Page 1

2

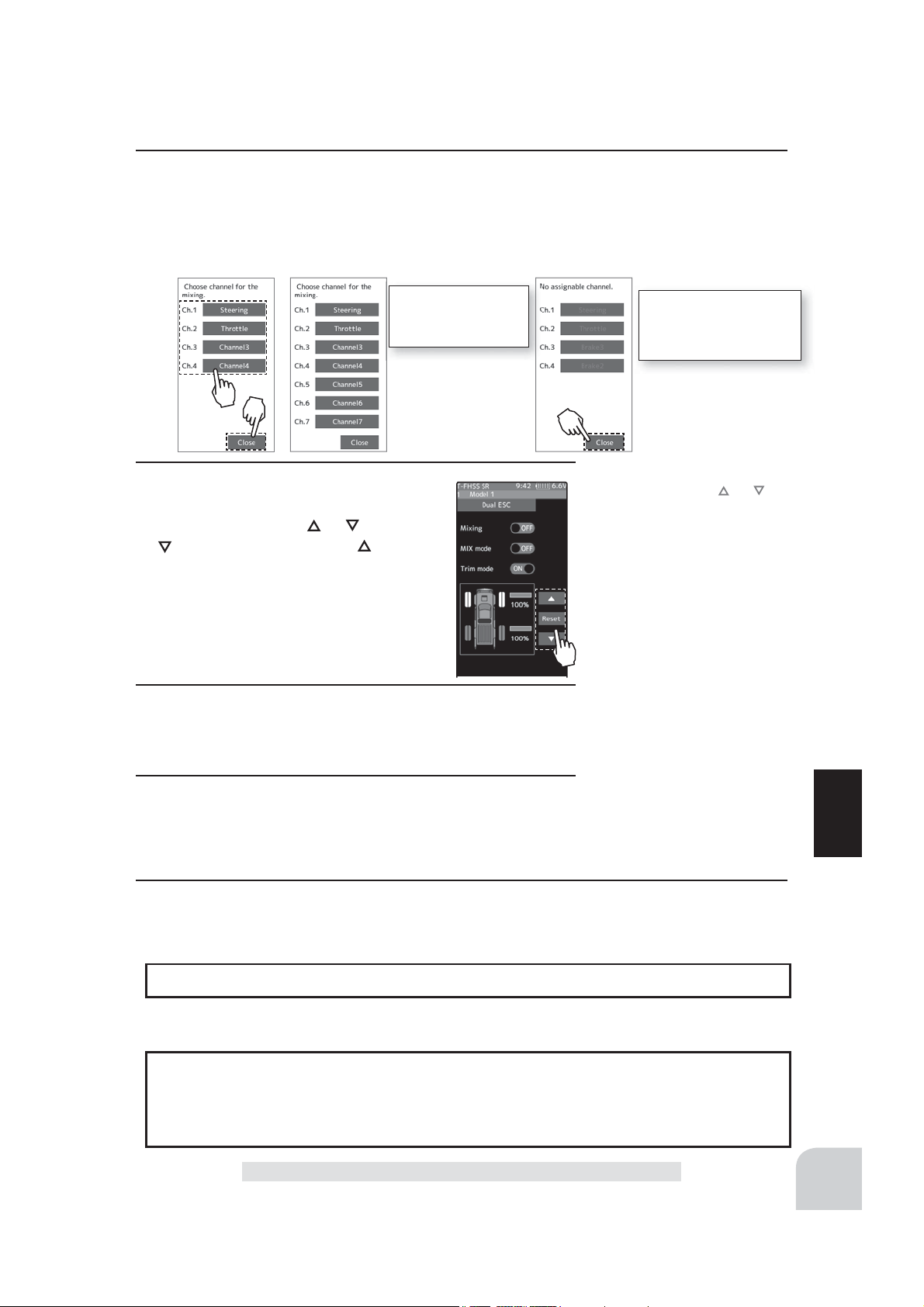

(Channel setup)

The channel list screen used for the front ESC channel is displayed. Tap the auxiliary channel that connected the front ESC channel.

- When all channels are in use, a screen saying "No assignable channel" is displayed, please turn off other mixing

and make an unused channel. You can check the mixing used on the channel setting screen (page 75).

For S-FHSS (analog)

system, 1 to 7 channels are displayed.

3

(Drive ratio adjustment)

Adjust the front and rear motor controller

operation amount by

button increases and the button de-

creases the rear ratio.

Both the front and rear ratios become

100%

4

(Mix mode setting)

Tap "MIX mode" (ON) or (OFF) to select ON / OFF.

"OFF" :The EXP function of the 2nd CH and other settings are not mixed.

"ON" :The EXP function of the 2nd CH and other settings are mixed.

5

(Trim mode setup)

Tap "Trim mode" (ON) or (OFF) to select ON / OFF.

"OFF" :The trim of the 2nd CH is not mixed.

"ON" :The trim of the 2nd CH is mixed.

or button. The

If there is no assignable

channel, tap [Close]. Turn

off other mixing and make

assignable channels.

Adjustment buttons

- Adjust with the and buttons.

- Return to the initial value by

tapping the [reset] buttons.

Rear rate (Rear mix rate)

0~100

Initial value:100

Setting

- Tap (ON) / (OFF).

Setting

- Tap (ON) / (OFF).

Function

6

When fi nished, return to the Mixing menu screen by pressing the HOME button twice.

Dial / Trim Setting

The dial select function can control the drive ratio with digital dial or digital trim.(page 66)

Note:

As this function drives 2 separate motor controllers simultaneously, a mutual load is applied. Use this function carefully so that the motor controllers are not damaged.

Futaba will not be responsible for motor controller, motor, and other vehicle trouble due

to use of this function.

Dual ESC

117

Page 2

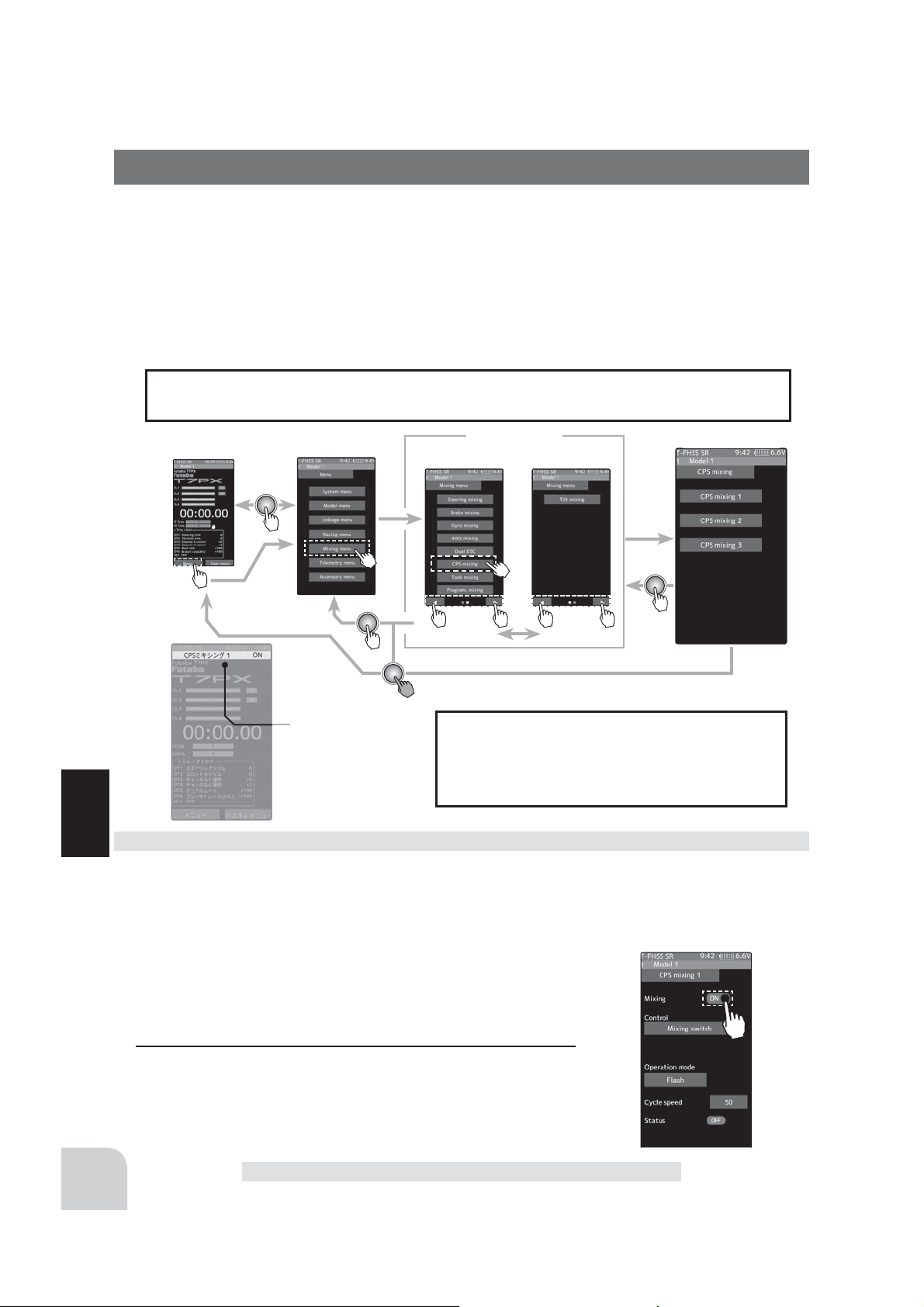

CPS Mixing (1, 2, 3 )

This function controls the Futaba CPS-1 channel power switch. Normally, when using the

CPS-1 unit to light the vehicle dress-up and other illumination (LED) the CPS-1 unit with

LED connected is connected to a vacant switch channel and the LEDs are turned on and off

by switch while the vehicle is running. However, when the CPS mixing function is used, the

LED can be turned on and off and À ashed in step with steering and throttle operation, as

well as being turned on and off by switch. The À ashing speed (cycle) can also be set. For in-

stance, the LED can be À ashed as a brake light by throttle brake side operation. Three lines

of CPS mixing can be used.

The CPS-1 unit does not operate in SR mode. When using with the T - FHSS SR system, connect it to the channel of the normal mode.

Home screen

Menu screen

Menu-1

The mixing function is assigned to auxiliary

channels used by other mixing cannot be used.

Display the current

drive mode.

Dual ESC mixing adjustment

Function

(Preparation)

- CPS-1 connects to the receivers auxiliary channel.

- When the LEDs are turned on and off by switch, use the function select switch function (page 69) to set the switch to be

used.

- From the CPS Mixing screen, tap [CPS Mixing 1] / [CPS Mixing 2] or [CPS Mixing 3] to display the setting screen.

When the number of channels is insuf¿ cient,

cancel the other mixing.

Mixing menu

CPS mixing

Menu-2

Setting

- Tap (ON) / (OFF).

118

1

(Function ON/OFF)

Tap "Mixing" (ON) or (OFF) to select ON / OFF.

"OFF" :Mixing function OFF

"ON" :Mixing function ON

CPS Mixing (1, 2, 3 )

Page 3

2

(Channel setup)

The channel list screen used for the front ESC channel is displayed. Tap the auxiliary channel that connected the front ESC channel.

- When all channels are in use, a screen saying "No assignable channel" is displayed, please turn off other mixing

and make an unused channel. You can check the mixing used on the channel setting screen (page 75).

3

(Control system setup)

Tap the [Control]. The mode list appears on the CP-1 mixing menu screen, and tap from the list and select the control

mode. To cancel, tap [Cancel].

"Mixing Switch" : ON/OFF by switch set at the CPS mixing

"Steering neutral" : ON at steering neutral

"Steering endpoint" : ON at both sides of steering

"Throttle neutral" : ON at throttle neutral

"Throttle forward" : ON at throttle forward side

"Throttle brake" : ON at throttle back (brake) side

"Throttle neutral & brake" : ON at throttle neutral and back (brake) sides

4

(ON / OFF switching position selection)

Tap the value button of the [ON/OFF point].

Value input buttons appear on the screen.

Use the [+] and [-] buttons to adjust the

operation point. Since the ON/OFF state is

displayed at the right side of the "Status",

setting can be confirmed while operating

the function to be controlled (for example,

throttle).

5

(Operation mode setup)

Tap the [Operation mode]. The mode list appears on the

CP-1 mixing menu screen, and tap from the list and select

the Operation mode. To cancel, tap [Cancel].

"ON/OFF" : Normal ON/OFF type

"Flash" : Flashing display

6

(Flashing cycle setting)

When "Operation mode" is set to "Flash" the "Cycle speed"

can be set to preferred setting. Tap the value button of the

[Cycle speed]. Value input buttons appear on the screen. Use

the [+] and [-] buttons to adjust the cycle speed amount.

Setting

- Tap control mode.

Adjustment buttons

- Adjust with the and buttons.

- Return to the initial value by

tapping the [reset] buttons.

ON/OFF position

5 ~ 95

Initial value:50

*Shows the ON/OFF state

Setting

- Tap operation mode.

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Cycle speed amount

1~100

Initial value: 50

Function

7

When finished, return to the Mixing menu screen by pressing the HOME button twice.

