Page 1

Futaba

DIGITAL PRO PORTI ONAL

RADIO CONTROL

PCM1024ZA

PCM1024ZH

PULSE CODE MODULATION SYSTEM

Page 2

Thank you for purchasing

a Futaba digital proportional radio control set.

Please read this manual carefully

before using your set.

ATTENTION:

1. Application of Product

This product is not intended for use in any application other than for the

control of models for hobby and recreational purposes. This product is

subject to regulations of the Ministry of Radio/Telecommunications and is

restricted under Japanese low to such purposes. The laws of other countries

may similarly restrict the use of this product. Futaba is not

responsible for any use that is not in compliance with applicable law.

2. Exportation of Product

If the product is exported from Japan, the prior approval of the Ministry of

Radio/Telecommunications is required regarding the country of destination.

If this product is reexported from other countries, it may be subject to

restrictions on such reexport and prior approval of government authorities

may be required.

3. Modification, Adjustment & Replacement of Parts

Futaba is not responsible for any use of this product that is not in

compliance with applicable law and disclaims all responsibility for any modification or alteration of the product, including the incorporation of the product into other products by third parties, that is not in compliance with applicable law.

ATTENTION:

The product that you have purchased contains a rechargeable battery.

The battery is recyclable. At the end of its useful life, under various state

and local laws, it may be illegal to dispose of this battery into the

municipal waste stream. Check with your local solid waste officials for

Ni-Cd

THE FOLLOWING STATEMENT APPLIES TO THE RECEIVER

This device complies with part 15 of t he FCC Rules.

Operation is subject to the following two conditions:

(1) This device m a y not cause harmful interference, a n d

(2) This device must accept any interference received,

details in your area for recycling options or proper disposal. (For U.S.A.)

including interference that may cause undesired operation.

(For U.S.A.)

Page 3

TABLE OF CONTENTS

Manual Introductory Section

System Features

Introduction

System

Manual Layout

FLYING SAFETY

Notable System Features

PCM 1024Z System Contents. ..............

Power-On Screen Displays

Working With The CAMPac Memory Module .....

Using

The

Operation Without Radio Transmission .........

System Monitor Lights & Warnings ............

System Status and Alarm Displays ............

Using Your Futaba System Contents. . .........

Radio Installation

Charging & Direct Servo Connect Operation .....

Stick Length Adjustment

Stick Tension Adjustment .................

Stick Angle Adjustment ..................

Antenna Angle Adjustment ................

Transmitter Battery Replacement ............

Rubber Protective Pad Installation ............

Transmitter RF Module ..................

Synthesized Frequency

Flight

Condition

SYSTEM MENU

Contents ...........................

MSL - Model Selection

VLT - Battery Voltage Display. ..............

TAC - Tachometer .....................

SR V - Servo Cycl e & Bar Graph Display .........

TRN - Trainer System ...................

DTN - Data Transfer Function ..............

CPM - Copy Model Function ...............

CPC - Copy Condition

PAR - Parameters (Sets Auto-Off and

Screen Contrast) ..................

UNA- User Name Registration ..............

FRO - Trans. Freq. Set ..................

Setting The Frequency Synthesizer Receiver ......

SWT - Switch setting ....................

MODEL SETTING SECTION

Contents........................... 39

CSL - Condition

TIM - Timers & Elapsed Time Counter .........

F/S - Failsafe/Hold Setting ................

PMD - Pulse Mode FM/PCM ................

REV -Servo Reversing Function .............

FNC - Function

RST - Data Reset ......................

CUT - Engine Cut .....................

CHD - Condition

TY P - Model Type Selection ...............

CH 9- Channel 9 Switch Definition ...........

MNA - Model Name Definition ..............

ALT - Alternate Switch ..................

THR - Throttle Curve ...................

SWH -Swashplate Type ..................

RDR - Rotor

INV - Inverted Pitch ....................

PIT - Pitch Curve ......................

COMMON CONDITIONS

Contents...........................

ATV - Adjustable travel volume & Channel delay ...

AFR - Adjustable

D/R - Dual rates & EXP

......................

........................

Usage

........................

.......................

.....................

.................

Soft

Keys

....................

.....................

.................

Module & Receiver

Switching

...................

Function

Select

..................

Control

..................

Hold

...................

Direction

..................

function

curve.

.................

................

.............

rate

..............

..............

......

2

3

4

6

7

9

11

.12

1

1

.18

19

21

21

35

.99

23

94

95

26

97

93

99

30

31

39

33

34

35

36

37

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

56

57

58

59

60

62

64

Manual Introductory Section, Page 1

PMX - Programmable

STM - Subtrim

TOF - Trim

CNA - Condition

TRM • Digital

10

3

14

14

15

16

7

19

20

20

AIRPLANE SECTION

Table of Contents

Airplane Controls & Functions

Airplane

Receiver

Airplane Setup Instructions

Aileron

Differential [ADF]

Rudder Coupling

V-Tail [VTL]

Rudder—Aileron

Elevons [EVN]

Elevator-»Flap

Flap-Elevator

Collective Pitch [CPT]

Ailvators

[ALV]

Flaperons [FPN]

Airbrake [ABK]

Snap Ro ll

Throttle Curve

HELICOPTER SECTION

Table of Co nten ts

Helicopter Controls

Helicopter Receiver and Servo

Sample Helicopter Setup Instructions

Pitch

Hovering Pitch [PHV] ...................105

Pitch Trim [PTM] .....................106

Throttle Curve [TCV]

Hovering Throttle [THV] .................108

Hovering Offset [HOF] ..................109

Throttle Hold [H LD] ...................110

Swashplate

Pitch—Rudder [P—R] .................. .112

Rudder—Throttle

Gyro Sensitivity [ GY R] ..................114

Acceleration [ACC]

Inverted Pitch [INV] .................. .117

SAILPLANE SECTION

Table of Contents

Sailplane Condition Menus ................119

Sailplane Transmitter Controls and Functions . . . .

Sailplane

Example Sailplane Setup Instructions ..........

Aileron Differential [ADF] ................

Aileron—Rudder Mixing

Aileron-Speed Flap Coupling [ASF] ..............................

V-Tail [VTL] .......................

Airbrake

Elevator—Brake

Elevator—Speed Flap

Brake Flap Mixi ng [BKF]

Speed Flap Mixing .....................

Speed

Butterfly Mixing [BFY] ..................

Butterfly

Elevator

Trim Mix 1 [TM1] & Trim Mix 2 [TM2] - 4-S .....

Flap-Elevator

Elevator-Flap Mix [E—F] ................. .143

Flaperon Mixing (FPN] -

COMMAND

[SNP]

Curve

Receiver

Mixing

Flap

Trim

Trim

mixing

.......................

offset

.....................

naming

trim

.....................

.....................

and Servo

[A—R]

........................

[R-A]

.......................

[E—F]

mix

[F—E]

......................

......................

......................

......................

Adj.

.....................

[PCV]

....................

Type

[SWP]

[R—T]

....................

and Servo

[ABE]

Flap Mixing [EBF]

Trim

[SFT]

Mix [BYE]

(ETM)

mix

[F—E]

LIST

.....................

...............

.................

..............

Connections

................

................

.................

.................

...................

.................

..................

(TCV)

................

....................

Connections

..................

...................................111

.................

........................................

Connections

[A-R].

............

..................

Coupling

..................

...................

................

............. . 130

(ESF)

..................... . . .132

................

2-S

............... 149

........

.......

..........

......

.........

65

68

69

70

71

73

74

76

77

80

81

32

83

84

85

86

37

33

39

91

93

94

95

96

93

99

.104

.107

.11

115

. 118

.120

.121

195

125

.126

127

.128

129

.131

135

139

140

142

143

145

..147

151

3

Page 4

Manual Introductory Section

Futaba's PCM 1024Z series of radio control systems is the most sophisticated available for aircraft, helicopters, and sailplanes.

Inside this radio is the logic necessary to

control virtually any aircraft imaginable

(both transmitter types are programmed

for all three aircraft).

System Features:

• 1024 High resolution system

• 9 Channels (select channel

• 10-Model Memory

• 8-Character Model names

• 16 added memories with CAMPac Module

• Up to 8 flight conditions for each model

• 5 programmable mixers with special advanced

functions for each model setup

• Each flight condition separately programmable

• Flight condition & channel delay setting

• Ready for aircraft, helicopters, and sai lplanes

• Deluxe carrying case included

• Carrying handle

• Ergonomic shape easy to hold

• Attractive neckstrap and mount

• Ball bearing control sticks

• Adjustable tension control sticks

• Adjustable length control sticks

• Adjustable angle control sticks

• Programmable transmitter switches

• Large liquid-crystal display

• Contrast adjustment

• Soft keys make programming simple

• Switchable FM/PCM

• Optional synthesized frequency

receiver

• Unique Digital Trim function (2 rates)

•

Electronic

volume, exponential

• Failsafe/Hold setting

• Powerful data copy functions

• Swiveling antenna stores in

• Detachable battery pack

• Two separate timers & elapsed

• Automatic system power-off

• Low-voltage alarm

• Special Mixer alarm

• Voltmeter with adjustable load for transmitter

and receiver batteries

• Built-in tachometer

• DSC System

• Trainer system

servo

centering, reversing,

order)

and operate

module &

throw

transmitter

time counter

Built into the system are a number of

menus designed to make it simple to tailor

the system's programs for YOUR aircraft.

Multiple menus provide unparalleled control of every aspect of the model's setup,

even some that you probably never thought

of before!

Airplanes

• Aileron Differential

• Rudder Coupling [AS-R]

• V-tail [VTL]

• Rudders-Aileron

• Elevons [EVN]

• Elevators-Flap [E-F]

• Flaps-Elevator [F-E]

• Collective pitch [CPT]

• Differential elevators [ELV]

• Flaperons [FLP]

• Airbrake [ABK]

• Snap Roll [SNP]

• Throttle Curve Adj. [TCV] (12 segment)

Helicopters

Pitch Mixing [PCV]

Hovering Pitch [PHV]

Pitch Trim [PTM]

Throttle Curve [TCV]

Hovering Throttle [THV]

Hovering Offset [HOF]

Throttle Hold [HLD]

Swashplate type [SWH]

Pitch-Rudder [P-R]

Rudder-Throttle [R-T]

Gyro Sensitivity [GYR]

Acceleration [ACC]

Inverted Pitch [INV]

Throttle curve adj. [THR]

Rotor Direction [RDR]

Sailplanes (Select from2,4, or 5-servos in wing)

• V-tail [VTL]

• Differential adjustment

• Rudder coupling [A-R]

• Aileron-flap coupling [ASF]

• Airbrake/Spoiler/Gear trim

• Elevator-flap coupling [EBF, ESF]

• Flap trim setting [SFT]

• Butterfly (Spoileron or Crow)

• Butterfly trim mix [BYE]

•

Elevator

• Flap-Elevator mix [F-E]

• Elevator-Flap mix [E-F]

• Flaperon mixing [FLP]

trim

sets

[ADF]

[R-A]

[ADF]

compensation [ABE]

[BFY]

[ETM]

Manual Introductory Section, Page 2

Page 5

INTRODUCTION

Manual Introductory Section

Thank you for selecting the Futaba®

PCM1024Z Radio System. The design of

this system has absolutely no compromises.

You now possess a system that will allow

you to fly your model — airplane, helicopter, or sailplane — with the highest per-

formance possible. With a // the power in

this system, setting up and adjusting is very

simple. We recommend that you read the

manual carefully to learn about the programming features, but if you are in a hurry, follow the example set-up instructions

in the beginning of the model setup procedures sections. We have provided detailed

examples for power aircraft, helicopters,

and sailplanes (with two, four, and five

wing servos).

The transmitter can be used with any

model type by using the desired special

mixing menus for the model you are interested in — a / / menus are contained in both

types of transmitters. The transmitters for

airplanes and sailplanes (PCM 1024ZA)

contain

different throttle stick feel than the heli-

copter system (PCM 1024ZH).

uses a unique menu system, which allows

the utmost in versatility. In stead of a single,

complicated loop that forces the user to

"step through" each menu on the way to

the desired setting, the PCM 1024ZA allows

you to proceed directly to the menu that

you need, bypassing those that do not need

any inputs. This system makes setting up

models both rapid and simple.

tings that may be called up by the setting

of a single FLIGHT CONDITION switch.

You may program up to eight different

flight conditions for each model in the

main memory area.

snap

roll

direction

The PCM 1024ZA System Transmitter

You may define different groups of set-

switches

and

a

The exclusive optional synthesized transmitter module and receiver allow you to

choose any frequency available without

switching crystals or modules, or changing

receivers. Electronically-activated trims are

memorized for each model in memory, and

can't be accidentally moved while the

transmitter is off. The optional CAMPac

Memory Module can store additional model

setups and easily transfer them to other

PCM1024Z transmitters.

All in all, the Futaba PCM1024Z is the

most advanced radio control system in the

world — we know that you enjoy using it

for pleasurable flying!

Manual Introductory Section, Pag e 3

Page 6

SYSTEM USAGE

Manual Introductory Section

The PCM 1024Z system that you have just

purchased has been designed to be the most versatile

radio

system

words about the layout of the radio are called for.

