Page 1

3PK

3-CHANNEL RADIO CONTROL SYSTEM INSTRUCTION MANUAL

Futaba© Digital Proportional R/C System

Technical updates and additional programming examples available at:

http://www.futaba-rc.com/faq/faq-3pk.html

FUTZ8533 for FUTJ32**/33** V1.0

Entire Contents © Copyright 2002

3PK with Optional Accessory Offset Adapter Installed

Page 2

2

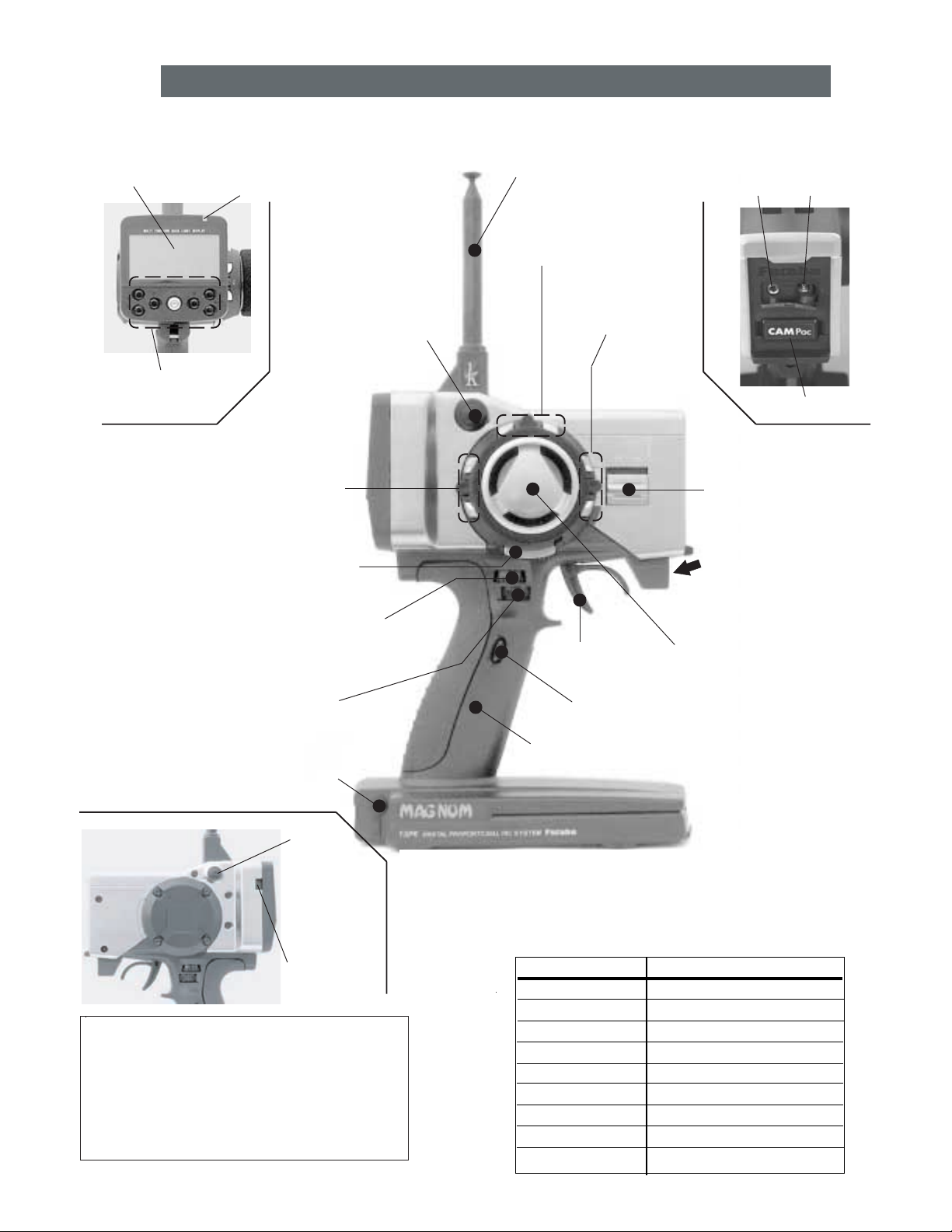

Transmitter Controls

DEFAULT ASSIGNMENT TABLE

The factory default functions activated by the switches and knobs are

shown below. Default assignments may be changed using the

FUNC-DIAL

and

FUNC-SW

programming (See pp. 34-35.) Features assigned to DL1, 2, 3, and

DT1, 2, 3 are displayed at all times on right side of LCD screen.

CONTROL DEFAULT

DT1 Steering trim

DT2 Throttle trim

DT3 NONE

DL1 Steering dual rate

DL2 ATL

DL3 Channel 3

PS1 NONE

PS2 NONE

PS3 NONE

*The switches, knobs and trimmers may all be reassigned. (see pp. 34-35)

LCD screen

Pilot lamp

Edit buttons

Digital trim 2

(DT2) (default throttle trim)

(See page 9 for operating instructions.)

Push switch 1 (PS1)

Digital Dial 1 (DL1)

(default steering dual rate)

(See page 9 for the operating instructions.)

Digital Dial 2 (DL2)

(default ATL)

(See page 9 for the operating instructions.)

(See page 12 for

instructions to

change colors.)

Digital Dial 3 (DL3)

(default CH3 knob)

Antenna

Digital trim 1 (DT1)

(default steering trim)

(See page 9

for operating instructions.)

Digital trim 3 (DT3)

(See page 9

for operating instructions.)

Throttle

trigger

Push switch 2 (PS2)

DSC

Port

CAMPac

Power

switch

Mechanical ATL

adjusting screw

(See page 50 for the

adjustment instructions.)

Steering wheel

Charge

Port

Sound port

Use a commercial earphone

with a 3.5mm diameter plug.

Push

switch

3

(PS3)

Display

switch

Precautions when turning the power

switch on and off.

When the data is changed using the edit keys or

trim levers, wait at least two seconds before

turning off the power. If the power is turned off

within two seconds after the data was changed,

the new data will not be written to memory.

Grip Handle

Page 3

INTRODUCTION

•

Transmitter Controls and Defaults.................................2

•

Owner’s Manual and Additional Technical Help ..........4

•

Support and Service .......................................................4

•

Contents and Technical Specifications ..........................5

•

Optional Accessories......................................................5

•

A Quick Introduction to the 3PK System......................6

•

Getting to Know the Transmitter...................................8

•

Display Switch .......................................................8

•

Digital Trim Operation...........................................9

•

Digital Grip Dial Operation ...................................9

•

Installation....................................................................10

PROGRAMMING..........................................................11

•

Menu Selection Overview............................................11

•

Direct Selection Menu Overview.................................11

•

LV1 Functions ...............................................................12

•

Level Selection LEVEL-SEL ...................................12

•

System Settings SYSTEM.......................................13

•

Backlighting LHT-MODE ............................13

•

Backlighting time LHT-TIME.......................13

•

LCD contrast CONTRAST ............................13

•

Buzzer tone BUZ-TONE ...............................13

•

LED pilot lamp LED-MODE ........................13

•

Home screen display DISPL-SEL ................13

•

Model Selection MDL-SEL ....................................14

•

Model Name MDL-NAME ......................................15

•

User Name (set within MDL-NAME) ..........15

•

Modulation MOD-MODE ........................................16

•

Failsafe and Battery Failsafe FAIL-SAFE ...............17

•

Servo Reversing CH-REV.......................................18

•

End Point Adjustment CH-EPA .............................18

•

Exponential ST-EXP, TH-EXP ..................................20

•

Sub-Trim SUB-TRIM..............................................22

•

LV2 Functions ...............................................................23

•

Speed ST-SPEED, TH-SPEED ...................................23

•

ABS ABS...............................................................24

•

Throttle Acceleration TH-ACCEL ...........................26

•

Idle-up IDLE-UP.....................................................27

•

Auto-Start/Engine Cut AT-START ..........................28

•

Timer TIMER .........................................................30

•

Lap List LAP-LIST..................................................31

•

Model Reset MDL-RES ..........................................32

•

Model Copy MDL-COPY ........................................33

•

Function FUNC-SW, FUNC-DIAL..............................34

•

Direct Selection Menu Options DIRC-CALL ..........36

•

LV3 Functions ...............................................................37

•

Throttle Electronic ATL TH-ATL............................37

•

Steering Dual Rates ST-D/R .................................38

•

Servo Display SERVO............................................39

•

Channel 3 Position CH3-POSI ...............................40

•

Programmable Mixes PRG-MIX1, PRG-MIX2.........40

•

Brake Mix BRAKE-MIX..........................................42

•

Boat Mode BOAT-MODE ........................................43

•

MC Setup MC-SETUP ............................................44

•

Adjuster ADJUSTER ...............................................45

APPENDICES ................................................................46

•

Appendix I - Precautions and Warnings ......................46

•

Application, Export and Reconstruction..............46

•

Liability and Warranty .........................................46

•

Battery Recycling.................................................46

•

Meaning of Special Markings..............................47

•

Safety Precautions

(DO NOT operate without reading) ....................48

•

Mandatory Procedures for Using

HRS Receivers.....................................................48

•

Caring for your NiCd Batteries............................49

•

Appendix II - Adjustments, Modifications

and Replacements

•

Mechanical ATL/Wheel Tension Adjustment......50

•

Changing Wheel Position and Modifying for Left

Hand Use .....................................................................51

•

Appendix III - Error Displays......................................54

•

GLOSSARY/INDEX ...................................................56

•

Quick Setup for Nitro Engines ....................................67

•

Layout Reminder Guide...............................................67

•

Quick Start Guide .........................................Back Cover

3

TABLE OF CONTENTS

Note that in the text of this manual any time we are using a feature’s specialized name or abbreviation as seen on the screen

of the 3PK, that name, feature, or abbreviation will be exactly as seen on the radio’s screen, including capitalization, and

shown in a DIFFERENT TYPE STYLE for clarity.

Page 4

4

INTRODUCTION

Thank you for purchasing a Futaba

®

digital proportional R/C system. In order for you to make the best use of your system

and to use it safely, please read this manual carefully. If you have any difficulties while using your system, please consult

the manual, our online Frequently Asked Questions (on the web pages referenced below), your hobby dealer, or the Futaba

Service Center.

Owner’s Manual and Additional Technical Help

This manual has been carefully written to be as helpful to you, the new owner, as possible. There are many pages of setup

procedures and examples. However, it need not be your sole resource of setup guidelines. For example, the back cover

includes a quick-start set of instructions and the Frequently Asked Questions web page referenced below includes this type

of step-by-step setup instructions for a variety of other model types.

Due to potential unforeseen changes in production procedures, the information contained in this manual is subject to change

without notice. No part of this manual may be reproduced in any form, at any time, without prior permission.

