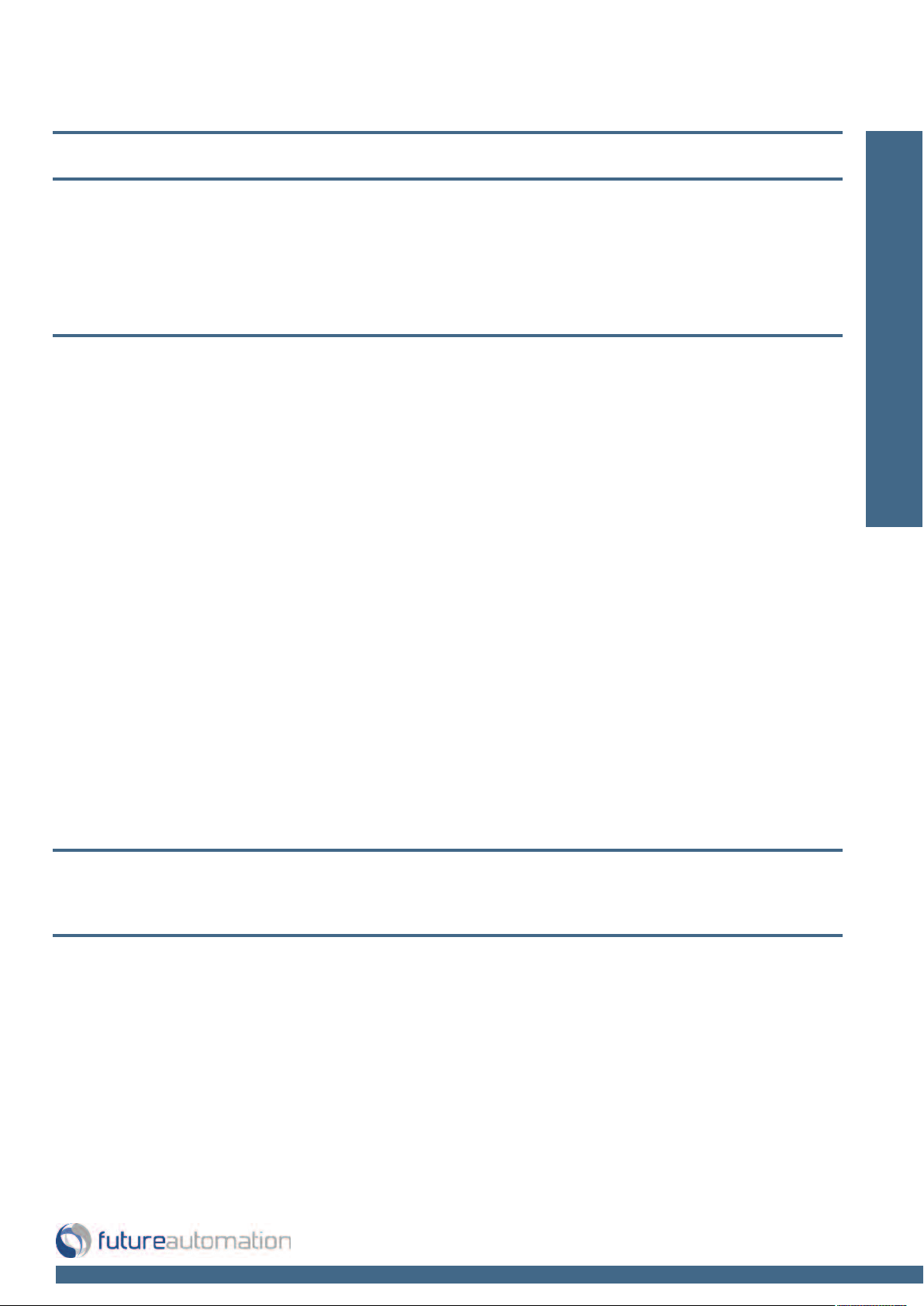

ET / ET60 - Electric Tilt Mechanism

Contents Page

Installation: Package Contents

Tool Indicator Icons

1. 2. 3. 4. 5. 6.

1. - Drill 3. - Allen Keys 5. - Screwdrivers 7. - Pencil

2. - Tape measure 4. - Spirit Level 6. - Spanners 8. - Saw

Page 3 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

7.

8.

