Page 1

Operating Manual

FUTEK Rotary Torque Sensors

TRD/ TRH/ TRS 600/605/705 Series

Page 2

Table of Content

1. IMPORTANT INFORMATION.............................................................................................................. 3

1.1 D

2. APPLICATION AND KEY FEATURES................................................................................................ 4

3. DESCRIPTION OF THE MEASURING SYSTEM .............................................................................. 5

3.1. M

3.2. E

3.2.1. E

3.3. R

3.4. A

4. ELECTRICAL CONNECTION ............................................................................................................ 10

4.1. I

4.2. P

4.2.1. I

4.3. C

4.3.1. C

5. MECHANICAL APPLICATION .......................................................................................................... 15

5.1. TRD/TRH 600/605

5.2. T

5.3. P

ISPOSAL INSTRUCTIONS FOR ELECTRICAL AND ELECTRONIC EQUIPMENT

ECHANICAL DESIGN

LECTRICAL BLOCK DIAGRAM

XAMPLES OF APPLICATION

OTATION ANGLE MEASURING SYSTEM

NGLE-PULSE OUTPUT

NSTRUCTION FOR ELECTRICAL INSTALLATION

LUG CONNECTION

NSTALLING THE SIGNAL LEAD

ONNECTING CABLE

ABLE DIAGRAM, PLUG (SENSOR), OPEN ENDS, MODEL

ORQUE MEASURING SHAFT (MODEL

OSSIBLE INSTALLATION OF MODEL

......................................................................................................................... 5

(TRD/TRH/TRS 605

............................................................................................................... 7

(TRD/TRH/TRS/605/705) ................................................. 8

(TRD/TRH/TRS/605/705) ........................................................................... 9

(12

PIN

) ............................................................................................................. 12

......................................................................................................... 12

......................................................................................................................... 13

MODELS

............................................................................................................. 15

TRS600/605/705) ................................................................ 16

TRS600/605/705 ..................................................................... 16

MODEL

)........................................................... 6

................................................................................ 11

ZCC911 .................................................. 14

........................................ 3

6. MAINTENANCE .................................................................................................................................... 17

7. REPAIRS ................................................................................................................................................. 17

2 EM1005

Page 3

1. Important Information

1.1 Disposal Instructions for Electrical and Electronic

Equipment

Do not discard old electronic instruments in

trash. For disposal at end of life, please return

to an authorized local electronic waste

contact the nearest Futek Instrument s

i

nstructions.