Support and Service: It is recommended to have your Futaba equipment serviced annually during your hobby’s “off

season” to ensure safe operation.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and programming. Please be sure to

regularly visit the Frequently Asked Questions web site referenced below. This page includes extensive programming, use,

set up and safety information on your radio system and is updated regularly. Any technical updates and US manual corrections

will be available on this web page. If you do not find the answers to your questions there, please see the end of our F.A.Q.

area for information on contacting us via email for the most rapid and convenient response.

Don’t have Internet access? Internet access is available at no charge at most public libraries, schools, and other public

resources. We find internet support to be a fabulous reference for many modelers as items can be printed and saved for future

reference, and can be accessed at any hour of the day, night, weekend or holiday. If you do not wish to access the internet for

information, however, don’t worry. Our support teams are available Monday through Friday 8-5 Central time to assist you.

FOR SERVICE ONLY: FOR SUPPORT:

Futaba Service Center (PROGRAMMING AND USER QUESTIONS)

1610 Interstate Drive Please start here for answers to most questions:

Champaign IL 61822 www.futaba-rc.com\faq\faq-3pk.html

www.hobbyservices.com FACSIMILE: 217-398-7721

PHONE: 217-398-8970 option 4

HOW TO SEND FOR SERVICE:

www.hobbyservices.com\techsupport\service-form-futaba.pdf

www.hobbyservices.com\techsupport\service-form-futaba.html

OUTSIDE NORTH AMERICA

Please contact your Futaba importer in your region of the world to assist you with any questions, problems or service needs.

Please recognize that all information in this manual, and all support availability, is based upon the systems sold in North

America only. Products purchased elsewhere may vary. Always contact your region’s support center for assistance.

Page 5

5

•

Transmitter, including RF module* (PK) and NiCd

battery pack NT8F700B (FUTM1462)

•

Receiver (R113iP or R203HRF)

•

110V wall charger FBC19B (USA)

•

Frequency Flag/Number set

•

Wheel position offset adapter (APA)

Transmitter T3PK (Pistol, 3 channels)

Operating system: FM/PCM1024/HRS

Transmitting frequency: 27, 75 MHz bands*

Modulation: FM/PPM, HRS-FM or PCM1024, switchable

Power supply: 9.6V NT8F700B NiCd battery

Current drain: 250 mA or less

Receiver R113iP ( PCM Single conversion, 3 channels)

Receiving frequency: 27, 75 MHz bands *‡

Intermediate freq.: 455 kHz

Power requirement: 4.8V or 6.0V NiCd battery or

4.8V (4 cells) alkaline

Current drain: 18 mA

Size: 1.69" x 1.13" x 0.63" [42.7 x 28.7 x 16.0mm]

Weight: 0.74oz [21g]

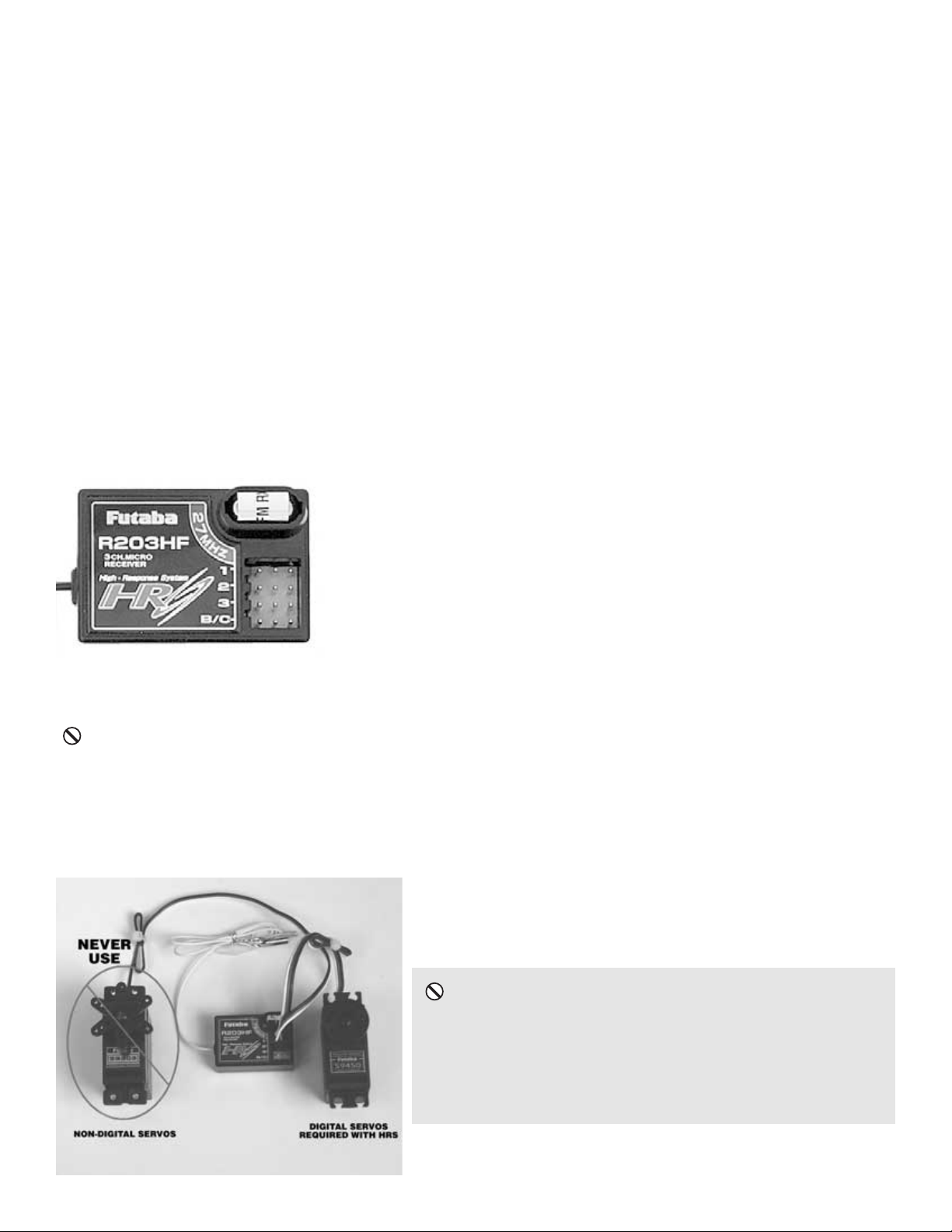

Receiver R203HF (3 channels, HRS single conversion)

Receiving frequency: 27, 75 MHz bands *‡

Intermediate frequency: 455kHz

Power requirement: 6.0V only (shared with servos)

Current drain: 14mA

Size: 1" x 1-1/2" x 9/16" [25.6 x 37.7 x 14.3mm]

Weight: .6oz [17g]

Always use only: “HRS” mode on transmitter

6V Digital Servo, including throttle

6V NiCd battery

* Transmitter band may only be changed by changing the

module. Receiver band cannot be changed. Band cannot be

changed by simply changing crystals.

‡ Only 27, 75MHz bands are legal for R/C ground use

in the North America.

Other bands are sold and used in other countries only.

CONTENTS AND TECHNICAL SPECIFICATIONS

(Specifications and ratings are subject to change without notice.)

Your system includes the following components:

The following additional accessories are available from your dealer. Refer to a Futaba catalog for more information:

•

CAMPac Memory module — the optional DP-16K CAMPac increases your model storage capability (to 20 models

from 10) and allows you to transfer programs to another 3PK transmitter. Note that data may not be transferred to/from

any other model of transmitter (3PJ, etc).

CAUTION - Insertion of a CAMPac containing data of a different transmitter type (ex: 3PJ) will result in

a complete CAMPac data reset and loss of all data.

•

Transmitter battery pack — the NT8F700B (700mAh) transmitter NiCd battery pack may be easily exchanged with a

fresh one to provide enough capacity for extended sessions.

•

Y-harnesses, servo extensions, etc – Genuine Futaba extensions and y-harnesses, including a Heavy-Duty version with

heavier gauge wire, are available to aid in your larger model and other installations.

•

5-cell (6.0V) receiver battery packs. All Futaba equipment (except that which is specifically labeled otherwise) is

designed to work with 4.8V (NiCd 4 cells) or 6.0V (NiCd 5 cells or alkaline 4 cells). Using a 6.0V pack increases the

current flow to the servos, which accelerates their rate of response and their torque. However, because of this faster

current draw, a 5-cell battery pack of the same mAh rating will last approximately ¾ the time of a 4-cell pack.

CAUTION - NOTE that HRS receivers require 6.0 volts and will not operate with 4.8V 4-cell packs.

•

Gyros – a variety of genuine Futaba gyros are available for your specialized model needs.

•

FailSafe: the FS1 FailSafe may be used with standard PPM/FM receivers to return throttle to idle in case of a loss of signal,

similar to the FailSafe function of PCM/HRS receivers. NOTE that HRS receivers can not operate with the FS1.

•

Battery Holder (Transmitter): This battery holder is necessary when using the transmitter with dry cell batteries. For a

description of how to install the battery holder to the transmitter, see “NiCd Replacement” on page 54.

•

DSC cord – allows setup and testing without transmitting. Requires DSC compatible receiver and DSC cord. With transmitter

and receiver off, plug cord into transmitter and then into receiver battery slot. Turn on receiver power. All programming and

setup may be done in this matter without transmitting. See glossary for a list of DSC-compatible receivers.

Page 6

6

A QUICK INTRODUCTION TO THE 3PK SYSTEM

TRANSMITTER: 3PK

•

Large graphic liquid-crystal display panel with 7 buttons for quick, easy set up.

•

128x64 dot large graphic LCD/with adjustable backlighting and graph displays for exponential, etc.

•

Includes 3 levels of flexibility to simplify programming for new users while still providing the most flexible system in

the world to those who wish to use it.

•

LV1: (Learning the system; quick setups, a single menu with enough for most models, including):

•

MDL-NAME 10-character model name

•

USR-NAME 10-character user name

•

MOD-MODE FM/PCM/HRS selection to match each model’s receiver

•

EPA End point adjustment for all servos

•

SYSTEM Adjust back light, contrast, volume, and items displayed on home screen

•

LEVEL-SEL Level Selection: Change programming complexity.

•

MDL-SEL Model Selection: Choose from the 10 models in memory or in optional CAMPac

•

MDL-RES Model Reset: Erase model memory for this model only

•

MOD-MODE Modulation: Transmission mode (PPM/PCM/HRS)

•

FAILSAFE Failsafe and Battery Failsafe: Program receiver's response in case of lost signal.

•

CH-REV Servo Reversing

•

EXP Exponential: Set exponential for braking and steering, and pick from 3 curve types for forward throttle,

•

LV2: (“Let’s Race!” Exploring 2 menus, with all of LV1, plus racer-focused features, including):

•

ABS Simulates antilock brakes with fully adjustable pulsing effect

•

SPEED Adjustable throttle/steering servo response on input and release

•

ACCEL Throttle acceleration minimizes delay in nitro engine/braking response

•

LAP Record lap times, set training target times, display 99 recorded times

•

AT-START/ENGINE CUT Avoid wheel spins or shut boat engines off safely

•

Idle-up Increased throttle setting for easy starts

•

FUNC Assigns features to any of the 6 dials/trims and 3 switches

•

Direct selection menu options Customize the Direct Selection Menu

•

MDL-COPY Copy one model memory into another for experimenting and more

•

LV3: (For the expert driver, boat or complex modeler, adds specialized features, including):

•

PRG-MIX 1,2 Programmable mixes in a car radio for your own special effects!

