Page 1

7CAP / 7CHP

T

7 CHANNEL RADIO CONTROL SYSTEM

INSTRUCTION MANUAL

echnical updates and additional programming examples available at: www.futaba-rc.com\faq\7c-faq.html

Entire Contents © Copyright 2003

1M23N13602

Page 2

INTRODUCTION .............................3

Additional Technical Help, Support and Service .....3

Application, Export and Modification .............4

Meaning of Special Markings ...................5

Safety Precautions (do not operate without reading) . .5

Introduction to the 7C . . .......................7

Contents and Technical Specifications ............9

Accessories . ..............................10

Transmitter Controls &

Switch Identification/Assignments ..............11

Charging the Ni-Cd Batteries ..................14

Stick Adjustments ...........................15

Radio Installation ...........................16

Range Checking & Aircraft Frequencies..........17

Transmitter Displays and Buttons . ..............18

Warning and Error Displays ...................19

AIRPLANE FUNCTIONS

Map of Functions . . . ........................21

Quick Guide to Setting up a 4-channel Airplane ....22

ACRO BASIC MENU FUNCTIONS ................25

MODEL Submenu: MODEL SEL. , COPY and NAME . .25

Parameter(PARA.) Submenu:

RESET,TYPE,MODUL,

CH5 & CH7

..............................28

Servo REVERSE .............................31

End Point (E. POINT) .......................32

Idle Management: THR-CUT

Dual Rates and Exponential ( D/R,EXP ).........34

TIMER ...................................37

TRAINER ..................................38

TRIM ...................................39

SUB-TRIM .................................40

Fail Safe (F/S) .............................41

ACRO ADVANCE MENU FUNCTIONS . . . .......42

Wing types . ...............................42

(FLAPRN)Flaperon ...................43

(FL-TRIM)Flap Trim ...................44

ELEVON (see tail types) ...................45

Tail types .................................45

ELEVON ................................45

V-TAIL ..................................46

SNAP ROLL................................47

Mixes: definitions and types ...................48

ELE-FLP ................................49

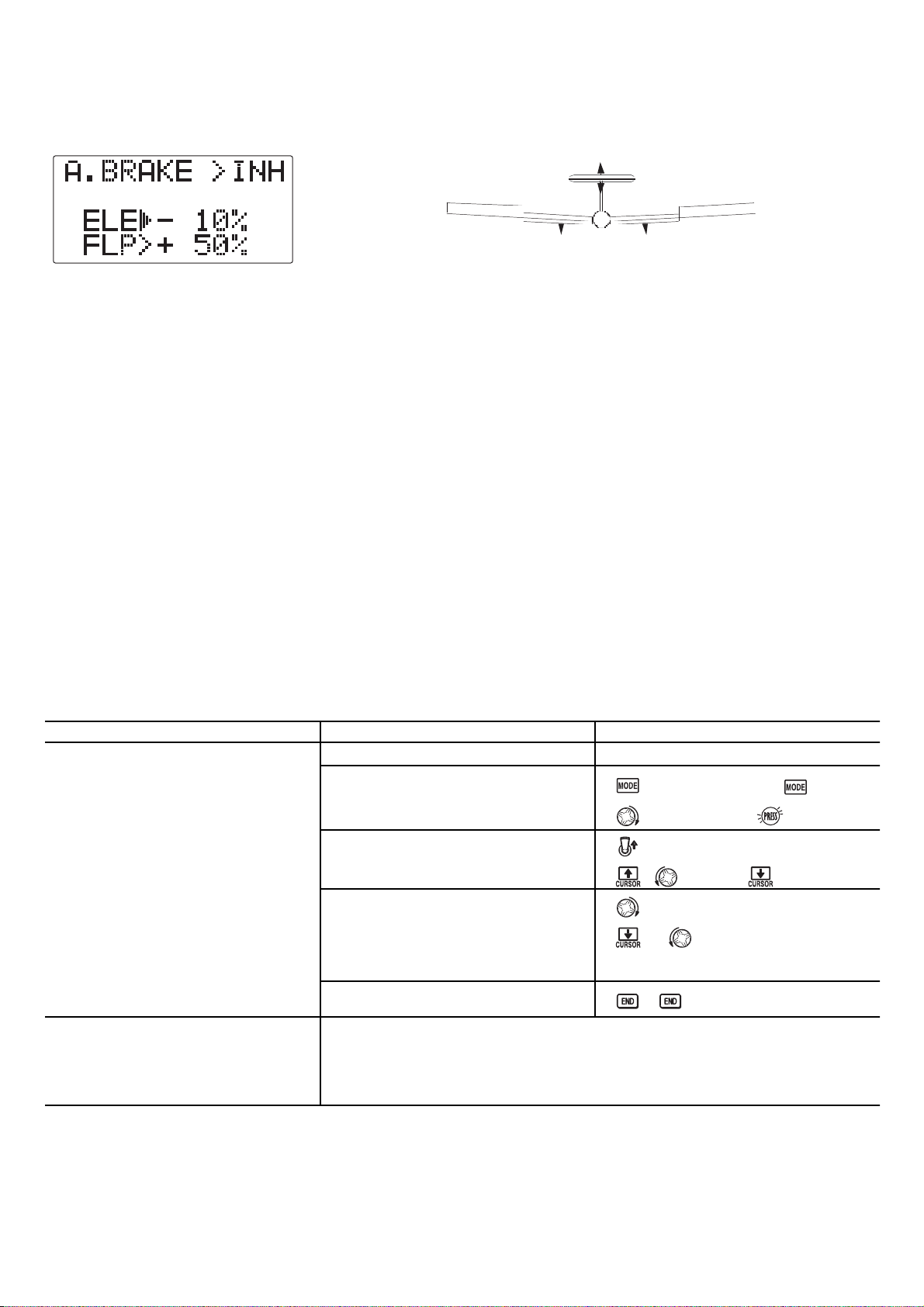

Air Brake (A.BRAKE) ......................52

FLP-ELE ................................50

AIL-RUD ................................51

Prog. Mixes (P-MIX1-3) .................53

Other Equipment . . . ..........................56

HELICOPTER FUNCTIONS ...................57

Table of contents and reference info for helicopters . .57

Getting Started with a Basic Helicopter . . . . . . . . . .58

HELI-SPECIFIC BASIC MENU FUNCTIONS . . . . .61

MODEL TYPE (PARA. submenu) . . . . . . . . . .61

SWASH AFR (swashplate surface direction and

travel correction) (not in H1 )..............63

Setting up the Normal Flight Condition . . . . . . .65

TH-CUT (specialized settings for helicopter specific

models)................................66

HELI-SPECIFIC ADVANCE MENU FUNCTIONS. . .67

Throttle Hold (TH-HOLD) ...................67

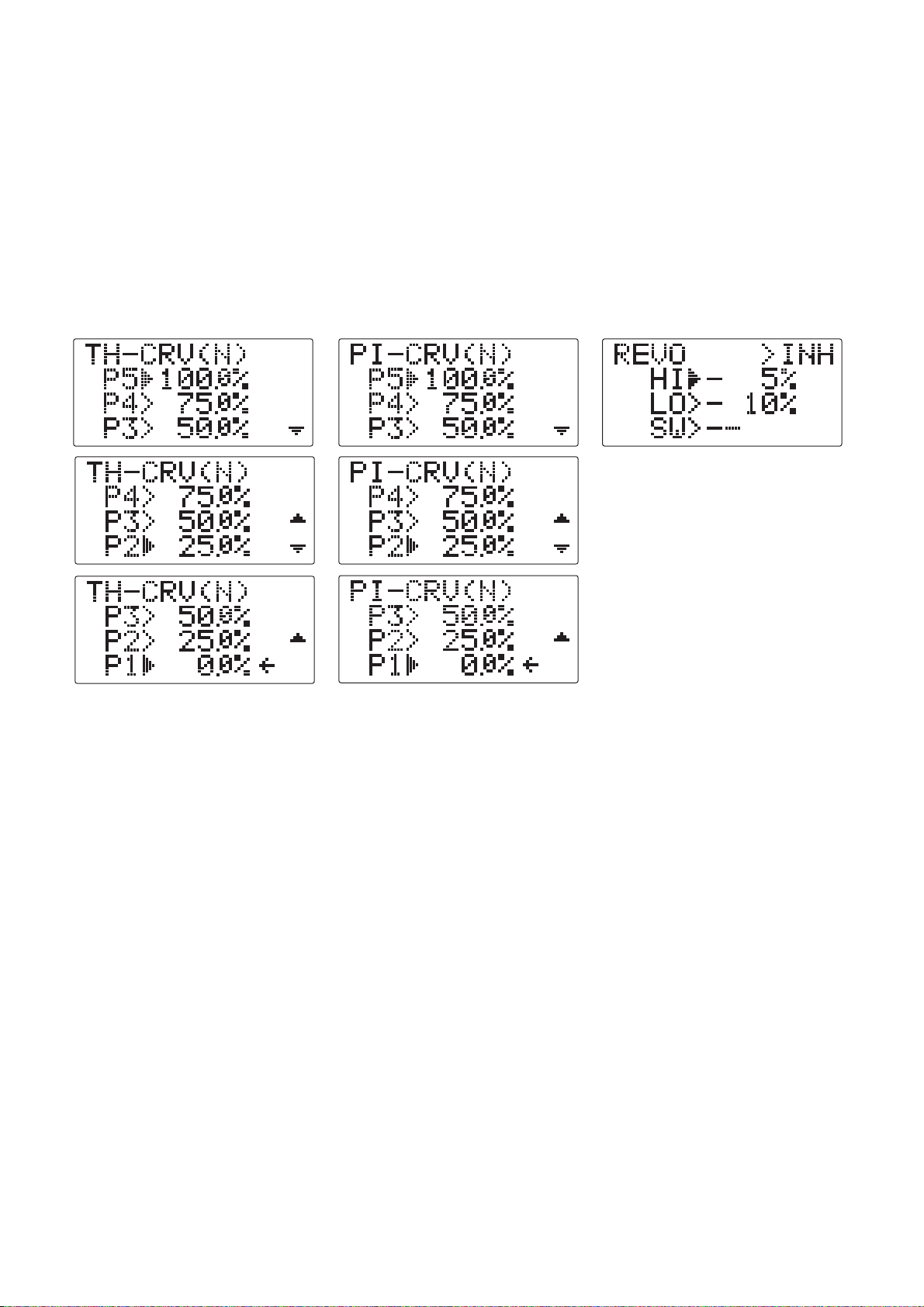

TH-CRV, PI -CRV and Revolution Mix(REVO).....68

Idle-ups . . . . . ...........................69

Trims/offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Hovering setups . . . . . . . . . . . . . . . . . . . . . . . . . .71

Gyros . . . ..............................72

Glossary . . . .................................74

Note that in the text of this manual, beginning at this point,

any time we are using a featureís specialized name or

abbreviation, as seen on the screen of the 7C, that name,

feature,or abbreviationwill beexactly asseen on the radio's

screen, including capitalization, and shown in a DIFFERENT

TYPE S TYLE for clarity . Any time we mention a specific

control on the radio itself, such as moving SWITCH A,KNOB

VR,ortheTHROTTLE STICK, those words will be

displayed as they are here.

2

TABLE OF CONTENTS

......................20

...................33

Page 3

INTRODUCTION

Thank you for purchasing a Futaba

®

7C series digital proportional R/C system. This system is extremely versatile and may

be used by beginners and pros alike. In order for you to make the best use of your system and to fly safely, please read this

manual carefully. If you have any difficulties while using your system, please consult the manual, our online Frequently

Asked Questions (on the web pages referenced below), your hobby dealer, or the Futaba Service Center.

Owner's Manual and Additional Technical Help

This manual has been carefully written to be as helpful to you, the new owner, as possible. There are many pages of setup

procedures and examples. However, it need not be your sole resource of setup guidelines for your 7C. For example, pages

22-24 include setup instructions for a basic 4-channel airplane. The Frequently Asked Questions web page referenced

below includes this type of step-by-step setup instructions for a variety of other model types, including multi-engine,

complex gear installation, 7-servo aerobatic models, 140 degree CCPM, etc.

Due to unforeseen changes in production procedures, the information contained in this manual is subject to change without notice.