disposal

ales

municipal

this

product

service or

office for return

3 EM1005

Page 4

2. Application and Key Features

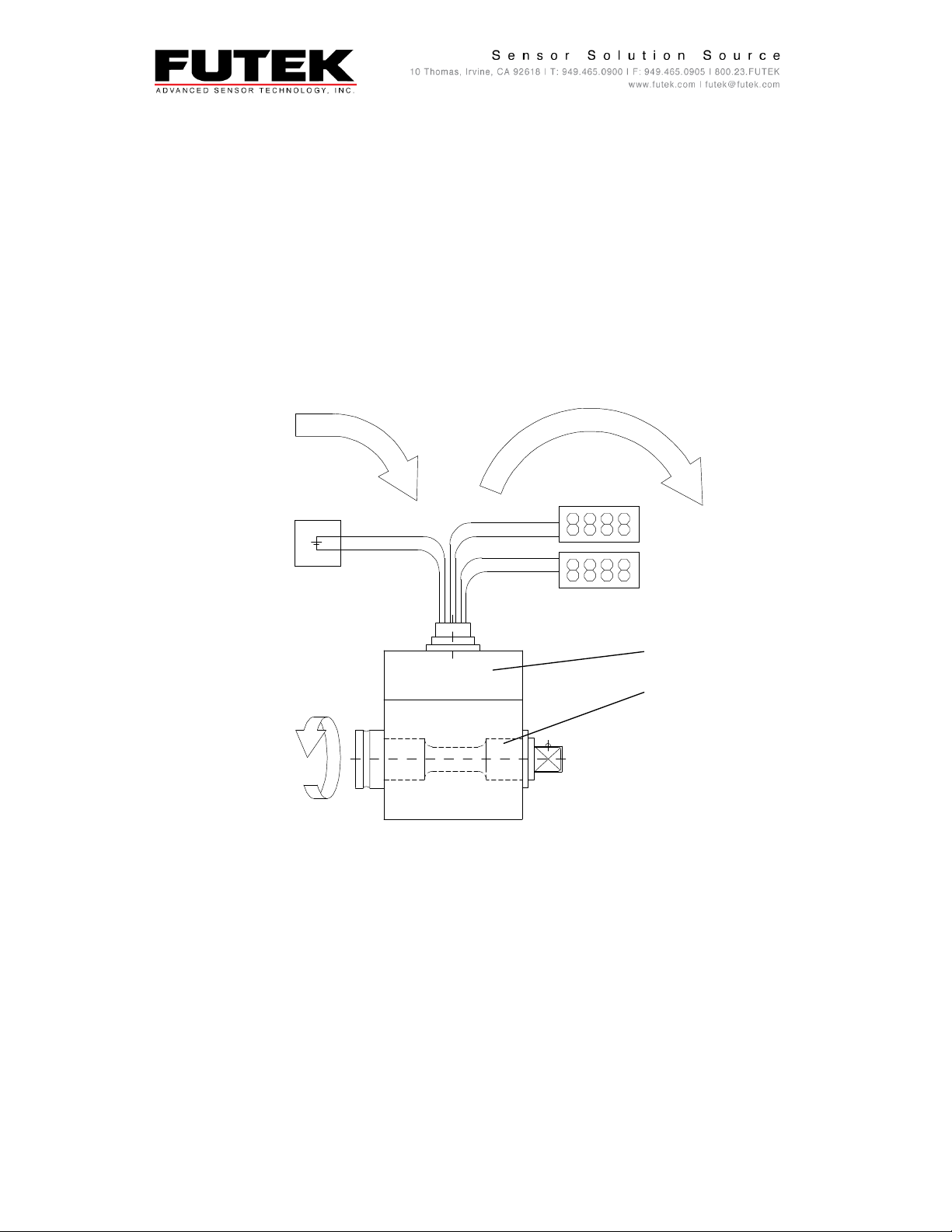

Torque sensor with strain gages measuring

Wear-resistant transmission of the measuring

integrated

Measurement of

Torque

Integrated

(TRD/TRH/TRS 605 models only)

Application in the laboratory,

quality control

Ideal for use with power tools (

models only) and

model only

11 t o 26 V

Suitable for low

Fig. 1: Rotary Torque Sensor

amplifier

constant

measurement

system for rotation angle

)