•

BRAKE-MIX Set up independently adjustable front and rear brakes.

•

BOAT-MODE Includes tilt steering (outboard/rudder mixing), ability to disable brake function

•

ST-D/R Two steering dual rates

•

SERVO Displays servo position to ease setup, test mixes prior to installation.

•

TH-ATL Adjust the brake's total travel

•

CH-3 Adjust channel 3's midpoint

•

MC SETUP Setup ESCs with HRS receivers

•

ADJUSTER Re-calibrate the radio for perfect performance every time

•

Supports Futaba’s new High Response System (H.R.S. system) receivers, as well as FM and PCM1024.

•

H.R.S. provides response times approximately 1/3 of that of an equivalent FM system.

•

CAMPac offers unlimited data storage.

•

User-defined home screen data display and quick-access Direct Call menu for Level 2 and 3 users.

•

Full function assignability for dials, digital trims, switches.

•

Adjustable wheel height and angle for perfect fit, as well as left-handed support.

•

Display switch allows programming setup without transmission.

•

Permanent memory storage via EEPROM with no backup battery to service or have fail.

Page 7

7

MODULE: 75PK-FM

•

Module may be easily removed and a module on a different channel (or even band) reinserted to change the

transmission frequency or band.

•

Module transmits FM (PPM), HRS-FM (HRS) and PCM. No need for a second module.

•

Module is protected under the RF module cover on the top of the radio.

•

All transmission circuitry is included in the module, so no retuning is needed when changing channels or even bands.

•

Frequency band is changed by inserting a module on the proper band, including for international use.

•

In North America it is against FCC regulation to change the crystal within the transmitter module to a different

channel. All such transmitter crystal changes must be performed by a certified radio technician. Failure to properly

tune a system to its new channel may result in decreased range and may also result in interference to other types of

frequency users on adjoining channels.

•

The FSS synthesized module for the 9Z family of radios is NOT compatible with the 3PK.

•

DISP displays instead of RF when main power is on and module is not installed.

•

It is normal for the module to get slightly warm during use.

•

Non-Futaba brand modules are not FCC certified for use with this radio and therefore are against FCC regulation to use.

•

Do not use other modules in the 3PK or the PK module in other radios.

•

Do not operate transmitter with module in and power switch on, while antenna is collapsed. Always extend antenna

if transmitting.

RECEIVER: R203HF or R113iP

•

The receiver included with your system is a high-sensitivity narrow-band

single-conversion receiver.

•

Any Futaba narrow band PPM(FM) receiver (all produced after 1991) on the

correct band and frequency may be used.

•

Any Futaba PCM 1024 receiver on the right band and frequency may be

used. (all 1024 receivers say PCM1024; receivers which say PCM but not 1024

are 512 resolution and not compatible).

•

Any Futaba HRS-FM receiver on the right band and frequency may be used. At

the time of this writing, only the R203HF is available. HRS receivers require 6.0V

batteries and digital servos, including for throttle.

•

In North America the receiver included with this system may have its frequency changed by simply changing the

crystal, as long as it remains in the same band. You may change anywhere from channel 61 through 90 in the 75MHz

band or A1 through A6 in the 27MHz band without requiring retuning.

NEVER attempt to change a receiver’s band by simply changing crystal (IE removing a 27MHz crystal and inserting

a 75MHz crystal). A receiver that has a crystal installed from a different frequency band without retuning will NOT

receive properly and will have dramatically decreased range if it responds at all.

SERVOS:

•

All Futaba PPM(FM) and PCM1024 receivers are compatible with all

J-plug Futaba servos, including retract, winch, standard and digital servos.

NEVER use non-digital servos with HRS

receivers. Severe damage to all electronics may

result, including the possibility of a fire. Only

digital servos may be used with HRS receivers,

including for throttle.

Page 8

8

GETTING TO KNOW THE TRANSMITTER

Display switch

• If the display switch is turned on without turning on the power switch, programming is possible without emitting

radio waves.

If power switch is turned on while display switch is on, transmitter will transmit, which

will interfere with other users operating on the same frequency. Always be sure you have

control of your frequency prior to turning on the primary power switch.

• LCD screen contrast can be adjusted (See SYSTEM, p. 13.)

• LCD may be difficult to read due to temperature change when exposed to direct sunlight

for more than a few minutes at a time, extreme heat, cold, or humidity.

• Always use only the display switch unless you want to transmit to your receiver and you

have control of the frequency.

• Transmitting with the antenna collapsed may damage the module.

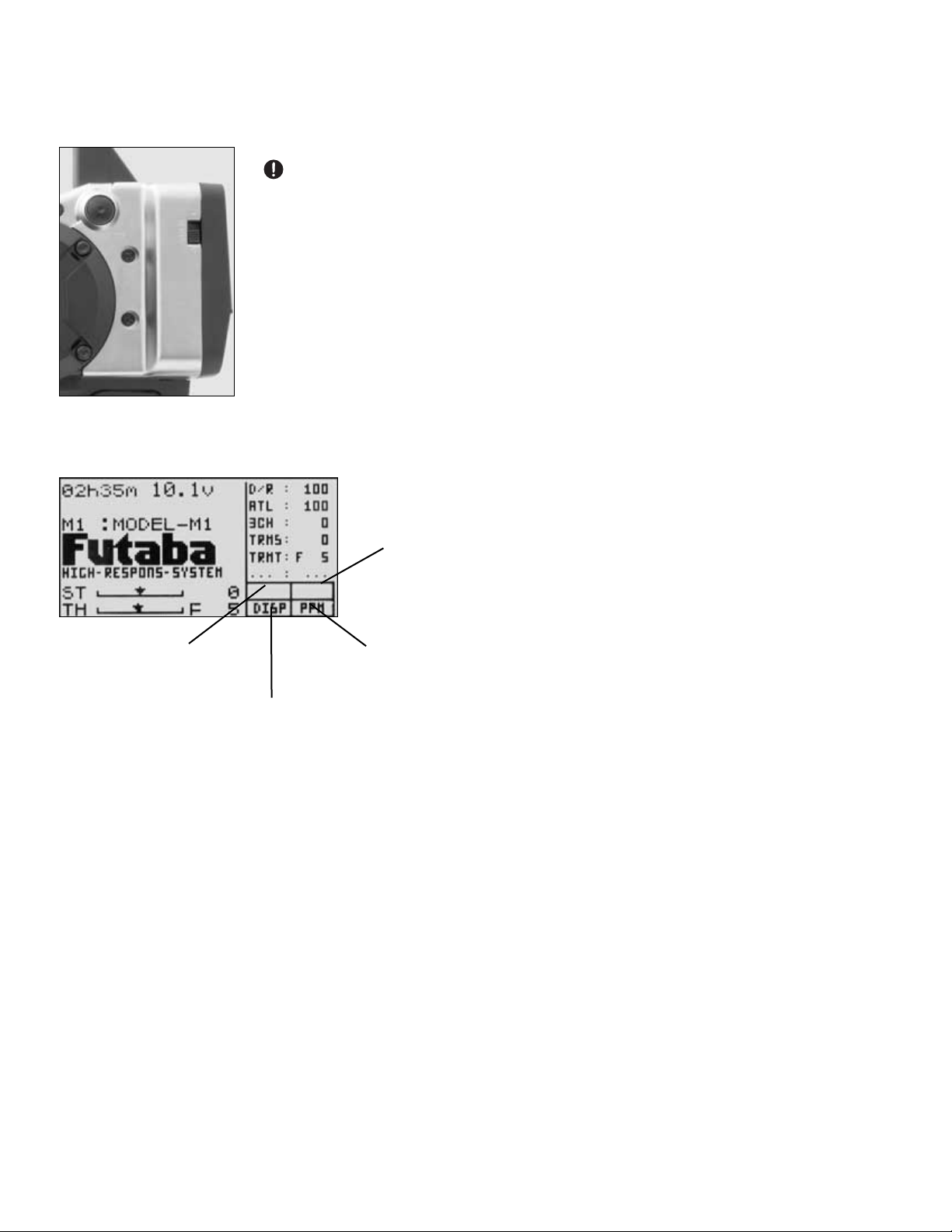

Power switch turned on: Beep confirmation sound is generated and the initial screen shown below appears.

• Total timer display (H:M) (see TIMER p. 30) and battery

voltage display

• Model name (10 characters) Futaba name can be changed to

display servo view or timers. (See SYSTEM, p. 13.)

• Steering trim display

• Throttle trim display

• Function names and rate assigned to dials/trims DL1-DL3 and

DT1-DT3 respectively.

• CAMPac, transmission, backlight and modulation status.

User name display: When the END button is held down for 1 second or longer at the initial screen, the Futaba logo and

user name are displayed for about 2 seconds.

BLHT

(if backlit)

DPAC

(if CAMPac installed)

RF (if transmitting)

DISP (if not transmitting)

PCM,

PPM

or

HRS

Page 9

9

Digital trim operation

•

Default assignments may be changed in FUNC-DIAL (pp. 34-35).

Features assigned to DL1, 2, 3, and DT1, 2, 3 are displayed at all

times on right side of LCD screen.

•

Digital trims can be used in 2 ways:

•

Operating by the lever: Push the lever to the left or right (up or down).

•

Operating by push button switch: Press the push button switch in

the desired direction.

•

The current position is displayed on the LCD screen in the bottom

three rows of the list.

•

Each step is indicated by a tone.

•

When the trim exceeds the maximum trim adjustment range, the beep

will change and the servo will not move any farther. Return to the

neutral position (center) by pressing both the push button switches

simultaneously for about one second.

•

Trim lever adjustments have no effect on the maximum servo travel.

This prevents the linkages from binding when adjustments are made.

Digital grip dial operation

•

Default assignments may be changed in FUNC-DIAL (pp. 34-35).

Features assigned to DL1, 2, 3, and DT1, 2, 3 are displayed at all

times on right side of LCD screen.

•

Initial settings: DL1=Steering Dual Rate, DL2=ATL

•

Operate the dials by turning them. The current set value is displayed

on the LCD screen.

•

A beep is made at each step.

•

When the maximum position is reached at each side, the length of the

beep changes. Thereafter, the set value does not change.

•

Remember, the dials are digital so the position of each dial is

remembered for each model separately.

Transmitter Checks Prior to Each Use

1. Turn on transmitter power.

2. Check the display screen for model name/number to

ensure you are working with the correct model.

3. Check the display screen for “RF”.

a. If RF is not displayed, check crystal/module installation.

Be sure module is clipped firmly into transmitter.

b. If RF is intermittent or non-existent, send for service

immediately.