Support and Service: It is recommended to have your Futaba equipment serviced annually during your hobby's "off

season" to ensure safe operation.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and programming. Please be sure to

regularly visit the 7C Frequently Asked Questions web site at www.futaba-rc.com\faq\faq-7c.html. This page includes

extensive programming, use, set up and safety information on the 7C radio system and is updated regularly. Any technical

updates and US manual corrections will be available on this web page. If you do not find the answers to your questions there,

please see the end of our F .A.Q. area for information on contacting us via email for the most rapid and convenient response.

Donít have Internet access? Internet access is available at no charge at most public libraries, schools, and other public

resources. We find internet support to be a fabulous reference for many modelers as items can be printed and saved for future

reference, and can be accessed at any hour of the day, night, weekend or holiday. If you do not wish to access the internet for

information, however, don't worry. Our support teams are available Monday through Friday 8-5 Central time to assist you.

FOR SERVICE ONLY: FOR SUPPORT :

Hobby Services (U.S. only) (PROGRAMMING AND USER QUESTIONS)

3002N, Apollo Drive, Suite 1 Please start here for answers to most questions:

Champaign, IL 61822 U.S.A. www.futaba-rc.com\faq\faq-7c.html

(217)398-0007

www.hobbyservices.com

FACSIMILE: 217-398-7721

PHONE: 217-398-8970 option 4

OUTSIDE NORTH AMERICA

Please contactyour Futaba importer in your region of the world to assist you withany questions, problemsor service needs.

Please recognize that all information in this manual, and all support availability, is based upon the systems sold in North

America only. Products purchased elsewhere may vary. Always contact your region's support center for assistance.

3

Page 4

Application, Export, and Modification

1. This product may be used for model airplane or surface (boat, car, robot) use, if on the correct frequency. It is not

intended for use in any application other than the control of models for hobby and recreational purposes. The product is

subject to regulations of the Ministry of Radio/Telecommunications and is restricted under Japanese law to such purposes.

2. Exportation precautions:

(a) When this product is exported from the country of manufacture, its use is to be approved by the laws governing the

country of destination which govern devices that emit radio frequencies. If this product is then re-exported to other

countries, it may be subject to restrictions on such export. Prior approval of the appropriate government authorities may

be required. If you have purchased this product from an exporter outside your country, and not the authorized Futaba

distributor in your country, please contact the seller immediately to determine if such export regulations have been met.

(b) Use of this product with other than models may be restricted by Export and Trade Control Regulations, and an application

for export approval must be submitted. In the US, use of 72MHz (aircraft only), 75MHz (ground models only) and 27MHz

(both) frequency bands are strictly regulated by the FCC. This equipment must not be utilized to operate equipment other than

radio controlled models. Similarly , other frequencies (except 50MHz, for HAM operators) must not

be used to operate models.

3. Modification, adjustment, and replacement of parts: Futaba is not responsible for unauthorized modification, adjustment, and

replacement of parts on this product. Any such changes may void the warranty.

The Following Statement Applies to the Receiver (for U.S.A.)

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesirable operation.

The RBRC™SEAL on the nickel-cadmium battery contained in Futaba products indicates that Futaba

Corporation of America is voluntarily participating in an industry-wide program to collect and recycle these

batteries at the end of their useful lives, when taken out of service within the United States. The RBRC

™

program provides a convenient alternative to placing used nickel-cadmium batteries into the trash or municipal

waste system, which is illegal in some areas.

(for USA)

You may contact your local recycling center for information on where to return the spent battery. Please call

1-800-8-BATTERY for information on Ni-Cd battery recycling in your area. Futaba Corporation of America’ s involvement

in this program is part of its commitment to protecting our environment and conserving natural resources.

NOTE: Our instruction manuals encourage our customers to return spent batteries to a local recycling center in order to

keep a healthy environment.

RBRC is a trademark of the Rechargeable Battery Recycling Corporation.

4

Page 5

Meaning of Special Markings

Pay special attention to safety where indicated by the following marks:

DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out properly.

WARNING -Procedures which may lead to a dangerous condition or cause death or serious injury to the user if not

carried out properly, or procedures where the probability of superficial injury or physical damage is high.

CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of injury, or

physical damage, if not carried out properly.

=Prohibited = Mandatory

Warning: Always keep electrical components away from small children.

FLYING SAFETY

To ensure the safety of yourself and others, please observe the following precautions:

Have regular maintenance performed. Although your 7C protects the model memories with non-volatile EEPROM

memory (which does not require periodic replacement) and nota battery,it still shouldhave regular checkups for wear

and tear. We recommend sending your system to the Futaba Service Center annually during your non-flying-season

for a complete checkup and service.

Ni-Cd Battery

Charge the batteries! (See Charging the Ni-Cd batteries, p. 14, for details.) Always recharge the transmitter and

receiver batteries for at least 15 hours before each flying session. A low battery will soon die, causing loss of contro

and a crash. When you begin your flying session, reset your 7C's built-in timer, and during the session pay attention

to the duration of usage.

Stop flying long before your batteries become low on charge. Do not

rely on your radioís low battery warning

systems, intended only as a precaution, to tell you when to recharge. Always check your transmitter and

receiver batteries prior to each flight.

Where to Fly

We recommend that you fly at a recognized model airplane flying field. You can find model clubs and fields by asking

your nearest hobby dealer, or in the US by contacting the Academy of Model Aeronautics.

Youcan also contactthe national Academy of Model Aeronautics (AMA), which has morethan 2,500 chartered clubs across the

country . Through any one of them, instructor training programs and insured newcomer training are available. Contact the AMA

at the address or toll-free phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

or via the Internet at http:\\www.modelaircraft.org

5

Page 6

Always pay particular attention to the flying field'srules, as well as the presence and location of spectators, the

I

l

A

A

a

wind direction, and any obstacles on the field. Be very careful flying in areas near power lines, tall buildings, or

communication facilities as there may be radio interference in their vicinity.

f you must fly away from a club field, be sure there are no other modelers flying within a three-to-five-mile range,oryoumay

ose control of your aircraft or cause someone else to lose control.

t the flying field

Before flying, be sure that the frequency you intend to fly with is not in use, and secure any frequency control

device (pin, tag, etc.) for that frequency before turning on your transmitter. It is never possible to fly two or more

models on the same frequency at the same time. Even though there are different types of modulation (AM, FM,

PCM), only one model may be flown on a single frequency at any one time.

To prevent possible damage to your radio gear, turn the power switches on and off in the proper sequence:

1. Pull throttle stick to idle position, or otherwise disarm your motor/engine.

2. Turn on the transmitter power and allow your transmitter to reach its home screen.

3. Confirm the proper model memory has been selected.

4. Fully extend the transmitter antenna.

5. Turn on your receiver power.

6. Test all controls. If a servo operates abnormally, donít attempt to fly until you determine the cause of the problem.

(For PCM systems only: Test to ensure that the FailSafe settings are correct by waiting at least 2 minutes after

adjusting and then turning the transmitter off and confirming the proper surface/throttle movements. Turn the

transmitter back on.)

7. Start your engine.

8. Complete a full range check (see p. 17).

9. After flying, bring your throttle stick to idle position, engage any kill switches or otherwise disarm your motor/engine.

10. Turn off receiver power.

11.Turn off transmitter power.

If you do not turn on your system in this order, you may damage your servos or control surfaces, flood your engine, or in the

case of electric-powered or gasoline-powered models, the engine may unexpectedly turn on and cause a severe injury.

While you are getting ready to fly, if you place your transmitter on the ground, be sure that the wind won't tip

it over. If it is knocked over, the throttle stick may be accidentally moved, causing the engine to speed up. Also,

damage to your transmitter may occur.

Before taxiing, be sure to extend the transmitter antenna to its full length.

collapsed antenna will reduce your flying range and cause a loss of control. It is a good idea to avoid pointing the transmitter

ntenna directly at the model, since the signal is weakest in that direction.

Don't fly in the rain! Water or moisture may enter the transmitter through the antenna or stick openings and cause erratic

operation or loss of control. If you must fly in wet weather during a contest, be sure to cover your transmitter with a plastic

bag or waterproof barrier. Never fly if lightning is expected.

6

Page 7

AQUICK INTRODUCTION TO THE 7C SYSTEM

TRANSMITTER:

•

Large graphic liquid-crystal display panel with 4 buttons and an easy set up turn-and-press Dial for quick, easy setup.

•

All transmitters include all 2 aircraft types with specialized programming for each, including:

•

Airplane (ACRO)

•

V-TAIL

•

Twin Aileron Servos (FLAPRN )

•

ELEVON

•

Air Brake

•

Snap Roll

•

Helicopter (6 swashplate types, including CCPM, see page 61)

•

2 Idle Ups

•

Throttle and Pitch Curves per Condition

•

Revo. Mixing

•

Gyro Mixing including Separate Settings per Condition

•

BASIC menu for quick, easy set up of less complex models.

•

ADVANCE menu for more complex, unique setups.

•

Four electronic TRIM LEVERS for rapid yet precise trim adjustment - no remembering to "store trims" between models

and no more "bumped trims" during transport.

•

TH-CUT (ACRO/HELI) (engine shut off) setups to allow precise engine control for taxi and landings.

•

10 complete model memories

•

New stick design with improved feel, adjustable length and tension.

•

Triple rates available by setting dual rates to 3-position switches.

•

Six SWITCHES DIALand 1 ; assignable in some applications.

•

Trainer system includes the "functional" (F )setting, which allows the student to use the 7C's mixing, helicopter, and

other programming functions even with a 4-channel buddy box. (Optional trainer cord required.)

•

Transmits in both FM (PPM)andPCM by selecting modulation/cycling transmitter. Requires receiver of proper modulation.

•

Permanent memory storage via EEPROM with no backup battery to service or have fail.

•

7CA transmitter features airplane friendly switch layout, with the trainer switch at the left hand, and a notched throttle

to minimize throttle changes with rudder input. Defaults to ACR O MODEL T YPE.

•

7CH transmitter features helicopter-friendly switch layout, with idle-up switch at the left hand, and

a smooth, ratchet-less (unsprung) throttle for perfect hovering. Defaults to H-1 MODEL TYPE.

Note that in the text of this manual, beginning at this point, any time we are usinga featureís specialized name or abbreviation

as seen on the screen of the 7C, that name, feature, or abbreviation will be exactly as seen on the radioís screen, including

capitalization, and shown in a DIFFERENT TYPESTYLE for clarity. Any time we mention a specific control on the radio itself,

such as moving S

WITCH A, KNOB VR,ortheTHROTTLE STICK, those words will be displayed as they are here.

7

In North America it is against FCC regulation to change the crystal within the transmitter to a different

•

channel. All such transmitter crystal changes must be performed by a certified radio technician. Failure to properly tune

a system to its new channel may result in decreased range and may also result in interference to other types of frequency

users on adjoining channels. Doing so also voids your AMA insurance.

Page 8

SERVOS

• Please see technical specifications page for specifics on the servos included with your system.

• The included receiver is compatible with all J-plug Futaba servos, including retract, winch, and digital servos.

8

RECEIVER: R127DF/R138DP

e

s

n

t

l

o

0

r

The R127DF FM 7-channel or the R138DP PCM 7-channel receiver included with your system is a high-sensitivity

•

narrow-band dual-conversion receiver.

Any Futaba narrow band FM receiver (all produced after 1991) on the correct frequency band and frequency may b

•

used with the 7C.

Any Futaba PCM 1024 receiver on the right frequency band and frequency may be used with the 7C (all 1024 receiver

•

say PCM1024; receivers which say PCM but not 1024 are 512 resolution and not compatible).

NEVER attempt to change a receiver's band

a 75MHz crystal). A receiver that has a crystal installed from a different frequency band without retuning will no

receive properly and will have dramatically decreased range.