You are already aware that the PCM 1024Z transmitter has numerous model memories, but it is

important to understand that each model memory

may

have

several

be switched during flight! This means that you

may really call up different trim settings, mixing,

and control feel as you fly the model. For example, an aircraft could have different takeoff and

acrobatic settings; a helicopter could have different

settings for hovering, aerobatics, and autorotation;

a sailplane might be set up with independent settings for launching, thermal I ing, speed, and landing.

Switching between these different settings is

easy as flipping a switch.

To accommodate this power, the PCM 1024Z

system has four levels of operation: the Home

Menu, the System Menu, the Model Menu, and the

Condition Menu. The Home Menu appears when

the system is first turned on, and displays such

items as battery voltage, trim positions, one or

more timers, and other functions. The top level

display is what is normally displayed during operation.

The next level down is the System Menu. The

System Menu is used to choose and call up the

items that apply to all model setups stored within

the PCM 1024Z transmitter. This menu includes

such items as Model Select (which chooses which

model setup to use), Copy Model and Copy Condition,

User

other items.

Next comes the Model Menu, which contains

unique information about each model stored within the PCM 1 0 24Z's memory. Within this menu are

settings that pertain to a particular model. Of

course, these settings can vary for each different

model. As an example, the Model Menu contains

the Servo Reversing function, which may be different for each model stored.

Name

possible.

flight

condition

inputting.

Because

setups

Switch

of this, a few

that

may

as

Setting,

and

Finally, you will find the Condition Menus.

These menus are customized to the different types

of models the PCM 1024Z system will accommodate: Airplane, Helicopter, and Sailplane (the

thr ee sai lplane menus are further broken into the

categories of 5 wing servos, 4 wing servos, and 2

wing servos). In the Condition Menus, you may set

up throws, mixing functions, and other items that

vary with flight conditions but are associated with

one model setup.

As mentioned earlier, the PCM 1024ZA System

Transmitter uses a unique menu system, which

allows the utmost in versatility. The PCM 1024ZA

allows you to proceed directly to the menu that

you need, bypassing those that do not need any

inputs, instead of forcing the owner to proceed

through a single, complicated loop one menu at a

time on the way to the desired setting. This system

makes setting up models both rapid and simple.

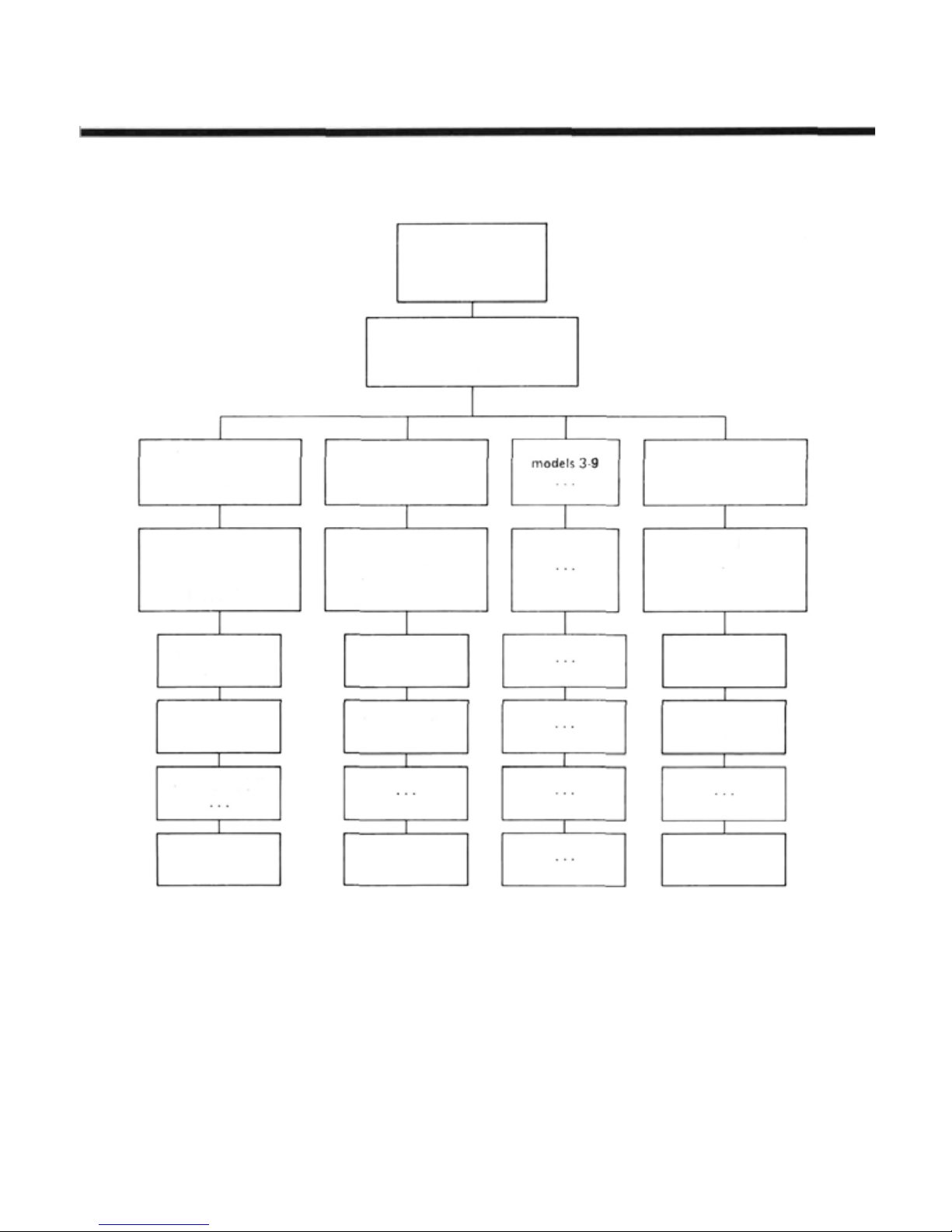

This menu configuration is illustrated below.

Manual Introductory Section, Page 4

Page 7

Startup Men u

Shows during

regular operation

System Menu

Settings that apply to all

models in storage

Manual Introductory Section

Model Menu 1

Settings for

Model #1

Condition Menus

Settings fo r all

conditions for

Model #1

Condition #1

Model #1

Condition #2

Model #1

conditions 3-7

Condition #8

Model #1

Model Menu 2

Settings for

Model #2

Condition Menus

Settings fo r all

conditions for

Model #2

Condition #1

Model #2

Condition #2

Model #2

Condition #8

Model #2

Model Menu 10

Settings for

Model #10

Condition Menus

Setting for all

conditions for

Model #10

Condition #1

Model #10

Condition #2

Model #10

Condition #8

Model #10

Manual Introductory Section, Page 5

Page 8

MANUAL LAYOUT

Manual Introductory Section

The instructions contained in this book are

written

in

great

detail

so

that

you may

understand the capabilities of your PCM 1024Z

system. We recommend that you spend some time

reading these instructions so that you can have a

good feel of what the system can do.

After this introduction are some words about

safety and proper operation of your Futaba

system. Next is a section on general operational

principles, including adjustments that you can

make on the transmitter to make it 'fit'your flying

style.

Next are instructions for system-level programming. This system-level programming is important

because it is used with a ll three types of models

that the PCM 1024Z system can be set up for. This

includes model menu selection, system voltmeter

operation, tachometer usage, servo bar graph display, trainer setup, and model data transmission

and copying.

A section on general model settings follows.

This section covers the topics of model setup that

are common to all model types, such as setting

throws, servo reversing, type selection, model naming, and others. The remainder of the menus are

specific to the particular type of model.

After the general section is a list of the common

condition menus that apply to all three types of

aircraft that the 1024A system can accommodate.

This is followed by three sections which describe

the setup procedures for aircraft, helicopters, and

sailplanes. At the beginning of each model setup

section is an example setup procedure that describes all the steps needed to set up all the desired

flight conditions for a model. Each of these section s assume that you are familiar with the general

system-level operations sections.

easily

The rear of the manual contains blank data

tables that may be used to record the data that

you have programmed into your system, and contains technical details of this system. Be sure to

make a photocopy of the blank data tables before

you write in them.

We hope that you find the PCM 1024Z System

Manual very hopeful. Please feel free to write to

Futaba if you feel that any corrections or clarifications should be made.

Manual Introductory Section, Page 6

Page 9

FLYING SAFETY

Manual Introductory Section

Safety is very important when you are flying

radio-controlled models. If you fail to follow the

installation, setup, and operation instructions in

this manual, or if you ignore warnings or rules set

by others, you may cause the partial or total destruction of your radio control system, aircraft,

and endanger yourself or other persons or property.

You

are

responsible

model, and may be held liable for any damages

your activities cause.

for

safe

operation of

your

Before flying, carry out a range check on the ground with the

transmitter antenna extended only one step. Note th e distance you

can achieve without loss of control — it should be at least 30 paces.

We recommend a range check before each flying session to verify

that your system is working properly.

When flying, be sure the antenna is fully extended. If the antenna

is not fully extended, your model's effective range is reduced, and

interference can cause difficulties even at short range.

Please maintain your system properly. Install it

in your aircraft using the proper procedures,

inspect the model frequently for correct operation

and structural and control authority, and be certain tha t you a re capable of handling the model in

unusual situations. Do not fly over or near spectators or where your model could injure any person

or property. Do not fl y unless you are sure of your

flying skills, radio installation, and model integrity.

Please

ask

for

assistance

if you are not sure about your qualifications.

from

an

experienced

pilot

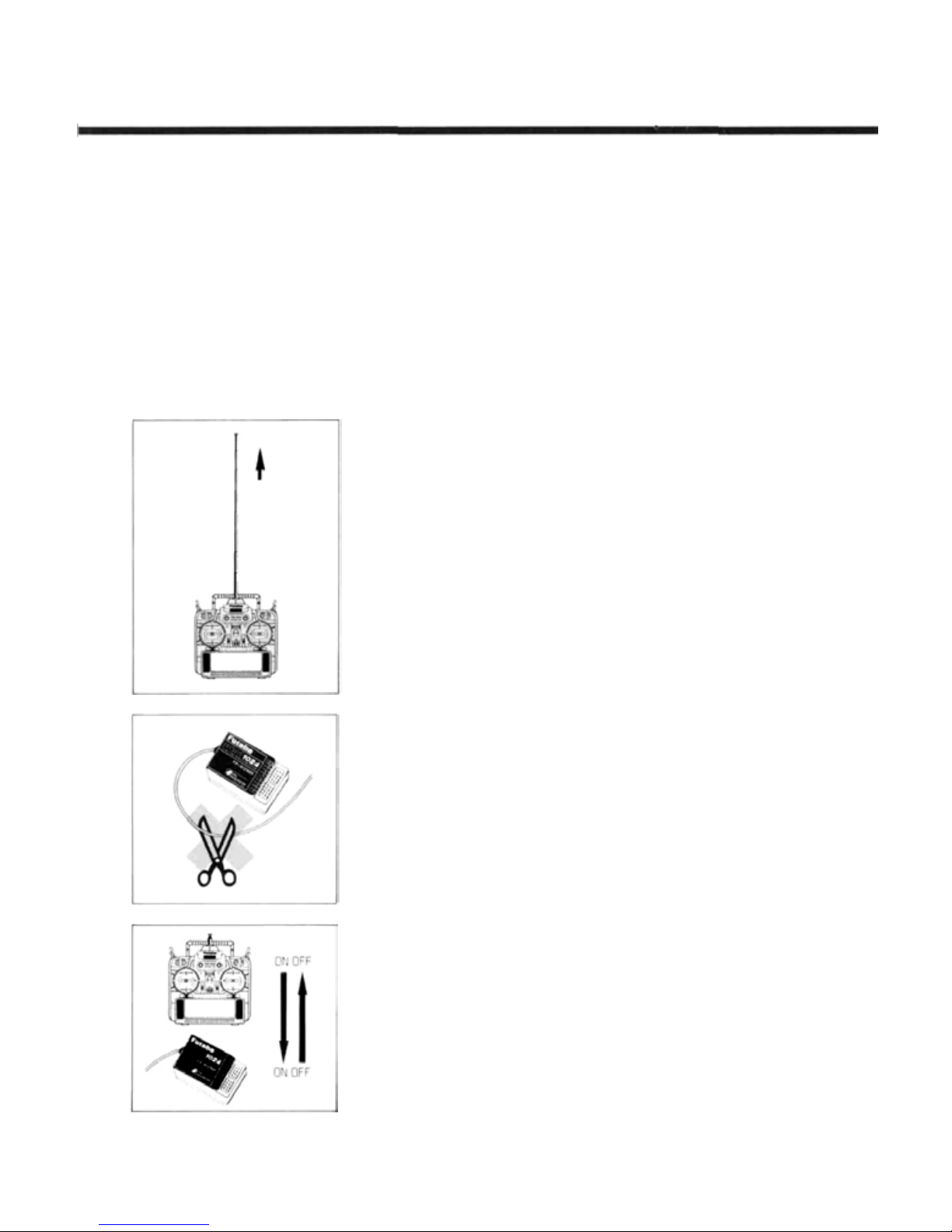

Be sure that you do not shorten the receiver antenna, either by

cutting

some

off,

or by coiling the

length trail behind or below the aircraft. Cutting the antenna will

reduce the effective range of the system and increase the chance of

interference.