4. Check the display screen for proper modulation to

match the receiver in this model.

a. FM receivers, such as R123F, must be set to PPM.

b. PCM1024 receivers, such as R113iP, must be set to PCM.

c. HRS-FM receivers, such as the R203HF, must be set to HRS.

5. Confirm function assignment. Notice the 6 features

listed in the box on the right of the screen, which shows

you the features assigned to the digital dials and digital

trims respectively, and their current settings.

6. Check trim, dual rate and ATL operation/positioning.

a. Steering trim is defaulted to the DT1 trim lever above

the steering wheel. Operate the lever and make sure

the marker moves on the ST graph. If default has

been changed, test steering trim in its new location.

b. Repeat test for throttle trim, defaulted to DT2.

c. Repeat test for steering dual rate, defaulted to DL1, at

the grip of the transmitter.

d. Repeat test for ATL, defaulted to DL2, below DL1.

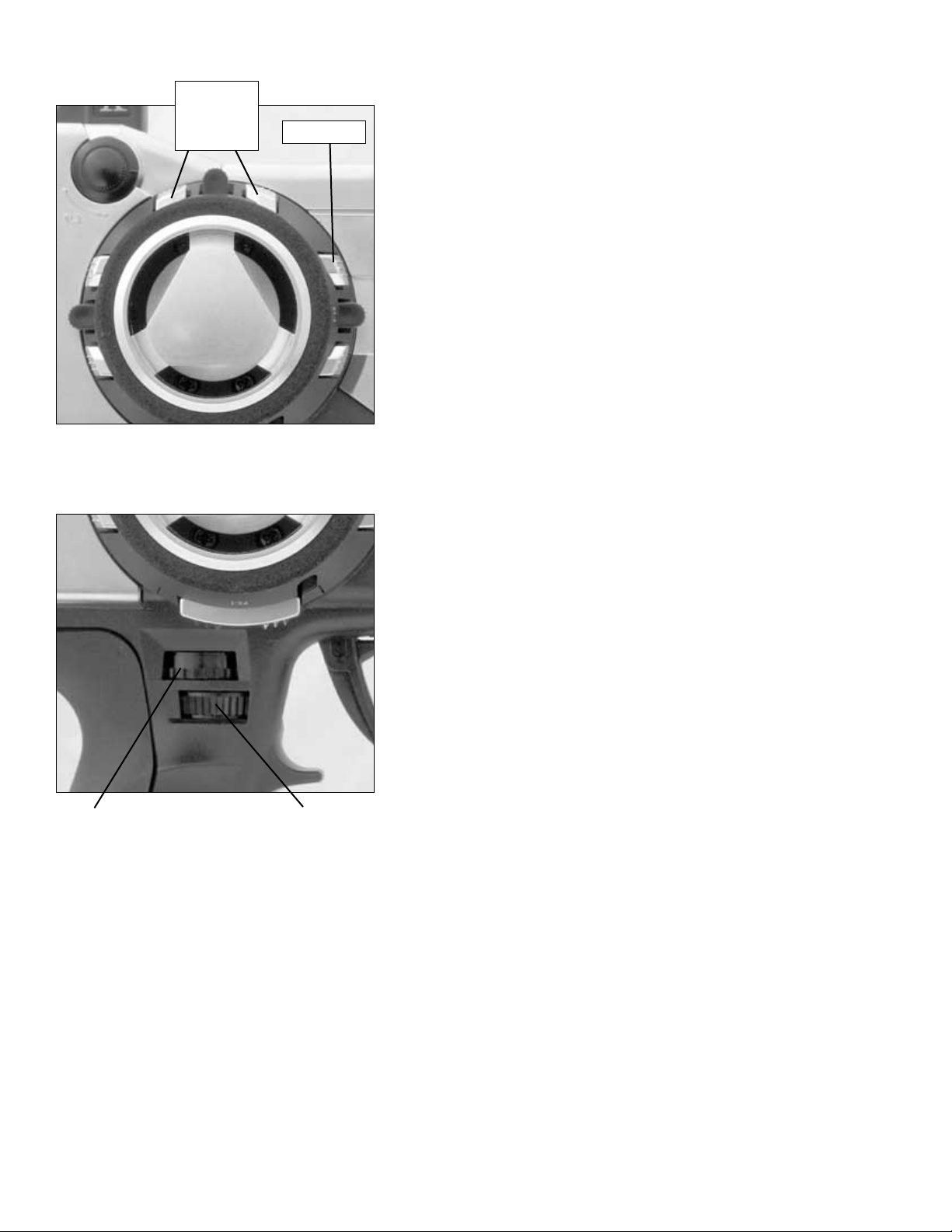

DL1

DL2

Trim Lever

Trim Push

Button

Switches

Page 10

10

INSTALLATION

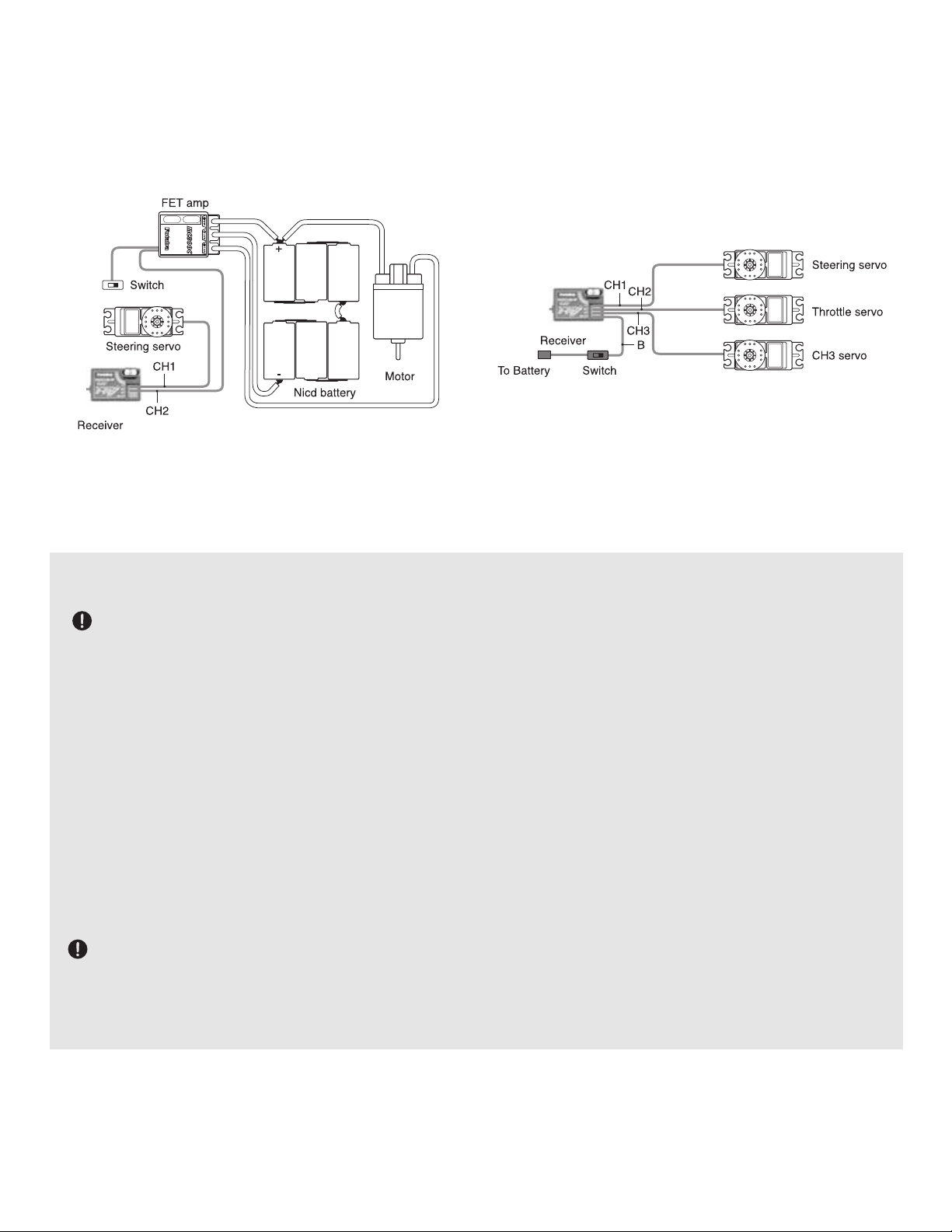

Receiver and Servo Connections

When connecting and installing the receiver and servos, read all safety precautions in the appendix.

Installation When an ESC is used (MC800C) Installation For Gas Powered Models

B/C port is for the receiver battery or a DSC cord. For information on DSC cord, see p 5.

Receiver Notes

DO NOT cut or fold the receiver antenna wire back on itself — cutting or folding changes the electrical length

of the antenna and may reduce range. Secure the antenna as instructed in your model's manual. You may run the antenna

inside of a non-metallic housing within the model, but range may suffer if the antenna is located near metal or carbon fiber

parts. Be sure to perform a range check before using.

When you insert Futaba servos, ESC, switch or battery connectors into the receiver, note that each plastic housing

has an alignment tab. Be sure the alignment tab is oriented properly before inserting the connector. To remove a

connector from the receiver, pull on the connector housing rather than the wires.

If your servos are too far away to plug into the receiver, use an extension cord to extend the length of the servo lead.

Additional Futaba extension cords of varying lengths are available from your hobby dealer. Always use an extension of the proper

length. Avoid plugging multiple extensions together to attain your desired length. If distance is greater than 18” or multiple or high

current draw servos are being used, Futaba Heavy-Duty servo extensions are recommended.

Receiver Vibration and Waterproofing

The receiver contains precision electronic parts. Be sure to avoid vibration, shock, and temperature extremes.

For protection, wrapping the receiver in foam rubber or other vibration-absorbing materials is ideal.

Mounting with double-sided tape is the next best option: It is also a good idea to waterproof the receiver by placing it

in a plastic bag and securing the open end of the bag with a rubber band. If you accidentally get moisture or fuel inside the

receiver, you may experience intermittent operation or a crash. If in doubt, send the receiver for service.

Page 11

Using the 3PK’s Functions:

The 3PK offers not only the most comprehensive menu of features available to provide optimum performance, but also

quick-access to utilize your favorite features. 3PK offers “Menu Selection” for onscreen lists of available features, and a

specialized, fully customizable version of “hot keys” called “Direct Selection.” (Don’t worry if terms seem overwhelming.

Check the glossary and read on to get more familiar with new terms.)