In NorthAmerica the receiver included with this system mayhave its frequency changed by simply changing the crysta

•

as long as it remains in the same half the band. A low band receiver between channels 11 and 35 may be changed t

any other channel between 11 and 35 without requiring any tuning. A high band receiver between channels 36 and 6

may similarly be changed. Receivers being changed from a high band channel to a low bandor vice versa require prope

tuning and service by the Futaba Service Center.

by simply changing crystal (I.E. removing a 72MHz crystal and inserti

Page 9

•

R127DF Receiver or R138DP Receiver

•

Servos, S3004, S3151, S3003 or S3001, with mounting

hardware and servo arm assortment

•

Switch harness

•

Aileron extension cord

•

110V wall charger (North America)

•

Frequency Flag

Transmitter T7CAP/T7CHP

Operating system: 2-stick, 7 channels

Transmitting frequency: 50 or 72 MHz bands

Modulation: FM/PPM or PCM, switchable

Power supply: 9.6V NT8S600B Ni-Cd battery

Current drain: 250 mA

Receiver R138DP

(PCM Dual conversion)

Receiving frequency: 50 or 72 MHz bands

Intermediate freq.: 10.7 MHz & 455 kHz

Power requirement: 4.8 - 6.0V Ni-Cd battery

Current drain: 16 mA

Size: 2.56 x 1.42 x 0.85 (65 x 36 x 21.5 mm)

Weight: 1.42 oz (40.3 g)

Channels: 8

Receiver R127DF

(FM Dual conversion)

Receiving frequency: 50 or 72 MHz bands

Intermediate freq.: 10.7MHz & 455 kHz

Power requirement: 4.8 - 6.0V Ni-Cd battery

Current drain: 10 mA

Size: 2.53 x 1.41 x 0.83 (64.3 x 35.8 x 21.0 mm)

Weight: 1.43 oz (40.5 g)

Channels: 7

Servo S3151 ( Standard, digital )

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8V (from receiver)

Output torque: 43.0 oz-in(3.1 kg-cm) at 4.8V

Operating speed: 0.21 sec/60 at 4.8V

Size: 1.59 x 0.79 x 1.42 (40.5 x 20 x 36.1 mm)

Weight: 1.48 oz (42 g)

Servo S3001 (Standard, ball-bearing)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 - 6.0V (from receiver)

Output torque: 41.7 oz-in (3.0 kg-cm)

Operating speed: 0.22 sec/60

Size: 1.59 x 0.78 x 1.41 (40.4 x 19.8 x 36 mm)

Weight: 1.59 oz (45.1g)

Servo S3003/S3004 (Standard/ball-bearing)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 - 6.0V (from receiver)

Output torque: 44.4 oz-in (3.2 kg-cm) at 4.8V

Operating speed: 0.23 sec/60 at 4.8V

Size: 1.59 x 0.78 x 1.41 (40.4 x 19.8 x 36 mm)

Weight: 1.31 oz (37.2 g)

9

CONTENTS AND TECHNICAL SPECIFICATIONS

(Specifications and ratings are subject to change without notice.)

Your 7CAP or 7CHP (packaged with a 7-channel PCM receiver or a 7-channel FM receiver) system includes

the following components:

Page 10

T

he followingadditional accessories areavailable fromyour dealer. Refer to a Futaba catalog for more information:

NT8S Transmitter battery pack - the (600mAh) transmitter Ni-Cd battery pack may be easily exchanged with a fresh

•

one to provide enough capacity for extended flying sessions.

Trainer cord - the optional training cord may be used to help a beginning pilot learn to fly easily by placing the instructor on

•

a separate transmitter . Note that the 7C transmitter may be connected to another 7C system, as well as to many other models

of Futabatransmitters. The7C transmitter uses the newerrectangular type cord plug. Bothnew-to-new and new-to-round plug

style trainer cords are available.

FTA8 Neckstrap - a neckstrap may be connected to your T7C systemto make it easier tohandle and improve your flying

•

precision, since your hands won't need to support the transmitter's weight.

Y-harnesses, servo extensions, etc - Genuine Futaba extensions and Y-harnesses, including a heavy-duty version with heavier

•

wire, are available to aid in your larger model and other installations.

5-cell (6.0V) receiver battery packs - All Futaba airborne equipment (except that which is specifically labeled otherwise) is

•

designed towork with 4.8V(Ni-Cd 4 cells)or 6.0V (Ni-Cd5 cells oralkaline 4 cells).Using a 6.0V pack increases the current

flow to the servos, which accelerates their rate of response and their torque. However , because of this faster current draw, a 5cell battery pack of the same mAh rating will last approximately æ the time of a 4-cell pack.

R309DPS - Synthesized receiver which can be changed to any 72MHz frequency with the turn of 2 dials, no tuning needed.

•

Gyros-avariety of genuine Futaba gyros are available for your aircraft or helicopter needs. See p. 56 for aircraft or

•

p. 72 for helicopter gyro information.

10

Page 11

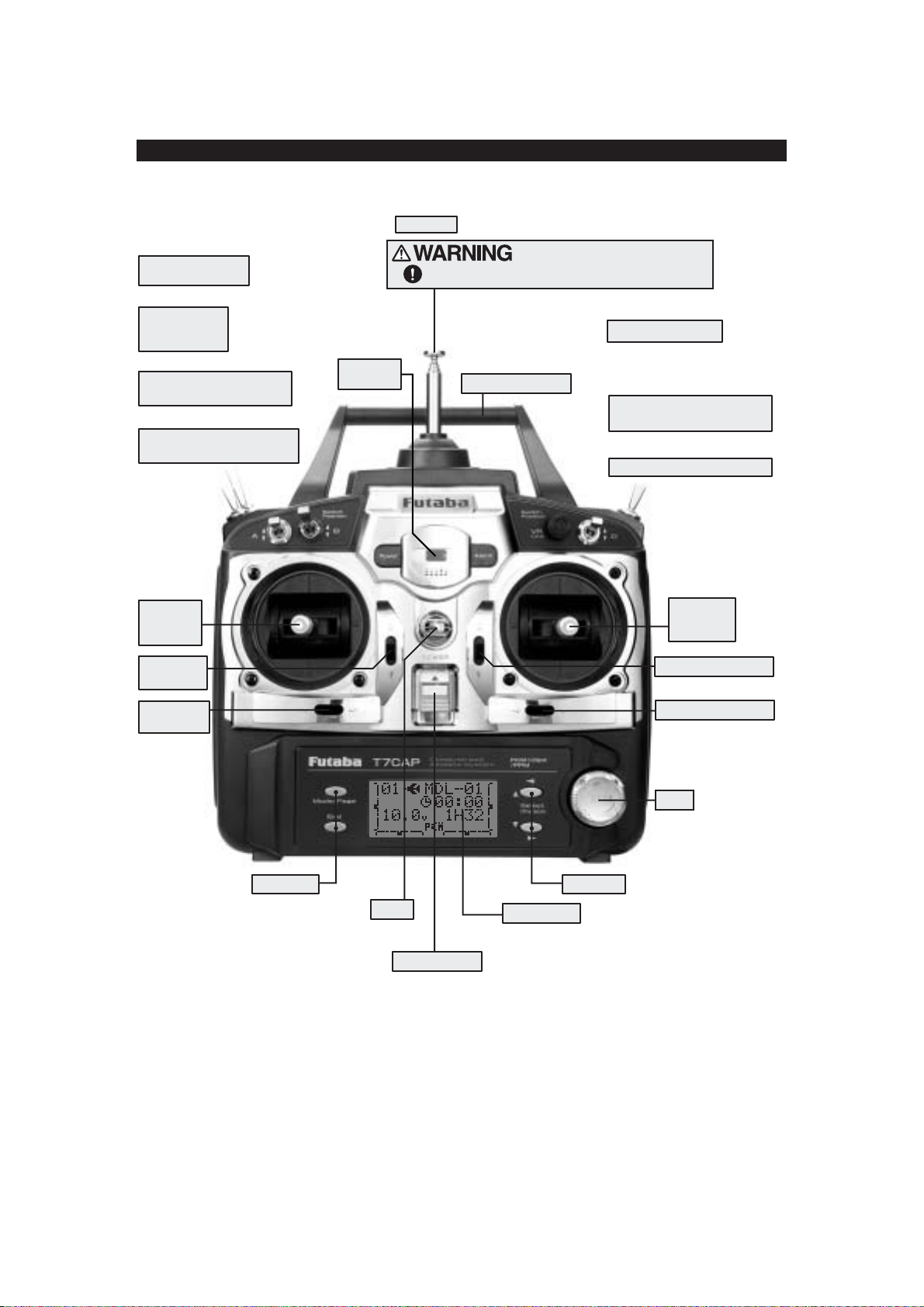

TRANSMITTER CONTROLS - AIRPLANE

SW(F)

Snap Roll or

Trainer Switch

SW(E)

Landing Gear

Switch

/CH5

SW(B)

Rudder Dual Rate Switch

/CH7

SW(A)

Elevator Dual Rate Switch

/TH-CUT/P-MIX/TIMER

Rudder

/Throttle

Stick

Throttle

Trim Lever

Power

LED*

Antenna

Be careful not to bend your antenna when you

collapse or extend it.

Antenna must be fully extended when flying.

VR

Carrying Handle

SW(G)

SW(D)

Flap Trim Control

This controls CH6, and if flaperon mixing

is activated controls the flap.

Elevator - Flap Mixing or

Airbrake Mixing Switch

Aileron Dual Rate Switch

Elevator

/Aileron

Stick

Elevator Trim Lever

Rudder

Trim Lever

Edit Keys

Hook

(for optional neckstrap)

Power Switch

(Up position: ON)

Edit keys

LCD Panel

Aileron Trim Lever

Dial

This figure shows the default switch assignments for a Mode 2 system as supplied by the factory.

You can change many of the switch positions or functions by selecting a new position within

the setting menu for the function you wish to move. (Example: move aileron dual rates to switch G

to create triple rates. See p. 34 for details.)

*Power LED blinks to indicate if any mix switches are activated.

11

Page 12

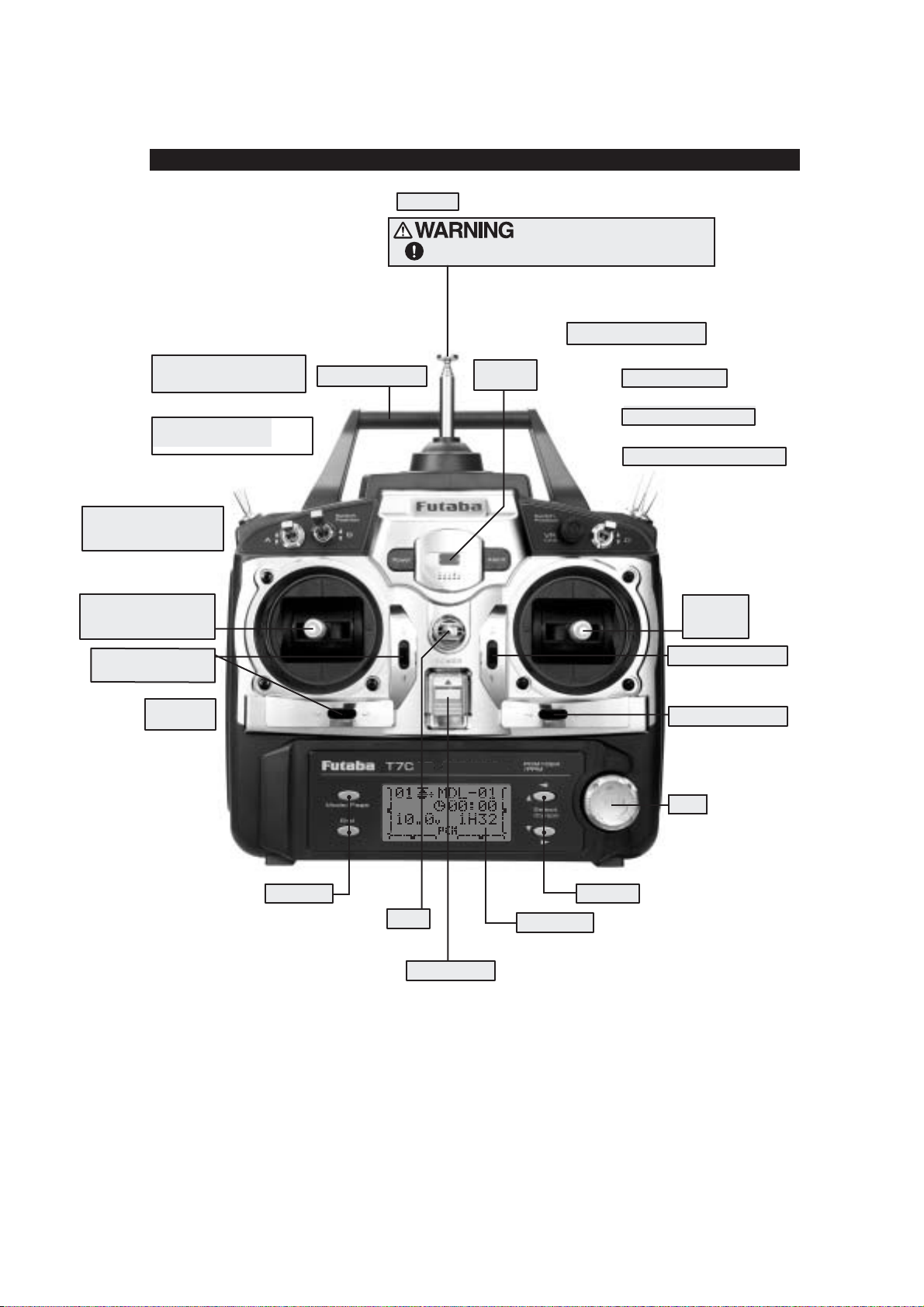

TRANSMITTER CONTROLS - H E L I

SW(B)

Rudder Dual Rate Switch

/CH7

SW(A)

Elevator Dual Rate Switch

/TH-CUT/P-MIX/TIMER

SW(E)

Idle-up 1&2 Switch

/CH5/OFFSET/GYRO

Throttle/Collective

Pitch & Rudder Stick

Throttle/Collective

Trim Lever

Antenna

Carrying Handle

Be careful not to bend your antenna when you

collapse or extend it.