When turning on your radio system, first turn on the transmitter,

then turn on the receiver. When turning off the power, turn off the

receiver first, then the transmitter. If these turn-on sequences are per-

formed in reverse order, the receiver may pick up spurious signals and

cause the servos to drive hard over, causing possible damage to the

radio system and the control linkages.

Manual Introductory Section, Page 7

excess

up.

Instead,

let the

excess

Page 10

Recharge

Manual Introductory Section

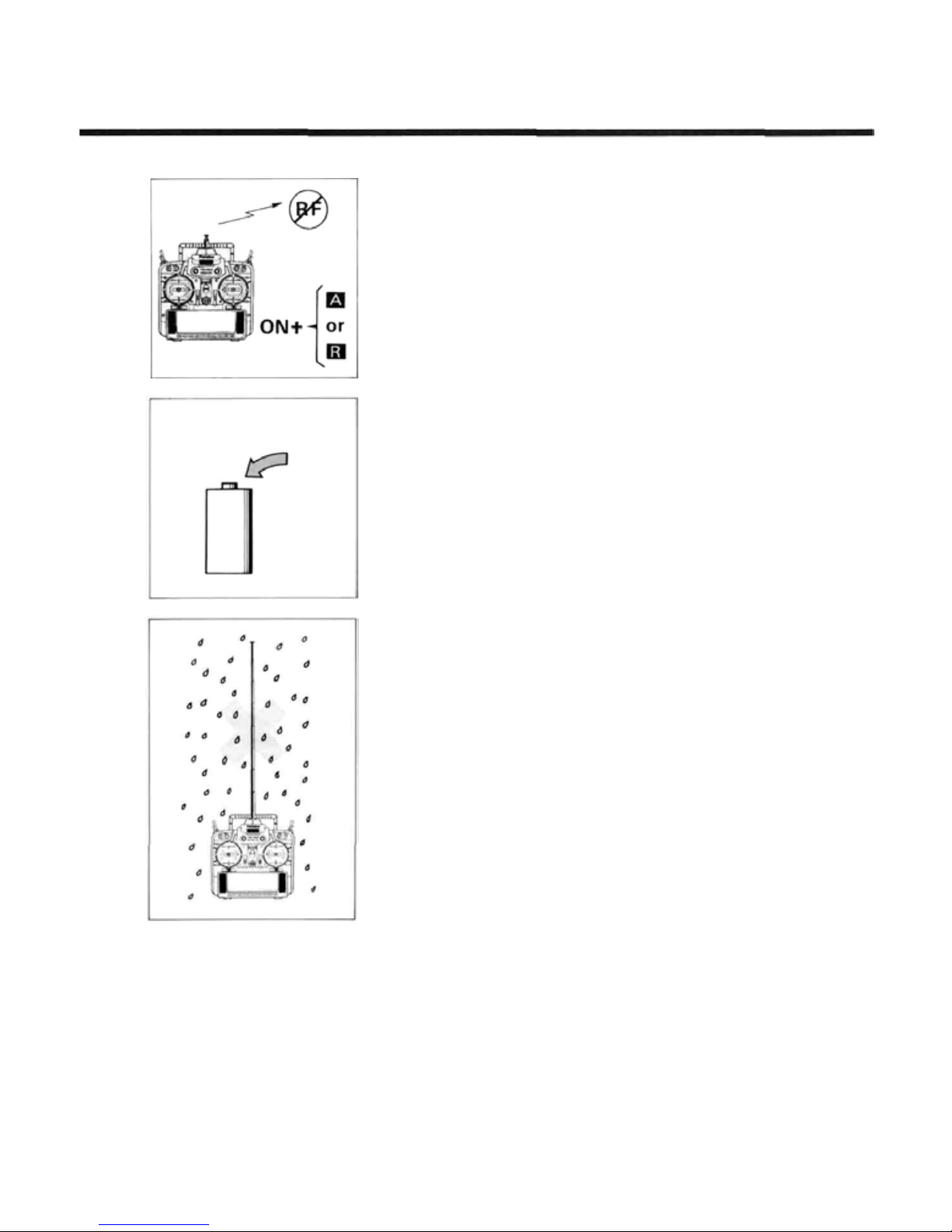

If you are using the Synthesized transmitter module FP-TK-FSS,

be sure that you know the transmitting frequency before switching

on. If yo u don't know the frequency, hold the [A] or [R] key down

as you switch on power. The transmitting frequency will be displayed

but radio transmission is deactivated. Once you h ave determined the

frequency,

secure

the appropriate frequency

control

device

and

turn

on power to operate normally.

Be sure to charge the transmitter and receiver batteries fully. If the

system has not been used for a long time, be sure to charge at least

24 hours before using the system, and check both batteries with the

system voltmeter at high load (500 mA). The transmitter battery

should remain above 9.4 volts, and the receiver should be above 4.7

volts. IF EITHER BATTERY INDICATES LOWER THAN THIS, DO

NOT FLY. Recharge the batteries first.

Do not quick charge the battery. Overcharging the battery will

cause the battery to overheat and creates a ver y dangerous situation.

Do not expose your system to rain or allow water to get inside the

case. If water does penetrate the case, control of the model could be

lost, resulting in a crash and danger to others. Use a waterproof cover

or wait until the conditions are dry before attempting to fly.

Manual Introductory Section, Page 8

Page 11

Manual Introductory Section

PCM 1024Z

• The optional CAMPac memory module stores up

to 10 model setups, and may be exchanged between different PCM 1024Z transmitters so that

model data may be rapidly transferred, or

backed up.

• The telescoping antenna is stored within the

transmitter, but when it is extended, it may be

easily rotated in any direction using the spherical

joint

on the

• Flight

• Switch Function Position Modification function

• The Type Selection Function allows any PCM

•

Condition Switching

trims, and other data to be matched to existing

flight conditions immediately upon movement

of a user-defined switch. A programmable Delay

circuit

makes

conditions. Each flight condition may have independent values for trims, mixing authorities,

and presets.

allows the owner to set the p o si ti o n and function

of all sticks, knobs, sliders, and switches as he

desires.

1024Z transmitter to be used for airplanes, helicopters, or sailplanes. The model type may be

selected from a menu screen.

Exclusive

changes

for each model in memory, and prevents unintentional trim changes. Trim functions may be

assigned to any stick or control.

Digital

easy

NOTABLE SYSTEM FEATURES

top

of

the

smooth

to

do,

transmitter

transitions

Trim

remembers the

case.

allows preset mixing,

between

function

makes

trim

flight

trim

status

• Large Liquid Crystal Display and Soft Keys

make model programming and data input easy.

Inputs change memory instantly, so immediate

verification of inputs is possible.

• The optional Frequency Synthesized Receiver

(R309DPS) allows rapid frequency changes to

eliminate frequency conflicts on crowded flying

fields.

• Programmable Trainer Function allows the

instructor to choose which functions are used

for training, and a special feature allows simple

correction by the instructor without disconnecting the student.

• Detachable Transmitter Battery Pack may be

easily removed from the transmitter and charged

separately, or used as an independent spare.

These are fust a few of the outstanding PCM

1024Z features. You can read about many more of

the features

never know what you've missed !

in

the manual.

Please

do

so — or

you'll

Manual Introductory Section, Page 9

Page 12

Manual Introductory Section

PCM 1024Z

SYSTEM CONTENTS

Manual Introductory Section, Page 10

Page 13

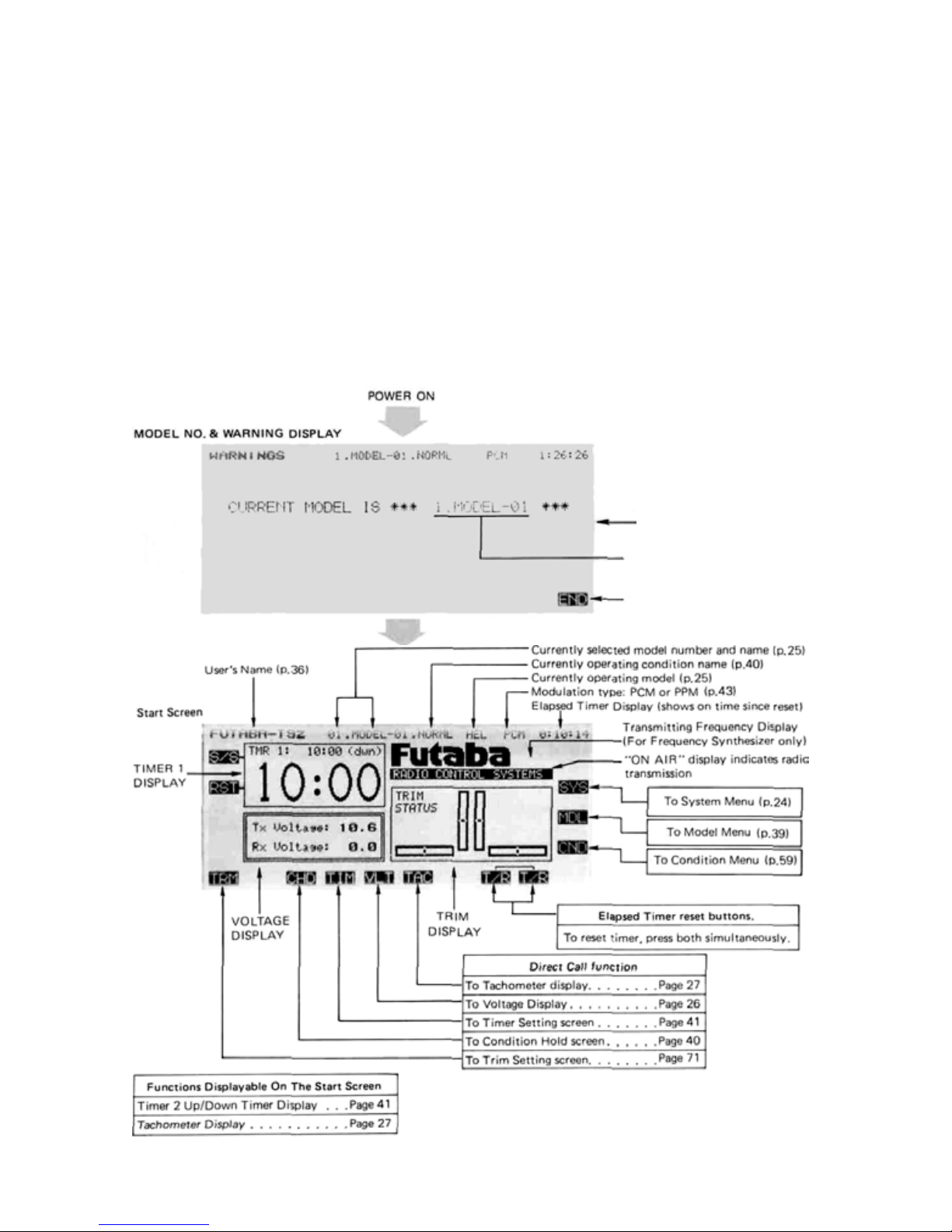

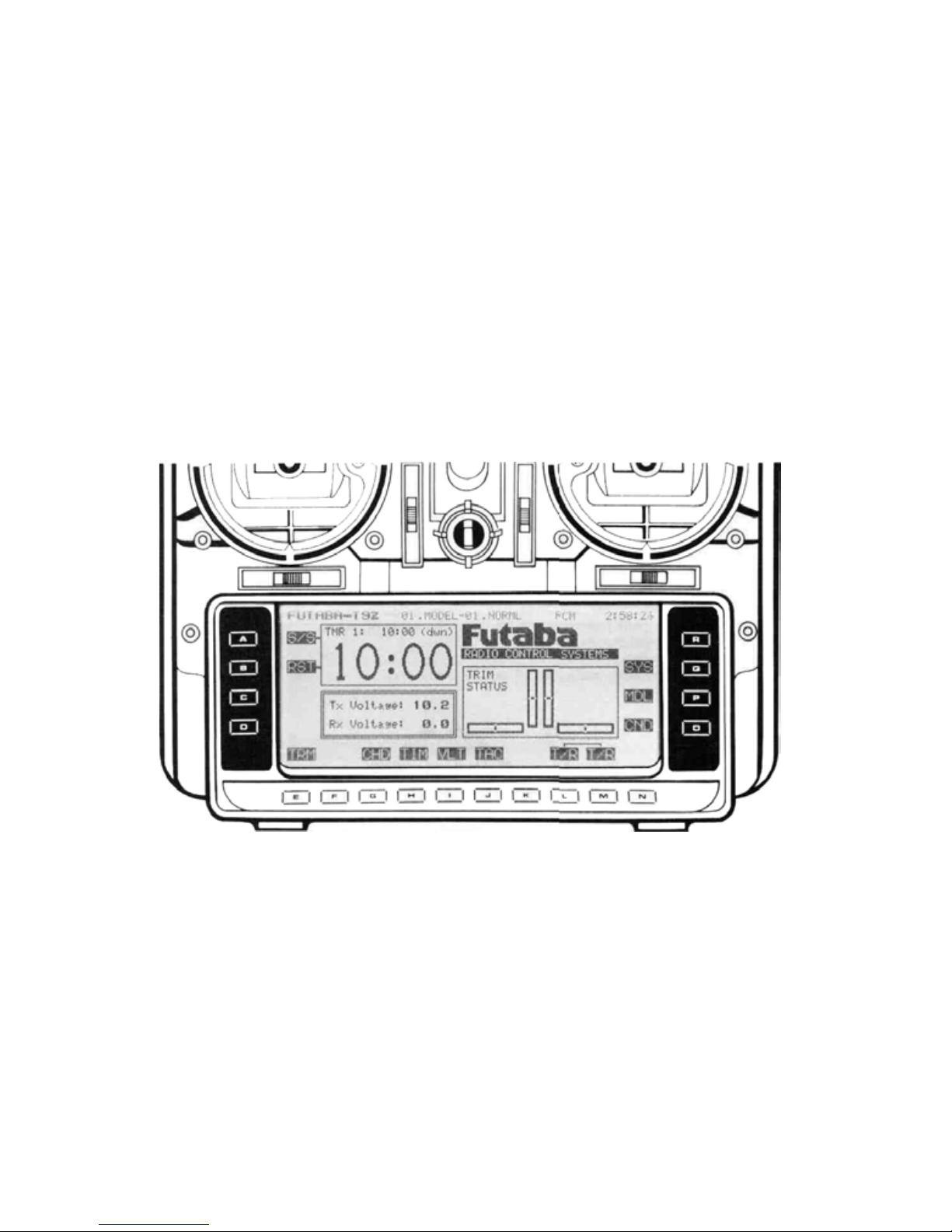

POWER ON SCREEN DISPLAYS

Manual Introductory Section

After the transmitter's power switch is turned

on, the current model number and name is displayed (see next page for what happens on the

initial turn-on). Check to verify it is the desired

model, otherwise you will have to change it in the

System menu. There may also be a caution message displayed for any special mix functions and/

or non-default flight condition switches that are

turned on. This caution message will be accompanied by a warning sound of six beeps repeated

every two seconds, and will continue until the offending switch is deactivated. You may hit the END

key, or wait a few moments to display the starting

screen.