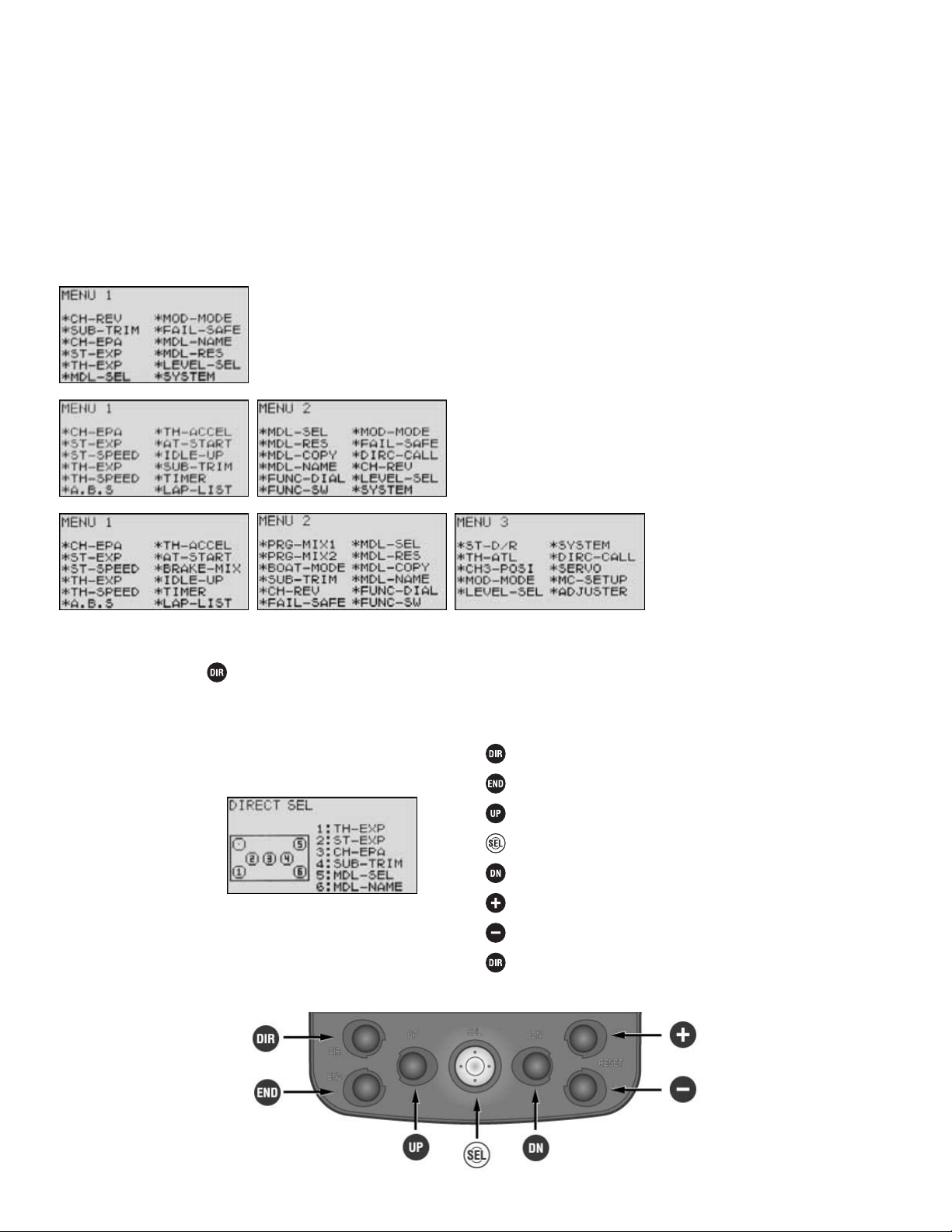

Menu Selection

•

Each function is easily selected from the function menu displayed on the LCD screen with the select key.

•

Three sets of function menus are available to match the level of use. To select the level for each model, use the Level

Select function (page 12). Note that functions are in different locations depending on the level selected. This is done

to keep level 1 simple, and keep related functions together on the higher levels.

•

Level 1 (LV1): For the new user, basic functions only.

•

Level 2 (LV2): Race-ready, including most popular racing

setup features.

•

Level 3 (LV3): All functions can

be selected. (For expert driver)

Direct Selection

•

The Direct Selection screen allows quick access to 6 user-selectable functions with just 2 keystrokes:

•

Press the key to open the Direct Selection Screen.

•

Press the button which corresponds to the feature’s number as shown on the on-screen diagram of the keys to

open that feature.

•

Direct Selection choices can be edited using the DIRC-CALL function (see p. 36).

11

Initial Settings

to Open

Throttle Exponential

Steering Exponential

End Point Adjustment (EPA)

Sub-trim

Model Select

Model Name

to Close

Page 12

A Look at the Radio’s Functions, Step by Step

LV1 FUNCTIONS for the New 3PK User and the Racers and Experts Alike

Level Selection LEVEL-SEL Levels LV1, LV2, LV3

DEFINITION: Selects the complexity of functions displayed on the menu screens.

Includes 3 levels of flexibility to simplify programming for new users and the

most flexible system in the world to those who wish to use it.

AVAILABLE FOR EACH INDIVIDUAL MODEL:

•

Selection of a lower level simply hides the higher level features from the menu;

however, setups in the higher level menus remain intact and as set prior to

changing the level.

•

Model reset clears all functions including those not visible in the displayed menus.

ADJUSTABILITY:

•

Level 1 (Learning the system; quick setups, a single menu with enough features for most models.) LV1

•

Level 2 (Expands upon Level 1 menu, with many race-ready features.) LV2

•

Level 3 (For the Expert driver, boat modeler, or other complex setups.) LV3

•

To view features available on each menu, see page 11.

DEFAULT: LV3

INTERACTION: NONE. Changing the complexity of what menu is visible has no effect on the programming whatsoever.

To adjust features set in a higher level and not currently visible, simply change the level back to the higher level and edit.

DESIRED END RESULT: Provide only as much information/access as needed without overwhelming the user with

features not currently desired.

CAUTION: Just because you change to a lesser level does NOT reset hidden functions to their defaults or to inhibited.

Be sure to inhibit any undesired functions and check settings which interact with other functions. (Example: throttle

ATL.)

12

GOAL:

Change setting from the default of Expert

Driver (LV3) to New User (LV1) to simplify

getting to know the basics of the radio. (If

on LV1 or LV2, scroll through menus, then

select LEVEL-SEL.)

Where next?

STEPS:

Open menu and display menu 3.

Select menu 3 & then select level

selection.

Select level 1.

Confirm your change.

Close.

INPUTS:

to LEVEL-SEL.

together for 1 second.

Screen displays LEVEL = LV1

Name the model (MDL-NAME): See p. 15.

Select modulation (FM/PCM/HRS) (MOD-MODE): See p. 16.

Channel reversing (CH-REV): See p. 18.

End point adjustment (ATV) (EPA): See p. 18.

Page 13

Levels LV1, LV2, LV3 System-Wide Settings SYSTEM

DEFINITIONS:

•

SYSTEM Adjusts system-wide settings. Settings are not model specific.

•

LHT-MODE LCD backlighting mode

•

LHT-TIME LCD backlighting time period

•

CONTRAST LCD screen contrast

•

BUZ-TONE Buzzer tone

•

LED-MODE LED pilot lamp

•

DISPL-SEL Home screen display settings

•

KEY-ON Back-lights whenever a programming key is pressed. Length of

time is adjustable with LHT-TIME.

•

ACT Activated.

•

SRV-VIEW Servo display shown on home screen.

AVAILABLE FOR: System-wide only. Not channel or model specific.

ADJUSTABILITY:

•

LCD backlight: OFF, KEY-ON, ON (constantly).

•

Backlight time period: OFF, ACT (when KEY-ON is selected in LHT-MODE).

•

1-30 seconds, length of time can be adjusted for backlight to stay on when a button (key) is pressed.

•

Screen contrast: -10 to +10.

•

Buzzer tone adjustment: OFF, 0-100.

•

Pilot lamp color: OFF, LIGHT BLUE, PURPLE, WHITE, GREEN, ORANGE, YELLOW, BLUE.

•

Home screen display: FUTABA, SRV-VIEW, TIMER.

INTERACTION:

•

When LHT-MODE is set to KEY-ON, backlight comes on automatically if any programming button is pressed, and time

period is automatically made ACT (active).

•

Pilot lamp blinks when key functions, such as ABS and speed limiter, are active.

DESIRED END RESULT: Custom setup to best meet user’s needs and style.

CAUTION: Adjusting display so dark/bright that it cannot be read and then turning transmitter off may require factory

service to reset.

13

GOAL:

Change the home screen display from

Futaba to timer while radio is in LV1 setting.

(If set to more complex menus, scroll

through menus with Up button until SYSTEM

is displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select SYSTEM.

Select DISP-SEL.

Change to TIMER.

Close.

INPUTS:

to SYSTEM.

Adjust backlight settings (repeat steps above but edit LHT.)

Adjust screen contrast (repeat steps above but adjust CONTRAST.)

Set up timer function (TIMER): See p. 30.

Reset system timer (from home screen for 1 second.)

Page 14

Model Selection MDL-SEL Levels LV1, LV2, LV3

DEFINITION: Selects from the 10 model memories stored within the transmitter,

or additional model memories in the optional CAMPac ©.

AVAILABLE FOR:

•

10 models in transmitter memory

•

Optional additional memories, 10 per CAMPac © (see p. 5).

ADJUSTABILITY:

•

Models M1-M10 within the transmitter, E11-E20 from optional CAMPac ©

•

Stores complete model setups with all functions separate per model (except

settings within SYSTEM).

INTERACTIONS:

•

Each model memory is a completely separate setup, and allows adjustment of all functions within each separate

model memory (except SYSTEM functions).

•

Each model memory may be set to a different modulation. If a model memory of a different modulation is selected,

the transmitter must be turned off and back on to change the modulation.

•

Example: Model 1 is HRS with R203HF receiver. Model 2 is FM with R133F receiver. Select model 2 and

close the menu. Note that HRS is still displayed on screen. Turn transmitter off and back on. Modulation now

shows PPM and will communicate with the R133F or other FM receiver. (If you do not cycle the power on the

transmitter, it cannot communicate with the PPM receiver. See MOD-MODE, p. 16.)

•

Each separate model memory may have a different level selection, so that simple models have only LV1 menu, with

LV2 and LV3 for other, more complex models.

•

To make a copy of one model memory for setting up another, similar model, or for experimentation, change

LEVEL-SEL to LV2 (p. 12), and use MDL-COPY (p. 33).

DESIRED END RESULT: Select a specific model’s setup within the radio or CAMPac data storage.

CAUTIONS:

•

Never remove the CAMPac © with the power switch on.

•

If a CAMPac-stored model (E11-20) is in use when the transmitter is turned off, and then the CAMPac is

removed, “SELECT ERROR” will be displayed on screen and model M1 will be automatically selected. Use model

select to select the desired model.

•

The transmitter does not recognize one CAMPac as being different from another. Model E11 is the first model

in the CAMPac currently in the port, regardless of what CAMPac was last in the port. (Imagine inserting a

floppy disk into your PC with a file on it labeled car1.doc. Close the file, remove the floppy, and insert another

floppy which also includes a file called car1.doc. Your PC doesn’t know or care that they may be different files;

it simply opens the file named car1.doc.)

14

GOAL:

Select model M3, changing from model M1

and using the LV1 programming menus. (If

set to more complex menus, scroll through

menus with Up button until MDL-SEL is

displayed on screen.)