Antenna must be fully extended when flying.

VR

Hovering - Pitch Knob

Power

LED*

SW(H)

Trainer Switch

SW(G)

Throttle - Hold Switch

SW(D)

Aileron Dual Rate Switch

Elevator

/Aileron

Stick

Elevator Trim Lever

Rudder

Trim Lever

Edit Keys

Hook

(for optional neckstrap)

Power Switch

(Up position: ON)

Edit keys

LCD Panel

Aileron Trim Lever

Dial

This figure shows the default switch assignments for a Mode 2 system as supplied by the factory.

You can change many of the switch positions or functions by selecting a new position within

the setting menu for the function you wish to move.

*Power LED blinks to indicate if any mix switches are activated.

12

Page 13

Trainer connector

t

5

Ni-Cd battery pack

Charging jack

Battery connector location

Battery cover

NOTE: If you need to remove or replace the transmitter battery, do not pull on its wires to remove it. Instead,

gently pull on the connector's plastic housing where it plugs into the transmitter.

SWITCH ASSIGNMENT TABLE

The factory default functions activated by the switches and knobs for a Mode 2 transmitter are shown below.

•

Most 7C functions may be reassigned to non-default positions quickly and easily.

•

Basic control assignments of channels 5 & 7 are quickly adjustable in PARA (see p. 28). For example, the channel

•

servo, which defaults to SWITCH E for retract use, can easily be unassigned (NULL)toallowfor easy use as a second

rudder servo in a mix, or to a dial for bomb door or other control.

Note that most functions need to be activated in the programming to operate.

•

Mode 1 transmitter functions are similar but reverse certain switch commands. Always check that you have the desired

•

switch assignment for each function during set up.

Switch/Knob Airplane (AC R O)Helicopter (HELI)

AorHTx.

WITCH A elevator dual rate elevator dual rate

S

Switch B rudder dual rate rudder dual rate

WITCH D aileron dual rate aileron dual rate

S

Switch E

Switch F

WITCH G OR E* idle-up 1 and 2,

S

NOB VR flap/ch 6 HOVERING PIT

K

OR G* landing gear/ch 5 throttle hold

OR H* snap roll/trainer trainer

up = ELE-FLP on

down = AIRBRAKE on

ch5/OFFSET/GYRO

(flap trim if FLAPERONon)

*On the 7CA transmitters, the TOP LEFT SWITCHES are spring-loaded and 3-position; on the 7CH, those switches are on the rightside. For consistency,

he switch positionís designation remains the same (upper left is F, etc), but the functions are moved to match the switch type.

13

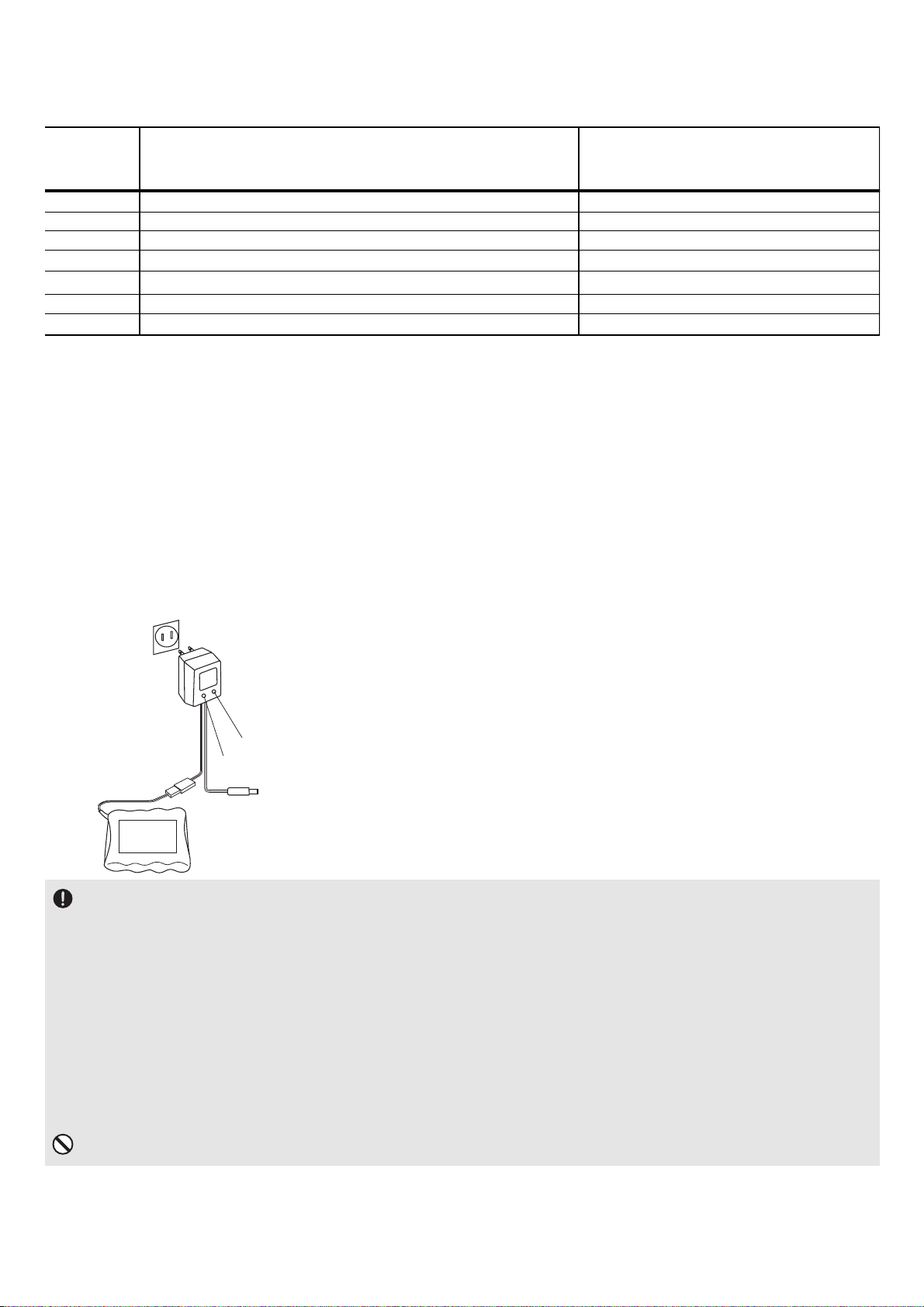

Page 14

2

(

C

C

2

3

e

e

m

c

i

b

d

b

r

R

ECEIVER AND SERVO CONNECTIONS

Receiver Aircraft (

Output and

ACRO

)Helicopter (

HELI

)

Channel

1 ailerons/combined right flap & aileron

1

aileron (cyclic roll)

2elevator elevator (cyclic pitch)

3throttle throttle

4 rudder rudder

5 spare/landing gear/combined left flap and aileron

6 spare/ flap(s)/combined left flap and aileron pitch (collective pitch)

7 spare/combined left flap and aileron spare/governor

1

Flaperon mode. (See p. 43).

1,2

1,2

1,2

spare/gyro

Using Second Aileron option, second aileron servo output is sent to channels 5-7toallowuseofa5-channel receiver.

AIL-2) (See p. 43)

HARGING THE Ni-Cd BATTERIES

harging Your Systemís Batteries

1. Connect the transmitter charging jack and airborne Ni-Cd batteries to the transmitter and receiver connectors of the charger .

. Plug the charger into a wall socket.

. Check that the charger LED lights.

The initial charge, and any charge after a complete discharge,

should be at least 18 hours to ensure full charge. The batteries

Charger

should be left on charge for about 15 hours when recharging the

standard NR-4J, NR4F1500 and NT8S600B Ni-Cd batteries.

TX: Transmitter charging indicato

RX: Receiver charging indicator

To transmitter charging jack

We recommend charging the batteries with the charger

supplied with yoursystem. Note that the useof a fast charger

Receiver Ni-Cd battery

may damage the batteries by overheating and dramatically

reduce their lifetime.

You should fully discharge your system's Ni-Cd batteries periodically to prevent a condition called memory. For

xample, if you only make two flights each session, or you regularly use only a small amount of the batteries' capacity, th

emory effect can reduce the actual capacity even if the batteryis fully charged. You can cycle your batteries with a commercial

ycling unit*, or by leaving the system on and exercising the servos by moving the transmitter sticks until the transmitter shuts

tself off. Cycling should be done every four to eight weeks, even during the winter or periods of long storage. Keep track of the

atteries' capacity during cycling; if there is a noticeable change, you may need to replace the batteries.

*Note that your 7C transmitter system is protected from accidental reverse polarity, power surges and other electrical

amage by a diode. The transmitter battery must be removed from the system to cycle. The battery easily unplugs from the

attery compartment and has a standard J-plug for easy cycling.

DO NOT attempt to charge your 8-cell transmitter pack on the 4-cell receiver plug of the wall charger!

14

Page 15

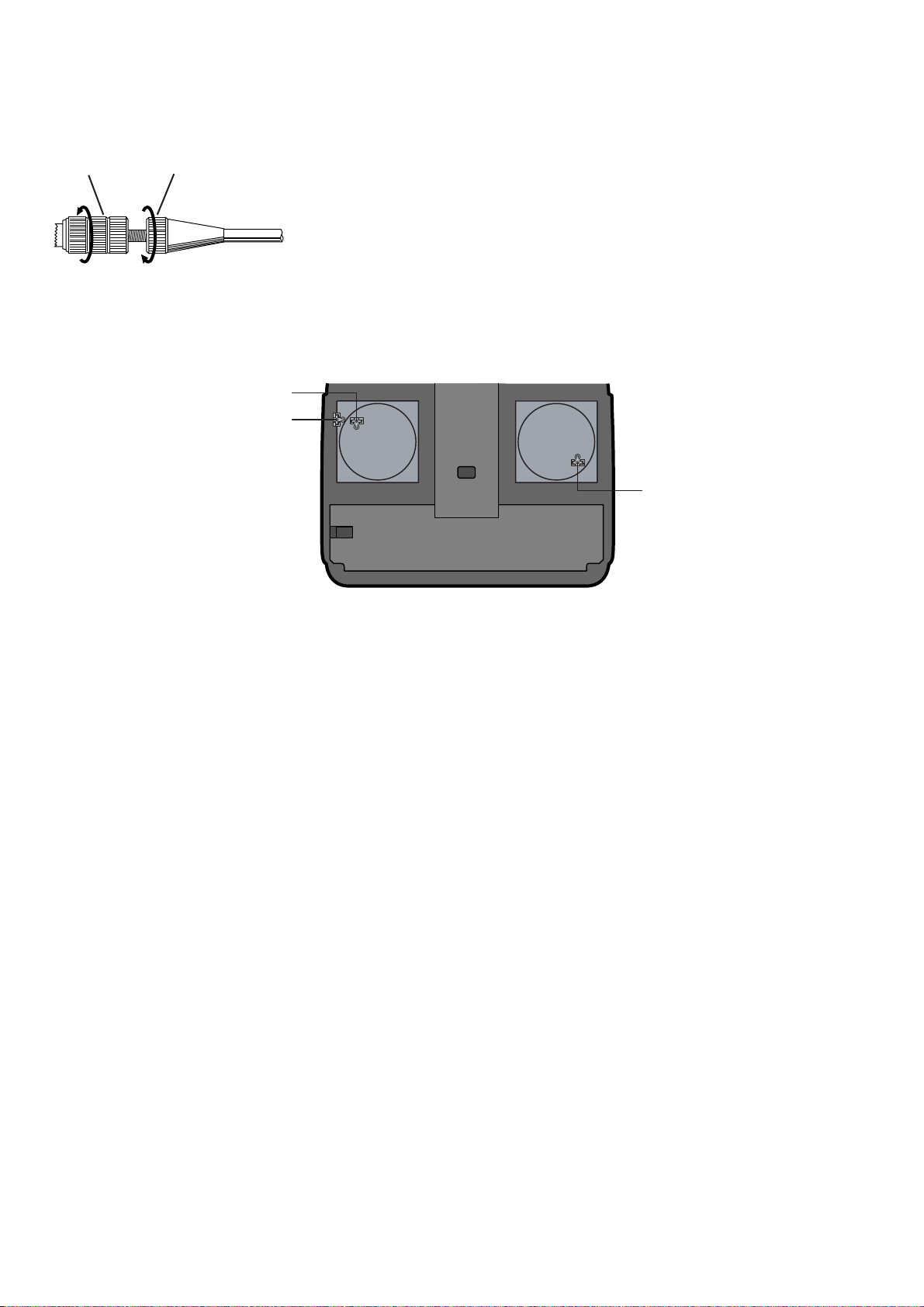

A

djusting the length of the non-slip control sticks

)