The Home screen displays the user's name, the

active model memory and flight condition, the

Timer #1 display, the system voltages, and the

trim

status. The

menus are also displayed. To switch to these dif-

ferent screens, press the desired key A to R .

BE SURE TO CHECK THE MODEL NAME AND

CONDITION BEFORE FLIGHT. One of the most

common

model setup loaded in the transmitter.

crash

selection

causes

keys

is

taking

• Displayed for several seconds

- Currently selected model

number and name

• Immediate switch to

start screen

off

to

with

the

the

various

wrong

Manual Introductory Section, Page 11

Page 14

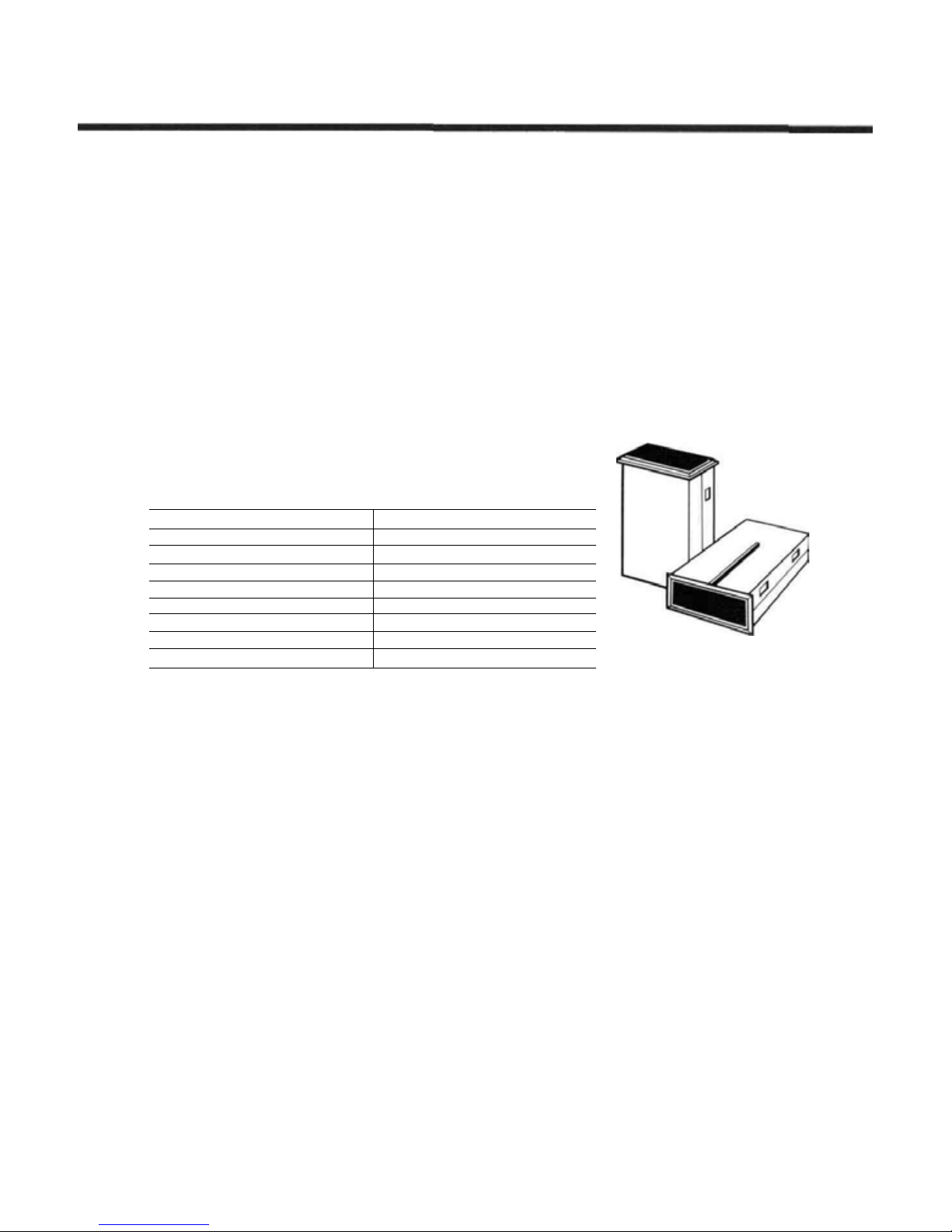

WORKING WITH TH E CAMPAC MEMORY MODULE

Manual Introductory Section

The optional CAMPac Memory Module can be

used to store model setup data separately from the

transmitter. Its advanced electronic design needs

no battery back-up power, so the CAMPac may be

used to transfer data directly into another PCM

1024Z system.

When the transmitter power switch is turned on

for the first time after the set is purchased, or

when the power switch is turned on after the

memory module has been changed, the "INITIALIZE EXT MEM?" message will appear at the

center of the screen. Press the YES key to initialize the memory module so it is ready to store

data.

Number of fl i gh t conditions

1

2

3

4

5

6

7

8

Memorizable model data

16

The CAMPac can store and memorize as many

as 16 s et s of model data, depending on the number

of flight conditions. When used in conjunction

with the transmitter's 10-model memory, as many

as 26 different model setups may be permanently

stored. The table below gives the numbers of

model data that the CAMPac can store, which

depends on the number of flight conditions. When

power is turned on, it may ta ke some time to copy

complicated model and flight condition data into

the transmitter's memory. This normally takes just

two or three seconds.

9

6

5

4

3

3

2

Moving the CAMPac from one PCM 1024Z

transmitter to another is one way of transferring

model setups from the f irs t to the second. Another

Manual Introductory Section, Page 12

way may be used with transmitters that do not

have the CAMPac installed. This method requires

an optional data transfer cord.

Page 15

USING THE SOFT KEYS

The soft keys are used to call up the different

menus during operation and programming. For

example, to call up the System Menu from the

home screen shown above, press the Q key (next

to the SYS label). Press the A to R keys that

correspond with the function names to get to that

particular function. Whenever a key is pressed, you

will

hear a confirmation

beep.

Manual Introductory Section

Manual Introductory Section, Page 13

Page 16

OPERATION WITHOUT RADIO TRAMSMISSION

Manual Introductory Section

If you'd like to make some small corrections to

a setup OR find out what frequency the Synthesizer module is set for without radiating AND

without removing the transmitter RF module or

using the DSC cable, you can do this by turning on

the power switch while simultaneously holding the

A or R keys. This may also be used to find out

what frequency the synthesizer transmitter module

will

way, check to be sure that the "ON AIR" display

is not on. You can now set the data or check what-

ever you need to. When you are done, you may

reset the transmitter by turning off the power

switch. The transmitter will radiate normally on

the next turn-on.

SYSTEM MONITOR LIGHTS & WARNINGS

There are two indicator lights above the power

switch on either side. The right-hand light flashes

when the transmitter is transmitting, or if a flight

condition or mixing switch is activated. The lefthand indicator lights when the system power is on,

and blinks during automatic data tra nsfe r.

In the airplane mode, either the Snap Roll

[SNP] or the Airbrake [ABK] switches will light

the indicator lights. For helicopters, Throttle Hold

[HLD] or Inverted switches [INV] will cause

flashing.

activate the light.

In

sailplanes,

Butterfly

mixing

[BFY]

will

every four seconds when Condition Hold [CHD] is

operating to remind you to turn it off. For your

convenience, the left and right sliders on the sides

of the transmitters emit a beep whenever they are

set at their center positions. This feature allows

you to center them without having to take your

eyes off of the model.

be using. When

You should also be aware that a beep sounds

you

power

up

the

system

this

CAUTION!

If you are using the Synthesized transmitter module FP-TK-FSS, be sure that you

know the transmitting frequency before

switching on. If you don't know the frequency, hold the A or R key down as you

switch on power. The transmitting frequency

will be displayed but radio transmission is

deactivated. Once you have determined the

frequency, secure the appropriate frequency

control device and turn on power to operate

normally.

Manual Introductory Section, Page 14

Page 17

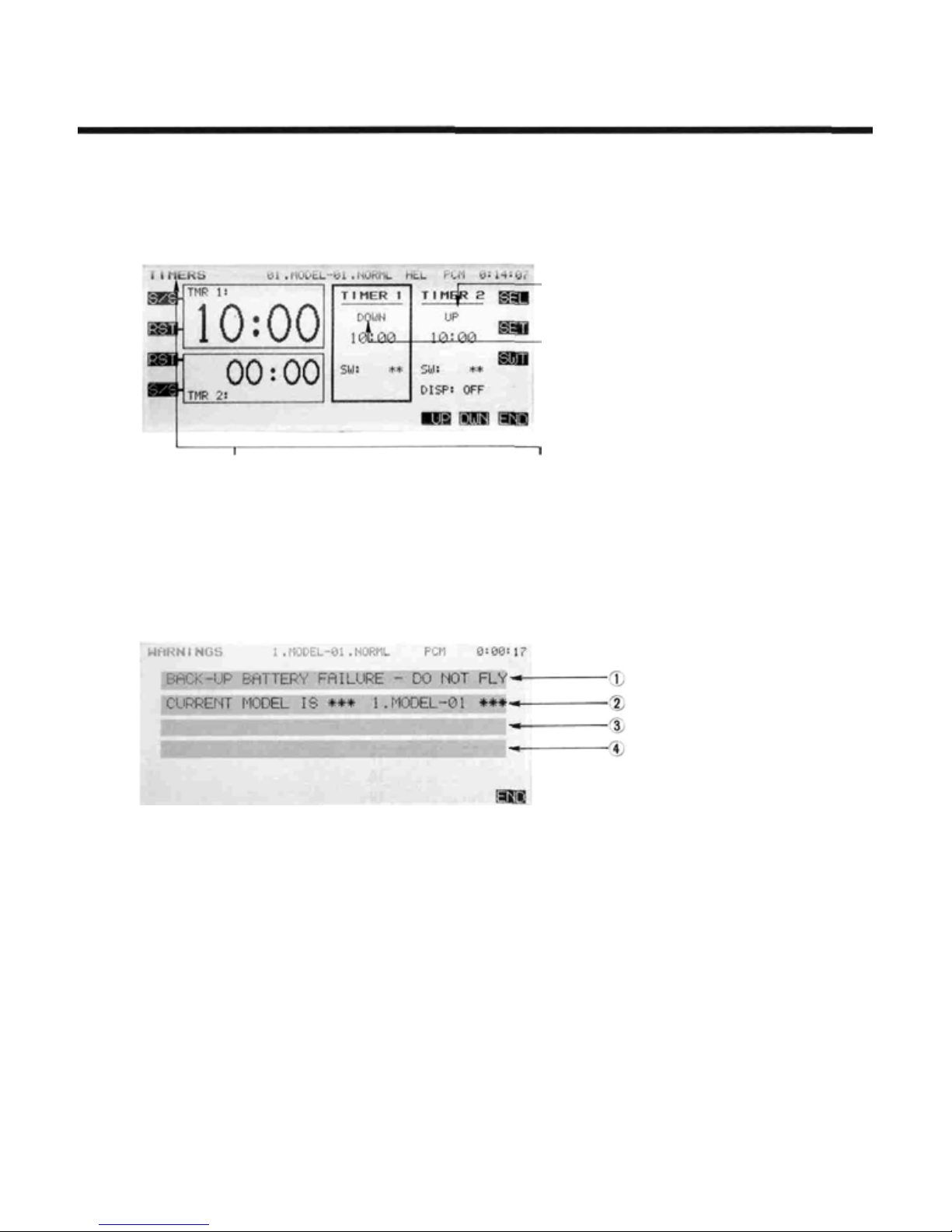

SYSTEM STATUS AND ALARM DISPLAYS

The PCM 1024Z System provides you with a

number of indicators and displays to show you

that your system is operating corr ectly. This sec-

tion will explain each display's function

Manual Introductory Section

ON AIR display and beep

This display is turned on when radio waves are

being transmitted.