ET / ET60 - Electric Tilt Mechanism

Installation: Stage 1

Before you start, check the following:

- The product is in good condition

- No damage to any parts

- Wiring is all secure

- The unit is in the closed position

Package Contents

1 - Mechanism

1.1 - Wall Mount Plate

1.2 - Control Box

1.3 - Strap

1.4 - Motor Tube

1.5 - Screen Uprights

2 - IR Remote

Not Shown On Page

3 - Multi pack of nuts and bolts

1.4

1.3

ET Mechanism

The only difference between

the ET & ET60 is the length

of the uprights as shown.

ET60 Mechanism

1.5

2

1.1

1.2

1.5

1

Important

Make sure to test that the

mechanism is working correctly.

Page 4 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Decide on the mechanism position

Before the mechanism can be fitted, it is important to decide on it’s exact position relative to

the screen. Place the screen face down on the floor and lay the mechanism on the back.

Measure from the top of the screen to a fixing hole so you can work out the positioning on

Installation: Stage 2

the wall.

Make sure that the screen is within 140mm from the bottom of the mechanism so it doesn't

foul on the wall when in the out position. For further details and dimensions please refer to

the technical sheets.

Mount offset

140mm MAX

Remember to account for any horizontal

off set on the screen mounting holes.

Page 5 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Fixing to the wall

After you have measured the screen positioning on the wall mark where the first fixing will go.

With the bracket hanging by the one fixing, make sure that the bracket is square and level by

using a spirit level. Once square, mark the other holes and fix accordingly.

Installation: Stage 3

Always use appropriate fixing types. Suitability of wall fixings will depend on the type of wall

the product is to be fixed to. If unsure, please seek instruction from your supply dealer.

Page 6 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Removing the uprights

Firstly remove the aluminium retaining collars. This will allow

the uprights to unhook off the mechanism, to then be fitted to

the rear of the screen.

Installation: Stage 4

Page 7 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

Retaining

collar X 4

ET / ET60 - Electric Tilt Mechanism

Fitting the uprights to the screen

Bolt the uprights to the back of the screen

using the appropriate fixings as shown below.

Installation: Stage 5

Page 8 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Fitting the screen to the mechanism

Hook the uprights back over the horizontal bars on the mechanism.

Installation: Stage 6

It is important that the aluminium retainers, which were removed in the earlier stage,

are replaced so that the screen can not be knocked off the bracket accidently.

Tighten the grub screws in the retainers so that the screen cannot slide left or right.

Page 9 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Adjusting the Out Position

Below in the detailed view you can see the motor control adjustment switches, using a

thin flat head screwdriver you can adjust the switches to alter the IN & OUT position.

Adjuster 1, adjusts the IN position.

Adjuster 2, adjusts the OUT position.