CPS Mixing (1, 2, 3 )

119

Page 4

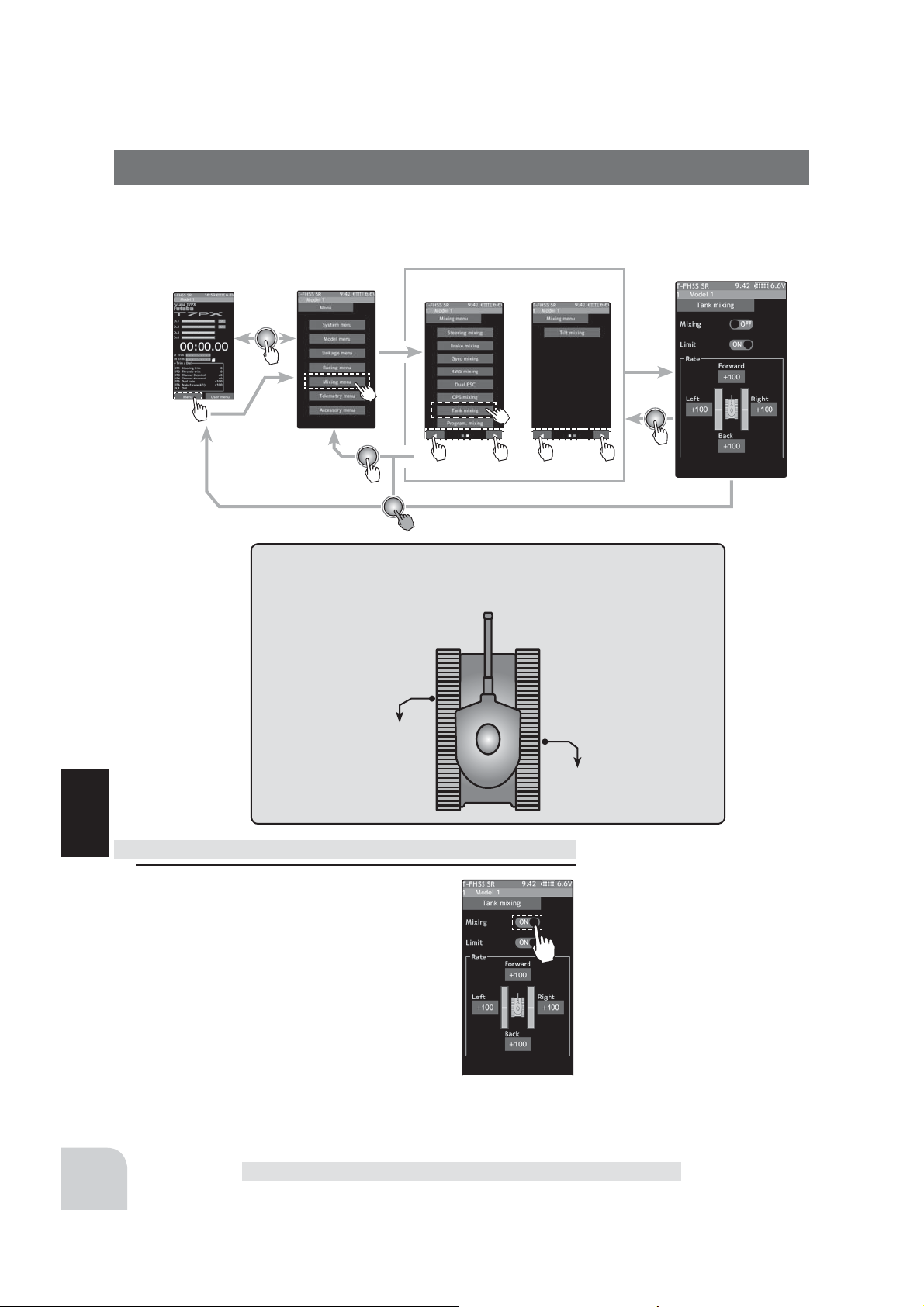

Tank Mixing

This function is intended for vehicles such as tanks and can be used to the pivotal turn, or

the ultra-pivotal brake turn, by steering and throttle operation.

Home screen

Menu screen

The channels connecting the left and right motor control-

lers are as shown in the figure.

Menu-1

Connection channel

Menu-2

Tank mixing

120

Tank mixing adjustment

Function

1

(Function ON/OFF)

Tap "Mixing" (ON) or (OFF) to select ON /

OFF.

"OFF" :Mixing function OFF

"ON" :Mixing function ON

Throttle channel

Steering channel

Setting

- Tap (ON) / (OFF).

Tank Mixing

Page 5

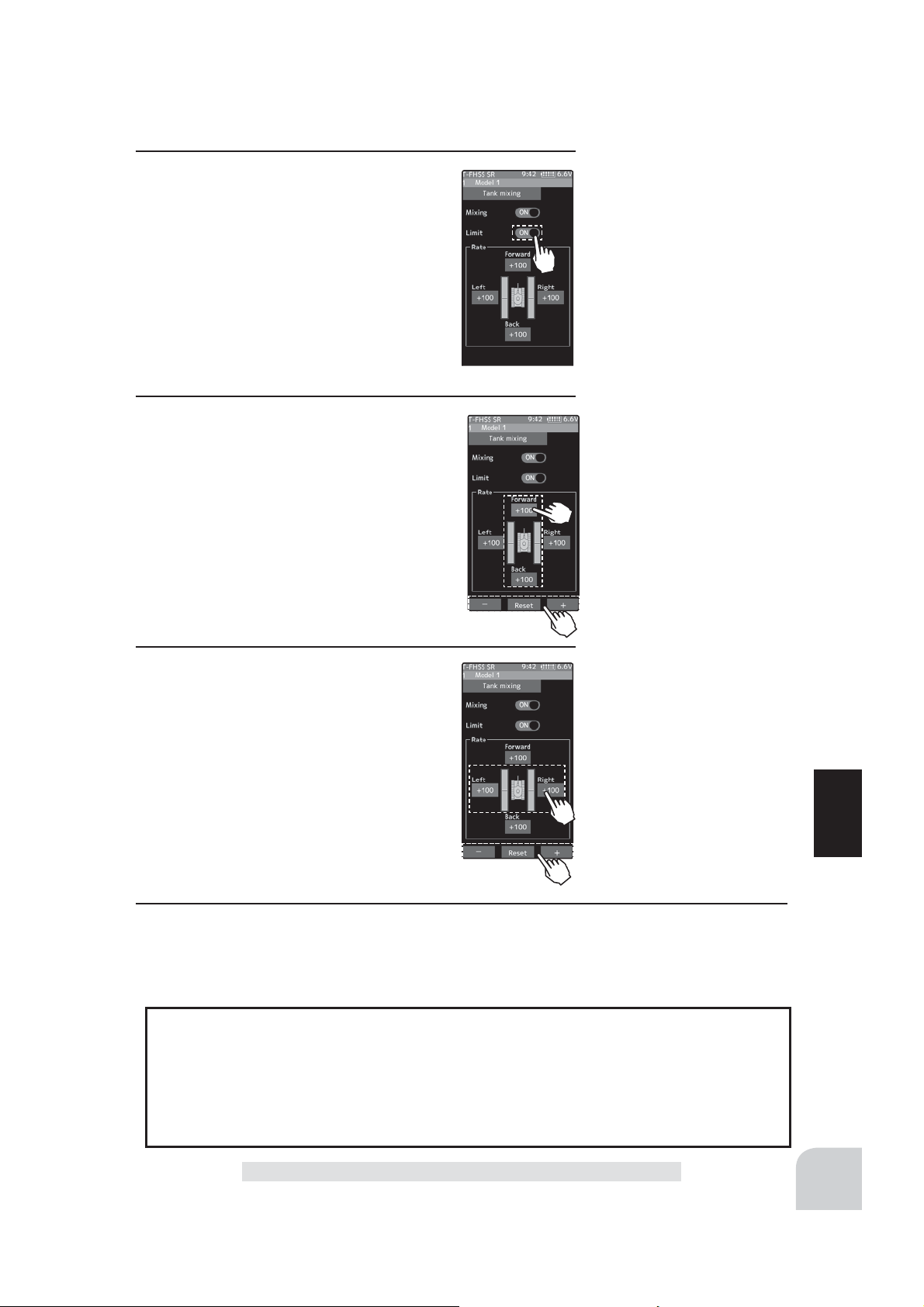

2

(Limit ON / OFF)

It is a function to limit the maximum operation amount of the steering and throttle

channel so that it does not exceed the limit

by the influence of the mixing amount.

Tap "Limit" (ON) or (OFF) to select ON /

OFF.

“OFF” :Limit function OFF

“ON” :Limit function ON

3

(Forward / backward rate adjustment)

Tap the value button of the [Forward] or

[Bsck]. Value input buttons appear on the

screen. Use the [+] and [-] buttons to adjust

the forward or reverse speed.

- The throttle channel and the steering channel operate

in conjunction with each other, and by operating the

trigger to the high side, the car body advances at the

[Forward] rate. When the trigger is operated to the

brake side, it operates at the [Bsck] rate.

Setting

- Tap (ON) / (OFF).

.

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Forward / backward rate

-100~+100

Initial value: +100

4

(Left / Right side travel adjust)

Tap the value button of the [Left] or [Right].

Value input buttons appear on the screen.

Use the [+] and [-] buttons to adjust the left

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

or right side travel amount.

- When the throttle channel and the steering channel

work in conjunction, when operating the steering

wheel to the right, the car body turns to the right at

the [Right] rate the pivotal turn. If you operate to the

left, the car will turn to the left at the [Left] rate the

pivotal turn.

5

When finished, return to the Mixing menu screen by pressing the HOME button twice.

Left / Right travel

-100~+100

Initial value: +100

When steering and trigger are operated at the same time.

If you manipulate the trigger to the high side and operate the steering wheel to the right,

the body will turn right at the rate of [forward], [right].

If you manipulate the trigger to the high side and operate the steering wheel to the left,

the body turns to the left at the rate of [forward], [left].

Operating the steering wheel while operating the trigger to the brake side will operate

the same as the forward side in the reverse direction.

Function

Tank Mixing

121

Page 6

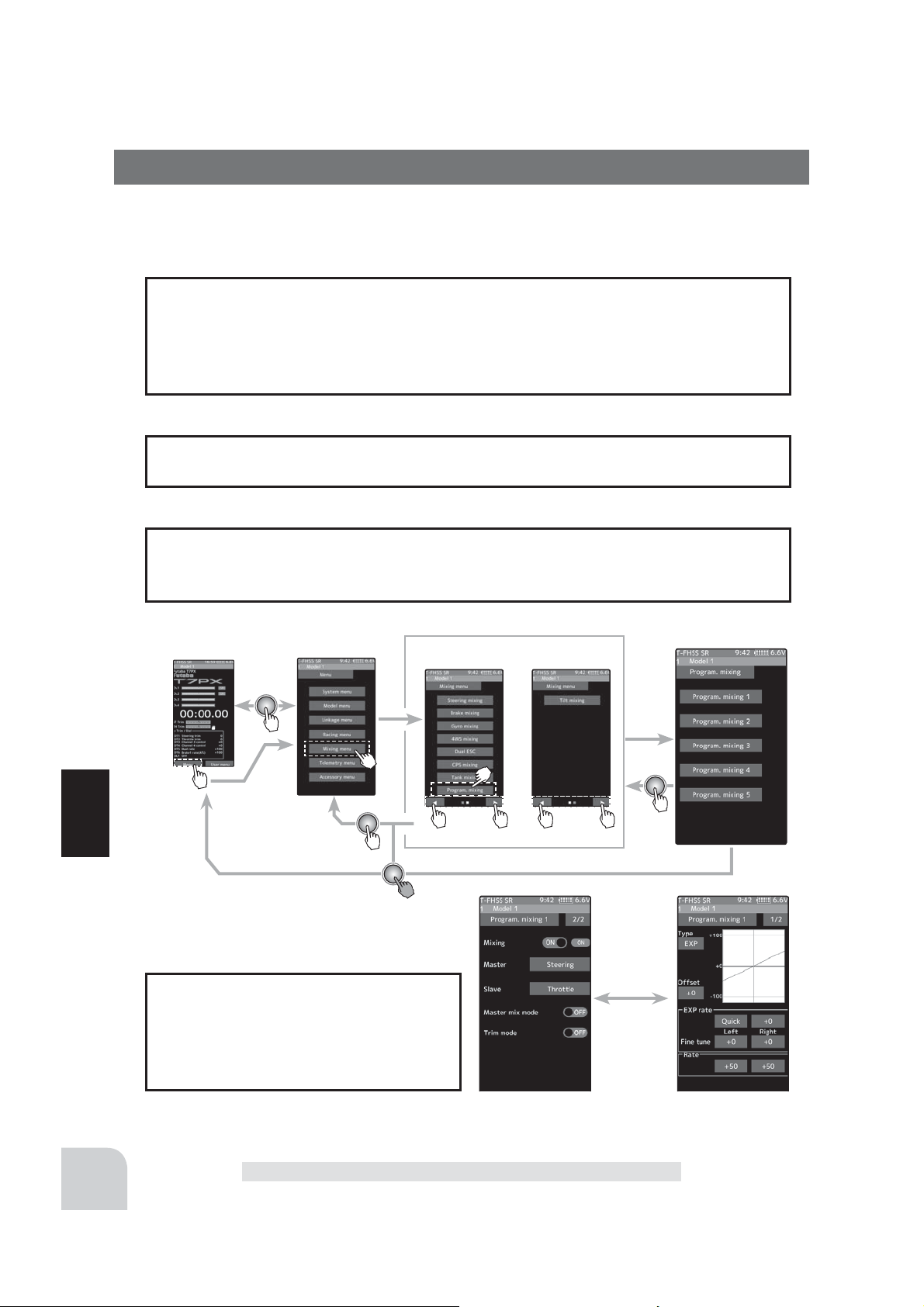

Program, Mixing (1, 2, 3, 4, 5 )

These functions allow you to apply mixing between the steering, throttle and auxiliary

channel.

Additional Functions

-When the steering or throttle channel is the master channel (channel that applies mixing), trim data can be added. (Trim mode)

- The mixing mode selection. (Master mixing mode)

- The master channel mixing center point (point at which the direction changes) can be

offset. (Offset function)

Movement of the slave channel side

The movement of the master channel side will be added to the movement of the slave

channel side.

When trigger ratio was set to 100:0

When trigger ratio (page 62) is set to 100:0, brake operation stops. When the master

channel is set to throttle, mixing operates only at the "Rate A (forward)" side. It does not

operate at the "Rate B (brake)" side.

Home screen

Menu screen

Menu-1

Menu-2

Program. mixing

Function

The mixing function is assigned to auxiliary channels used by other mixing

cannot be used. When the number of

channels is insuf¿cient, cancel the other

mixing.

122

On the page 1, the setting screen such as the curve, mix-

ing rate adjustment screen, page 2, mixing ON / OFF etc.

is displayed.

Program, Mixing (1, 2, 3, 4, 5)

Page 7

Program composite adjustment

(Preparation)

- Use the switch select function (page 69) to select the switch. (as

desired)

- From the Program Mixing screen Tap [Program Mixing 1] [Program Mixing 5] to use to move to the setting screen.

1

(Function ON/OFF)

Tap [1/2] at the upper right of the screen to display page 2.

Tap "Mixing" (ON) or (OFF) to select ON / OFF.

"OFF" :Mixing function OFF

"ON" :Mixing function ON

2

(Master / Slave channel setup)

Tap the [Master] or [Slave], and the channel setting screen

will be displayed. Tap on that channel to select.

To cancel, tap [Close].

Setting

- Tap (ON) / (OFF).

Setting

- Tap channel.

3

(Mix mode setting)

Tap "MIX mode" (ON) or (OFF) to select ON / OFF.

“OFF” :The EXP function of the 2nd CH and other settings are not mixed.

“ON” :The EXP function of the 2nd CH and other settings are mixed.

4

(Trim mode setup)

Tap "Trim mode" (ON) or (OFF) to select ON / OFF.

"OFF" :The trim of the 2nd CH is not mixed.

"ON" :The trim of the 2nd CH is mixed.

Program, Mixing (1, 2, 3, 4, 5)

For S-FHSS (analog)

system, 1 to 7 channels are displayed.