Enter ID No. display

This display indicates when the security mode

is set. In this case, model data cannot be

changed. See the section on data protection to

reset this display.

EXT MEM ER R display

This display blinks when a data error occurred

during transmission of data between the transmitter memory and the memory module. Turn

off the power. DO NOT REMOVE OR INSERT

THE MEMORY MODULE WITH THE POWER

TURNED ON. THIS ACTION COULD DESTROY THE MODULE.

(D BACK-UP BATTERY FAILURE - DO NOT FLY

This warning is displayed when the data stored has been

lost for some reason. A beep wi ll sound simultaneously.

When the power sw itch is turned on again, the error display goes off and the data returns to the factory default

state. The lithium data backup battery needs to be replaced, or there is a fault in the system. Return the

system to the Futaba service center for assistance. The

life of the lithium battery varies, but is usually at least

five years.

2 CURRENT MODEL I S* ** ##.NAME ***

This display shows the model number and model name

currently stored in the active area of the transmitter. It

will disappear a few seconds after the system is turned on.

DATA PAC IS MISSING - LOADED MODEL1

This message is displayed whenever the transmitter is

turned on with the memory module removed and the

active model data was stored on the module. Without the

desired model data, the system loads the Model 1 data

instead.

Manual Introductory Section, Page 15

LOW BATTERY display and beep

This display and warning beep are to notify the operator

that the transmitter battery is low.

TO PREVENT PROBLEMS, LAND THE MODEL

AS SOON AS POSSIBLE.

PLL ERROR and beep

This display blinks and sounds when the synthesized

frequency module is removed during operation.

Be sure to turn off power before installing the module.

Do not remove or insert the module with power on.

3 CAUTION: NON-DEFAULT COND IS ACTIVE

This warning message is displayed, and a beep sounds,

whenever the transmitter is turned on with a flight condition switch activated. This display and alarm will turn

off as soon as the fl ight condition switch is turned off.

4 CAUTION: SPECIAL MIX FNCT IS ACTIVE

This message and alarm a re activated when the transmitter

is turned on with a mixing switch activated. The alarm

monitor above the power switch also blinks. All of these

wil l stop as soon as the mix switch is changed to i ts OFF

position.

CAUTION: ENGINE CUT FNCT IS ACTIVE

If the power is turned on with the engine cut switch on,

this message is displayed and a beep sounds. When the

engine cut switch is turned off, the display and alarm

stop.

Page 18

USING YOUR FUTABA SYSTEM

This section contains information on charging the batteries in your

system, and installing the airborne components in your model. We will

also tell you all the ways that you may customize your PCM 1024Z

System mechanically, so it "feels right" in your hands.

Then, we will show you all the features that are used by all the

model types that may be controlled by the PCM 1024Z system. This

will include all the exclusive PCM 1024Z features, including timers,

trim settings, voltmeter with load, direct-servo connect, and trainer

systems.

Manual Introductory Section

Using Your Futaba System: Contents

Installation

Radio

Charging & Direct Servo Connect Operation .............. 18

Stick Length Adjustment ........................... 19

Stick Tension Adjustment .......................... 19

Stick

angle

Antenna Angle Adjustment

Rubber Protective Pad Installation ..................... 21

Transmitter Battery

Transmitter

Optional Synthesized Frequency Module & Receiver

(see caution message) ............................. 22

Flight

Condition

................................

adjustment

RF

.............................

.........................

Replacement

Module

Switching

............................

.....................

..........................

17

20

20

21

22

23

Manual Introductory Section, Page 16

Page 19

RADIO INSTALLATION

Manual Introductory Section

Please observe the following precautions during

the installation of the radio into your model and

subsequent flying activities:

Servo Installation

Mount each servo snugly to a sturdy plywood

servo tray or use the provided mounting trays. Use

the supplied rubber grommets on the mounting

ears, and tighten the screws to hold things snugly

but try not to crush the grommets completely.

If you squeeze them too much, their vibration

dampening characteristics will be reduced.

Receiver connections

Connect the receiver, servos, switch, battery,

and gyro (if used) in accordance with the model

setup directions given in the appropriate model

sections. For aircraft, see page 80. For helicopters,

refer to page 104. For sailplanes and electrics, use

page 130.

Receiver Installation

Wrap the receiver in cushioning foam rubber,

and place it in a sealed plastic bag to prevent it

from fuel leaks or inadvertent water landings. Use

rubber bands wrapped around the receiver to

provide strain relief for the antenna, switch, and

servo wiring. Secure with foam pieces on all sides.

Run the antenna down the inside of the fuselage, or secure it to the top of the vertical fin

with a small

antenna wire, or tie it into a bundle. Reduced

range could result. If you experience problems

with an internal antenna, tr y routing it differently,

or move it outside of the model fuselage.

Switch Harness Installation

When you install the switch harness, be sure

that the rectangular hole is slightly longer than the

full switch stroke, so that it moves smoothly from

On to Off and vice versa. Try to install the switch

on the opposite side from the engine exhaust, and

away

from

rubber

dust

or

band.

dirt.

Do

not

shorten

excess

Now, connect each servo with its pushrod.

Again move each transmitter control in succession,

verifying that control movement is the proper

direction. If a servo does not move in the proper

direction, use the reversing function [REV] in the

Model menu.

Servo Throw Adjustment

Operate each

check

that

no loose connections. If the servo does bind, the

current drain will be very high, and yo ur battery

will

not

last

crashing due to a low receiver battery.

Make sure that the servo can move its entire

throw amounts (including trim) without binding

anywhere. If necessary, use the Adjustable Throw

Volume [ATV] menu to reduce servo travel so it

does not bind.

Range Check

After installation is complete, perform a ground

range check by extending the transmitter antenna only

one step. With the receiver antenna full length, step

25-50 paces from the model. The servos should

operate normally at this distance. Continue walking

away until control is lost, and note the approximate

distance. This is your ground range, and should be

repeated before each flying session.

Electrical Noise

Electrical noise is created by the touching of

two

metal parts, and

that heard on an AM radio during a thunderstorm.

Your Futaba radio set is resistant to electrical

noise, but no set may be made completely immune. For best flying range, avoid metal-to-metal

contact wherever possible.

the

for

control

servos

much

over

don't

time.

creates

bind

This

its

and

"static"

full

travel,

that

there

exposes a risk

similar

and

are

of

to

System and Servo Operation Check

Turn on the transmitter power first, then the

receiver power. Be sure that the transmitter anten-

is

fully

na

neutral positions. Operate the transmitter sticks,

knobs, and levers individually and be sure that the

appropriate servo follows the control movement.

If a servo does not move as it should, first check to

see that it is plugged into the correct receiver output. If it is not, move it to the correct output. If it

is in the correct location, verify that you have

activated the appropriate mixing functions.

extended.

All

servos

will

travel

to

their

Manual Introductory Section, Page 17

Page 20

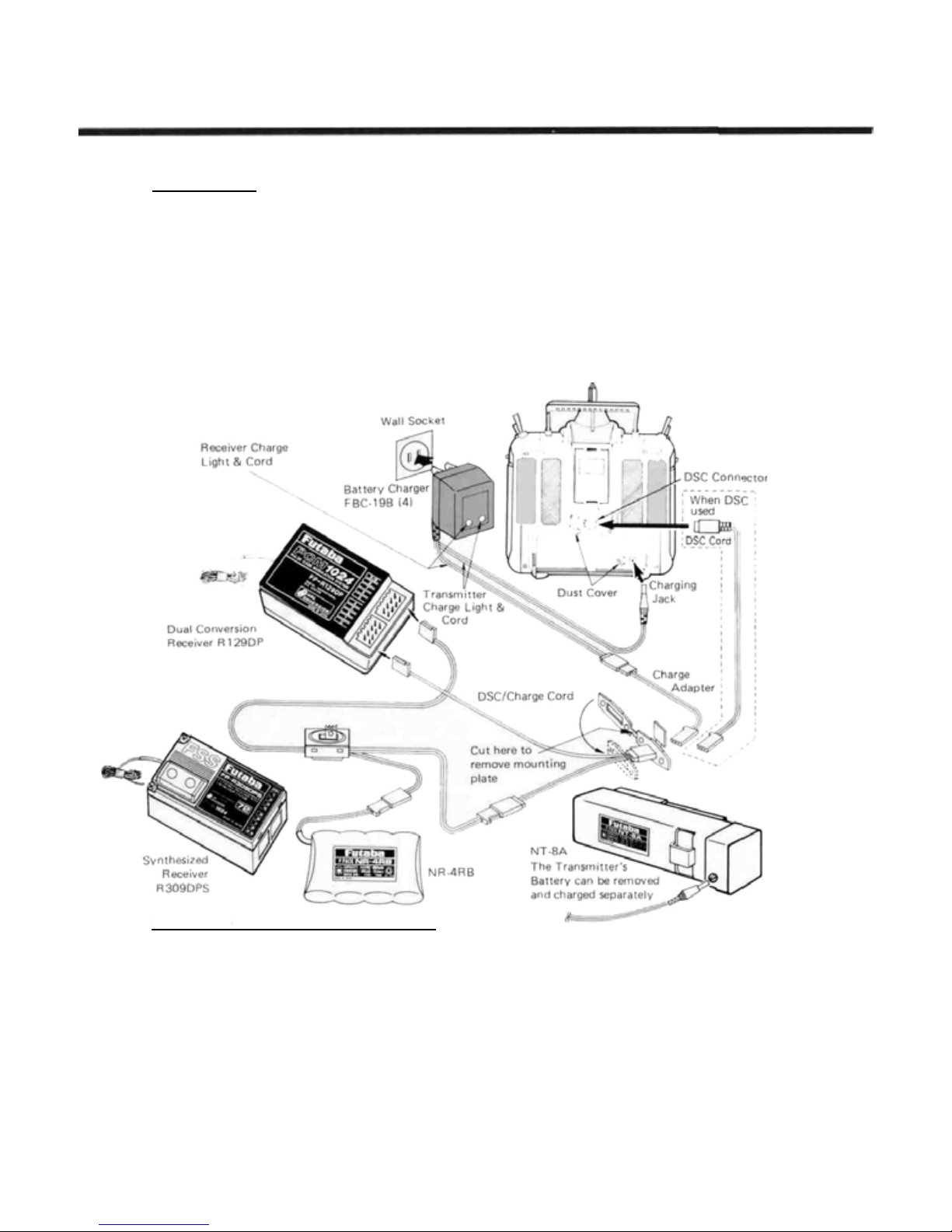

CHARGING & DIRECT SERVO CONNECT OPERATION

Manual Introductory Section

Battery Charging

Your Futaba FP-9ZAP and -9ZAH system is

equipped with rechargeable Nickel-Cadmium batteries. The figure shows the necessary connections

for charging the transmitter and receiver battery

packs. Both packs may be charged at the same

time or they may be charged individually. The

charging connections bypass the power switches,

so the set will not operate ev en if switched on.

The minimum recommended charge time for a

spent battery is 15 hours, but it will not damage

the batteries to charge them longer. However, if

the battery has not been used for some time, it

may take several charge/discharge cycles before

the battery resumes its full-capacity flight duration.

When fully charged, the system will provide

approximately 60-80 minutes of flying time,

providing there is no stalling of the servos. Be sure

to check the state of the receiver battery frequently with the built-in voltmeter function [VLT] in

the System menu. If the receiver battery drops

below 4.4 volt s under load, do not attempt to fly.

Direct Servo Connect (DSC) Cord Connection

Using the DSC system, you may directly con-

nect the transmitter

to

the

receiver

to transmit radio waves. This feature can be extremely useful for adjusting any settings on the

model

ance.

Additionally,

without

worrying

with

about

the

cord may be used to measure the receiver battery

voltage (for this display, see

menu).

When you wish to use the DSC system, you will

need to install the accessory DSC/Charge Cord

into

the

side

of

the

model fuselage (t his

without

frequency

receiver

VLT

in the System

also be used for

DSC

having

cable into the receiver jack, then plug the

round DIN connector into the back of the transmitter. Switch

transmitter.