Y

t

b

N

t

N

U

i

W

b

W

Stick tip A Locking piece B

Stick lever tension adjustment

Aileron

Elevator

Youmay change the length of the control sticks to make your transmitter more

comfortable to hold and operate. To lengthen or shorten your transmitterís sticks,

first unlock the stick tip by holding locking piece B and turning stick tip A

counterclockwise. Next, move both pieces up or down (to lengthen or shorten

When the length feels comfortable, lock the position by turning locking

piece B counterclockwise, while holding piece A.

Stick Stick

Rudder

Mode 2 transmitter with rear cover removed.

ou may adjust the tension of your sticks to provide the feel that you prefer for flying.

o remove the rear case of the transmitter. First, remove the battery cover on the rear of the transmitter. Next, unplug the

attery wire and remove the battery from the transmitter.

ext, using a screwdriver, remove the four screws

hat hold the transmitterís rear cover in position, and put them in a safe place. Gently ease off the transmitterís rear cover.

ow you'll see the view shown in the figure above.

sing a small Phillips screwdriver, rotate the adjusting screw for each stick for the desired spring tension. The tension

ncreases when the adjusting screw is turned clockwise.

hen you are satisfied with the spring tensions, reattach the transmitter's rear cover. Check that the upper printed circuit

oard is on its locating pins.

hen the cover is properly in place, reinstall and tighten the four screws. Reinstall the battery cover.

Adjusting Display Contrast

To adjust the display contrast, from the home menu press and hold the End button.

Turn the dial while still holding End button:

clockwise to brighten

counterclockwise to darken the display

Let go off the dial and the button.

To adjust your springs, youíll have

Changing Modes:

Hold down the MODE and End buttons while turning on the transmitter. The screen reads "STK-MD". Change this to

the correct mode. Note that this will NOT change the throttle and elevator rachets, etc. Those are mechanical changes

that must be done by a service center.

15

Page 16

RADIO INSTALLATION

While you are installing the battery, receiver, switch harness and servos into your model's fuselage, please pay attention to

the following guidelines:

Use the supplied rubber grommets when you mount each servo. Be sure not to

over-tighten the screws. If any portion of the servo case directly contacts the fuselage or

the servo rails, the rubber grommets will not dampen the vibration, which can cause

mechanical wear and servo failure.

Servo Throw

Once you have installedthe servos, operate each one over its full travel and check that the pushrod and output

arms do not bind or collide with each other, even at extreme trim settings. Check to see that each control linkage does

not require undue force to move (if you hear a servo buzzing when there is no transmitter control motion, most likely there

is too much friction in the control or pushrod). Even though the servo will tolerate loads, any unnecessary load applied to

the servo arm will drain the battery pack quickly.

Switch Harness Installation

When you are ready to install the switch harness, remove the switch cover and use it as a template to cut screw holes

and a rectangular hole slightly larger than the full stroke of the switch. Choose a switch location on the opposite side of

the fuselage from the engine exhaust pipe, and pick a location where it canít be inadvertently turned on or off during

handling or storage. Install the switch so it moves without restriction and snaps from ON to OFF and vice versa.

Receiver Antenna

It is normal for the receiver antenna to be longer than the fuselage.

DO NOT cut or fold it back on itself --- cutting or folding changes the electrical length of the antenna and may

reduce range. Secure the antenna to the top of the vertical fin, and let the excess wire length trail behind. You may run the

antenna inside of a non-metallic housing within the fuselage, but range may suffer if the antenna is located near metal or

carbon fiber pushrods or cables. Be sure to perform a range check before flying.

Receiver Notes

When you insert servo, switch or battery connectors into the receiver, note that each plastic housing has an

alignment tab. Be sure the alignment tabis oriented properly before inserting the connector.Toremove a connector

from the receiver, pull on the connector housing rather than the wires.

If youraileron servo(or others)are toofar away toplug intothe receiver, use an aileron extension cord toextend thelength

of the servo lead. Additional Futaba extension cords of varying lengths are available from your hobby dealer . Always use an

extension of the proper length. Avoid plugging multiple extensions togetherto attain your desired length. If distanceis greater than

18" or multiple or high current draw servos are being used, use Futaba Heavy-Duty servo extensions.

Receiver Vibration and Waterproofing

The receiver contains precision electronic parts. Be sure to avoid vibration, shock, and temperature extremes.

For protection, wrap the receiver in foam rubber or other vibration-absorbing materials. It is also a good idea

to waterproof the receiver by placing it in a plastic bag and securing the open end of the bag with a rubber band before

wrapping it with foam rubber. If you accidentally get moisture or fuel inside the receiver, you may experience intermittent

operation or a crash. If in doubt, send the receiver for service.

t

16

Wood screw

Rubber grommet

Brass eyelet

Servo moun

or rail

Page 17

Range Testing Your R/C System

Please note that different systemsdemonstrate differentrange checksand thesame systemwill rangecheck differentlyin different

conditions. Also, the receiver antenna's installation affects the range test -- exiting the top of the model is ideal.

This is a brief explanation of range test. For more in-depth specifics on receiver antenna mounting, additional checks if

unsatisfactory range is demonstrated, range checking with gasoline powered engines, etc, please see our F.A.Q. page a

www .futaba-rc.com.

•

Leave the transmitter's antenna retracted and be sure both batteries are fully charged.

•

Position the aircraft away from wires, other transmitters, etc.

Test one - engine/motor off, minimum of 100 ft. range

•

Have a friend view the model but not hold it, engine off. (People conduct signals, too!)

•

Walk away from the model, working all controls constantly. Stop when the servos jitter significantly (a jitter here and

there is normal), control movement stops (PCM), or you lose control altogether.

•

Measure the distance. If greater than 100 feet, great! Proceed to Test 2. Less than 100 feet of range check means you

need more information to determine if your systemis safe to fly. Please see our web site or call support for additional

tests to perform before flying your system.

•

Repeat with friend holding the model. Note any differences.

Test two - engine/motor on

•

Repeat the test with the model'sengine running and withsomeone holding the model. If a decreaseof more than 10%

is noted, research and resolve the cause of interference prior to flying your model.

What your fully operational system demonstrates is the normal range for your system in those conditions. Before every flying

session, it is critical that you perform a range check. It is also required by the AMA Safety Code. If you notice a significant

decrease in range with fully charged batteries, do not attempt to fly.

Aircraft (fixed wing and helicopter) Frequencies

17

72 MHz band

Ch. MHz Ch. MHz

11 72.010 36 72.510

12 72.030 37 72.530

13 72.050 38 72.550

14 72.070 39 72.570

15 72.090 40 72.590

16 72.110 41 72.610

17 72.130 42 72.630

18 72.150 43 72.650

19 72.170 44 72.670

20 72.190 45 72.690

21 72.210 46 72.710

22 72.230 47 72.730

23 72.250 48 72.750

24 72.270 49 72.770

25 72.290 50 72.790

26 72.310 51 72.810

27 72.330 52 72.830

28 72.350 53 72.850

29 72.370 54 72.870

30 72.390 55 72.890

31 72.410 56 72.910

32 72.430 57 72.930

33 72.450 58 72.950

34 72.470 59 72.970

35 72.490 60 72.990

50 MHz Band (Amateur Radio Operator "HAM" license required)

Ch. MHz Ch. MHz

00 50.800 01 50.820

02 50.840 03 50.860

04 50.880 05 50.900

06 50.920 07 50.940

08 50.960 09 50.980

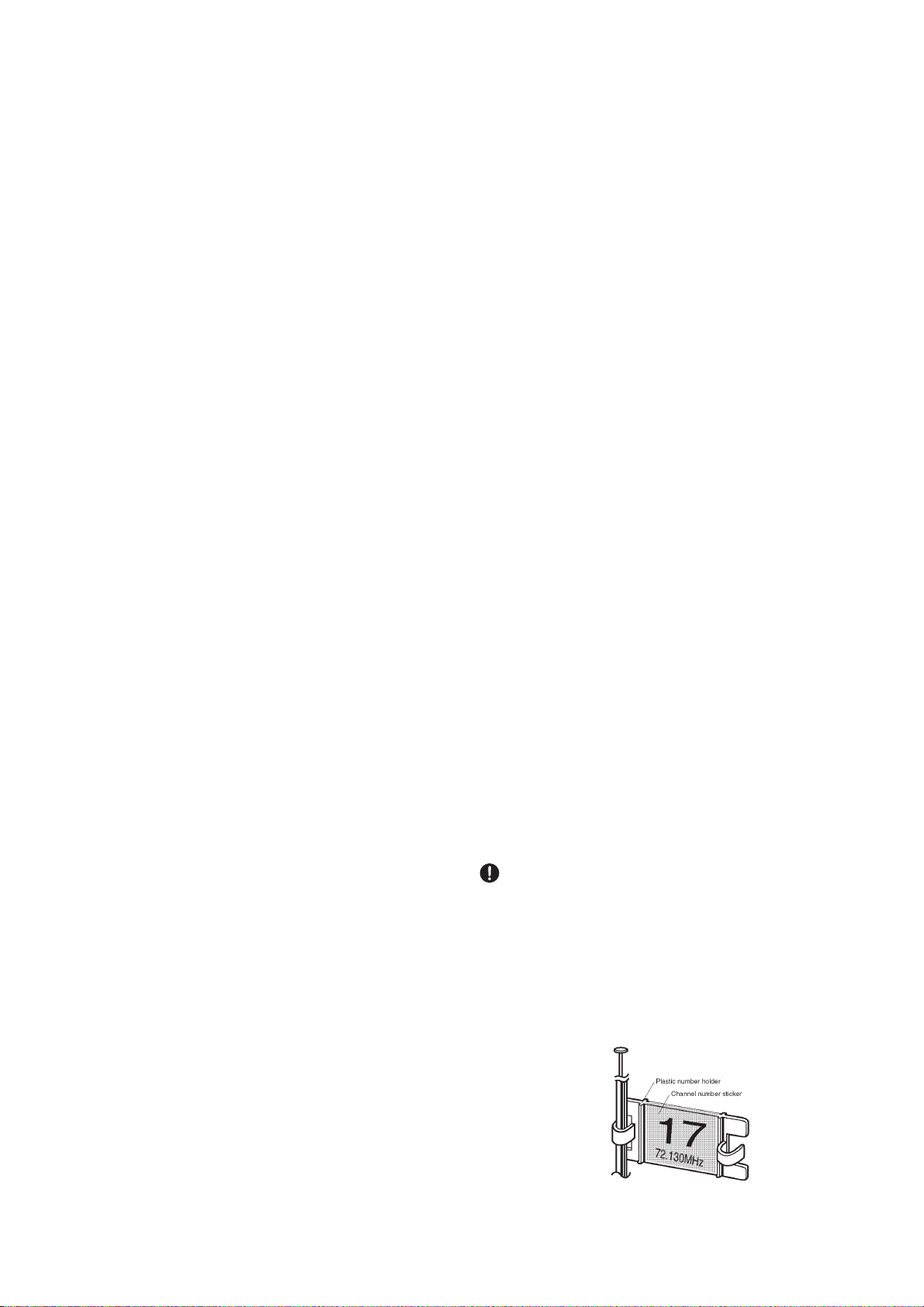

Installing your frequency number flag:

It is very important that you display your

transmitting channel number at all times. To install your

flag, peeloff the channel number's backingsheet, and carefully

stick the numbers to both sides of the number holder.Now you

can snap the number holder onto the lower portion of the

antenna as shown in the figure --- use the clip that fits more

snugly on your antenna. You may wish to cut off the other,

unused clip on the other side of the flag.