Setting

- Tap (ON) / (OFF).

Function

123

Page 8

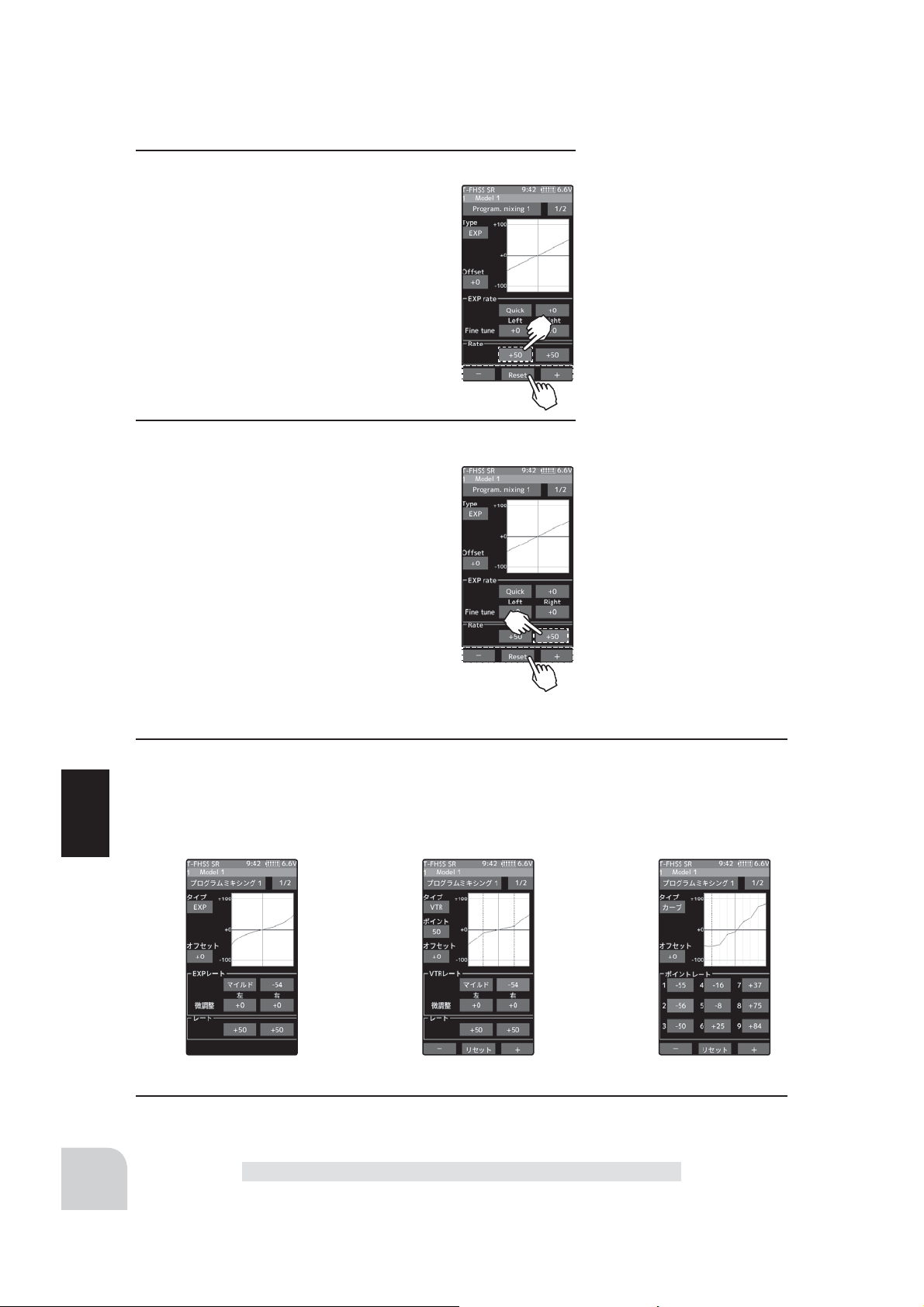

5

(Left, Forward or A side mixing amount adjustment)

Tap the value button of the "Rate" [Left],

[Forward] or [Rate A] . Value input buttons

appear on the screen, adjust each of the

left, forward or A steering angles using the

[+] or [-] button.

6

(Right, brake or B side mixing amount adjustment)

Tap the value button of the "Rate" [Right],

[Brake] or [Rate B] . Value input buttons

appear on the screen, adjust each of the

right, brake, or rate B steering angles using

the [+] or [-] button.

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Left / Forward / A side rate

-120~0 ~+120

Initial value: +50

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Right / Blake / B side rate

-120~0 ~+120

Initial value: +50

124

7

(Curve setting)

"EXP / VTR / Curve" mixing can be set from master channel to slave channel. For details on

how to set each curve, please read the steering curve and the throttle curve (pages 78 to

83).

Function

EXP curve VTR curve Curve

8

When finished, return to the Mixing menu screen by pressing the HOME button twice.

Program, Mixing (1, 2, 3, 4, 5)

Page 9

Tilt Mixing

Tilt mixing uses an outboard engine and applies bidirectional mixing from rudder to steady

to Àap and from Àap to rudder so that with a boat, rudder operation and tilt mixing opera

tion can be performed 2 servos.

Tilt mixing can be performed by rudder operation, by steering wheel and Àap channel.

Effect of the set value of other functions on tilt mixing

Steering end point function, curve function, speed function, or D/R function setup also

effects Àap channel operation. However, even if set, steering reverse function setup does

not reverse the Àap channel.

-

Home screen

Menu screen

Menu-1

Menu-2

mixing

The mixing function is assigned to auxiliary channels used by other mixing cannot be

used. When the number of channels is insuf¿cient, cancel the other mixing.

Program composite adjustment

(Preparation)

- Use the "Trim/dial select" function to select the flap channel

operation dial. (page 662)

Function

1

(Function ON/OFF)

Tap [1/2] at the upper right of the screen to

display page 2.

Tap "Mixing" (ON) or (OFF) to select ON /

OFF.

"OFF" :Mixing function OFF

"ON" :Mixing function ON

Tilt Mixing

Setting

- Tap (ON) / (OFF).

125

Page 10

2

(Channel setup)

The channel list screen used for the gain steering channel is displayed. Tap the auxiliary

channel that connected the gain steering channel.

- When all channels are in use, a screen saying "No assignable channel" is displayed, please turn off other mixing

and make an unused channel. You can check the mixing used on the channel setting screen (page 75).

If there is no assignable

channel, tap [Close]. Turn

off other mixing and make

assignable channels.

For S-FHSS (analog)

system, 1 to 7 channels are displayed.

3

(Flap rate check and adjustment)

Select the "Flap" by (JOG) button up or down operation, and

adjust the fl aps by [+] or [-] operation.

4

(Rudder to Flap mixing amount adjustment)

Tap the value button of the "Rudder to Flap", Value input buttons appear on the screen, and use the [+] and [-] buttons to

adjust the mixing amount.

“+” :Operate in same direction as steering

“-” :Operate in opposite direction of steering

5

(Flap to Rudder mixing amount adjustment)

Tap the value button of the "Flapto Rudder", Value input buttons appear on the screen, and use the [+] and [-] buttons to

adjust the mixing amount.

Function

“+” :Operate in same direction as auxiliary channel

“-” :Operate in opposite direction of auxiliary channel

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Mixing amount (Rudder to Flap)

-100~+0~+100

Initial value: +100

Mixing amount (Flap to Rudder)

-100~+0~+100

Initial value: -100

126

6

When fi nished, return to the Mixing menu screen by pressing the HOME button twice.

Dial / Trim Setting

The mixing rate amount can be controlled with digital dial or digital trim, using the dial

select function.(page 66)

Tilt Mixing

Page 11

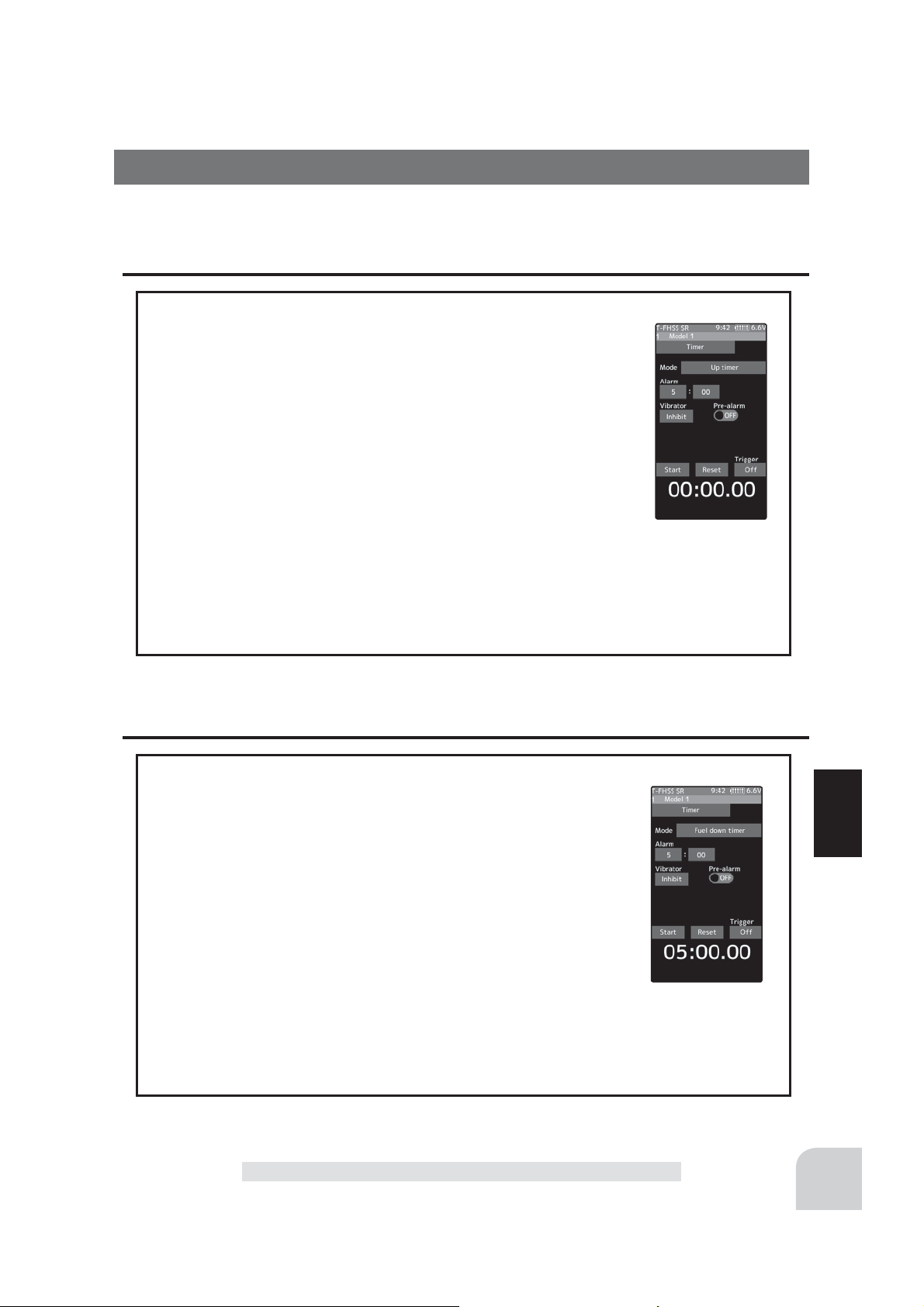

Timer

Use the timer by selecting one of the four timers Up timer, Fuel down timer, Lap timer and

Lap navigate timer.

Up timer function

- The Up timer can be used to count the time between start and stop, etc.

- The timer repeatedly starts and stops each time the switch is operated and accumulates the time between each start and stop. (When

the count reaches 99 minutes 59 seconds, it returns to 00 minutes 00

seconds and repeats the count.)

- The ¿rst start operation can be linked to the throttle trigger.

- An alarm sound can be set. The passage of time is announced by

sounding of a buzzer (beeps) each minute after starting.

- Alarm :Generates a beep at the set time (minutes).

- Pre-alarm :Alarm advance announcement sound. Sounding begins 10 seconds before the set alarm time.

- After starting, the timer is enabled and can be stopped by switch even when the display

switches to another screen.

Fuel down timer function

- The Up timer can be used to count the time between start and stop, etc.

- The timer repeatedly starts and stops each time the switch is operated and accumulates the time between each start and stop. (When

the count reaches 99 minutes 59 seconds, it returns to 00 minutes 00

seconds and repeats the count.)

- The ¿rst start operation can be linked to the throttle trigger.

- An alarm sound can be set. The passage of time is announced by

sounding of a buzzer (beeps) each minute after starting.

- Alarm :Generates a beep at the set time (minutes).

- Pre-alarm :Alarm advance announcement sound. Sounding begins 10 seconds before the set alarm time.

- After starting, the timer is enabled and can be stopped by switch even when the display

switches to another screen.

