Page 1

Drawing Number: F3189

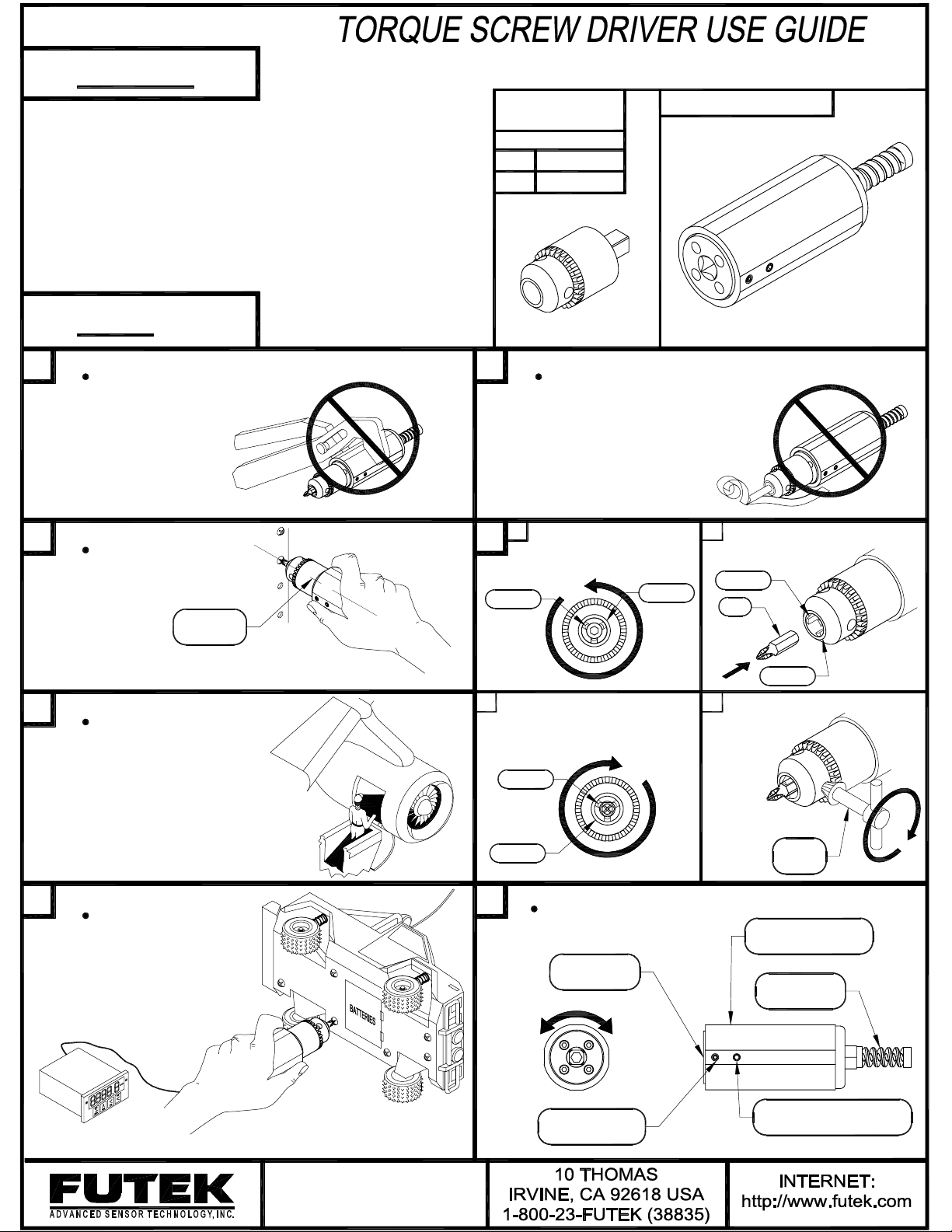

CAUTIONS

1) DO NOT PULL ON OR CARRY TORQUE SENSOR BY CABLE.

2) ANY TAMPERING OR REMOVAL OF COVER, CABLE,

CONNECTOR AND/ OR OVERLOAD STOP WILL VOID

WARRANTY.

3) ALWAYS HAVE SENSOR PLUGGED IN DURING

USE TO MONITOR OUTPUT TO AVOID PERMANENT

ZERO SHIFT AND OVER LOAD.

IN USE

1 2

3 5

DO NOT USE

WRENCH OR

OTHER DEVICES

TO BOOST

LEVERAGE.

TORQUE SHOULD

BE IN LINE

AXIS OF

ROTATION

FUTEK OPTIONAL

CHUCK ASSEMBLY

ACCESSORY NO.

F1416

1/16 to 3/8" Dia. BIT

5/64 to 1/2" Dia. BIT

F2995

SCREW DRIVER ASSEMBLY

SCREW DRIVER IS FOR

TORQUE PURPOSES ONLY.

DO NOT USE AS A CHISEL,

PRY BAR SCRAPER OR

ANY OTHER USES THAT IT

IS NOT DESIGNED FOR

A

HOLD SCREWDRIVER AND

ROTATE HEAD UNTIL TEETH OPEN

TEETH

FRONT

B

INSERT DESIRED BIT

TEETH

BIT

4

TORQUE SCREWDRIVER

C

IS USED ANYWHERE

YOU NEED OR DESIRE

PRECISION IN ASSEMBLY

OR MAINTENANCE

6 7

TORQUE

SCREWDRIVER

COMES IN LOW

CAPACITIES FOR

PLASTIC OR LIGHT

APPLICATIONS

HOLD SCREWDRIVER AND

ROTATE HEAD UNTIL TEETH CLOSE

ON BIT

TEETH

FRONT

TORQUE SCREWDRIVER

STANDARD FEATURES

3/8" SQUARE

DRIVE

SET SCREW TO

SECURE CHUCK

FRONT

D

HOLD SCREWDRIVER

AND HAND

TIGHTEN

BIT

WITH

CHUCK

KEY

CHUCK

KEY

KNURLED SURFACE

FOR SURE GRIP

FLEX RELIEF

FOR CABLE

OVERLOAD PROTECTION

ON LOWER CAPACITIES

This drawing is submitted solely for the information and

exclusive use of the origina l addressee. It is not to be divulged

in whole or in part, b y any firm or individual without written

permission from FUTEK

Loading...

Loading...