and high speed

and variable

on the rotating

test stand

system

signal,

torques

shaft

measurement

manufacture

TRD/TRH 605

construction (TRS605

ranges

and

Torque

Rotation

Measuring

Strain

measuring

Angle

Gage

shaft

electronics

4 EM1005

Page 5

3. Description of the Measuring System

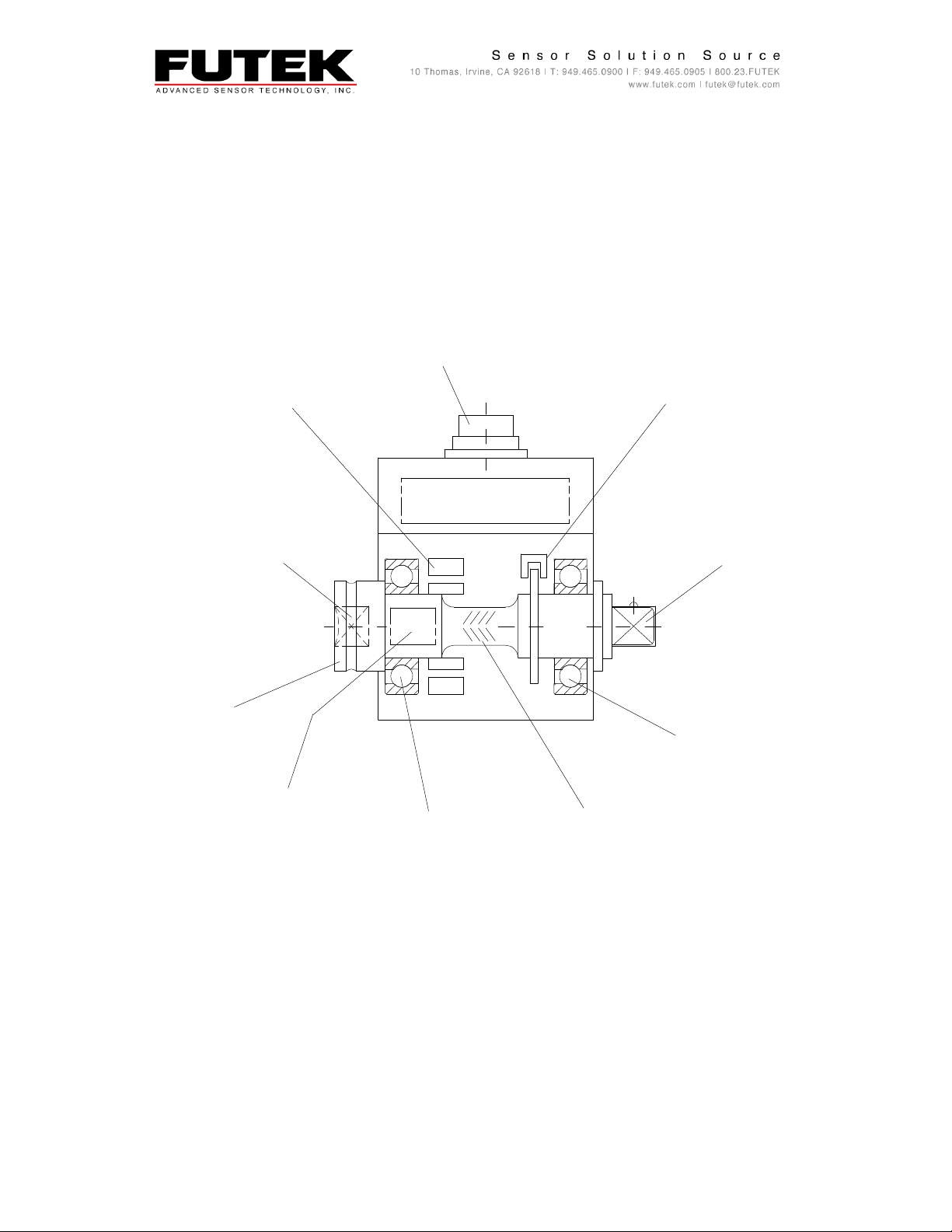

3.1. Mechanical Design

Torque Sensors consist of a base body

standard square

with

strain gauges and a signal

contains the

Sensor (TRD/TRH/TRS605 model )

Square Socket (TRD600/605) Square End (TRD600/605) or

or Hexagon Socket (TRH600/605) Hexagon End (TRH600/605)

or round shaft (TRS600/605) or round shaft (TRS600/605)

connections

stationary electronics for the signal

Shaft

Rotating Electronics

Bearing Strain Gages

or

Fig. 2: Mechanical Design Non-contact Torque

which

contains the measuring shaft. The shaft ends

stand

ard

hexagon

amplifier with

Cable/Connector

Rotation Angle Measuring System

ends.

On the measuring shaft there is a torsion distance

A/D transformer.

formation.