Timer

Function

127

Page 12

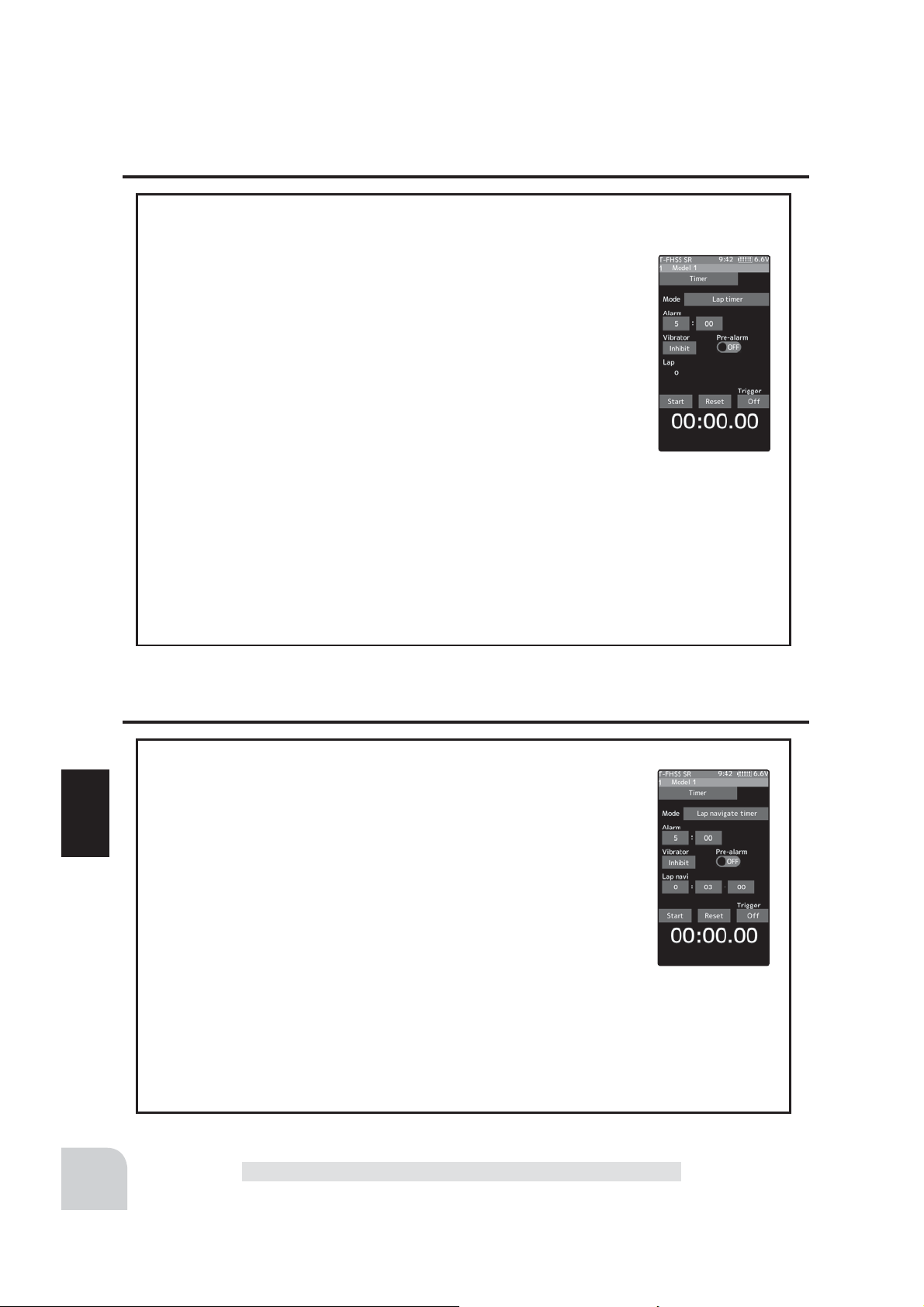

Lap timer function

Lap timer function

- The Lap timer can memorize each lap time of each switch operation. (80 laps)

- The race time can be set. Switch operation after the set time by

alarm has elapsed automatically stops the timer. Pre-alarm can also be

set. The passage of time is announced by sounding of a buzzer (beeps)

each minute after starting.

-Alarm :Generates a beep at the set time.

Pre-alarm :Starts sounding the set time (second) before the alarm. (beeps)

- The ¿rst start operation can be linked with the throttle trigger.

(Lap timer operation)

- When lap timer is selected, the number of laps (LAP) and the lap memory No. (No.) and

current lap time (TIME) are displayed on the setup screen.

* LAP: Counted up each time the switch is pressed after starting. After the switch was pressed, the numbers

pause for 3 seconds. To prevent erroneous counting, switch operation is not accepted during this time

* Lap memory: The lamp memory saves the lap times of 80 laps.

* The lap time data stored in the lap memory can be checked at the lap list (page 134) screen.

Lap navigate timer function

Lap navigate timer function

- This function sounds a buzzer at a fixed interval after the timer

starts. Since only the buzzer can be restarted when the switch is

pressed during timer operation, this function can be used as the train

ing run, etc. target time. (Lap navigation alarm) The passage of time

Function

is announced by sounding of a buzzer (beeps) every minute after

starting.

- The ¿rst start operation can be linked with the throttle trigger.

- The alarm sounds (alarm/Pre-alarm) can be set separately from the

¿xed interval buzzer.

- Alarm :Generates a beep at the set time (minutes).

- Pre-alarm :Alarm advance announcement sound. Sounding begins 10 seconds before the set alarm time.

- After starting, the timer is enabled and can be stopped by switch even when the display

switches to another screen.

-

128

Timer

Page 13

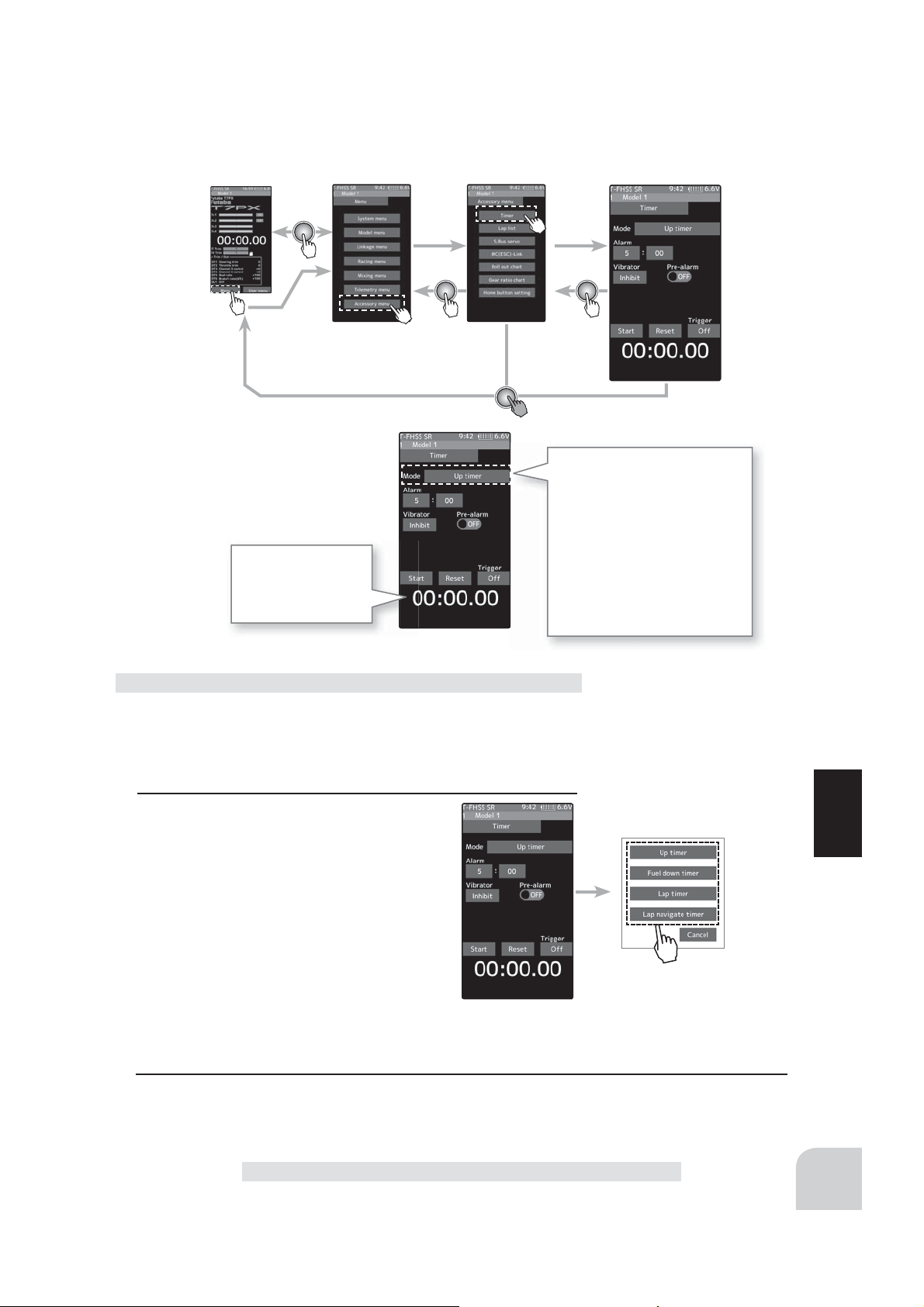

Home screen

Time display

Minute display (m)

Second display (s)

1/100 second display

Menu screen Accessory menu screen

Timer

Timer selection

First, select the type of timer

at the "Mode" item. The setup

screen varies depending on the

type of timer. This fi gure shows

the Up timer setup screen.

-Up timer

-Fuel down timer

-Lap timer

-Lap navigate timer

Racing timer type selection

(Preparation)

Assign the "Timer start" switch using the Switch select func-

Setting type

- Tap to select

tion (page 69). When resetting by switch, assign "Timer reset"

also.

1

(Racing timer type selection)

Tap the "Mode". The mode list appears on

the "Timer" menu screen, and tap the racing timer type.

Up timer

Fuel down timer

Lap timer

Lap navigate timer

2

When fi nished, return to the Accessory menu screen by pressing the HOME button.

Function

Timer

129

Page 14

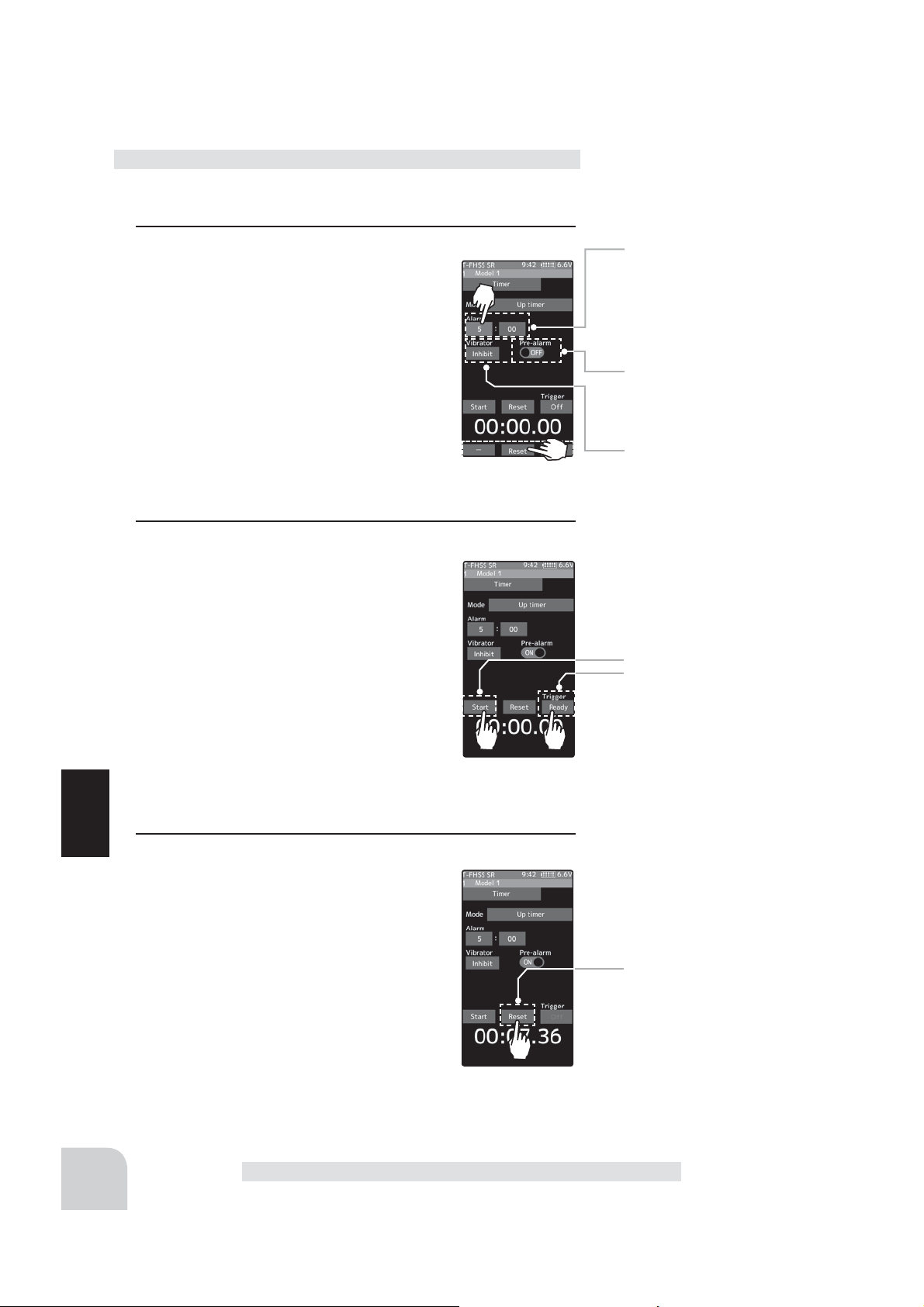

Using the Up timer

(Preparation)

Select the “Up timer” from the timer type list and tap.

1

(Alarm time setting)

Tap the value button of the "Alarm time".

Value input buttons appear on the screen.

use the [+] and [-] buttons to set the time

amount.

Tap [Vibrate] and select the vibration pattern of the alarm from 3 types of patterns

and disable (OFF).

(Pre-alarm setting)

Tap (ON) or (OFF) of pre-alarm and select

ON / OFF.

2

(Timer start/stop operation)

When the switch (Timer start) assigned by

switch select function is pressed, the timer

starts. When you press the switch (Timer

start) or [Start] / [Reset] on the screen during timer operation, the timer stops.

- Linking only start to the throttle trigger

Tap [OFF] of the trigger to display [Ready]

and wait for the trigger operation. When

you operate the trigger to the forward side,

the timer starts. Stop is the same as when starting with a

switch.

Alarm time

OFF, 1 ~ 99 minutes

Initial value: 5 minutes

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Pre-alarm time

OFF, ON

Initial value: OFF

- Tap (ON) / (OFF).

Grip vibrator type (pattern)

Inhibit(Off), Type1,2,3

Initial value: Inhibit

- Tap (ON) / (OFF).

Start / Stop

Status display

130

3

Function

(Timer reset operation)

With the timer stopped, press the switch

(timer reset) set by the Switch setting function, or tap [Reset] on the screen. The

timer is reset with the beeping sound.

Timer reset

Brake Mixing

Page 15

Using the fuel down timer

(Preparation)

Select the "Fuel down timer” from the timer type list and tap.

1

(Alarm time setting)

Tap the value button of the "Alarm time".

Value input buttons appear on the screen.

use the [+] and [-] buttons to set the time

amount.

Tap [Vibrate] and select the vibration pattern of the alarm from 3 types of patterns

and disable (OFF).

(Pre-alarm setting)

Tap (ON) or (OFF) of pre-alarm and select

ON / OFF.

2

(Timer start/stop operation)

When the switch (Timer start) assigned by

switch select function is pressed, the timer

starts.

When the switch ("Timer start") is pressed

while the timer is operating, the timer is reset and simultaneously restarted. (Restart)

When you press the [Reset] on the screen

during timer operation, the timer stops.

- Linking only start to the throttle trigger

Tap [OFF] of the trigger to display [Ready] and wait for the

trigger operation. When you operate the trigger to the forward

side, the timer starts. Stop is the same as when starting with

a switch.