To

check the receiver battery voltage, switch

off,

clear-

the

DSC

off the receiver and move to the VLT menu in the

System area. You may apply different current

loads

to

assess

tery. When you are through with DSC and/or

Receiver battery monitoring, remove the DIN

cord

may

Manual Introductory Section, Page 18

connector from the rear of the transmitter.

charging). To operate,

plug the

on the receiver ONLY — not the

the

condition

of the

receiver

bat-

Page 21

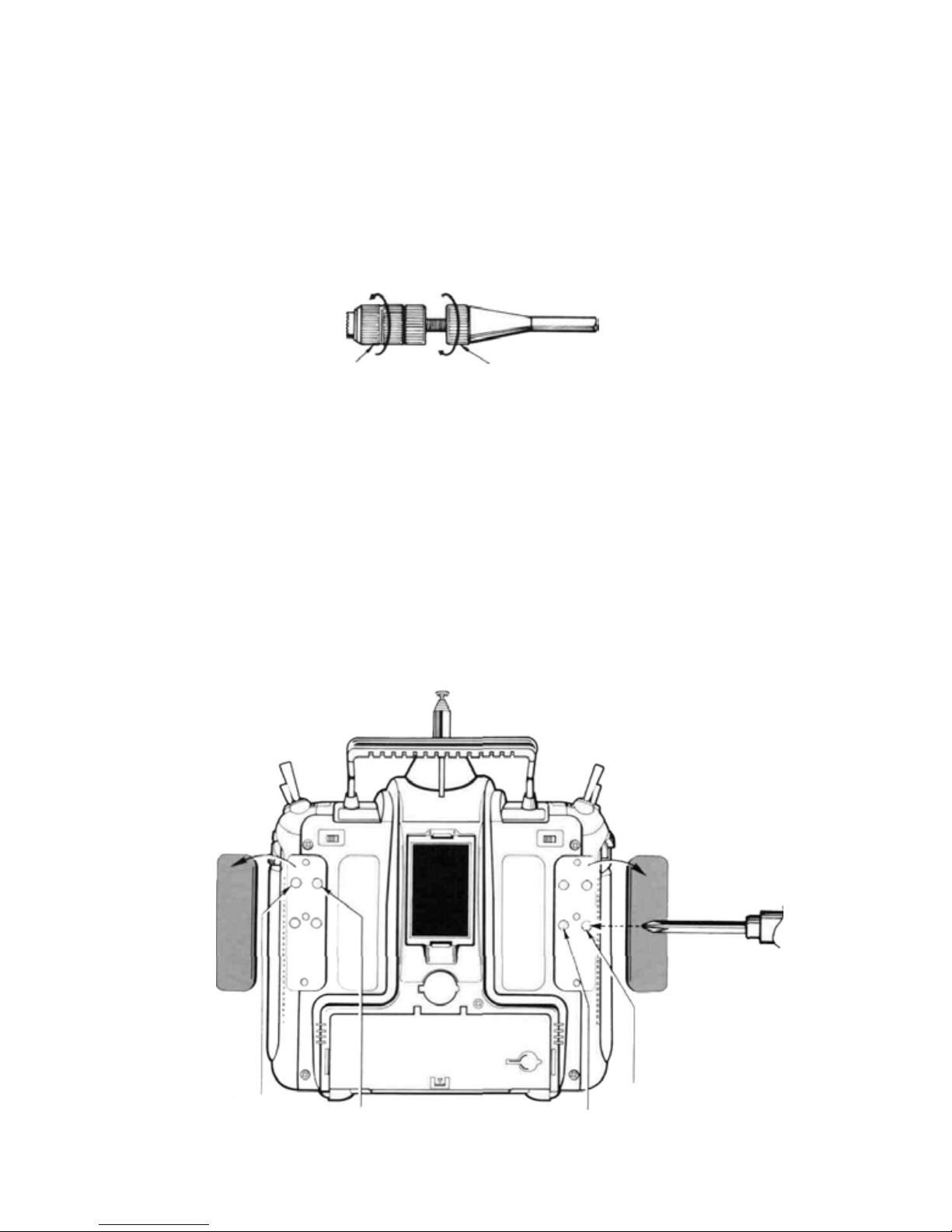

STICK LENGTH ADJUSTMENT

Manual Introductory Section

The sticks on your PCM 1024Z System feature

non-slip ends, and the length may be adjusted to

be most comfortable for the pilot. To change stick

length, unlock the stick tip by turning counter-

Non-Slip Stick Tip

STICK TENSION ADJUSTMENT

You may easily adjust the tension in the PCM

1024Z sticks to suit your personal preferences. To

adjust, you

ment screws in the back of the tr an smitter.

Gently pull up on the rubber grip and remove it

from the rear of the transmitter. Then, use a small

will

need

to

get

access

to

the

adjust-

clockwise. Move the tip to the desired position,

and then lock to length by moving the locking

piece upwards counterclockwise.

Locking piece

cross-point screwdriver to change the length of the

springs which tightens or loosens them. Be careful

not to push too hard, as it is possible to damage

the inside of the transmitter. Always turn off

transmitter power before adjusting stick tension.

Elevator

(Mode 1)

Elevator (Model)

Aileron Rudder

Manual Introductory Section, Page 19

Page 22

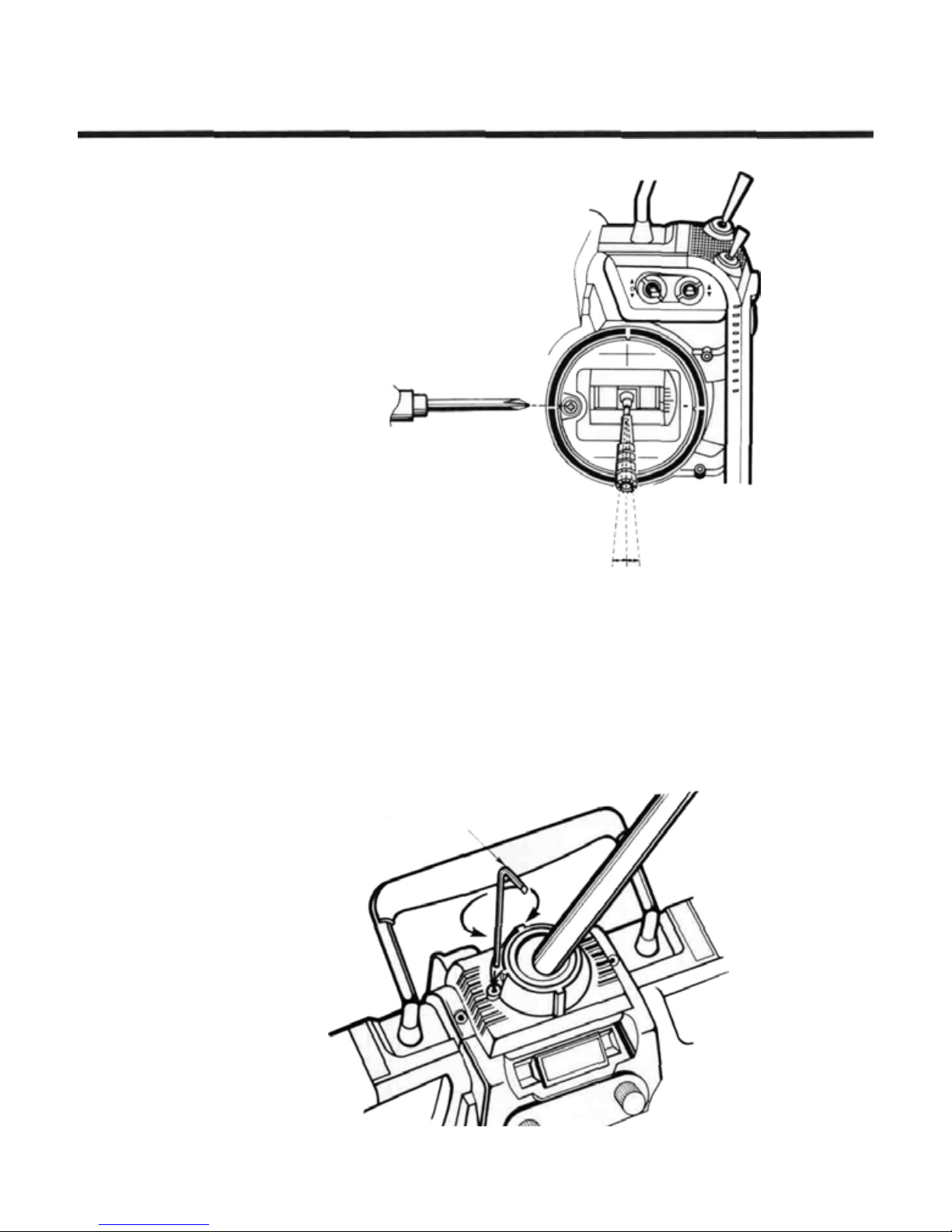

STICK ANGLE ADJUSTMENT

For the comfort of the operator, the angle of

the open gimbal s tic ks may be adjusted f ro m 3 to

the inside to 4.5° to the outside of the transmitter

case. This angle is adjusted by rotating the adjustable screw as shown in the figure. Simply turn

adjusting screw to change the s tic k angle in or out.

Manual Introductory Section

ANTENNA ANGLE ADJUSTMENT

Your PCM 1024Z system features an antenna

that may easily be pivoted to a direction that you

like. Simply move it to the desired pointing angle.

Before collapsing the base of the antenna into the

transmitter, return it to the straight-up position. If

Use the supplied hexagon wrench to adjust the

resistance to movement. Clockwise tightens,

counterclockwise loosens.

the antenna is til t e d, it will not fit into its housing.

The force required to pivot the antenna may be

easily adjusted. If the antenna movement is too

tight,

collapsing

into

the

case

will

be

difficult.

