Page 1

The FP-G153/G153BB/G133/G133BB is a single axis rate

gyro designed to stabilize aircraft. Like full size aircraft,

stabilisation is accomplished by detecting angular acceleration with the rate gyro. Detected motion information is fed

to the control amplifier, which then sends a counteraction

signal to the appropriate control surface.

•A very sensitive magnetic motion sensor with excellent

voltage characteristics, linear sensitivity, high speed

response is used. This results in superior neutral characteristics. Such characteristics make it ideal for use with the

rudder channel of a model helicopter or in the aileron/

elevator channel of a model aircraft.

•Large 2mm diameter gyro motor shaft for long life and

strength.

•The

highest

bearing. (G153BB/G133BB only)

quality

ball bearing

is

used

as

the motor

•The FP-G153/G153BB is for Futaba J, M, and SG

Series (1520 us neutral) digital proportional radio control

sets.

•The FP-G133/FP-G133BB is for Futaba E, F, G, H. and

L Series digital proportional radio control sets.

•Voltage regulated gyro motor supply maintains constant

motor speed and allows consistent gyro performance. The

voltage regulator is effective only when used with an external 6V. (five cell Nicad battery).

•Direction of correcting mix can be switched at the control

amplifier (internal reverse amp switch).

•Centering of the channel being stabilized can be adjusted

by a neutral trimmer built into the control amplifier.

•The gyro can be bypassed without affecting normal operation by

•Gyro output ("sensitivity") can be switched to one of two

preset outputs at the transmitter (use the retract switch if

possible, or any avail, channels).

turning

the gyro power switch

"off".