The connection box of the base body

Bearing

Sensor

are

performed

as

5 EM1005

Page 6

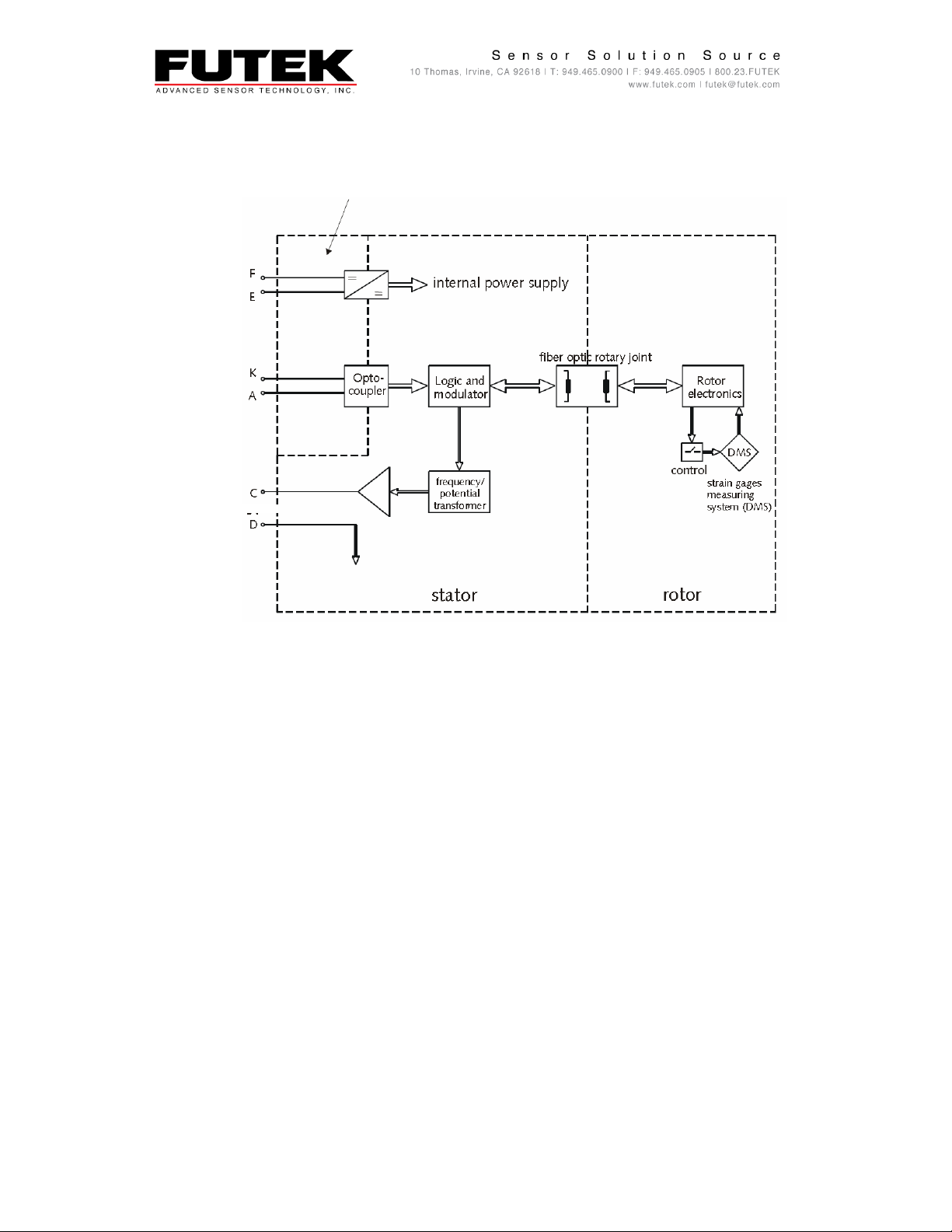

3.2. Electrical Block Diagram (TRD/TRH/TRS 605 model)

Feed and inspection input

measuring

Supply

11 to 26 VDC

1 Watt

Shunt

Calibration

Supply

4.5 to

30 VDC

Output

± 5 VDC

equipment is

Fig. 3: Electrical block diagram

of

electronic

electrically

isolated

6 EM1005

Page 7

Shield

Shield

Shunt Cal.

Power

Power

Torque

Power

DAQ/

Supply

Evaluation

Shunt Cal.

Torque

3.2.1. Examples of Application

Example of

electrical isolation for supply and s ignal

measurement.

Example of combining the power supply and signal measurement in the Evaluation Electronic.