IN Position

Installation: Stage 7

Rotate anticlockwise to

stop higher

OUT Position

Rotate anticlockwise to

stop lower

Rotate

clockwise to

stop lower

Rotate

clockwise to

stop higher

Page 10 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

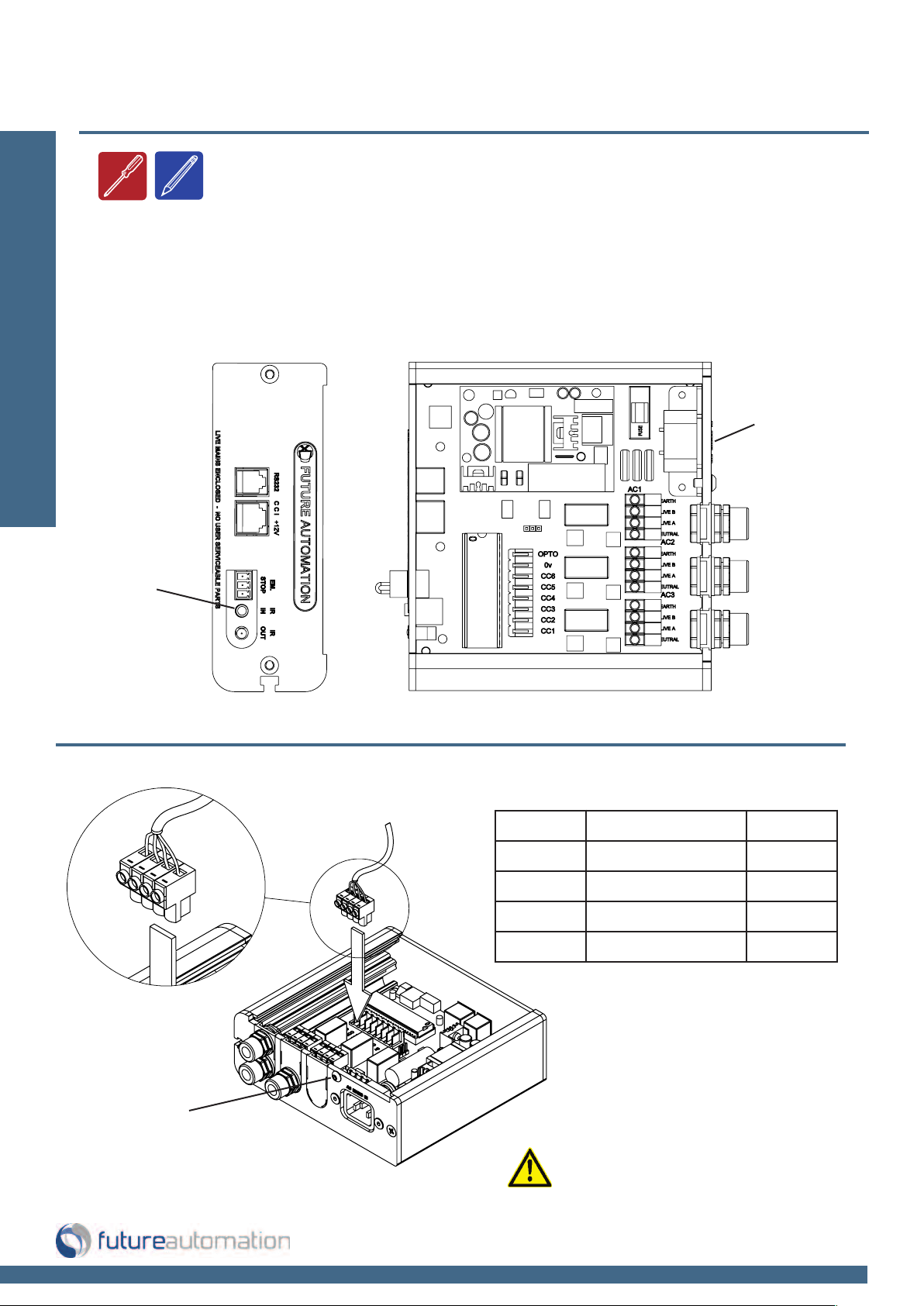

ET / ET60 - Electric Tilt Mechanism

Connections

- The mechanism must be connected to the AC1.

Connect IEC

Installation: Electrical Connection

power lead here

Connect infrared

sensor here

240v AC2 Connection 110v

Earth Green

Brown Live B Black

Black Live A Red

Blue Neutral White

Remove this screw

to release the lid

Page 11 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

Ensure the plug is connected

correctly and secure

ET / ET60 - Electric Tilt Mechanism

S

LQV

568A 568B

1 12V SUPPLY

12V SUPPLY - CURRENT LIMITED

W/G W/O

2 12V LATCH

When 12V attached, device will go OUT. When

12V removed, device will go IN.

GO

3GROUND GROUND W/OW/G

4 PIN 4 NOT USED BL BL

5 DEVICE LATCH

Short to GROUND (pin 3), device will go OUT,

remove short device will go IN.

W/BL W/BL LED 4

6 DEVICE STOP

Momentary short to GROUND (pin 3), stops

device in current position.

O G LED 3

7 DEVICE OUT

Momentary short to GROUND (pin 3), makes

device go OUT.

W/BR W/BR LED 2

8 DEVICE IN

Momentary short to GROUND (pin 3), makes

device go IN.

BR BR LED 1

PIN DESCRIPTION ACTION

WIRE / CABLE

CONTACT CLOSURE

LED INDICATOR

Contact Closure

- Use an RJ45 connector in the CCI

socket on the control box to operate

via contact closure

Installation: Electrical Connections

NOTE:

LED 1

LED 2

LED 3

LED 4

LED 5

Earlier versions of the control board

may not have these contact closure

LED indicators.

Page 12 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

CONTACT CLOSURE INPUT

ET / ET60 - Electric Tilt Mechanism

SLQV

RS232

- Use an RJ25 connector

in the socket marked

RS232 on the control box

to operate using RS232

Pin 1: RX

Pin 6 : TX

Pin 3 & 4: GROUND

Details

Baud rate: 9600

Installation: RS232 and Operation details

Stop bit: 1

RJ25 9 PIN D

Parity: None

Databits: 8

PIN 1: RX TO PIN 2: TX

PIN 6: TX TO PIN 3: RX

IMPORTANT

Ensure protocol is entered exactly

PIN 3: GROUND TO PIN 5: GROUND

PIN 4: GROUND TO PIN 5: GROUND

as written, including Carriage Return

(Enter / ASCII 13).