The following frequencies and channel numbers may be used for flying aircraft in the United States:

Page 18

TRANSMITTER DISPLAYS & BUTTONS

When you first turn on your transmitter, a confirmation double beep sounds, and the screen shown below appears. Before

flying, or even starting the engine, be sure that the model type and name appearing on the display matches the model that

you are about to fly! If you are in the wrong model memory, servos may be reversed, and travels and trims will be wrong,

leading to an immediate crash.

Edit buttons and Start-up Screen (appears when system is first turned on):

MODE/PAGE BUTTON: (key)

Press and hold MODE BUTTON for one second to open programming menus. Press MODE BUTTON to switch between

BASIC and ADVANCE menus. HELI only: Press MODE BUTTON to scroll between conditions in certain functions.

END BUTTON:(key)

Press END BUTTON to return to previous screen. Closes functions back to menus, closes menus to start-up screen.

SELECT/CURSOR BUTTONS:(key)

Press SELECT/CURSOR BUTTON to scroll through and select the option to edit within a function.

Press S

ELECT/CURSOR BUTTON to page up/page down within BASIC or ADVANCE menu.

Turn Dial:

Turn D

IAL clockwise or counterclockwise to quickly scroll through functions within each menu.

Turn DIAL clockwise or counterclockwise to scroll through choices within an option of a function (for example, to

select which switch controls dual/triple rates).

Press Dial:

Press DIAL to select the actual function you wish to edit from the menu.

Press DIAL and hold one second to confirm major decisions, such as the decision to: select a different model from

memory, copy one model memory over another, trim reset, store channel position in FailSafe, change model type, reset

entire model. System will ask if you are sure. Press D

IAL again to accept change.

18

Throttle trim

display

Mode

key

End

key

Modulation indicator

(PCM shown)

Model

number

Rudder trim

display

Battery voltage

Model

Aileron trim

name

display

Elevator trim

display

Select

key

Dial

Page 19

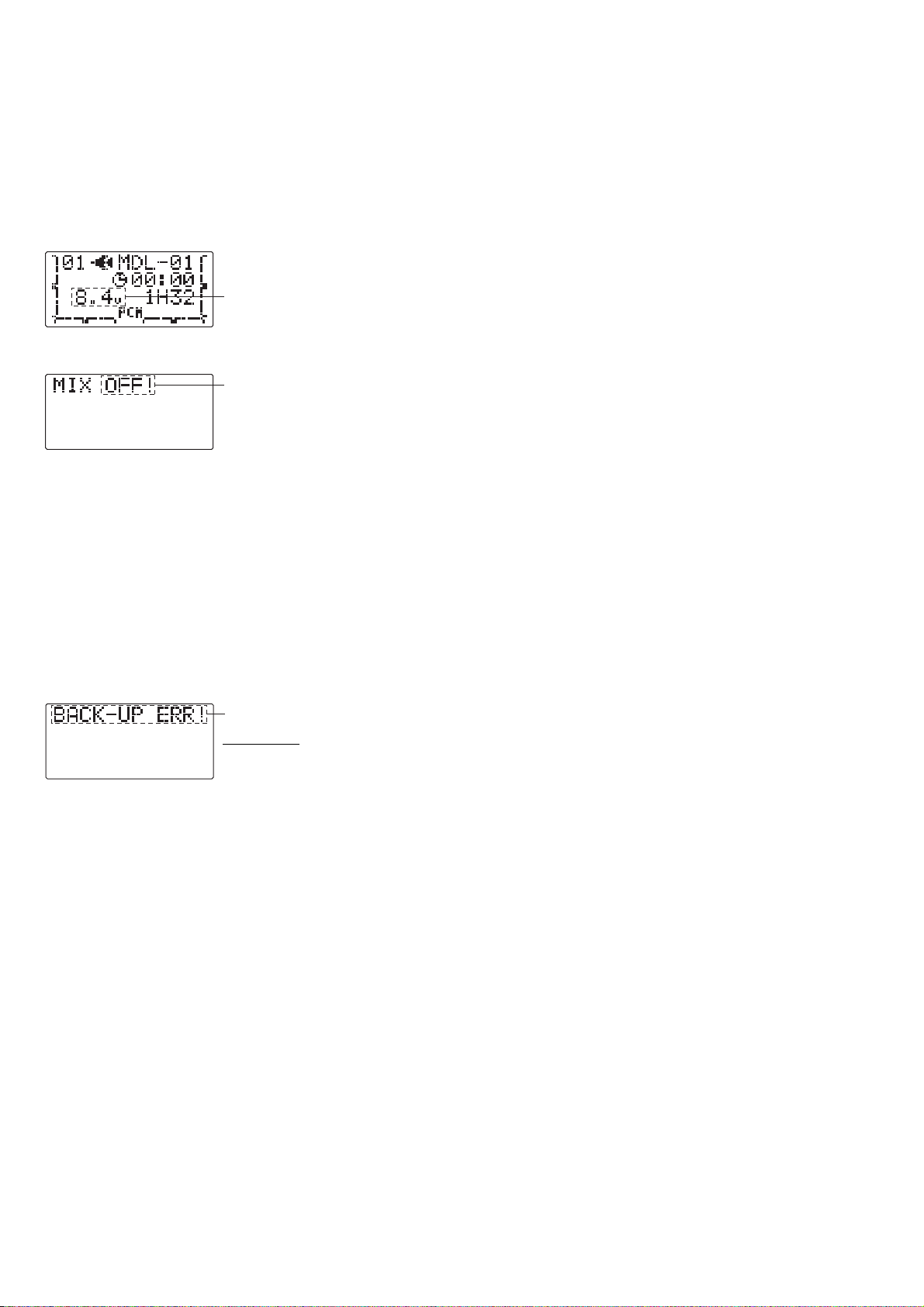

WARNING & ERROR DISPLAYS

An alarm or error indication may appear on the display of your transmitter for several reasons, including when the

transmitter power switch is turned on, when the battery voltage is low, and several others. Each display has a unique sound

associated with it, as described below.

LOW BATTERY ERROR: Warning sound: Continuous beep until transmitter is powered off.

The LOW BATTERY warning is displayed when the transmitter battery voltage drops below 8.5V.

Land your model as soon as possible before loss of control due to a dead battery.

MIXER ALERT WARNING: Warning sound: 5 Beeps (repeated until problem resolved or overridden)

The MIXER ALERT warning is displayed to alert you whenever you turn on the transmitter with any of

mixing switches active. This warning will disappear when the offending switch or control is deactivate

Switches for which warnings will be issued at power-up are listed below:

ACRO: Throttle cut, snap roll, airbrake HELI:Throttle hold, idle-up

If turning a switch OFF does not stop the mixing warning: When the warning does not stop even when the mixing switch

indicated by the warning display on the screen is turned off, the functions described previously probably use the same

switch and the OFF direction setting is reversed. In short, one of the mixings described above is not in the OFF state. In

this case, reset the warning display by pressing both S

ELECT BUTTONS simultaneously. Then change one of the switch

settings of the mixings duplicated at one switch.

BACKUP ERROR: Warning sound: 4 beeps (repeated continuously)

The BACKUP ERROR warning occurs when the transmitter memory is lost for any reason. If this occurs, all of the data will

be reset when the power is turned on again.

Do not fly when this message is displayed -all programming has been erased and is not

available. Return your transmitter to Futaba for service.

19

flash

flash

flash

Page 20

AIRCRAFT (ACRO) MENU FUNCTIONS

Please note that all BASIC menu functions are the same for airplanes (ACRO)andhelicopters (H-1/H-2/HR3/HN3/H-3/HE3

; the helicopter BASIC menu includes additional features(swashplate adjustment and throttle/pitch curves and revofor Norm

20

flight mode) that are discussed in the Helicopter section.

AIRPLANE (ACRO)FUNCTIONS ................20

Map of Functions ...........................21

Quick Guide to Setting up a 4-channel Airplane ....22

ACRO BASICMENU FUNCTIONS ................25

MODEL Submenu: MODEL SEL. , COPY and NAME . .25

Parameter(PARA.) Submenu:

CH5 & CH7

..............................28

RESET,TYPE,MODUL,

Servo REVERSE .............................31

End Point (E. POINT) ........................32

Idle Management: THR-CUT ...................33

Dual Rates and Exponential ( D/R,EXP ) ..........34

TIMER ...................................37

TRAINER ..................................38

TRIM .....................................39

SUB-TRIM .................................40

Fail Safe (F/S).............................41

ACRO ADVANCE MENU FUNCTIONS ............42

Wing types ................................42

(FLAPRN)Flaperon ...................43

(FL-TRIM)Flap Trim ...................44

ELEVON (see tail types) ...................45

Tail types .................................45

ELEVON ................................45

V-TAIL ..................................46

SNAP ROLL................................47

Mixes: definitions and types ...................48

ELE-FLP ................................49

FLP-ELE ..............................50

AIL-RUD .... ..........................51

Air Brake (A.BRAKE) ..... ................52

Prog. Mixes (P-MIX1-3) .................53

Page 21

21

(Startup screen)

Mode/Page Select

End Selection

Cursor Down

Cursor Up

Dial Left

Dial Right

Dial Right or Left

Press Button

Switch Up

Switch at Center

Switch Down

Stick Up

Stick Right

Stick Down

Stick Left

Turn Knob Right

Turn Knob Left

To enter the Basic Menu, press the

ode key for one second.

M

(for one second)

Select

(Cursor)

Select

(Cursor)

Mode/Page

ACRO Basic Menu

(Basic Menu 1)

(Basic Menu 2)

(Basic Menu 3)

End

To return to the Startup screen, press the

End key.

Mode/Page

ACRO

ADVANCE

Press Mode/Page key to toggle back

and forth between BASIC and

ADVANCE menus.

Menu

Press Select/Cursor keys to page up and down through the 3 pages of

screens in each menu.

Turn the Dial clockwise or counterclockwise to

highlight function in Menu screen. Then press the

Dial to choose that function.

Page 22

A QUICK GUIDE: GETTING STARTED WITH A BASIC 4-CHANNEL AIRCRAFT

This guide is intended to help you get acquainted with the radio, to give you ajump start on using your new radio, and togive you

some ideas and direction in how to do even more than you may have already considered. It follows our basic format of all

programming pages: a big picture overview of what we accomplish; a "by name" description of what we're doing to help acquaint

you with the radio; then a step-by-step instruction to leave out the mystery when setting up your model.

For additional details on each function, see that function's section in this manual. The page numbers are indicated in the

goals column as a convenience to you.

See p.21 for a legend of symbols used.

GOALS of EXAMPLE STEPS INPUTS for EXAMPLE

Prepare your aircraft. Install all servos, switches, receivers per your model's instructions.

Turn on transmitter then receiver; adjust all linkages so surfaces are nearly centered.

Mechanically adjust all linkages as close as possible to proper control throws.

Check servo direction.

Make notes now of what you will need to change during programming.

22

Name the model.

P. 25.

[Note that you do not need to do

anything to "save" or store this data.

Only critical changes such as a MODEL

RESET require additional keystrokes to

accept the change.]

Reverse servos as needed for proper

control operation.

P. 31.

Adjust Travels as needed to match

model's recommended throws (usually

listed as high rates). P. 32.

Open the BASIC menu, then open the

MODEL submenu.

Go to MODEL NAME.

Input aircraft's name.

Close the MODEL submenu.

In the BASIC menu, open (servo)

REVERSE.

Choose desired servo and reverse its

direction of travel. (Ex: reversing

rudder servo.)

From BASIC menu, choose END POINT.

Adjust the servo's end points.

(Ex: throttle servo)

Close the function.

Turn on the transmitter.

for 1 second.

(If ADVANCE, again.)

as needed to highlight MODEL.

to choose MODEL.

to NAME.

(First character of model's name is flashed.)

to change first character.

When proper character is displayed,

to move to next character.

Repeat as needed.

to return to BASIC menu.