Alarm time

OFF, 1 ~ 99 minutes

Initial value: 5 minutes

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Pre-alarm time

OFF, ON

Initial value: OFF

- Tap (ON) / (OFF).

Grip vibrator type (pattern)

Inhibit(Off), Type1,2,3

Initial value: Inhibit

- Tap (ON) / (OFF).

Start / Stop

Status display

Function

3

(Timer reset operation)

With the timer stopped, press the switch

(timer reset) set by the Switch setting function, or tap [Reset] on the screen. The timer

is reset with the beeping sound.

Brake Mixing

Timer reset

131

Page 16

Using the lap timer

(Preparation)

Select the "Lap timer" from the timer type list and tap.

1

(Alarm time setting)

Tap the value button of the "Alarm time".

Value input buttons appear on the screen.

use the [+] and [-] buttons to set the time

amount.

Tap [Vibrate] and select the vibration pattern of the alarm from 3 types of patterns

and disable (OFF).

(Pre-alarm setting)

Tap (ON) or (OFF) of pre-alarm and select ON / OFF.

2

(Timer start operation)

Perform the start and lap count operations with the switch

("Timer start") assigned by function select

switch function.

- Linking only start to the throttle trigger

Tap [OFF] of the trigger to display [Ready]

and wait for the trigger operation. When

you operate the trigger to the forward side,

the timer starts. Stop is the same as when

starting with a switch.

Alarm time

OFF, 1 ~ 99 minutes

Initial value: 5 minutes

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Pre-alarm time

OFF, ON

Initial value: OFF

- Tap (ON) / (OFF).

Grip vibrator type (pattern)

Inhibit(Off), Type1,2,3

Initial value: Inhibit

- Tap (ON) / (OFF).

Start / Stop

Status display

132

3

(Timer stop and lap reset operation)

When the lap count switch or ("Timer reset") switch is pressed after the time set by

Function

"Alarm" has elapsed and the lap time, total

time, and average lap time are saved and

checked. (Lap list page 134) If the switch

Timer reset

("Timer reset") set by switch setting function is pressed, the timer is reset.

When a switch is not set, tap [Reset] on the

screen. The timer is reset with the beeping

sound.

Brake Mixing

Page 17

Using the lap navigate timer

(Preparation)

Select the "Lap navigate timer" from the timer type list and tap.

1

(Alarm time setting)

Tap the value button of the "Alarm time".

Value input buttons appear on the screen.

use the [+] and [-] buttons to set the time

amount.

Tap [Vibrate] and select the vibration pattern of the alarm from 3 types of patterns

and disable (OFF).

(Pre-alarm setting)

Tap (ON) or (OFF) of pre-alarm and select

ON / OFF.

(Lap navigation time setting)

Tap the value button of the "Lap navi". Value input buttons

appear on the screen. use the [+] and [-] buttons to set the

time amount.

2

(Timer start / navigation restart operation)

When the switch ("Timer start") assigned

by switch select function is pressed, the

timer starts.

- Linking only start to the throttle trigger

Tap [OFF] of the trigger to display [Ready]

and wait for the trigger operation. When

you operate the trigger to the forward side,

the timer starts. Stop is the same as when

starting with a switch.

When your own lap time is less than the target time and the

lap counts overlap, the lap navigation alarm timing is too big.

The alarm timing can be corrected by pressing the switch

("Timer start") during measurement.

Alarm time

OFF, 1 ~ 99 minutes

Initial value: 5 minutes

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Pre-alarm time

OFF, ON

Initial value: OFF

- Tap (ON) / (OFF).

Grip vibrator type (pattern)

Inhibit(Off), Type1,2,3

Initial value: Inhibit

- Tap (ON) / (OFF).

Navi alarm time (NAVI)

OFF, 1 ~ 99 seconds

Initial value: 3 seconds

Start / Stop

Status display

Function

3

(Timer stop / reset operation)

Press the switch ("Timer reset") set by the

Switch setting function, or tap [Reset] on

the screen. The timer is stops.

With the timer stopped, press the switch

("Timer reset") set by the Switch setting

function, or tap [Reset] on the screen. The

timer is reset with the beeping sound.

Brake Mixing

Timer reset

133

Page 18

Lap List

Call Lap list when checking the lap memory data (each lap time) memorized by lap timer

(page 132 ) operation.

- After the lap timer is started, the lap time is sequentially memorized at each switch opera

tion.

-The total time and average time are displayed. The faster time is displayed in red characters.

-Lap time data is saved in each model data.

-Up to 80 laps can be saved.

-If the lap timer is reset, the lap list is also cleared.

-

Using the lap memory

1

(Lap memory check)

Function

The lap time list displays 40 laps per page and 80 laps maximum on 2 pages. If there is a

list on page 2, tap [1/2] / [2/2] at the upper right of the screen to change the display of the

page.

Home screen

Menu screen Accessory menu screen

Timer

134

2

When finished, return to the Accessory menu screen by pressing the HOME button.

Lap list

Page 19

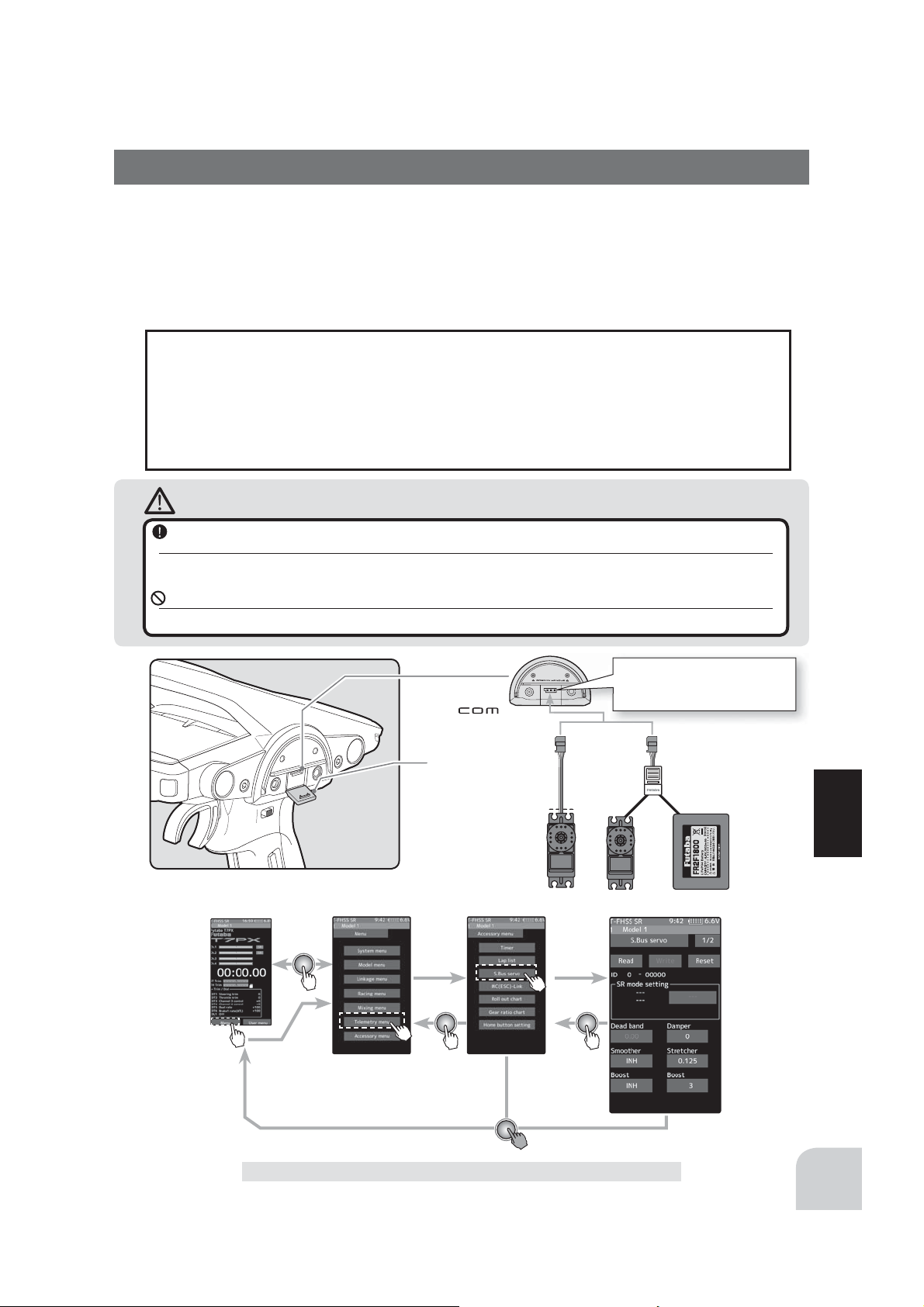

S.Bus Servo

This is a special function which allows Futaba S.BUS/S.BUS2 servo parameter changes to

be set by the T7PX transmitter. However, some data changes require a PC and S-Link software. This function is used by connecting Futaba S.BUS/S.BUS2 servo directly to the transmitter. Use the various optional servo extension cords according to the distance between

the transmitter and servo. (SR mode setting is for T7PX only, it can not be set with S-Link

software.)

-If shutting off while writing the parameters, the servo may fail. Please use this function

with suf¿ cient battery power.

-Power is supplied to the servo from the transmitter, but the corresponding voltage is for

high voltage servo (HV) use. Since an overvoltage will be applied to servos other than

this, connect the corresponding battery to the servo. When the battery is connected, the

supply of power from the transmitter automatically stops.

Caution

When connecting an S-BUS servo that does not support high voltage, connect a battery matched

to the servo specifi cations.

High voltage servo support voltage is supplied from the transmitter. If a servo that does not support high voltage is connected, unreasonable force will be applied to the servo and will cause trouble.

Do not disconnect the servo connector or turn off the transmitter power while writing parameters.

It may cause the servo to malfunction.

Home screen

Menu screen

Communication port.

Cover

Accessory menu screen

Connecting S.BUS/S.BUS2

servo connector to the transmitter Communication port.

Function

S.Bus Servo

S.Bus Servo

135

Page 20

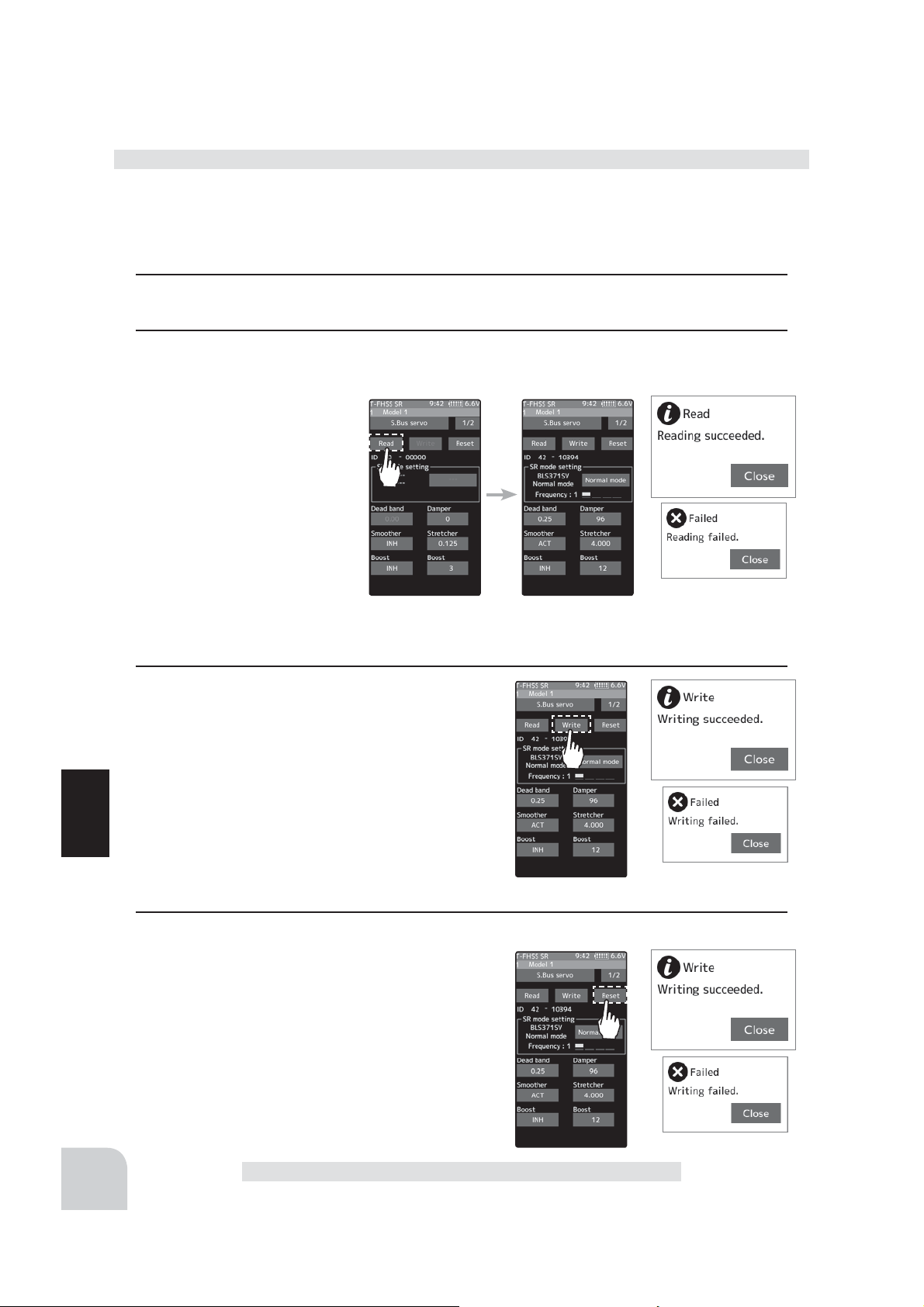

Using the S.Bus servo function

(Preparation)

- Connect the T7PX and S.BUS or S.BUS2 servo in accordance with the connection diagram shown on page 135.

- Connect the battery to a non-high voltage(HV) support S.BUS/S.BUS2 servo.

1

Turn power on the transmitter. "S.Bus servo" menu is displayed referring to the map of

page135.

2

(S.BUS/S.BUS2 servo read)

Execute this function to read the connected servo type and the data currently set at the

servo. Tap the [Read]. The

confirmation screen will be

displayed. To execute, tap

[Yes] to hear an electronic

sound and finish setting. To

cancel, select [No] and touch

it.

-"Reading succeeded" is displayed

on the screen and the servo’s ID

cord and currently set contents are

read.

- If "Failed" is displayed on the screen, communication with the servo is not being performed normally.

Check the T7PX and servo connection to servo and repeat [Read]. (Connect the battery to a non-high volt-

age(HV) support servo.)