Pin 2: TX

Pin 3: RX

Pin 5: GROUND

Protocol Action

fa_in Carriage Return (Enter ) Device IN

fa_out Carriage Return (Enter ) Device OUT

fa_stop Carriage Return (Enter ) Device STOP (At any position)

Operation Details

AC1

Gives an output of 240V

(or 110V).

AC2

Outputs stay live for 120

seconds after the OUT or

IN functions are selected.

EMERGENCY STOP

This connection will stop all

functions of the mechanism once

broken / removed. This is where we

recommend wiring a safety device For a range of safety devices see

control, safety & accessories section

in product brochure.

Page 13 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

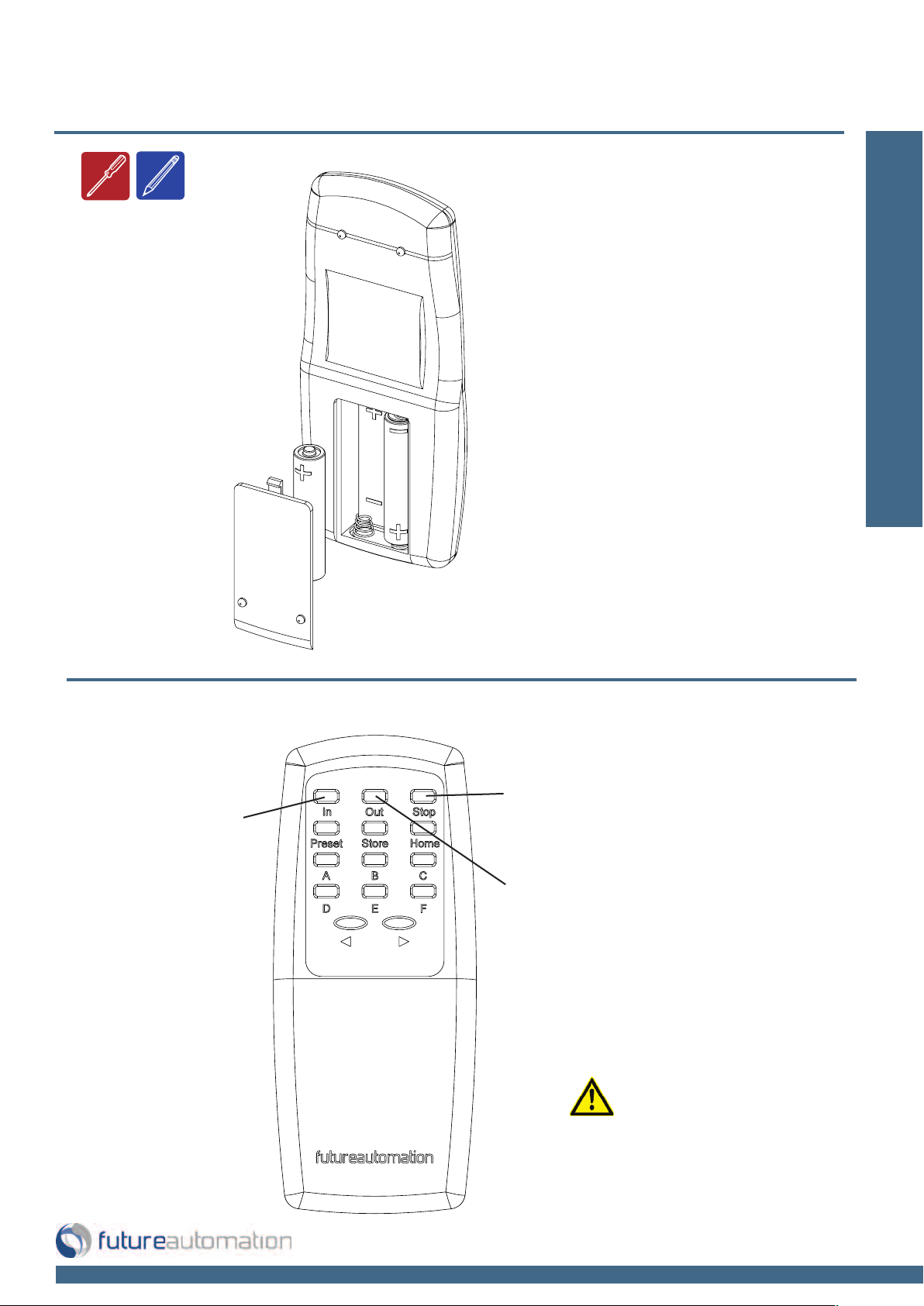

ET / ET60 - Electric Tilt Mechanism

Replacing batteries

Future Automation IR Remote

Controller needs x2 AAA batteries

which are provided within the

packaging

Operation: Remote Control

Operation Buttons

In - Raises

the screen

Stop - Will stop

the operation at

any point

Out - Lowers

the screen

Safety Note

When the mechanism is moving

if you press any button apart

from IN and OUT it will stop the

operation.

Page 14 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

SymptomCause RemedyPage

Emergency stop removed Replace emergency stop 13

Remote control or batteries

faulty

Replace batteries or remote 14

Motor or control box faulty

Apply mains power directly, via AC1

on control box

16

Incorrect pin configuration

Terminate 8-pin RJ45 to 568/b pin

configuration

12

Faulty wiring Replace connector or cable 12

Faulty control box Test contact closure on control box 12

Incorrect settings Refer to instructions 13

Incorrect pin configuration

Terminate 6-pin RJ11 to

configuration supplied

13

ASC11 protocol error Amend Protocol 13

Mechanism not working

Contact closure not working

RS232 not working

ET Electric Tilt Mechanism - Trouble shooting guide

Having problems? - Check the following:

1. Are all the connections correct?

Trouble Shooting:

If the mechanism does not operate correctly, check the items listed in the table below.

Should the problem persist, there may be a malfunction. If this is the case, disconnect the