4steps to REVERSE.

to choose REVERSE.

to CH4: RUDD

so REV is selected.

Repeat as needed.

2steps to END POINT.

to choose END POINT.

to THROTTLE.

T

HROTTLE STICK.

until carb barrel closes as desired.

T

HROTTLE STICK.

until throttle arm just opens carb

fully at full THROTTLE STICK.

Repeat for each channel as needed.

Page 23

With digital trims you don't shut the engine off with THROTTLE TRIM.Let's set up throttle cut (THR-CUT)now.

GOALS of EXAMPLE STEPS INPUTS for EXAMPLE

23

THR-CUTshuts the engine off completely

with the flip of a switch. P . 33.

Set up dual/triple rates and

exponential (D/R,EXP).

P. 34.

(Note that in the middle of

the screen is the name of the

channel AND the switch position you

are adjusting. Two or even THREE

rates may be set per channel by

simply choosing the desired switch

and programming percentages with

the switch in each of its 2 or 3

positions.)

From the BASIC menu, choose THR-CUT.

Activate, assign S

WITCH and adjust.

Close the function.

From the BASIC menu, choose

D/R,EXP.

Choose the desired control, and set the

first (Ex: high) rate throws and

exponential.

to THR-CUT.

to choose THR-CUT.

to OFF.toSW.

to desired switch and position.

(default: A and down position)

to RATE . A to down position.

T

HROTTLE STICK.

until throttle barrel closes

completely.

to D/R,EXP.

to choose D/R,EXP.

A to up position.

to CH> .

to choose CH>2 (elevator).

to D/R .

to set desired percentage.

to EXP.

to set desired percentage.

Page 24

GOALS of EXAMPLE STEPS INPUTS for EXAMPLE

24

Where next?

Set the second (low)rate throws and

exponential.

Optional: change dual rate switch

assignment. Ex: elevator to switch G

(7CA) or E (7CH) with 3 positions.

A to down position.

to D/R.

Repeat steps above to set low rate.

to SW.toG or E.

G or E to center position.

Repeat steps above to set 3rd rate.

(Other functions you may wish to set up for your model.)

TRAINER p. 38.

Multiple wing and/or tail servos: see wing types and tail types, p. 42, 45.

Elevator-to-flap, flap-to-elevator , and other programmable mixes p. 48.

Retractable Gear, Flaps on a Switch, Smoke systems, kill switches,

auxiliary channel (ch5 and ch7) setups. p. 28.

Page 25

A

LOOK AT THE RADIO'S FUNCTIONS STEP BY STEP

M

L

.

G

N

f

c

C

m

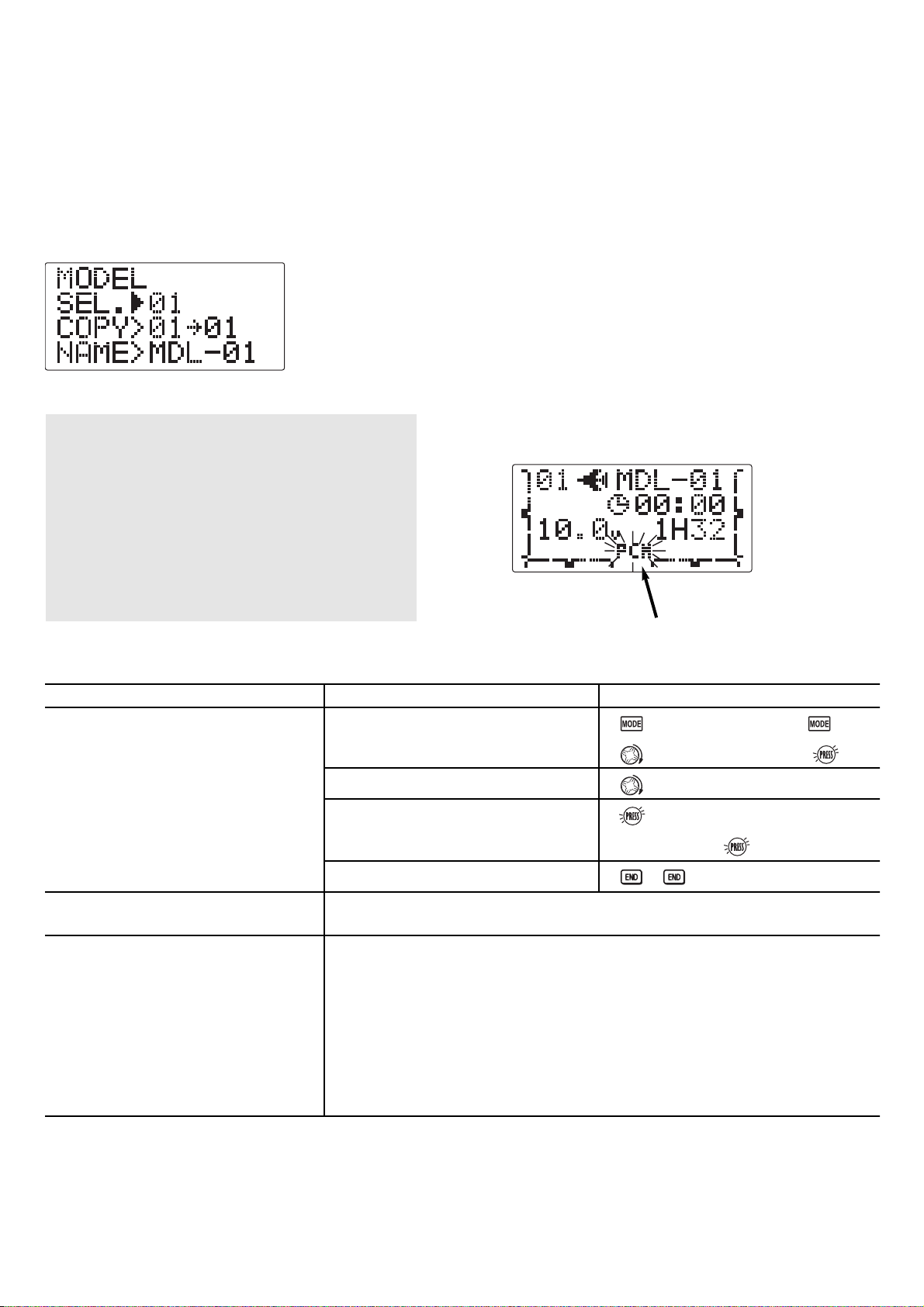

MODELsubmenu: includes three functions that manage model memory: MODEL SELECT, MODEL COPY and MODEL NA

Since these functions are all related, and are all basic features used with most models, they are together in the MODE

submenu of the BASIC menu.

MODEL SELECT: This function selects which of the 10 model memories in the

transmitter to set up or fly.

(Each model memory may be of a different model type from the other memories

NOTE: When you choose a new model in the

MODEL SELECT function, if the new model is set to

the other modulation, you must cycle the transmitter

power to change modulations. If you do not cycle

the power, the modulation type will flash on the

home screen to remind you. You are still

transmitting on the other modulation until you affect

this change.

OAL: STEPS: INPUTS:

Select Model #3.

OTE: This is one of several functions

or which the radio requires

onfirmation to make a change.

onfirm proper modulation of new

odel memory.

Where next?

FLASHING

Open BASIC menu, then open MODEL

submenu.

Choose Model #3.

Confirm your change.

Close.

If PPM or PCM are flashing in the middle of the lower side, then the new model is se

for the other receiver type. Turn the transmitter off/on to change the modulation.

NAME the model: see p. 27.

Change MODEL TYPE (aircraft, heli): see p. 28.

Change modulation [FM (PPM)orPCM]: see p. 28.

Utilize servo REVERSE: see p. 31.

Adjust END POINTs: see p. 32.

Set up TH-CUT for throttle management: see p. 33.

for 1 second.

if required to MODEL.

to 3.

for 1 second.

sure? displays.

(If ADVANCE, again.)

25

Page 26

MODEL COPY: copies the current model data into another model memory in the transmitter.

a

h

E

G

t

C

N

f

c

The number of the model memory you are copying from and into is displayed.

Notes:

Any datainthemodelcopiedto will be written over and lost, including name, type

•

modulation. It cannot be recovered.

With the trainer FUNC mode it is not necessary to have the student radio contain t

•

setup of the aircraft. See TRAINER,p.38.

xamples:

Start a new model that is similar to one you have already programmed.

•

Copy the current model data into another model memory as a backup or before experimenting with new settings.

•

Edit a copy of your modelís data to fly the model in different conditions (i.e. Helicopter using heavier weight blades;

•

airplane model at extreme altitudes).

OAL of EXAMPLE: STEPS: INPUTS:

opy model 3 into model 5.

OTE: This is one of several

unctions for which the radio requires

onfirmation to make a change.

Where next?

*Radio shows progress on screen as the model memory is being copied. Note that if the power switch is turned off prior to completion,

he data will not be copied.

Open the BASIC menu, then open

MODEL submenu.

Confirm you are currently using the

proper model memory. (Ex: 3)

Go to MODEL COPY and choose the

model to copy into.(Ex:5)

Confirm your change.

Close.

SELECT the copy you just made: see p. 25.

Rename it (it is currently named exactly the same as the model copied): see p. 25.

for 1 second.

to MODEL.

If SELECT does not indicate 3,

use MODEL SELECT,p.25.

for 1 second.

sure? displays. *

(If ADVANCE, again.)

to 5.

26

Page 27

MODEL NAME: assigns a name to the current model memory. By giving each model a name that is immediatel

y

r

h

c

N

u

c

a

t

G

N

t

ecognizable, you can easily comfirm the correct model, and minimize the chance of flying the wrong model memorywhic

ould lead to a crash.

OTE:Whenyou COPY one model memory over another, everything is copied, including the model's name. Similarly, if yo

hange MODEL TYPE ordo a MODEL RESET,the entirememory is reset,including MODEL NAME.So the firstthing you will w

odoafter you COPY a model, change its type, or start from scratch, is rename the new copy to avoid confusion.

OAL of EXAMPLE: STEPS: INPUTS:

ame model 3 "CAP-01" (where

he underline represents a blank

space.)

Adjustability and values:

Up to 6 characters long.

•

Each character may be a letter, number, blank, or a symbol.

•

The default names assigned by the factory are in MDL-xx format (MDL-01 for

•

first model memory, etc.)

Open MODEL submenu.

Confirm you are currently using the

proper model memory. (Ex: 3)

Go to NAME and change the first

character. (Ex: M to C)

Choose the next character to change.

for 1 second.

to MODEL.

If SELECTdoes not indicate 3,

perform MODEL SELECT,p.25.

(If ADVANCE, again.)

to C.

Where next?

Repeat the prior steps to complete

naming the model.

Close.

Change the MODEL TYPE to helicopter: see p. 28.

Change the receiver modulation setting from PPM to PCM or vice versa: see p. 28.

Utilize servo REVERSE : see p. 31.

Adjust servo travel with END POINT :seep. 32.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

to A

Repeat.

27

Page 28

PARAMETER submenu: sets those parameters you would likely set once, and then not disturb again.

F

y

y

r

T

e

N

a

f

T

G

t

N

f

Once you have selected the correct model you wish to work with, the next step is

setting up the proper parameters for this specific model:

What is the model's type?

•

What type is the receiverís modulation [PPM(FM) or PCM]?

•

If you are utilizing either of the twin aileron functions, do you need to tell the

•

your receiver is only 5 channels?

irst it is important to clear out any old settings in the memory from prior use, using the MODEL RESET.

MODEL RESET: completely resets all data in the individual model you have currently selected. Don't worry - there is no wa

ou can accidentally delete all models in your radio with this function. Only a service center can completely reset your

adio's entire memory at once. To delete each model in your radio's memory (for example when selling), you must SELEC

ach model, reset that memory, then go SELECT the next memory, etc.

ote that when you COPY one model memory into another or change the model's type, you need not delete all existing dat

irst by using this function. COPY completely overwrites anything in the existing model memory, including MODEL NAM

he MODEL TYPE function overwrites all data except name and MODUL.

OAL of EXAMPLE: STEPS: INPUTS:

Reset model memory 1.

OTE: This is one of several

unctions for which the radio requires

confirmation to make a change.

Confirm you are currently using the

proper model memory. (Ex: 1)

Open PARAMETER submenu.

Reset the Memory.

On home screen, check model name

and number on top right. If it is not

correct, use MODEL SELECT,p.25.

for 1 second.

to 3rd page of menu.

to PARAMETER.

for one second.