Where next?

STEPS:

Open and Select Menu 1.

Select MDL-SEL.

Choose M3.

Confirm your change.

Close.

INPUTS:

to M3.

together for 1 second.

Change menu to LV1 (LEVEL-SEL): See p. 12.

Name the model (MDL-NAME): See p. 15.

Copy the model (MDL-COPY): See p. 33.

Reset the model data (MDL-RES): See p. 32.

Select modulation (FM/PCM/HRS) (MOD-MODE): See p. 16. (Hint: remember to power

off and back on to begin transmitting in new modulation.)

Page 15

Levels LV1, LV2, LV3 Model and User Names MDL-NAME, USR-NAME

DEFINITION: Provides a 10-character name for each of the model memories in

the transmitter to easily select the correct setup for the model currently in use.

Also provides a 10-character user name that is constant to all model memories.

AVAILABLE FOR: M1-M10 in transmitter memory, E11-E20 if using optional CAMPac.

ADJUSTABILITY: Includes 0-9, A-Z and numerous symbols.

INTERACTIONS: Model name is reset to factory default with model reset, and

copied with model copy.

DESIRED END RESULT:

•

Clearly label each model for easy selection.

•

User name can be set to display on home screen (see SYSTEM, p. 13) for easy

confirmation of radio ownership.

CAUTIONS:

•

User name is constant across all model memories, so changing it changes it system-wide.

•

Model names may be the same between models; model # will still be displayed and will still be different.

15

GOAL:

Rename the current model FUTABA-1,

while using the LV1 programming menus. (If

set to more complex menus, scroll through

menus with Up button until MDL-NAME is

displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select MDL-NAME.

Change first character to F.

Move to the second letter.

Repeat steps above to change name.

Close.

INPUTS:

7 times to F.

6 times to U.

16 times to T. Repeat.

Adjust the user name (USR-NAME): repeat steps above, but past model name to

user name and edit each character.

Copy the model (MDL-COPY): See p. 33.

Select modulation (FM/PCM/HRS) (MOD-MODE): See p. 16. (Hint: remember to power

off and back on to begin transmitting in new modulation.)

Channel reversing (CH-REV): See p. 18.

Page 16

Modulation Select MOD-MODE Levels LV1, LV2, LV3

DEFINITIONS:

•

Modulation select: Chooses the modulation (language) used by the transmitter to

give instructions to the receiver.

•

PPM: Pulse Position Modulation, commonly called “FM”. Transmitted via FM,

not encoded.

•

PCM: Pulse Code Modulation. Transmitted via FM, but encoded for increased

noise resistance. Includes FailSafe programming. (See p. 17.)

•

HRS: High Response System. Transmitted via FM at accelerated rate; includes

FailSafe programming. (See p. 17.)

•

FM: Type of transmission of data. (Similar to FM car radio.) Used for PPM,

PCM and HRS.

AVAILABLE FOR: Each individual model memory separately.

ADJUSTABILITY:

•

PPM (Pulse Position Modulation, commonly called “FM”) for FM receivers such as R133F

•

PCM (Pulse Code Modulation, 1,024 step resolution) for PCM receivers such as R113iP

•

HRS (High Response System) for HRS receivers such as R203HF

INTERACTIONS:

•

Modulation is set separately for each model. One model can be PCM and another HRS, and still another PPM(FM).

•

Modulation is not reset when a Model Reset is performed.

•

Modulation is stored for each specific model. Turn transmitter off/on if new model is in different modulation.

•

Both transmitter switches MUST be turned off and back on for a change to take effect. If transmitter is not turned off

after modulation is changed, it continues to transmit in the last modulation. Display shows the current method of

transmission under NOW OPERATION and the modulation that will be used as soon as the transmitter is turned off and

back on under MEMORY.

DESIRED END RESULT: Change transmitting “language” so the receiver can understand the transmitter’s instructions.

CAUTIONS:

•

While there are 3 types of modulation (4 if you include AM, not supported by 3PK), all are transmitted on the

same frequency band. NEVER attempt to operate more than one model on the same frequency at the same time.

•

Transmitter must be turned off and back on for change to take effect.

16

GOAL:

Change Modulation from HRS to PPM to

operate with standard Futaba FM receivers

such as R133F, while using model M1 and

the LV1 programming menus. (If set to

more complex menus, scroll through

menus with Up button until MOD-MODE

displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select MOD-MODE.

Choose PPM.

Confirm your change.

Close.

Cycle transmitter power to transmit in

new modulation.

INPUTS:

6 times.

together for 1 second.

Turn both switches off.

Turn both switches back on.

Confirm screen reads PPM.

Name the model (MDL-NAME): See p. 15.

Copy the model (MDL-COPY): See p. 33.

Channel reversing (CH-REV): See p. 18.

End point adjustment (EPA): See p. 18.

Set up FailSafe reactions (FAILSAFE): See p. 17.

Change menu complexity (LEVEL-SEL): See p. 12.

Page 17

Levels LV1, LV2, LV3 FailSafe Settings FAIL-SAFE

DEFINITIONS:

•

FAILSAFE: Settings stored by the receiver, used only if the receiver fails to

receive clean, intelligible signal from a transmitter.

•

HOLD: Maintain the last instruction provided by the transmitter before clean

signal was lost.

•

SET: Position servos are to be moved to if FailSafe activates.

•

BATTERY F/S: When “on” the receiver will move the throttle servo to the preset

FailSafe position when the receiver battery is low. Release and pull trigger to

reactivate throttle for approximately 30 seconds.

AVAILABLE FOR Steering, Throttle, Channel 3, only with HRS/PCM receivers

and HRS/PCM modulation settings (see MOD-MODE, p. 16).

ADJUSTABILITY: Hold or set (to go to a preset position).

INTERACTIONS:

•

FailSafe operates only during interference or loss of transmitter signal.

•

Modulation is not reset when a model reset is performed, but the FailSafe settings are reset.

DESIRED END RESULT:

•

FailSafe: Provide receiver pre-recorded instructions of how to perform in the event it does not receive clean, clear

transmission from a transmitter on its channel in Futaba PCM1024 language.

•

Battery FailSafe: Warn user the receiver battery is getting so low that safe vehicle operation will soon end.

CAUTION: Settings are sent to the receiver every 2 minutes. Always allow at least 2 minutes’ time to pass prior to

testing any FailSafe settings.

17

GOAL:

Change FailSafe settings for your throttle

servo on your PCM receiver from

“HOLD” to full brake position, while

using the LV1 programming menus. (If set

to more complex menus, scroll through

menus with Up button until FAILSAFE

displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select FAIL-SAFE.

Choose throttle channel.

Store desired throttle position.

Close.

Cycle transmitter power to test settings.

INPUTS:

5 times.

Hold T

HROTTLE TRIGGER to full brake.

together for 1 second.

Wait at least 2 minutes.

Turn master power switch off.

Observe response of throttle servo. It should

go to full brake setting.

Set battery FailSafe to obey stored FailSafe position in case of low receiver battery

voltage (BATTERY F/S): Repeat steps above but change MODE to ON.

Channel reversing (CH-REV): See p. 18.

End point adjustment (EPA): See p. 18.

Change menu complexity (LEVEL-SEL): See p. 12.

Set steering exponential (ST-EXPO): See p. 20.

Page 18

Channel Reverse CH-REV Levels LV1, LV2, LV3

DEFINITION: Reverses the direction the servo moves when given an input. If the

vehicle is turning right when wheel is turned left (or vice versa), reverse the

setting for the steering. If the engine accelerates when brake is pushed, reverse

the setting for the throttle.

AVAILABLE FOR: Steering, throttle, channel 3

ADJUSTABILITY: Normal, reverse

INTERACTION: Servo reversing affects all other functions, including EPA.

DESIRED END RESULT: Change the servo’s direction to exactly the opposite.

CAUTION: Servo reversing affects all functions, including ATL.

End Point Adjustment EPA Levels LV1, LV2, LV3

DEFINITION: End point, commonly called EPA or ATV, adjusts (shortens or

lengthens) the total travel of the servo. For example, a steering servo travels 60°

each way. Decreasing the right EPA to 50% results in a steering servo that will

move 60° to the left but only 30° to the right.

AVAILABLE FOR: Steering, throttle, channel 3.

ADJUSTABILITY: 0-120% on all 3 channels. Default: 100%.

18

GOAL:

When brake is applied, the engine

accelerates. Reverse the throttle servo

direction, while using the LV1 programming

menus. (If set to more complex menus,

scroll through menus with Up button until

CH-REV displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select CH-REV.

Choose throttle channel.

Reverse the servo.

Close.

INPUTS:

End point adjustment (EPA): See p. 18.

Change menu complexity (LEVEL-SEL): See p. 12.

Set throttle exponential (TH-EXPO): See p. 20.

Set engine cut and smooth start features (AT-START): see p. 28.

Page 19

INTERACTIONS:

•

EPA is a primary function. EPA’s should be set prior to doing any other programming and not adjusted (except for

servo replacement, etc.) once other programming has been set. If EPA is adjusted after features such as dual rates,

ATL, mixing, etc, the other functions must be readjusted based upon the new EPA.

•

EPA is not limiting or absolute. Other programming functions can override the end point set by EPA. Always double

check for binding after adjusting:

•

Sub trim (all channels)

•

Program mixing slave side (all channels)

•

Tilt mixing (steering, channel 3)

•

Idle up (throttle)

•

Throttle preset (throttle)

•

ATL trim (set ATL trim dial center prior to adjusting throttle channel EPA.) (LV3 only.)

•

EPA is not tied to any mixing. EPA adjusts each individual servo regardless of brake mixing, boat mode mixing, etc.

NOTE: When EPA is increased to maximum (120%) but more servo travel is needed, the servo’s motion can be

increased with programmable mixing, up to the servo’s physical limits. (See programmable mixes, pp 40-41.)

•

Interaction Example:

•

Original setup:

•

Steering servo linkage allows 30° of servo rotation to the left.

•

Steering EPA is adjusted to 90%, creating 27° of left travel.

•

Steering dual rate is adjusted to 50%, or 13.5° of travel.

•

Adjusting EPA to 120% results in 36° of left travel; dual rate now provides 18° of travel, not 13.5°.

•

Steering dual rate adjusts the servo’s total travel as if EPA was adjusted. ATL adjusts braking travel. Both can be

assigned to dials (see FUNC-DIAL, pp. 34-35).

DESIRED END RESULT:

•

All channels: Servo is not binding or chattering, trying to move the linkage farther than it is physically able.

•

All channels: Servo moves the attached pushrod just enough, creating the desired maximum servo movement.

•

All channels: Linkage does not stick, bind, or catch on anything on the vehicle.

•

Steering: Full right and full left turns result in the desired turning radius.

•

Channel 3: Function moves the desired distance when full up/down, left/right or pressed/unpressed button are applied.

CAUTIONS:

•

Servo binding drains receiver batteries very quickly and may result in a loss of control.