mains power immediately and contact your installer

2. Is the mechanism being operated correctly?

Page 15 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

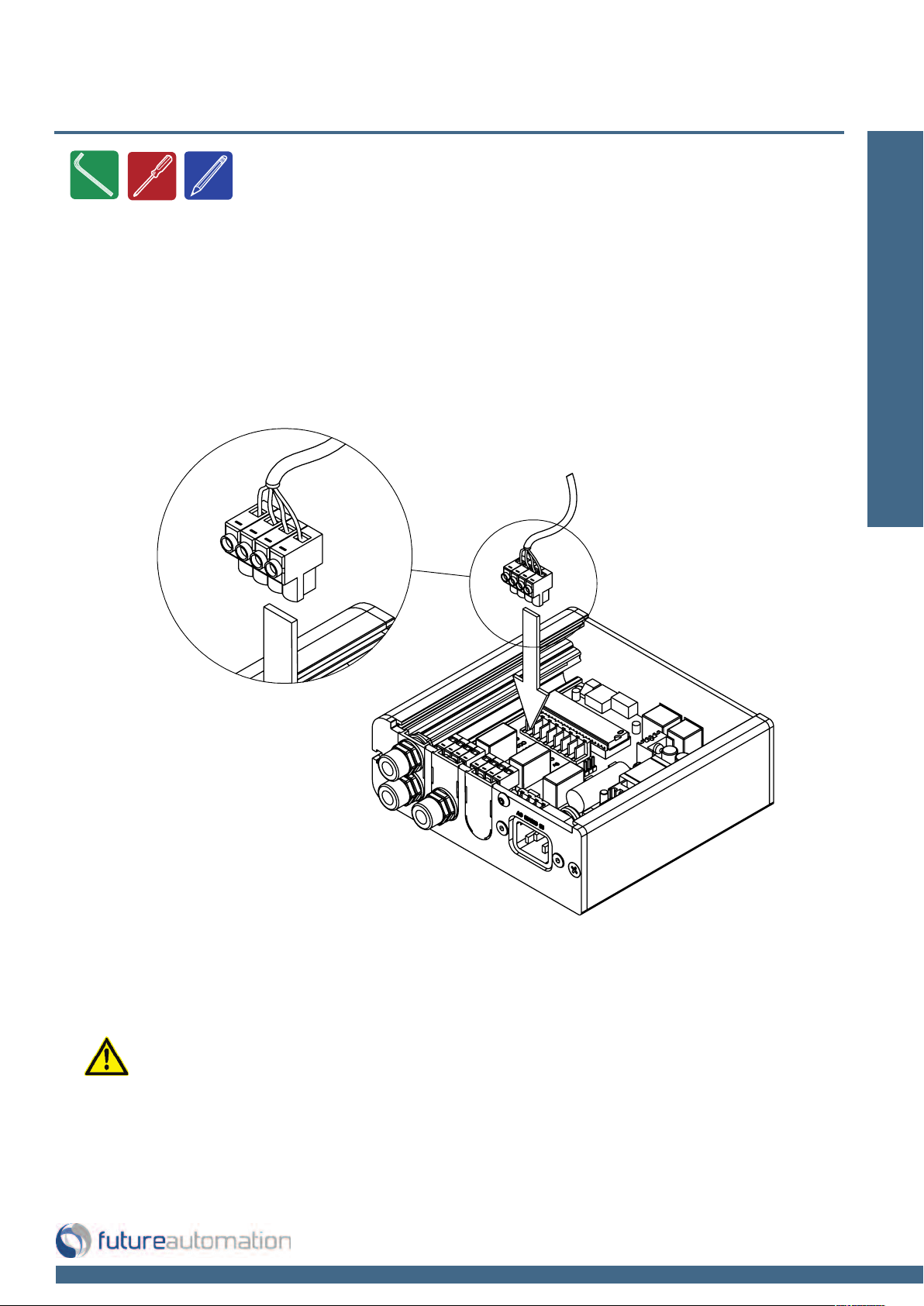

ET / ET60 - Electric Tilt Mechanism

Test motor operation

If the mechanism is not working, you can test the motor directly. To do so, you will need to

locate and open the control box.

Trouble Shooting:

CAUTION. Apply mains voltage taking all necessary grounding precautions.

Use live (brown) and switch live (black) to change direction of motor. If the

motor works, contact manufacture to replace control box.

Page 16 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

ET ET60

Product Dimensions (W,D,H)

685x57x495mm

[27x2.2x19.5"]

685x57x605mm

[27x2.2x23.8"]

Weight (Kg) 12Kg [26.5lb] 13Kg [28.7lb]

Power Consumption 110W 110W

Power Consumption on Standby 3W 3W

Lifting Capacity 50Kg [110.2lb] 50Kg [110.2lb]

Standard Colour Black Black

Max Drop Angle 20 Degrees 20 Degrees

Screen Size Range 32" - 50" 50" - 70"

Control

IR Remote, RS232 &

Contact Closure

IR Remote, RS232 &

Contact Closure

Power Supply 240V or 110V 240V or 110V

Control of 3rd Party Product Yes Yes

Output Power supply 12V - 240V 12V - 240V

Control Box Size (W,D,H)

150x150x52mm

[5.9x5.9x2"]

150x150x52mm

[5.9x5.9x2"]

Shipping Details

Dimensions (W,D,H)

800x200x600mm

[31.5x7.9x23.6"]

800x200x700mm

[31.5x7.9x27.6"]

Weight (Kg)

15Kg [33.1lb] 16Kg [35.3lb]

A general technical overview of the ET & ET60 electric tilt bracket

Technical overview:

Page 17 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

ET / ET60 - Electric Tilt Mechanism

Notes...