Page 2

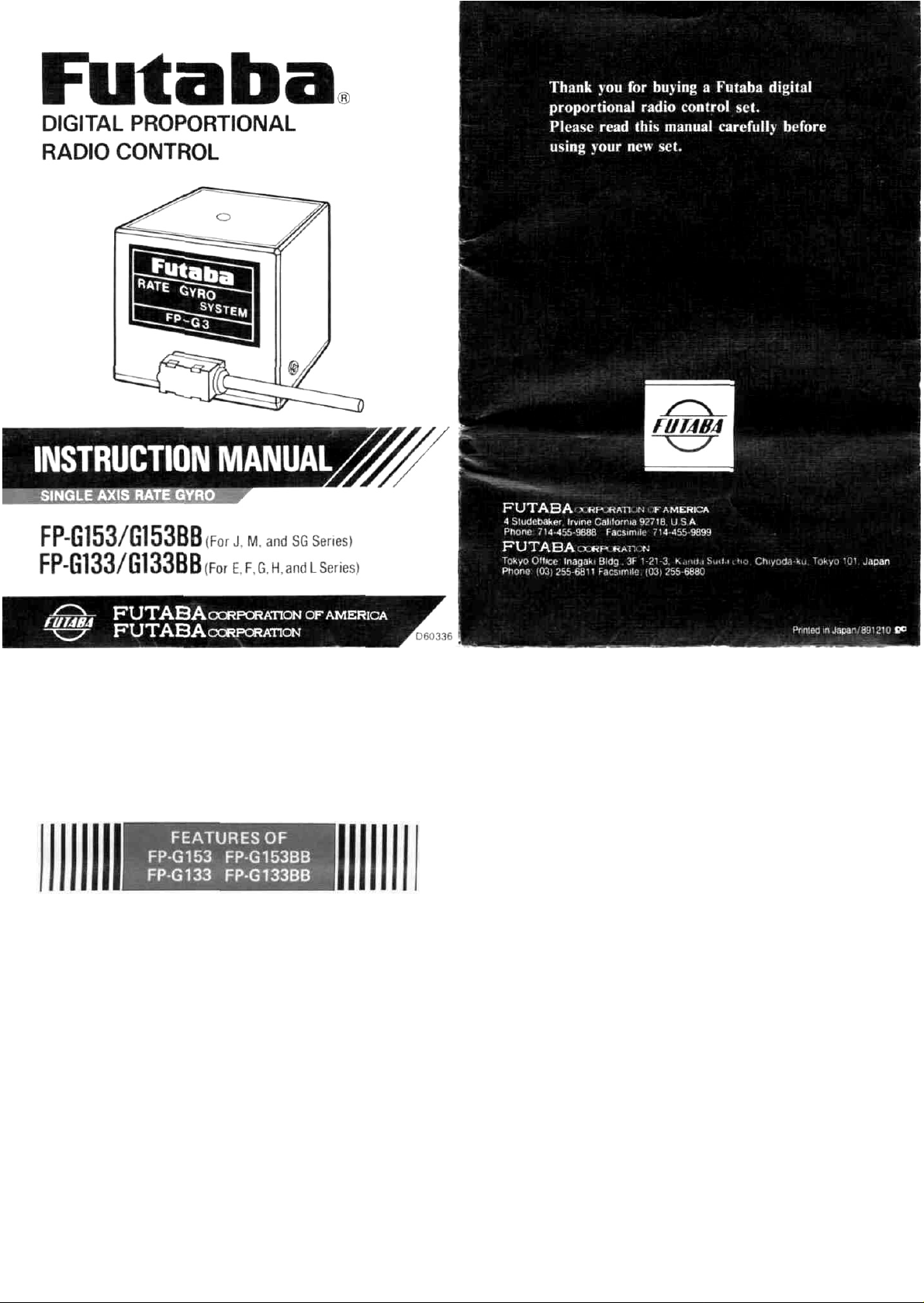

OUTPUT ADJUSTMENT

•When using the switchable gyro output sensitivity feature,

connect connector (B) to the retract channel if possible.

However, a proportional channel can be used. The output

sensitivity switching point will then be at the center or

neutral area.

*When the transmitter landing gear switch is pulled for-

ward (or down), the output sensitivity can be adjusted

from 0 to 100% with trimmer (1).

*When the transmitter landing gear switch is pushed

back (or up), the output sensitivity can be adjusted

from 0 to

mers (1) and (2) do not interfere with each other, and

can be adjusted independently.

•When the output is fixed or there is no spare channel (as

with 4 channel set), do not connect connector (B). In this

case, adjust the output with control box trimmers (1) and

(2). (Insulate the terminals with vinyl tape so they cannot

be touched.)

100%

with

trimmer

(2).

In this

case,

trim-

EXAMPLE

Adjustment when installed in a helicopter:

When using the switchable output sensitivity:

Set trimmer (1) to about the 80% of maximum output sensitivity position (100% is full clockwise) as a starting point.

Hover

with

the

wind

and readjust

hunting" does not occur. However, do not reduce output

sensitivity to a point where the nose will turn upwind when

"lifting off".

Set trimmer (2) to about the 60% position when a large

rudder travel is unnecessary, such as 540° stall turns, etc.

trimmer

Approx. 60%

(1)

so

that

Approx. 80%

"tail

*When trimmer (1) is 0, the output can be adjusted

from 0 to 50% with trimmer (2).

*When trimmer (1) is 100%, the output can be adjusted

from 50 to 100% with trimmer (2).

POWER SUPPLY

•When using the rate gyro with a separate power supply

(utilizing the motor voltage regulator), connect the five

cell Nicad battery pack (6V) to connector (C). Thereby,

maintaining constant motor speed and consistent gyro

performance. A four cell Nicad (4.8V) battery pack cannot be connected to connector (C).

•Whenever a four cell Nicad battery pack (4.8V) is used, it

must be as a common power supply for the receiver and

gyro. Connect the accessory jumper connector to connector (C), when using a 4.8 volt power supply.

•When the receiver and gyro use a common power supply,

rudder/servo power consumption and the power con-

sumed by the gyro, increases the total power consumption.

This decreases the number of permissible flights. The use

of a high capacity (4.8/1,000mA) Nicad battery is recommended. (The Futaba NR-4I (4.8V/1000mA) Nicad battery pack can be purchased separately.)