(If ADVANCE, again.)

Confirm the change.

Close.

Where next?

*Radio shows progress on screen as the model memory is being reset. Note that if the power switch is turned off prior to completion,

he data will not be reset.

Now that the memory is reset, name has returned to the default (Ex: MDL-01).

NAME the model: p. 25.

COPY adifferent model into this memory: p. 25.

SELECT a different model to edit or delete: p. 25.

Change the MODEL TYPE to helicopter: see p. 28.

Change the receiver modulation from FM(PPM)toPCM or vice versa: see p. 28.

Utilize servo REVERSE:seep. 31.

Adjust servo travel with END POINT:seep. 32.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

28

sure? displays. *

Page 29

MODEL TYPE: sets the type of programming used for this model.

T

B

ft

(

,

t

I

y

G

m

[

he 7C has 10 model memories, which can each support:

efore doing anything else to set up your aircraft, first you must decide which MODEL TYPE best fits this particular aircra

Each model memory may be set to a different model type.) If your transmitter is a 7CA, the default is ACRO.Ifitisa7CH

he default is H-1.

f you are using a heli

our model setup. Note that changing

MODEL TYPE

one powered aircraft (ACR O)memory type (with multiple wing and tail

•

configurations. See FRAPERON, ELEVON and V-TAIL for further information.);

six helicopter swashplate types, including CCPM. See Helicopter MODEL TYPE

•

for details, p. 61.

, please go to that chapter now to select the proper model type and support

MODEL TYPE

resets all data for the model memory, including its name.

OAL of EXAMPLE: STEPS: INPUTS:

Select the proper MODEL TYPE for your

odel. Ex: ACRO.

NOTE: This is one of several functions

that requir es confirmation to make a

change. Onlycritical changes require

additional keystrokes to accept

the change.]

Open the BASIC menu, then open the

PARAMETER submenu.

Go to MODEL TYPE.

Select proper MODEL TYPE.

Ex: ACRO.

Confirm the change. Close PARAMETER.

Turn on the transmitter.

for 1 second.

then to highlight PARAMETER

to choose PARAMETER.

to TYPE.

to ACRO.for1second.

sure? displays. to confirm.

to return to BASIC menu.

(If ADVANCE, again.)

29

Page 30

Modulation select (MODUL): sets the type of modulation transmitted.

The modulation of your receiver will determine whether you utilize PPM or PCM setting in MODUL during transmission

Note that you have to turn your transmitter off and back on before a modulation change becomes effective. If you choose

PCM,besure you understand and set the FailSafe (F/S) settings as you intended (see p. 41).

PCM = Pulse Code Modulation PPM =Pulse Position Modulation (also called FM).

Adjustability:

•

PCM setting for all Futaba PCM1024 receivers, regardless of number of channels

(ie.R138DP/148DP/149DP, R309DPS);

•

PPM setting for all Futaba compatible (negative shift) FM receivers, regardless of

number of channels (ie. R127DF, R123F, R148DF).

•

Not compatible with PCM512 receivers such as the R128DP and R105iP.

•

Not compatible with other brands of PCM receiver, or positive shift FM receivers

(ie. JR, Airtronics).

GOAL of EXAMPLE: STEPS: INPUTS:

NOTE: When you change models in MODEL SELECT,ifthe

new model is set to the other modulation type, you must

cycle the transmitter power to change modulations. The

modulation will flash on the home screen to remind you

until you do so. See p. 25, MODEL SELECT, for details.

30

Change model 1 from FM (PPM)to

PCM

Where next?

Confirm you are currently using the

proper model memory (Ex: 1)

Open BASIC menu, then open

PARAMETER submenu.

Go to MODUL and change setting.

Close menu and cycle power.

On home screen, check model name and

number on top and the modulation

on bottom. If it is not the correct

model, use MODEL SELECT,p.25.

for 1 second.

(If ADVANCE, again.)

to 3rd page of menu.

to PARAMETER.

to MODUL.toPCM.

PCM flashes on screen

P

OWER OFF.POWER ON.

Now that the model is in the proper modulation, the 7C should communicate

with the receiver. If it does not, confirm the modulation/frequency of the

receiver. [Futaba receivers ending in F use PPM (ex: R127DF), ending in P use

PCM (ex: R149DP)].

Change MODEL TYPE to helicopter: see p. 28.

Set F/S settings for when PCM receiver sees interference: see p. 41.

Utilize servo REVERSE:seep. 31.

Adjust servo travel with END POINT:seep. 32.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

Page 31

Servo reversing (REVERSE): changes the direction an individual servo responds to a CONTROL STICKmotion.

For CCPM helicopters, be sure to read the section on SWASH AFR (p. 63) before reversing any servos.

Except with CCPM helicopters, always complete your servo reversing prior

to any

other programming. If you use pre-built ACRO functions that control multiple servo

such asFLAPERON or V-TAIL,itmay be confusing to tell whether the servoneeds to be

reversed or a setting in the function needs to be reversed. See the instructions for each

specialized function for further details.

Always check servo direction prior to every flight as an additional precaution to confirm proper model memory,

hook ups, and radio function.

NOTE: THR-REV is a special function that reverses the entire throttle control, including moving the trim functionality to the

Stick's upper half. To use THR-REV,turn off the transmitter, hold down the MODE and END keys, turn on. CURSOR DOWN to

THR-REV and turn the DIAL to REV.Turn the transmitter off and back on. This change affects all models in the radio.

GOAL of EXAMPLE: STEPS: INPUTS:

31

Reverse the direction of the elevator

servo.

Where next?

Open REVERSE function.

Choose proper channel and set

direction. (Ex: ELE REV)

Close.

for 1 second.

(If ADVANCE, again.)

to REVERSE.

to ELE.

to REV.

Adjust servo travel with END POINT:seep. 32.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

Set up flight timers: see p. 37.

Set up trainer functions: see p. 38.

uxiliary channel function (CH5 and CH7): defines the relationship between the transmitter

ontrols and the receiver output for channels 5 and 7.

Adjustability:

channels 5 and 7 may be assigned to any SWITCH (A-H)ornone (null).

•

(for example, moving flaps to a switch)

multiple channels may be assigned to the same switch.

•

channels set to "NULL" are only controlled by mixes.

•

(Ex: utilizing 2 channels for 2 rudder servos. See mixes, p. 53.)

Remember that if you assign primary control of a channel to a switch which you later use for other functions (like

ual/triple rates or airbrakes), every time you use that other function you will also be moving the auxiliary channel.

Page 32

Adjustability:

•

Can set each direction independently.

•

Ranges from 0% (no servo movement at all) to 140%. At a 100% setting, the throw o

the servo is approximately 40º for channels 1-4 and approximately 55º for channels 5

•

Reducing the percentage settings reduces the total servo throw in that direction.

Adjust the throttle high end to avoid binding at the carburetor, and low end to allow for proper carburetor closure.

Adjust flap so up travel is only sufficient for straight and level flight trimming, with full down travel.

END POINT may be adjusted to 0 to keep a servo from moving one direction, such as flaps not intended to also operate

as spoilers.

Retract servos are not proportional. Changing END POINT will not adjust the servo.

end point (and moving the linkage) = torque, accuracy, but transit time to get there.

end point (instead of adjusting linkages) = travel time, but torque, accuracy.

32

Open END POINT function.

Choose proper channel and set

direction. (Ex: flap up 5%)

Close.

for 1 second.

(If ADVANCE, again.)

to END POINT.

to flap.

flap control [default is V

R ].

to 5%.*

V

R(A).to85%.

Move auxiliary channels 5 or 7 to different switch(es): see p. 28.

Set up THR-CUT to cut the engine: see p. 33.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

Set up flight timers: see p. 37.

Set up trainer functions: see p. 38.

Set up twin aileron servos: see p. 43.

Page 33

33

Engine idle management: THR-CUT: functions which work with the digital THROTTLE TRIM to provide a simple,

consistent means of engine operation. No more fussing with getting trim in just the right spot for landings!

OAL of EXAMPLE: STEPS: INPUTS:

ecrease the throttle setting (at idle) to

pthe engine with the flip of a switch.

Open BASIC menu, then open

THR-CUT function.

for 1 second.

(If ADVANCE, again.)

to THR-CUT.

efault: SWITCH A in the down

osition)

Activate the function. Choose desired

switch, and the position which

activates the function.

to ON(OFF).

to SW.

to select the desired

switch and position.

With T

HROTTLE STICK at idle, adjust the

A to down position.

rate until the engine consistently shuts

off but throttle linkage is not binding.*

THROTTLE STICK.

here next?

to RATE. until shuts off.

Close.

Set up dual/triple rates and exponential (D/R,EXP): see p. 34.

Set up TRAINER functions: see p. 38.

Set up twin aileron servos: see p. 43.

Page 34

Dual/Triple Rates: reduce/increase the servo travel by flipping a switch,

or (ACRO )they can be engaged by any stick position. Dual rates affect the control

listed, such as aileron, not just a single (ex: channel 1) servo. For example, adjus

aileron dual rate will affect both aileron servos when using FLAPERON, ELEVON, and

aCCPM helicopter.

•

Any SWITCH, A-H.Ifyou choose a 3-position switch, then that dual rate instantly becomes a triple rate (see example).

•

Stick position (ACRO ). (Ex: On rudder you normally use only the center 3/4 of the stick movement except

for extreme maneuvers such as snaps/spins/stalls. As long as your RUDDER STICK does not exceed 90% of maximum

throw, the rudder responds at your lower rate, allowing small, gentle corrections. When the stick passes 90% (ie. stall

turn), the rudder goes to high rate's 90%, which is a MUCH higher amount of travel than your low rate at 89%.)

Ex: EPA = 1" Low Rate = 50% High Rate = 100%

At 89% Low Rate = .45"

At 90% High Rate = .9"

Adjustability:

•

Range: 0 - 140% (0 setting would deactivate the control completely .)

Initial value=100%

•

Having made no changes yet in the D/R,EXP screen, move S

WITCH D to "down" (toward the AILERON STICK

).

•

Cursor down to EXP and dial to 100%.

•

Move SWITCH D up. Hold the AILERON STICK at 1/4 stick and move SWITCH D down.

•

Notice how much less travel there is.

•

Go to 3/4 stick and repeat. Notice how the travel is much closer, if not identical.

34

100% 100%

90% 90%0%

High R ate

Low Rate

High R ate

High R ateLow Rate

100%30%0%

Page 35

•

More sensitive around neutral. (positive exponential, see example)

•

Less sensitive around neutral. (negative exponential, see example)

35

Open D/R,EXP.

Choose channel and switch position.

Set rate and exponential (Ex: high rate

= 95%, 0% exponential.)

Go to 2

nd

switch position and set rate

and exponential.

Optional: if usinga3position switch,

set 3rdrate.

for 1 second.

(If ADVANCE, again.)

to D/R,EXP.

to desired channel.

to 95%.

Confirm 0% EXP.

Repeat above.

Repeat above.

Page 36

36

Open D/R,EXP function.

Choose the channel to change

(Ex: aileron is already selected)

Optional: change switch assignment.

Confirm switch is in desired position

and set rate. (Ex: up = high rate, 75%).

Move S

WITCH to 2nd rate position and

set this particular rate.

(Ex: center = low rate, 25%).

Optional: if using a 3 position

SWITCH, move SWITCH to 3rd position

and set this rate (Ex: down = 3D rate,

140%).

Optional: instead of using a switch,

you can set high rates to be triggered

when the stick moves past a certain

point. To test this, set aileron high

rate to 25%.

Move

AILERON STICK

and notice the huge jump in travel

after the stick moves 90% of its

distance.

to the right

Set each rate's EXP.

(Ex: 0%, +15%, -40%)

Close.

for 1 second.

(If ADVANCE, again.)

to D/R,EXP.

to desired channel.

to G.

G to up position.

G to center position.

G to down position.

You may also change the trigger point

by holding the stick at the desired point,

then pressing and holding the

DIAL.

G to up position.

confirm EXP reads 0.

G to down position.

G to center position.

Set up flight timers: see p. 37.

Set up TRAINER functions: see p. 38.

Adjust the sensitivity of the trims: see p. 39.

Set up twin aileron servos: see p. 43.

Set up programmable mixes to meet your specific needs: see p. 53.

Repeat above steps for elevator and rudder.

to 75%

to 25%

to 140%

to 1.

to 25%

to 15%

to -40%

Page 37