This product carries a warranty that covers the cost of labour and spare parts incurred by any defects in materials and workmanship under normal use

during a two year period from date of purchase. Support for any problems that are not hardware faults are excluded from the warranty entitlement.

This warranty does not affect your statutory consumer rights.

The following is excluded from warranty service:

• Malfunctioning caused by misuse or damage, accidental or otherwise, or service modification by persons not authorised by Future Automation,

or the use of any non Future Automation supplied parts;

• Any electrical, or other environmental work external to your Future Automation mechanism including power cuts, surges or lightning strikes;

• Additional items not supplied by Future Automation although they may have been supplied together by the retailer;

• Any 3rd party software products controlling your mechanism;

• Any transfer of ownership. Warranty is provided only to the initial purchaser;

• Compensation for loss of use of the product, and consequential loss of any kind;

• Use of the product over the specified weight capacity;

• Any damage to products during transit that is not checked and notified as “unchecked” or “damaged” upon receipt of delivery.

Any part of your system that needs to be replaced during a warranty repair becomes the property of Future Automation.

Page 18 of 18 // email info@futureautomation.co.uk tel: +44 (0) 1438 833577 fax: +44 (0) 1438 833565

Product Warranty

Future Automation

Unit 2 Kimpton Enterprise Park

Claggy Road

Kimpton

Hertfordshire

SG4 8HP

United Kingdom

Tel: +44 (0) 1438 833 577

Fax: +44 (0) 1438 833 565

Email: info@futureautomation.co.uk

www.futureautomation.co.uk

Loading...

Loading...