(C) connector

Jumper connector

Control box

•Do not expose the rate gyro to shock and vibration

•Do not disassemble or modify the rate gyro

When the inside of the gyro must be inspected, remove

the three screws on the side of the case and remove the

cover. Do not loosen the screws on the bottom of the

case. If these screws are loosened, the neutral position

may change at sensitivity or polarity switching.

•This gyro is not interchangeable with other

gyros or control amps.

When requesting repair after long use, accident, or

if any other trouble has occurred, describe the

problem in as much detail as possible. This will

allow us to isolate the trouble point quickly and

reduce the repair time.

FP-G133/G133BB

(C) connector

Connect the following to the (C) connector (control amplifier BATT):

* Five cell Nicad battery pack (6V) Our optional NR-5PB

(6V/450mAH) Nicd battery pack, etc. is recommended.

* Jumper connector, when the gyro and receiver use a com-

mon power supply

Jumper connector

Page 3

RATE GYRO INSTALLATION

NOTE: Be sure gyro is mounted as shown; for stabilization of the correct axis.

Helicopter - For

Connect connector (A) to the receiver rudder channel and connector (D) to the rudder

servo.

rudder

use

Aircraft - For aileron use

Connect connector (A) to the receiver aileron

channel and connector (D) to the aileron

servo.

Aircraft

Connect connector (A) to the receiver elevator channel and connector (D) to the elevator servo.

• For

elevator

(pitch

shaft)

use

•When the gyro is mounted 180° out of phase, the

direction of the correcting mix will be reversed.

To correct this situation,

switch the internal reverse

amp switch to "REV".

After mounting the gyro

to the fuselage, recheck

its direction of operation.

INSTALLING THE GYRO BODY

•The best mounting position is at the center of gravity of

the aircraft; however, it may also be installed a short distance away from the center of gravity.

•Install the gyro where there is little engine vibration.

•Attach the gyro to the fuselage with double-side ad-

hesive tape.

Use double-sided adhesive

tape

(Clean the mounting surface and stick the gyro to

it with double-side adhesive tape.)

Use double-side adhesive

tape about 3mm thick and

10mm wide.