•

More is NOT always better! Start with the desired steering throws recommended for your vehicle.

•

Always check for binding and servo “chatter” prior to each use.

•

Always set dual rates, sub trims, and all other functions to their defaults prior to adjusting EPA.

19

GOAL:

Change end point for steering servo so

servo arm does not strike chassis in right

turns, while using the LV1 programming

menus. (If set to more complex menus,

scroll through menus with Up button until

CH-EPA displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select CH-EPA.

Go to steering channel right side setting.

Set desired end point (example 98%).

Close.

INPUTS:

to 98%.

Set sub-trim (SUBTRIM): See p. 22.

Set exponential (ST-EXP, TH-EXP): See p. 20.

Change menu complexity to access additional features (LEVEL-SEL): See p. 12.

Set idle-up (IDLE-UP): See p. 27.

Set anti-lock braking (ABS): See p. 24.

Page 20

Exponential (ST-EXP, TH-EXP) Levels LV1, LV2, LV3

DEFINITIONS:

•

Exponential adjusts the sensitivity of the servo around the neutral position.

Exponential creates a true curve, not a hard climb to a certain point then a softer

climb from there. Negative exponential makes the servo less responsive around

center; positive exponential makes the servo significantly more responsive

around center. Only exponential is available for steering and braking.

•

TH-EXP offers far more than just exponential for forward: it also offers a 5-point

throttle “curve” and a Variable Trace Rate (VTR) option.

•

VTR: Variable Trace Rate is basically a 3-point line, where one point may be

raised or lowered, forming two straight lines, and where the user can select the

point where the line breaks into two.

•

The “curve” function offers 5 points along the range of the servo, and draws

straight lines of response between each point. It is not a true curve, as is

exponential, and there are noticeable steps in the responsiveness as each rate of

response is entered.

20

Expo Curve

Expo Curve

Throttle Curve

(forward throttle only)

Variable Trace Rate (VTR)

(forward throttle only)

Page 21

AVAILABLE FOR: Steering (ST-EXP), Throttle (TH-EXP)

ADJUSTABILITY:

•

Range: -100% to +100%

•

Throttle: Forward and Braking

•

Steering: Left and right

•

Types: (TH-EXP forward only) Variable trace, curve, or exponential curves.

•

May be assigned to a dial for on-the-track adjustability. (See FUNC-DIAL, pp. 34-35.)

INTERACTIONS:

•

Exponential affects the servo’s response around center, and affects all built-in and programmable mixing functions

such as throttle acceleration, brake mixing, ABS, etc. All mixing functions respond based upon the position the

transmitter is telling the servo to go to, not the amount of trigger being pulled or wheel turned.

•

EPA affects the total travel of the servo, and exponential is proportional to and affected by that total travel.

•

AT-START, TH-SPEED, TH-ACCEL and other features interact with this function. For example, a very high VTR rate will

result in rapid acceleration early in the trigger movement. Therefore, the engine reaches wide open at, for example,

half throttle trigger. This may make it seem as though Speed Limiter programming is needed when you really should

adjust the VTR rate to create a more normal throttle response.

DESIRED END RESULT:

•

Positive exponential makes the servo move farther for the same amount of input when around neutral (for sharper

steering when small inputs are given, for example).

•

Negative exponential makes the servo move less for the same input when around neutral (to make a nitro engine’s response

to the throttle trigger smoother and more consistent between the first 1/4 of the trigger and the last 1/4 of the trigger.)

CAUTIONS:

•

Too much positive exponential can make the model so overly sensitive it may be impossible to control.

•

Too much negative exponential can make the model so non-responsive, your inputs may be too little too late,

resulting in a crash.

•

Too high of a rate on a throttle VTR will result in the engine reaching full throttle well before the trigger is at full

throttle, which may result in wheel spin, especially upon acceleration.

21

GOAL:

Making the steering servo less responsive

around center to get rid of oversteering

when trying to make corrections at high

speeds, while using the LV1 programming

menus. (If set to more complex menus,

scroll through menus with Up button until

ST-EXP displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select ST-EXP (TH-EXP for throttle.)

Add negative exponential until servo is in

desired position.

Close.

INPUTS:

to –25%.

Create a throttle VTR with a rate of 0 and a trigger point of 50%. See how it is just a

straight throttle response? Now hold the throttle at 1/2 trigger while adjusting the rate.

See how increasing or decreasing the VTR will then cause the throttle servo to open

sooner, or slower, on a smoothly linear response?

Adjust braking expo for softer response around neutral. Repeat steps above in TH-EXP.

Set FailSafe (FAIL-SAFE): See p. 17.

Change menu complexity to access additional features (LEVEL-SEL): See p. 12.

Set speed of response for steering/throttle (ST-SPEED, TH-SPEED): See p. 23.

Set acceleration rate to avoid wheel spin (AT-START): See p. 28.

Page 22

Sub-Trim SUBTRIM Levels LV1, LV2, LV3

DEFINITION: Fine tuning adjustment for the center point of each servo. Similar to

using electronic trims on the radio, but subtrim moves the entire servo’s travel

rather than just sliding the servo left/right within the total travel. The setting is

stored within the programming and the onscreen displays continue to show neutral.

AVAILABLE FOR: Steering, throttle, channel 3

ADJUSTABILITY:

•

Steering: left 100 to right 100

•

Throttle: brake 100 to throttle 100

•

Channel 3: -100 to +100

•

May be assigned to a dial/trim. (See

FUNC-DIAL

, pp. 34-35.)

INTERACTIONS:

•

ALWAYS adjust your digital trims back to neutral prior to adjusting your subtrim. Then adjust the subtrim until the

servo is at the desired location without needing any digital trim.

•

Subtrim adjusts the entire range of the servo to one side or the other; it does NOT adjust the servo’s center point

toward one end of the total travel like digital trims.

•

Subtrim affects the neutral point for the servo for all other functions.

DESIRED END RESULT: Fine-tune the servo’s center point to correct for minor linkage problems.

CAUTION: The range of subtrim is limited. Always adjust linkages to get the servo’s center as close to the desired

location mechanically and only use trim functions as absolutely necessary.

22

GOAL:

Moving the steering servo arm one tooth

on the servo results in a slight right turn;

moving it back one causes a slight left

turn. Adjust the servo’s center (example:

5) so that the vehicle travels perfectly

straight with no steering input, while using

the LV1 programming menus. (If set to

more complex menus, scroll through

menus with Up button until SUB-TRIM

displayed on screen.)

Where next?

STEPS:

Open and select menu 1.

Select SUB-TRIM.

Cursor down to throttle and up to steering

to see the cursor positioning.

Add trim until servo is in desired position.

Close.

INPUTS:

to L5.

Set end point (EPA): See p. 18.

Set exponential (ST-EXP, TH-EXP): See p. 20.

Change menu complexity to access additional features (LEVEL-SEL): See p. 12.

Set idle-up (IDLE-UP): See p. 27.

Set throttle acceleration (TH-ACCEL): See p. 26.

Page 23

LV2 FUNCTIONS for the Race-Ready Driver

Levels LV2, LV3 Only Servo Maximum Speed Limiter (ST-SPEED,TH-SPEED)

DEFINITION: Speed Limiter decreases the maximum speed of the servo. This

may be adjusted individually for turning and returning the servo to neutral

(steering), and for high and low throttle settings.

A servo which responds too rapidly to a full-wheel input may cause the vehicle to

oversteer; to compensate many drivers steer too slowly, resulting in understeer

and not completing a clean corner. Others slow down to make the model more

controllable, losing valuable seconds. Speed Limiter helps in both these cases.

Similarly, applying throttle too suddenly results in wheel spin and wasted energy.

It may also cause a nitro engine to stall.

AVAILABLE FOR: Steering (ST-SPEED), Throttle (TH-SPEED)

ADJUSTABILITY:

•

1% (slowest possible response) to +100% (normal response)

•

On input and return (ST-SPEED only); High speed and low speed (TH-SPEED only)

•

On/off switch may be assigned for TH-SPEED only. Switch selection made in FUNC-SW (see pp. 34-35).

•

Throttle speed and steering turn/return may each be assigned to a dial. See FUNC-DIAL (pp. 34-35).

INTERACTIONS/COMPARISONS:

•

Increasing EPA decreases the rate at which a servo reaches a given point mechanically; therefore, adjusting EPA will

also adjust the actual rate of response of that servo.

•

Negative exponential softens how far the servo responds to a given input vs. how fast. Either is used to settle a

“twitchy vehicle”, but the driver must first determine if the servo is moving too far, or simply too quickly.

•

ABS pulsates the amount of brake given for a certain input to avoid overbraking and skidding the entire time brake

is applied. Speed Limiter slows the brake command and decreases skidding only when brakes are first applied.

•

Throttle acceleration gives a significant sudden movement of the throttle servo only when the trigger is first moved;

Speed Limiter would slow that quick step off idle and diminish the effectiveness of acceleration. Thus, modifying

Speed Limiter may require adjustments to acceleration, and vice versa.

•

Auto-start moves/holds the servo to a preset position when the throttle is applied the first time, then allows the servo

to operate through its normal travel for the rest of the run; Speed Limiter slows the performance of the throttle servo

at all times. If the problem is spinning on starts only, then auto-start should be adjusted, NOT Speed Limiter.

•

Idle-up increases the throttle idle as if throttle trim were applied, and is used to make starting nitro engines easier.

Speed Limiter will only effect how rapidly the engine responds when additional throttle is applied.

•

ATL adjusts the end point of the braking side only; Speed Limiter affects how quickly that total distance is traveled.

Adjustments to either may require fine adjustments to the other.

DESIRED END RESULTS:

•

Servo reaches actual travel commanded by trigger/wheel position, just at a more gradual rate.

•

Minimize wheel spin, harsh acceleration out of corners, understeering and spins.

23

GOAL:

Decrease throttle rate of response when

applying more than 40% throttle, to

minimize torque/spinning when accelerating

out of turns, while using the LV2

programming menus. (If set to LV3, select

TH-SPEED from menu 1). (If set to LV1, first

change level selection. See p. 12.)

Where next?

STEPS:

Open and select menu 1.

Select TH-SPEED. (use ST-SPEED to adjust

steering servo speed.)

Make active only above 40% trigger.

Decrease response speed to 50%.

Activate the function.

Close.

INPUTS:

to H40.

to 50%.

Assign on/off for throttle speed (FUNC-SW): See pp. 34-35.

Set ABS braking (ABS): See p. 24.

Page 24

Anti-Lock Braking ABS Levels LV2, LV3 Only

DEFINITIONS:

•

ABS: Simulates a full size car’s antilock braking by pulsing the brake on and

off rapidly.

•

ABP: Amount of brake return, how far the braking response is decreased

during the pulses.

•

DLY: Delay; determines how long the braking is applied before ABS begins

to operate.

•

CYC: Cycle speed adjustment, sets how rapidly the brakes cycle from full

brake to ABP and back.

•

TGP: Trigger point, sets at what point ABS will be activated. ABS does not

respond if less brake is provided than the trigger point setting.