Manual Introductory Section, Page 20

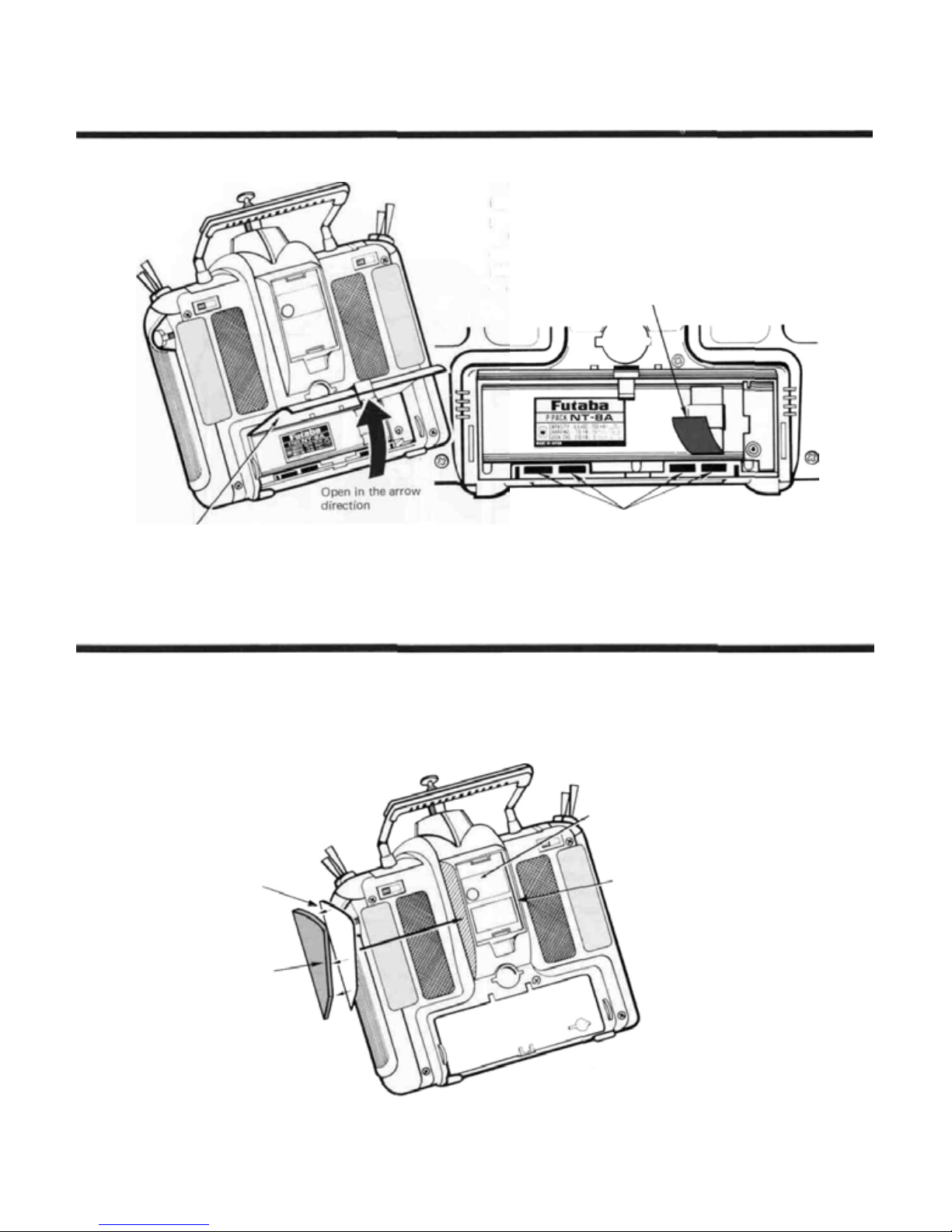

Page 23

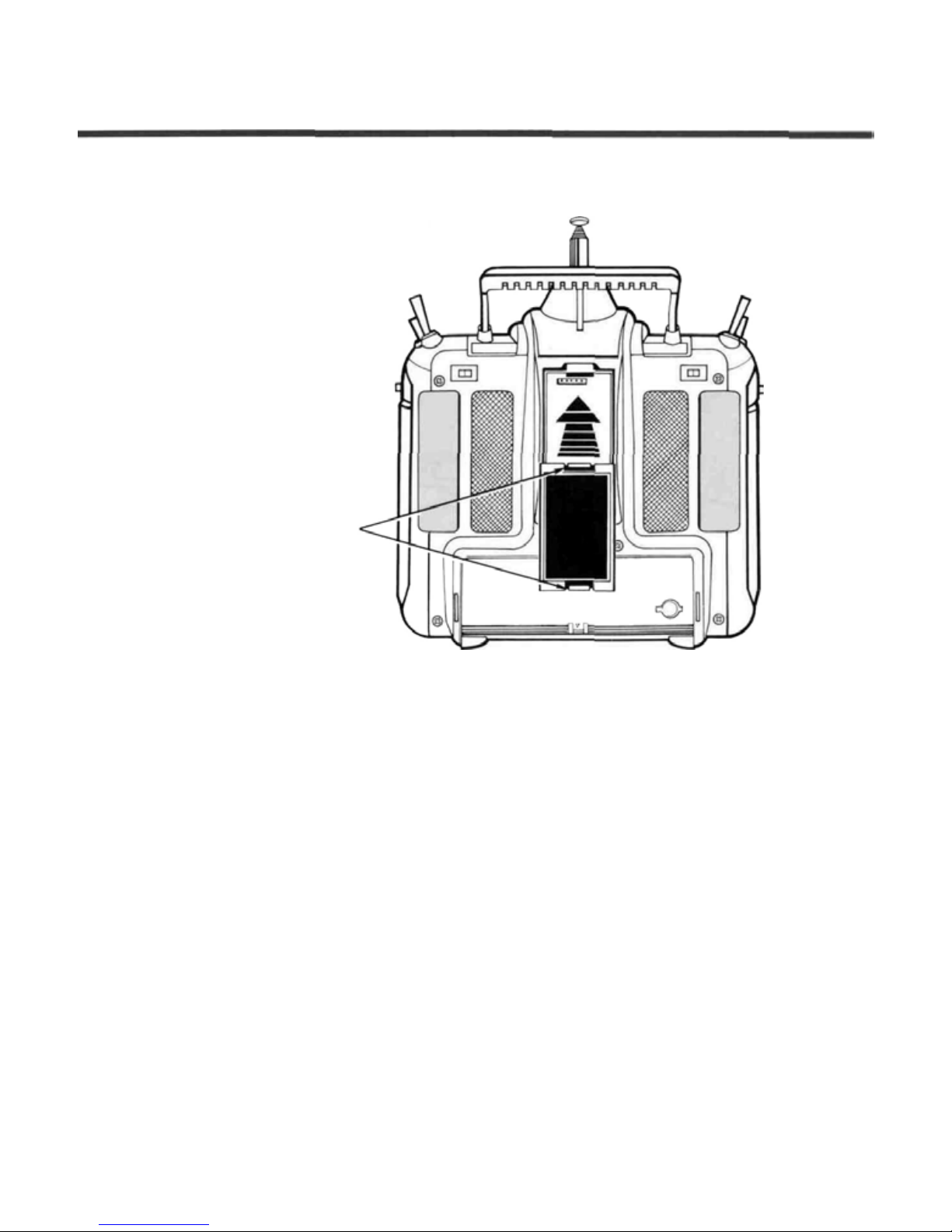

TRANSMITTER BATTERY REPLACEMENT

Battery Cover

Manual Introductory Section

The transmitter battery is easily removed and

replaced, making it simple to have a spare battery

pack for extended flying duration.

Open the battery cover and remove the rechargeable battery pack by pulling outward on the

ribbon. Be careful not to damage the battery cover

or drop the battery pack.

RUBBER PROTECTIVE PAD INSTALLATION

We recommend that rubber protection pads be

installed in case the transmitter is ever rested on its

back.

Double-sided tape

Stick the do ubl e-si ded

tape to t he inside of the

protection pad

RF Module

Repeat for other side.

Stick the protection pads to the

shaded area of the transmitter.

Manual Introductory Section, Page 21

Page 24

TRANSMITTER RF MODULE

The PCM 1024Z transmitter is designed to work

with either the FP-TK-FM or the FP-TK-FSS frequency-synthesized Radio Frequency (RF) mod-

ules. Other modules may not be used.

It is normal for the module's temperature to

rise during operation.

To remove the module, press

inwards on the top and bottom

tabs and simultaneously pull the

module away from the rear of the

transmitter.

Manual Introductory Section

OPTIONAL

The R309DPS synthesized-frequency receiver

and matching transmitter frequency module are

supplied with the PCM1024ZAPS and PCM

1024ZHPS systems. The transmitting and receiving

frequency may be easily changed without removing any crystals or exchanging frequency modules.

The ability to rapidly change frequency is a great

advantage on a crowded flying field or in contest

entry.

The receiver will also work with any other

Futaba 1024 systems. For more information on

the synthesized system, refer to page 37.

SYNTHESIZED FREQUENCY

Manual Introductory Section, Page 22

MODULE

CAUTION

If you are using the Synthesized transmitter module FP-TK-FSS, be sure that you

know the transmitting frequency before

switching on. If you don't know the frequency, hold the A or R key down as you

switch on power. The transmitting frequency

will be displayed but radio transmission is deactivated. Once you have determined the fre-

quency, secure the appropriate frequency

control device and turn on power to operate

normally.

&

RECEIVER

Page 25

FLIGHT CONDITION SWITCHING

Manual Introductory Section

Flight control switching is among the most

powerful features available in your PCM 1024Z

system. It is a function that allows you to change

virtually all the models' trims, mix settings, and

responses with the flick of a switch — while your

model is airborne! You can think of this as a

means of switching between as many as eight dif-

ferent model setups as you desire.

All the mixing and deflection angles can be

changed during flight condition switching. You

may pick and choose those settings that result in

the best flight characteristics for your model, and

leave the rest alone.

As an example, you may set up different condi-

tions corresponding to varying crosswind situations, or you can have different response "feels",

like a reduced control authority for smoother

landings. You may call up an entire group of

settings for a snap roll on a single switch. Helicopters may be set up for best response for aerobatics

and autorotation. Sailplanes may have settings

matched to the very different flight conditions for

launching, normal cruise, speed, distance, and

landing.

You may think of the different condition set-

tings as sheets of paper in a folder, and the trans-

mitter as an envelope with a clear window. As you

select each flight condition, you see its parameters

through the window, and not those of the others.

Each "sheet" can have completely different settings on it.

Manual Introductory Section, Page 23

Page 26

System Section

SYSTEM

The following controls and menus are used for system-wide settings.

These are settings that are stored fo r, or may be used for any and all

of the different model setups stored in the PCM 1024Z's memory.

To select any of these keys, first select the horizontal line contain-

ing the item you wish to select, using the B or C keys adjacent to

the

left-hand

F to L keys underneath the display.

Select Line With

These Keys

MENU

side

of

the

screen.

Then,

select

the

desired

Function Selection Keys

item

with

the

To Home Screen

To Model Menu

To Condition Menu

Listed below are the contents of the System Settings Menu:

System Menu Contents

Item_______Definition____________

MSL . .

VLT. . .

TAC.

SRV . .

TRN . .

DTN . . .Data Transfer Function . . . .Copies model data to another.... 30

CPM . . .Copy Model Function . . . . .Copies a setup into a second. .... 31

CPC. . . .Copy Condition Function . . .Copies a single condition to ..... 32

PAR.

UNA . . .User Name Registration . . . .Set up your name & security . . . . 34

FRQ . . .Transmitter Frequency. . . . .1024ZAPS/HPS Synthesized .... 35

Setting The Frequency Synthesizer. . . .Choosing the desired frequency . . . 36

Receiver

SWT

.Model

Selection

.Voltmeter

. .

.Tachometer

.Servo

Test & Bar

Graph Display and cycles

.Trainer System

. .

.Parameters.

Setting systems only (See C AUT IO N

. .

.Switch

Setting.

........

...........

..........

.......

........

..........

........

.Sets

.Use

Function

.Use

to

load desired model's

settings

.Use

adjustable load

check batteries

.Measures

speed

.Displays

channels

1024Z

memory

another

.Sets

Contrast

code

message)

activate functions

propeller

servo

desired

instructional.

Auto-Off and

to

define switch

Page

.....

to

........

rotational

positions

Screen

to.

....

.......

......

......

.......

25

26

27

28

29

33

37

System Section, Page 24

Page 27

MS L—MODEL SELECTION

System Section

This function is used to load the settings of the

desired model into the PCM 1024Z's memory. The

settings may be selected from either the transmitter's built-in memories, or from an optional

CAMPac. Remember that up to 10 memories are

Transmitter Model Memory List

Model Memory Selection Keys

To load a desi red model from internal transmitter

memory to the active area:

1. Select the desired model number with the A to J

( 1 to 1 0 ) keys

2. Press the L ( YES ) key if correct, otherwise use the

M ( NO ) key to start over. Verify that the chosen

model number and name is now shown in the display's

top center.

3. Finish by pressing the N ( END ) key.

To load a desired model from CAMPac memory

module to the active area:

1. Press the P (

models in the memory module's contents. Press it

again to get the remaining models. To return to the

previous model list, press (

desired model number with the

21 t o 26 ) keys.

2. Press the L ( YES ) key if correct, otherwise use the

M ( NO ) key to start over. Verify that the chosen

model number and name is now shown in the display's

top center.

3. Finish by pressing the N ( END ) key.

NXT

) key to display the first ten

PRE

A

to J (11 to 20 or

). Select the

available in the transmitter, and as many as 16 may

be stored in the CAMPac. The CAMPac is not

loaded with default models initially; they must be

loaded with the Copy Model [CPM] function.

Active Model No. and Name

Selected Model

No. and Name

END returns to

System Menu

To DELETE a desired model from CAMPac memory module:

1. Press the P (

models in the memory module's contents. Press it

again to get the remaining models. To return to the

previous model list, press (

desired model number with the A to J ( 11 to 20 or

21to 26 ) keys.

2. Press the L (

R( DEL ) key to start over. Verify that the chosen

model number and name is now shown in the display's

top center.

3. Press the R (

4. If this is the correct model to delete, press the

L (

YES

(

NO) key.

5. Verify the deletion from the model list. Then, exit by

pressing the

NXT

) key to display the first ten

PRE

). Select the

YES

) key if correct, otherwise use the

DEL

) key.

) key. To choose another, press the M

N(END

) key.

System Section, Page 25

Page 28

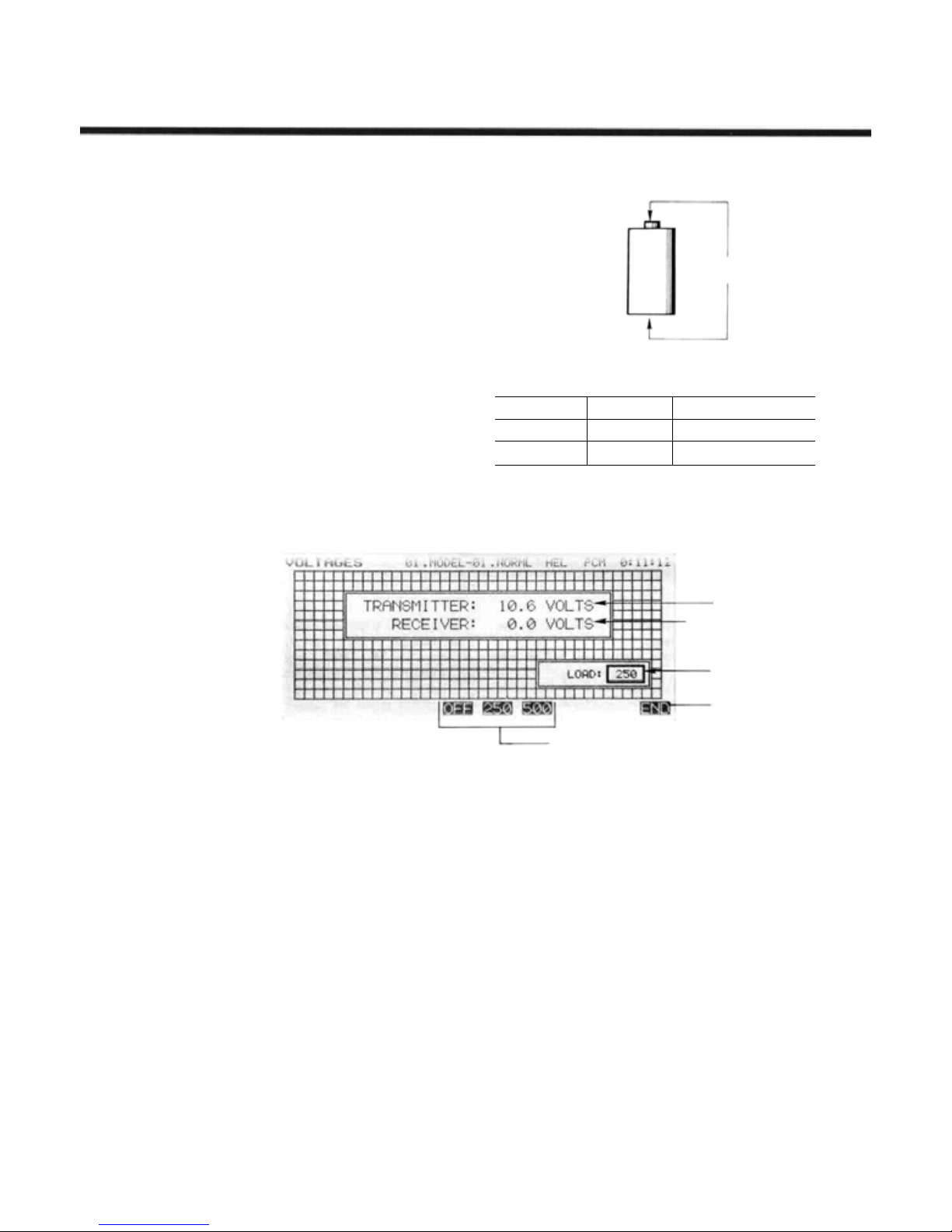

VLT—BATTERY VOLTAGE DISPLAY

This function may be used to check the voltage

of both the

a high-accuracy digital voltmeter, which continuously displays the measured results. The table

below indicates the measurement range of the

voltmeter.