136

3

(Writing to S.BUS/S.BUS2)

Execute this function to write the setting data to

servo. See pages 138 to139 for the setting data

contents.Tap the [Write]. The confirmation screen

will be displayed. To execute, tap [Yes] to hear an

electronic sound and finish setting. To cancel, select [No] and touch it.

-"Writing succeeded" is displayed on the screen and the setting

Function

data is written to servo.

- If "Failed" is displayed on the screen, communication with the

servo is not being performed normally. Check the T7PX and servo connection to servo and repeat [Write]. (Connect

the battery to a non-high voltage(HV) support servo.)

4

(Initialization)

Write the factory set servo setting data to the connected servo. Tap the [Reset]. The confirmation

screen will be displayed. To execute, tap [Yes] to

hear an electronic sound and finish setting. To cancel, select [No] and touch it.

-"Writing succeeded" is displayed on the screen and the setting

data is written to servo.

- If "Failed" is displayed on the screen, communication with the

servo is not being performed normally. Check the T7PX and

servo connection to servo and repeat "Write". (Connect the

battery to a non-high voltage(HV) support servo.)

S.Bus Servo

Page 21

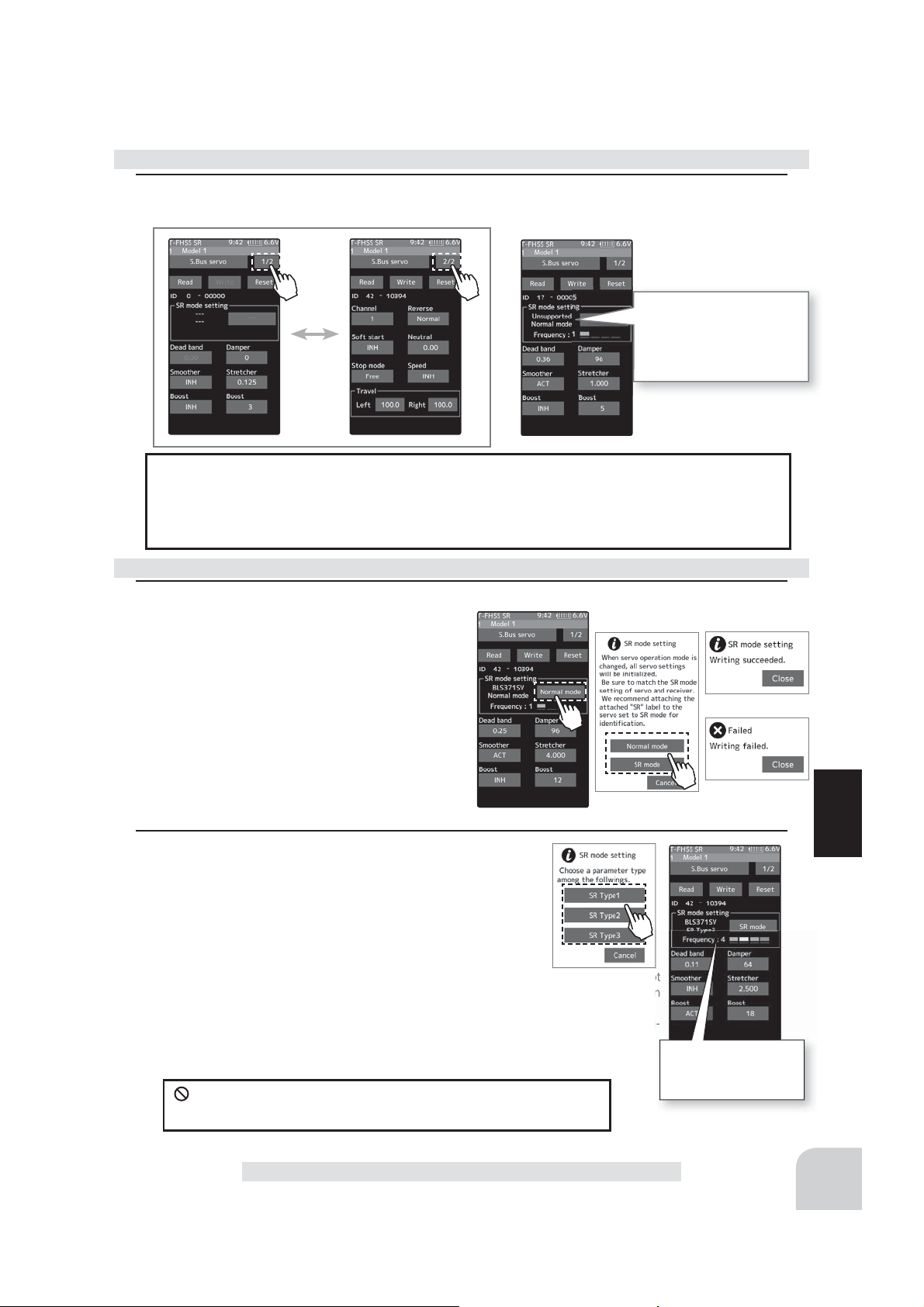

Display data list

1

The type and data of the loaded servo are displayed. Since there are two setting items,

change the page as follows.

When the connected servo

type is not compatible with

the SR mode, "Unsupported Normal mode" is

displayed

- Do not plug in or disconnect servos, or connect other servos while keeping the screen

where data was read by [Read]. Be sure to connect the servo in the state where [Write]

or [Reset] is ¿ nished, or press the Home button to access the accessory menu screen.

- The loaded data can not be written to another servo.

SR mode setting

1

(Writing to servo)

Tap [SR mode] or [Normal mode] of SR mode

setting. A confirmation screen of "Notes on

SR setting" is displayed, so read carefully

and tap [Normal mode] or [SR mode].

- When [Normal mode] is selected, "Writing succeeded"

is displayed on the screen, and the setting data is written to the servo.

- If "Failed" is displayed, communication with the servo is

not performed normally. Check the connection between

the T7PX and the servo, and then execute the write

operation again.

2

(When SR mode is selected by writing to servo)

In the confi rmation screen of "Notes on SR setting", tap

[SR mode], the screen for selecting the SR type is displayed. Three types with different feeling are prepared.

(Please repeat the test and choose the type. )

- "Writing succeeded" is displayed on the screen and the setting

data is written to the servo. If "Failed" is displayed, communication with the servo is not

performed normally. Check the connection between the T7PX and the servo, and then

execute the [Write] operation again.

- For the servo set to SR mode, affi x the attached SR label so that the mode can be recog-

nized.

Do not connect absolutely to the S. BUS channel of all receivers

for the servo set to SR mode. The servo will fail.

S.Bus Servo

Function

The type of servo and

the set SR type are displayed.

137

Page 22

S.BUS function setup

1

On the setting screen of each function, if you tap the item to be set, [-] [reset] [+] will be dis-

played at the bottom of the screen, tap the [-] [+] on the panel Set. Tap[Reset] to return to

the initial value. There are items with no [reset]. In case of selection type, data is switched

by tapping an item.

ID

Displays the ID of the servo whose parameters are to be read. It cannot be changed.

Dead band

The dead band angle at stopping can be

specified.

[Relationship between dead band set value and servo operation]

Small - Dead band angle is small and the

servo is immediately operated by a small signal change.

Large - Dead band angle is large and the servo does not operate at small signal changes.

(Note)

increase and the life of the servo will be shortened.

Damper

The characteristic when the servo is stopped can be set.

When smaller than the standard value, the characteristic becomes an overshoot characteristic. If the value is larger than the standard value, the brake is applied before the stop position.

Especially, when a large load is applied, overshoot, etc. are suppressed by inertia and hunting may occur, depending on the conditions. If hunting (phenomena which cause the servo

to oscillate) occurs even though the Dead Band, Stretcher, Boost and other parameters are

suitable, adjust this parameter to a value larger than the initial value.

[Relationship between damper set value and servo operation]

Small - When you want to overshoot. Set so that hunting does not occur.

Function

Large - When you want to operate so that braking is not applied. However, it will feel like the

servo response has worsened.

(Note)

also be shortened.

If the dead band angle is too small, the servo will operate continuously and the current consumption will

If used in the hunting state, not only will the current consumption increase, but the life of the servo will

138

Smoother

This function makes servo operation smooth. Set it according to your taste. Normally set it

to "ACT". Set it to "INH" when want especially quick operation. When the smoother function was set to "ACT" and the servo was operated the distance up to the target position is

changed in steps so movement is smooth.

Stretcher

The servo hold characteristic can be set. The torque which attempts to return the servo to

the target position when the current servo position has deviated from the target position can

be adjusted.

S.Bus Servo

Page 23

This is used when stopping hunting, etc., but the holding characteristic changes as shown

below.

[Relationship between stretcher and servo operation]

Small - Servo holding force becomes weaker.

Large - Servo holding force becomes stronger.

(Note)

When this parameter is large, the current consumption increases.

Boost/Boost (ON/OFF)

INH : It is the boost ON at the time of low-speed operation. (In the case of usual)

ACT : It is always the boost ON. (When quick operation is hope).

The minimum current applied to the internal motor when starting the servo can be set. Since

a small travel does not start the motor, it essentially feels like the dead band was expanded.

The motor can be immediately started by adjusting the minimum current which can start the

motor.

[Relationship between boost set value and servo operation]

Small - Motor reacts to a minute current and operation becomes smooth.

Large - Initial response improves and output torque increases. However, if the torque is too large, operation will be-

come rough.

Channel

This is the S.BUS system channel assigned to the servo. When connected to the receiver

S-BUS2 connector as an S.BUS system, the channel used by the transmitter is assigned.

When the normal receiver channel is used, channel setting is unnecessary.

Reverse

The direction in which the servo rotates can be changed.

Soft Start

Restricts operation in the specified direction the instant the power is turned on. By using this

setting, the first initial movement when the power is turned on slowly moves the servo to the

specified position.

Neutral

The neutral position can be changed. When the neutral offset is large value, the servo’s

range of travel is restricted on one side.

Stop Mode

The state of the servo when the servo input signal is lost can be specified. The “Hold” mode

setting holds the servo in its last commanded position even if using AM or FM system.

Speed

Speeds can be matched by specifying the operating speed. The speed of multiple servos can be matched without being affected by motor fluctuations. This is effective for load

torques below the maximum torque.

However, note that the maximum speed will not be exceed what the servo is capable of

even if the servos operating voltage is increased.

Function

Travel [Left] / [Right]

The maximum left and right travels centered about the neutral position can be set independently.

S.Bus Servo

139

Page 24

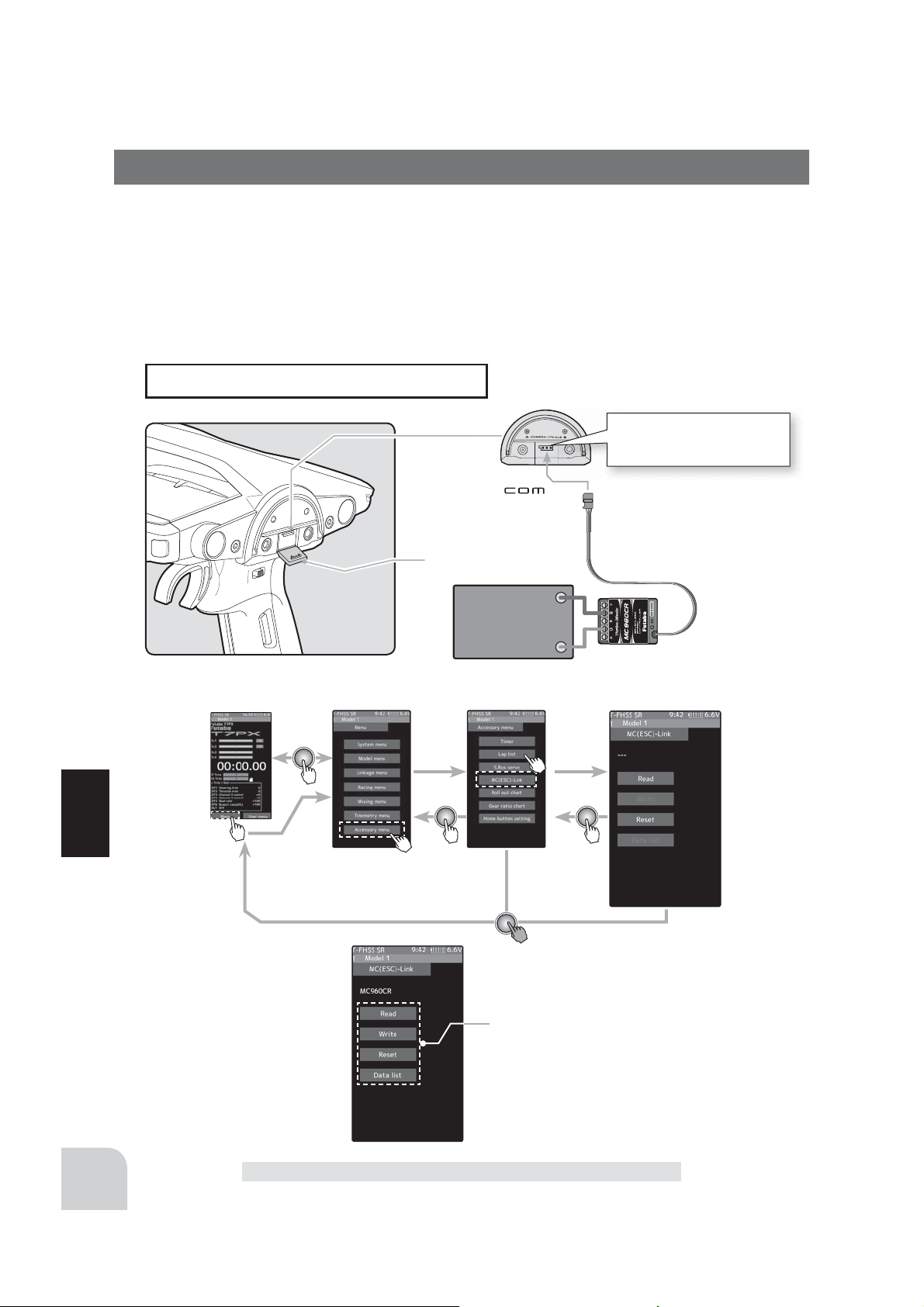

MC Link (ESC Link)

This is a special function which allows Futaba motor controller (MC) data changes to be set

by the T7PX transmitter (MC960CR, MC950CR, MC851C, MC602C, MC402CR, etc.).

However, some data changes require a PC and Link software.

This function is used by connecting ESC directly to the transmitter.

Use the various optional servo extension cords according to the distance between the transmitter and ESC.

-Also connect the battery at the ESC side.