•

DTY: Cycle duty ratio, sets the proportion of the total cycle spent with brakes

applied full vs. ABP.

•

STM: Steering mix setup, controls when the ABS is triggered based upon amount of steering input. Designed to

decrease skidding when vehicle is in a turn, and minimize spin outs.

AVAILABLE FOR: Braking only.

ADJUSTABILITY:

•

ABP: 0 (no ABS) to 100% [Servo goes to neutral (no brake) during pulse].

•

DLY: 0 (ABS responds immediately) to 100% (1.7 seconds of full brake before ABS takes over).

•

CYC: 1 (fastest) to 30 (slowest). Default=10.

•

TGP: 10-100.

•

DTY: -3 (longest full brake application — most likely to skid) to + 3 (shortest full brake – least likely to skid).

•

STM: OFF, N10-N100, E10-E100.

•

MODE:Inhibited, Active but switch is off, Active and switch is on.

•

Switch assignment can be changed in FUNC-SW (see pp. 34-35).

•

Each ABS variable can be assigned to dials in FUNC-DIAL (pp. 34-35) for on-the-course adjustability.

INTERACTIONS:

•

EPA, servo reversing, dual rates, Speed Limiter, acceleration, auto-start, and exponential all interact to create the

overall braking effect.

•

Brake mixing works with ABS as if only one brake servo were used. No second setup for ABS is required.

•

Trigger point, steering mix and assigned switch each control ABS. All three must “say OK” for ABS to respond.

DESIRED END RESULT: Model stops as rapidly as possible without skidding.

CAUTIONS:

•

Careful analysis of the problem causing skids is required to adjust the proper portion of ABS for best results.

•

Adjustments to EPA, auto-start, expo, speed, brake mixing, vehicle’s suspension, tire compounds, engine

tuning and ATL will all affect the performance of the ABS settings.

24

Page 25

25

GOAL:

Set up a fairly rapid servo (such as S9402)

on a nitro off-road vehicle, while using LV2.

(If using LV3, select ABS from menu 1.)

(If using LV1, first change level selection.

See p. 12.)

Desired settings:

Fairly mild return (ABP) 30%

Use ABS if brakes are applied for more

than approx. 1/4 second (DLY): 10%

Pulse quickly (CYCL): 5-7

Use ABS only if braking hard: TGP: 70%

Leave proportion of brake on to brake off

even (DUTY): 0

Leave steering mix off (STM): 0

View onscreen demonstration of braking

and make adjustments as needed.

Fine tuning:

Where next:

STEPS:

Open and select menu 1.

Select ABS.

Make ABS active.

Set rate of return to 30% (ABP).

Delay ABS coming on to 10% of the

maximum available delay (DLY).

Decrease the cycle value to increase the

cycle rate (CYCL).

Set the trigger position where ABS

becomes effective to 70% (TGP).

Leave the difference in brake-on to brakeoff in each cycle to 0 (DUTY).

Allow ABS to work whether vehicle is

turning or not (STM).

View ABS working within the function on

screen to confirm proper setup. (Hint: LV3

users can also view braking activity and

all other servo actions on screen using the

SERVO function.)

Close function and menus.

INPUTS:

to 30.

to 10.

to 5.

to 70.

(Leave at 0.)

(Leave at OFF.)

Gradually push the throttle trigger to

approximately half brake. Screen should

still read “MODE: ACT (OFF)”.

Push past 70%. Display now reads “MODE:

ACT (ON)” and you can see how brake

commands will be transmitted to the servo

right on the screen.

If brakes still lock during all stops, analyze the problem, then try:

Increasing ABP so less brake is applied during pulses.

Decreasing DLY so that ABS takes effect more rapidly.

Increasing CYC so the brakes pulse more rapidly, each on/off cycle is shorter.

Decrease the TGP so ABS takes over with less brake application.

Decreasing DTY so that brake off time is longer than brake on.

If brakes lock in turns but are not enough on straights:

Set STM so ABS functions only when turning (ex: E50).

NOTE: All of these functions interact with the throttle servo as well and are all interrelated. Adjusting any one may affect the performance of the others, as described in

Interactions for each function.

Adjust the throttle servo’s overall speed (TH-SPEED): See p. 23.

Adjust throttle exponential (TH-EXP): See p. 20.

Adjust throttle servo’s response only immediately around neutral to correct for nitro

engine’s lag due to linkage setup (TH-ACCEL): See p. 26.

Set up smooth acceleration off of the start or engine cut (AT-START): See p. 28.

Set up a high idle for starting/racing, and keep a normal idle to keep the car sitting still

on start line (IDLE-UP): See p. 27.

Adjust brake mixing for separate front/rear brakes (BRAKE-MIX) (LV3): See p. 42.

Page 26

Rapid Throttle Acceleration THR-ACCEL Levels LV2, LV3 Only

DEFINITION: Due to the shape of some nitro engine linkages, throttle servo

movement near neutral results in very little movement of the pushrod. Throttle

acceleration simply jumps the servo from neutral to a portion of the total

available throw whenever the trigger is moved away from center. It does NOT

change the speed of the servo; the servo will jump to the input position at its

maximum possible speed. Unlike exponential, which adjusts the whole throttle

movement into a curve, throttle acceleration simply “jumps” away from neutral

and then leaves the remaining response linear. Accelerate is a pre-programmed

VTR throttle exponential (see p. 20).

AVAILABLE FOR: Throttle and braking separately.

ADJUSTABILITY: 0-100%.

•

At 100% the throttle servo moves immediately to

approximately 40% of the total EPA.

•

At 100% the brake servo moves immediately to full brake.

•

Each setting may be assigned to a dial or trim for on-thetrack adjustability. (See FUNC-DIAL, pp. 34-35.)

INTERACTIONS:

•

EPA will affect how far the servo moves in the jump. Changes in EPA may require adjusting throttle acceleration.

•

Brake mixing works with acceleration as if only one brake servo were used. No second setup is required.

DESIRED END RESULT: Model responds to throttle/brake immediately, similar to an electric car.

CAUTION: High brake settings will result in locked brakes. Adjust throttle acceleration only enough to pick up the

slack in the linkage; then, utilize ABS to fine tune braking performance.

26

GOAL:

Remove throttle and braking “lag” due to

linkage in a 4WD nitro powered car, while

using LV2. (If using LV3, select TH-ACCEL

from Menu 1.) (If using LV1, first change

the level selection. See p. 12.)

Where next:

STEPS:

Open and select menu 1.

Select TH-ACCEL.

With receiver on, adjust forward until the

linkage opens the carb with the slightest

throttle input.

With receiver on, adjust brake until the

linkage applies brake with the slightest

brake input.

Close function and menu.

INPUTS:

6 times

as needed.

as needed.

NOTE: All of these functions interact with the throttle servo as well and are all interrelated. Adjusting any one will affect the performance of the others.

Adjust the throttle servo’s overall speed (TH-SPEED): See p. 23.

Adjust throttle exponential (TH-EXP): See p. 20.

Setup ABS braking (ABS): See p. 24.

Set up smooth acceleration off of the start or engine cut (AT-STAR T): See p. 28.

Set up a high idle for starting/racing, and keep a normal idle to keep the car sitting still

on start line (IDLE-UP): See p. 27.

Adjust brake mixing for separate front/rear brakes (BRAKE-MIX) (LV3): See p. 42.

Page 27

Levels LV2, LV3 Only Idle-Up IDLE-UP

DEFINITION: Adjusts the throttle’s idle/neutral point, usually used to create a

raised idle, making it easier to start the engine. May adjust either toward higher

idle (U) or toward braking (D).

AVAILABLE FOR: Throttle only.

ADJUSTABILITY:

•

D50-1, 0, U1-50%. D = brake side. U = throttle side.

•

Rate may be assigned to a dial or trim for on-the-track adjustability (see FUNC-

DIAL, pp. 34-35).

INTERACTION:

•

Requires switch assignment in the FUNC-SW screen (see pp. 34-35).

•

EPA does NOT affect the preset position of idle-up.

•

Idle-up could actually exceed your total EPA. Idle-up obeys only the actual total servo travel and servo reversing, and

no other programmed changes.

DESIRED END RESULT: Throttle servo moves to a preset position when button is pushed and throttle trigger is at

idle. Has no effect at other throttle positions.

CAUTION: If you have to adjust your EPAs after setting up this function, be sure to double check that the pre-set

travel is still what is desired.

27

GOAL:

Set a high idle of 25% of servo travel to get

engine to start easily even when warm

from racing, while using LV2 programming

(If LV3, select IDLE-UP from menu 1). (If

using LV1, first change the level selection

to LV2. See p. 12.)

Where Next:

STEPS:

Set desired switch (FUNC-SW).

Open and select menu 1.

Select IDLE-UP.

Set desired rate to up (increase) 50%.

Test function on screen.

Close function and menu.

INPUTS:

See FUNC-SW (pp. 34-35).

to U 50%.

Press selected switch (ex: PS-1).

Note screen now reads “ON” and LED

blinks. Release switch.

NOTE: All of these functions interact with the throttle servo as well and are all interrelated. Adjusting any one will affect the performance of the others.

Adjust throttle EPA (EPA): See p. 18.

Adjust the throttle servo’s overall speed (TH-SPEED): See p. 23.

Adjust throttle exponential (TH-EXP): See p. 20.

Setup ABS braking (ABS): See p. 24.

Set up smooth acceleration off of the start or engine cut (AT-START): See p. 28.

Adjust brake mixing for separate front/rear brakes (BRAKE-MIX) (LV3): See p. 42.

Page 28

Auto-start Throttle Settings and Engine Cut AT-START Levels LV2, LV3 Only

DEFINITIONS:

•

Auto-start: A pre-set throttle position, less than full throttle, to be used for the

initial acceleration off the line without having wheel spin. When the trigger is

released, auto-start is turned off and throttle operates normally again.

•

ATS: Auto-start status.

•

Engine Cut: Shuts the engine off without having to adjust the throttle trim. Takes

the throttle servo to a preset position when the switch is pressed. (Not available

to models using braking/reverse from the throttle servo. Primarily for boats.)

•

TG.P: Trigger point at which auto-start is activated.

•

PRST: Preset throttle servo position when function is activated. Preset is a

“true” preset – it is not a mix or a portion of the EPA. It is truly a

command to move the servo to a set position regardless of other inputs,

including trigger.

•

MODE: Which function is being utilized at this time. (Engine cut and auto-start can not be used together).

•

AT&SW: Auto-start is activated by throttle trigger or switch. Switch can be assigned in FUNC-SW (pp. 34-35) and

used to turn on/off the auto-start feature without having to pull or release the throttle trigger to do so.

•

INH: Inhibited. Function is electronically inhibited and will not operate until changed to another setting.

•

SW: Switch operated. Auto-start is inhibited and engine cut is available. (Assigned in FUNC-SW, pp. 34-35.)

AVAILABLE FOR: Throttle servo only.

ADJUSTABILITY:

•

MMOODDEE