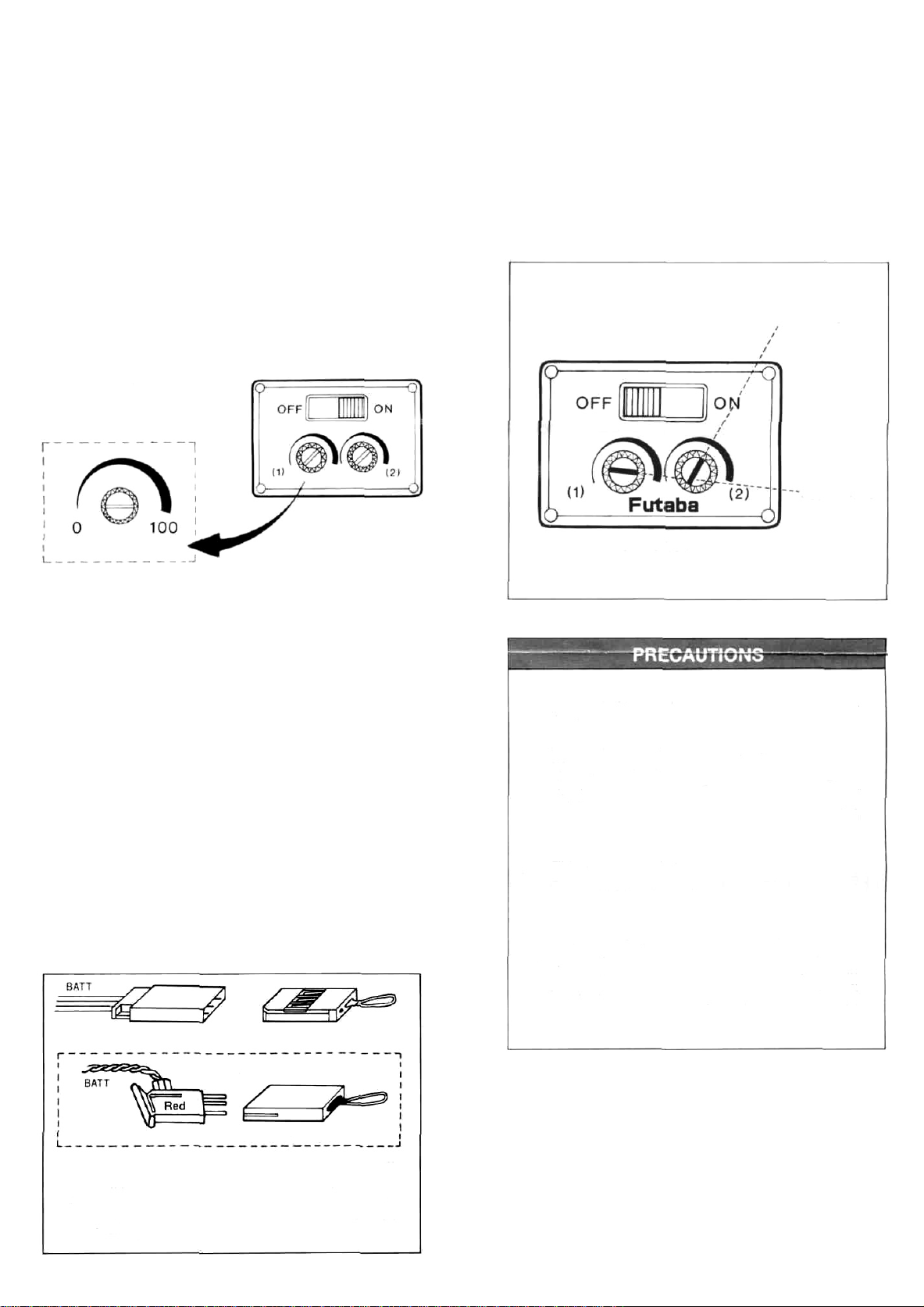

INSTALLING THE CONTROL BOX

Using the control box nameplate as a template, drill four

holes and cut an opening for the slide power switch. Mount

the control box on the fuselage, away from engine exhaust

and where there is minimal vibration.

-Pan head tapping screw(2)

2x8

Switch box nameplate

Switch box (top)

Switch box (bottom)

•Wrap the control amplifier in sponge, to prevent vibration

problems.

Page 4

RATEINGS

Power supply voltage

Current drain

4.8V shared with receiver (6V for external supply)

Motor: 100mA, Amplifier: 20mA (at 4.8V)

Dimensions and weight

CONNECTIONS

(B) Connector

G133/G133BB

White

Connect to receiver

retract or auxiliary channel

(for gyro sensitivity switching)

Gyro body: 1.57 x 1.65 x 1.60 in. (42 x 34 x 39mm)

-

2.86

oz

Control amplifier: 1.73 x 2.28 x .63 in.(44 x 58 x 16mm) - 1.61 oz.(45g)

Control box: .94 x 1.34 x .59 in. (24 x 34 x 15mm) -

Connection connector

(Can be connected/disconnected in the arrow direction.)

Connected servo (rudder servo for helicopter)

neutral trimmer (this trimmer is operative even

when the control box power switch is off).

.54oz.(15g)

(69g)

Gyro

body

(B) Connector

(A) Connector

G133/G133BB

(A) Connector

Gyro direction

reverse switch

Black

Connect to receiver channel

to be stabilized

(rudder channel for helicopter)

Control amplifier

Special 6V five cell Nicad battery

pack connector for motor regulated power supply. (Insert the

jumper connector when a shared

power supply is used.)

Connect to the servo (rudder servo for helicopter)

Gyro power switch

Gyro output trimmer

(C) Connector

Jumper connector

(C) Connector

G133/G133BB

(D) Connector

Black

The G153/G153BB and G133/G133BB are interchangeable by changing the connectors and

readjusting the neutral trimmer.

(D) Connector

G133/G133BB

Loading...

Loading...