Connecting ESC receiver

connector to the transmitter

Communication port.

Communication port.

Cover

Battery

Home screen

Menu screen Accessory menu screen

Timer

Function

Setup item (after it reads)

Read

Write

Reset

Data list

140

MC Link (ESC Link)

Page 25

Using the ESC Link function

(Preparation)

-

Connect the T7PX and ESC in accordance with the connection diagram shown on page 140.

-Connect the battery to ESC.

1

Turn power on the transmitter. "MC link" menu is displayed referring to the map of page 140.

Set the FET amp power switch to the ON position.

2

(ESC read)

Execute this function to read

the connected ESC type and

the data currently set at the

ESC. Tap the [Read]. The

confirmation screen will be displayed. To execute, tap [Yes] to

hear an electronic sound and

finish setting. To cancel, select

[No] and touch it.

- "Reading succeeded"

- If "Failed"

T7PX and ESC connection and the battery connection to ESC and the ESC power switch and repeat [Read].

is displayed on the screen

is displayed on the screen

, communication with the ESC is not being performed normally. Check the

and the ESC type and currently set contents are read.

3

(Writing to ESC)

Execute this function to write the setting data to

ESC. See pages 143 to 148 for the setting data contents.Tap the [Write]. The confirmation screen will be

displayed. To execute, tap [Yes] to hear an electronic

sound and finish setting. To cancel, select [No] and

touch it.

- "Writing succeeded" is displayed on the screen and the setting

data is written to ESC.

- If "Failed" is displayed on the screen, communication with the

ESC is not being performed normally. Check the T7PX and ESC

connection and the battery connection to ESC and the ESC power switch and repeat [Write].

- Different type ESC data cannot be written. If writing is attempted, "Failed" is displayed on the screen.

4

(Initialization)

Write the factory set ESC setting data to the connected ESC. Tap the [Reset]. The confirmation

screen will be displayed. To execute, tap [Yes] to

hear an electronic sound and finish setting. To cancel, select [No] and touch it.

- "Writing succeeded" is displayed on the screen and the setting

data is written to ESC.

- If "Failed" is displayed on the screen, communication with the

ESC is not being performed normally. Check the T7PX and ESC

connection and the battery connection to ESC and the ESC

power switch and repeat [Write].

Function

MC Link (ESC Link)

141

Page 26

Display data list

-ESC is read referring to the explanation of page 139.

1

Tap the [Data list].

Depending on the ESC type, the setting items are different.

If there are multiple pages, move the page as follows.

To page 1

MC940/960CR page 1

950CR page 1

MC940/960CR page 2 MC940/960CR page 3 MC940/960CR page 4

To page 1

950CR page 2 950CR page 3

Function

601CR/850C page 1

602CR/851C page 1

601CR/602CR/851C page 2 850C page 2

142

402CR page 1

401CR page 1 401CR/402CR page 2

MC Link (ESC Link)

Page 27

PWM frequency (min)

MC950CR :0.5kHz(500Hz) 30kHz(30000Hz)

MC940,960CR :1kHz(1000Hz) 30kHz(30000Hz)

MC401,402CR/601,602C/850,851C :0.1kHz(100Hz) 10kHz (10000Hz)

Same as Link software PWM frequency (at Min. load),

MIn sets the "0" PWM frequency at minimum load.

PWM frequency (max)

MC950CR:0.5kHz(500Hz) 30kHz(30000Hz)

MC940,960CR:1kHz(1000Hz) 30kHz(30000Hz)

MC401,402CR/601,602C/850,851C:0.1kHz(100Hz) 10kHz (10000Hz)

Same as Link software PWM frequency (at Max. load).

MAX sets the PWM frequency at maximum load at the output current

limit value set by Current Limiter.

PWM frequency (brake)

MC402CR/602C/851C (MC401,601,850 cannot be adjusted 2kHz fi xation)

:Normal(2000Hz) /Hard(1000Hz) /Super hard(500Hz)

MC950CR :0.5kHz(500Hz)30kHz(30000Hz)

MC940,960CR :1kHz(1000Hz)30kHz(30000Hz)

Same as Link software Brake PWM at frequency.

This setting can set the brake PWM frequency.

"min" which sets the frequency when the load is small, is set to the high frequency side (large

value) when extension is desired after straightaways and curves.

"max" which sets the frequency when the load is large, is set to the high frequency side (large

value) when you want to suppress the rise from low speed and when motor heating and

commutator roughness are sensed.

When the rise from low speed is poor, and becomes bad even when "max" is set to the low

frequency side, use the log data to check if there was a momentary voltage drop. When you

want to suppress the overall power, lengthen the run time, and otherwise improve effi ciency,

set both "max" and "min" to the high frequency side. When you want to set a fi xed PWM frequency at full range regardless of the load current, set PWM frequency (at Max. load) and

PWM frequency (at Min. load) to the same value.

Dead Band

All type :±2μs~±50μs

Same as Link software Dead Band.

This sets the range (neutral point range) over which the ESC does

not respond to transmitter throttle operation.

The larger the set value, the wider this range.

Dead Band

Position at which motor

starts to run

Point at which brakes start

taking effect

Throttle neutral position

MC Link (ESC Link)

Function

143

Page 28

Low battery protection

MC401,402CR/601,602C/850,851C:2.5V 6.0V

MC950CR/MC940,960CR 2.5V 7.5V

Same as Link software Low Bat Protection.

When the power supply voltage drops, the output current to the motor is limited and supply voltage to the receiver is ensured. When

the power supply voltage drops to the set voltage, a protection circuit operation alarm is activated and output to the motor is cut. The

protection circuit is automatically reset by recovery of the power

supply voltage

Current limiter

MC401,402CR/601,602C/850:50A 300A, INH

MC851C :50A~300A(can not INH)

MC950CR/MC940,960CR:50A~500A, INH

Same as Link software PWM frequency (at Max. load).

MAX sets the PWM frequency at maximum load at the output current limit value set by

Current Limiter.

Current limiter INH/ACT setting

MC950CR and MC940 / 960CR tap INH OR ACT by tapping the current limiter INH/ACT.

The MC851C does not have an INH(Off) settin

Current limit timer

MC401,402CR/601,602C/850,851C:0sec(OFF)240sec

MC940,960CR:0sec(OFF)~240sec (MC950CR can not)

Same as Link software Current Limit timer.

The output current can be limited up to the set time lapse from the start of running. This is

effective in preventing the motor from outputting wasted energy when the voltage is high immediately after the power battery was recharged.

"Current Limiter (time)" sets the time the output current is limited. This function is disabled

when set to "0" sec.

Since the Current Limit Timer starts when

the throttle is operated to the forward side

and current is output to the motor, this func-

Function

tion begins to operate when the motor is

run during trim adjustment, etc.

Current limiter (time)

MC401,402CR/601,602C/850,851C :50A~300A

MC940,960CR :50A~500A (MC950CR can not)

"Current Limit timer" sets the maximum

output current within the time the output

current is limited.

144

MC Link (ESC Link)

Page 29

100

50

0

%

100

50

0

Brake max. duty

All type :0%~100%

Same as Link software Brake Max. Duty.

This setting can set the braking force between the neutral

point and Max brake point.

The larger this value, the greater the braking force. When

set to "0%", the brakes are not effective.

Brake (Reverse) operation

Reverse max. duty

MC401,402CR/MC950CR/MC940,960CR :0%~100%

Same as Link software Reverse Max. Duty.

This setting can set the reverse power between the

neutral point and Max reverse point.

The larger this value, the greater the reverse power.

When set to "0%", the reverses are not

effective.

MC401,402CR

MC950CR

MC940,960CR

Neutral brake

All type :0%~100%

Same as Link software Current Limit timer.

Make this setting when you want to use the brakes at the neutral throttle (OFF) position by

throttle operation. The larger this value, the greater

the braking force. When you want to use the neutral

brake, set this value to "0%".

MC601,602C

MC850,851C

Braking force

Reverse Power

Reverse mode shift level

MC401,402CR/MC950CR/MC940,960CR :0%~100%

Same as Link software Reverse Mode Shift Level.

The reverse operation can be done with the throttle

trigger to be thrown from brake status to the neutral.

The value can set the amount of the brake in order

to switch to the reverse operation.

Forward BOOST

MC401,402CR/MC601,602C/MC851C :0%~100%

Same as Link software Forward Boost (Boost).

Operation near the throttle trigger neutral position

becomes a sharp rise.

Throttle response

FWB "0"

Forward operation

MC401,402CR

MC401,402CR

MC950CR

MC940,960CR

Function

MC601,602

851C

MC Link (ESC Link)

145

Page 30

Reverse cancel

MC401,402CR/MC950CR/MC940,960CR :ACT/INH

Same as Link software Reverse Cancel.

When set to "ACT", reverse operation is not performed.

Robot mode

MC401,402CR/MC950CR/

MC940,960CR :ACT/INH

Same as Link software Robot

Model.

When set to "ACT", brake operation is not performed, there

is only forward and reverse

operation.

MC401,402CR MC940,960CR MC945CR

Brake slope

MC940,960CR/ :0~300

Same as Link software Brake Slope.

This function adjusts the braking effect when the throttle was returned (throttle off). It cancels operation like that called engine brake of actual vehicles.

Brake timer

MC940,960CR/MC950CR :0sec~300sec

Same as Link software Brake Timer.

When the reverse function is used, ordinarily if the trigger is not

moved to the brake (reverse) side and then returned from the brake

operation position to the neutral position, reverse operation will not be

performed. However, when used by intentionally moving the neutral

point to the forward side, if brake operation is repeated, reverse operation may be performed even if the trigger is not returned to the neutral position. The time required to switch to reverse operation can be set to prevent this from occurring.was returned

Function

(throttle off). It cancels operation like that called engine brake of actual vehicles.

Lead angle

MC950CR/ :0~1500

Same as Link software Lead Angle.

The lead angle of the motor can be set at the MC950CR side. However, we recommend that it normally be set to "0". Since this setting is

premised on setting by referring to the speed log by the Link software.

MC940,960CR

146

MC945CR

MC Link (ESC Link)

Page 31

BEC voltage

MC940,960CR/ :6.0V/7.4V

Same as Link software BEC Volt.

The receiver BEC voltage can be selected from 6.0V and 7.4V. Match

the voltage to the rating of the servo connected to the same receiver.

This BEC voltage cannot output a voltage higher than the input voltage.

For instance, if a 6.0V receiver and servo are used with a power supply

voltage of 7.4V or more, set the BEC voltage to 6.0V and when a high

voltage receiver and servo are used, set the BEC voltage to 7.4V.

MC940,960CR

Turbo mode

MC940,960CR/ :Turbo0/Turbo1/Turbo2

Same as Link software Turbo Mode.

This function sets the turbo mode. More power can be displayed by using the turbo mode.

Depending on the setting, the motor and ESC may be damaged so make this setting carefully.

(Note) When "Lead angle use" is INH, lead angle setting will not operate even if set to "Turbo1" or "Turbo2". (Turbo mode disabled, Turbo0=Off)

-Turbo0 mode: (No Lead Angle mode) Lead angle - No

When used in races in which the lead angle setting function is inhibited by

ESC, set to this mode. The lead angle function is disabled the same as if “Lead

angle use” was turned off.

When the lead angle function was disabled by the method described above,

the MC940,960CR shows that the lead angle function is off by blinking a blue

LED at an ON 0.1 second, OFF 0.9 second cycle at the neutral point.

-Turbo1 turbo mode: (Lead Angle mode) Lead angle – Yes

The output can be increased by setting a lead angle.

Depending on the set value, the motor may be damaged so increase the lead

angle value in steps from a small value while observing the conditions.

Turn on “Lead angle use” and adjust the lead angle by “Lead angle” and point A,

B, C, D, E (A, B, C, D, E Lead angle) value.

-Turbo2 power mode: (Power Mode) Lead angle – Yes

Displays still more power than a turbo.

However, since even a motor applies a large load on the ESC, make the lead angle larger in steps from

a small value while observing the conditions.

Turn on “Lead angle use” and adjust the lead angle by “Lead angle” and point A, B, C, D, E (A, B, C, D,

E Lead angle) value.

Power point A

MC940,960CR/ :6.0V/7.4V

Same as Link software Power Point A.

When the turbo mode is power 2 (Power mode) and the lead angle is large, movement may

become stiff when entering the course, etc. In this case, make operation smooth by lowering

the set speed at power point A.

This function is not performed in modes other than Turbo 2.

Function

MC Link (ESC Link)

147

Page 32

Lead angle use

A B C D E

A

B

C

D

E

A B C D E

A

基準進角

B

C

D

E

MC940,960CR :ACT/INH

Same as Link software Lead Angle Use.

This function is effective when Turbo Mode is Turbo1 or

Turn on "Lead angle use"

Turbo2 and sets whether or not lead angle is

used. This setting has priority over the Turbo

Mode setting. When using in races in which

the lead angle function is inhibited by the ESC

set this function to INH.

INH : Lead angle function not used.

ACT : Lead angle used

Point A,B,C,D,E Lead angle

MC940,960CR :0deg~59deg

Same as Link software Boost Angle.

Point A,B,C,D,E Rotation

MC940,960CR :0rpm~120,000rpm

Same as Link software Boost Angle rpm.

When "Lead Angle Use" is turned on the lead angle versus motor speed of the 5 points A to

E can be set. The lead angle can be set up to 59 degrees in 1 degree increments.

The "Lead angle" and "Point A, B, C, D, E Lead angle" relationship is shown on the graphs

below. Graph [1] shows the relationship when the same value is set at "Points A, B, C, D, E

Lead angle" of [1] and [2] and the "Lead angle" was set to "0" and graph [2] shows the relationship when a value other than "0" was set at "Lead angle". As shown in the graphs, [2] is

added to the "Points A, B, C, D, E Lead angle" set lead angle and [1] is added to the "Lead

angle" set lead angle. For example, if "3" is set at Point A and "Lead angle" of [2] is set to "2,

the actual Point A becomes 3+2=5 (deg). Since "Lead angle" of [A] is "0", the actual Point A

also becomes 3+0=3 (deg).

1 (Lead angle ="0") Lead Angle(deg) 2 (Lead angle >"0") Lead Angle(deg)

Function

rpm rpm

When using in races in which the lead angle setting function is inhibited by the ESC, set

Lead angle use" to "INH". The "Lead angle use" setting has priority over "Turbo mode".

"

If "Lead angle use" is set to "INH", the lead angle setting function can be turned off

even if "Turbo mode" is set to "Tu rb o1" or "Tu rb o2".

The MC940,960CR shows that the lead angle setting function is OFF ("0" timing) by

148

blinking a LED.