Supply

Supply

Input

Signal

Output

Fig. 4: Separate Encoder and Torque Measuring Power Supply Diagram

Instrument

Input

Input

Signal

Output

Fig. 5: Power and measuring supply in the

Instruments containing Power Supply & Signal Device (IHH500 & IPM650)

evaluation

electronic

Device

Electronic

combined,

7 EM1005

Page 8

3

0 V

2

1

3

4

G B H E

+5 V

0 V

3.3. Rotation Angle Measuring System (TRD/TRH/TRS/605/705)

Fig. 6: Diagram showing the design of the

1. Rotating Torque

2. Pulse Disk

3. Forked Light Barrier with

4. Operation Amplifier

Shaft

LED

rotation

and Photo

angle measuring

Diode

system

Features:

360 light-dark stripes on the pulse disk

Two forked light

Pulse number

barriers shifted by phase angle

proportional

to the rotation

angle

90°

8 EM1005

Page 9

Rotation

Rotation

Rotation

3.4. Angle-Pulse Output (TRD/TRH/TRS/605/705)

Output

Output

A 1

Drive

(TRD605 models)

Pin B

Pin G

With drive on square socket or hexagon end direction

View A 1:

Side

of

rotation CW

Direction

of

A 2

Drive

Side

(TRH605 models)

A 3

Drive

Side

(TRS605/705 models)

Fig. 7:

View A 2:

View A 3:

Angle-pulse

output

Direction

Direction

of

of

9 EM1005

Page 10

4. Electrical Connection

Shielded Cable

Mating

Connector

Fig. 8: Electrical

Connections

Use Futek ZCC911 cable

To power supply unit and

Torque Sensor (all models)

disp

lay

10 EM1005

Page 11

min.

Ø

0.025 in²

Connector

Plug

Stator

Stator Support

Load

ing Torque Device

Sensor

Max. length 164 ft.

Sensor

4.1. Instruction for Electrical Installation

Housing

Ø0.980

Fig. 9: Electrical Instal

lation

Unit

11 EM1005

Page 12

4.2. Plug Connection (12 pin)

Function

Torque

Torque

Torque

Torque

Angle

Angle

Angle 1/ Speed

Angle 2 (90° shifted to Angle 2)

Shunt Calibration

Shunt Calibration

Shield

Not Connected

Not Connected

* Torque and Angle share the same pin for Ground.

, Power Supply

, Power Supply, Ground

, Signal Output

, Signal Output, Ground D

, Power Supply H

, Power Supply, Ground *E

, Inside the sensor to housing

, Signal Output B

, Signal Output

, Power Supply

, Power Supply, Ground

Pin

F

*E

C

G

K

A

M

J

L

Top View Built-In Plug

4.2.1. Installing the Signal Lead

Do not run the lead parallel to power cables or

Do not place the lead

transformers,

the lead inside

Make a loop in the lead

vibration.

used for the torque signal

torq ue outp ut

welders,

earthed steel

If supply and evaluation unit are galvanically

sign

contactors,

al.

close to

equipment producing

electric

conduit.

when affixing it at the

to

prevent the voltage drop on the power su p p l y ground affecting the

motors,

12 EM1005

control

etc.

torque

circuits.

strong

If such situations cannot be avoided, run

connected, a differential input must be

electromagnetic

sensor so that it is not

fields, such as,

damaged

by

Page 13

Cable Length

12 Pin Plug

12 Pin Binder

Flexible Cable

4.3. Connecting Cable

Cable Diagram with Plugs on Both Sides, Model ZCC914

Plug

Fig. 10: Cable diagram with plugs on both sides

Binder Pin Out

F

Torque

*E

C

D

H

*E

B

G

K

A

M

J

L

* Torque and Angle share the same pin for Ground.

Function

, Power Supply

Torque

, Power Supply, Ground

Torque

, Signal Output

Torque

, Signal Output, Ground

Angle

, Power Supply

Angle

, Power Supply, Ground

Angle 1/ Speed

Angle 2 (90° shifted to Angle 2)

Output

Shunt Calibration

Shunt Calibration

Shield

, Inside the sensor to housing

Not Connected

Not Connected

, Signal Output

, Power Supply

, Power Supply, Ground

, Signal

13 EM1005

Page 14

12 Pin Binder

Flexible Cable

Cable Length

Pigtail

Tinned End

4.3.1. Cable Diagram, Plug (Sensor), Open Ends, Model ZCC911

Binder Pin Out Function

F

*E

C

D

H

*E

B

G

K

A

M

J

L

Plug

Fig. 11: Cable Diagram, Plug (Sensor), Open

Torque

, Power Supply

Torque

, Power Supply, Ground

Torque

, Signal Output

Torque

, Signal Output, Ground

Angle

, Power Supply

Angle

, Power Supply, Ground

Angle 1/ Speed

Angle 2 (90° shifted to Angle 2)