The receiver battery may be tested with either

no load, or a load of 250 or 500 mA current flow.

Testing of the receiver battery requires a DSC cord

(the transmitter is always connected internally).

Be sure that the polarity of the receiver battery is

correct, or damage to the transmitter may result.

An alarm in the PCM 1024Z transmitter will go

off when the transmitter battery voltage becomes

too low. If you happen to be flying when this

alarm goes of f, be sure to land as soon as possible

before control is lost.

transmitter and

receiver

batteries

with

Item

No Load

Load (Choose)

Voltage Range

0-18V

3-

7V

System Section

Voltage Display

Remarks

OFF

Approx. 250 or 5 00 mA

To

switch loads on the receiver battery:

1. For no load, press the 0 (

2. For the 250 mA load, press the J ( 250 ) key

3. For the 500 mA load, press theK(

4. To leave the voltmeter function, press the

key.

Note: if you do not activate the second timer, the volt-

meter display appears on the regular screen.

OFF

) key

500

) key.

N ( END )

Transmitter Battery

Voltage Display

Receiver Battery

Voltage Display

Load Current

Setting

Return to System

Menu

• Receiver Load

Current Selection

System Section, Page 26

Page 29

TAC—TACHOMETER

System Section

The tachometer function in the PCM 1024Z

transmitter may be conveniently used to measure

the rotational speed of any propeller or rotor

blade, up to a maximum of 50,000 RPM. This is

very useful for testing engine performance, rotor

settings, etc. If you like, you may have the TAC

display always appear on the Home screen.

Activates TAC display

in Home screen

To choose the number o f blades on the propeller, use the

G to L ( 1 to 6 ) keys. To display the TAC display on

the Home screen, press the

toggles the display on or off. Use the N (

exit the TAC display.

Propeller Speed Measurement

1. BE VERY CAREFUL IN THE VICINITY OF THE

PROPELLER. KEEP YOUR HANDS AND ALL

EQUIPMENT AWAY FROM THE TURNING PROP.

E (DSP )

key. This key

END

) key to

Speed

RPM Display

Home Screen

Display Indicator

No. of Blades

Return to System

Menu

Keys to Select No. of Blades

2, Point the sensor, which is located in the left-hand side

of the PCM 1024Z transmitter, towards the propeller.

Read the measured rotational speed. You may have to

change the relative orientation to get a steady reading.

NOTE: Fluorescent lights in the vicinity of the

propeller can produce erroneous readings. If

you can't make your measurements outdoors, use an incandescent li ght or flashlight

to get a true reading.

System Section, Page 27

Page 30

SRV—SERVO CYCLE & BAR GRAPH DISPLAY

System Section

This key has two different functions: a servo

cycling mode, which slowly moves each servo to

its extreme positions, and a servo bar graph indication, which pictorially shows the position to

which each servo is being commanded. The servo

test function is useful for finding unevenness in

servos, and t h e bar graph function may be used fo r

roughly setting up models without using a receiver

or servos. This can be particularly handy in setting

up models with complicated mixing functions,

because the results of each stick, lever, knob,

switch input and delay circuit may b e immediately

seen.

The servo bar graph display is always operating

in this mode. To activate the servo cycling func-

tion,

first

turn

on the airborne

E (ON) key to start the servo cycling mode,

and use the F (OFF) key to stop the cycling.

When using the Bar Graph display to set up a

model or mix, be sure to verify that all controls

move the proper directions when actuated. Depending on servo orientation, it is possible that the

bar graph may indicate what appears to be the

correct directions of throw when one or more

servos actually need reversing.

Use the END key N to leave this function

and return to the System Menu.

system.

Press

the

Check Servos By Cycling

Check Functions and Mixing

Bar Graph Display

Return to

System Menu

Turn Servo Test On & Of f With These Keys

System Section, Page 28

Page 31

TRN—TRAINER SYSTEM

System Section

The Trainer function makes it possible for the

instructor pilot to choose which functions and

channels are to be used for instruction, making it

possible to match the training difficulty to the

student's skill level. A special function called Cor-

rection Control makes it possible for the instructor

to make corrections without overriding the student's inputs. Two transmitters must be connected

by an optional Trainer/Data Transfer cord, and the

Instructor transmitter should be programmed for

trainer operation, as described below.

Operation is simple: when the Instructor acti-

vates the trainer switch, the Student has control of

the aircraft (if the mixing mode is turned on, the

Instructor can make corrections while the student

has control). When the Instructor releases the

switch, control is regained. This is very useful

when the Student gets the aircraft into an undesirable situation.

The training system will work with any PCM

1024Z series transmitter. Futaba's 5U and 7U

series of transmitters may also be connected for a

student's usage. Note that in some cases a low

battery warning may appear on the 7U series, but

operation is unaffected by this warning.

- ACT/ INH Selection

Correction Mixing

Channel Selection

Instructor-Controlled

Channel Selection

ON/OFF Toggle

Switch Setting

Return to System

Menu

Channel Selection Keys

TRAINER MODE SETUP

To place the PCM 1024Z into the Trainer mode, press

the

TRN

key

sively toggles between ACTIVATE and INHIBIT, with the

from the System Menu. T he

current mode displayed just to the left of the k ey. Once

activated, the operation mode for each channel is selected.

PLACE THE STUDENT TRANSMITTER IN PPM PULSE

MODE. The instructor's transmitter may be in any transmission mode.

Controls and functions in both transmitters should be

matched. With two PCM 1024Z transmitters, matching

may be done easily using the Data Transfer

described on page 30. When using 5U and 7U transmitters,

be sure that EACH transmitter command works properly

before flying. All channel assignments and throw direc-

tions must be identical.

The Instructor's power switch should be turned on,

with its antenna fully extended. The student's transmitter

switch must always be turned o f f. In addition, the student

must not operate his trainer switch, or problems may

occur.

Rkey

succes-

DTN

key

CHANNEL SELECTION

Select the desired channel using the E to L up-arrow

keys. At this point, one can choose from student-only

control and correction control. For Student-only control,

press the

square in the chosen channel to become filled. For Cor-

rection

fills in the upper square in the active channel. If neither

square is filled, only the instructor can control this particular function.

P (TRN)

control,

key. This will cause the lower

press

the(MIX) key. This action

SETTING UP THE ON/OFF SWITCH

The default switch fo r the trainer ON/OFF function is

the spring-loaded switch SW(H), with forward in the ON

position. This switch must be held ON continuously for

the student to have control. For convenience, the alternate switch function (ALT) may be used to set this switch

so that it is alternately turned on and off successively

each time the switch is operated.

The location of the activation switch, as well as its

direction and operation, may changed using the switch

setting screen available by pressing the

For more details on the switch setting menu, see page 37.

O

(SWT) key.

System Section, Page 29

Page 32

DTN—DATA TRANSFER FUNCTION

System Section

This function may be used to exchange model

setup data between two PCM 1024Z transmitters.

Identical model setups are needed for trainer oper-

ation,

and

it

is

also useful

friend's transmitter to speed the setup process for

a model with complicated mixing and flight

modes, to avoid doing the setup process from

scratch.

An optional Trainer/Data Transfer Cable is

necessary for this operation. The time needed

Model Memory Menu

1. Press the TRN ( K ) key.

2. Select the Source model (to be

6. Press the TNS ( K ) key to

7a A successful transfer displays the

8. To continue data transfer, press

to

transfer data

Source Transmitter

(with the desired model setup

stored in its memory)

copied) with the A to J ( 1to

10 ) keys.

have the Source transmitter send

the desired data.

message "TRANSMITTING . . .

COMPLETED". If an error is

generated, the di s play will read

"ERROR:DATA FAULT

PLEASE RETRY".

the CNT ( L ) key. To end, press

END (N)

.

to

transfer data depends on the number of flight conditions, and ranges fro m 1 to 18 seconds.

Data Transfer Mode Setup

a

to

Transmit

First, connect th e tw o PCM 1024Z transmitters

with the data transfer cord. To place the PCM

1024Z into the Data Transfer mode, press the

DTN key from the System Menu. Then, follow

the following instructions (if you want to start

over

the

beginning,

Receive

Destination Transmitter

(to be loaded wi th th e setups from

the Source transmitter)

3. Press the RCV ( L ) key.

4. Use the A to J keys ( 1 to 10 )

to select the memory in whi ch the

source model is to be stored.

5. Press the RCV ( K ) key to

place the Destination transmitter

into the receive mode.

7b When the dat a transfer is

successful, the message

"RECEIVING . . . COMPLETED"

is displayed. If an error is

generated, the display will read

"ERROR:DATA FAULT PLEASE

RETRY".

8. To continue data transfer, press the

CNT ( L ) key. To end, press END

(N).

press

the

abort ABT key L.

Return to System

Menu

Target Transmitter

Connector

Trainer/Data Transfer Cord

System Section, Page 30

Page 33

CPM—COPY MODEL FUNCTION

System Section

This function is used to copy one set of model

data

into a second

mitter.

This

be used for getting a head-start on setting up

models

with

ences need to be modified, instead of entering the

whole thing from scratch). Also, this function may

function

almost

memory

is

very

the

same settings

within

the

same trans-

handy

because

Model Memory Menu

Model Memory Selection Keys

(only

it

may

differ-

be used to make a backup copy of a model setup

before making changes.

The CPM function may be used to copy to and

from the optional CAMPac as well. The number of

models that may be stored in the CAMPac depends

on the number of flight conditions each contains.

This relationship is shown in detail on page 12.

Source Model Name

Destination Model

Name

Return to System Menu

Usage of the Copy Model Function

(Note: source and destination may be both in transmitter, both in CAMPac, or

one in each)

Transmitter

1a Select the Source model with

the A to J ( 1 to 10 ) keys.

2a Select the Destination model

wit h the A to J (1 to 10 )

keys.

Optional CAMPac Memory Module

1b Press the NXT ( P ) key to get to

the CAMPac (model nos. 11 to 20 );

press the NXT (P ) key again to

get to models 21-26. Select the

desired Source model wi th the A to

J( 11 to20 or21 to26 ) keys.

2b Press the NXT (P ) key to get to

the CAMPac (model

press the N XT ( P ) k ey again to

get to models 21—26. Select the

desired Destination model wi t h the

nos. 11

to 20

A to J (11 to 20 or 21to26)

keys.

3. To copy all the flight conditions, press t he ALL ( M ) key.

To copy just the default flight condition, press the DEF ( L ) key.

4.• If

you

are

executes the copy function, which may take anywhere from 2 to 18

satisfied

seconds. A beep indicates completion. Verify that the data were copied

under the destination model name.

• If you wish to repeat the select on process, press the NO (

5. To continue copying, press the YES ( L ) key and repeat beginning at

step 1.

To end the process and return to the System Menu. press the END ( N )

key.

with

your

choices,

press

the

YES

(L)

key.

This

M

) key.

);

System Section, Page 31

Page 34

C

PC—COPY Condition Function

System Section

This function may be used to copy individual

flight conditions. One use would be to copy the

default flight condition, with all its subtrims,

mixing, etc. to another flight condition, and changing only the necessary parts. This procedure can

save a lot of time and unnecessary effort.

This

function

conditions (other than default) from the CAMPac

memory module. The MSL (Model Select) function

may

be

used

may

to

also be

delete

used

to

delete

the

model

data.

Destination Condition Number -

Numeric Keys Used to Choose Condition Numbers

flight

The entire model data may be copied under the

following conditions:

1. If the destination type is different from the

source, the set data are copied.

2. If the destination type is the same as the source,

all the set data are copied except for the condi-

tion name.

3. If the source is not allocated to a model mem-

ory ("00"), all the set data, including the model

name, is copied.

Source Condition Number

-Show Condition List

-Confirm Condition

Number

Return to System

Menu

Reading the Condition List

To display the condition list, press the

key. This displays conditions 1—10. To view the next t e n

conditions, press the

preceding ten conditions, press the

Conditions nos. 01-50 are stored in the transmitter, and

nos. 51-70 are stored in the optional CAMPac memory

module.

Flight Condition Copying

Follow the following instructions to copy one flight condition to anoth e r :

1. Use the numeric keys on the display bottom to input

the Source condition number. The 1,15,30,45,60,

and 72 keys input the key's value directly. The ( + )

and ( - ) keys may be used to increase or decrease

the displayed value by one for each key press. When

you are satisfied with the source number, press the

SET (O)

2. Now use the numeric keys to enter the Destination

condition number. Once again, enter the condition

number with the numeric keys at the display bottom,

and press the

3. If you are happy with both condition numbers, press

the

the NO (M) key to stop copying.

4. To continue copying further sets of conditions, press

the CNT (L) key and repeat the instructions

To end copying, press the