MC Link (ESC Link)

Page 33

Roll Out Chart

This function is designed for pan cars. The roll out chart can be calculated from input values for the number of teeth of the spur gear and pinion gear, and the tire diameter, and displayed as a table.

Home screen

Use of Roll out chart function

1

(Setting of step of the tire diameter input)

Tap the value button of the [Step]. Value

input buttons appear on the screen. Use

the [+] and [-] buttons to set the step of input

numerical value of tire diameter amount.

- The step amount can be set in the range of 0.1 mm

to 1.0 mm.

Menu screen Accessory menu screen

Roll out chart

Setup item

Pinion

Sper

Step

Diameter

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

2

(Setting of number of teeth of spur gear)

Tap the value button of the [Super]. Value input buttons appear on the screen. Use the [+] and [-]

buttons to set the spur gear. The roll out is then calculated, and the list is updated.

3

(Setting of number of teeth of pinion gear)

Tap the value button of the [Pinion]. Value input buttons appear on the screen. Use the [+]

and [-] buttons to set the pinon gear. The roll out is then calculated, and the list is updated.

3

(Setting of tire diameter)

Tap the value button of the [Diameter]. Value input buttons appear on the screen. Use the [+]

and [-] buttons to set the tire diameter. The roll out is then calculated, and the list is updated.

4

When fi nished, return to the Accessory menu screen by pressing the HOME button.

Roll Out Chart

Function

149

Page 34

Gear Retio Chart

The Gear Retio Chart can be calculated from input values for the number of teeth of the

spur gear and pinion gear, and secondary gear ratio, and displayed as a table.

Home screen

Use of Roll out chart function

1

(Setting of number of teeth of spur gear)

Tap the value button of the [Super]. Val-

ue input buttons appear on the screen.

Use the [+] and [-] buttons to set the spur

gear. The roll out is then calculated, and the

list is updated.

Menu screen Accessory menu screen

Gear ratio chart

Setup item

Pinion

2nd Gear ratio

Sper

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

150

2

Function

(Setting of number of teeth of pinion gear)

Tap the value button of the [Pinion]. Value input buttons appear on the screen. Use the [+]

and [-] buttons to set the pinon gear. The roll out is then calculated, and the list is updated.

2

(Setting of number of secondary gear ratio)

Tap the value button of the [2nd gear ratio]. Value input buttons appear on the screen. Use

the [+] and [-] buttons to set the 2nd gear ratio. The roll out is then calculated, and the list is

updated.

3

When fi nished, return to the Accessory menu screen by pressing the HOME button.

Gear Retio Chart

Page 35

Home Button Setting

You can select the screen to display when you push the Home button on the Home screen,

menu or user menu. You can not change the screen to display by push and holding the Home

button from the menu screen or each function screen.

- Push------------------Display menu screen or custom menu screen.

- Long press-----------Trim lock or display the function screen of your choice.

Home screen

How to set the home button

1

(Setting for push)

Tap "Puah" [Menu] or [User menu] to select "Menu" / "User

menu".

Menu screen Accessory menu screen

Home hutton setting

2

(Setting for long press)

Tap "long press".

The function list appears on the home button setting menu screen. Tap and select

the function you want to use. To cancel, tap

[Close].

- Since there are multiple pages, tap the mark and

move the page.

3

When finished, return to the Accessory menu screen by pressing the HOME button.

Home Button Setting

Function

151

Page 36

Telemetry System

With the telemetry system, the running status can be displayed at the transmitter and also

recorded as a data log by installing various sensor units to the chassis

(The T-FHSS SR, S-FHSS and FASST systems do not have a telemetry function.)

-The sensor data can be checked at the transmitter by connecting the telemetry sensor sold

separately to the S.BUS2 connector of the R334SBS receiver.

-To log this information, a start/stop switch is set by switch setting (page 69).

The log data recorded on a microSD card can be converted to CSV format by the telemetry

log converter released at our home page. When copying or moving the log ¿le, always select

both .FLI and .FLD ¿les.

-The ¿gure is an example of connection of a telemetry sensor. The data of up to the follow

ing 3 types of sensor and the receiver power supply voltage can be transmitted by using the

3-way extension cord or double extension cord sold separately.

The receiver power supply can also be connected to the S.BUS2 connector or channel 1 to 4

connector. A receiver power supply voltage sensor is unnecessary.

-

Connection

diagram

Transmitter

Signal

Info

Function

T-FHSS Receiver

Connect to S.BUS2 Connector

-Usable sensor options(As of May 2017)

*Temperature sensor (SBS-01T) Perfect for engine head, etc.

*Temperature sensor (SBS-01TE) Used by attaching to a motor, etc.

*RPM Sensor (SBS-01RM) Measures speed over the 0 to 999,900rpm range.

*Voltage Sensor (SBS-01V) Measures external power supply voltages up to 100V.

*Current sensor (SBS-01C)

*GPS sensor (SBS-01/02G) Detect the GPS and measure the position and speed of the car body.

*Compatibility with non-Futaba sensors (Castle TL0). (Refer to the sensor instruction manual for more information.)

Measures external power supply voltages up to 70V, capacity and consumption capacity.

Info

HUB

Power battery voltage is

displayed at the transmitter.

Info

Switch

Info

voltage

Info

Voltage Sensor

Temperature

Sensor

RPM Sensor

Battery voltage is displayed

at the transmitter.

152

Telemetry System

Page 37

Telemetry

It is necessary to turn on the telemetry on the receiver setting screen to use the telemetry

function. (pace 52) This screen displays and sets the various information from the receiver.

An alarm and vibration can be generated depending on the information. The alarm and

the vibration are set by each information screen. For example, a drop in the voltage of the

receiver battery housed in the model car can be reported by an alarm. The telemetry data

received last is memorized. Therefore, even if the receiver power is turned off, information display, audio guide, and alarms remain until the transmitter power is turned off. The

speech function can be turned on and off with the speci¿ ed switch. See the switch select

function (page 69).

Home screen

Menu screen Accessory menu screen

Telemetry

Receiver-Voltage display

Temperature display

RPM display

EXT-Voltage display

Speed display

EXT-Current display

Using Telemetry function

(Preparation)

The sensor used is connected with the receiver referring to the connection diagram of page 152.

1

(Function ON/OFF)

Tap telemetry (ON) or (OFF) to select ON / OFF.

"OFF" :Telemetry function OFF

"ON" :Telemetry function ON

Function

2

When fi nished, return to the Linkage menu screen by press-

ing the HOME button.

Telemetry

Telemetry function ON

153

Page 38

Telemetry :Receiver Battery Voltage

This function displays and sets the receiver power supply battery. The sensor sold separately

does not have to be installed. The transmitter initial state voltage is also displayed. For a

description of alarm setting when the voltage drops, see the description of the procedure on

this page.

Telemetry

Sets the limiter voltage

(Voltage that sounds an alarm)

Alarm and Vibrator function setup

1

(Limit adjustment)

Tap the [Limit]. Value input buttons appear on the screen.

Use the [+] or [-] button to adjust the limit voltage.

2

(Alarm function setup)

Tap the [Alarm] type and select [Inhibit], [Buzzer]or [Voice].

"Inhibit" :No audible alarm

"Buzzer" :Audible alarm

"Voice" :Voice alarm

Current receiver battery voltage

The minimum and maximum when

powering ON are shown.

Alarm/vibrator ON/OFF and type

setting (The

alarm is generated when the power

supply voltage drops below the set

value.)

The Speech function (ON/OFF)

arrow indicates that an

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Setting

- Tap alarm type.

Inhibit/ Buzzer/ Voice

154

3

(Vibrator function setup)

Function

Tap the [Vibrator] type and select [Inhibit], [Type 1], [Type 2],

or [Type 3].

"Inhibit" :No active vibration

"Type1" :Continuous vibration

"Type2" :Intermittent vibration for a long time

"Tyoe3" :Intermittent vibration for a short time

4

(Speech function setup)

Setting

- Tap Vibrator type.

TInhibit/ Type 1/ Type 2/ Type 3

Setting

- Tap (ON) / (OFF).

Tap the "Voice" (ON) or (OFF) to select ON / OFF.

"OFF" :No voice guide

"ON" :Information loaded by voice

5

When fi nished, return to the Telemetry screen by pressing the HOME button.

Telemetry

*The voice guide loading inter-

val is set by sensor menu.

Page 39

Telemetry :The Drive Battery Voltage

With an external power supply, one voltage of the batteries (drive battery, servo power supply battery, etc.) mounted separately in the chassis can be displayed at the transmitter. The

receiver S.BUS2 connector is used to connect the SBS-01V sensor and the battery.

* A drive battery sensor must be installed in the model car. Install and connect the sensor in accordance

with the sensor instruction manual.

Telemetry Current drive battery voltage

The minimum and maximum when

powering ON are shown.

Alarm/vibrator ON/OFF and type

setting (The

alarm is generated when the power

supply voltage drops below the set

value.)

arrow indicates that an

Sets the limiter voltage

(Voltage that sounds an alarm)

Alarm and Vibrator function setup

1

(Limit adjustment)

Tap the [Limit]. Value input buttons appear on the screen.

Use the [+] or [-] button to adjust the limit voltage.

2

(Alarm function setup)

Tap the [Alarm] type and select [Inhibit], [Buzzer]or [Voice].

"Inhibit" :No audible alarm

"Buzzer" :Audible alarm

"Voice" :Voice alarm

3

(Vibrator function setup)

Tap the [Vibrator] type and select [Inhibit], [Type 1], [Type 2],

or [Type 3].

"Inhibit" :No active vibration

"Type1" :Continuous vibration

"Type2" :Intermittent vibration for a long time

"Tyoe3" :Intermittent vibration for a short time

4

(Speech function setup)

Tap the "Voice" (ON) or (OFF) to select ON / OFF.

"OFF" :No voice guide

"ON" :Information loaded by voice

The Speech function (ON/OFF)

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Setting

- Tap alarm type.

Inhibit/ Buzzer/ Voice

Setting

- Tap Vibrator type.

TInhibit/ Type 1/ Type 2/ Type 3

Setting

- Tap (ON) / (OFF).

*The voice guide loading inter-

val is set by sensor menu.

Function

5

When fi nished, return to the Telemetry screen by pressing the HOME button.

Telemetry

155

Page 40

Telemetry :RPM

Speed information from an SBS-01RM (telemetry rotation sensor) sold separately is displayed and set at this screen. The speed of the engine, motor, etc. of the chassis while running can be viewed at the transmitter. When the speed becomes higher (lower) than the set

speed, it can be announced by an alarm and vibration.

* A RPM sensor must be installed in the model car. Install and connect the sensor in accordance with the

sensor instruction manual.

Telemetry

Current RPM

The maximum when powering

ON are shown.

Alarm and vibrator ON/OFF and

type setting (The

that an alarm is generated when the

speed drops below the set value and

the

arrow indicates that an alarm is

generated when the speed exceeds

the set value.)

arrow indicates

Sets the limit speed

Upper limit/ lower limit

(Speed that sound an alarm)

Alarm and Vibrator function setup

1

(Gear ratioadjustment)

Tap the [Gear ratio]. Value input buttons appear on the

screen.

Use the [+] or [-] button to adjust the Gear ratio.

2

(Limit adjustment)

Tap the "

" [

Limit] or "

Use the [+] or [-] button to adjust the limit voltage.

3

(Alarm and vibrator function setup)

Function

Tap the "

"Inhibit":No audible alarm/ "Buzzer":Audible alarm/ "Voice":Voice alarm

Tap the "

"Inhibit" :No active vibration

"Type1" :Continuous vibration

"Type2" :Intermittent vibration for a long time

"Tyoe3" :Intermittent vibration for a short time

" / ""

[Alarm] type and select [Inhibit], [Buzzer]or [Voice].

" / ""

[Vibrator] type and select [Inhibit], [Type 1], [Type 2], or [Type 3].

Gear ratio

The Speech function (ON/OFF)

" [

Limit]. Value input buttons appear on the screen.

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

156

4

(Speech function setup)

Tap the "Voice" (ON) or (OFF) to select ON / OFF.

"OFF" :No voice guide

"ON" :Information loaded by voice

5

When fi nished, return to the Telemetry screen by pressing the HOME button.

Telemetry

*The voice guide loading inter-

val is set by sensor menu.

Page 41

Telemetry :Temperature

This screen displays and sets the temperature information from an SBS-01T (telemetry

temperature sensor) sold separately. The temperature of the engine, motor, amp, etc. of the

chassis while running can be viewed at the transmitter. When the temperature becomes

higher (lower) than the set value, it can be announced by an alarm and vibration.

* A temperature sensor must be installed in the model car. Install and connect the sensor in accordance

with the sensor instruction manual.

Telemetry

Current temperature

The minimum and maximum the

when powering ON are shown.

Limit temperature setting

(Temperature that sounds

an alarm)

Alarm and Vibrator function setup

1

(Limit adjustment)

Tap the "

" [

Limit] or "

" [

Limit]. Value input buttons appear on

the screen.

Use the [+] or [-] button to adjust the limit voltage.

2

(Alarm and vibrator function setup)

Tap the "

" / ""

[Alarm] type and select [Inhibit], [Buzzer]or

[Voice].

"Inhibit":No audible alarm/ "Buzzer":Audible alarm/ "Voice":Voice alarm

Tap the "

" / ""

[Vibrator] type and select [Inhibit], [Type 1],

[Type 2], or [Type 3].

"Inhibit" :No active vibration

"Type1" :Continuous vibration

"Type2" :Intermittent vibration for a long time

"Tyoe3" :Intermittent vibration for a short time

Alarm and vibrator ON/OFF and

type setting (The

that an alarm is generated when the

speed drops below the set value and

the

arrow indicates that an alarm is

generated when the speed exceeds

the set value.)

The Speech function (ON/OFF)

Adjustment buttons

- Adjust with the [+] and [-] buttons.

- Return to the initial value by

tapping the [reset] buttons.

Setting

- Tap alarm type.

Inhibit/ Buzzer/ Voice

Setting

- Tap Vibrator type.

TInhibit/ Type 1/ Type 2/ Type 3

arrow indicates

Function

3

(Speech function setup)

Tap the "Voice" (ON) or (OFF) to select ON / OFF.

"OFF" :No voice guide

"ON" :Information loaded by voice

4

When fi nished, return to the Telemetry screen by pressing the HOME button.

Telemetry

Setting

- Tap (ON) / (OFF).

*The voice guide loading inter-

val is set by sensor menu.

157

Page 42

Telemetry :The Drive Battery Electric Current

When the SBS-01C (electric current sensor) sold separately is mounted on the vehicle, the

electric current, voltage and consumption capacity of the power battery, etc., can be displayed.

* A drive battery electric current sensor must

be installed in the model car. Install and

connect the sensor in accordance with the

sensor instruction manual.