Output

Shunt Calibration

Shunt Calibration

Shield

, Inside the sensor to housing

Not Connected

Not Connected

, Signal Output

, Signal

, Power Supply

, Power Supply, Ground

Ends

Wiring Code

Red

Black

Green

White

Orange

Black

Blue

Brown

Purple

Yellow

-

-

-

14 EM1005

Page 15

Motor/

Lead

Torque Sensor

Lead

Socket Spanner/bit

5. Mechanical Application

5.1. TRD/TRH 600/605 models

Torque sensor series TRD600/605 have square

3121.

Torque sensor series TRH600/605 have

The torque sensor is attached to a drive spi

Connector

TRD600/605 TRH600/605

Fig. 12: Application examples models TRD600/605 &

hexagon

ndle

Application examples:

connections

connections

as shown

Electric or

Pneumatic

Wrench

Connector

for plug-in tools according to DIN

according to DIN 3126, form E/F.

below

TRH600/605

15 EM1005

Page 16

Specimen with

Full Coupling

Full Coupling

Specimen

Drive brake with

Firm stator

5.2. Torque Measuring Shaft (Model TRS600/605/705)

The signal lead should not exceed a length

shunt cal.

circuits. The pin connection is explained in

On each side of the torque measuring shaft there is a high quality bearing installed, and it contains an

i

ntegrat

ed

housing base. The installation can have any

applied

measuring

to

balance geometrical false

shaft.

adjustments

Radial, Axial, Diagonal and Angular errors can be

Multi-disk Couplings

Diaphragm

Claw

Coupling

Coupling

s

of 100 ft. Do not run the lead parallel to power cables or

chapter 4.2 of this

position,

and like that

compen

however offset couplings must always be

keep

sated by the use of:

manual.

false loads

away from the torque

5.3. Possible Installation of Model TRS600/605/705

fixed bearing

Full coupling on both sides

Fixed bearing on both sides

Retaining Angle

fixed bearing

Fig. 13: Application example TRS705

Installation and operational Tips:

The Keys on the shaft are removable, may require to be removed before installing the couplings.

The sensor is only part of the complete drive shaft and depending on the speed the alignment

must be made in a proper way. Each type of coupling can compensate certain misalignment (of

radial, axial and angular character). Customer is responsible for damage to the shaft due to

misalignment and overloading on the shaft.

Radial and torsional vibrations can severely impact the performance of the torque sensor. For

this reason speeds at or near the torque sensor’s natural frequency should be avoided.

For coupling recommendation, see link on website under support/futek manuals/

TRD/TRH/TRS-Series.

16 EM1005

Page 17

Shaft stiff to turn

Bearing failure due to:

d) Bent shaft

Return to factory

Solution

Zero shift less than 2%

Torsional vibration

The zero reading may be

Zero shift between approx.

Zero shift more than 5%

Torque sensor has been

Torque sensor overloaded by

The zero reading may be

Torque sensor overloaded by

Hysteresis between

6. Maintenance

TRD/TRH/TRS Series sensors are almost

replaced by factory after its life time.

Durability of bearings in compensated temperature range is approx. 20,000 hours.

Durability of bearings in operating temperature range is approx. 10,000 hours.

For Precision applications: Calibration of the sensor should be done at FUTEK or with adequate

calibration equipment.

Calibration: Yearly calibration is recommended but it depends on the criticality of the application &

requirement and may require smaller calibration intervals.

Inspect torque sensor cable and mating connector for damage on a monthly basis.

maintenance-

free where the bearing needs to be

7. Repairs

2 and 5% of full scale

Fault

Possible Causes

a) Torsional or flexural

vibration

b) High axial or radial loads

c) Worn bearings

Torsional Shock

overloaded

Torsional vibration

Torsional shock

high alternating loads or

torsional vibration

re-adjusted at display

re-adjusted at the

display

Return to factory

clockwise and counterclockwise torque

Return to factory

high alternating loads or

torsional vibration

17 EM1005

Loading...

Loading...